Page 1

INSTALLATION / OPERATION / MAINTENANCE

Applies to: Model VPT 120V 60Hz

Gas-Fired, Tubular, Radiant,

Low-Intensity Infrared Heater

Model VPT

High/Low Burner/Control Box

with 20 - 70 ft Tube/Reflector Length

Doc No 700106 (06-15), Page

Part No. 270684

Page 2

Introduction.

Welcome to the new range of powered HiLo

infra-red heaters. Local regulations may vary

and it is the installer’s responsibility to ensure

that such regulations are satisfied.

All installation, assembly, commissioning and

service procedures must be carried out by

suitable qualified competent persons and

conform with local building codes, or in the

absence of local codes, with the National Fuel

Gas Code ANSI Z223.1/NFPA 54 or the

National Gas and Propane Installation Code

CSA B149.1.

When assembling, installing, commissioning

Document Index.

1 Installation Requirements

1.1 Health & Safety

1.2 Heater Suspension

1.3 Clearance to Combustibles

1.4 Gas Connection & Supply Details

1.5 Electrical Connections

1.6 Ventilation Requirements

1.6.1 Unvented Units

1.6.2 Vertical Venting

1.6.3 Horizontal Venting

1.7 Fresh Air Intake

1.8 Technical Details

2 Assembly Instructions

2.1 Tools Required

2.2 Assembly Notes

2.2.1 Emitter tubes

2.2.2 Turbulator Strips and Burner Inserts

2.2.3 Brackets

2.2.4 Couplers

2.2.5 Reflectors

2.2.6 End Caps (optional)

2.2.7 Bends (where required)

2.2.8 Burner/Fan Assembly

2.2.9 Detailed Assembly Drawings

and servicing is undertaken on radiant tube

heaters specified in these instructions, due care

and attention is required to ensure that working

at height regulations are adhered to

PLEASE READ this document prior to

installation to familiarize yourself with the

components and tools you require at the various

stages of assembly.

All Dimensions shown are in inches unless

otherwise stated.

The manufacturer reserves the right to alter

specifications without prior notice.

3 Start Up Instructions

3.1 Tools Required

3.2 Start up procedure

4 Servicing Instructions

4.1 Tools Required

4.2 Burner Description

4.3 Burner Removal

4.4 Burner Gas Injector Servicing

4.5 Burner Head and Electrode Servicing

4.6 Combustion Fan Assembly

4.7 Emitter Tube Servicing

4.8 Reflector Servicing

4.9 Cleaning of Vent

4.10 Re-commissioning after Service

5 Troubleshooting Guide

6 Replacing Parts

6.1 Burner Controller Replacement

6.2 Air Pressure Switch Replacement

6.3 Gas Valve Replacement

7 User and Operating Instructions

7.1 To Start Heater

7.2 To Switch Off Heater

7.3 Servicing

1. Installation Requirements.

1.1 Health and Safety

A. Heater is intended for heating

non-residential indoor spaces and should

only be installed where flammable gases or

vapors are not present.

B. Heaters can be suspended horizontally or at

any angle along the axis of the tubes but

can only be rotated about the burner head 0

to 55°. See section 1.3 for clearance

dimensions.

Doc No 700106 (06-15), Page 2

C. The installation must conform with local

building codes or, in the absence of local

codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or the Natural Gas

and Propane Installation Code, CSA B149.1.

D. The unit shall be electrically grounded in

accordance with National Electric Code

ANSI/NFPA 70 and Canadian Electrical

Code CSA C22.1.

E. The heater may be installed in aircraft

hangars in accordance with the Standard for

Aircraft Hangars, ANSI/NFPA 409 and in

Page 3

automotive garages when installed in

accordance with the Standard for Parking

Structures, ANSI/NFPA 88A, or the

Standard for Repair Garages, ANSI/NFPA

88B, or the Canadian Natural Gas and

Propane Installation Code, CSA B149.1,

and are so marked.

Ensure that minimum clearances will be

maintained to vehicles parked below the

heater.

F. The standard heaters are approved for

installations between 0 - 2000ft (0 - 610m)

above sea level for the US and 0 - 4500 ft

(1370m) above sea level for Canada.

Conversion kits are available for installations

above these heights in the USA.

G. Massachusetts Requirement: If the

heater is being installed in the Commonwealth

of Massachusetts, this unit must be installed by

a licensed plumber or licenced gas fitter.

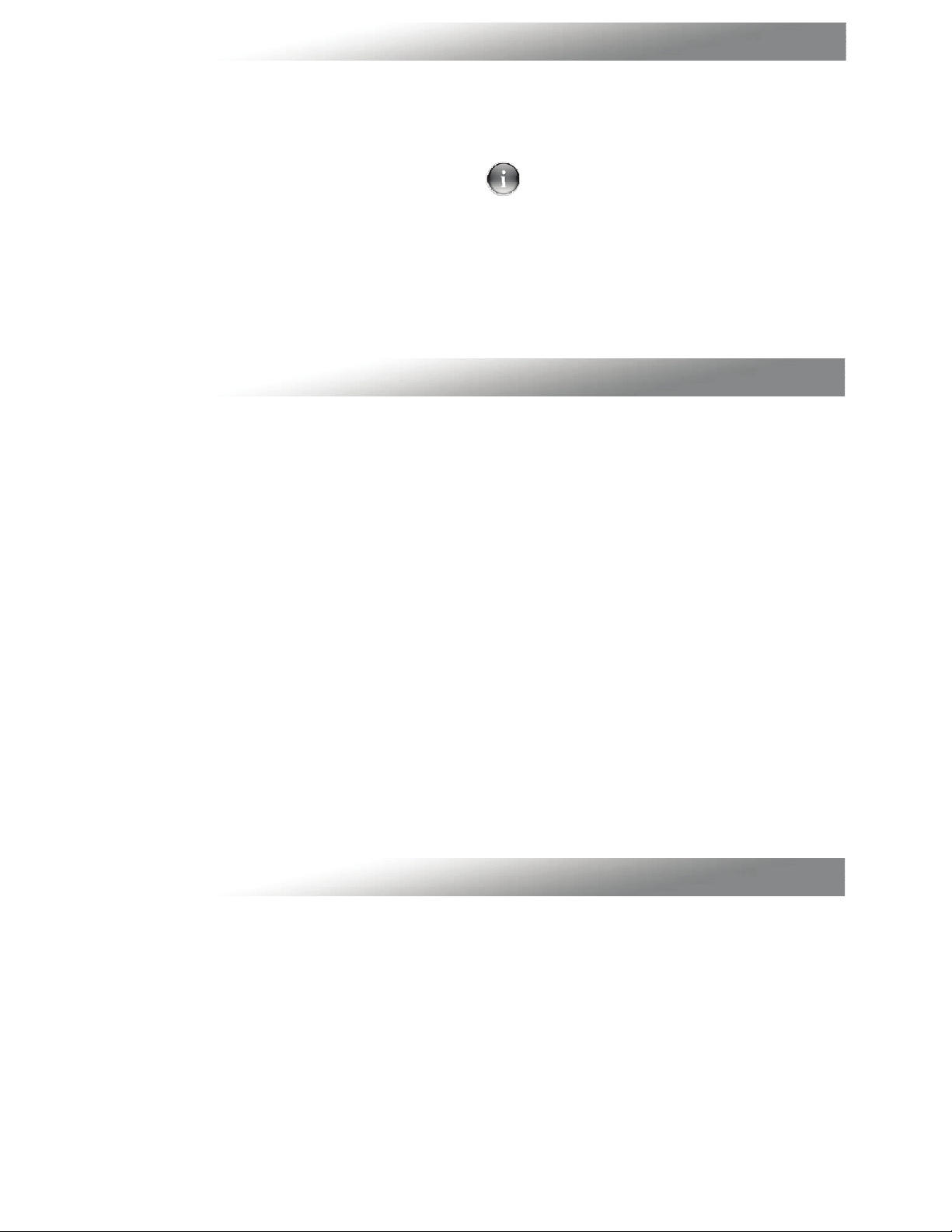

1.2 Heater Suspension

Attachment to the heater support lugs should

be made by D shackle. The hanging

attachments to overhead steelwork etc. have

to be designed and produced in accordance

with sound engineering practices. They must be

adequately fixed and designed to carry the

whole weight of the heater. In the event of

suitable roof steelwork being unavailable,

additional steelwork should be fitted to enable

vertical hangers to be used for suspending the

heaters.

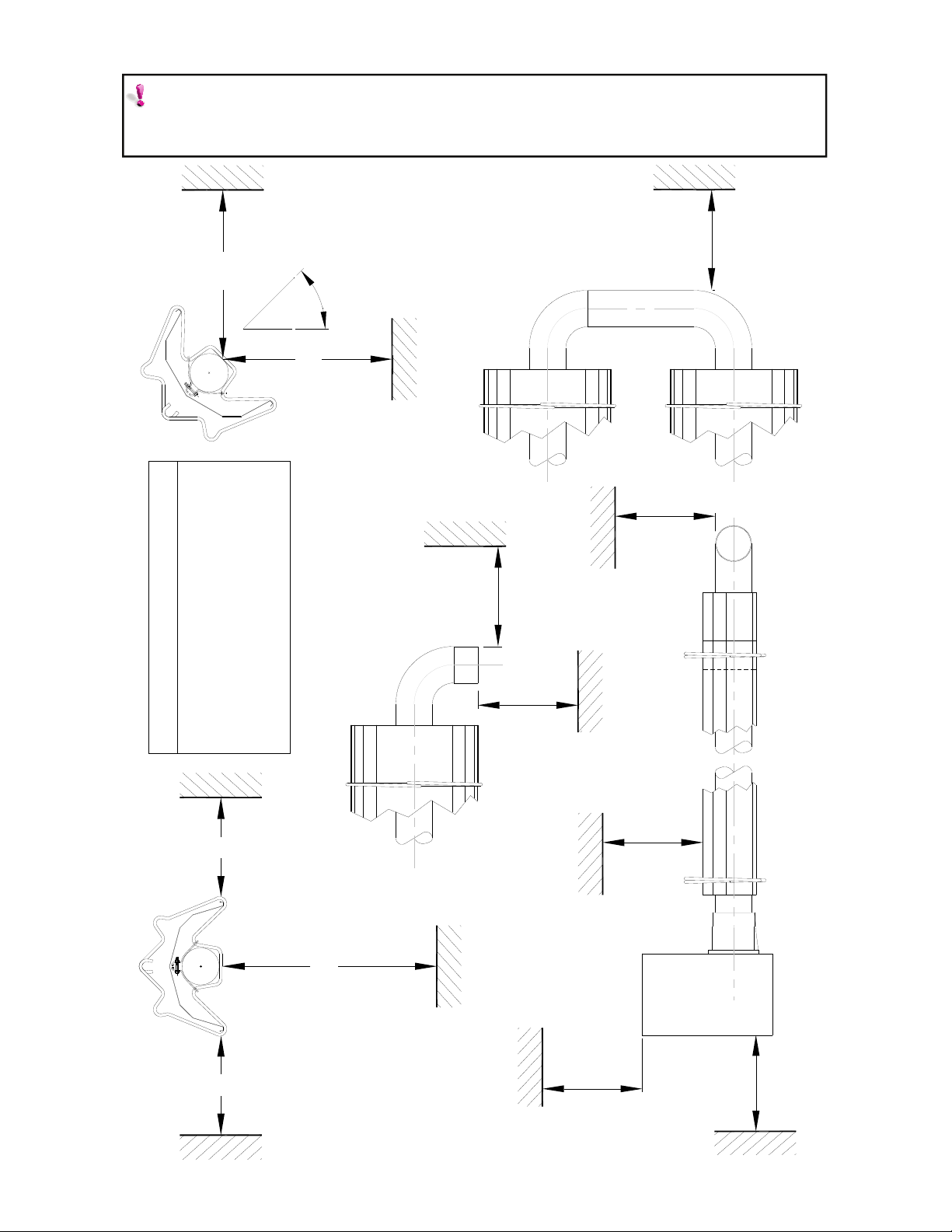

These methods are illustrated in Figure 1. If

there are any doubts as to the strength or

suitability of roof steelwork to which heaters are

to be suspended, please refer to a Consultant,

Architect or owner of the building.

It is recommended that the heater is raised to its

final position once the assembly of the emitter

tube/bracket/reflector has been completed.

Longer tube assemblies may be raised in more

than one sub-assembly with final emitter tube

connection made in the air.

Ensure that the installer uses the burner roof

support mounting bracket when suspending the

heater. This is situated on the front of the

burner. When packed the bracket is reversed

and must be turned to its correct state for

mounting. (ref page 15)

WARNING:

If not installed, operated and maintained in accordance with the manufacturer’s

instructions, this product could expose you to substances in fuel or from fuel combustion

which are known to the state of California to cause cancer, birth defects or other

reproductive harm.

U TUBE VARIANTS

NOTE.

'S' HOOKS ARE TO

BE CLOSED UP

AFTER ASSEMBLY

SUITABLE CHAIN

WORKING LOAD

LIMIT 100LB

EXHAUST

END

CHAIN

55° SUSPENSION

Figure 1. Recommended Methods of Heater Suspension.

Doc No 700106 (06-15), Page 3

BURNER

END

Page 4

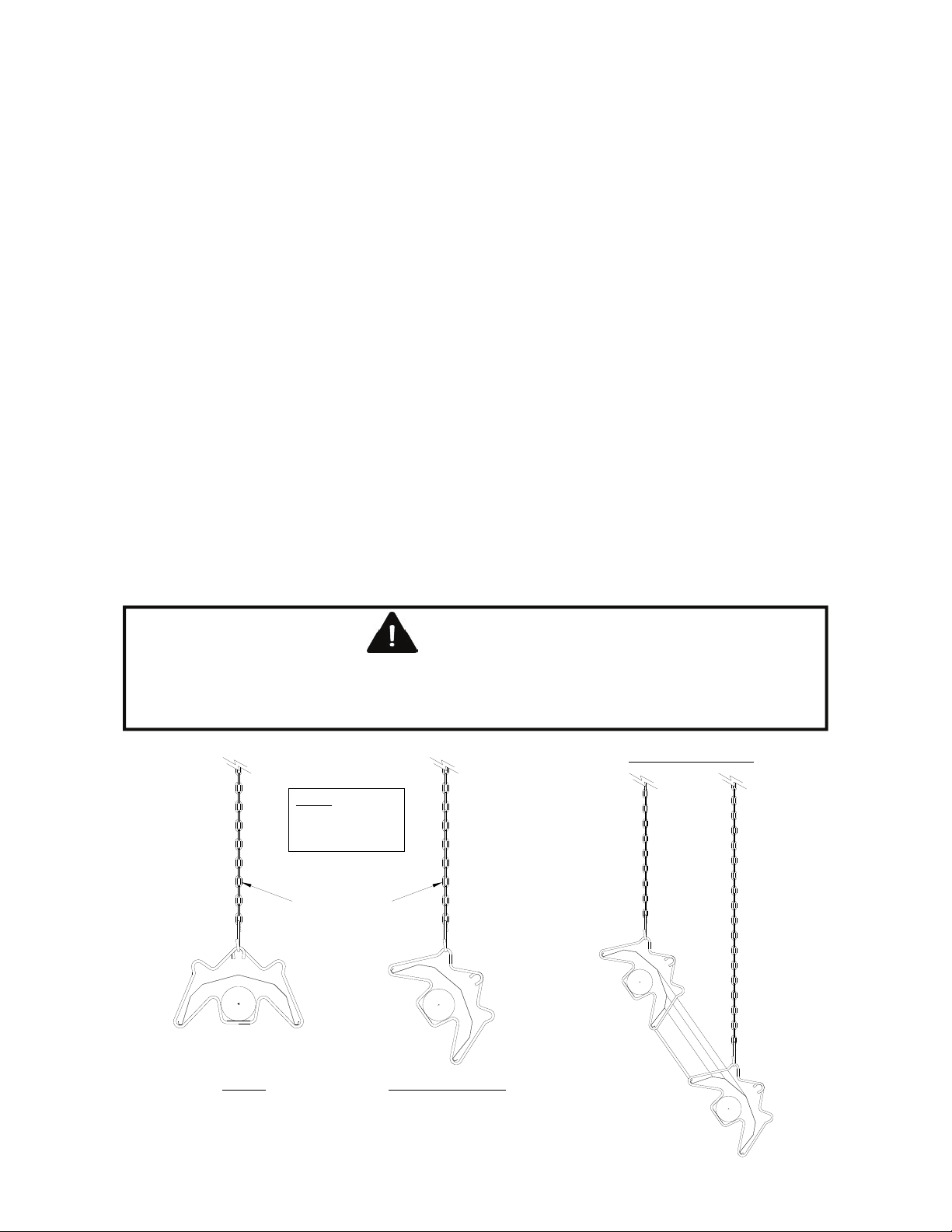

ON VENTED HEATERS, THE HEATER SHOULD SLOPE DOWNWARDS AWAY FROM

THE BURNER AND ON UNVENTED HEATERS SHOULD SLOPE DOWNWARDS

TOWARDS BURNER BY APPROX. ½” FOR HORIZONTAL INSTALLATIONS AS SHOWN

BELOW (DIAGRAMS EXAGGERATED FOR CLARITY)

1/2”

VENTED

1/2”

UNVENTED

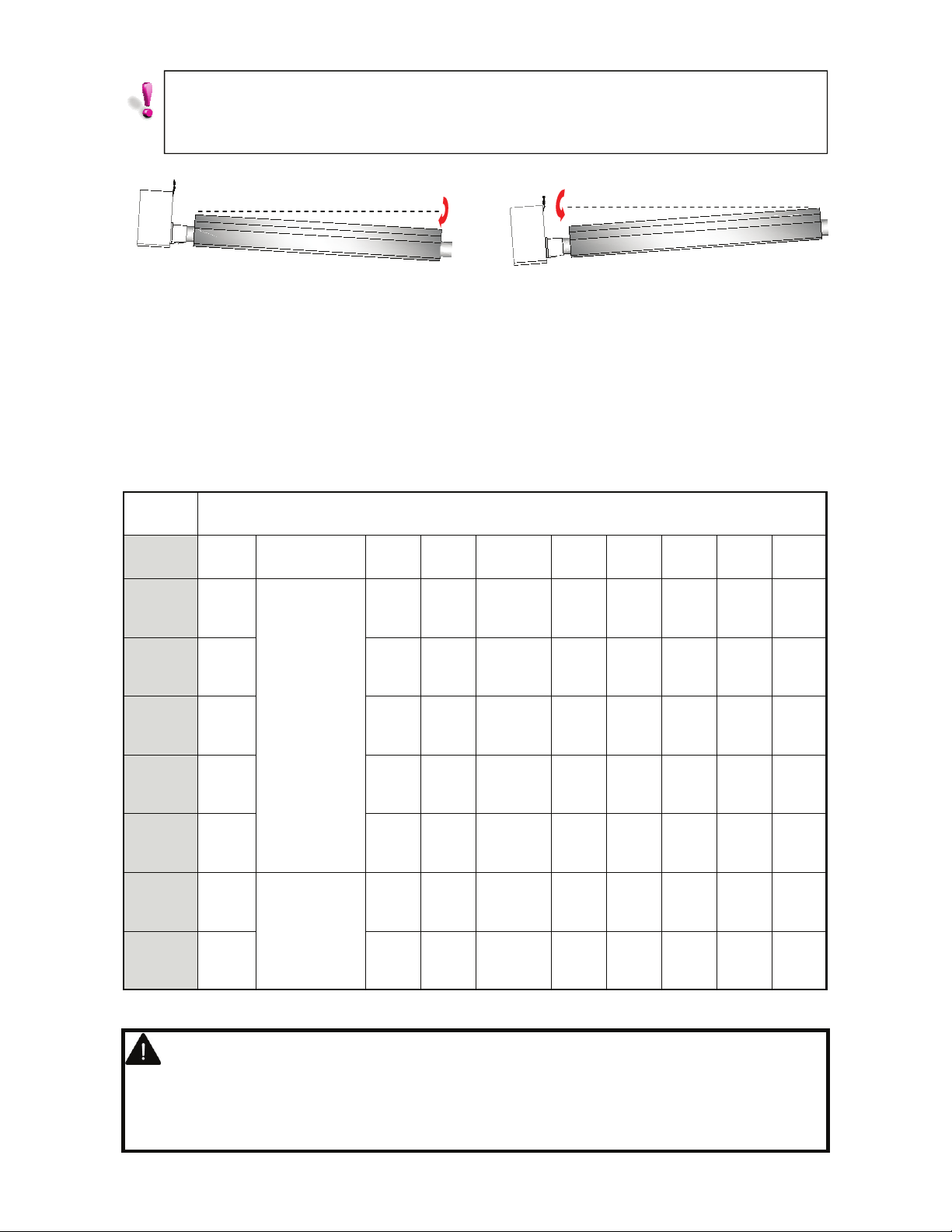

1.3 Clearance to Combustibles.

Minimum clearance to combustibles are shown in Table 1 below.

IMPORTANT:

The stated clearance to combustibles represents a surface temperature of 90°F (50° C) above room

temperature. Building material with a low heat tolerance (such as plastics, vinyl siding, canvas, tri-ply,

etc.) may be subject to degradation at lower temperatures. It is the installer’s responsibility to assure

that adjacent materials are protected from degradation.

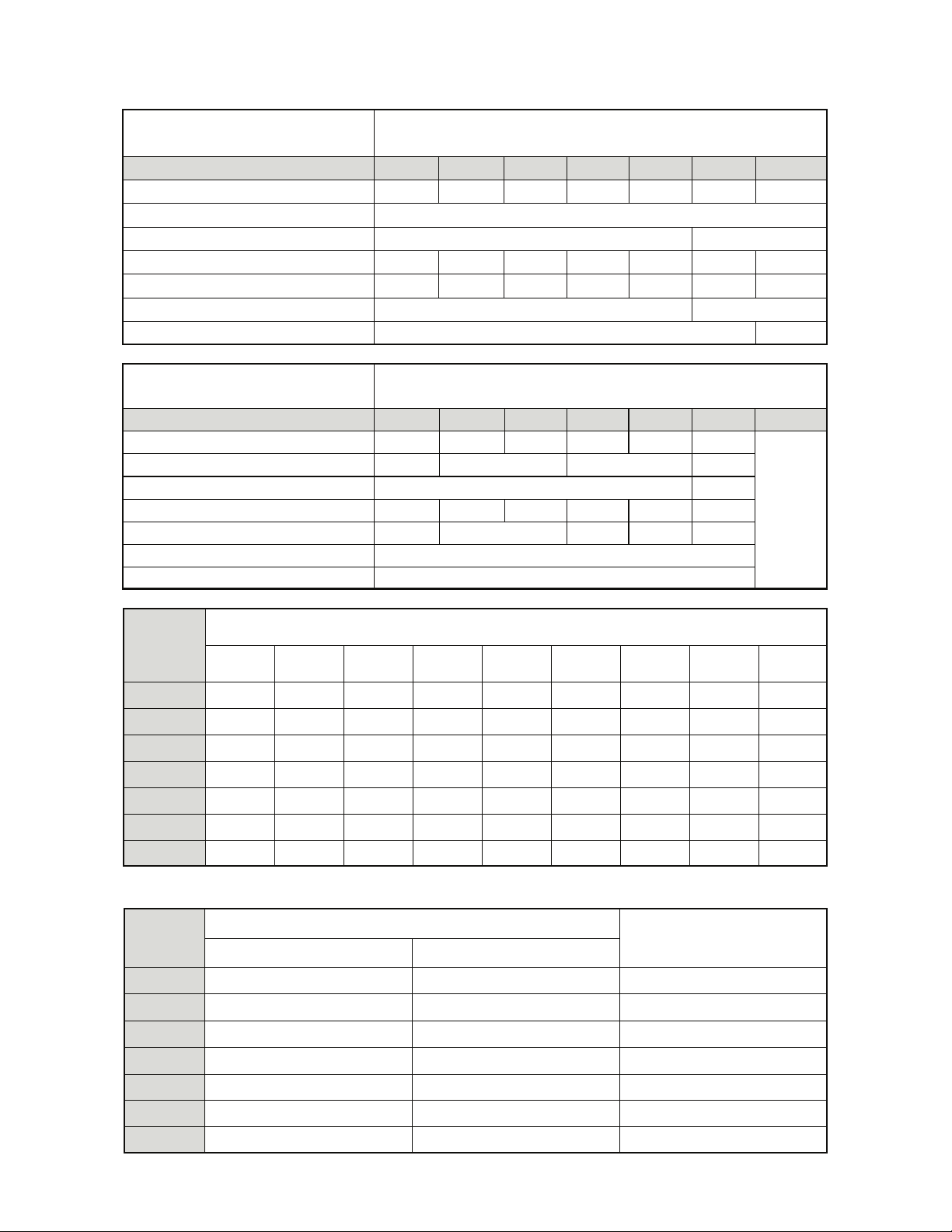

Table 1

MODEL A A1 / A2 B B1 C1 C2 C3 D1 D2 E

Clearance to Combustibles, inches (cm)

60

74

(188)

29

(74)

41

(105)

20 (51) /

10* (26)*

8

(21)

22

(56)

8

(21)

12

(31)

12

(31)

80

74

(188)

29

(74)

41

(105)

20 (51) /

10* (26)*

8

(21)

22

(56)

8

(21)

12

(31)

12

(31)

15° = 72 (183)

25° = 68 (173)

100

74

(188)

35° = 61 (155)

45° = 53 (135)

32

(82)

41

(105)

20 (51) /

10* (26)*

8

(21)

22

(56)

8

(21)

16

(41)

12

(31)

55° = 43 (110)

125

150

170

74

(188)

74

(188)

86

(219)

15° = 82 (209)

25° = 78 (199)

39

(99)

39

(99)

48

(122)

47

(120)

48

(122)

48

(122)

20 (51) /

10* (26)*

20 (51) /

10* (26)*

20 (51) /

10* (26)*

8

(21)

8

(21)

11

(28)

22

(56)

22

(56)

22

(56)

20

(51)

20

(51)

20

(51)

18

(46)

18

(46)

20

(51)

12

(31)

12

(31)

12

(31)

35° = 71 (181)

45° = 61 (155)

200

* distance with end caps fitted.

86

(219)

WARNING:

55° = 50 (127)

Minimum clearance from the heater must be maintained from vehicles

parked below heater. In all situations, clearances to combustibles must be

48

(122)

48

(122)

20 (51) /

10* (26)*

11

(28)

22

(56)

20

(51)

20

(51)

12

(31)

maintained. Signs should be posted in storage areas to specify maximum stacking height to

maintain required clearance to combustibles. Such signs must either be posted adjacent to

the heater thermostats or in the absence of such thermostats in a conspicuous location.

Refer to mounting clearance tables.

Doc No 700106 (06-15), Page 4

Page 5

Figure 2 Clearance to Combustibles (Standard indoor reflectors)..

The minimum clearances to combustible materials are given in Table 1 These minimum

distances MUST be adhered to at all times. Adequate clearance MUST be provided around air

openings into the combustion chamber and there MUST be suitable clearance for accessibility and

for combustion / ventilating air supplies.

D2

A2

.

0° to 55°

Angled view.

Return end on

U tube heater

A1

C3

WARNING!

combustion and ventilation air supply.

provision in the building for

Ensure that there is adequate

Installation must meet minimum

B

requirements and applicable codes.

Below

A

Outlet end.

heater

D1

End

B1

Side

unvented

unvented

unvented

Above outlet

Above

Reflector

C2

Burner end.

B

Side

Doc No 700106 (06-15), Page 5

vented

End view.

C1

Above

Burner

Above

C1

Burner

E

E

Service

distance

Service

distance

Page 6

1.4 Gas Connection and Supply

WARNING: Before installation, check

that the local distribution conditions,

nature of gas and pressure, and adjustment

of the appliance are compatible.

The gas connection on the heater is ½” N.P.T

internal thread.

Injector sizes and manifold pressure for the

burners are shown in the table 3. The gas

supply piping and connections must be installed

so that the minimum pressure stated is

achieved.

A gas shut off valve and union should be fitted

in the gas supply line close to the heater and a

⅛” N.P.T plugged tapping, accessible for test

gauge connection, provided immediately

upstream of the appliance gas inlet.

It is essential to provide some flexibility in the

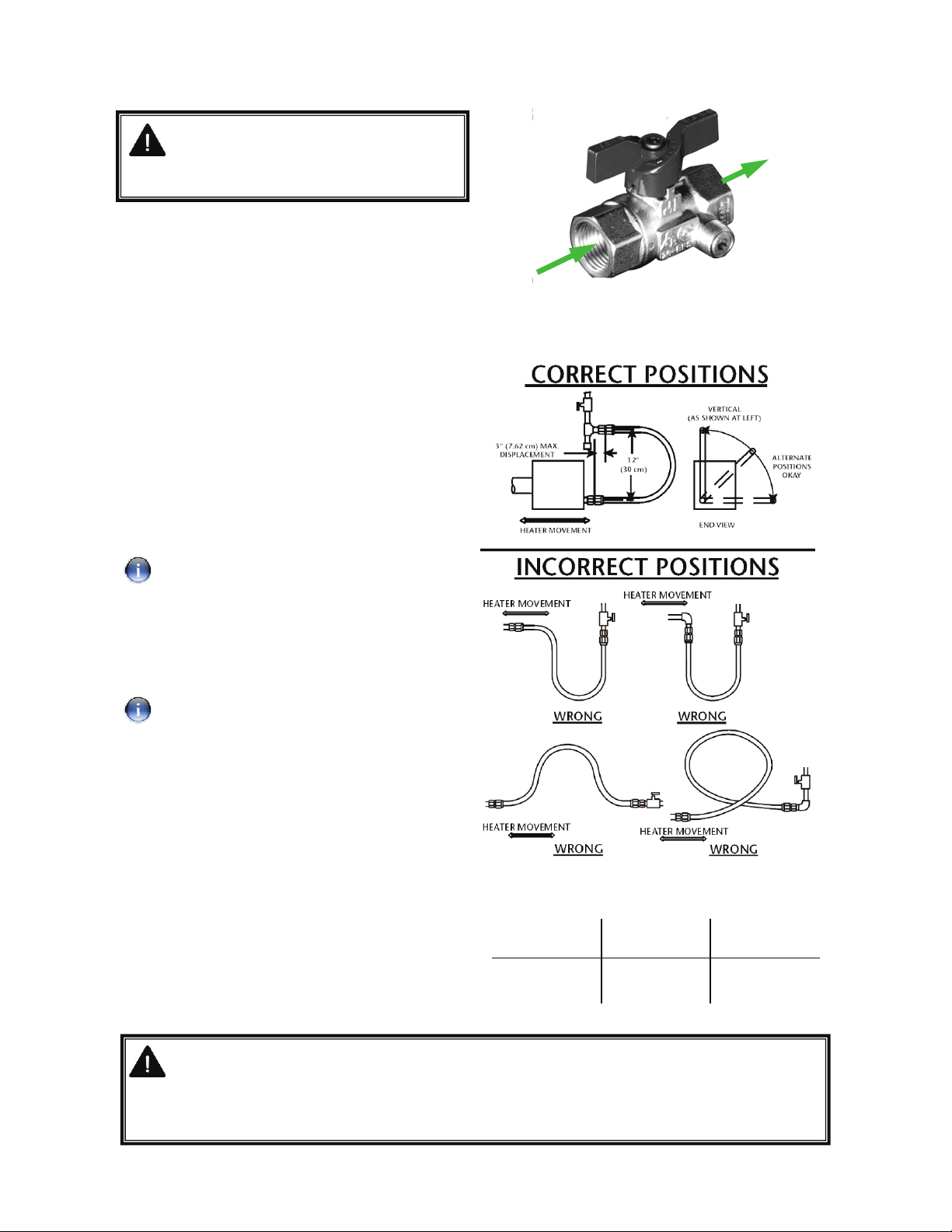

final gas connection by use of an approved

flexible gas connector. (See Fig 4.)

Take care when making a gas connection

to the heater not to apply excessive turning

force to the internal controls.

Care must be taken to observe the pipe bend

diameter of 12” (30cm) and pipe displacement

distance of 3” (7.62cm).

The correct installation as shown will allow

for approx 4” of movement due to

expansion.

Figure 3. Correct orientation of Ball Valve

Gas Flow

Gas Flow

Figure 4. Correct Installation of Flexible

Gas Connection

* Connector must be certified for use on a radiant tube

type infrared heater and must comply with Standard for

Connectors for Gas Appliances, ANSI Z21.24/CSA 6.10 or

with the Standard for Elastomeric Composite Hose and

Hose Couplings for Conducting Propane and Natural Gas,

CAN/CGA 8.1.

For heaters up to 150,000Btu/h, ½” ID x 24” long

For heaters 150,000Btu/h and above, ¾” ID x 36” long

NOTE: For Canada all heaters MUST use a hose 36” long

(See Table 3)

Table 3

HOSE SIZE USA CANADA

3/4” CE4

CONTACT

FACTORY

WARNING: FIRE OR EXPLOSION HAZARD - It is essential to provide some flexibility in

the final gas line connection by use of an approved flexible connector as shown in the

drawings. Expansion of the radiant pipe occurs with each firing cycle causing the burner to

move with respect to the gas line. This can result in a gas leak producing an unsafe

condition.

Doc No 700106 (06-15), Page 6

Page 7

CONNECTOR MUST BE INSTALLED IN A “U” CONFIGURATION. FOR HEATERS UP

TO 150,000 BTU/H, A 24” LONG CONNECTOR OF AT LEAST ½” ID MUST BE USED.

FOR HEATERS ABOVE 150,000 BTU/H, A 36” LONG CONNECTOR OF AT LEAST ¾”

NOMINAL ID MUST BE USED.

Table 4 Gas Supply Pressures

Gas Type

Min Required Gas Pressure (in W.C)

Max Supply Pressure (in W.C)

Natural Gas LP/Propane Gas

7.0 11.0

14.0 14.0

Gas Supply Connection ½” N.P.T thread

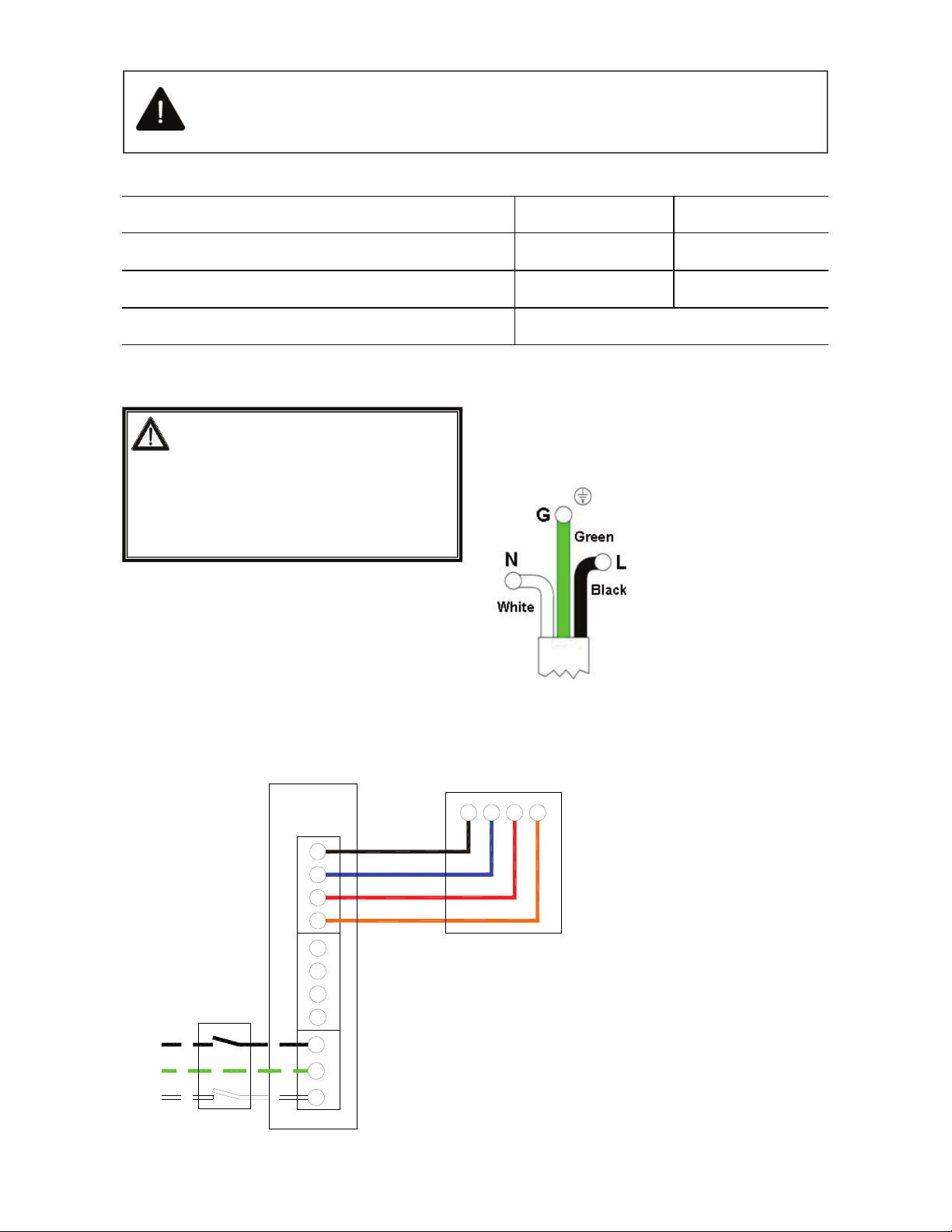

1.5 Electrical Connections

Important: All electrical work should be done by a

qualified electrician in strict accordance with the

WARNING: Before making electrical

connections, switch OFF the main

electrical disconnect. There may be more

than one disconnect switch. Lock out

and tag switch with a suitable warning

label. Electrical shock can cause

personal injury or death.

National Electrical Code ANSI/NFPA 70 or

Canadian Codes CSA C22.1.

The electrical supply to

the heater is by three

wires: hot (Live), neutral

and ground connections.

Install in accordance with

This appliance must be electrically grounded

Supply 120V 60Hz single phase.

Standard heater 0.16HP.

Current rating (inductive):

1.8 amp max (models 60 - 150)

1.0 amp max (models 170 & 200)

all state & local codes.

Where alternative

manufacturers controls

are used, please refer to

their instructions for their

installation details.

Fuse: external 3 amp.

Figure 5. External Wiring Schematic

Burner 1

BK

BL

R

O

120V AC

Supply

24V AC

Terminals

(120V AC Fan

Terminals)

BK

G

W

Doc No 700106 (06-15), Page 7

R

C

W1

W2

F1

F2

E

N

L

E

N

24V AC 2-Stage

Thermostat (Ext.)

W1 W2

RC

KEY:

BK-BLACK

BL-BLUE

R-RED

O-ORANGE

G-GREEN

W-WHITE

Notes:

Use 18/4 class 2 thermostat cable

between heater and thermostat.

Max. length @ 18 Awg (0.8mm²) =

100ft.

Only one burner can operate from

one thermostat as supplied.

When servicing heaters ensure

the electricity supply is isolated

from the mains supply.

120V AC supply is still present at

each burner when the thermostat

is switched off.

Page 8

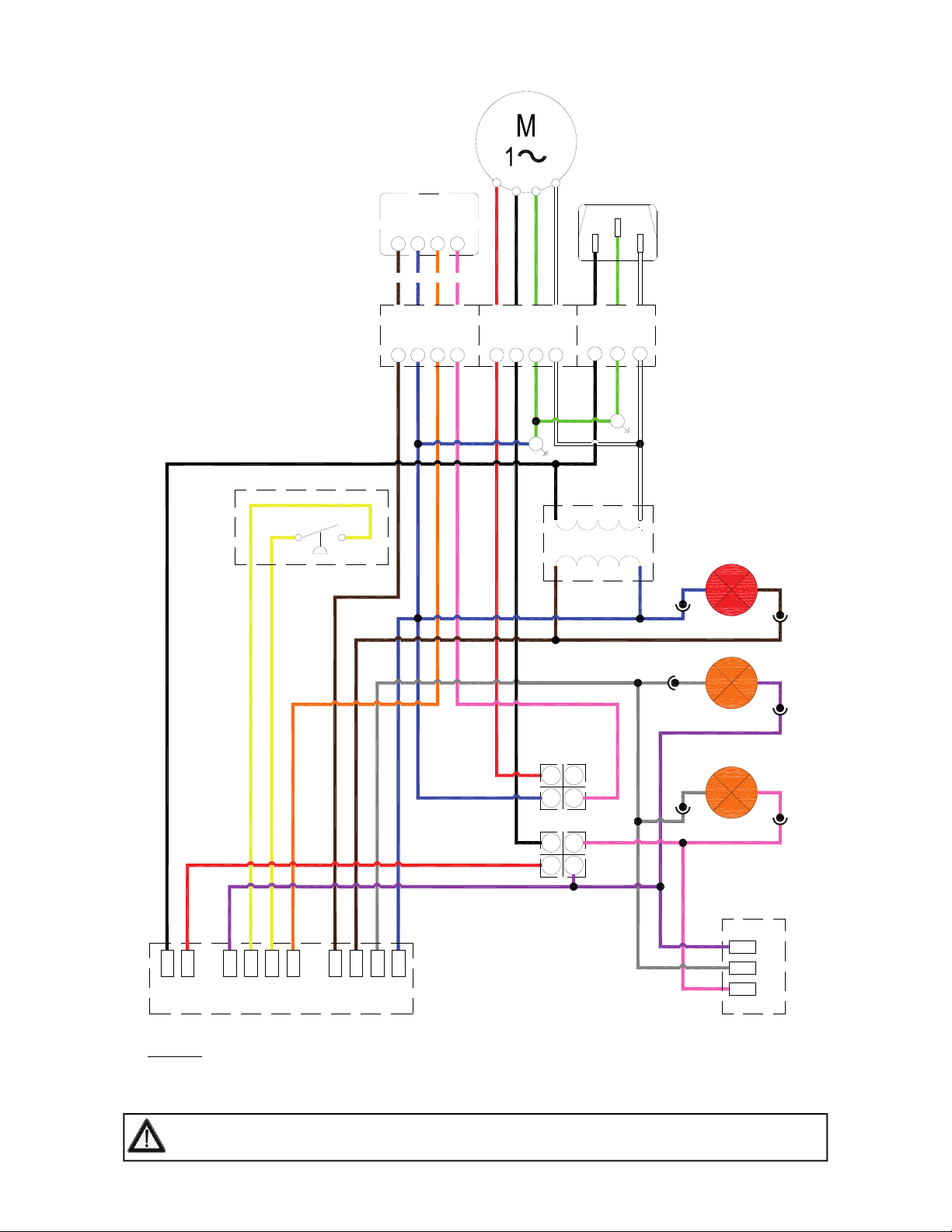

Figure 6a. Internal Burner Wiring Diagram.

24V Two stage

Thermostat

R

BR

24V AC Stat

Terminals

R

BR

YY

Pressure Switch

E

LN

W2W1

C

G

O

BL

120V AC Fan

W

BK

120V AC

G

R

K

Terminals

W2W1

C

O

BL

F1 NEF2

K

G

R

W

BK

BK

Supply

LNE

G

BK

W

KEY:

BL - BLUE

BK - BLACK

W

BR - BROWN

GR - GREY

G - GREEN

E

E

K - PINK

R - RED

W - WHITE

Y - YELLOW

BK

120V/24VAC 60Hz

Transformer

BR

W

O - ORANGE

P - PURPLE

Power ON (red)

BL BR

High Fire

Low Fire

Relay

R

1222

A2

24V AC

RELAY

21

NC

A1

COIL

1424

NO

11

COM

BL

BK

R

Y

Y

P

R

BK

L1

IND

MV

O

BR

R

W1

PS1

PS0

BR

BL

GR

X

C

COM

Gas Control

(amber)

High Fire

P

M

GR

C

K

HI

NOTES:Power On light is permanently illuminated when 120V / 60 Hz AC external supply is connected to burner.

Additional wiring is required to install an optional extra thermostat and / or time clock.

Wire specification:- 18 AWG (1.0mm²), Tri-rated, 105°C

PGR

KGR

Gas Valve

If any of the original wire as supplied with the appliance must be replaced, it must be replaced

with wiring material having a temperature rating of at least 220°F/105°C

Doc No 700106 (06-15), Page 8

Page 9

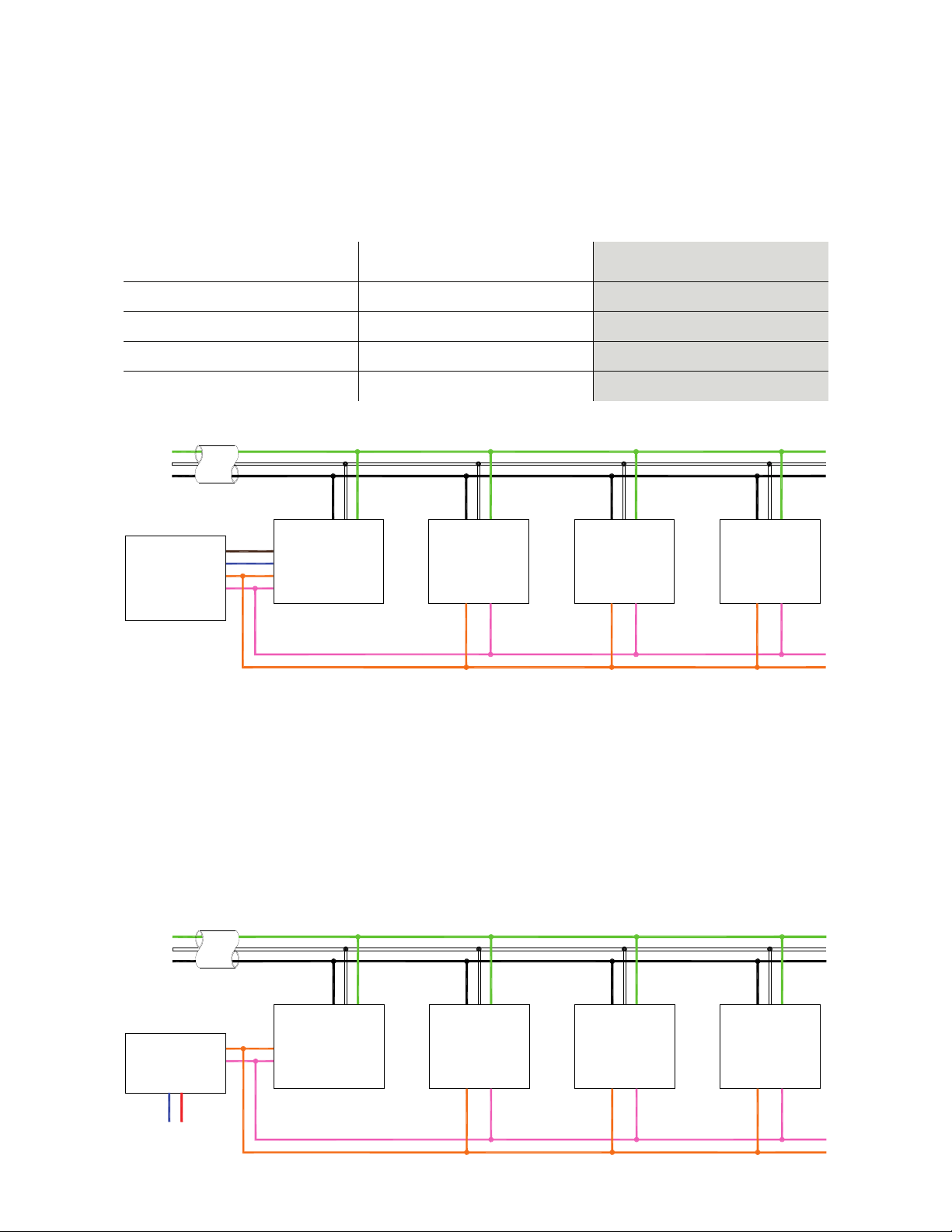

1.5.1 Multiple burner configurations (Master

& Slave) via Optional Relay .

Refer to figure 6b and 6d.

Multiple VPT burners can be controlled via one

main burner. In this scenario the main burner is

knows as the ‘Master’ and any additional

burners are known as ‘Slaves’.

The external two stage thermostat is connected

to the Master burner and powered via the inbuilt

transformer. The total burner load for the Master

is 20VA. Each additional ‘Slave’ burner is 1.6VA

The Thermostat chosen to control the multiple

heaters must not have a power requirement

exceeding the spare capacity as shown in the

examples below:

CONFIGURATION TOTAL BURNER LOAD SPARE FOR THERMOSTAT

Master PLUS 1 Slave 21.6VA

Master PLUS 3 Slaves 24.8VA

Master PLUS 5 Slaves 28.0VA

Master PLUS 7 Slaves 31.3VA

Figure 6b. Wiring schematic. Multiple Burners Master and Slave.

GND

L2

L1 (HOT)

120V 60Hz 1 Ph

Supply circuit

R

C

W1

W2

MASTER

BURNER

W1

W2

R

C

THERMOSTAT

24VAC 60Hz 1 Ph Hi/Lo circuit

1.5.2 Multiple burner configuration via

independently powered two stage

thermostats. Refer to figures 6c and 6d.

Note: If the thermostat has an independent

power supply, all burners in the zone to be

controlled MUST be Slave burners.

The maximum number of Slave burners per

thermostat is dependent on the maximum

power output of the thermostat selected.

LEN

SLAVE

BURNER

W1 W2

Each ‘Slave’ burner is rated at 1.6VA 24VAC

60Hz.

The external two stage thermostat is powered

via its own power supply and must output to

each Slave burner - 24VAC for low fire to

terminal W1 and 24VAC for hi fire to both

terminals W1 and W2

Refer to thermostat manufactures literature for

details.

18.4VA

15.2VA

12.0VA

8.8VA

LENLENLEN

SLAVE

BURNER

W1 W2 W1 W2

SLAVE

BURNER

Figure 6c. Wiring schematic. Multiple Burners via independently powered Relay.

GND

L2

L1 (HOT)

120V 60Hz 1 Ph

Supply circuit

Low fire output

Hi fire output

THERMOSTAT

Supply Circuit

(by others)

Doc No 700106 (06-15), Page 9

24VAC 60Hz 1 Ph Hi/Lo circuit

W1

W2

SLAVE

BURNER

LEN

SLAVE

BURNER

W1 W2

LENLENLEN

SLAVE

BURNER

W1 W2 W1 W2

SLAVE

BURNER

Page 10

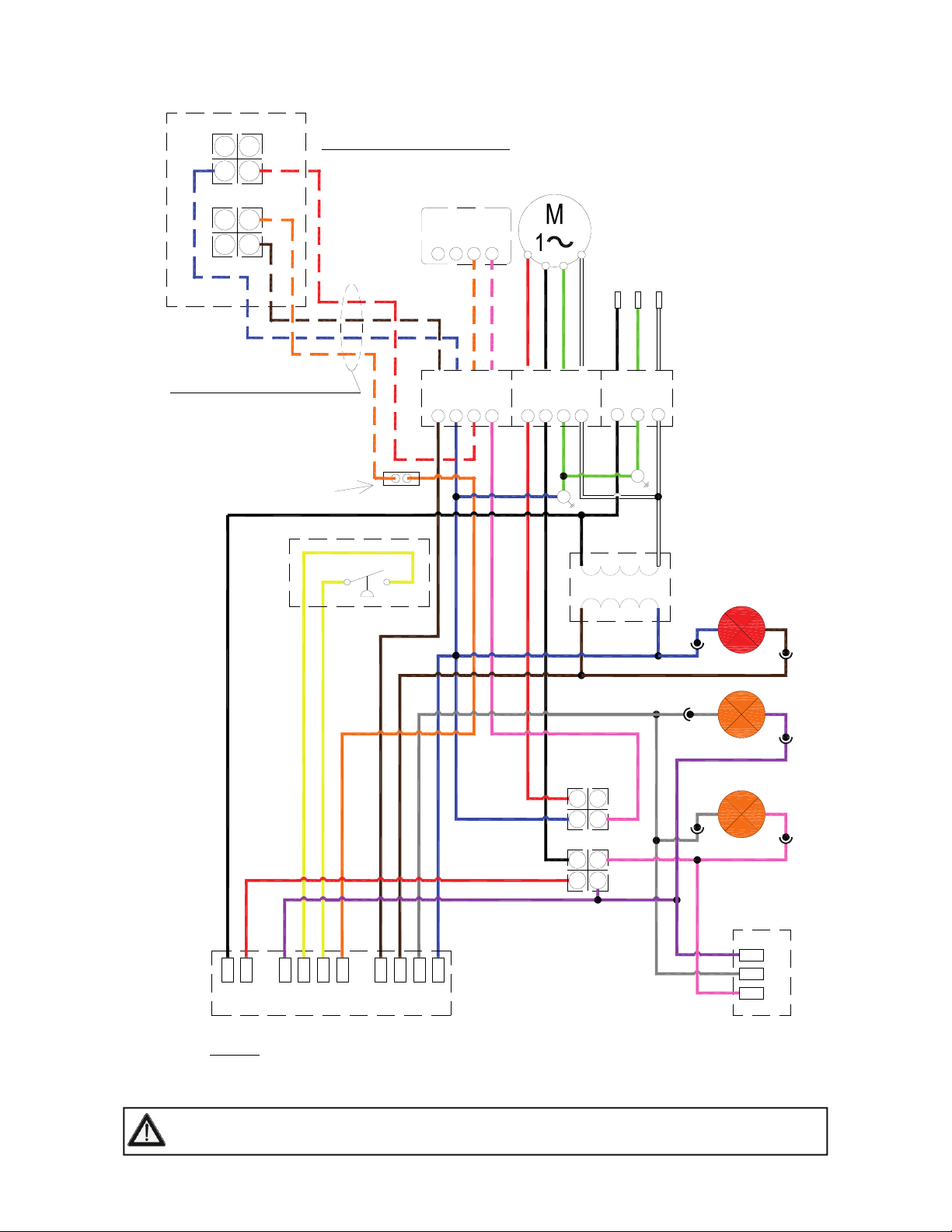

Figure 6d. Internal Slave Burner Wiring/External Schematic Diagram with Optional Relay.

1222

A2

24V AC

RELAY

21

R

A1

COIL

O

1424

NO

11

BL

OPTIONAL RELAY WIRING

COM

O

BR

BL

Relay mini harness leads

5A connector

24V Two stage

Thermostat

R

24V AC Stat

Terminals

R

BR

YY

Pressure Switch

W2W1

C

K

O

G

R

W

BK

120V AC Fan

Terminals

W2W1

C

BL

F1 NEF2

K

G

R

W

BK

E

E

L

G

BK

120V AC

Supply

LNE

G

BK

E

N

W

KEY:

BL - BLUE

BK - BLACK

W

BR - BROWN

GR - GREY

G - GREEN

K - PINK

R - RED

W - WHITE

Y - YELLOW

BK

120V/24VAC 60Hz

Transformer

BR

W

O - ORANGE

P - PURPLE

Power ON (red)

BL BR

PGR

High Fire

Relay

R

1222

A2

24V AC

RELAY

21

NC

A1

COIL

1424

NO

11

COM

BL

BK

R

Y

Y

P

R

BK

L1

MV

IND

O

BR

R

W1

PS1

PS0

BL

BR

GR

X

C

COM

Gas Control

Low Fire

(amber)

High Fire

P

M

GR

C

K

HI

KGR

Gas Valve

NOTES:Power On light is permanently illuminated when 120V / 60 Hz AC external supply is connected to burner.

Additional wiring is required to install an optional extra thermostat and / or time clock.

Wire specification:- 18 AWG (1.0mm²), Tri-rated, 105°C

If any of the original wire as supplied with the appliance must be replaced, it must be replaced

with wiring material having a temperature rating of at least 220°F/105°C

Doc No 700106 (06-15), Page 10

Page 11

1.6 Vent Requirements and Details

1.6.1 Unvented units

Heaters may be installed unvented providing

the governing building codes are met and

consideration is properly given to

possibilities of condensation on cold surfaces.

Installation shall meet the following

requirements when unvented:

• Natural or mechanical means shall be

provided to supply and exhaust at least 4

CFM per 1000 BTU per hour input of

installed heaters.

• Combustion gases shall not impinge on

combustible materials.

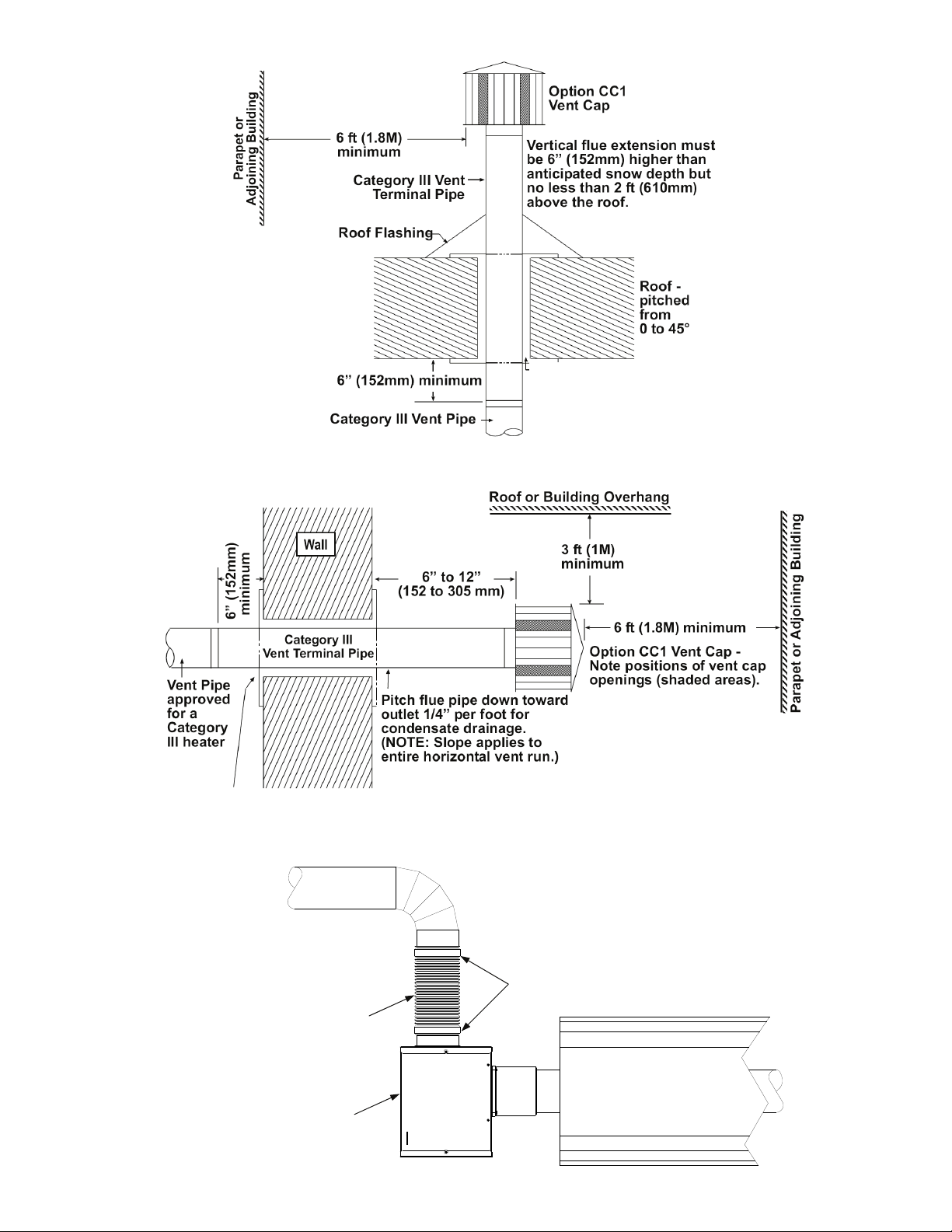

1.6.2 Vertical venting

The heater can be installed with a vertical vent.

All vent piping should be adequately supported

from the building structure and terminated with

an approved terminal.

recommended vent length is 25ft (7.6m) with

a maximum of two elbows

should be properly sealed. refer fig 7a

1.6.3 Horizontal venting

Individual units can be vented horizontally

through side walls. Recommended terminals

are Part Numbers 111848 for 4” and 111850 for

6”.

Distances from adjacent public walkways,

adjacent buildings, openable windows and

building openings, consistent with the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 or the

Natural Gas and Propane Installation Code,

CSA B149.1.

The maximum recommended vent length is

25ft (7.6m) with a maximum of two 90°

elbows.

However runs up to 12ft (3.6m) can

use 4” (101mm) vent pipe. Runs over 12ft

(3.6m) should always use 6” (152mm) vent

pipe.

An approved clearance thimble is required

when the flue pipe passes through combustible

materials. Follow the requirements of the

thimble manufacturer.

Standard vent terminals must extend at least

6” (152mm) from the wall and at least

The maximum

. All connections

24” (609mm) from any combustible overhang.

This protects the building material from

degradation by the vent gases.

Vent joints should be sealed and secured

according to the vent manufacturers

instructions. Should condensation occur the

vent should be shortened or insulated.

The terminal should be at least 3ft (0.91m) from

any air intake to the building.

The vent terminal must be installed at a suitable

height above the ground to prevent blockage by

snow.

1.7 Fresh Air Intake

Whenever the heater is installed in locations

where airborne dust or other pollutants are

present, a fresh air supply should be ducted to

the burner.

If the heater is equipped with ducted combustion

air, the vent terminal must be at least 3ft

(0.91m) away from the air inlet and located

higher than the inlet.

A fresh air duct of 4” (101mm) diameter should

be installed from the fresh air to the air intake

connection on the fan housing. A flexible

jointing piece should be installed at the fan

connection with hose clamps to facilitate

expansion and contraction.

The maximum recommended length air duct is

25ft (7.6m) and the maximum number of elbows

is two. The minimum length is 18” (456mm).

The location of the fresh air duct inlet must be

where it will receive dust free clean air. An inlet

cap with bird screen must be fitted at the inlet of

the duct. If the duct inlet is located above the

roof the underside of the inlet terminal must be

at least 2ft (0.61m) above roof level (or above

projected snow load) and at least 10” (254mm)

above any projection on the roof within 7ft

(2.1m) of the inlet. Intake pipe, fittings and

sealant are not furnished by the manufacturer.

Refer fig 7c & d.

Note the vent terminal must NOT be installed

below the fresh air intake, and should have a

minimum separation distance of 36” from the air

intake.

Note The vent terminal should be installed so as

to be in the same atmospheric pressure zone as

the combustion air inlet of the appliance.

Doc No 700106 (06-15), Page 11

Page 12

Figure 7.a Vertical Venting.

Figure 7.b Horizontal Venting (plan view shown).

Approved clearance thimble is

required when the flue pipe

extends through combustible

materials. Follow the requirements

of the thimble and/or Category III

vent pipe manufacturer.

Approved clearance thimble is required when the flue pipe

extends through combustible materials. Follow the

requirements of the thimble and/or Category III vent pipe

manufacturer.

Aluminum 4” (101mm) O.D. pipe.

Max length = 25’0” (7.62M) with 2

x 90° long radius bends.

Clamps

4” (101mm) O.D. flexible duct

Burner

Note The vent terminal

should be installed so as

to be in the same atmospheric

pressure zone as the combustion

air inlet of the appliance.

Note the vent terminal must NOT

be installed below the fresh air

intake, and should have a

minimum separation distance of

36” from the air intake.

Figure 7.c Fresh Air Ducted Intake.

Doc No 700106 (06-15), Page 12

Page 13

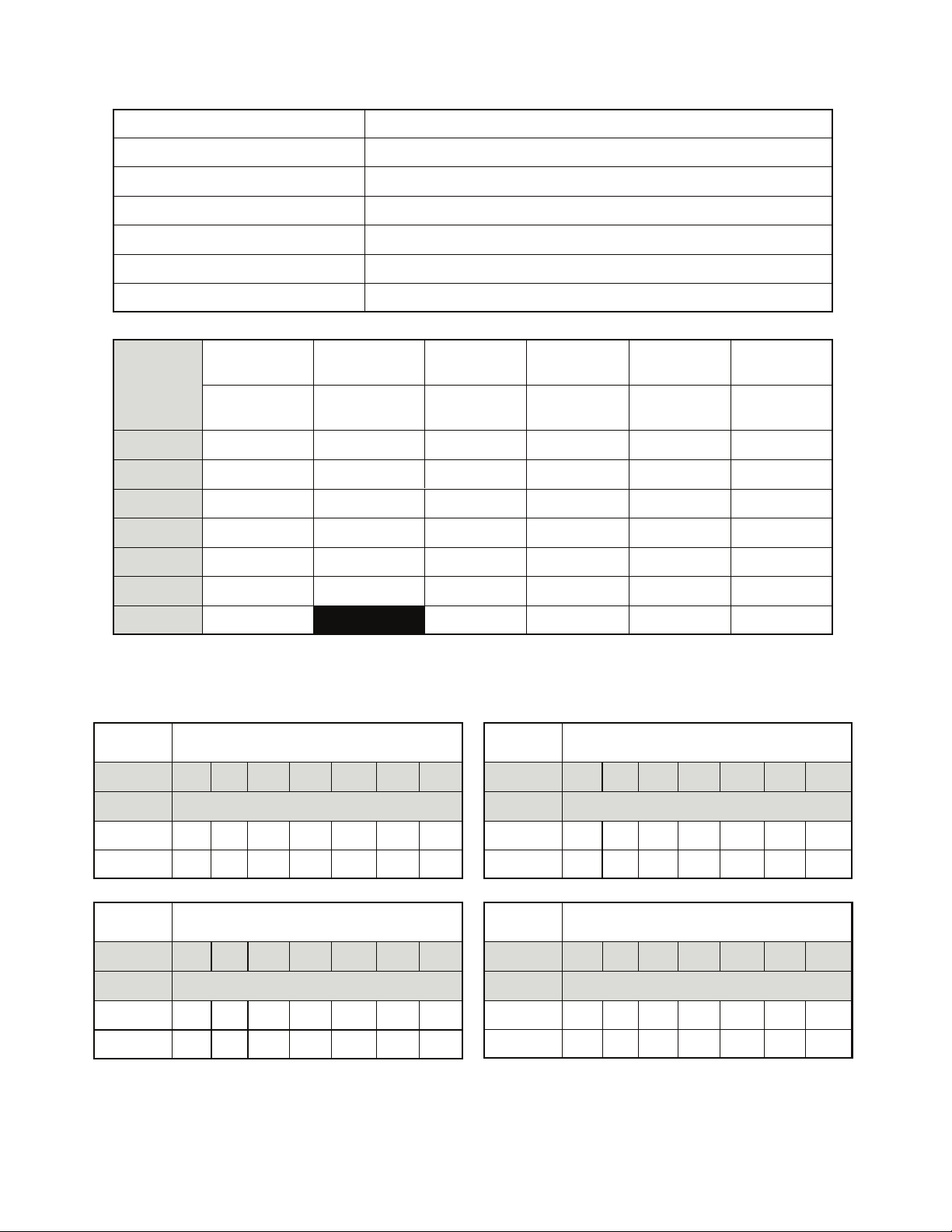

1.8 Technical Details - Table 5

No of Injectors

Gas Connection

Electrical Supply

Vent size (in)

Unitary Fan Motor Details

Current Rating

Ignition

Natural Gas LP Gas

MODEL

High / Low High / Low

60

80

100

125

150

60,000/48,000 60,000/48,000

80,000/60,000 80,000/60,000

100,000/75,000 100,000/75,000

123,500/95,000 125,000/95,000

150,000/100,000 150,000/100,000

1

½” N.P.T

120 volt 1 phase 60Hz

4” or 6” (101mm or 152mm)

120 volt 1 phase 60Hz

1.8A MAX (models 60 - 150); 1.0A MAX (models 170 & 200)

Electronic Program Start up with Spark Ignition

Min. Heater

Length

Max. Heater

Length

Min. Heater

Length

Max. Heater

Length

S ft S ft U ft U ft

20 40 20 40

30 40 40 40

30 40 40 40

30 50 40 40

40 60 40 60

170

200

169,000/125,000 169,000/125,000

200,000/160,000

N/A

50 70 60 60

50 70 60 60

Appliances can be installed up to 10,000ft above sea level in the USA. Altitude conversion kits are

available on request.

USA 0- 2000 ft (0-610m) above sea level

Size

Gas

Hi “WC

Lo “WC

60 80 100 125 150 170 200

Natural Gas

3.9 3.5 4.5 4.3 4.0 3.3 4.0

2.6 2.3 3.0 2.7 2.1 1.9 2.5

USA 0- 2000 ft (0-610m) above sea level

Size

Gas

Hi “WC

60 80 100 125 150 170 200

LP Gas

5.5 5.2 8.0 7.6 7.0 6.1 N/A

CANADA 0- 2000 ft (0-610m) above sea level

Size

Gas

Hi “WC

Lo “WC

60 80 100 125 150 170 200

Natural Gas

3.9 3.5 4.5 4.3 4.0 3.3 4.0

2.6 2.3 3.0 2.7 2.1 1.9 2.5

CANADA 0- 2000 ft (0-610m) above sea level

Size

Gas

Hi “WC

60 80 100 125 150 170 200

LP Gas

5.5 5.2 8.0 7.6 7.0 6.1 N/A

Lo “WC

Doc No 700106 (06-15), Page 13

3.5 2.9 4.4 4.6 3.3 3.6 N/A

Lo “WC

3.5 2.9 4.4 4.6 3.3 3.6 N/A

Page 14

Technical Details continued

USA & CANADA Natural Gas 0- 2000 ft (0-610m)

Size

Burner Orifice Plate Part No.

Flame Plate Part No.

Fan Part No.

Fan Orifice Part No.

Injector Part No.

Injector Carrier Part No.

Pressure Switch Part No.

60 80 100 125 150 170 200

269941 269942 269943 269944 1005513 269946 269946

N/A

270464

269922 269925 269925 269930 269931 266935 269938

270400 270402 270403 270405 270407 270409 270410

270375 270376

270389 270390

USA & CANADA LP Gas 0- 2000 ft (0-610m)

Size

Burner Orifice Plate Part No.

Flame Plate Part No.

Fan Part No.

Fan Orifice Part No.

Injector Part No.

Injector Carrier Part No.

Pressure Switch Part No.

60 80 100 125 150 170 200

269948 269949 269950 269951 269952 269953

269957 269958 269959 269960

270464 270467

269924 269925 269929 266931 269933 269937

270398 270400 270401 270403

270399

270375

270389

270467

N/A

MODEL

VCT

U20 U40 U60 S20 S30 S40 S50 S60 S70

60

80

100

125

150

170

200*

* Nat Gas ONLY

MODEL

VCT

60

80

100

125

150

170

200

U Tube Straight Tube

● ●

● ● ●

● ● ●

● ● ●

● ● ● ●

● ● ● ● ●

● ● ● ●

● ● ● ●

Emitter Tube Type Material

Calcoat™ Mild Steel

Min. Distance to Bend

ft (m)

TUBE 1 REMAINDER 10 (3.0)

TUBE 1 REMAINDER 10 (3.0)

TUBE 1 REMAINDER 15 (4.6)

TUBE 1 REMAINDER 15 (4.6)

TUBE 1 REMAINDER 20 (6.1)

TUBE 1 & 2 REMAINDER 25 (7.6)

TUBE 1 & 2 REMAINDER 25 (7.6)

Doc No 700106 (06-15), Page 14

Page 15

2. Assembly Instructions.

PLEASE READ this section prior to

assembly to familiarize yourself with the

components and tools you require at the

various stages of assembly. Carefully open the

packaging and check the contents against the

parts and check list.

The manufacturer reserves the right to alter

specifications without prior notice.

2.1 Tools Required.

The following tools and equipment are advisable

to complete the tasks laid out in this manual.

Saw

Horses

Cordless

Drill

Leather

Faced

Gloves

5/16”

Drive

Please ensure that all packaging is

disposed of in a safe environmentally

friendly way.

For your own safety we recommend the

use of safety boots and leather faced

gloves when handling sharp or heavy items. The

use of protective eye wear is also

recommended.

Suitable alternative tools may be used.

Phillips

Screwdriver

3/16” (5mm)

5/32” (4mm)

Allen

wrench

Wrench

Set

Tape

Measure

2.2 Assembly Notes.

Please read these assembly notes in

conjunction with the correct assembly

drawings (figs 9 to 17).

2.2.1 Emitter Tubes

Each heating unit has two types of emitter tube.

For details of the tube types and position

please refer to the table (page 14 of this

instruction manual).

Identify and position emitter tubes on saw

horses. For aesthetics it is advisable to position

all tube seams facing down. Position coupling

fastener so that these cannot be seen from

beneath the heater.

Mark out the position of the bracket centers

from the dimensions shown on the assembly

drawings.

2.2.2 Turbulator Strips and Burner

Inserts

Ensure that the correct turbulator or burner

insert is fitted, as this could void your warranty if

they are incorrectly fitted or omitted when

necessary.

2.2.2.1 Turbulator Strips

Turbulator strips should be inserted (when

required) into the correct emitter tube exactly as

indicated in the assembly drawings.

Locate turbulator strip sections. Install the first

turbulator strip into the open end of the last

emitter tube (only after it has been suspended

and connected to the previous emitter tube.)

Interlock the next section of turbulator strip as

shown in the diagram below.

Doc No 700106 (06-15), Page 15

Page 16

Slide the connected sections into the emitter

tube(s). Add further strips to form the correct

length required.

2.2.2.2

Where a heater configuration requires more

than three turbulator strips and has the exhaust

heat exchanger tube adjacent to an “L” or “U”

heat exchanger tube, refer to the diagram below

for positions.

For specific configurations see detailed

assembly diagrams on pages 21 to 29.

Vent

Model 200 S50 fan orifice plate

This model has a different fan orifice plate (Part

No.269939) to all other models in the range. It

is supplied with every burner as a loose item

and should be discarded if not needed. This

must be fitted to the 200 S50 model only.

Note: There should be 22 10mm x 10mm

square holes in the replacement plate.

Remove the top cover of the burner to expose

the combustion fan.

Remove the four screws (arrowed), three of

which can not be seen in the photograph. Lift

out the fan assembly to access the fan.

Remove the four fixing screws securing the

existing orifice plate, then fit the replacement

orifice plate with the correct air inlet hole

orientation as shown in the picture opposite.

Fit three turbulator strips here

Vent

Fit the remaining turbulator strips here

Doc No 700106 (06-15), Page 16

Page 17

2.2.2.2 Burner Inserts

The burner insert (when required) is inserted

into the first heat exchanger emitter tube from

where it is joined to the second emitter tube.

2.2.3 Brackets

There can be various styles of brackets

supplied with these heaters:

2.2.3.1 Suspension Brackets

2.2.3.1.1 Fixed suspension bracket assembly

part #270126 & tube straps part #270572.

ONLY used as the first suspension bracket

positioned CLOSEST TO THE BURNER.

SUSPENSION

BRACKET

SUSPENSION

BRACKET

RADIANT

TUBE

PART #270126

2.2.3.2 Reflector Support Brackets

Reflectors are positioned above the emitter

tube with a reflector support bracket part

#270569.

RADIANT

TUBE

TUBE

STRAP

SUPPLIED

NUT &

BOLT

SUPPLIED

NUT & BOLT

RADIANT

TUBE

"A"

VIEW ON "A"

PARTS #270126 plus #270572

TUBE

STRAP

Slip the suspension first bracket assembly part #270126 onto the first section of emitter

tube in the position as indicated on the

assembly drawing.

Locate the tube strap assembly part #270572

and loosen the nut and bolt.

Position the strap over the emitter tube and

hook the two straps onto the suspension

bracket.

Finally tighten the nut and bolt to secure the

bracket onto the emitter tube.

2.2.3.1.2 Suspension brackets #270126 with

no tube straps. For

ALL other suspension

brackets

Once the emitter tubes have been assembled

using the couplers (see section 2.2.4), position

all other suspension brackets part #270126

onto the emitter tube(s) in their relevant

positions as shown on the assembly drawing.

REFLECTOR BRACKET #270569

Locate a suspension support bracket and

remove the bolt fixing the strap to the bracket.

Position the bracket over the emitter tube and

loosely replace the bolt.

Roughly position the support brackets in place

along the emitter tube assembly as indicated on

the assembly drawing. The positioning may

need to be adjusted when the reflector is added.

2.2.4 Couplers

The couplers are used for joining emitter tubes

and U or L bends.

Slide the coupling onto the end of the existing

emitter tube. Slide the end of the next emitter

tube into the other side of the coupling.

Doc No 700106 (06-15), Page 17

Page 18

With both emitter tube ends pushed fully into

the coupling and the bolts towards the bottom,

using a 9/16” wrench, tighten the coupling bolts

moving between each bolt in sequence to

ensure equal pressure is applied to each bolt.

Complete assembly by drilling and screwing

self tapping retention zip screws.

At this point raise the tube assembly into

position and suspend from previously fixed

chains (Working Load 100lb). Longer tube

assemblies may be raised in more than one

sub-assembly with the final emitter tube

connection made in the air.

2.2.5 Reflectors.

All reflectors must be positioned/

attached to the brackets exactly as

detailed in the assembly drawings.

After removing the coloured protective plastic

coating (where fitted), slip the reflectors through

the suspension brackets until they overlap each

other.

The first two reflectors are assembled and

overlapped by a pre determined distance, as

shown on the assembly drawing, and are fixed

onto the emitter tube using the reflector support

bracket part #270569.

Each reflector must OVERLAP the

previous one as indicated by their

individual assembly sheets.

(TWISTED LINK, PLATED)

NOTE.

HOOKS ARE TO

BE CLOSED UP

AFTER ASSEMBLY

2/0 GA CHAIN

Reflectors. Note: each reflector must overlap the previous one

Reposition the reflector support bracket if

necessary then tighten the clamp bolt.

These two reflectors are fixed in place by

tightening the fixing screws/locknuts as below.

These are known as ‘non-slip’ overlaps.

TIGHTEN SCREWS

TO FIX REFLECTOR

The next reflector is assembled and overlapped

by the pre determined distance. The reflector is

fitted onto the emitter tube using another

reflector support bracket part #270569.

Reposition the reflector support bracket if

necessary, then tighten the clamp bolt.

These overlapped reflectors are allowed to

‘float’ within the support bracket by leaving a

minimum of 1/8” gap of the fixing screws before

tightening the locknuts. These are known as

‘slip’ overlaps.

1

8

" min

1

ALLOW REFLECTOR TO SLIDE

LEAVE

" MIN GAP TO

8

Further reflectors are assembled and

overlapped onto the emitter tube by alternating

‘non-slip’ and ‘slip’ until complete length is

covered.

Continue this method to the final reflector/

support bracket.

See stetch below for typical ‘slip’ and ‘non-slip’.

Further reflectors to be

overlapped in the same method

Burner

Suspension Bracket

part #270126

and fixing #270572

Doc No 700106 (06-15), Page 18

Support Bracket

part #270569

non-slip overlap

Support Bracket

part #270569

slip overlap

Support Bracket

part #270569

non-slip overlap

Page 19

2.2.6 End Caps (optional)

Position an end cap beneath the reflector

profile (where required) with the end cap

flanges facing inwards. Fasten to reflector

using the four ’Z’ clips.

End

2.2.7 Bend(s) (where fitted)

The heater can be installed with 1 or 2 90°

bends or a 180° U bend.

Slide the bend into the open end of the

coupler ensuring that the screw stop has butted

up to the emitter tube ends. Refer to 2.2.4 for

fastening.

90° Elbow

Corner reflector

90° Bend

2.2.8 Burner/Fan Assembly.

Slide the burner assembly onto the open emitter

tube end, ensuring it is fully engaged. Secure

with set screws.

For the purpose of unvented applications, a 4”

90° elbow should be used on the terminating

end of the emitter tube sections and completed

using a vent cap.

Connect Gas and Electrical supplies as

described in sections 1.4 and 1.5.

2.2.9 Detailed Assembly Drawings

The following pages show the technical

dimensional details for the range of heaters

available.

Please note the heater type, length and

reference number from the delivery/advice note

before identifying the correct model drawing.

Corner reflector kit

16” crs

U Bend

Doc No 700106 (06-15), Page 19

End Caps

End Caps

15”

Page 20

Figure 8. Possible Heater Orientations

S20

S30

S40

S50

S60

Bends must be fitted at a distance of at least 50% of the total heat exchanger

e.g. for a 60ft long heater, the closest to the burner a bend can be is 30ft.

S70

U20

U40

U60

Doc No 700106 (06-15), Page 20

Page 21

Figure 9. Heater Assembly: Model Linear 60-S20.

END CAPS

(OPTIONAL)

PART #270126

SUSPENSION BRACKET

6"-9" REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

TURBULATOR(S)

(SEE DETAIL)

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

L

C

PART #205546

QTY 1 REQUIRED

STANDARD 4" COUPLER

2" MINIMUM

REFLECTOR SUPPORT BRACKET

TURBULATOR SECTION

DETAIL

PART #116019

QTY 3 REQUIRED

21'6½" NOMINAL OVERALL ASSEMBLED LENGTH

SUSPENSION BRACKET

PART #270126

SUSPENSION BRACKET

DISTANCE BETWEEN

SUSPENSION POINTS

PART #270126 PLUS

STRAP PART #270572

COUPLER

(SEE DETAIL)

BURNER INSERT

NO TO EXCEED 12'

10' 3" REFLECTORS TYPICAL OF 2

4"

END CAPS

(OPTIONAL)

BURNER

6"

ASSEMBLY OVERVIEW

DETAILS

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

QTY 2 REQUIRED

QTY 1 REQUIRED OF EACH

PART #270489 (5FT)

BURNER INSERT DETAIL

QTY 1 REQUIRED NAT GAS ONLY

PART #270569

QTY 2 REQUIRED

REFLECTOR SUPPORT BRACKET

Doc No 700106 (06-15), Page 21

Page 22

Figure 10. Heater Assembly: Model Linear 60-S30, 80-S30, 100-S30 and 125-S30.

END CAPS

(OPTIONAL)

SUSPENSION BRACKET

SUSPENSION BRACKET

PART #270126

PART #270126

6" REFLECTOR OVERLAP

6" REFLECTOR OVERLAP

TURBULATOR

COUPLER

(SEE DETAIL)

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

L

C

PART #205546

STANDARD 4" COUPLER

2" MINIMUM

DETAIL

REFLECTOR SUPPORT BRACKET

QTY 2 REQUIRED

PART #116019

TURBULATOR SECTION

QTY 3 REQUIRED SIZE 80/100 ONLY

QTY 4 REQUIRED SIZE 100 LPG ONLY

QTY 5 REQUIRED SIZE 125 ONLY

31'6½" NOMINAL OVERALL ASSEMBLED LENGTH

SUSPENSION BRACKET

PART #270126

SUSPENSION BRACKET

DISTANCE BETWEEN

SUSPENSION POINTS

PART #270126 PLUS

STRAP PART #270572

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

COUPLER

(SEE DETAIL)

BURNER INSERT

NO TO EXCEED 12'

10' 3" REFLECTORS TYPICAL OF 3

4"

END CAPS

(OPTIONAL)

BURNER

6"

ASSEMBLY OVERVIEW

DETAILS

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

QTY 3 REQUIRED

QTY 1 REQUIRED OF EACH

BURNER INSERT DETAIL

REFLECTOR SUPPORT BRACKET

PART #270489 (5FT)

QTY 1 REQUIRED SIZE 60-100 NG ONLY

PART #270569

QTY 3 REQUIRED

PART #1005500 (3FT)

QTY 1 REQUIRED SIZE 125 NG ONLY

Doc No 700106 (06-15), Page 22

Page 23

Figure 11. Heater Assembly: Model Linear 60-S40, 80-S40, 100-S40, 125-S40 and 150-S40.

END CAPS

(OPTIONAL)

41'6½" NOMINAL OVERALL ASSEMBLED LENGTH

PART #270126

SUSPENSION BRACKET

3" REFLECTOR

PART #270126

SUSPENSION BRACKET

6" REFLECTOR

PART #270126

SUSPENSION BRACKET

OVERLAP

OVERLAP

TURBULATOR

COUPLERCOUPLERCOUPLER

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

(SEE DETAIL)

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

L

C

PART #205546

QTY 3 REQUIRED

STANDARD 4" COUPLER

2" MINIMUM

DETAIL

REFLECTOR SUPPORT BRACKET

PART #116019

TURBULATOR SECTION

QTY 4 REQUIRED SIZE 125/150 ONLY

6" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

DISTANCE BETWEEN SUSPENSION POINTS NO TO EXCEED 12'

TYPICAL OF 4

10' 3" REFLECTORS

PART #270126 PLUS

STRAP PART #270572

SUSPENSION BRACKET

END CAPS

(OPTIONAL)

Doc No 700106 (06-15), Page 23

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

QTY 4 REQUIRED

QTY 1 REQUIRED OF EACH

BURNER INSERT DETAIL

REFLECTOR SUPPORT BRACKET

PART #270489 (5FT)

QTY 1 REQUIRED SIZE 60-100 NG ONLY

PART #270569

QTY 4 REQUIRED

PART #1005500 (3FT)

QTY 1 REQUIRED SIZE 125 NG ONLY

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

(SEE DETAIL)

BURNER INSERT

4"

6"

BURNER

ASSEMBLY OVERVIEW

DETAILS

Page 24

Figure 12. Heater Assembly: Model Linear 125-S50, 150-S50, 170-S50 and 200-S50

END CAPS

(OPTIONAL)

2" MINIMUM

PART #270126

SUSPENSION BRACKET

3" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

REFLECTOR SUPPORT

BRACKET PART #270569

REFLECTOR SUPPORT

SLIP REFLECTOR OVERLAP

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

NOTE: The 200 S50 model

requires a different fan orifice

plate. See P16 for details.

L

C

DETAIL

REFLECTOR SUPPORT BRACKET

3" REFLECTOR

OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

PART #270126

SUSPENSION BRACKET

6" REFLECTOR

OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

51'6½" NOMINAL OVERALL ASSEMBLED LENGTH

SUSPENSION BRACKET

SUSPENSION BRACKET

PART #270126

PART #270126

6" REFLECTOR

OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

COUPLER COUPLER COUPLER COUPLER

PART #205546

QTY 4 REQUIRED

STANDARD 4" COUPLER

QTY 5 REQUIRED

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

TURBULATOR SECTION

BURNER INSERT DETAIL

PART #116019

QTY 4 REQUIRED SIZE 200 NG ONLY

PART #270489 (5FT)

QTY 1 REQUIRED SIZE 100 NG ONLY

QTY 2 REQUIRED SIZE 200 LPG ONLY

PART #1005500 (3FT)

QTY 1 REQUIRED SIZE 125 NG ONLY

TYPICAL OF 5

10' 3" REFLECTORS

DISTANCE BETWEEN SUSPENSION POINTS NO TO EXCEED 12'

PART #270126 PLUS

STRAP PART #270572

SUSPENSION BRACKET

END CAPS

(OPTIONAL)

BURNER

Doc No 700106 (06-15), Page 24

4"

6"

(SEE DETAIL)

BURNER INSERT

PART #270569

QTY 5 REQUIRED

QTY 1 REQUIRED OF EACH

REFLECTOR SUPPORT BRACKET

ASSEMBLY OVERVIEW

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

DETAILS

Page 25

Figure 13. Heater Assembly: Model Linear 150-S60, 170-S60 and 200-S60.

END CAPS

(OPTIONAL)

PART #270126

SUSPENSION BRACKET

3" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

3" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

3" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

REFLECTOR SUPPORT

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

BRACKET PART #270569

2" MINIMUM

L

C

DETAIL

REFLECTOR SUPPORT BRACKET

NON-SLIP REFLECTOR OVERLAP

PART #205546

QTY 5 REQUIRED

STANDARD 4" COUPLER

NON-SLIP REFLECTOR OVERLAP

61'6½" NOMINAL OVERALL ASSEMBLED LENGTH

DISTANCE BETWEEN SUSPENSION POINTS NO TO EXCEED 12'

6" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

6" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

PART #270126 PLUS

STRAP PART #270572

SUSPENSION BRACKET

END CAPS

TYPICAL OF 6

10' 3" REFL'S

(OPTIONAL)

Doc No 700106 (06-15), Page 25

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

QTY 6 REQUIRED

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

REFLECTOR SUPPORT

BRACKET PART #270569

COUPLER COUPLER COUPLER COUPLER COUPLER

4"

6"

NON-SLIP REFLECTOR OVERLAP

PART #270569

QTY 6 REQUIRED

QTY 1 REQUIRED OF EACH

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

ASSEMBLY OVERVIEW

BURNER

DETAILS

REFLECTOR SUPPORT BRACKET

Page 26

Figure 14. Heater Assembly: Model Linear 170-S70 and 200-S70.

END CAPS

(OPTIONAL)

PART #270126

SUSPENSION BRACKET

PART #270126

SUSPENSION BRACKET

PART #270126

SUSPENSION BRACKET

PART #270126

SUSPENSION BRACKET

3" REFLECTOR

3" REFLECTOR

3" REFLECTOR

3" REFLECTOR

OVERLAP

OVERLAP

OVERLAP

OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

REFLECTOR SUPPORT

REFLECTOR SUPPORT

BRACKET PART #270569

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

SLIP REFLECTOR OVERLAP

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

SLIP REFLECTOR OVERLAP

L

C

PART #205546

QTY 6 REQUIRED

2" MINIMUM

DETAIL

REFLECTOR SUPPORT BRACKET

STANDARD 4" COUPLER

PART #270126

71'6½" NOMINAL OVERALL ASSEMBLED LENGTH

SUSPENSION BRACKET

6" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

6" REFLECTOR

OVERLAP

PART #270126

SUSPENSION BRACKET

DISTANCE BETWEEN SUSPENSIO N POINTS NO TO EXCEED 12'

PART #270126 PLUS

STRAP PART #270572

SUSPENSION BRACKET

END CAPS

TYPICAL OF 7

10' 3" REFL'S

(OPTIONAL)

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

SLIP REFLECTOR OVERLAP

QTY 7 REQUIRED

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

REFLECTOR SUPPORT

BRACKET PART #270569

COUPLER COUPLER COUPLER COUPLER COUPLER COUPLER

4"

6"

NON-SLIP REFLECTOR OVERLAP

PART #270569

QTY 7 REQUIRED

QTY 1 REQUIRED OF EACH

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

BURNER

ASSEMBLY OVERVIEW

DETAILS

REFLECTOR SUPPORT BRACKET

Doc No 700106 (06-15), Page 26

Page 27

Figure 15. Heater Assembly: Model U tube 60-U20.

2" MINIMUM

3' 3"

L

C

DETAIL

REFLECTOR SUPPORT BRACKET

REFLECTOR SUPPORT

BRACKET PART #270569

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

SUSPENSION BRACKET

PART #270126

COUPLERS

BURNER INSERT

NON-SLIP REFLECTOR OVERLAP

PART #270126

SUSPENSION BRACKET

(SEE DETAIL)

PART #205546

QTY 2 REQUIRED

STANDARD 4" COUPLER

PART #116019

TURBULATOR SECTION

QTY 1 REQUIRED SIZE 60 ONLY

SUSPENSION POINTS

DISTANCE BETWEEN

NO TO EXCEED 12'

12'1½" NOMINAL OVERALL ASSEMBLED LENGTH

TURBULATOR

(SEE DETAIL)

10' 3" REFLECTORS TYPICAL OF 2

PART #270126

SUSPENSION BRACKET

END CAPS

(OPTIONAL)

Doc No 700106 (06-15), Page 27

4"

BURNER

6"

PART #270126 PLUS

STRAP PART #270572

SUSPENSION BRACKET

QTY 3 REQUIRED

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

BURNER INSERT DETAIL

PART #270489 (5FT)

QTY 1 REQUIRED NAT GAS ONLY

PART #270569

QTY 2 REQUIRED

QTY 1 REQUIRED OF EACH

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

ASSEMBLY OVERVIEW

DETAILS

REFLECTOR SUPPORT BRACKET

Page 28

Figure 16. Heater Assembly: Model U tube 60-U40, 80-U40, 100-U40, 125-U40 and 150-U40.

3' 3"

SLIP REFLECTOR OVERLAP

BRACKET PART #270569

REFLECTOR SUPPORT

PART #270126

SUSPENSION BRACKET

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

SLIP REFLECTOR OVERLAP

BRACKET PART #270569

REFLECTOR SUPPORT

L

C

PART #270126

COUPLERS

6"-9" REFLECTOR OVERLAPS

SUSPENSION BRACKET

SUSPENSION POINTS

NO TO EXCEED 12'

DISTANCE BETWEEN

COUPLERS

PART #205546

QTY 4 REQUIRED

STANDARD 4" COUPLER

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

2" MINIMUM

DETAIL

REFLECTOR SUPPORT BRACKET

PART #116019

TURBULATOR SECTION

QTY 4 REQUIRED SIZE 150 ONLY

22'1½" NOMINAL OVERALL ASSEMBLED LENGTH

PART #270126

SUSPENSION BRACKET

TURBULATOR

PART #270126

SUSPENSION BRACKET

END CAPS

(SEE DETAIL)

(OPTIONAL)

10' 3" REFLECTORS TYPICAL OF 4

BURNER

BURNER INSERT

4"

6"

PART #270126

SUSPENSION BRACKET

(SEE DETAIL)

SUSPENSION BRACKET

STRAP PART #270572

PART #270126 PLUS

ASSEMBLY OVERVIEW

DETAILS

TUBE & REFLECTOR SUSPENSION

FIRST SUSPENSION POINT BRACKET

QTY 5 REQUIRED

BRACKET PART #270126

PART #270489 (5FT)

PART #1005500 (3FT)

BURNER INSERT DETAIL

QTY 1 REQUIRED SIZE 125 NG ONLY

QTY 1 REQUIRED SIZE 60-100 NG ONLY

PART #270569

QTY 4 REQUIRED

QTY 1 REQUIRED OF EACH

PART #270126 plus STRAP #270572

REFLECTOR SUPPORT BRACKET

Doc No 700106 (06-15), Page 28

Page 29

Figure 17. Heater Assembly: Model U tube 150-U60, 170-U60 and 200-U60.

3' 3"

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

REFLECTOR SUPPORT

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

L

C

2" MINIMUM

DETAIL

32'1½" NOMINAL OVERALL ASSEMBLED LENGTH

REFLECTOR SUPPORT

REFLECTOR SUPPORT

COUPLERS

COUPLERS

REFLECTOR SUPPORT

REFLECTOR SUPPORT

PART #270126

SUSPENSION BRACKET

SLIP REFLECTOR OVERLAP

BRACKET PART #270569

PART #270126

PART #205546

SUSPENSION BRACKET

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

QTY 6 REQUIRED

STANDARD 4" COUPLER

REFLECTOR SUPPORT BRACKET

PART #270126

COUPLERS

SUSPENSION BRACKET

6" REFLECTOR OVERLAPS

SLIP REFLECTOR OVERLAP

BRACKET PART #270569

PART #270126

SUSPENSION BRACKET

6"-9" REFLECTOR OVERLAPS

BRACKET PART #270569

NON-SLIP REFLECTOR OVERLAP

PART #270126

SUSPENSION BRACKET

DISTANCE BETWEEN SUSPENSION

POINTS NO TO EXCEED 12'

PART #270126

SUSPENSION BRACKET

END CAPS

(OPTIONAL)

Doc No 700106 (06-15), Page 29

10' 3" REFLECTORS TYPICAL OF 6

BURNER

QTY 7 REQUIRED

BRACKET PART #270126

TUBE & REFLECTOR SUSPENSION

PART #270126

SUSPENSION BRACKET

(SEE DETAIL)

BURNER INSERT

SUSPENSION BRACKET

STRAP PART #270572

PART #270126 PLUS

4"

QTY 1 REQUIRED OF EACH

PART #270126 plus STRAP #270572

FIRST SUSPENSION POINT BRACKET

BURNER INSERT DETAIL

REFLECTOR SUPPORT BRACKET

PART #1005500 (3FT)

PART #270569

QTY 1 REQUIRED SIZE 125 NG ONLY

QTY 6 REQUIRED

6"

ASSEMBLY

OVERVIEW

DETAILS

Page 30

3. Start Up Instructions.

These appliances should be commissioned by a qualified mechanical contractor.

3.1 Tools Required.

The following tools and equipment are advisable

to complete the tasks laid out in this manual.

Leather

Faced

Gloves

Phillips

Screwdriver

Suitable alternative tools may be used.

Small Flat

Head

Screwdriver

Large Adjustable

Wrenches for fitting

Of Gas Flex.

½”

Wrench

5/32” (4mm)

Allen

Wrench

3.2 Start Up Procedure

Inspect installation and ensure that it has been

carried out in accordance with these

instructions. Ensure that electrical and gas

supplies are isolated.

The gas supply should be purged and tested for

leaks in accordance with local and National

Safety codes.

Open shut off gas valve and test gas

connections for leaks using soap solution.

Open the control housing door by unscrewing

the securing screw. Ensure all internal

components are securely fixed and all

connections securely made.

Switch on the electrical supply to start the

heater and observe the correct start up

sequence. Ensure that the setting of any time

clock and thermostat are such that the heating

system will be required to operate.

The fan will start to run and the ‘power on’ lamp

will illuminate. Safe-start checks are carried out

automatically.

After the fan has run up to full speed and a

satisfactory vent pressure condition has been

established, the ignition sequence will

commence. The spark ignition will be energized

producing a spark at the ignition electrode. The

gas solenoid valve will energize at the same

time and the ‘burner on’ lamp will illuminate. If

the ignition is successful, the flame is detected

by the flame sensing probe and the ‘burner on’

lamp will remain on.

If ignition is unsuccessful, after approximately 15

seconds the gas valve will close and the spark

ignition will de-energize.

For approximately 30 seconds the fan will purge

the system, then re-ignition will be attempted.

After 2 further attempts at ignition the control

unit will ‘lock-out’, the ‘power on’ lamp will

remain illuminated and the fan will run for 120

seconds and then stop.

To reset after ‘lockout’ switch off the power

supply to the system and wait 2 minutes. Then

turn the power on. If repeated ‘lockout’ occurs,

investigate the cause.

Set burner gas pressure as follows:

Switch off the power supply to the heating

system.

Connect a ‘U’ tube or digital manometer to the

pressure test point provided on the combination

gas control valve.

Remove the cover from the pressure regulator

to reveal the adjusting screw.

Start the heater and using a suitable

screwdriver adjust the pressure regulator,

turning the screw clockwise to increase the

pressure or counter-clockwise to decrease the

pressure.

Set the pressure to appropriate inches w.c. from

the table of gas pressures and orifice plate

dimensions for correct heater description.

(See section 1.8 page 13)

Manometer

Multimeter

Doc No 700106 (06-15), Page 30

Page 31

The high fire gas pressure should be set first

followed by the low fire gas pressure. Re-check

the high fire and re-adjust if necessary.

To enable post purge ensure that the setting of

any time switch and thermostat are such that

the heating system will be required to turn off.

Switch off the power supply to the heating

system. Disconnect manometer, then secure

screw in pressure test nipple.

Check the operation of the flame safeguard

equipment as follows:

With the heater running normally, switch off the

gas supply at the shut off valve. The heater

should attempt to relight then ‘lock-out’ should

occur. This is indicated by the ‘power on’ lamp

being illuminated and fan running, but the

‘burner on’ lamp being off.

Check the operation of the pressure proving

switch as follows:

With the heater running normally, pull off the

silicone rubber tube connecting the vacuum

switch to the combustion chamber. The burner

should shut off within 4 seconds .

Replace the tube securely and observe that the

heater proceeds to ignite in the normal way.

Close the controls door and secure with the

screw.

Doc No 700106 (06-15), Page 31

Page 32

Commissioning chart

Check installation has

been carried out to these

instructions.

Remove burner from tube and inspect burner head.

Replace burner on tube

and secure.

Check thermostat is set to

maximum and is calling

for heat.

Ensure gas and electricity

supplies are isolated.

(See servicing instructions)

Reconnect gas hose.

Open Manual valve.

Check soundness.

Switch on electrical supply.

The red neon should now

be illuminated. If restarting

heater a delay of 15sec

should be allowed.

Disconnect gas hose from

burner

Open control housing and

check that all components

are securely fastened.

The heater should now

run through its start up

sequence and ignite.

Check gas pressure.

Leave the instructions

with a responsible person.

A successful ignition is indicated

by the amber light illuminating

and remaining illuminated.

Close control housing

Turn off power and check

that all components are

securely fastened.

NO

Has the

burner lit?

YES

Check operation on flame failure.

Check gas pressure.

Check operation of

air pressure switch.

Doc No 700106 (06-15), Page 32

Page 33

4. Servicing Instructions.

These appliances should be serviced annually by a competent person to ensure safe

and efficient operation. In mildly dusty or polluted conditions more frequent servicing

may be required. Servicing work should be carried out by a qualified mechanical contractor.

4.1 Tools Required.

The following tools and equipment are advisable

Leather

Faced

Gloves

½”

Wrench

4.2 Burner Description.

Figure 20. Burner breakdown

Flame Plates (Q)

269960

170 LP

269959

125/150 LP

F

Phillips

Screwdriver

5/32”

(4mm)

Allen

Wrench

P

to complete the tasks laid out in this manual.

Suitable alternative tools may be used.

Small Flat

Head

Screwdriver

Manometer

Multimeter

K

Large Adjustable

wrenches for fitting

of Gas Flex.

Note: Cables Omitted

For Clarity

A

Soft

Brush

L

N

I

Q

G

G

269958

80/100 LP

M

269957

60 LP

Part Number

A Ignition Controller 204955

B Gas Valve 270373 (NG) 270498 (LP)

C Power On Red Lamp 270474

D Low Fire Amber Lamp 270473

E High Fire Amber Lamp 270473

F Burner Tube 270424

G Burner head 270425

H Injector See section 1.8 P14

Doc No 700106 (06-15), Page 33

C

Part Number

I Igniter Assembly 270441

J Injector Carrier

K Combustion Fan

L Pressure Switch

M Gaskets

N Transformer

O 24V Relay 270472

P Burner Orifice Plate

Q Flame Plate (not shown)

E

D

H

J

O

B

See section 1.8 P14

See section 1.8 P14

See section 1.8 P14

2 off 270366

194808

See section 1.8 P14

See photos above

Page 34

4.3 Burner Removal

Step 1: Isolate power and gas supplies.

Step 2: Disconnect the external power/control

connections.

Step 3: Detach the gas supply as shown

below, taking care to support the burner

connection.

Step 6: Remove the burner and position the

burner in a safe area to prevent the burner or

components attached to the burner from falling

to the ground.

4.4 Burner Gas Injector Servicing

Step 1:

Remove the 4 retaining screws, then

remove the burner support casting and gasket.

Step 4: If ducted air is connected, loosen hose

clip and remove the flexible hose from the

burner.

Step 5: Loosen the set screw on the burner

support casting to enable the burner to be

removed from the radiant tube.

Doc No 700106 (06-15), Page 34

Step 2: The burner head assembly can be

disconnected by separating the connectors of

the ignition lead assembly and removing the

earth lead and pressure switch silicon tube.

Page 35

Step 3: The gas injector can be inspected and

replaced if contaminated or blocked.

When replacing the gas injector ensure

approved thread sealant is used.

Step 4: Reconnect ignition leads and silicone

tube to test nipple. Refit gasket and support

casting.

4.5 Combustion Fan Servicing

Step 1: Remove the four top lid screws to

reveal the combustion fan shown below.

Step 2: Disconnect the fan cables after first

noting their positions, then pull cable through to

fan compartment.

Step 4: Remove fan orifice plate.

Step 5: Inspect the impeller and remove any

dust with a soft brush.

Step 6: Remove any dust from fan scroll and

from around the motor.

Step 7: Ensure the impeller rotates freely.

Step 8: Refit components.

4.6 Burner Head and Electrode Servicing

Step 1:

Check the pepper pot burner head for

contamination. If necessary this can be

removed. See below.

Step 3: Remove the four fan fixing screws then

withdraw the fan complete with mounting

bracket as shown below.

Doc No 700106 (06-15), Page 35

This can be cleaned together with the inside of

the burner head.

Step 2: The pepper pot burner head can be

replaced ensuring the 5 holes on the outer ring

are aligned alongside the probes.

Step 3: The condition of the igniter assembly

can be checked for deterioration. However, we

advise replacement at each service to ensure

Page 36

continued reliability. Detach the electrode

assembly from the burner head by removing

the two screws as shown and separating the

igniter assembly lead connectors.

Step 4: Refit the electrode assembly and

ensure the connections are secure to prevent

incorrect sparking of the spark electrode.

Step 5:

Check the positions and spark gap as

shown in diagram below.

Step 6: The burner assembly is ready to refit

after servicing the combustion fan and the

radiant tube assembly.

Step 7: Refit components.

4.7 Radiant Tube Servicing

Step 1:

Brush any dust from the exterior of the

tubes.

Step 2: Inspect the fan and burner tubes

visually. If the tubes appear clean, skip to

servicing the reflector.

Step 3: If required the interior of the tubes can

then be cleaned using an industrial vacuum

cleaner or by using long poles and a scraper.

4.8 Reflector Servicing

The condition of the reflectors should be noted.

If necessary the reflectors can be cleaned with a

mild detergent. This can significantly improve

the efficiency of the appliance.

4.9 Cleaning of Vent

Inspect the fresh air inlet duct and vent to

ensure they are free from any blockage or

obstruction. The air inlet terminal and vent

terminal should be inspected to ensure they are

not liable to obstruction.

4.10 Re-commissioning After Service

After servicing of the heater has been

undertaken, it will be necessary to

re-commission the heater as detailed in the

commissioning chart in these instructions.

Doc No 700106 (06-15), Page 36

Page 37

5. Troubleshooting Guide.

START

Ensure gas & electricity

supplies are enabled.

Turn any external timer

to call for heat (if fitted).

YES

Does the Power On

light illuminate?

NO

CHECK: -

1. Operation of any timer or control.

2. External fuses.

3. Supply Voltage is 120VAC 60Hz

Is there power to the

burner?

NO

CHECK: -

1. Transformer

YES

2. Integrity of wiring connections.

3. Light.

YES

Set two-stage thermostat to

call for heat at maximum

setting (High Fire).

Does the fan run? NO

CHECK: -

1. Relays is correctly fitted

2. Voltage across terminals A1 & A2 is 24VAC/60Hz(when calling for high fire).

3. Integrity of wiring connections.

4. Pressure switch operation.

5. Ignition controller.

6. Transformer.

Do the amber

lights illuminate after a

purge period?

Is there power to

NO

the fan?

NO

Does the Pressure

switch close?

CHECK: -

1. Voltage supply to fan terminal F2(F1on low fire is 120VAC 60Hz

YES

2. Integrity of wiring connections.

3. Fan.

CHECK: -

1. Pressure switch wiring connections.

YES

4. Integrity of wiring connections.

5. Amber lights.

6. Ignition controller.

5. Transformer

YES

Doc No 700106 (06-15), Page 37

NO

CHECK: -

1. Hose connection to vacuum switch.

2. Air inlet, outlet, and emitter tubes for obstructions.

3. Pressure switch operation.

4. Supply voltage 120VAC / 60Hz

5. Transformer.

6. Ignition Controller.

Page 38

To aid in the trouble shooting process

the UT controller has an LED flash code

diagnostic sequence:

Steady Off No control Power

Steady On Power Applied, Control OK

1 Flash Combustion Pressure Switch Open With Blower On

2 Flashes Combustion Pressure Switch Closed With Blower Off

3 Flashes Lockout From The Three Ignition Trials

4 Flashes Lockout From Five Flame Losses

5 Flashes Control Hardware Fault Detected

6 Flashes Lockout From Five Pressure Switch Losses

Doc No 700106 (06-15), Page 38

Page 39

6. Replacing Parts.

Turn off gas and any electrical supplies to

the heater before starting repair work.

6.1 Burner Controller Replacement

Step 1:

bottom access door.

Step 2: Disconnect burner controller from the

wiring harness.

Remove the four screws securing the

Step 2: Remove the two electrical chassis

retaining screws arrowed.

Step 3: Disconnect the Spark Lead from burner

controller.

Step 4: Remove burner controller from its

retaining screws and remove.

Step 5: Fit new burner controller.

Step 6: Refit spark lead and wiring harness

connector.

Step 7: Test product and close access door.

6.2 Air Pressure Switch Replacement

Step 1:

the pressure switch.

Disconnect the two silicone tubes from

Step 3:

It may be necessary to partially disconnect the

chassis wiring to access the pressure switch

mounting screws at the rear.

Disconnect pressure switch wiring.

Doc No 700106 (06-15), Page 39

Page 40

Step 4: Turn chassis over and remove the two

pressure switch retaining screws.

Step 5: Fit the new air pressure switch in

reverse order ensuring the silicone tubes are

connected as shown below.

Step 4: Remove the gas valve wiring

connections, noting their positions.

Step 6: Re-connect wiring.

Step 7: Test product and close access door.

6.3 Gas Valve Replacement

Step 1:

Remove the burner assembly as

described in the Servicing section.

Step 2: Open the rear access door.

Step 3: Remove the two securing screws

(arrowed) from the base of the injector tube,

noting earth terminal connection.

Doc No 700106 (06-15), Page 40

Step 5: Remove the four screws (arrowed)

securing the gas valve inlet plate to the burner

housing and remove plate.

Step 6: Remove gas valve rearwards as shown.

Step 7: The jet carrier and gas inlet can now be

detached from the gas valve.

Step 8: Replace gas valve and Re-connect

wiring.

Step 9: Set burner pressure.

Step 10: Test product and close access door.

Page 41

Doc No 700106 (06-15), Page 41

Page 42

Doc No 700106 (06-15), Page 42

Page 43

Doc No 700106 (06-15), Page 43

Page 44

7. User & Operating Instructions.

Radiant tubular infrared heaters are designed for overhead heating of industrial and commercial

buildings. Individual heating units are suspended from the roof.

1. This appliance must only be installed by qualified installer in accordance with

the requirements of local and National Codes.

2. This appliance must be grounded in accordance with the National Electrical

Code ANSI/NFPA No.70 or Canadian Codes.

3. Never rest anything, especially ladders, against the heaters.

7.1 To Start the Heater

1. First ensure that the gas supply to each

heater is turned on by opening the main

gas shut off valve.

2. Switch on the electrical supply to the

heater. The ‘power on’ lamp will illuminate.

3. Ensure that the settings of the two stage

thermostat and any time switch are set so

that the heating system will be required to

operate.

4. The fan will start and the ignition sequence

will commence.

5. Ignition of the burner will occur and the ‘low

fire’ light only will illuminate for low fire and

both the ‘low fire’ and ‘high fire’ lights will

illuminate for high fire.

6. If ignition is unsuccessful the gas valve will

close and the spark ignition de-energize

after approximately 15 seconds. For

approximately 30 seconds the fan will

purge the system then re-ignition will be

attempted. After 3 attempts at ignition the