Page 1

Low NOx Universal Gas Commercial Water Heaters

Available in Sizes Ranging From 35 - 100 Gallon Tank-Type Models

125,000 BTU/Hr. thru 400,000 BTU/Hr.

Universal Low NOx Gas Commercial Water Heaters are specifically

designed to minimize the difficulty of replacing failed water heaters and are

versatile for new installations. These products are designed for applications

requiring large quantities of hot water.

Construction Features:

Complies With

SCAQMD Rule 1146.2

For Low NOx

Emissions

Small Jacket

Diameters

Short

Floor-to-Vent

Heights

Multiple

Water Connection

Options

• Universal tank design –

maximizes installation adaptability

by offering models with Top, Front

Side and Rear Side Inlet/Outlet

water connections.

• Universal space saver design –

short heights and small jacket

diameters result in greater

installation flexibility.

• Patented multi-flue tank design

– proprietary steel formulation,

patented multi-flue design, and

two coats of high temperature

porcelain enamel to maximize

corrosion resistance result in a

superior heat exchanger design.

• Low profile automatic flue

damper –

low profile design minimizes overall product height. New heavy duty

vent hood supports are designed

to withstand rigors of installation.

• Spark-To-Pilot ignition system –

standard on all models. Provides

reliable and energy saving ignition

sequencing by igniting the pilot

only when the thermostat calls for

heat.

• System Sentinel

diagnostic system –

our exclusive diagnostic system,

with glowing LED lights, verifies

system operation sequence by

sequence.

• Full port, full flow brass drain

valve

• Low NOx Burner – The Power

Assist enclosed burner design

incorporates stainless steel multiport burner tubes for long term

Low NOx compliant performance.

A sight glass allows for burner

observation and the entire

assembly is easily removable.

A blower guard is provided

against post-installation damage.

The entire design is highly

resistant to the effects of negative

air pressures common to modern

commercial buildings.

™

LED

Certifications and Ratings:

• Efficiency – these models have been tested according to ANSI test

procedures, and exceed the thermal efficiency and standby loss

requirements of ASHRAE (Part of the Federally mandated Energy Policy

Act (EPact)). Also exceeds energy efficiency codes of all states including

California Energy Commission (CEC).

(On Selected

Models)

• Safety and construction – these products are design certified by the

CSA: a) For operation at 180°F. b) To meet all safety and construction

requirements of ANSI Z21.10.3. c) As an automatic storage or instantaneous water heater. d) As an automatic circulating tank water heater.

e) For operation on combustible floors and in alcove installations.

All models are North Carolina Code compliant.

CERTIFIED FOR A 150 PSI MAXIMUM WORKING PRESSURE

(160 PSI FOR ASME MODELS).

• Optional constructions – ASME construction is available on designated

models.

Continued next page.

Page 2

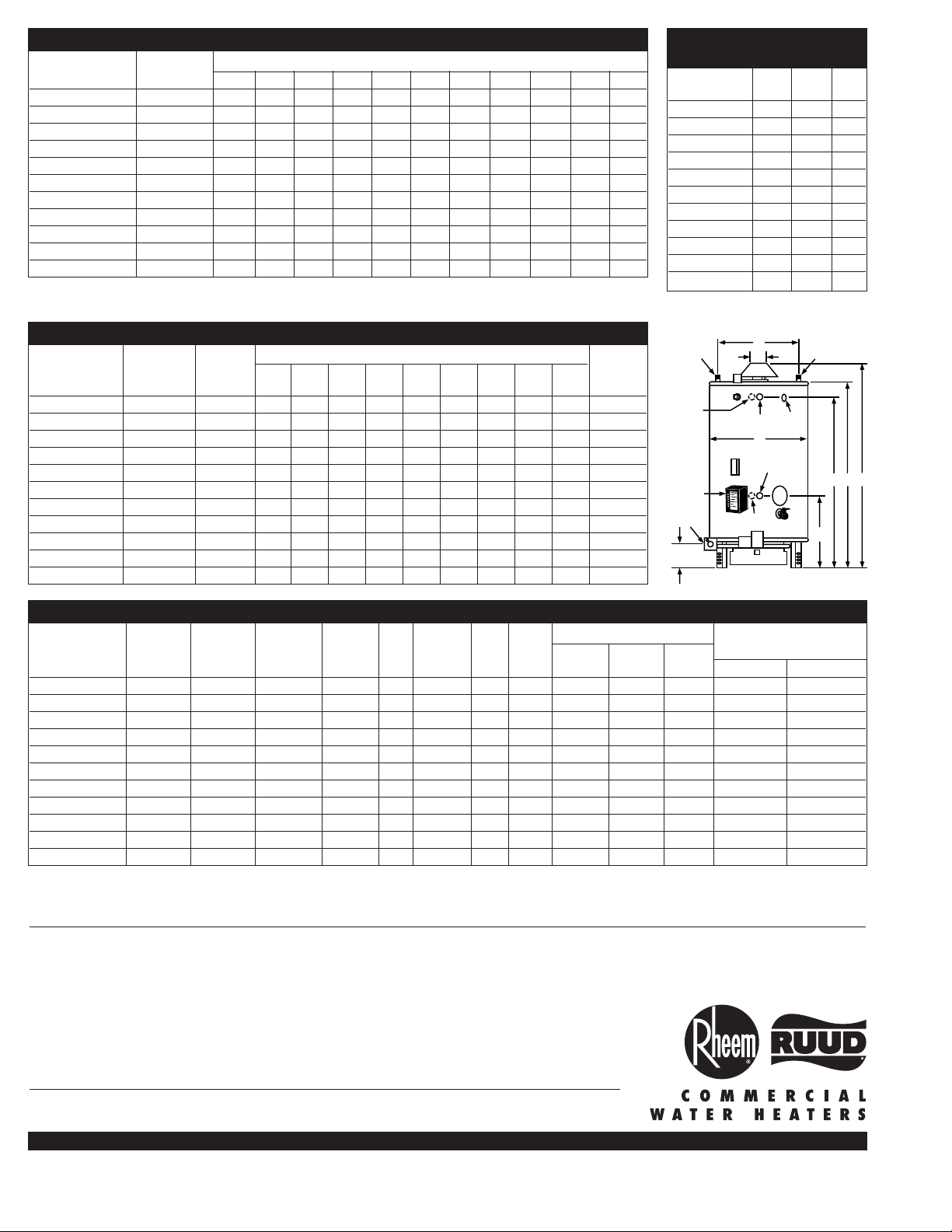

RECOVERY CAPACITIES (80% thermal efficiency)

C

H

E

ABF

D

OUTLET

T

OP

INLET

T

OP

OUTLET

F

RONT SIDE

OUTLET

R

EAR SIDE

S

YSTEM

SENTINEL

T

&P

I

NLET

FRONT SIDE

INLET

REAR SIDE

G

7

"

(178mm)

ODEL INPUT

M

NUMBER BTU/HR. 40°F 50°F 60°F 70°F 80°F 90°F 100°F 110°F 120°F 130°F 140°F

N75-125 125,000 303 242 202 173 152 135 121 110 101 93 87

G

GN82-156 156,000 378 303 252 216 189 168 151 138 126 116 108

GN37-200 199,900 485 388 323 277 242 215 194 176 162 149 138

GN76-200 199,900 485 388 323 277 242 215 194 176 162 149 138

GN91-200 199,900 485 388 323 277 242 215 194 176 162 149 138

GN100-200(A) 199,900 485 388 323 277 242 215 194 176 162 149 138

GN72-250(A) 250,000 606 485 404 346 303 269 242 220 202 186 173

GN100-250(A) 250,000 606 485 404 346 303 269 242 220 202 186 173

GN100-270(A) 270,000 655 524 436 374 327 291 262 238 218 201 187

N65-360(A) 360,000 873 698 582 499 436 388 349 317 291 269 249

G

GN100-400(A) 399,900 969 776 646 554 485 431 388 353 323 298 277

Recovery ratings are based on thermal efficiencies obtained in a CSA certified laboratory.

(A) indicates available ASME model.

GPH

FIRST TIME DELIVERY (Includes useable storage and recovery for indicated times.)

MODEL TANK CAP. INPUT 5 10 15 20 30 45 60 120 180 to Rec.

NUMBER

GALLONS

BTU/HR. Min. Min. Min. Min. Min. Min. Min. Min. Min. Contents

GN75-125 75 125,000 63 73 83 93 113 143 174 295 416 37

GN82-156 82 156,000 70 83 95 108 133 171 209 360 511 33

GN37-200 35 199,900 41 56 72 88 119 167 214 403 562 11

GN76-200 76 199,900 69 86 102 118 150 199 247 441 635 24

GN91-200 91 199,900 80 96 112 128 161 209 258 451 645 28

GN100-200(A) 100 199,900 86 102 118 135 167 215 264 458 652 31

GN72-250(A) 72 250,000 71 91 111 131 172 232 293 535 778 18

GN100-250(A) 100 250,000 90 110 131 151 191 252 312 555 797 25

GN100-270(A) 100 270,000 92 114 135 157 201 266 332 594 855 23

GN65-360(A) 65 360,000 75 104 133 162 220 307 395 744 1093 11

GN100-400(A) 100 399,900 102 135 167 199 264 361 458 846 1233 15

TEMP. RISE AT 100°F IN GALLONS Min.

CLEARANCE TO

COMBUSTIBLES (inches)

MODEL

NUMBER SIDE REAR TOP

GN75-125 2212

GN82-156 2212

GN37-200 2212

GN76-200 2212

GN91-200 2212

GN100-200(A) 2412

GN72-250(A) 6612

GN100-250(A) 2412

GN100-270(A) 2412

GN65-360(A) 6612

GN100-400(A) 6612

DIMENSIONS (Inches)

WATER CONNECTIONS APPROXIMATE

MODEL TOP FRONT REAR

NUMBER AB CDEFGHIN/OUT SIDE SIDE STD. ASME

GN75-125 65-1/2 61 26-1/4 25 5 56 3/4 20 1-1/2 1-1/2 1-1/2 480 lbs. N/A

GN82-156 68-13/16 64 26-1/4 25 6 58-5/8 3/4 20 1-1/2 1-1/2 1-1/2 490 lbs. N/A

GN37-200 49-1/4 43-3/8 26-1/4 25 6 37-5/8 3/4 20 1-1/2 1-1/2 1-1/2 405 lbs. N/A

GN76-200 68-13/16 64 26-1/4 25 6 58-5/8 3/4 20 1-1/2 1-1/2 1-1/2 540 lbs. N/A

GN91-200 76-5/16 71-13/16 26-1/4 30-5/8 6 66-3/8 3/4 20 1-1/2 1-1/2 1-1/2 600 lbs. N/A

GN100-200(A) 73-1/16 66-1/8 30-1/4 23-1/4 6 57-1/2 3/4 23 1-1/2 22780 lbs. 835 lbs.

GN72-250(A) 71-1/16 64-1/2 26-1/4 25 6 58-5/8 3/4 20 1-1/2 1-1/2 1-1/2 590 lbs. 630 lbs.

GN100-250(A) 73-1/4 66-1/8 30-1/4 23-1/4 6 57-1/2 3/4 23 1-1/2 22795 lbs. 835 lbs.

GN100-270(A) 73-7/8 66-1/8 30-1/4 23-1/4 6 57-1/2 3/4 23 1-1/2 22805 lbs. 845 lbs.

GN65-360(A) 70-11/16 64-1/2 26-1/4 25 8 58-5/8 3/4 N/A N/A 1-1/2 1-1/2 640 lbs. 680 lbs.

GN100-400(A) 76 68-1/2 30-1/4 32-1/4 8 61-3/4 1 23 1-1/2 22770 lbs. 810 lbs.

All Models Require a 120V / 1.5 Amp Power Source. (A) Suffix Indicates ASME Tank Construction Available.

SHIPPING WEIGHT

Recommended specifications (for trade reference only)

Water heater(s) shall be UNIVERSAL model ________________, manufactured by RHEEM-RUUD, having gas input of __________ Btu/hr. and a recovery rate of _____________ GPH at a

100°F temperature rise when tested and certified at ____________ thermal efficiency.Water heater(s) shall have a storage capacity of _________ gallons. Water heater(s) shall have the CSA

seal of certification and supplied with a factory installed AGA/ASME rated temperature and pressure relief valve. Tank(s) shall be furnished with a tube bundle having a double coating of high

temperature porcelain enamel and furnished with magnesium anode rods rigidly supported. Water heater(s) shall meet or exceed the thermal efficiency and standby loss requirements of

ASHRAE Standard 90.1b-2001. Tanks shall have a working pressure rating of 150 psi, and shall be completely factory assembled, including a pressure regulator properly adjusted for operation

on ___________ gas with stainless steel burners. Controls will be arranged for safety shutoff in event of pilot failure. Water heater(s) with

inputs less than 360,000 Btu/hr. shall have top, front and rear side inlet/outlet water connections. Water heater(s) shall be covered by a

three year limited warranty against tank leaks.

• Add for ASME construction –

Boiler and Pressure Vessel Code, Section IV Part HLW.

Limited Warranty

This product features a three year limited warranty against tank leaks. Please refer to Commercial Warranty Information brochure for

complete warranty information.

In keeping with its policy of continuous progress and product improvement, Rheem-Ruud reserves the right to make changes without notice.

Rheem Water Heaters • 101 Bell Road, Montgomery, Alabama 36117-4305 • www.rheem.com

P R I N T E D IN U. S . A 0 5 / 0 7 W P

Water heater(s) shall be constructed in accordance with the requirements of the ASME

Form No. RR102C-1CA Rev. 3

Loading...

Loading...