Page 1

WARNING: Plumber – Be Aware

Use copper pipe ONLY. Plastic pipe MUST NOT be used.

It is a requirement of a solar water heater installation that all

pipe work be in copper and not plastic, due to the effects of

high water temperatures and pressures.

Installation Instructions

Solar Collector Kit

Solar Collector Add On Kit

NPT 200 SOLAR COLLECTORS

This collector kit must be installed and serviced by a qualified person

Please leave this guide with the householder.

Page 2

WARNING: Plumber – Be Aware

The solar hot and solar cold pipes between the solar storage tank and the

solar collectors MUST BE of copper. All compression fittings must use

brass or copper olives.

The full length of the solar hot and solar cold pipes MUST BE insulated.

The insulation must:

be of a closed cell type or equivalent, suitable for a solar water heating

application and capable of withstanding the temperature of the water

generated by the solar collectors under stagnation conditions

The specification of the chosen insulation material should be checked

with the insulation manufacturer prior to installation as different

materials may vary in temperature tolerance.

be at least 13 mm thick, however thicker insulation may be required to

comply with the requirements of either AS/NZS 3500.4 or

AS/NZS 3500.5:2012 Section 3 (for a Class 1a or Class 10 building) as

applicable under the Plumbing Code of Australia

be weatherproof and UV resistant if exposed

extend through any penetrations in the eaves, ceiling and roof

cover valves and fittings in the solar pipe work

be fitted up to and cover the connections on both the solar storage tank

and the solar collectors.

Note: Failure to observe these requirements also increases the risk

of freeze damage.

Uninsulated pipe work, including concealed in cavities and roof spaces or

where it may be in contact with a metal roof, may lead to freeze damage.

The system has NO WARRANTY for freeze damage if the solar hot and

solar cold pipes are not insulated in accordance with the installation

instructions.

The insulation is essential to assist in providing freeze protection, will offer

protection to a metal roof against corrosion due to water running off the

copper pipes, assist in avoiding accidental contact with the solar pipe work

as very high temperature water can flow from the solar collectors to the

solar storage tank, and also reduce pipe heat losses.

Plumber: It is important to refer to and read in full the complete

“Warning: Plumber – Be Aware” statement commencing on page 13.

2

Page 3

CONTENTS

HOUSEHOLDER - This installation instruction booklet is

intended for the installer but you may find it of interest.

Notice to Victorian Customers from the

Victorian Plumbing Industry Commission.

This water heater must be installed by a licensed person

as required by the Victorian Building Act 1993.

Only a licensed person will give you a Compliance Certificate, showing that

the work complies with all the relevant Standards. Only a licensed person will

have insurance protecting their workmanship for 6 years. Make sure you use

a licensed person to install this water heater and ask for your Compliance

Certificate.

Components And Kit Contents .................................................. 4

System Installation ...................................................................... 5

Installation – Solar Storage Tank ............................................... 7

Installation – Solar Collectors .................................................... 8

Roof Assembly Of Solar Collectors ......................................... 17

Connection Details .................................................................... 25

Pipe Work Roughing In Dimensions ........................................ 29

Installation – Solar Collectors .................................................. 31

Warranty Note ............................................................................ 35

3

Page 4

SOLAR COLLECTOR KIT AND COLLECTOR ADD ON KIT

For installation with a solar storage tank.

Your solar water heater is designed for the solar collectors to be roof mounted

and the solar storage tank to be installed at ground or floor level. The collector

kits are suitable for:

Collector Kit (1 or 2 solar collectors)

299139 NPT 200 solar collectors Screwed fittings

Collector Add On Kit (for each additional solar collector)

299140 NPT 200 solar collector Screwed fittings

Note: One Collector Add On Kit is required for each additional solar collector.

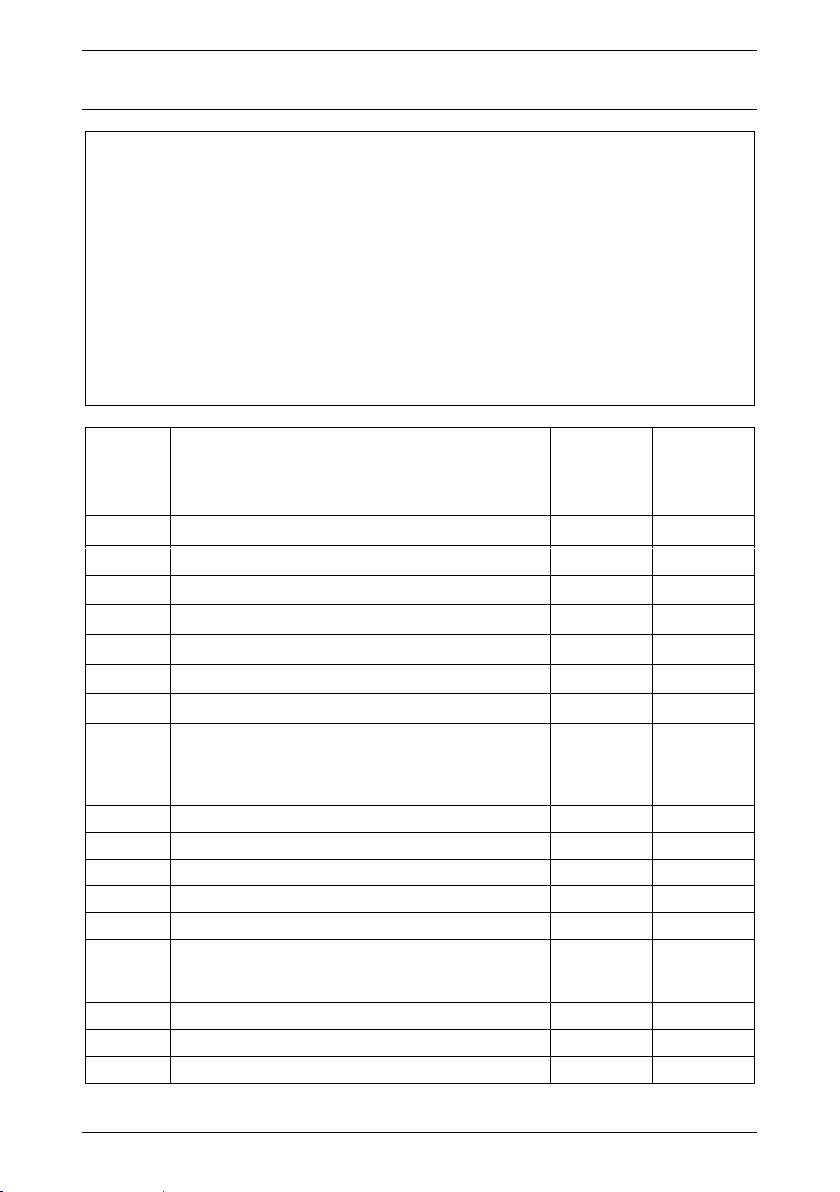

Part No

Kit Components and Description

299139

Collector

kit

NPT 200

299140

Add on kit

NPT 200

129870

Installation instructions roof kit

1

-

191614

Collector angle 1 panel

-

1

191613

Collector angle 2 panel

1

-

191801

Collector straps

4

3

080022

Screws self tapper ½” x 8G ZP pan head

8

3

330695

Collector union assembly

2

2

063603

Connector M33

1

-

063604

Sensor connector M33 assembly – consisting of:

1 x 063605 fitting M33-15BSP for temp sensor

1 x 088062 sensor nipple solar loline

1 x 087026 O ring 5/16” ID x 1/16 BS011 silicone

1

-

088027

Compression olive copper ½”

2

-

080055

Compression nut brass ½”

2

-

063602

End plug collector M33

2

-

330606

Blanking disc

2

-

330171

O ring 25 ID x 3.2

8

4

056001

or

056029

Hot sensor assembly Loline

1

-

087025

O ring 5/32” ID x 1/16

2

-

123204

Label hot pipe / cold pipe

1

-

348071

Cable ties 150 mm long

3

-

COMPONENTS AND KIT CONTENTS

4

Page 5

SYSTEM INSTALLATION

THIS WATER HEATER IS NOT SUITABLE FOR POOL HEATING.

The system is suitable for installation with NPT 200 solar collectors as part of an

open circuit system installation.

The system is not suitable for installation above 400 metres altitude.

IMPORTANT NOTES

Working on roofs is and should always be considered a hazardous activity,

particularly early in the morning, late in the evening, when the roof is wet and

during and after periods of rain.

All work must be carried out in accordance with Local, State and Federal

Occupational Safety, Health and Welfare Regulations. In particular, the

requirements for safety whilst manual lifting, working at heights and on roofs.

Installers must be competently trained in:

Height Hazard Assessment

Working at Height Procedures

Assessment / Use / Wearing of correct height safety equipment

(harnesses etc.)

All other relevant safety factors specific to the installation and

maintenance work to be compliant with suitable Occupational, Health and

Safety Regulations / Codes.

All relevant permits shall be obtained from the regulatory authorities before

commencing work to install the solar hot water system.

All work carried out must be performed by appropriately qualified

tradespeople or be suitably supervised for trades assistant duties.

Every care must be taken to protect and warn occupants of the building and

the public from personal injury which may occur from falling tools, roof

materials, fittings or any other hazards of a general nature.

Advise the occupants of any inconvenience which may occur due to

disconnection of existing water and electrical supplies.

The connection, attachment, integration or general association of other

equipment or parts which either directly or indirectly affect the operation or

performance of this equipment could void the warranty.

5

Page 6

SYSTEM INSTALLATION

INSTALLATION STANDARDS

The water heater must be installed:

by a qualified person, and

in accordance with the installation instructions, and

in compliance with Standards AS/NZS 3500.4 or AS/NZS 3500.5:2012

Section 3 (for a Class 1a or Class 10 building) as applicable under the

Plumbing Code of Australia, AS/NZS 3000 and all local codes and regulatory

authority requirements.

In New Zealand, the installation must also conform to Clause G12 of the New

Zealand Building Code.

WATER HEATER APPLICATION

This water heater is designed for use in a single family domestic dwelling for the

purpose of heating potable water. Its use in an application other than this may

shorten its life.

If this water heater is to be used where an uninterrupted hot water supply is

necessary for the application or business, then there should be back-up

redundancy within the hot water system design. This should ensure the continuity

of hot water supply in the event that this water heater was to become inoperable

for any reason. We recommend you provide advice to the system owner about

their needs and building back-up redundancy into the hot water supply system.

OPEN CIRCUIT SYSTEM INSTALLATION

An open circuit system has a collector circuit which is directly connected to the

potable water in the solar storage tank. Potable water from the solar storage tank

circulates through and collects heat gained by the solar collectors and then

circulates back into the solar storage tank.

Freeze Protection

The system has a level of freeze protection designed to guard the system against

damage from freeze conditions. The system must be installed with the full length

of the solar hot and solar cold pipes insulated to offer protection against freeze

damage (refer to “Warning: Plumber Be Aware” on page 13). Freeze conditions

occur below 6°C.

The system has NO WARRANTY for freeze damage when installed above

400 metres altitude or if the solar hot and solar cold pipes are not insulated in

accordance with the installation instructions (refer to “Warranty Note” on

page 35).

Note: Warranty against freeze damage applies only to systems installed in

Australia.

6

Page 7

INSTALLATION – SOLAR STORAGE TANK

SOLAR WATER HEATER STORAGE TANK LOCATION

The solar storage tank should be installed close to the most frequently used

outlet and its position chosen with safety and service in mind.

Consideration must also be given to the position of the solar storage tank in

relation to the solar collectors. There are limitations on the maximum length of

the solar hot and solar cold pipes between the solar storage tank and the solar

collectors. Refer to “Solar Collector Location” on page 8, to “Pipe Lengths” on

page 12 and to “Maximum Height to Collectors” on page 15.

Refer to the installation instructions supplied with the solar storage tank for

installation details of the solar storage tank.

7

Page 8

INSTALLATION – SOLAR COLLECTORS

SOLAR COLLECTOR LOCATION

Consideration must be given to the position of the solar collectors in relation to

the solar storage tank. There are limitations on both the maximum length of the

solar hot and solar cold pipes and the maximum height between the solar storage

tank and the solar collectors. Refer to “Solar Collector Location” on page 8, to

“Pipe Lengths” on page 12 and to “Maximum Height to Collectors” on page 15.

The solar collectors must be installed in a shade free position. The surrounds

should be checked for higher buildings or trees which may cause shade at other

times of the year and for small trees which may grow and shade the solar

collectors in the future.

The installation must comply with the requirements of either AS/NZS 3500.4 or

AS/NZS 3500.5:2012 Section 3 (for a Class 1a or Class 10 building) as

applicable under the Plumbing Code of Australia, and all local codes and

regulatory authority requirements.

Refer to the installation instructions supplied with the solar storage tank for

details on the installation of the solar storage tank.

ROOF STRENGTH

The installer must ensure the structural integrity of the building is not

compromised by the solar water heater installation and the roof structure is

suitable to carry the full weight of the solar collectors and frame (if one is

installed). If in any doubt of the construction or the condition of the roof, the roof

should be suitably strengthened. Consult a structural engineer. Each solar

collector and its fittings weighs approximately 42 kg when full of water.

ROOF AREA FOR INSTALLATION

Roof area required for solar collectors:

4 solar collectors – 4.6 m wide x 2.0 m deep. Weight (full) 168 kg approx.

3 solar collectors – 3.5 m wide x 2.0 m deep. Weight (full) 126 kg approx.

2 solar collectors – 2.4 m wide x 2.0 m deep. Weight (full) 84 kg approx.

1 solar collector – 1.3 m wide x 2.0 m deep. Weight (full) 42 kg approx.

In addition to this area, a minimum of one (1) metre clearance is recommended

to be left around the solar collectors on all four sides for safe service access.

8

Page 9

INSTALLATION – SOLAR COLLECTORS

Maximum Number of Collectors

The maximum recommended number of these non-selective collectors for each

tank size as part of an open circuit system is:

410 model tank – 4 x NPT200 collectors

325 model tank – 3 x NPT200 collectors

270 model tank – 3 x NPT200 collectors

ORIENTATION OF SOLAR COLLECTORS

To help maximise system performance, solar collectors should be installed with

an optimum orientation facing true north (in the southern hemisphere) or true

south (in the northern hemisphere). Always check for true north or true south

using a compass or other suitable device.

The solar performance of a system reduces as the orientation of the collectors

moves away from the optimum orientation, resulting in the need for increased

boosting to supply the same hot water load. Solar collectors facing up to 45° from

the optimum orientation will receive about 4% to 5% less total solar radiation.

However, the optimum orientation of solar collectors is not always practical or

achievable. Solar collectors may be installed up to 90° from the optimum

orientation. Where the orientation is greater than 60° from the optimum, it may

be possible for an additional solar collector to be installed or to install selective

surface collectors in lieu of non-selective surface collectors to help make up for

the reduction in solar performance compared to the optimum orientation. Each

option should be discussed with the system owner.

If neither of these options are possible nor acceptable to the system owner, then

the system owner needs to be made aware of, understand and accept that

increased boosting may be required to meet their hot water requirements.

9

Page 10

INSTALLATION – SOLAR COLLECTORS

INCLINATION OF SOLAR COLLECTORS

To help maximise system performance, solar collectors should be installed with

an optimum inclination. This is equal to 90% to 100% of the local latitude angle

when collectors are oriented within 60° of true north or true south, and between

10° and 20° when the collectors are oriented between 60° and 90° from the

optimum orientation.

Generally, improved summer performance is obtained from an angle of

inclination less than the optimum angle and improved winter performance is

obtained by an angle of inclination greater than the optimum angle. If the angle

of inclination varies by 20° from the optimum angle, the solar collectors will

receive about 10% less total annual solar radiation. The latitude of some

Australian cities are listed on page 11.

However, the optimum inclination of solar collectors is not always practical or

achievable. Solar collectors may be installed at the roof angle for simplicity of

installation and appearance, but must never be flat for a pumped solar open

circuit water heater installation. Although the solar collectors can be installed with

an inclination of less than 10°, this is not advised. The risks include:

the collector glass not 'self-cleaning', leading to dirty collector glass reducing

solar performance, and

condensation on the underside of the glass taking longer to clear, and

condensation droplets falling onto the absorber plate potentially causing

discolouration.

The collector kit is suitable for installations with an inclination of up to 30°. Where

the solar collectors are installed at inclinations greater than 30°, a With Pitch

frame is necessary. Refer to your local Solar Distributor for details.

A Variable Pitch frame can be installed to increase the angle of inclination of the

collectors used in a solar pumped water heater installation. This type of frame

should be used if the roof pitch either varies by more than 20° from the optimum

angle or is less than 10°.

The use of a Variable Pitch frame should be discussed with the system owner. If

this option is neither possible nor acceptable to the system owner, it may be

possible for an additional solar collector to be installed or to install selective

surface collectors in lieu of non-selective surface collectors to help make up for

the reduction in solar performance compared to the optimum inclination. Each

option should be discussed with the system owner.

If these options are neither possible nor acceptable to the system owner, then

the system owner needs to be made aware of, understand and accept that

increased boosting may be required to meet their hot water requirements.

10

Page 11

INSTALLATION – SOLAR COLLECTORS

Adelaide

35°S

Cairns

17°S

Hobart

42°S

Port Hedland

20°S

Alice Springs

24°S

Canberra

35°S

Mildura

34°S

Rockhampton

24°S

Brisbane

27°S

Darwin

12°S

Melbourne

38°S

Sydney

34°S

Broken Hill

31°S

Geraldton

28°S

Perth

32°S

Townsville

19°S

CYCLONIC OR HIGH WIND AREAS

For an installation of solar collectors on a pitched roof in a cyclonic or high wind

area, a suitable With Pitch frame is required. Refer to your local Solar Distributor

for details.

The installation of these solar collectors on a suitable frame, subject to the

frame’s design criteria not being exceeded:

may be suitable for installation in geographic locations up to and within Wind

Region D (With Pitch frame) or up to and within Wind Region C (Variable

Pitch frame), as defined in the Building Code of Australia, Australian

Standard AS 4055 and the Australian / New Zealand Standard

AS/NZS 1170.2, or equivalent locations, and

may provide an acceptable method of installation where it is necessary to

satisfy the requirements of the Building Code of Australia for high wind

areas, or equivalent requirements.

LATITUDE OF SOME AUSTRALIAN CITIES

11

Page 12

INSTALLATION – SOLAR COLLECTORS

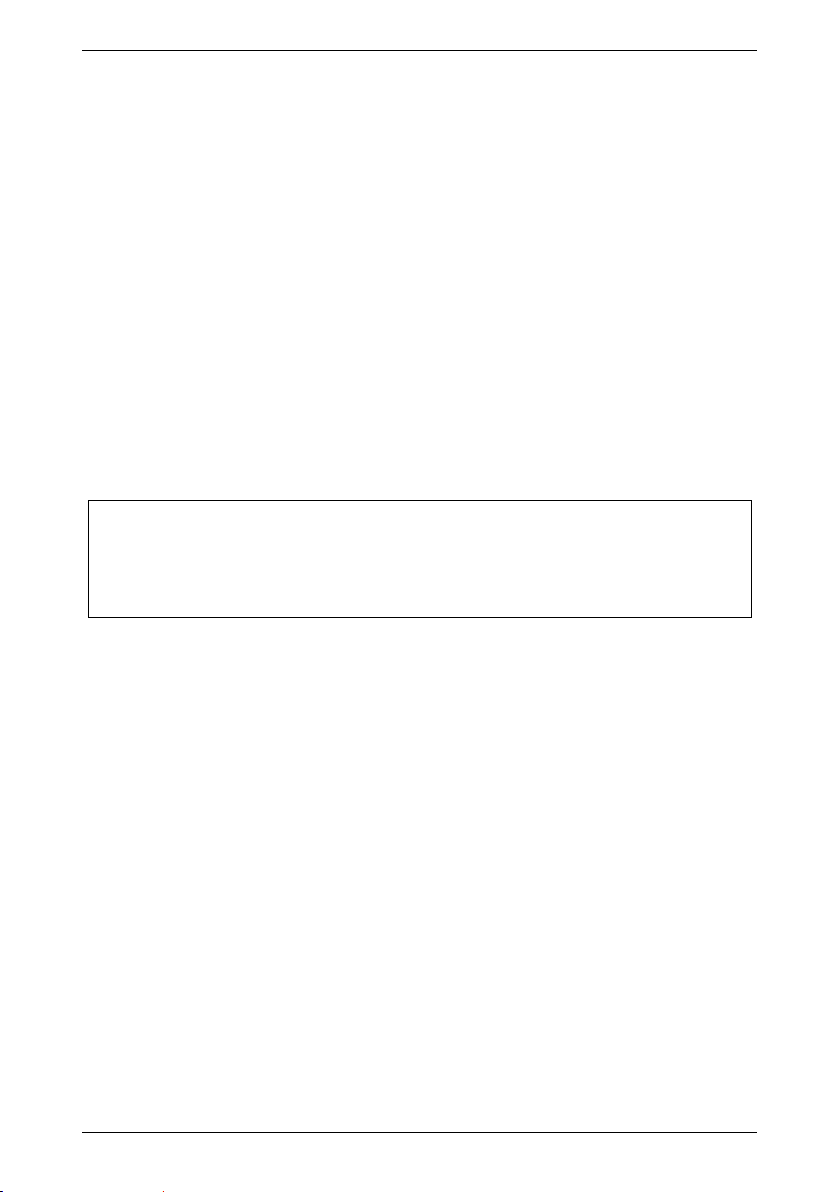

Maximum recommended total combined pipe length (solar hot + solar cold)

and number of 90° bends

Pipe Size

1 or 2 Collectors

3 Collectors

4 Collectors

Pipe Length

90°

Bends

Pipe Length

90°

Bends

Pipe Length

90°

Bends

DN15

40 metres

20

30 metres

20

15 metres

20

DN20

NR

NR

40 metres

20

40 metres

20

For each additional 90° bend, reduce the maximum total pipe length by 0.5 metres.

For each additional metre of pipe length, reduce the number of 90° bends by two.

Note: One 90° elbow is equal to two 90° bends. NR – not recommended.

PIPE LENGTHS

The solar hot and solar cold pipes between the solar storage tank and the solar

collectors shall:

be of bendable grade or hard drawn copper tube.

Annealed or soft copper shall not to be used.

have a continuous fall from the solar collectors to the solar storage tank.

Horizontal runs of pipe work are acceptable and may be installed as part of

an open circuit system.

Care must be taken to ensure the pipe work maintains a continuous fall or

horizontal runs over the life of the installation. Pipe work should be fixed at

regular intervals to assist in maintaining this requirement.

not exceed the maximum recommended combined lengths as specified in

the table.

Notes:

It is important to connect the solar hot and solar cold pipes to the correct

connections at the solar collectors and at the solar storage tank.

The solar cold pipe connects to the bottom of the solar collector array and

may connect to either the left or right hand side. The solar hot pipe must

connect to the top of the solar collector array diagonally opposite to the solar

cold pipe connection. The solar hot outlet connection is to be the highest

point of the system.

The hot sensor connection is at the solar hot outlet where the solar hot pipe

connects to the solar collector for this open circuit system.

Refer to “Warning: Plumber – Be Aware” on page 13.

It is essential for these requirements to be followed for the system to operate

correctly and efficiently. Solar pipe work which is oversized, or is too long, or

does not have a continuous fall can result in a reduction in performance or the

system not operating effectively.

12

Page 13

INSTALLATION – SOLAR COLLECTORS

WARNING: Plumber – Be Aware

The solar hot and solar cold pipes between the solar storage tank and the

solar collectors MUST BE of copper. All compression fittings must use

brass or copper olives.

The full length of the solar hot and solar cold pipes MUST BE insulated.

The insulation must:

be of a closed cell type or equivalent, suitable for a solar water heating

application and capable of withstanding temperatures of up to 150°C,

which may be generated by the solar collectors under stagnation

conditions

The specification of the chosen insulation material should be checked

with the insulation manufacturer prior to installation as different

materials may vary in temperature tolerance.

be at least 13 mm thick, however thicker insulation may be required to

comply with the requirements of either AS/NZS 3500.4 or

AS/NZS 3500.5:2012 Section 3 (for a Class 1a or Class 10 building) as

applicable under the Plumbing Code of Australia

be weatherproof and UV resistant if exposed

extend through any penetrations in the eaves, ceiling and roof

cover valves and fittings in the solar pipe work

be fitted up to and cover the connections on both the solar storage tank

and the solar collectors.

Note: Failure to observe these requirements also increases the risk

of freeze damage.

Uninsulated pipe work, including concealed in cavities and roof spaces or

where it may be in contact with a metal roof, may lead to freeze damage.

The system has NO WARRANTY for freeze damage if the solar hot and

solar cold pipes are not insulated in accordance with the installation

instructions.

The insulation is essential to assist in providing freeze protection, will offer

protection to a metal roof against corrosion due to water running off the

copper pipes, assist in avoiding accidental contact with the solar pipe work

as very high temperature water can flow from the solar collectors to the

solar storage tank, and also reduce pipe heat losses.

13

Page 14

INSTALLATION – SOLAR COLLECTORS

WARNING: Plumber – Be Aware

The insulated copper pipe work:

should be fixed at suitable locations to prevent or reduce the possibility

of noise from water hammer and vibration from occurring

is not to be placed or installed in contact with plastic pipe work.

Likewise, plastic pipe work is not to be placed or installed in contact

with the insulated copper pipe work after the collector circuit is installed.

The solar hot outlet and hot sensor connection is to be the highest point of

the system. The highest point of the solar hot and solar cold pipes must be

where they connect to the solar collectors, to avoid the possibility of air

locks occurring in the system. There MUST BE a continuous fall in the

pipe work from the solar collectors to the solar storage tank. Horizontal

runs of pipe work are acceptable and may be installed as part of an open

circuit system.

Plastic pipe MUST NOT be used, as it will not withstand the temperature

and pressure of the water generated by the solar collectors under

stagnation conditions. Extremely high water temperatures up to 150°C for

non-selective surface collectors and greater than 200°C for selective

surface collectors and extremely high water pressures can be generated

under these conditions. Plastic pipe cannot withstand these temperatures

and pressures and MUST NOT be used. Failure of plastic pipe can lead to

the release of high temperature water and cause severe water damage

and flooding.

The pressure applied to the collector circuit and solar collectors during a

pressure test of an open circuit system MUST NOT exceed 1000 kPa

where NPT200 solar collectors are installed, otherwise damage may

result.

Refer to “Pressure Testing” on page 16.

Upon completion of the installation of the NPT200 solar collectors the

packaging material may be removed, whether or not the collector circuit is

connected to the solar storage tank and / or the solar water heater is

commissioned.

14

Page 15

INSTALLATION – SOLAR COLLECTORS

Maximum Height to Collectors

The maximum height of a pumped open circuit solar installation, from the solar

controller (circulator) to the top of the solar collectors, is determined by the

maximum recommended total pipe length for the system and the water supply

pressure.

The maximum recommended total pipe length of the collector circuit should not

be exceeded and a minimum water supply pressure of 200 kPa should be

available at the inlet to the system, otherwise the system performance may be

reduced or the collector circuit may not be purged of air during the commissioning

of the system.

Open Circuit System

Pipe Work Installation Requirements

15

Page 16

INSTALLATION – SOLAR COLLECTORS

Pressure Testing

The solar water heater, including the collector circuit, is to be isolated during the

testing and commissioning of the heated water reticulation system in a building

in accordance with Clause 9.3 (a) of AS/NZS 3500.4:2015 or Clause 3.34.2 (a)

of AS/NZS 3500.5:2012 for a Class 1a or Class 10 building as applicable under

the Plumbing Code of Australia. The collector circuit includes the solar hot and

solar cold pipes and solar collectors.

It may be necessary to pressure test the collector circuit to comply with codes

and regulatory authority requirements or on other occasions where the solar

collectors and solar hot and solar cold pipes are installed prior to the solar

storage tank, such as on a building site.

Collector Circuit

Warning: The pressure applied to the collector circuit during a pressure test

of an open circuit system MUST NOT exceed 1000 kPa where NPT200 solar

collectors are installed, otherwise damage may result to the solar collectors.

Open Circuit System

If the solar collectors, solar pipe work and solar storage tank are installed and

commissioned together, then the flooding of the collector circuit with water under

mains pressure for an open circuit system and checking the pipe work for leaks

during the commissioning procedure can be substituted for the pressure testing

of the collector circuit.

16

Page 17

ROOF ASSEMBLY OF SOLAR COLLECTORS

Notes:

These solar collectors have passed the AS/NZS 2712 requirements for

resistance to hailstone damage, so it is not normally necessary to fit a guard

to a collector. Stone Guards are available to provide a level of protection to

the collectors against vandalism or accidental damage. Refer to your local

Solar Distributor for details.

Warranty DOES NOT cover breakage of solar collector glass. Check your

insurance policy covers collector glass breakage.

Warning: No attempt should be made to remove or replace broken

collector glass.

The collector glass is not offered as a replacement part. Should the solar

collector require replacement, contact your local Solar Distributor for details.

Warning: Do not remove the solar collector packaging completely, prior

to the installation as the solar collector surface can become very hot. Remove

only sufficient packaging material to enable the installation of the solar

collectors.

Upon completion of the installation of the NPT200 solar collectors, such as

on a building site, the packaging material may be removed whether or not the

collector circuit is connected to the solar storage tank and / or the solar water

heater is commissioned.

The solar collector packaging must be removed completely prior to the

permanent operation of the water heater.

All connectors, end plugs, ‘O’ rings, brass fittings, collector straps and

collector angle required for the installation are included with the collector kit.

Suitable screws or anchors will be required to fix the collector straps to the

rafters for a pitched roof installation.

Screws to secure the collector straps and collector angle to the solar

collectors must not be longer than 15 mm. Suitable screws are provided in

the collector kit.

All olive compression fittings must use brass or copper olives.

Use an approved thread sealant such as Teflon tape on all other threaded

joints. Fittings with an O-ring do not require a thread sealant.

Roof Condition: Check the condition of the roof and advise the client of any

broken tiles or damaged roof sheeting before commencing the installation.

17

Page 18

ROOF ASSEMBLY OF SOLAR COLLECTORS

Numbers in parentheses refer to items in the diagrams on pages 31 (two solar

collector installation) and 32 (three or four solar collector installation).

DO NOT MODIFY THESE PARTS IN ANY WAY.

1. Solar Frame: If a solar frame is to be installed, determine the location of the

frame(s). Refer to “Solar Collector Location” on page 8 and the installation

instructions provided with the frame(s).

Assemble and fix the frame(s) to the roof in accordance with the installation

instructions provided with the frame.

Depending upon the positioning of the frame on the roof and any minor fall

the roof may have, ensure the collector rail is either horizontal or is higher

on the hot outlet side of the solar collectors. If in doubt use a spirit level.

Proceed to step 4.

2. Solar Collector Location: If a solar frame is not installed, select a suitable

position for the solar collectors.

Refer to “Solar Collector Location” on page 8.

3. Collector Angle – Pitched Roof Installation: Determine the location of the

collector angle(s) (1). If more than two solar collectors (17) are installed,

locate the collector angle(s) (1) from the Collector Add On kit(s) adjacent to

the first collector angle (1).

Hook two collector straps (2) to each bottom collector angle (1).

When positioned, the collector angle is to be either horizontal or have a rise

across the solar collectors from the solar cold connection side up to the solar

hot connection side for an open circuit system. The solar hot outlet and hot

sensor connection is to be the highest point of the system.

Note: Refer also to “Tile Roof with a flat tile profile” on page 18 if the

installation is on a tile roof where the tile has a flat profile. Additional

requirements for the positioning of the collector rail and installation of the

solar collectors apply.

Tile Roof with a flat tile profile: If the installation is on a tile roof with a flat

tile profile, the solar collectors (17) must be installed at an angle from the

horizontal to assist in rainwater runoff. The solar hot outlet side must be on

the left hand side and the solar cold inlet must be on the right hand side of

the collector array.

The top end of the solar collector on the solar cold inlet side must sit atop

the lower end of a tile lap. Measure down the roof approximately 1940 mm

from this point to determine the position of the bottom collector rail.

18

Page 19

Horizontal

Horizontal

Solar Hot

Outlet

Position top

of collector

as low as

practical

on roof tile

Solar Hot

Outlet

Horizontal

Position top

of collector

as low as

practical

on roof tile

FOLDED TRAY COLLECTORS

EXTRUDED RAIL

ENVELOPE COLLECTORS

EXTRUDED RAIL

30-40mm

from

horizontal

15-20mm

from horizontal

30-40mm

from

horizontal

Solar Cold Inlet

15-20mm

from horizontal

Solar Cold Inlet

15-20mm

from horizontal

Solar Cold Inlet

30-40mm

from

horizontal

Position top

of collector

as low as

practical

on roof tile

ROOF ASSEMBLY OF SOLAR COLLECTORS

Ensure the end of the collector angle (1) at the outlet side (left hand side) of

the solar collectors is higher up the roof than the end of the collector angle

at the inlet side (right hand side) of the solar collectors by:

15 – 20 mm for one solar collector, or

30 – 40 mm for two solar collectors, or

45 – 60 mm for three solar collectors.

This is to provide a downward angle along the top end of the collectors to

assist in rainwater runoff in order to prevent pooling.

Flat Tile Profile – Collector Angle From Horizontal

Failure to adhere to this requirement may result in pooling of rainwater at

the top of the collectors. If the top end of the collector array is too close to

the lap of the tiles, there is a risk of pooling water seeping up and under the

tile lap. The rainwater runoff is to flow from left to right to reduce the risk of

water working through the joints between tiles.

Tile Roof: Remove the tiles on the next row above the position of the

collector angle (1) to expose the rafters. Position the collector angle (1) and

fix the collector straps (2) directly to the rafters, using suitable screws or

anchors. Replace the tiles.

Metal Roof: Once the collector angle (1) is in position, fix the collector

straps (2) to the rafters, through the metal roofing material, using suitable

screws or anchors. Care should be taken not to mark Colorbond or other

metal roof sheet with a marking pen and to remove all swarf from the metal

roof as these can cause deterioration of the metal roofing material.

19

Page 20

ROOF ASSEMBLY OF SOLAR COLLECTORS

Note: Fixings must penetrate only through the high point in the roof material

profile. AS/NZS 3500.4 states a minimum of three (3) screws 40 mm long

be used per fixing strap. Longer screws or anchors may be required to

achieve a 40 mm minimum embedment into rafters for a metal roof.

Additional screws or anchors may be required.

4. Solar Collectors: Using a lifting device, lift the first solar collector (17) onto

the roof and place it carefully with the lower end seated in the collector

angel (1) and prior to positioning the next solar collector, screw the collector

angle (1) to the solar collector (17) using one of the screws (13) provided.

Repeat this procedure for additional collectors (17), screwing the collector

angle (1) to the solar collector (17) using one of the screws (13) provided.

Solar Frame Installation: Using a lifting device, lift the first solar collector (17)

onto the roof and place it carefully with the lower end seated in the collector

rail (1) and prior to positioning the next solar collector, firmly clamp (two

clamps per collector) to the collector rail using the clamps, hex screws,

washers and nuts provided.

Repeat this procedure for additional collectors (17), firmly clamping each

collector to the collector rail (1) with two clamps (13) prior to positioning a

subsequent collector.

Note: Screwing or firmly clamping each solar collector to the collector rail

as it is placed in position reduces the possibly of the collector(s) accidently

moving or sliding off the collector rail.

Remove the red transit plugs from the collector sockets.

5. Collector Unions: Couple the solar collectors (17) together using the

collector unions (3) and ‘O’ rings (6) supplied in the collector kit.

Refer to “Coupling Collector to Collector – Screwed Fittings” on page 25.

Note: It will be necessary to remove the screw or loosen the clamps on a

collector prior to it being coupled to its adjacent collector. Secure the screw

or the clamps again on each collector after it is coupled to the adjacent

collector.

6. Fixing Collector (bottom): Ensure the solar collectors (17) are correctly

positioned, centred and well seated in the collector angle (1).

Pitched Roof Installation: Screw the collector angle (1) to the solar

collectors (17) (two screws per collector), using the screws (13) provided.

Solar Frame Installation: Tighten the clamps (13) on each solar

collector (17).

20

Page 21

ROOF ASSEMBLY OF SOLAR COLLECTORS

7. Collector Strap (top) – Pitched Roof Installation: Position a collector

strap (2) against the top end of each solar collector (17).

Tile Roof: Remove the tiles on the next row above the top edge of the solar

collectors (17) to expose the rafters. Once in position, fix the collector

straps (2) directly to the rafters, using suitable screws or anchors. Replace

the tiles.

Metal Roof: Once in position, fix the collector straps (2) to the rafters,

through the metal roofing material, using suitable screws or anchors. The

collector straps (2) may be cut to a length of approximately 100 mm to retain

the aesthetics of the installation.

Note: Fixings must penetrate only through the high point in the roof material

profile. AS/NZS 3500.4 states a minimum of three (3) screws 40 mm long

be used per fixing strap. Longer screws or anchors may be required to

achieve a 40 mm minimum embedment into rafters for a metal roof.

Additional screws or anchors may be required.

Screw the collector straps (2) to the solar collectors (17) using the

screws (13) provided.

Solar Frame Installation: Ensure the solar collectors are correctly

positioned, centred and well seated in the top collector rail. Clamp the solar

collectors (two clamps per collector) to the collector rail, using the clamps,

hex screws, washers and nuts provided with the frame.

8. Connector: Fit a connector (10) to the inlet of the solar collector array using

an ‘O’ ring (6) provided.

Refer to “Coupling Cold and Hot Pipes to Collector – Screwed Fittings” on

page 27.

9. Sensor Connector: Fit the sensor connector (4) (with hot sensor port) to

the outlet of the solar collector array using an ‘O’ ring (6) provided.

Note: If the installation is on a tiled roof, the orientation of the hot sensor

port and hot sensor probe (when installed) must be angled between the

perpendicular (90°) to the roof to a maximum 30° off perpendicular down the

roof. Refer to Detail E on page 28.

Refer to “Coupling Cold and Hot Pipes to Collector – Screwed Fittings” on

page 27.

10. End Plugs: Fit the end plugs (5) to the two remaining solar collector

connections using the ‘O’ rings (6) and blanking discs (7) provided.

Refer to “End Plug Assembly – Screwed Fittings” on page 26.

21

Page 22

ROOF ASSEMBLY OF SOLAR COLLECTORS

11. Solar Hot and Solar Cold Pipes: Install the solar cold pipe from the solar

storage tank to the solar collectors (17) and the solar hot pipe from the solar

collectors (17) to the solar storage tank.

The solar hot and solar cold pipes should be a minimum DN15, but sized to

suit the installation for an open circuit system. Refer to “Pipe Lengths” on

page 12.

The solar hot and solar cold pipes must have a continuous fall from the solar

collectors to the solar storage tank. Horizontal runs of pipe work are

acceptable and may be installed for an open circuit system.

The full length of the solar hot and solar cold pipes must be insulated. The

insulation must be capable of withstanding the temperatures generated by

the solar collectors under stagnation conditions.

Warning: Plumber – Be Aware: It is important you refer to “Warning:

Plumber – Be Aware” on page 13 for important information relating to the

installation of the solar hot and solar cold pipes.

Refer also to installation diagrams on pages 31 and 32 and to “Pipe Work

Roughing In Dimensions” on page 29.

Notes:

Penetrations through the roofing material must be:

■ at the high point of the roof tile or metal sheet;

■ made neatly and kept as small as practicable;

■ waterproofed upon installation of the solar hot and solar cold pipes.

Exposed insulated pipe work between the solar collectors and the

penetration through the roofing material should be kept to a minimum to

maintain the aesthetics of the installation.

12. Connecting the Solar Hot and Solar Cold Pipes to Collectors: Connect

the solar cold pipe to the connector (10) at the inlet of the solar

collectors (17) and the solar hot pipe to the sensor connector (4) at the outlet

of the solar collectors (17) using the compression nuts and olives provided.

Refer to “Coupling Cold and Hot Pipes to Collector – Screwed Fittings” on

page 27 and the installation diagrams on pages 31 and 32.

22

Page 23

ROOF ASSEMBLY OF SOLAR COLLECTORS

13. Hot Sensor Lead – Collector Connection: Insert the sensor probe of the

hot sensor lead assembly (9) into the sensor connector (4), ensuring the

‘O’ ring is in position on the probe. Lock it into position with the locking

washer and clip provided.

Hot Sensor Lead – Solar Storage Tank Connection: Run the hot sensor

lead down to the solar storage tank. An extension sensor lead is available if

the hot sensor lead is not long enough to reach the solar control unit.

Connect the hot sensor lead to the hot sensor cable connecting socket

located at the underside of the solar control unit screwed to the side of the

solar storage tank.

14. Cable Ties: Secure the hot sensor lead at appropriate locations with the

cable ties (14) provided.

Notes:

The hot sensor lead may be cable tied to the outside of the insulation

on the solar pipe work.

Ensure the hot sensor lead is not in direct contact with the solar pipe

work at any point of the collector circuit, otherwise damage to the

sensor lead can occur due to the high temperatures which can be

experienced within the pipe work.

Damage to the hot sensor lead can result in solar gain not being

achieved and the freeze protection system being rendered inoperative.

15. Labels: At ground or floor level, adjacent to the location of the solar storage

tank, attach the ‘Solar Cold Pipe’ label (16) to the insulation on the solar cold

pipe to the solar collectors and the ‘Solar Hot Pipe’ label (15) to the

insulation on the solar hot pipe from the solar collectors.

Ensure the arrows on the labels are pointing in the correct direction of water

flow.

16. Pressure Testing the Collector Circuit: Upon completion of the solar

collector and solar hot and solar cold pipe installation, it may be required to

pressure test the collector circuit. Refer to “Pressure Testing” on page 16.

17. Connecting the Solar Hot and Solar Cold Pipes to the Solar Storage

Tank: Refer to “Connections – Plumbing” and “Installation – Solar Control

Unit” in the Owner’s Guide and Installation Instructions supplied with the

solar storage tank for details on the solar hot and solar cold pipe connections

to the solar storage tank.

18. Commissioning: Upon completion of the installation, refer to the Owners

Guide and Installation instructions supplied with the solar storage tank for

the commissioning procedure of the solar water heater.

23

Page 24

ROOF ASSEMBLY OF SOLAR COLLECTORS

INSTALLATION CHECK LIST

Once the installation is complete, it is important to check the following:

Maximum recommended total combined solar hot and solar cold pipe length

is not exceeded.

Solar hot and solar cold pipes are insulated in accordance with the

installation instructions.

The solar hot and solar cold pipes have a continuous fall from the solar

collectors to the solar storage tank. Horizontal runs of pipe work are

acceptable.

Ensure the collector angle is either horizontal or is higher on the hot outlet

side of the solar collectors. If in doubt use a spirit level.

Or if the installation is on a tile roof with a flat profile tile, then the end of the

collector angle at the outlet side (left hand side) of the solar collectors is

higher up the roof than the end of the collector angle at the inlet side (right

hand side) of the solar collectors by:

15 – 20 mm for one solar collector, or

30 – 40 mm for two solar collectors, or

45 – 60 mm for three solar collectors.

24

Page 25

CONNECTION DETAILS

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

Solar Collector Solar Collector

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

P/No: 33-0695

Collector Union

Solar Collector

COUPLING COLLECTOR TO COLLECTOR – SCREWED FITTING

Refer to installation diagrams on pages 31 and 32 for position and Detail A on

page 25.

1. Seat an ‘O’ ring (6) into each of the collector connections to be joined.

2. Fit a collector union (3) to each collector connection of the first solar

collector (17) to receive the second solar collector and screw in the unions

until they seat firmly against their ‘O’ ring (6). Hand tighten only so the solar

collectors can be shifted and centred.

3. Place the collector unions (3) into the collector connections on the second

solar collector and screw in the unions until they seat firmly against their

‘O’ ring (6). Hand tighten only so the solar collectors can be shifted and

centred.

4. Repeat steps 1 and 2 for a third and fourth solar collector (if installed).

5. After the solar collectors are centred on the collector rail(s), tighten each

collector union (3) with a spanner applying medium pressure.

DETAIL A – COLLECTOR UNION ASSEMBLY – SCREWED FITTING

25

Page 26

CONNECTION DETAILS

P/No: 33-0606

Blanking Disc

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

P/No: 063602

Collector M33 End Plug

Solar Collector

END PLUG ASSEMBLY – SCREWED FITTING

Refer to installation diagram on page 31 for position and Detail B on page 26.

1. Seat an ‘O’ ring (6) into the collector connection.

2. Place a blanking disc (7) over the seated ‘O’ ring (6).

3. Place the end plug (5) into the collector connection and screw in until it seats

firmly against the blanking disc (7), applying medium pressure with a

spanner to tighten.

DETAIL B – END PLUG ASSEMBLY – SCREWED FITTING

26

Page 27

CONNECTION DETAILS

Solar Collector

Solar Collector Solar Collector

O-Ring 25mm ID x 3.2 Thk

Connector M33 - NPT

P/No: 063603

Copper Compression

Olive 1/2"

P/No: 088027

Brass Compression

Nut 1/2" x 15

P/No: 080055

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

COUPLING COLD AND HOT PIPES TO COLLECTOR – SCREWED FITTING

Refer to installation diagram on page 31 for position and Detail C on page 27,

Detail D on page 28 and Detail E on page 28.

1. Seat an ‘O’ ring (6) into the collector connection.

2. Place the connector (10) into the collector connection and screw in the union

until it seats firmly against the ‘O’ ring (6), applying medium pressure with a

spanner to tighten.

3. Place the compression nut (11) and olive (12) over the end of the solar cold

pipe. Position the cold pipe into the connector (10), seat the olive (12) and

tighten the compression nut (11).

4. Repeat this procedure with the sensor connector (4) to couple the solar hot

pipe to the solar collector (17).

Note: If the installation is on a tiled roof, the orientation of the hot sensor

port and hot sensor probe (when installed) must be angled between the

perpendicular (90°) to the roof to a maximum 30° off perpendicular down the

roof. Refer to Detail E on page 28.

DETAIL C – CONNECTOR ASSEMBLY – SCREWED FITTING

(WATER CONNECTION TO SOLAR COLLECTOR)

27

Page 28

CONNECTION DETAILS

Solar Collector

DETAIL B

CONNECTOR

(BETWEEN COLLECTORS)

(LOLINE AND HILINE)

Brass Compression Nut 1/2" x 15

P/No: 080055

Solar Collector

Copper Compression Olive 1/2"

P/No: 088027

Sensor Lead,

Thermister sensor head & clip assbly

P/No: 056001

O-Ring 5/32" ID x 1/16" Thk

P/N 087025

Solar Collector Solar Collector

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

P/No: 33-0695

Collector Union

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

Connector M33 Assbly for

Temp Sensor - NPT

P/No: 063604

DETAIL A

CONNECTOR

(WATER CONNECTION TO COLLECTOR)

(LOLINE)

Connector M33 - NPT

P/No: 063603

Copper Compression

Olive 1/2"

P/No: 088027

P/No: 33-0171

O-Ring 25mm ID x 3.2 Thk

Tiled roof

30°

Down roof

Hot sensor & connector

assembly range is from

perpendicular to maximum

30° off perpendicular

"down" roof

Perpendicular

to roof

30°

DETAIL D – SENSOR CONNECTOR ASSEMBLY – SCREWED FITTING

DETAIL E – SENSOR CONNECTOR ORIENTATION – TILED ROOF

28

Page 29

PIPE WORK ROUGHING IN DIMENSIONS

Pipe Work to Solar

Storage Tank

A B C

D

Hot

Outlet

Solar Hot

Flow

Solar

Cold

Return

Cold Inlet

Electric Boost

270 litre tank

1190

685

635

73

325 litre tank

1430

754

635

73

410 litre tank

1600

820

643

81

Refer to the diagrams for roughing in dimensions for pipe work to the solar

collectors and to the solar storage tank.

Note: * the roughing in dimensions for B and C are 200 mm above fitting to allow room for

bends and valve installation.

Electric Boost Solar Storage Tank

29

Page 30

PIPE WORK ROUGHING IN DIMENSIONS

Pipe Work to

Solar Collectors

E

F

1 Collector

1240

1880

2 Collectors

2360

1880

3 Collectors

3480

1880

4 Collectors

4600

1880

Solar Pipe Work Roughing In Dimensions

30

Page 31

INSTALLATION – SOLAR COLLECTORS

SOLAR COLD PIPE

SOLAR HOT PIPE

Note: Although the drawings illustrate the solar cold pipe connecting the bottom

left hand corner of the solar collector array, the solar cold pipe may be connected

to either the bottom right or the bottom left hand corner. The solar hot pipe must

connect to the top of the solar collector array diagonally opposite to the solar cold

pipe connection.

INSTALLATION WITH SCREWED FITTING SOLAR COLLECTORS

SUPPLIED IN COLLECTOR KIT (SCREWED FITTINGS) (299139)

1. Collector angle

2. Collector strap

3. Collector union

4. Sensor connector

5. End plug

6. ‘O’ ring

7. Blanking disc

9. Hot sensor lead assembly

10. Connector

11. Compression nut

12. Compression olive

13. Screws

14. Cable tie

15. Label – solar hot pipe

16. Label – solar cold pipe

(Supplied separately)

17. Solar collector

31

Page 32

INSTALLATION – SOLAR COLLECTORS

Solar Loline Collector Installation - Additional Collector (Exploded View)

with NPT 200 Solar Collectors

Supplied In Additional

Collector Kit (299140)

INSTALLATION – ADDITIONAL SOLAR COLLECTOR – SCREWED FITTING

SUPPLIED IN COLLECTOR ADD ON KIT (SCREWED FITTINGS) (299140)

1. Collector angle

2. Collector strap

3. Collector union

6. ‘O’ ring

13. Screws

(Supplied separately)

17. Solar collector

32

Page 33

This page is intentionally blank.

33

Page 34

This page is intentionally blank.

34

Page 35

WARRANTY NOTE

The solar water heater and its components are covered by a manufacturer’s

warranty. For full details, refer to the Owners Guide and Installation Instructions

supplied with the solar storage tank.

The part extracts from the “Terms Of The Warranty And The Exclusions To It” of

the water heater Warranty should be noted before commencing the installation

of the solar collectors.

TERMS OF THE WARRANTY AND EXCLUSIONS TO IT

2.5 Where the water heater is installed in a position that does not allow safe or ready access,

the cost of that access, including the cost of additional materials handling and/or safety

equipment, shall be the owner’s responsibility. In other words, the cost of dismantling or

removing cupboards, doors or walls and the cost of any special equipment to bring the water

heater to floor or ground level or to a serviceable position is not covered by this warranty.

2.7 The warranty does not cover faults that are a result of:

c) Installation not in accordance with the Owner’s Guide and Installation Instructions or with

relevant statutory and local requirements in the State or Territory in which the water

heater is installed.

d) Connection at any time to a water supply that does not comply with the water supply

guidelines as outlined in the Owner’s Guide and Installation Instructions.

k) Breakage of collector glass for any reason including hail damage (we suggest that the

collector glass be covered by the home insurance policy).

l) Ice formation in the waterways of a water heater system incorporating a freeze protection

system where the electricity supply has been switched off or has failed or where it is

installed at an altitude more than 400 metres above sea level.

2.8 Subject to any statutory provisions to the contrary, this warranty excludes any and all claims

for damage to furniture, carpet, walls, foundations or any other consequential loss either

directly or indirectly due to leakage from the water heater, or due to leakage from fittings and/

or pipe work of metal, plastic or other materials caused by water temperature, workmanship

or other modes of failure.

35

Page 36

Revision Date: 2016 August 129870N

RHEEM AUSTRALIA PTY LTD - ABN 21 098 823 511

1 Alan Street Rydalmere NSW 2116 Australia

(PO Box 7508 Silverwater NSW 2128 Australia)

PATENTS

This water heater may be protected by one or more patents or registered designs

in the name of Rheem Australia Pty Ltd.

®

Registered trademark of Rheem Australia Pty Ltd.

TM

Trademark of Rheem Australia Pty Ltd.

TRADEMARKS

Note: Every care has been taken to ensure the accuracy in preparation of this

publication. No liability can be accepted for any consequences,

which may arise as a result of its application.

36

Loading...

Loading...