Page 1

Form P-VALVES (Version F.3)

Obsoletes Form P-VALVES (Version F.2)

Replacement Parts

Applies to: Serial No. Explanation; Model No. Explanation;

Replacement Ignition Systems and Gas Valves by Serial No. Code;

and Maxitrol System Components by Serial No. Sufx

Table of Contents

SAFETY WARNINGS AND GUIDELINES ................................................1

Instructions for Selecting a Replacement Ignition Controller

and/or Valve ........................................................................................2

Serial Number and Model Codes ...........................................................3

Serial No. Decoding ............................................................................ 3

Serial Number Key - Month and Year of Manufacture .... 4

Heater Serial No. PREFIX and SUFFIX Codes .............. 5

Model No. Decoding ............................................................................ 5

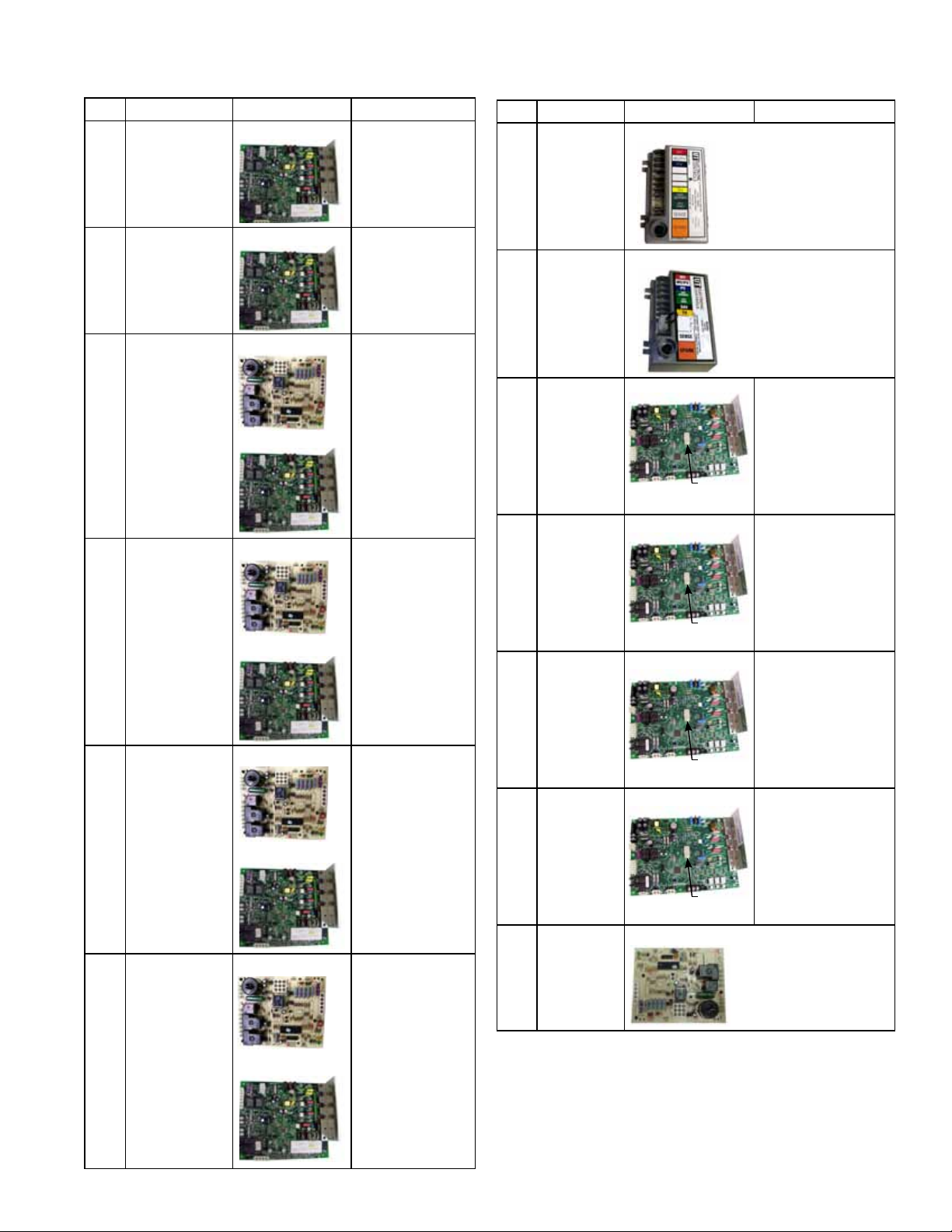

Safety Pilot or Ignition System by Serial No. Code .........................6-10

Type of Gas Valve by Serial No. Code ...........................................11-27

Maxitrol Components for Electronic Modulation .........................28-31

WARNINGS

Selection of replacement control parts from this manual and all servicing to Reznor® products must

be done by a Reznor® Distributor or other qualied technician. Improper selection or servicing

could result in severe personal injury, death, or property damage. Reznor Corporation will accept

no responsibility or liability as a result of improper servicing of Reznor® products.

®

In the United States, all installations of Reznor

Standards of the NFPA (National Fire Protection Association), the National Fuel Gas Code, and all

local authorities. In Canada, all installations of Reznor

with the CAN/CSA Installation Code for Gas Burning Appliances and Equipment and all provincial

and local authorities.

gas-red products must be in accordance with the

®

gas-red products must be in accordance

SAFETY WARNINGS AND GUIDELINES FOR A QUALIFIED SERVICE TECHNICIAN

When selecting a replacement control, always have the complete Model No. and Serial No. of the heater.

(See pages 2-4 for instructions on decoding those numbers.) If the model and serial number are not

available, contact your Reznor® Representative. DO NOT SELECT REPLACEMENT CONTROLS WITH-

OUT COMPLETE INFORMATION.

Before servicing a heater, always turn off the gas and the power supply. Because of the electrical safety

features, never turn off the power supply without turning off the gas.

The electrical operating valve is the primary safety shutoff. The gas supply line must be free of dirt or

scale before connecting the valve.

Leak test all gas connections including pilot connections. Test using a commercial leak detecting or a

soap solution. WARNING: DO NOT TEST WITH OPEN FLAME. If a leak cannot be stopped by tightening,

replace the part.

In the event of pilot outage or improper ignition, wait at least ve minutes before attempting to relight

the heater.

After any service is completed, always test for proper operation. Re-connect the electrical supply and

turn on the gas. Verify against operating sequence information on the heater and in the heater installation manual. Safety check the installation and equipment. CHECK THAT ALL SAFETY DEVICES ARE

FUNCTIONING PROPERLY.

Form P-VALVES, P/N 263995R4, Page 1

Page 2

FOR YOUR SAFETY

WARNINGS

The use and storage of gasoline or other ammable vapors and liquids in the

vicinity of this heating appliance is hazardous.

DANGER

The gas burner in all Reznor® gas-red equipment is designed and equipped to provide safe, complete

combustion. However if the installation does not permit the burner to receive the proper supply of

combustion air, complete combustion may not occur. The result is incomplete combustion which

produces carbon monoxide, a poisonous gas that can cause death. Safe operation of indirect-red

gas burning equipment requires a properly operating vent system which vents all the products to

the outside atmosphere. Failure to provide proper venting will result in a health hazard which could

cause serious personal injury or death.

Always comply with the combustion air requirements in the installation codes and instructions.

Combustion air at the burner should be regulated only by manufacturer-provided equipment.

NEVER RESTRICT OR OTHERWISE ALTER THE SUPPLY OF COMBUSTION AIR TO ANY HEATER.

Indoor units installed in a conned space must be supplied with air for combustion as required

by code and in the installation manual. ON INDIRECT-FIRED EQUIPMENT, MAINTAIN THE VENT

SYSTEM IN PROPERLY FUNCTIONING CONDITION. Direct-red and other unvented installations

should provide for air changes as required by applicable installation codes.

Instructions

for Selecting a

Replacement

Ignition Controller

and/or Valve

Serial No. Codes - Identify the code of the valve or ignition controller needing replacement.

Serial No. Codes are dened on pages 3-5. IMPORTANT NOTE: Serial No. and Model No.

Codes apply only to original equipment.

IGNITION CONTROLLER - To select the replacement ignition controller, locate the Serial No.

safety pilot code in the listing on pages 6-10. Select carefully, reading all applicable notes. If the

part is no longer available from Reznor, a functional replacement or alternative instructions are

listed.

VALVE - To select a replacement valve, locate the Serial No. valve code in the listing on pages

12-19. The valve supplied on the heater is described. If the valve is no longer available from

Reznor, a functional replacement or alternative instructions may be listed. Select carefully, read-

ing all applicable notes. All valve code notes are on pages 20-22. See pages 23-27 for representative illustrations of valves.

VALVE WIRING TERMINAL IDENTIFICATION/WIRE COLOR

Valve Manufacturer Common Pilot Main or Low Stage High Stage

TR TH-TR TH

Honeywell

White-Rodgers

Robertshaw C P M

Original Wire Color

(exceptions possible)

PV-MV PV MV

C PV MV H1

C P M

C1-C2 -- W1 W2

2 4 1 3

White or

Brown

Blue Black Red

IMPORTANT: The controls identied in this form are the controls factory-installed on units

manufactured beginning in 1963. Much of the earlier information provided is for reference only and

does not mean that replacing parts is recommended or that replacement parts are available. See

date code information on page 4.

IMPORTANT

ORDERING

REMINDERS

Form P-VALVES, P/N 263995R4, Page 2

1. Always include complete heater model and serial number so that any specication

change can be considered for parts shipment. It can save time and expense.

2. Specications are subject to change without notice.

3. We reserve the right to substitute functional replacements.

4. Order either by Kit or Component Part No.

Page 3

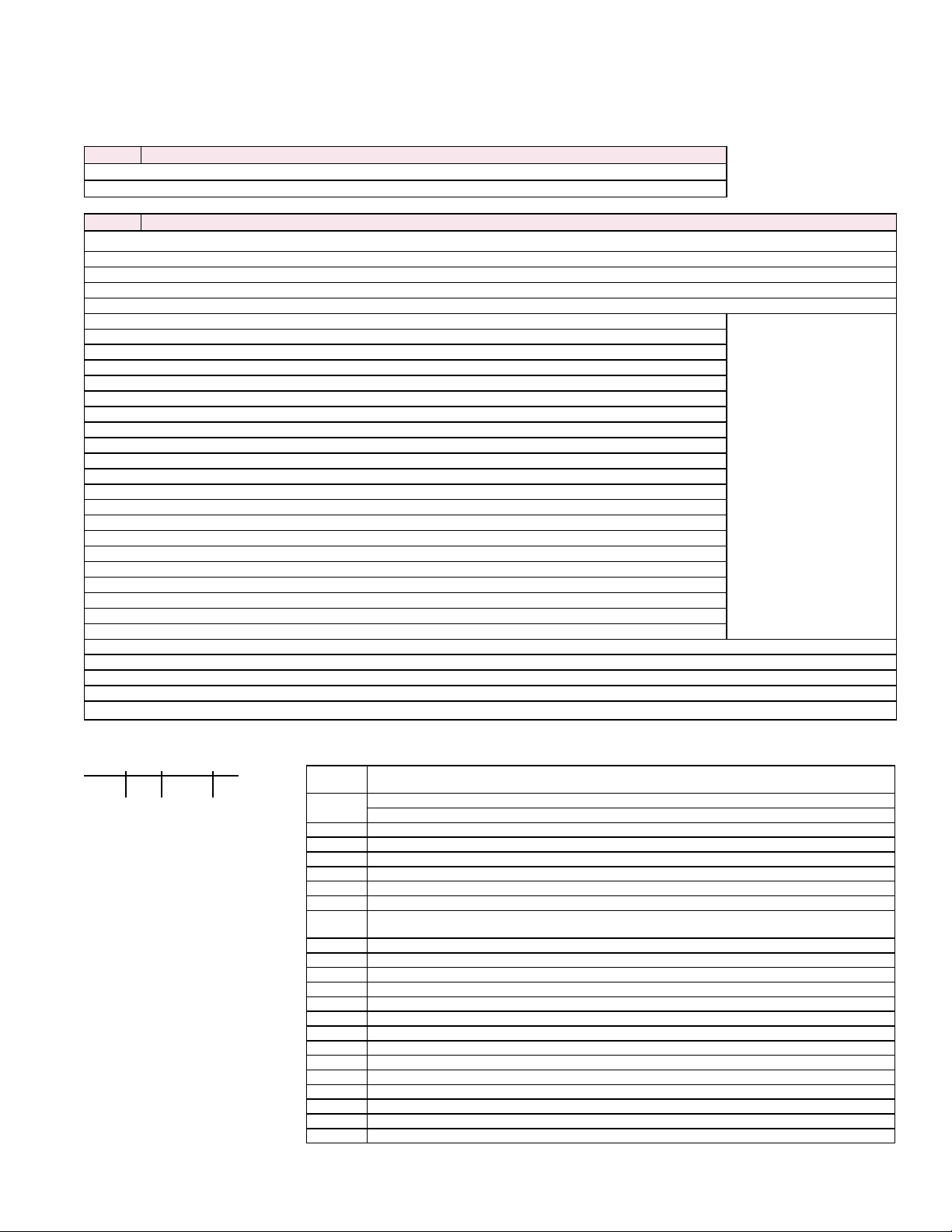

Serial Number and Model Codes

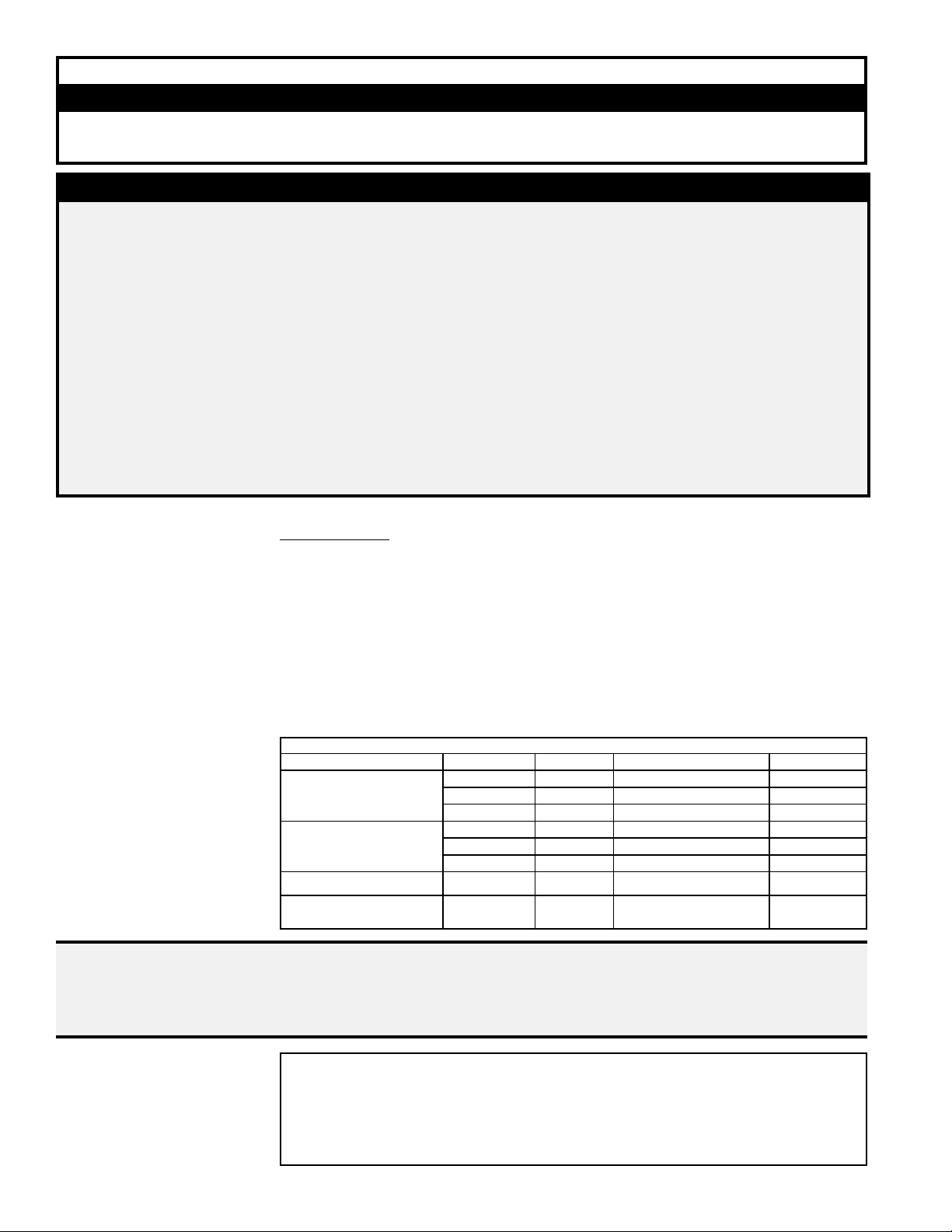

Example of a Rating Plate that applies to most Reznor® Models showing Model and Serial Numbers

Serial No. Decoding

Sample of a Serial No. for Units manufactured from 1963 through

Mercer, PA 16137

DUCT FURNACE

CATEGORY I

FOR INDUSTRIAL/COMMERCIAL USE ONLY NRTL

DESIGN CERTIFIED UNDER ANSI Z83.8a-1998

DUCT FURNACE

MODEL HX100E-8-S OCT 2004

SERIAL# EBDJ66W8N12345

115 VOLTS 1PH 60HZ MAXIMUM TOTAL INPUT .5AMPS

TYPE OF GAS NATURAL

ORIFICE SIZE #41 DRILL HAS BEEN FACTORY ADJUSTED

FOR USE AT 0-2000 FEET (0-610 METERS) OF ALTITUDE

SEA LEVEL ALT ADJUSTED

NORMAL INPUT 100000 100000 BTU/HR

OUTPUT CAPACITY 80000 80000 BTU/HR

MIN. INPUT (2, M, MB, MV MODELS) 50000 50000 BTU/HR

NORMAL MANIFOLD PRESSURE 3.5 IN. W.C.

MIN. PERMISSIBLE GAS SUPPLY PRESSURE

FOR PURPOSE OF INPUT ADJUSTMENT 5.0 IN. W.C.

MAXIMUM THROUGHPUT 3704 CFM

MINIMUM THROUGHPUT 988 CFM

CLEARANCE TO COMBUSTIBLE CONSTRUCTION: TOP - 6";

FLUE CONNECTION - 6"; SERVICE SIDE - WIDTH OF UNIT;

OPPOSITE SIDE - 6"; BOTTOM - 3", MAY BE INSTALLED ON

NONCOMBUSTIBLE FLOORS.

INSTALL ON THE POSITIVE PRESSURE SIDE OF AIR

CIRCULATING BLOWER.

THIS UNIT MAY BE INSTALLED DOWNSTREAM FROM A

REFRIGERATION SYSTEM (USE DRAIN OPTION CS1).

FOR ALTERNATE INSTALLATION, USE THE LATEST OF THE

APPROPRIATE STANDARDS LISTED BELOW:

FOR AIRCRAFT HANGARS USE STANDARD ANSI/NFPA 409

FOR PARKING STRUCTURES USE STANDARD ANSI/NFPA 88A

FOR REPAIR GARAGES USE STANDARD ANSI/NFPA 88B

1974:

OA 1 2 N 693 Serial No.

1 2 3 4 5 Element

Sample of a Serial No. for Units manufactured beginning in 1975:

BDJ 66 W8 N 12345 Serial No.

1 2 3 4 5 Element

Element Key:

1 = Month and Year of manufacture; see page 4.

2 = Type of safety pilot or ignition system; see pages 6-10 for Code

explanation.

3 = Type of valve; see pages 12-22 for Code explanation and illustra-

tions on pages 23-27. (A dash indicates that the valve was eld

supplied.)

4 = Type of gas that the heater was originally manufactured to burn

D = Dual fuel, natural and propane; L = Propane; N = Natural

(Check for gas conversion label.)

5 = Consecutive number of heater manufactured. Used for identi-

cation purposes only.

In addition to the basic ve elements, the serial number may also include

prex and/or sufx codes. See page 5 for a listing and explanation of

these codes. All codes apply to original equipment only.

®

Example of a Reznor

MAPS® Unit Rating Plate

Showing Model and Serial Numbers

REZNOR

MERCER, PA, U.S.A. 16137

FOR INDUSTRIAL/COMMERCIAL USE ONLY

SUITABLE FOR OUTDOOR USE

MODEL [ A ] [ B ]

SERIAL NO. [ ]

[D] VOLTS +/- 10% [D] PHASE [D] HZ

MINIMUM CIRCUIT AMPACITY (MCA) [ F ] AMPS

MAXIMUM FUSE SIZE/*CKT BREAKER [ G ] AMPS

SUPPLY AIR BLOWER MOTOR 1 [ E ] [ C ]

CONDENSER FAN MOTOR (S) [ T ] [ U ] [ Z ]

COMPRESSOR A [ H ] [ I ] [ J ]

COMPRESSOR B [ K ] [ L ] [ M ]

COMPRESSOR C [ N ] [ O ] [ P ]

COMPRESSOR D [ Q ] [ R ] [ S ]

COMPRESSOR E [ GG ] [ HH ] [ II ]

REFRIGERANT - R-410a CHARGE - LBS

TEST PRESSURES HIGH 600PSIG LOW 45PSIG

EQUIPPED FOR OPERATION AT AN AIR FLOW OF [ CC ] SCFM

AGAINST A STATIC PRESSURE OF [ DD ] INCHES WATER COLUMN

DRIVE RPM [ EE ]

WIRE DIAGRAM [ FF ]

REFER TO RATING PLATE IN THE FURNACE SECTION (WHEN USED)

FOR ADDITIONAL INFORMATION.

*HACR TYPE REQUIRED PER NEC

CIRCUITS A B C D E

®

MADE IN USA

ELECTRICAL

QTY FLA (EA) HP (EA)

QTY RLA (EA) LRA (EA)

[ V ] [ W ] [ X ] [ Y ] [ JJ ]

Rating Plate Key for MAPS® Model Series RCA,

RDA, RCB, RDB, RCC, and RDC

(NOTE: To decode a MAPS Serial No., see page 4.)

A = Model

B = Manufacturing Date (Month/Year)

C = Blower Motor HP

D = Volts/Phase/Hertz

E = Full Load Amps (FLA) of Blower Motor

F = Minimum Circuit Ampacity (MCA)

G = Maximum Fuse Size (MOP)

H = Quantity - Compressor A

I = Rated Load Amps of Compressor A

J = Locked Rotor Amps of Compressor A

K = Quantity - Compressor B

L = Rated Load Amps of Compressor B

M = Locked Rotor Amps of Compressor B

N = Quantity - Compressor C

O = Rated Load Amps of Compressor C

P = Locked Rotor Amps of Compressor C

Q = Quantity - Compressor D

R = Rated Load Amps of Compressor D

S = Locked Rotor Amps of Compressor D

T = Quantity Condenser Fan Motors

U = Rated Load Amps of Condenser(s)

V = Refrigerant Charge (lbs) - Circuit A

W = Refrigerant Charge (lbs) - Circuit B

X = Refrigerant Charge (lbs) - Circuit C

Y = Refrigerant Charge (lbs) - Circuit D

Z = Condenser Fan Motor HP

Form P-VALVES, P/N 263995R4, Page 3

CC = SCFM Airow

DD = External

Static Pressure

(“ w.c.)

EE = Drive (Option

AM)

FF = Wiring Dia-

gram No.

GG = Quantity -

Compressor E

HH = Rated Load

Amps of Compressor E

II = Locked Rotor

Amps of Compressor E

JJ = Refrigerant

Charge (lbs) Circuit E

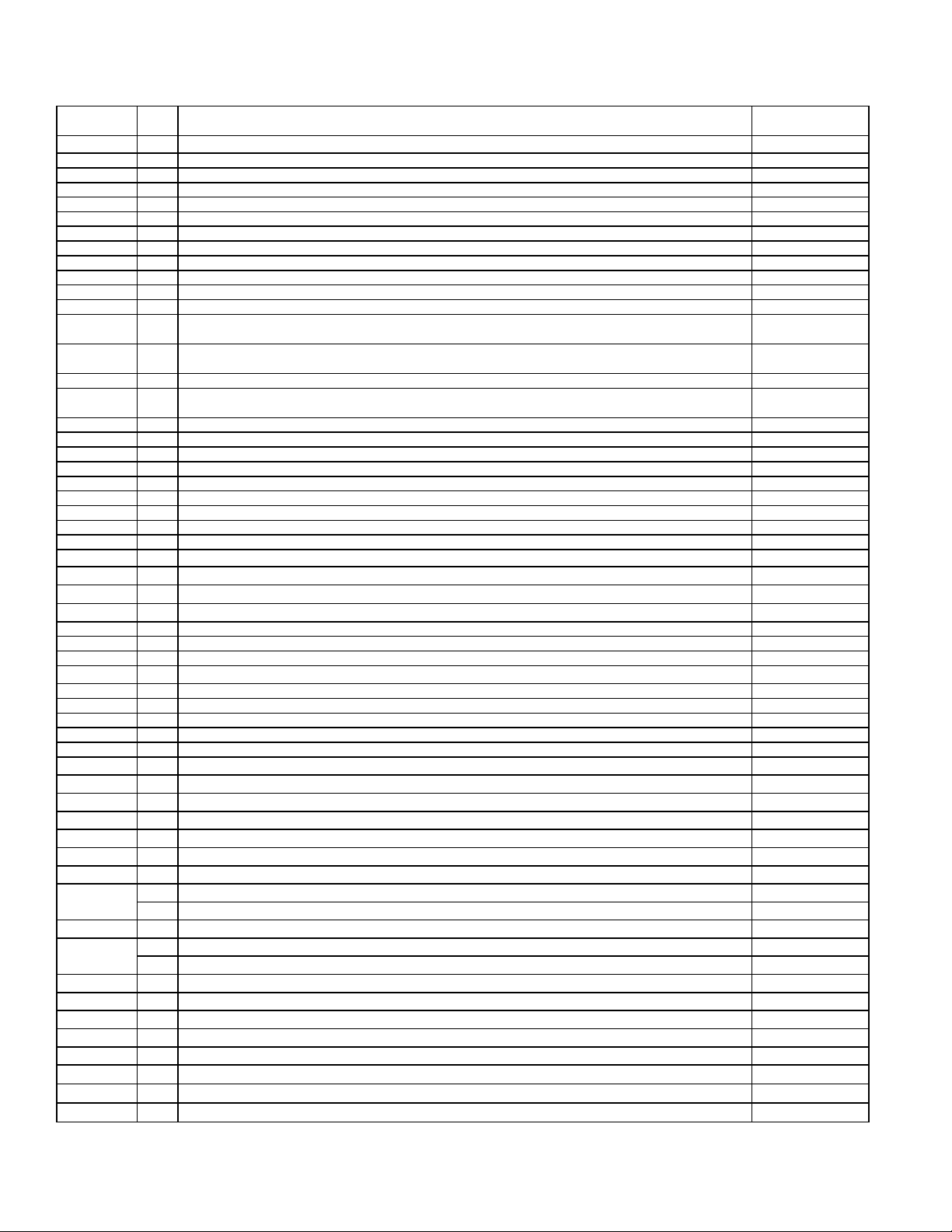

Page 4

Serial

Number

and Model

Codes

(cont'd)

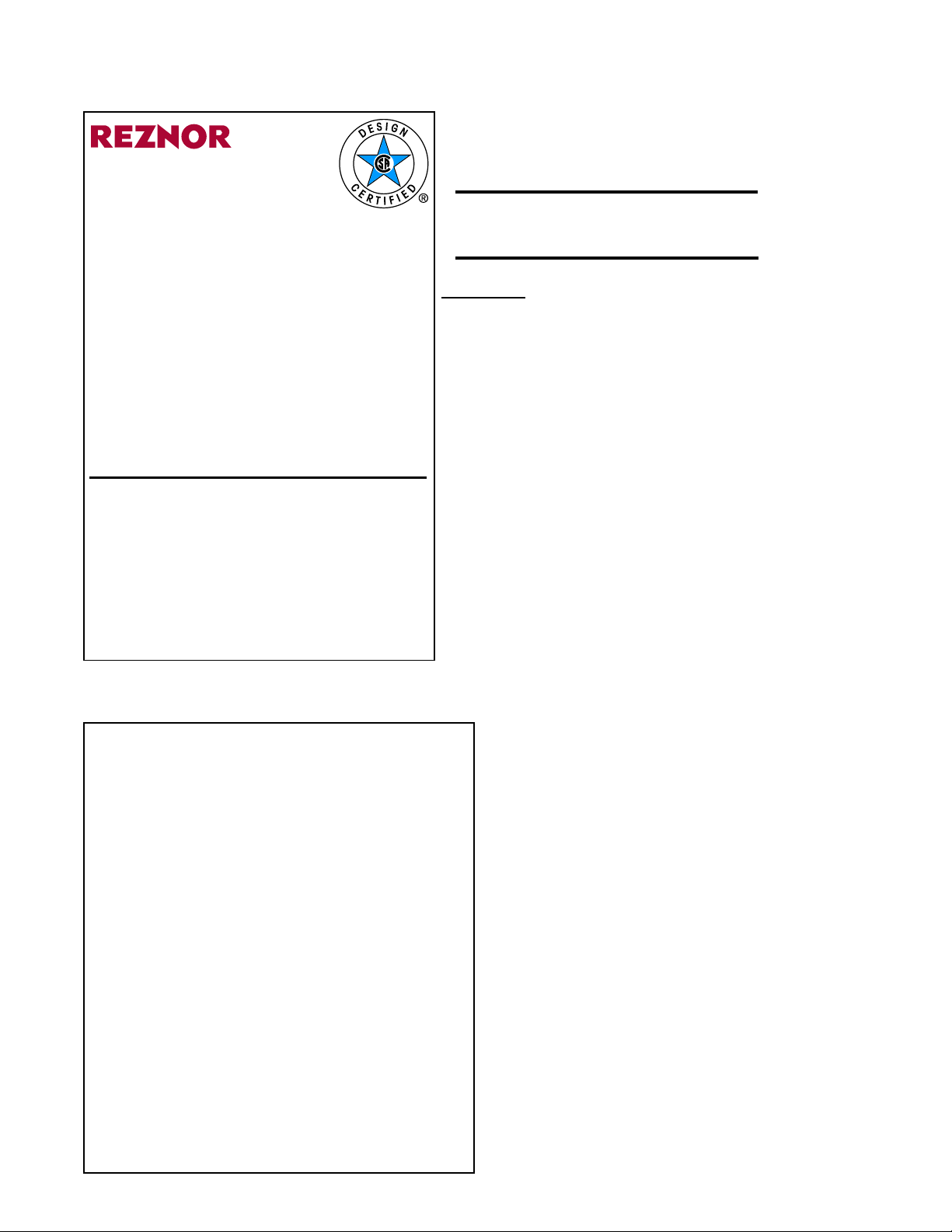

Decoding a MAPS® Unit Serial No.

Serial No. Sample: 3 BIJ 789 BK 08 N 96 7D

Elements of No.: 1| 2 | 3 | 4 | 5 |6| 7 | 8

Elements 1-5 apply to all MAPS

Elements 6-8 apply to a MAPS

®

models.

®

with a gas heat section .

Key: 1 = Phase (1 or 3)

2 = Date CODE (See table below.)

3 = Consecutive number

4 = Drive (See Form P-MAPSII or P-MAPSIII)

5 = Motor HP (See explanation on the right.)

6 = Type of Gas (N = Natural)

7 = Ignition CODE (See pages 6-10.)

8 = Valve CODE (See pages 12-22.)

Motor HP Serial No. Code

1/2 03

3/4 04

1 05

1-1/2 06

2 07

3 (3450 rpm) 08

5 (3450 rpm) 09

7-1/2 11

15 12

10 13

20 14

3 (1800rpm) 15

5 (1800rpm) 16

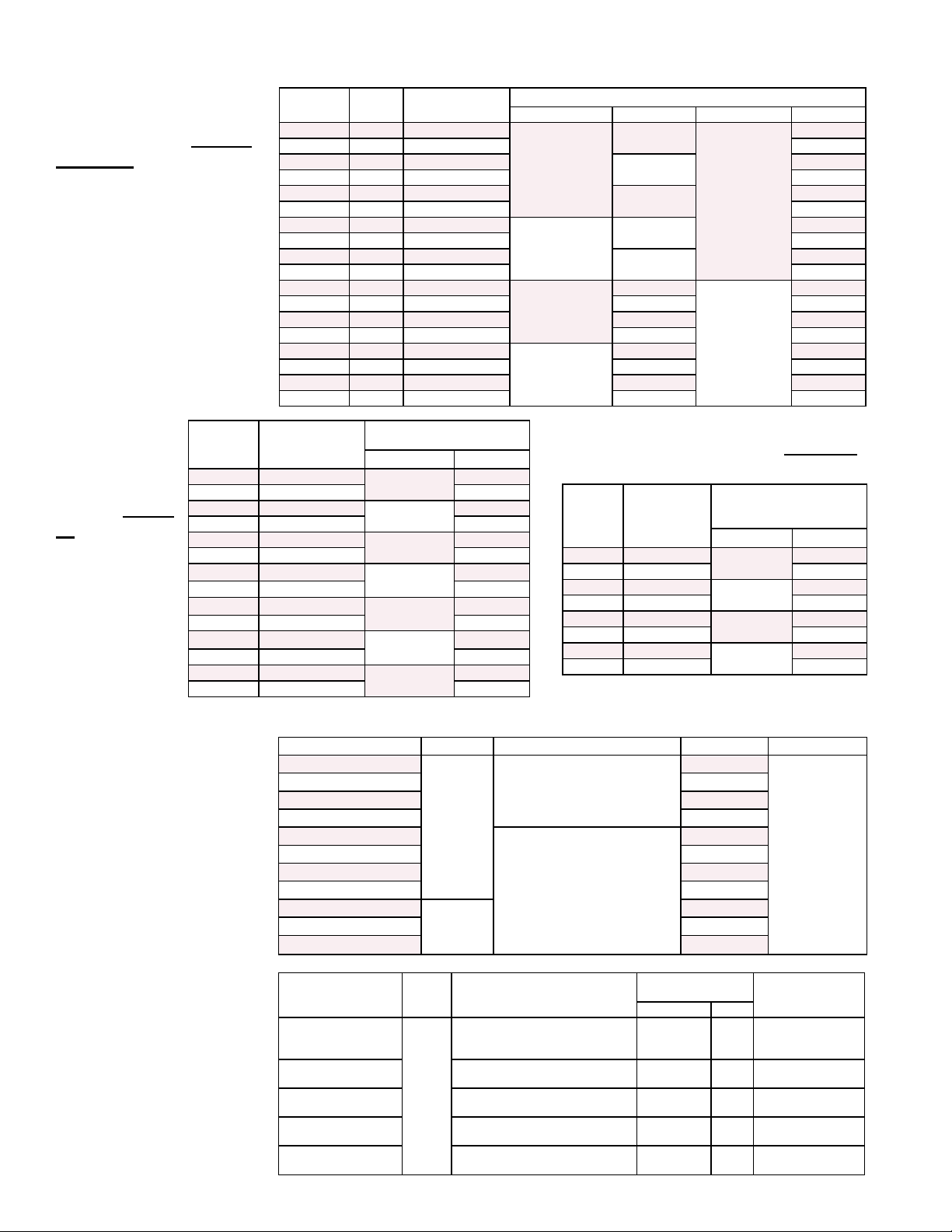

Serial Number Key - Month and Year of Manufacture

Year Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec

1963 OA OB OC OD OE OF OG OH OI OJ OK OL

1964 PA PB PC PD PE PF PG PH PI PJ PK PL

1965 QA QB QC QD QE QF QG QH QI QJ QK QL

1966 RA RB RC RD RE RF RG RH RI RJ RK RL

1967 SA SB SC SD SE SF SG SH SI SJ SK SL

1968 TA TB TC TD TE TF TG TH TI TJ TK TL

1969 UA UB UC UD UE UF UG UH UI UJ UK UL

1970 VA VB VC VD VE VF VG VH VI VJ VK VL

1971 WA WB WC WD WE WF WG WH WI WJ WK WL

1972 XA XB XC XD XE XF XG XH XI XJ XK XL

1973 YA YB YC YD YE YF YG YH YI YJ YK YL

1974 ZA ZB ZC ZD ZE ZF ZG ZH ZI ZJ ZK ZL

1975 AAA AAB AAC AAD AAE AAF AAG AAH AAI AAJ AAK AAL

1976 ABA ABB ABC ABD ABE ABF ABG ABH ABI ABJ ABK ABL

1977 ACA ACB ACC ACD ACE ACF ACG ACH ACI ACJ ACK ACL

1978 ADA ADB ADC ADD ADE ADF ADG ADH ADI ADJ ADK ADL

1979 AEA AEB AEC AED AEE AEF AEG AEH AEI AEJ AEK AEL

1980 AFA AFB AFC AFD AFE AFF AFG AFH AFI AFJ AFK AFL

1981 AGA AGB AGC AGD AGE AGF AGG AGH AGI AGJ AGK AGL

1982 AHA AHB AHC AHD AHE AHF AHG AHH AHI AHJ AHK AHL

1983 AIA AIB AIC AID AIE AIF AIG AIH AII AIJ AIK AIL

1984 AJA AJB AJC AJD AJE AJF AJG AJH AJI AJJ AJK AJL

1985 AKA AKB AKC AKD AKE AKF AKG AKH AKI AKJ AKK AKL

1986 ALA ALB ALC ALD ALE ALF ALG ALH ALI ALJ ALK ALL

1987 AMA AMB AMC AMD AME AMF AMG AMH AMI AMJ AMK AML

1988 ANA ANB ANC AND ANE ANF ANG ANH ANI ANJ ANK ANL

1989 AOA AOB AOC AOD AOE AOE AOG AOH AOI AOJ AOK AOL

1990 APA APB APC APD APE APF APG APH API APJ APK APL

1991 AQA AQB AQC AQD AQE AQF AQG AQH AQI AQJ AQK AQL

1992 ARA ARB ARC ARD ARE ARF ARG ARH ARI

1993 ASA ASB ASC ASD ASE ASF ASG ASH ASI ASJ ASK ASL

1994 ATA AT B ATC ATD ATE AT F AT G ATH ATI ATJ ATK ATL

1995 AUA AUB AUC AUD AUE AUF AUG AUH AUI AUJ AUK AUL

1996 AVA AV B AVC AV D AVE AVF AVG AVH AVI AV J AV K AVL

1997 AWA AWB AWC AWD AWE AWF AWG AWH AWI AWJ AWK AWL

1998 AXA AXB AXC AXD AXE AXF AXG AXH AXI AXJ AXK AXL

1999 AYA AY B AYC AY D AYE AYF AYG AYH AYI AY J AY K AYL

2000 AZA AZB AZC AZD AZE AZF AZG AZH AZI AZJ AZK AZL

2001 BAA BAB BAC BAD BAE BAF BAG BAH BAI BAJ BAK BAL

2002 BBA BBB BBC BBD BBE BBF BBG BBH BBI BBJ BBK BBL

2003 BCA BCB BCC BCD BCE BCF BCG BCH BCI BCJ BCK BCL

2004 BDA BDB BDC BDD BDE BDF BDG BDH BDI BDJ BDK BDL

2005 BEA BEB BEC BED BEE BEF BEG BEH BEI BEJ BEK BEL

2006 BFA BFB BFC BFD BFE BFF BFG BFH BFI BFJ BFK BFL

2007 BGA BGB BGC BGD BGE BGF BGG BGH BGI BGJ BGK BGL

2008 BHA BHB BHC BHD BHE BHF BHG BHH BHI BHJ BHK BHL

2009 BIA BIB BIC BID BIE BIF BIG BIH BII BIJ BIK BIL

2010 BJA BJB BJC BJD BJE BJF BJG BJH BJI BJJ BJK BJL

2011 BKA BKB BKC BKD BKE BKF BKG BKH BKI BKJ BKK BKL

2012 BLA BLB BLC BLD BLE BLF BLG BLH BLI BLJ BLK BLL

2013 BMA BMB BMC BMD BME BMF BMG BMH BMI BMJ BMK BML

2014 BNA BNB BNC BND BNE BNF BNG BNH BNI BNJ BNK BNL

2015 BOA BOB BOC BOD BOE BOF BOG BOH BOI BOJ BOK BOL

2016 BPA BPB BPC BPD BPE BPF BPG BPH BPI BPJ BPK BPL

2017 BQA BQB BQC BQD BQE BQF BQG BQH BQI BQJ BQK BQL

2018 BRA BRB BRC BRD BRE BRF BRG BRH BRI BRJ BRK BRL

Form P-VALVES, P/N 263995R4, Page 4

ARJ ARK ARL

Page 5

Heater Serial No.

PREFIX and SUFFIX

Codes

In addition to the ve elements found in every serial number, the heater serial number may be

coded with prexes and sufxes that further identify optional equipment or capabilities applicable

to that particular unit. All prex and sufx codes are listed below. See pages 3-4 for explanation

of the basic elements of a serial number.

Serial Number PREFIX Codes and Denitions:

Code Explanation

E = E3 (409) stainless steel heat exchanger

S = 316 or 321 stainless steel heat exchanger

Serial Number SUFFIX Codes and Denitions:

Code Explanation

B = Baso pilot (indicates Baso pilot in place of General Controls pilot)

CA = Constant air volume

EE = Energy efcient motor

FD = Fan duct furnace (spotter)

HV = High throw fan assembly

MP1 = Modulating gas control with 20%-100% ring rate (AG39)

MP2 = Modulating gas control with 20%-100% ring rate with signal conditioner for DDC (AG40)

MP3 = Modulating gas control 20-100% ring rate on 1st furnace; 2-stage on 2nd (AG41)

MP4 = Modulating gas control 20-100% on 1st furnace; 2-stage on 2nd - w/signal conditioner for DDC (AG42)

MP5 = 1-stage on 1st furnace; 2-stage on 2nd furnace (AG43)

MP6 = 1-stage on 1st furnace; 2-stage on 2nd furnace - with signal conditioner for DDC (AG44)

MV1 = Maxitrol 20AH Electronic Modulation (50-100%) System (AG7 for single furnace)

MV2 = Maxitrol 30AH Electronic Modulation (50-100%) System (AG7 for multiple furnaces)

MV3 = Maxitrol 21H Electronic Modulation (50-100%) System (AG8 for single furnace)

MV4 = Maxitrol 21HR Electronic Modulation (50-100%) System (AG9 for single furnace)

MV5 = Maxitrol 31H Electronic Modulation (50-100%) System (AG8 for multiple furnaces)

MV6 = Maxitrol 31HR Electronic Modulation (50-100%) System (AG9 for multiple furnaces)

MV7 = Maxitrol 14 Electronic Modulation System (AG30 and AG31)

MV8 = Maxitrol 14A and 14B Electronic Modulation Systems (AG32 and AG35)

MV9 = Maxitrol 44 Electronic Modulation System (AG33)

MVA = Maxitrol Electronic Modulation (50-100%) System w/Signal Conditioner for DDC on Indirect-Fired Equipment (AG21)

MVB = Maxitrol 94 Electronic Modulation System for Paint Booth for Direct-Fired Equipment (AG36)

MVC = Maxitrol Electronic Modulation System with Signal Conditioner for DDC on Direct-Fired Equipment (AG37)

MVD = Maxitrol DFM14E Digital Control System (AG47) (Direct-red RDF or DV)

MVE = Maxitrol DFM 44E Digital Control System (AG48) (Direct-red RDF or DV)

MVF = Maxitrol DFM 44E Digital Control System with Remote Sensor (AG51) (RDF or DV)

RA = Recirculation air

TE = Totally enclosed motor

TS = Two speed motor

VA = Variable air volume

X = Manufactured in Mexico

For a list of components of

Maxitrol electronic modulation

systems used on Model Series X,

SC, RX, RPV, RG, RP, and EEDU

indirect-red equipment, see pag-

es 25-27. For list of components

of Maxitrol electronic modulation

systems used on Model Series

ADF, DV, and RDFdirect-red

equipment, see pages 27-28.

(Reference NOTE: For PREEVA

indirect-red models, see Form

P-PREEVA for modulation control

components.)

Model No. Decoding

HX 100 8 S

Model Size Series Sufx

The Model No. may or may

not include sufx code(s) that

further identify the heater. See

the listing in the table for their

identication.

*Effective 12/96, Codes J, JR,

and Y are no longer used.

Heater Model No. SUFFIX Codes

SUFFIX

Code

-2 = Two stage heating/MUA control

-2L = Two stage control (heating/MUA) with 33% low re and constant thermal efciency (AG60, AG61, AG62)

-C = Unit with a C.G.A. rating plate

-CV = Common vent

-D2 = Digital control, space temperature, 2-stage heating/3-stage cooling (DG1)

-D2J = Digital control, electronic modulation heating/3-stage cooling (DG2)

-DM = Digital control, discharge temperature (makeup air), 2-stage heating/3-stage cooling (DG5)

-DMJ = Digital control, discharge temperature (makeup air), electronic modulation heating/3-stage cooling (DG6)

-E =

-H = Oriced for high altitude

-IL = Manifold arrangement and remote console for Illinois School Code

* -J = Makeup air (code appears on blower cabinet plate only)

* -JR = Makeup air with evaporative cooling (code appears on blower cabinet plate only)

-LN = Low noise

-M = Mechanical modulation

-MB = Mechanical modulation with full re bypass

-MP = Electronic modulation (20-100% ring rate)

-MV = Electronic modulation (50-100% ring rate)

-R = Evaporative cooling

-S = Stainless steel heat exchanger

-W = Wide heater cabinet on Models RX75 and 100 Series 5 and 6

* -Y = High re lightoff

-Z = Equipped with “Z” bafe for 4-foot stack extension

Explanation

Intermittent spark pilot (Applies to Models F, B, X, XE, XL, XLB that have a standard match lit pilot; models

that have a standard spark pilot do not have this code.)

Form P-VALVES, P/N 263995R4, Page 5

Page 6

Safety Pilot or Ignition System Originally Supplied, Identied by Serial No. Code --

See Serial No. Decoding on pages 3-4. (N/A = Not available; see other notes below.)

Serial No.

Code

1 J/C 8856-5

2 J/C 861-4

3 G/C A100G741 (3-wire)

4 J/C 856-A5

5 J/C 619 Automatic relight system - 115 volt transformer

6 J/C 619 Automatic relight system - 220 volt transformer

7 J/C 619 Automatic relight system - 24 volt transformer

8 J/C A100G544 (2-wire)

9 G/C Safety Pilot is part of B57, B59 valve

10 T 32T Automatic relight

01 J/C Remote push button relighting system non-100% shutoff (includes 861-4, 115 volt push button station)

02 J/C Remote push button relighting system non-100% shutoff (includes 861-4, 230 volt push button station)

03 J/C

04 J/C

05 J/C Remote push button relighting system non-100% shutoff (includes 861-4, 24 volt push button station)

06 J/C

07 T 32T Recycling safety pilot switch

08 J/C Safety pilot is part of Baso 92D2204A valve

09 J/C Safety pilot is part of Baso CS212A-2

11 J/C Safety pilot is part of Baso CS222A-1

12 M/H Safety pilot is part of M/H Y343B

13 J/C G13BG01 spark ignition system

14 M/H RA890E protector relay

15 J/C Part of G-28 spark ignition, non-100% shutoff

16 J/C Part of 67800-2T's master control

17 J/C G18MG02 spark ignition system - For replacement, use ignition conversion package

18 M/H C591A002 pilotstat

19 J/C G19MG02 automatic relight, 100% shutoff - For replacement, use ignition conversion package

20 W/R 30A48 with 50" lead

21 W/R 30A46 with 50" lead

22 J/C G29BG01 automatic relight, non-100% - For replacement, use ignition conversion package

23 J/C G29BG02 automatic relight, 100% shutoff - For replacement, use ignition conversion package

24 J/C 830 - 1/2 safety pilot valve

25 J/C G28MG01, 100% (Model RHD Series)

26 F Spark ignition system 05-120103-000 with combination valve, 100% shutoff - See Code 32

27 J/C 861-4

28 G/C A100G741

29 J/C G19 Automatic relight system - For replacement, use ignition conversion package

30 G/C A100G544

31 Part of combination valve with standing pilot

32 F Spark ignition, non-100%

33 J/C G18BG02 spark ignition, non-100%

34 J/C G33BAG-1 spark ignition, 100% shutoff - For replacement, use ignition conversion package

35 F 05-13031-501 spark ignition, 100% shutoff (Model DFT)

36 F G13CG-1 spark ignition, 100% shutoff (Model DFT)

37

38 W/R 5070A-1 spark ignition, 100% shutoff (Model DFT)

39

40 J/C G60AAG-3 ignition controller (used with 100% recycling pilot)

41 J/C G60AAG-3 ignition controller (used with non-100% relight)

42 J/C G60AAG-3 ignition controller (used with 100% shutoff and Y79 lockout device)

43 F No. 05-142202-005 spark ignition (Model DFT 250, 260, 295, 325)

44 J/C G60QBG-7 ignition controller with valve and regulator all in one body -

45 J/C G60CPG-1 ignition controller, propane gas with separate lockout

46 J/C G60QBG-7 ignition controller, natural gas with lockout, Y79 timing device

47 J/C G60PFH ignition controller with lockout all in one body, natural or propane gas

1

F = Fenwall; G/C = General Controls; M/H = Minneapolis Honeywell; J/C = Johnson Controls; T = Thermodisc; W/R = White-Rodgers

2

Functional replacement may require eld-furnished wiring.

3

This item is no longer available. Suggest you contact the control manufacturer for replacement or functional replacement.

Form P-VALVES, P/N 263995R4, Page 6

Mfr 1Description Replacement P/N

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

N/A

3

N/A

3

Remote push button relighting system 100% shutoff (includes 861-4, 115 volt pilot valve, 115 volt push

button station)

Remote push button relighting system 100% shutoff (includes 861-4, 230 volt pilot valve, 230 volt push

button station)

Remote push button relighting system 100% shutoff (includes 861-4, 24 volt pilot valve, 24 volt push

button station)

M/H R4795A-1016 spark ignition, 100% shutoff

G/C with K3R11A2N4 pilot line solenoid valve (Model DFT)

M/H R4795A-1016 spark ignition, 100% shutoff

G/C with K3R11A2N4 pilot line solenoid valve (Model DFT)

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

3

3

3

N/A

N/A

N/A

2

Page 7

Safety Pilot or Ignition System Originally Supplied, Identied by Serial No. Code (cont'd) -See Serial No. Decoding on pages 3-4. (N/A = Not available; see other notes below.)

Serial No.

Code

48 J/C G60QRH-1 ignition controller, propane gas valve with regulator and lockout all in one body N/A

49 M/H L626B3 N/A

50 J/C G65BCG-1 ignition controller and natural gas valve with regulator all in one body, 1/2" 67983-N/A

51 J/C G65DCM-1 ignition controller & propane gas valve w/regulator & lockout, 1 body, 1/2" 68055-N/A

52 J/C G65BBG-4 ignition controller and natural gas valve with regulator all in one body, 1/2" 79887-N/A

53 J/C G65BKG-2 ignition controller and natural gas valve with regulator all in one body, 3/4" 79888-N/A

54 J/C G65BCM-1 ignition controller & natural gas valve w/regulator & lockout, 1 body, 1/2" 79808-N/A

55 J/C G65BBM-3 ignition controller & natural gas valve w/regulator & lockout, 1 body, 1/2" 84570-N/A

56 J/C G65BKM-2 ignition controller & natural gas valve w/regulator & lockout, 1 body, 3/4" 79900-N/A

57 J/C

58 M/H

59 M/H

60 M/H

61 M/H

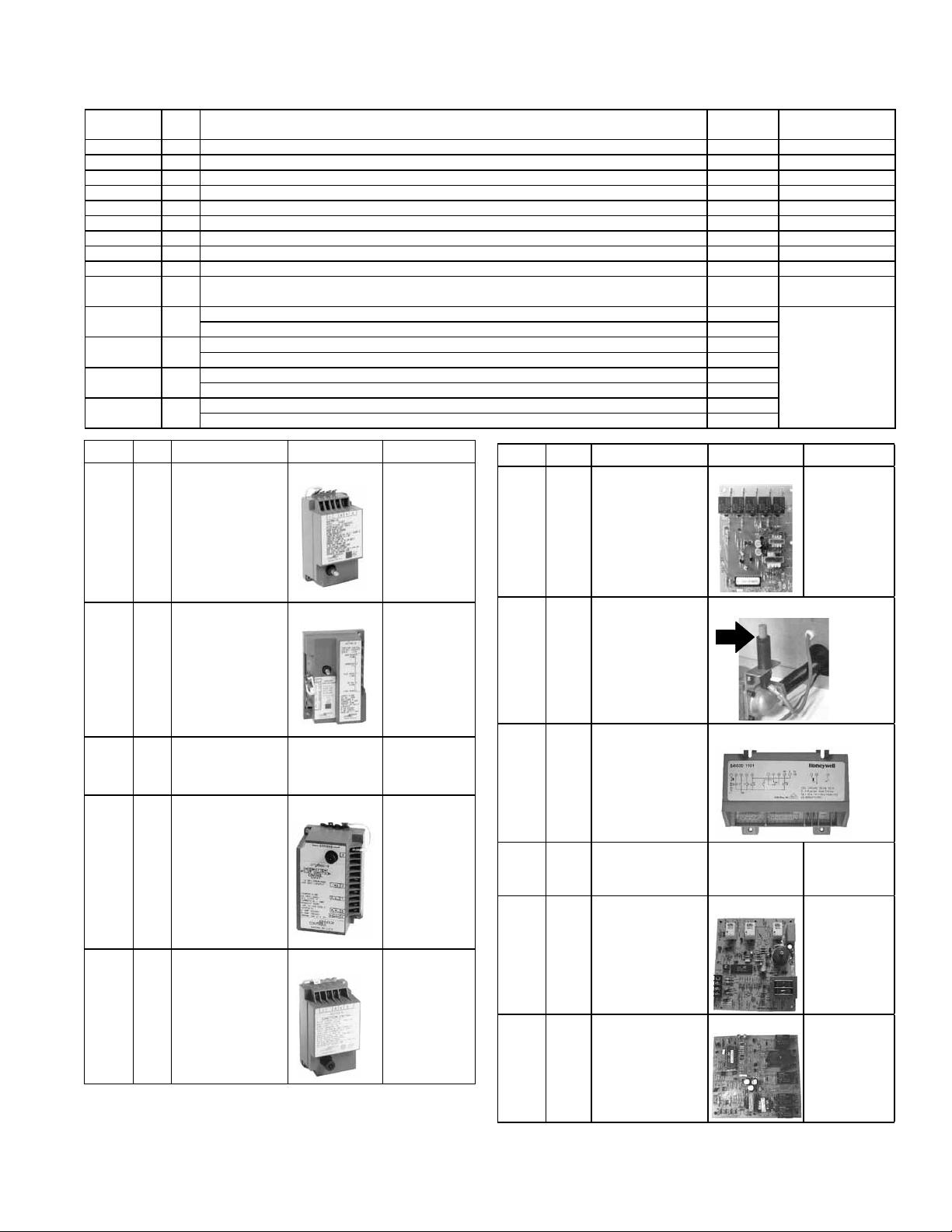

Code Mfr Description P/N Replaced by

62 J/C Ignition controller

Mfr 1Description P/N Replacement P/N

G66BMG-1 ignition controller and natural gas valve with regulator and lockout all in one

body, 1/2" - Special for export

Solid state ame safeguard, RA890F (ame rectication) 86972

Solid state spark generator, Q624A1006 or Q624A1014 86974

Solid state ame safeguard, RA890G (ultraviolet) 89409

Solid state spark generator, Q624A1006 or Q624A1014 86974

Solid state ame safeguard, R7795B (ame rectication) 89407

Solid state spark generator, Q624A1006 or Q624A1014 86974

Solid state ame safeguard, R7795A (ultraviolet) 89436

Solid state spark generator, Q624A1006 or Q624A1014 86974

Code Mfr Description P/N Replaced by

G67BG-2, natural

gas or propane

89314-N/A Kit P/N

257472

67 RAM Hot surface

ignition module

H4MC2

on outdoor units

only

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

3

N/A

N/A

3

N/A

To replace with HSI:

New wiring dia-

gram PLUS Kit P/N

146268; or kits with

200VA transformer,

P/N 146318 (115V);

P/N 146319 (208V,

240, 480, 575V)

121543 204376

(Code 82)

2

63 J/C Ignition controller

G67NG-2,

natural gas or

propane on

outdoor units

only

64 M/H Safety pilot for

Bell Telephone,

L62GB

65 J/C Ignition controller

G770NGC-4 with

lockout, natural

gas or propane

66 J/C Ignition controller

G67BG-5, natural

gas or propane

on outdoor units

only

89488-N/A Kit P/N

257473

N/A N/A

97547-N/A Kit P/N

257473

except for

Model TR,

use P/N

216970

97782-N/A Kit P/N

257472

68 M/H Piezo Ignitor

Q635A1010

69 M/H Ignition controller

GS4S6DD

70 M/H Ignition Controller

S4560B1055-

ML11149

71 RAM Direct Spark

Integrated

Control Board

3MC4-03

72 RAM Hot surface

ignition module

H4MC2

125836

134780

145714

147102 Kit P/N

257531

157953 204376

(Code 82)

1

F = Fenwall; G/C = General Controls; J/C = Johnson Controls;

M/H = Honeywell; T = Thermodisc; W/R = White-Rodgers

2

Functional replacement may require eld-furnished wiring.

3

This item is no longer available. Suggest you contact the control manufacturer for replacement or functional replacement.

Form P-VALVES, P/N 263995R4, Page 7

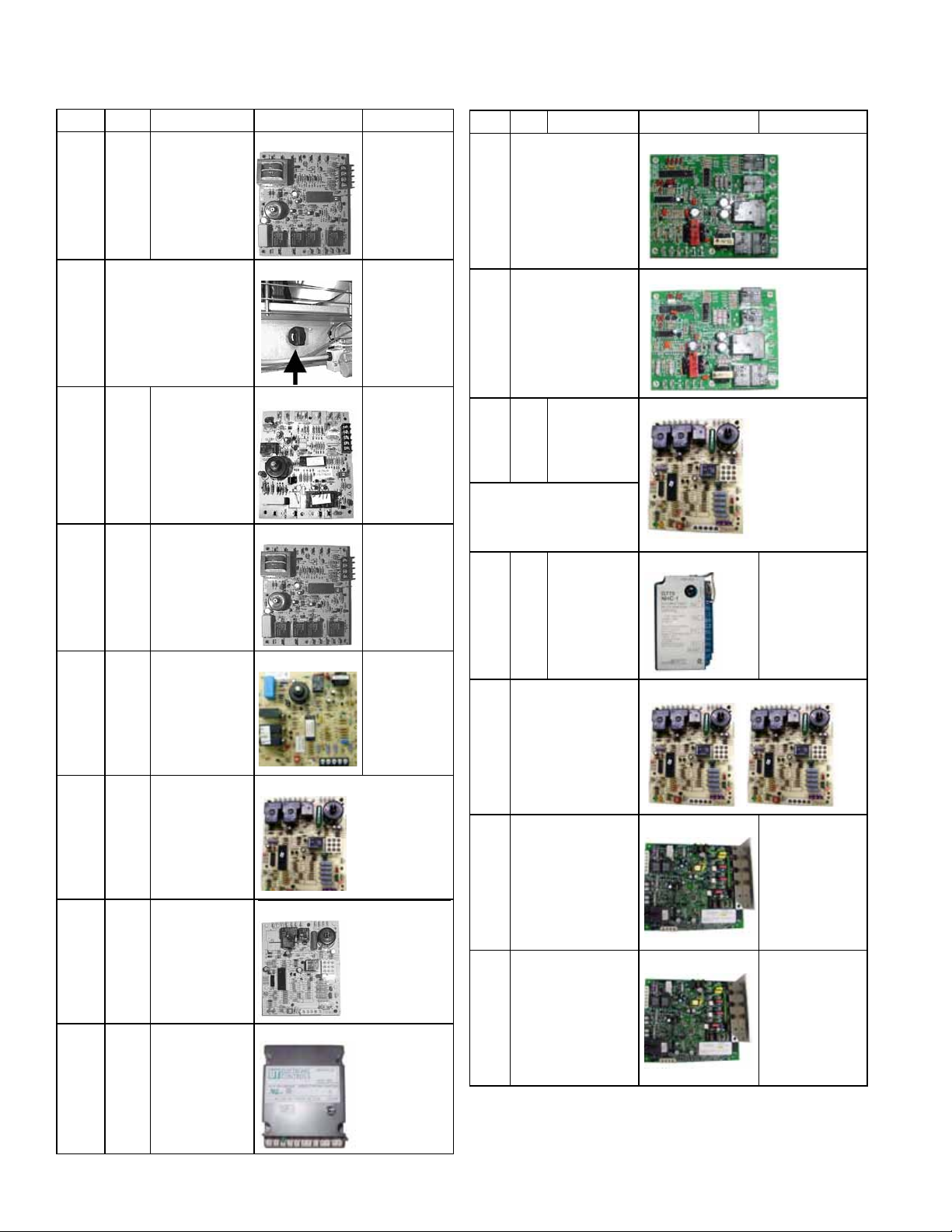

Page 8

Safety Pilot or Ignition System Originally Supplied, Identied by Serial No. Code (cont'd) -- See

Serial No. Decoding on pages 3-4. (N/A = Not available; see other notes below.)

Code Mfr Description P/N Replaced by

73 RAM Direct Spark

integrated

164326 Kit P/N

258251

Control Board

3MC4-04

74 Channel Products

173036

1691-06, Rotary Piezo

Electric Ignitor (Used

on Model UF for

Ambirad.)

75 J/C Direct Spark

Ignition

174260 Kit P/N

257531

Module,

#G861KCC5401D

76 RAM Direct Spark

Integrated

178453 Kit P/N

258251

Control Module

3MC4-06

77 J/C Direct Spark

Ignition

193804 Kit P/N

258251

Control Board,

G822KCC5401 D

Code Mfr Description P/N Replaced by

81 Synetek IH1104C

204166

Dual Flame

Ignition Module

82 Synetek

204376

IH-11040B-C

Single Flame Rod

Ignition Module

83 UTC Direct Spark

214979

Ignition Module with Cool-

ing Relay,

#1097-211

(Same as CODE 78 with

DIP switch adjusted for

a 45 second blower off

delay)

84 J/C Intermittent

234012-N/A Kit P/N 257473

Pilot Ignition

Control with

lockout and

vent damper

connections,

G770NHC-1

85 UTC #1097-211,

(2) 195573

Direct Spark Ignition with Cooling

Relay

78 UTC Direct Spark

195573

Ignition with

Cooling Relay,

UTC #1097-

211

79 UTC Direct Spark

195265

Ignition, UTC

#1097-210

80 UTC Direct Spark

204955

Ignition Board,

UTC #1016-

426

Form P-VALVES, P/N 263995R4, Page 8

86 Varidigm VB4-

H500 Combustion

Board (RDCB/

RDDB H500)

223554-N/A Contact your

Reznor

®

Representative

or the factory

for replacement

information.

87 Varidigm VB4-

H600 Combustion

Board (RDCB/

RDDB H600)

223555-N/A Contact your

Reznor

®

Representative

or the factory

for replacement

information.

1

J/C = Johnson Controls; M/H = Honeywell; RAM = RAM

Electronics

2

Functional replacement may require eld-furnished wiring.

Page 9

Safety Pilot or Ignition System Originally Supplied, Identied by Serial No. Code (cont'd) -- See

Serial No. Decoding on pages 3-4.

Code Description P/N(s) Replaced by

88 Varidigm

VB4-H700

Combustion

Board (RDCB/

RDDB H700)

223556-N/A Contact your

Reznor

®

Representative

or the factory

for replacement

information.

89 Varidigm

VB4-H800

Combustion

Board (RDCB/

RDDB H800)

222678 - N/A Contact your

Reznor

®

Representative

or the factory

for replacement

information.

90 UTC #1097-

211 Direct

Spark Ignition

and Varidigm

VB4-H500

Combustion

Board (RDCB/

RDDB H10C)

91 UTC #1097-

211 Direct

Spark Ignition

and Varidigm

VB4-H600

Combustion

Board (RDCB/

RDDB H12C)

92 UTC #1097-

211 Direct

Spark Ignition

and Varidigm

VB4-H700

Combustion

Board (RDCB/

RDDB H14C)

93 UTC #1097-211

Direct Spark

Ignition and

Varidigm VB4

Combustion

Board (RDCB/

RDDB H16C)

195573

223554 - N/A

195573

223555 - N/A

195573

223556 - N/A

195573

222678 - N/A

P/N 223554

is no longer

available. Contact

your Reznor

Representative

or the factory

for replacement

information.

P/N 223555

is no longer

available. Contact

your Reznor

Representative

or the factory

for replacement

information.

P/N 223556

is no longer

available. Contact

your Reznor

Representative

or the factory

for replacement

information.

P/N 222678

is no longer

available. Contact

your Reznor

Representative

or the factory

for replacement

information.

®

®

®

®

Code Description P/N Replacement

94 UTC #1003-

257009

638-A

Recyclying

Ignition

Controller

95 UTC #1003-

257010

514 Ignition

Controller

with Lockout

96 Varidigm

VB12005-RZNR-C

257246 NOTE: If CODE 96

board is replaced,

the ID plug must

either be replaced

also or removed and

installed on the new

ID Plug

board. See page 10

for a list of ID plugs.

97 Varidigm

VB12005-RZNR-AB

258319 NOTE: If CODE 97

board is replaced,

the ID plug must

either be replaced

also or removed and

installed on the new

ID Plug

board. See page 10

for a list of ID plugs.

98 Varidigm

VB1200-2RZNR-PVA

260252 NOTE: If CODE 98

board is replaced,

the ID plug must

either be replaced

also or removed and

installed on the new

ID Plug

board. See page 10

for a list of ID plugs.

99 Varidigm

VB1200-5RZNR-SHH

260917 NOTE: If CODE 99

board is replaced,

the ID plug must

either be replaced

also or removed and

installed on the new

ID Plug

board. See page 10

for a list of ID plugs.

A1 Direct Spark

269867

Ignition,

UTC #1097218, 7 Sec

TFI

Form P-VALVES, P/N 263995R4, Page 9

Page 10

Ignition Systems

Miscellaneous Information

ID Plugs for Varidigm

Deep Modulation

Boards, Ignition CODES

96 and 97, on page 9

ID Plugs for

Varidigm Deep

Modulation

Board,

Ignition CODE

98, on page 9

ID Plug

P/N

258081 PREEVA 175NG

258082 PREEVA 175LP Propane

258083 PREEVA 200NG

258084 PREEVA 200LP Propane

258085 PREEVA 225NG

258086 PREEVA 225LP Propane

258087 PREEVA 250NG

258088 PREEVA 250LP Propane

258089 PREEVA 300NG

258090 PREEVA 300LP Propane

258091 PREEVA 350NG

258092 PREEVA 350LP Propane

258093 PREEVA 400NG

258094 PREEVA 400LP Propane

ID Plug

P/N

258113 13 MAPS A100NG

258114 14 MAPS A100LP Propane

258115 15 MAPS A150NG

258116 16 MAPS A150LP Propane

258117 17 MAPS A200NG

258118 18 MAPS A200LP Propane

258129 29 MAPS B250NG

258130 30 MAPS B250LP Propane

258131 31 MAPS B300NG

258132 32 MAPS B300LP Propane

258133 33 MAPS C400NG

258134 34 MAPS C500NG 500 Natural

258135 35 MAPS C600NG 600 Natural

258140 40 MAPS C700NG 700 Natural

258141 41 MAPS D500NG

258142 42 MAPS D600NG 600 & 1200 Natural

258143 43 MAPS D700NG 700 & 1400 Natural

258144 44 MAPS D800NG 800 & 1600 Natural

ID Plug Label

ID Plug

No.

Applies to Model RDH with

ID Plug Label

Ignition CODE 98

Heat Section Gas

175

200

225

250

300

350

400

Natural

Natural

Natural

Natural

Natural

Natural

Natural

Model Heat Section Ignition CODE Gas

Models RDCB,

RDDB, RDCC, &

RDDC

Models RDCB,

RDDB, RDCC, &

RDDC

Models RDCB,

RDDB, RDCC, &

RDDC

Models RDCB &

RDDB

ID Plugs for Varidigm Deep

Modulation Board, Ignition CODE 99,

on page 9

ID Plug

P/N

258101 SHH 130NG

258102 SHH 130LP Propane

258103 SHH 180NG

258104 SHH 180LP Propane

258105 SHH 260NG

258106 SHH 260LP Propane

258107 SHH 350NG

258108 SHH 350LP Propane

Applies to

100

150

200

250

300

400

500 &1000 Natural

ID Plug

Label

97

96

Applies to Model RHH

and Model SHH with

Ignition CODE 99

Heat Section Gas

130

180

260

350

Natural

Natural

Natural

Natural

Natural

Natural

Natural

Natural

Natural

Natural

Ignition Conversion

Kits to Convert from

Match-Lit Pilot to Spark

Pilot for Models F and

B

Ignition Conversion

Kits to Convert Pilot

Systems to Updated

Spark Pilot, Hot

Surface, or Direct Spark

Ignition System for

Models listed

Form P-VALVES, P/N 263995R4, Page 10

Model F or B Gas Kit Description Kit P/N Instructions

F/B 25-165

F/B 200-250 100526

F 300-400, B 300 100527

B 400 102348

F/B 25-165 Spark-ignited, intermittent

Natural

F/B 200-250 100529

F 300-400, B 300 100530

B 400 102349

F/B 25-200

F 250-400, B 250-300 100532

Propane

B 400 102350

Ignition System being

Replaced

Replaces Pilot Codes

62, 63, 65, 66, 84

Replaces Pilot Code 71

or 75

Spark - ame rectication or ultraviolet

Model CAUA with Pilot

Code 76 or 77

Model TR with Spark

Pilot Code 65 or 66

Gas

Natural

or

Propane

257473 (Ignition Controller 257010)

257472 (Ignition Controller 257009)

257531 (Ignition Controller 195265)

258251 (Ignition Controller 195573)

Spark-ignited, intermittent

safety pilot without lockout

(UTEC Model 1003-638A,

P/N 257009)

safety pilot with lockout

(UTEC Model 1003-514, P/N

2570010)

(NOTE: Controller includes

terminal for connecting vent

damper.)

Conversion Kit P/N (Type of Igni-

tion Controller in the Kit)

146268, 146318, 146319

(HSI P/N 204376)

216970 (DSI P/N 204955)

CP-RDF-HSI 146321

CP-CAUA-

IGN CNTRL

CP-TR-IGN

100525

100528

100531

Instructions

(in the Kit)

Form P/N

CP-IGN

CNTRL

CP-DSI

CNTRL

CNV

134704

265905 FT, SFT, TRP

178435

215975

Form

CP-F/B IGN,

P/N 100550

Applies to Models

Indirect-red models

with Pilot Code 62,

63, 65, 66, or 84

RDF with Pilot Code

58, 59, 60, or 61

CAUA with Pilot Code

76 or 77

TR/TR-H with Pilot

code 65 or 66

Page 11

Type of Valve Originally Supplied -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages 19-22. N/A = Not Available. See illustrations on pages 23-27.

Serial No.

Code

1

2

3

4

5

6

7

8

9

01

02

03

04

05

06

07

08

09

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Original Valve on Heater

5

GF21G18 or 91F21G18 J/C 3/8 N/A

5

GA4G18 or 91A4G18 J/C 1/2 (sm) N/A

5

GD4G18 or 91D4G18 J/C 1/2 (lg) N/A

5

GS5G18 J/C 3/4 N/A

5

2509-206 W/R 3/4 N/A

5

2509-207 W/R 3/4 N/A

5

2509-208 W/R 1 N/A

5

V-80 M/H 1/2 N/A

5

V-80 M/H 3/4 N/A

5

NC1013-2T M/N 1/2 N/A

5

NC1014-2T M/N 3/4 N/A

5

NC1030-2E or NC1058-2T M/N 1 N/A

5

VA84A1004 M/H 1-1/4 N/A

5

VA84A1012 M/H 1-1/2 N/A

6

K3J41A102, 2 stage G/C 1/2 N/A X2

6

K3J51A102, 2 stage G/C 3/4 N/A X3

6

K3J61A102 G/C 1 N/A

5

VA835 M/H 1/2 N/A

5

VA835 M/H 3/4 N/A

5

VA84 M/H 1 N/A

5

91S5G18 J/C 3/4 N/A

5

2509-204 W/R 1/2 N/A

5

K3A G/C 1-1/4 N/A

5

V81A1060 M/H 1/2(sm) N/A

5

V81A1078 M/H 3/4(sm) N/A

5

91A4G3 J/C 1/2(sm) N/A

5

91D4G3 or H91EG-3 J/C 1/2(lg) N/A

7

B57 (Natural), single stage G/C 1/2 N/A K6

8

B57 (Propane), single stage G/C 1/2 N/A K9

5

V81D262 M/H 1 N/A

5

3601-228 W/R 1/2 N/A

5

3606-228 (Propane) W/R 1/2 N/A

5

NC1054-2E M/N 3/4 N/A

5

1200AER R 3/8x1/2 N/A

9

92D2204-A-1, 100% shutoff, 115V J/C 1/2 N/A

9

CS212-A2, 100% shutoff, 115V J/C 1/2 N/A

9

CS222A-1, 100% shutoff, 115V J/C 1/2 N/A

Valve

1

Mfr

Pipe Size P/N

30 Direct Spark, 115V, V4225B100, Propane M/H 1/2 N/A

31 Direct Spark, 115V, V4224A1077, Natural M/H 1/2 N/A

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56 V48A2144 Diaphragm Type M/H 1 N/A

57

7

B59R02-Natural or B59R109, single stage G/C 1/2 N/A K6

7

B59R06-Natural or B59R111, single stage G/C 3/4 N/A K7

8

B59A01-Propane or B59A15, single stage G/C 1/2 N/A K9

8

B59A05-Propane or B59A110, single stage G/C 1/2 N/A K9

5

V8257-A1244 M/H 1/2 N/A

5

V829A-1001 M/H 1/2 N/A

5

V81A-1359 M/H 3/4 N/A

5

V88A-1345 M/H 1-1/2 N/A

5

V81A-1086 M/H 1 N/A

5

V8292A-1001 M/H 3/4 N/A

5

V8146A102 M/H 3/4 N/A

5

V8146B-1023 M/H 3/4 N/A

5

V88A13372 M/H 1 N/A

13

NC1014-1E M/N 3/4 N/A

13

92D4004A1 J/C 1/2 N/A

5

V8202A M/H 3/4 N/A

5

25A15-226 with plug for electric ignition W/R 3/8 N/A

5

25046-404 W/R 1/2 N/A

5

92D4004G3 J/C 1/2 N/A

5

K3A G/C 1/2 N/A

5

K3A G/C 3/4 N/A

5

K3A G/C 1 N/A

5

25G10-204 W/R 1/2 N/A

5

K40AC251 G/C 3/4 N/A

Form P-VALVES, P/N 263995R4, Page 11

2

Functional Replacement

Code P/N

10

10

10

10

10

10

5

10

10

10

10

5

5

5

3

10

10

5

10

10

3

10

10

10

10

12

12

5

10

10

5

3

3

3

3

3

3

12

12

12

12

10

10

5

3

5

10

5

5

5

3

3

3

3

3

3

5

5

5

10

3

3

88242

88242

88242

88242

88242

88242

112922

88242

88242

88242

88242

112922

112922

112922

11

177396

11

177397

88242

88242

112922

88242

88242

88242

88242

88242

88242

96300

96303

112922

88242

88242

112922

96300

96301

96303

96303

88242

88242

112922

112922

88242

112922

112922

112922

112922

112922

112922

88242

(continued)

Page 12

Type of Valve Originally Supplied (cont'd) -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages 19-22. N/A = Not Available. See illustrations on pages 23-27.

Serial No.

Code

58

59

60

61

62 963006-G J/C 3/4 N/A

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94 8215B30 J/C 3/4 N/A

95

96

97

98

99

A1

A2

A3

A4

A5

A6

A7

A8

A9

B1

B2

B3

Original Valve on Heater

14

G52BAG-12 (Natural) J/C 3/4 N/A

14

G52DAG-13 (Natural) 2-stage (lg) J/C 1/2 N/A

5

K40AC361 G/C 1 N/A

14

96AGT-9 J/C 1/2 N/A

14

G52BLG-12 (Propane) J/C 3/4 N/A

14

G52AAG-12 (Natural) J/C 1 N/A

15

G52AAY-1; DFT 250,260,290,325; Natural J/C 1 N/A

5

2509-207 W/R 3/4 N/A

5

2509-208 W/R 1 N/A

5

2509-206 (Small) W/R 3/4 N/A

7

B590RA44 - Natural G/C 3/4 N/A K7

18

B590AA45 - Propane G/C 3/4 N/A

19

B59RJ155 - Natural G/C 1/2 N/A

19

B59RJ157 - Propane G/C 3/4 N/A

18

B59AJ156 - Propane G/C 1/2 N/A

18

B59RJ158 - Propane G/C 3/4 N/A

5

H91DG-3 Natural and Propane J/C 1/2 N/A

5

H91DG-3 Natural; H91DG-2 Propane J/C 1/2 N/A

5

NC1014-2T Natural M/N 3/4 N/A

H91DG-2 Propane M/N 1/2 N/A

5

NC1014-2T Natural M/N 3/4 N/A

H91EG-3 Propane M/N 1/2 N/A

5

NC1054-2T Natural M/N 3/4 N/A

H91EG-2 Propane M/N 1/2 N/A

5

NC1054-2T M/N 3/4 N/A

H91LG-1 M/N 3/4 N/A

5

G95AGL-1 Natural - Model RHD J/C 1/2 N/A

5

G95GL-1 W/Kit Y71AA-4 Propane - Model RHD J/C 1/2 N/A

16

K72R13 Natural - side entrance 90° outlet valve, single stage G/C 1/2 39298-N/A K6

17

K72A14 Propane - side entrance 90° outlet valve, single stage G/C 1/2 39299-N/A G9 82396

18

G50AAY-1 Natural, 1-stage - DFT250 (includes built-in regulator) J/C 1 N/A

6

G52BLY-1, 2-stage, Propane, DFT 250, 260, 290, 325 J/C 3/4 N/A

5

G50BLY-1, 1-stage, Propane, DFT250 J/C 3/4 N/A

13

1014-1E Natural, High Stage, DFT 300,400 M/N 3/4 N/A

13

1013-1E Natural, Low Stage, DFT 300,400 M/N 1/2 N/A

13

1054-1E Natural, High Stage, DFT 500 M/N 3/4 N/A

13

1013-1E Natural, Low Stage, DFT 500 M/N 1/2 N/A

13

V48H-100-1, Natural, High Stage, DFT 600 M/N 3/4 N/A

13

1013-1E Natural, Low Stage, DFT 600 M/N 1/2 N/A

14

G52BAG-6, 2-stage, Natural, DFT 220 J/C 3/4 N/A

14

G52AAG-6, 2-stage, Natural, DFT 285,340,395 J/C 1 N/A

23

G52BLG-10, 2-stage, Propane, DFT 285,340,395 J/C 3/4 N/A

5

H91LG-1 91D4G-3 J/C 3/4 47537-N/A

22

B59SJK171 Natural, 2 stage G/C 1/2 N/A X2

22

B59BJK172 Propane, 2 stage G/C 1/2 N/A X1

22

B59SJK163 Natural, 2 stage G/C 3/4 N/A X3

22

B59BJK164 Propane, 2 stage G/C 3/4 N/A X1

22

B590SAK50 Natural, 2 stage G/C 3/4 N/A X3

22

B590BAK51 Propane, 2 stage G/C 3/4 N/A X1

13

SNC1054-1 M/N 3/4 N/A

7

7000ERHC 455-501-501 Natural, single stage R 3/4x1 N/A K7

21

242NS 242-111121-1101 Natural, single stage E 1/2 47380-N/A Q2

21

242NS 242-131121-1101 Natural, single stage E 3/4 47381-N/A 9A 221525

21

242NSU 242-111120-2101 Propane, single stage E 1/2 N/A Q4

21

242NSU 242-131120-2101 Propane, single stage E 3/4 N/A Q4

17

7000GVER-HC Natural, single stage R 3/4x1 N/A 9A 221525

5

K3A441 G/C 1/2 N/A

5

K3A451 G/C 3/4 N/A

5

K3A461 G/C 1 N/A

Valve

Mfr

Pipe

1

Size

P/N

B4 G60QBG-7 with Controller - Natural J/C 1/2 50448-N/A

B5 H91MG Natural J/C 1 47538-N/A

B6

B7

38, 7

7000BER Natural 300-501-502, single stage R 1/2 48577-N/A K6

7

7000BER Natural 302-501-502A, single stage R 3/4 N/A K7

Form P-VALVES, P/N 263995R4, Page 12

2

Functional Replacement

Code P/N

4

4

3

4

3

4

4

3

5

5

10

12

4

4

4

4

4

10

10

5

10

5

10

5

10

5

10

3

3

12

3

3

3

3

3

3

3

3

3

3

3

3

3

10

24

24

24

24

24

24

3

12

25

25

25

10

5

5

3

5

12

12

112922

112922

88242

96301

88242

88242

112922

88242

112922

88242

112922

88242

112922

88242

96300

88242

177396

177395

177397

177395

177397

177395

96301

121598

121600

121600

88242

112922

112922

112922

96300

96301

36

36

Page 13

Type of Valve Originally Supplied (cont'd) -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages19-22. N/A = Not Available. See illustrations on pages 23-27.

Serial No.

Code

B8

B9

C1

C2

C3

C4

C5

C6

C7

C8

C9

D1

D2

D3

D4

D5

D6

D7

D8

D9

E1

E2

E3

E4

E5

E6

E7

E8

E9

F1

F2

F3

Original Valve on Heater

8

7000BE Propane 300-505-501, single stage R 1/2 N/A K9

8

7000BE Propane 302-505-501, single stage R 3/4 N/A K9

17

7000BGVER Natural 312-501-503 R 1/2 N/A

17

7000BGVER Natural 307-501-503 R 3/4 N/A

28

7000BGVE Propane 312-505-526 R 1/2 N/A

28

7000BGVE Propane 307-505-501 R 3/4 N/A

38 7

V800A1039 Natural, single stage M/H 3/4 51299-N/A K7

8

G50DAG-1 Natural, single stage

22

V852A1097 Natural, 2-Stage M/H 1/2 51357-N/A X2

22

V852A1071 Natural, 2-Stage M/H 3/4 51358-N/A X3

22

V852A1105 Propane, 2-Stage M/H 1/2 51359-N/A X1

22

V852A1089 Propane, 2-Stage M/H 3/4 51360-N/A X1

26

G60CPG-1 Propane w/separate lockout device J/C 1/2 N/A

Y79 Lockout Device only, Y70BBA J/C 46869-N/A

26

G60QBG-7 Natural J/C 1/2 N/A

Y79 Lockout Device only, Y70BBA J/C 46869-N/A

27

V850A1133 Natural, 2-Stage M/H 3/4 52886-N/A P8

27

V850A117 Natural, 2-Stage M/H 3/4 N/A

14

G52AAG-16 DFT units J/C 1 N/A

38, 7

242 N-1 (Natural) 242-131131-1181, single stage E 3/4 59341-N/A K7 12 96301

28

H91EG J/C 1/2 N/A

31

H91EG J/C 1/2 N/A

30

B79B77RK34 Natural, 2-Stage G/C 1/2 60609-N/A X2

30

B79B77WK35 Natural, 2-Stage G/C 3/4 60610-N/A X3 12 177397

30

B79B77WK36, Propane, 2-Stage G/C 1/2 60611-N/A X1

21

SX242 242-131121-1214 Natural, single stage E 3/4 61098-N/A 9A 221525

21

SX242LS 242-111122-1215 Propane, single stg (also could

be used on natural gas units equipped with Maxitrol controls)

32

V4036B1019, 115V M/H 1/2 N/A

32

V4036B1084, 240V M/H 3/4 N/A

38, 7

RS7000BER 300-502-719 Propane, single stg (also could

be used on natural gas units equipped with Maxitrol controls)

15

K72S32 Side Entrance Propane, single stage G/C 1/2 64420-N/A G9 82396

30

V850A1166 2-Stage, Natural M/H 1/2 62966-N/A P8 115351

30

V850A1158 2-Stage, Propane M/H 1/2 62967-N/A P9 115352

VR852A1068 2-Stage, Propane M/H 1/2 62946-N/A X1

F4 G60QRH-1

F5

F6

F7

F8

F9 and G1

G2

G3

G4

G5

G6

G7

G8

G9

H1

H2

H3

H4

H5

H6

H7

SX242LSH 242-131122-1248 Propane, single stg (also could

be used on natural gas units equipped with Maxitrol controls)

23

36D05-201 Natural W/R 1/2 62972-NA

23

36D05-401 Natural W/R 3/4 62973-N/A

23

36D05-202 Propane W/R 1/2 62974-NA

29

G65BC Natural - Code F9

29

G65DCM-1 Propane - Code G1

15

7000BER 379-501-502 Side Entrance Natural R 1/2 N/A K6

16

7000BE 379-501-501 Side Entrance Propane R 1/2 N/A G9 82396

7

7000BER 403-501-729 Nat, single stage (no ECO cnntr) R 1/2 82196-N/A K6

7

7000BER 403-502-719 Propane, single stg (also could be

used on natural gas units equipped with Maxitrol system)

7

7000BER 408-501-502 Nat, single stg (with ECO cnntr) R 1/2 82198-N/A K6

7

7000BER 408-502-719 Propane, Side Entrance, single

stage (with ECO connector)

37, 7

36C03270 Natural, Side Entrance, single stg, w/ECO W/R 1/2 82395-N/A K6

37, 7

36C03-433 Natural & Propane, Side Entrance, single

stage, w/ECO

38, 7

V800A7028 Natural, single stage, w/ECO terminal M/H 3/4 82398-N/A K7

38, 7

36C03-258 Natural, single stage, w/ECO terminal W/R 1/2 82397-N/A K6

38, 7

700BER 403-501-832 Nat, single stg, w/ECO terminal R 1/2 82624-N/A K6

7

700BER 403-502-835 Pro, single stg, w/ECO terminal R 1/2 82669-N/A K9

30

36D13-208 Natural, 2-Stage W/R 1/2 87430 X2

30

36D13-405 Natural, 2-Stage W/R 3/4 87432 X3

30

36D13-209 Propane, 2-Stage W/R 1/2 87431 X1

Valve

Mfr

Pipe

Size

P/N

1

J/C 3/4 N/A

Replacement for Standing Pilot K7 96301

Replacement for Spark Pilot 9A 221525

E 1/2 61099-N/A Q4

R 1/2 62969-N/A K9

Propane J/C 1/2 56826-N/A

E 3/4 63282-N/A 1B 221526

Valve Codes F9 and G1 indicate G65

ignition (Codes 50-56) and gas valve.

R 1/2 82197-N/A 221634

R 1/2 82199-N/A G9 82396

W/R 1/2 82396

Form P-VALVES, P/N 263995R4, Page 13

2

Functional Replacement

Code P/N

12

12

3

3

3

3

12

12

12, 24

12, 24

12, 24

12, 24

3

3

20

4

3

3

3

12

12

25

3

3

12

12

3

3

3

3

3

3

12

12

12

12

12

12

12

12

12, 39

12, 39

12, 39

96303

96303

96301

177396

177397

177395

177395

115351

177396

177395

121600

96303

177395

96300

96300

96300

96300

96301

96300

96300

96303

177396

177397

177395

36

(continued)

Page 14

Type of Valve Originally Supplied (cont'd) -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages 19-22. N/A = Not Available. See illustrations on pages 23-27.

Serial No.

Code

Original Valve on Heater

Valve

1

Mfr

Pipe

Size

P/N

H8 36D05-403 Propane W/R 1/2x3/4 88243-N/A

H9 VR8440C3031 Propane, single stage M/H 1/2x3/4 93386-N/A Q4 121600

J1 (Two

Valves)

J2

J3 (Two

Valves)

J4 (Three

Valves)

J5

J6

J7

J8

J9

K1

K2

5

(2) K3A562S, T, or U, or 2LB27BB6127, 115V

V5055A1004 Fluid Power, 115V M/H

V4055A1007 Actuator M/H 86993

(2) V5055A1004 Fluid Power, 115V M/H

(2) V4055A1007 Actuator M/H 86993 (2 required)

V5055A1004 Fluid Power, 115V M/H

V4055A1007 Actuator M/H 86993

5

(2) K3A562S, T, or U, or 2LB27BB6127, 115V

17

DER7100 71P11A-000 Natural, single stage R 1/2 89461-N/A M4 96307

17

DER7100 71P11C-013 Propane, single stage R 1/2 89462-N/A M7 96310

17

VR8440A2092B Natural, single stage M/H 1/2 89370-N/A Q2 121598

17

36C68-441 Natural, single stage W/R 3/4 89397-N/A 9A 221525

17

VR8440A2100B Propane, single stage M/H 1/2 89371-N/A Q4 121600

17

36C68-442 Pro, single stage (also could be used on

natural gas units equipped with Maxitrol controls)

V50551012 Fluid Power, 115V M/H

V4055A1007 Actuator M/H 86993

G/C, ASCO,

or Skinner

1 86966 (2 required)

1

1

86992

86992 (2 required)

86992

G/C, ASCO,

or Skinner

1

86966 (2 required)

W/R 3/4 89398-N/A 1B 221526

1-1/4

89356

K3 FT8215C20, 115V (for Bell Telephone) ASCO 1/2 N/A

K4

V50551038 Fluid Power, 115V M/H

V4055A1007 Actuator M/H 86993

2

91079

K5 V8200M7003, Natural, single stage M/H 1/2 96299 9B 208920

K6 36C03-211 Natural, single stage W/R 1/2 96300

K7 V800M7009 Natural, single stage M/H 3/4 96301

K8 V8200M7011 Propane, single stage M/H 1/2 96302 1C 209412

K9 V800M7017 Propane, single stage M/H 3/4x3/4 96303

M1 V850E7003 Natural, 2-stage M/H 1/2 96304-N/A P8

M2 V850E7029 Natural, 2-stage M/H 3/4 96305-N/A P8

M3 V850E7011 Propane, 2-stage M/H 1/2x3/4 96306-N/A P9

M4 VR8204M1000 Natural, single stage M/H 1/2 96307

M5 VR8440A2159 Natural, single stage M/H 1/2 96308-N/A Q3 121599

M6 36C68-452 Natural, single stage W/R 3/4 96309-N/A Kit P/N 222037

M7 VR8204M1018 Propane, single stage M/H 1/2 96310

M8

36C68-325 Pro, single stage (also could be used on

natural gas units equipped with Maxitrol controls)

W/R 1/2x3/4 96311-NA Kit P/N 221634

M9 36D13-304 Propane, 2-stage W/R 1/2x3/4 96312 X4

N1 36D19-402 Natural, 50-90°F W/R 3/4x3/4 100321-N/A

N2 36D19-403 Natural 90-130°F W/R 3/4x3/4 100322-N/A

N3 36D19-405 Propane, 50-90°F W/R 3/4x3/4 100323-N/A

N4 36D19-406 Propane 90-130°F W/R 3/4x3/4 100324-N/A

N5 (Two

Valves)

N6 (Two

Valves)

N7 (Two

Valves)

N8 (Two

Valves)

N9 (Two

Valves)

O1&P1

33

(Two

Valves)

O2&P2

33

(Two

Valves)

Mechanical modulation 50-90°F, Code N3, with bypass, Code M7, for Sizes 75-200

36D19-405 Propane W/R 3/4x3/4 100323(N3)-N/A

VR8204M1018 Propane, single stage M/H 1/2 96310(M7)

Mechanical modulation 50-90°F, Code N3, with bypass, Code M8, for Sizes 225-400

36D19-405 Propane W/R 3/4x3/4 100323(N3)-N/A

36C68-325 Propane, single stage W. R 1/2x3/4 96311(M8)-N/A Kit P/N 221634

AG13 Mechanical modulation 50-90°F, Code N1, with bypass, Code M4, for Sizes 75-150

36D19-402 Natural W/R 3/4x3/4 1003213(N1)-N/A

VR8204M1000 Natural, single stage M/H 1/2 96307(M4)

AG13 Mechanical modulation 50-90°F, Code N1, with bypass, Code M5, for Sizes 175-250

36D19-402 Natural W/R 3/4x3/4 1003213(N1)-N/A

VR8440A2159 Natural, single stage M/H 1/2 96308-N/A Q3 121599

AG13 Mechanical modulation 50-90°F, Code N1, w/bypass, Code M6, Sizes 300-400 and ADF/ADFH Nat & LP

36D19-402 Natural W/R 3/4x3/4 100321(N1)-N/A

36C68-452 Natural, single stage W/R 3/4 96309-N/A Kit P/N 222037

AG14 Mechanical modulation 90-130°F, Code N2, with bypass, Code M4, for Sizes 75-150

36D19-403 Natural W/R 3/4x3/4 100322-N/A

VR8204M1000 Natural, single stage M/H 1/2 96307 (M4)

AG14 Mechanical modulation 90-130°F, Code N2, with bypass, Code M5, for Sizes 175-250

36D19-403 Natural W/R 3/4x3/4 100322-N/A

VR8440A2159 Natural, single stage M/H 1/2 96308-N/A Q3 125199

Form P-VALVES, P/N 263995R4, Page 14

2

Functional Replacement

Code P/N

3

36

W1 (alternate for J2; both

Codes are approved)

W1 (alternate for J2; both

Codes are approved)

36

W3 (alternate for K2; both

Codes are approved)

W4 (alternate for K4; both

Codes are approved)

40

40

40

12, 39

34

3

34

3

34

34

34

34

34

3

3

115351

115351

115352

177398

Page 15

Type of Valve Originally Supplied (cont'd) -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages 19-22. N/A = Not Available. See illustrations on pages 23-27.

Serial No.

Code

O3&P3

33

(Two

Valves)

O4&P4

33

(Two

Valves)

O5&P5

33

(Two

Valves)

P6 (Two

Valves)

P7 (Two

Valves)

Original Valve on Heater

Valve

1

Mfr

AG14 Mechanical modulation 90-130°F, Code N2, w/bypass, Code M6, Sizes 300-400 and ADF/ADFH Nat & LP

36D19-403 Natural W/R 3/4x3/4 100322-N/A

36C68-452 Natural, single stage W/R 3/4 96309(M6)-N/A Kit P/N 222037

AG14 Mechanical modulation 90-130°F, Code N4, with bypass, Code M7, for Sizes 75-200

36D19-406 Propane W/R 3/4x3/4 100324-N/A

VR8204M1018 Propane, single stage M/H 1/2 96310(M7)

AG14 Mechanical modulation 90-130°F, Code N4, with bypass, Code M8, for Sizes 225-400

36D19-406 Propane W/R 3/4x3/4 100324-N/A

36C68-325 Propane, single stage W/R 1/2x3/4 96311(M8)-N/A Kit P/N 221634

Mechanical modulation 50-90°F, Code N1, with bypass, Code Q3, for Sizes 175-250

36D19-402 Natural W/R 3/4x3/4 100321(N1)-N/A

VR8304M2816 Natural, single stage M/H 1/2 121599(Q3)

Mechanical modulation 90-130°F, Code N2, with bypass, Code Q3, for Sizes 175-250

36D19-403 Natural W/R 3/4x3/4 100322-N/A

VR8304M2816 Natural, single stage M/H 1/2 121599(Q3)

Pipe

Size

P/N

P8 36C40-408 2-Stage, Natural (std pilot) W/R 3/4 115351

P9 36C41-408 2-Stage, Propane (std pilot) W/R 3/4 115352

Q2 VR8304M2808 Natural, single stage M/H 1/2 121598

Q3 VR8304M2816 Natural, single stage M/H 1/2 121599

Q4 VR8304H3802 Propane, single stage M/H 1/2x3/4 121600

Q5 (Two

Valves)

Q6 (Two

Valves)

Q7 (Two

Valves)

Q8 (Two

Valves)

Q9 (Two

Valves)

R1 (Two

Valves)

R2

R3

R4

Mechanical modulation 50-90°F, Code N1, with bypass, Code J8, for Sizes 300-400

36D19-402 Natural W/R 3/4x3/4 100321(N1)-N/A

36C68-441 Natural, single stage W/R 3/4 89397(J8)-N/A 9A 221525

Mechanical modulation 90-130°F, Code N2, with bypass, Code J8, for Sizes 300-400

36D19-403 Natural W/R 3/4x3/4 100322-N/A

36C68-441 Natural, single stage W/R 3/4 89397(J8)-N/A 9A 221526

Mechanical modulation 50-90°F, Code N1, with bypass, Code Q2, for Sizes 75-250

36D19-402 Natural W/R 3/4x3/4 100321(N1)-N/A

VR8304M2808 Natural, single stage M/H 1/2 121598 (Q2)

Mechanical modulation 90-130oF, Code N2, with bypass, Code Q2, for Sizes 75-250

36D19-403 Natural W/R 3/4x3/4 100322-N/A

VR8304M2808 Natural, single stage M/H 1/2 121598 (Q2)

Mechanical modulation 50-90oF, Code N3, with bypass, Code Q4, for Sizes 75-200

36D19-405 Propane W/R 3/4x3/4 100323(N3)-N/A

VR8304H3802 Propane, single stage M/H 1/2x3/4 121600(Q4)

Mechanical modulation 90-130oF, Code N4, with bypass, Code Q4, for Sizes 225-400

36D19-406 Propane W/R 3/4x3/4 100324-N/A

VR8304H3802 Propane, single stage M/H 1/2x3/4 121600(Q4)

5

K3A651SF Natural & Propane G/C 3/4 123604

5

K3A561-U Natural & Propane ASCO 1 123603

5

K3A671SF Natural & Propane G/C 1-1/4 123605

R5 V4600A1023 Nat or V4600A1031 Nat/Pro M/H 1/2 113766

R6 V4400A10093 M/H 1/2 113767

35

R7 3B0-341-A04 or 3F1241A04 Natural, 50-100°F, Mod R 3/4 131453

35

R8 5N7-341-A04 or 5R9241A04 Natural, 50-100°F, Mod R 1 131455

35

R9 3B0-342-A05 or 3F1242A05 Propane, 50-100°F, Mod R 3/4 131454

35

S1 5N7-342-A05 or 5R9242A05 Propane, 50-100°F, Mod R 1 131456

S2 (Two

Valves)

S3 (Two

Valves)

S4 (Two

Valves)

S5 (Two

Valves)

3B0-341-A04 or 3F1241A04 Natural, 50-100°F, Mod R 3/4 131453(R7)

36C68-325, Propane, single stage W/R 1/2X3/4 96311(M8)-N/A Kit P/N 221634

5N7-341-A04 or 5R9241A04 Natural, 50-100°F, Mod R 1 131455(R8)

36C68-442, Propane, single stage W/R 3/4 89398(K1)-N/A 1B 221526

3B0-342-A05 or 3F1242A05 Propane, 50-100°F, Mod R 3/4 131454(R9)

36C68-325, Propane, single stage W/R 1/2x3/4 96311(M8)-N/A Kit P/N 221634

5N7-342-A05 or 5R9242A05 Propane, 50-100°F, Mod R 1 131456(S1)

36C68-442 Propane, single stage W/R 3/4 89398(K1)-N/A 1B 221526

Mechanical modulation 50-100°F, with bypass, Code Q2, for Sizes 75-225

S6 (Three

Valves)

3B0-341-A04 or 3F1241A04 Natural, 50-100°F R 3/4 131453(R7)

36C68-325, Pro, single stage W/R 1/2x3/4 96311(M8)-N/A Kit P/N 221634

VR8304M2808 Natural, single stage M/H 1/2 121598(Q2)

Mechanical modulation 50-100°F, with bypass, Code J8, for Sizes 250-350

S7 (Three

Valves)

3B0-341-A04 or 3F1241A04 Natural, 50-100°F R 3/4 131453(R7)

36C68-442, Pro, single stage W/R 3/4 89398(K1)-N/A 1B 221526

36C68-441 Natural, single stage W/R 3/4 89397(J8)-N/A 9A 221525

Form P-VALVES, P/N 263995R4, Page 15

2

Functional Replacement

Code P/N

34

3

3

34

3

34

3

34

3

34

3

(continued)

Page 16

Type of Valve Originally Supplied (cont'd) -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages 19-22. N/A = Not Available. See illustrations on pages 23-27.

Serial No.

Code

S8 (Three

Valves)

S9 (Three

Valves)

T1 (Three

Valves)

T2 VR8304M4911 Natural M/H 1/2 134358

T3 VR8304M2824 Natural, single stage M/H 1/2 136193

T4 VR4601AA1010 Nat or VR4601AA1044B Nat/Pro M/H 1/2 134778 - N/A

T5 VR4601AB1000 Nat or VR4601AB1026 Nat/Pro M/H 3/4 134779 - N/A

T6 Maclaren GM7542-3043 Natural J/C 1/2 142664

T7 Modify Valve P/N 113766 M/H 1/2 144276

T8 K3A661-T G/C 1 146472

T9 7222DER Natural, single stage R 1/2 147133 - N/A 7E 260604

U1 7222DERLP Propane, single stage R 1/2 147134 - N/A 8E 260606

U2 VR8205M1130 Natural, single stage M/H 1/2 147830 - N/A 7E 260604

U3 VR8205M1148 Propane, single stage M/H 1/2 147560 - N/A 8E 260606

U4 L821480 Natural Asco 2 163136

U5 L821440 Natural Asco 3 163137

U6 VR8305M4009, Natural, single stage M/H 3/4 150839

U7 VR8305M4017, Propane, single stage M/H 3/4 150840

U8 36C68-334, Propane, single stage W/R 1/2x3/4 157167 - N/A Kit P/N 221634

U9 36C68-480, Propane, single stage W/R 3/4x3/4 157168 - N/A Kit P/N 221634

V1 VR8405M5228, Natural & Propane, single stage M/H 1 159743

V2 (Two

Valves)

V3 (Two

Valves)

V4 (Two

Valves)

V5 (Two

Valves)

V6 (Two

Valves)

V7 (Two

Valves)

V8 (Two

Valves)

V9 #VR8305N4917 Propane, DSI, 2-stage M/H 3/4x3/4 195737

W1

W2 (Two

Valves

W3

W4

W5 VR8105M2817 Natural, single stage M/H 1/2x1/2 172552 - N/A 7E 260604

W6 VR8105M2825 Propane, single stage M/H 1/2x1/2 172553 - N/A 8E 260606

W7 VR8104M2505, Natural, single stage M/H 1/2x1/2 170609

W8 VR8204M1901, Natural, single stage M/H 1/2x1/2 176680

W9 VR8204H1907, Propane, single stage M/H 1/2x1/2 176681 - N/A Kit P/N 221093

X1 VR8204Q2400, 2-Stage Propane M/H 1/2 177395

X2 VR8204Q2418, 2-Stage Natural M/H 1/2 177396

X3 VR8304Q4404, 2-Stage Natural M/H 3/4 177397

X4 VR8304Q4412, 2-Stage Propane M/H 1/2x3/4 177398

X5 VR8305Q4925, 2-Stage, Natural M/H 3/4 195739

X6 VR8300M3127, Natural, single stage M/H 1/2x3/4 195740

X7orZ3 VR8105K2942, Natural, single stage M/H 1/2 196848 - N/A 6E 260603

Original Valve on Heater

Mechanical modulation 50-100°F, with bypass, Code Q4, for Sizes 75-225

3B0-342-A05 or 3F1242A05 Propane, 50-100°F R 3/4 131454 (R9)

36C68-325 Propane, single stage W/R 1/2x3/4 96311 (M8) - N/A Kit P/N 221634

VR8304H3802 Propane, single stage M/H 1/2x3/4 121600 (Q4)

Mechanical modulation 50-100°F, with bypass, Code K1, for Sizes 250-400

3B0-342-A05 or 3F1242A05 Propane, 50-100°F R 3/4 131454 (R9)

36C68-442, propane, single stage W/R 3/4 89398 (K1) - N/A 1B 221526

36C68-442, propane, single stage W/R 3/4 89398 (K1) - N/A 1B 221526

Mechanical modulation 50-100°F, with bypass, Code M6, for ADF/ADFH Natural or Propane

5N7-341-A04 or 5R9241A04 R 1 131455 (R8)

36C68-442, propane, single stage W/R 3/4 89398 (K1) - N/A 1B 221526

36C68-452, natural, single stage W/R 3/4 96309 (M6) - N/A Kit P/N 222037

(2) K3A651SF Natural & Propane G/C 3/4 123604 (R2)

(2) K3A661-T Natural & Propane ASCO 1 146472 (T8)

(2) K3A6715F Natural & Propane ASCO 1-1/4 123605 (R4)

(2) L821480, 24V, Natural & Propane ASCO 2 159736

(2) L82146OC Natural & Propane ASCO 1-1/4 159731

(2) L821480C Natural & Propane ASCO 2 159841

(2) L821440 Natural ASCO 3 163137

Fluid Power Valve, V710FAS ASCO 1x1 172667

Actuator, 120V, AH2B112A 172680

(2) Fluid Power Valve, V710FAS ASCO 1x1 172667

(2) Actuator, 120V, AH2B112A 172680

Fluid Power Valve, V710GAS ASCO 1-1/4x1-1/4 172678

Actuator, 120V, AH2B112A 172680

Fluid Power Valve, V710JAS ASCO 2x2 172679

Actuator, 120V, AH2B112A 172680

Valve

Mfr

Pipe Size P/N

1

2

Functional Replacement

Code P/N

3

3

J2 (W1 alternate for J2; both

Codes are approved.)

J3 (W2 alternate for J3; both

Codes are approved.)

K2 (alternate for W3; both

codes are approved.)

K4 (alternate for W4; both

codes are approved.)

Form P-VALVES, P/N 263995R4, Page 16

Page 17

Type of Valve Originally Supplied (cont'd) -- See Serial No. Decoding on pages 3-4.

A dash (-) in the serial number means that no electric valve was furnished. All valves are 24 volt unless noted otherwise.

See ALL notes on pages 19-22. N/A = Not Available. See illustrations on pages 23-27.

2

Serial No.

Code

Original Valve on Heater

Valve

1

Mfr

Pipe

Size

P/N

X8orZ4 VR8105N2949, Nat, 2-stage M/H 1/2 196849 - N/A Y8or4A 197066

X9orZ5 VR8105K2959, LP, single stage M/H 1/2 196850 - N/A 9E 263999

Y1orZ6 VR8105N2931, LP, 2-stage M/H 1/2 196851 - N/A 2A 197064

Y2orZ7 VR8205K2957, Natural, single stage M/H 1/2 196980 - N/A 6E

Y3orZ8 VR8305K4241, Natural, single stage M/H 3/4 196981

Y4orZ9 VR8205K2965, LP, single stage M/H 1/2 196982 - N/A 9E

Y5or1A VR8305K4258, LP, single stage M/H 3/4 196983

Y6or2A VR8205N2913, LP, 2-stage M/H 1/2 197064

Y7or3A VR8305N4289, LP, 2-stage M/H 3/4 197065

Y8or4A VR8205N2921, Natural, 2-stage M/H 1/2 197066

Y9or5A VR8305N4297, Natural, 2-stage M/H 3/4 197067

Z1 2-STG VLV, LP, VR8205N2939 M/H 1/2 195736

Z2 2-STG VLV, NAT, VR8205N2947 M/H 1/2 195738

6A VR8205M2955, Nalural, single stage M/H 1/2 204301

7A V8295A1031, 2PSI Natural & Propane M/H 1 203860

8A V8295A1049, N & P M/H 1-1/4 203861

9A 36H32-441 Natural, single stage W/R 3/4 221525

1B 36H32-442 Propane, single stage W/R 3/4 221526

2B V8944N-1053, 2-Stage, Natural M/H 1 203866

3B V5155B-2548, Mech Mod Vlv 40-160° M/H 1 203868-N/A

4B V5155A Mech Mod Vlv 40-120° M/H 1 203869

5B (Two

Valves)

6B (Three

Valves)

7B (Three

Valves)

8B (Three

Valves)

41

AG55, 3:1 Turndown with two 1-stage valves, natural gas, RDCA/RDDA w/Heat Section 200, 250, 300

VR8105K2942, Nat, single stage (Code X7 or Z3) M/H 1/2 196848 (X7orZ3) - N/A 6E 260603

VR8205K8905, Nat, single stage (Code Y2 or Z7) M/H 1/2 196980 (Y2orZ7) - N/A 6E 260603

42

AG57, 6:1 Turndown w/two 1-stage valves & a modulating valve, nat gas, RDCA/RDDA w/Heat Section 100, 150

VR8105K2942, Nat, single stage (Code X7 or Z3) M/H 1/2 (2)196848 (X7orZ3) - N/A 6E (2) 260603

MR410-1, Maxitrol Modulating Valve Maxitrol 1/2 205582

42

AG57, 6:1 Turndown w/two 1-stage valves & a modulating valve, nat gas, RDCA/RDDA with Heat Section 200

VR8105K2942, Nat, single stage (Code X7 or Z3) M/H 1/2 196848 (X7orZ3) - N/A 6E 260603

VR8205K8905, Nat, single stage (Code Y2 or Z7) M/H 1/2 196980 (Y2orZ7) - N/A 6E 260603

MR410-1, Maxitrol Modulating Valve Maxitrol 1/2 205581

2

AG57, 6:1 Turndown w/two 1-stage valves & a modulating valve, nat gas, RDCA/RDDA w/Heat Section 250, 300

VR8105K2942, Nat, single stage (Code X7 or Z3) M/H 1/2 96848 (X7orZ3) - N/A 6E 260603

VR8205K8905, Nat, single stage (Code Y2 or Z7) M/H 1/2 196980 (Y2orZ7) - N/A 6E 260603

MR510, Maxitrol Modulating Valve Maxitrol 1/2 205580

9B VR8200M7005 , Natural, single stage, w/stnd pilot M/H 1/2 208920

1C VR8200M7013, LP, single stage, w/stnd pilot M/H 1/2 209412

2C (Two

Valves)

3C (Three

Valves)

4C (Two

Valves)

5C (Two

Valves)

6C (Three

Valves)

7C (Three

Valves)

8C (Three

Valves)

9C (Three

Valves)

41

AG55, 3:1 Turndown with two 1-stage valves, natural gas, RDCA/RDDA with Heat Section 100, 150

VR8105K2942, Nat, single stage (Code X7 or Z3) M/H 1/2 196848 (X7orZ3) - N/A 6E 260603

VR8105K2942, Nat, single stage (Code X7 or Z3) M/H 1/2 196848 (X7orZ3) - N/A 6E 260603

41