Page 1

10.0 Maintenance

and Service

(cont’d)

10.2 Maintenance

Procedures

(cont’d)

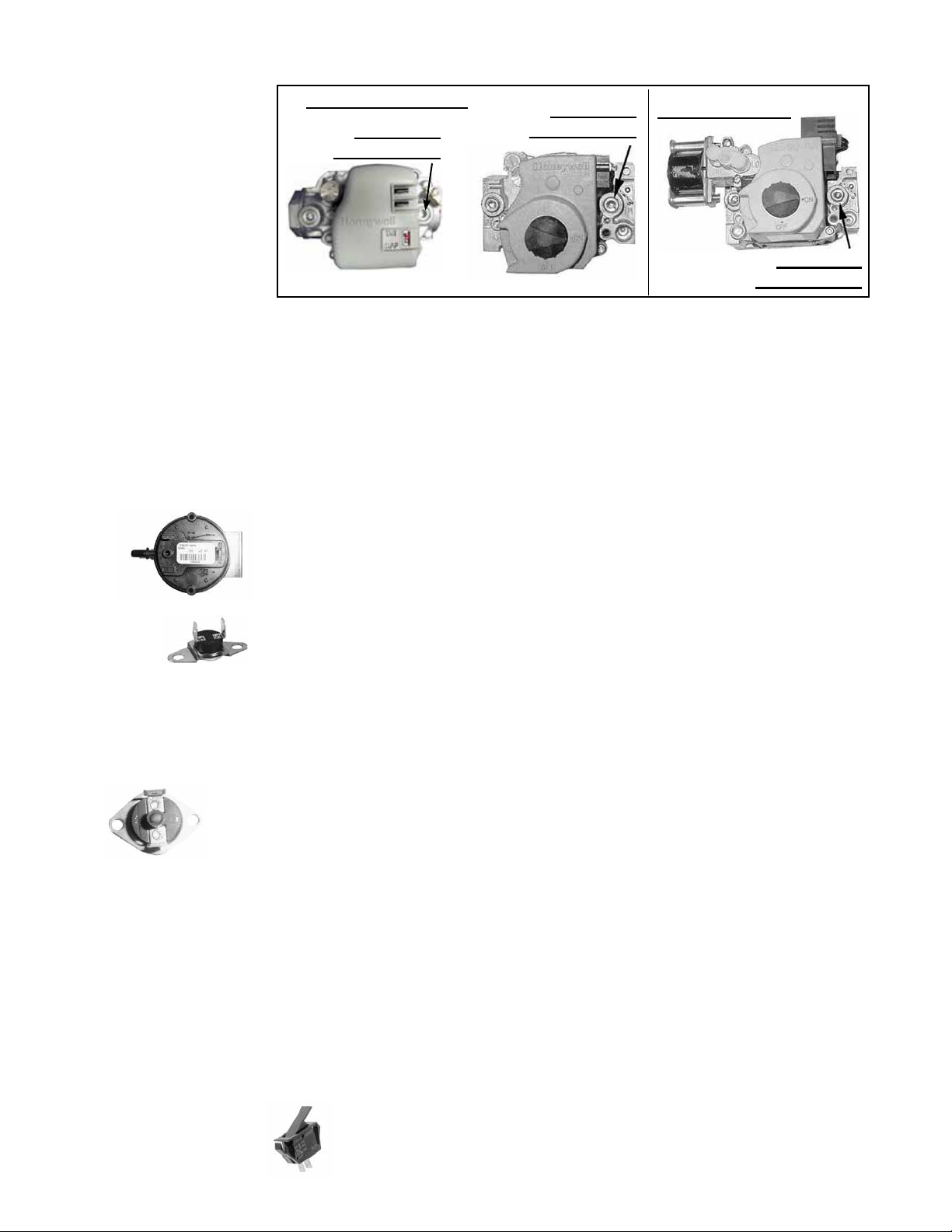

FIGURE 24 - Pressure

Tap for Checking Gas

Flow Shuto

10.2.7 Operating Gas Valve (cont’d)

Single-Stage Valves

1/8ʺ Outlet

Pressure Tap

1/8ʺ Outlet

Pressure Tap

Two-Stage Valve

1/8ʺ Outlet

Pressure Tap

NOTE: Operational

pressure settings and

instructions for checking

pressure settings are in

Paragraph 6.1.

10.2.8 Combustion Air

Pressure Switch

10.2.9 Limit

Control

10.2.10 Flame Rollout

Switch—Sizes 30–125

only

2) With the manual valve turned o to prevent ow to the gas valve, connect a

manometer to the 1/8ʺ outlet pressure tap in the valve. NOTE: A manometer (uidlled gauge) is recommended.

3) Turn the manual valve to the ON position and the heater OFF. Use your nger to

fully block the main burner orice for several seconds. Observe the manometer

with the orice blocked, and if any pressure is indicated, the gas valve is leak-

ing. A leaking gas valve must be replaced before the heater is put back in

operation.

See FIGURE 18, page 30, for location. (NOTE: Depending on date of manufacture and

size, pressure switch may not be in the location indicated. Check the control bracket

on the bottom of the compartment or further down on the compartment wall.) If it is

determined that the pressure switch needs replacing, use only the factory-authorized

replacement part that is designed for the model and size of heater being serviced.

NOTE: A unit operating above 6000 ft (1830M) elevation requires a high altitude pressure switch (see Paragraph 3.2).

If it is determined that the limit control needs replacing, use only a factory-authorized

replacement part that is designed for the size of heater.

For approximate limit location, see FIGURE 18, page 30.

The cause of a ame rollout switch activating must be determined. Activation of the

manually reset ame rollout switch could be caused by one or more of the following:

• Restricted or plugged heat

exchanger

• Too much building exhaust

• Manifold gas pressure too

high

• Restricted combustion air inlet or exhaust outlet

in combination with a defective pressure switch

• Electrical power interruption during operation

• Unit being operated with a line voltage

disconnect (a 24-volt thermostat is required)

If a ame rollout switch trips, inspect the burner/control compartment for signs of

excessive heat and burned wiring.

For location, see

FIGURE 18, page 30.

If the compartment appears normal, reset by depressing the red button on the

switch. 15 to 20 minutes are required for the switch to cool suciently for resetting. A distinct click will be felt when the switch resets. Operate the furnace. If the

ame rollout switch trips again, determine and correct the cause before resetting

the switch.

If there is damage to the control compartment, repairs must be made before

resetting the switch.

If it is determined that the ame rollout switch needs replacing, use only the factory-

authorized replacement part that is designed for that size of heater.

The disconnect switch is located in the sealed electrical box inside the control com-

partment with the toggle on the rear of the heater.

10.2.11 Door

Switch—Separated

Combustion Model

only

Page 34, D300519A (04-18) I-UDA&APD Series

If it is determined that the door switch needs replacing, use only a factory-

authorized replacement part that is designed for the heater.

For approximate switch location, see FIGURE 18, page 30.

Page 2

10.2.12 Transformer

Trial for Ignition

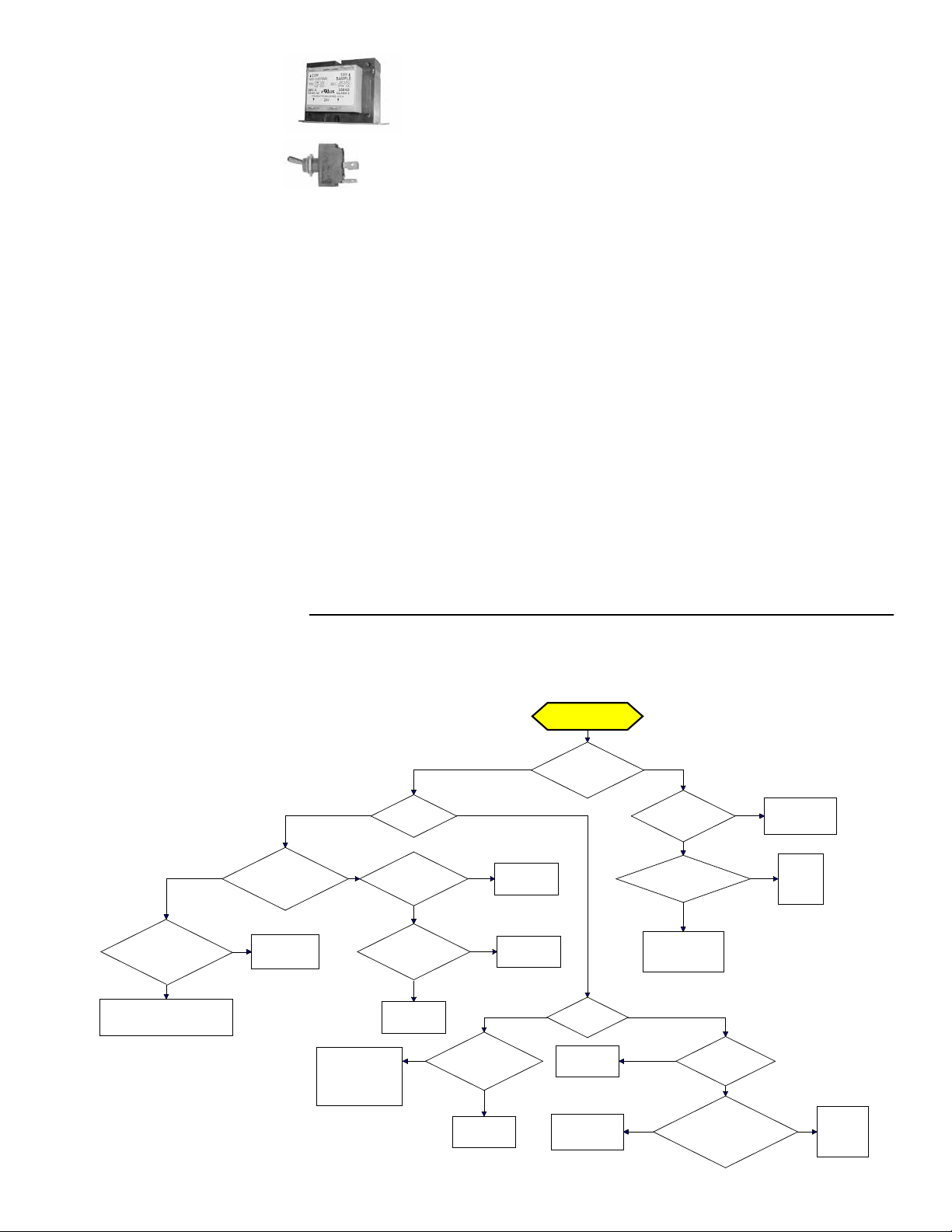

Call for Heat

Is there a

spark across gap at

ignitor?

Does gas

ignite?

Is there minimum

flame current at the

flame sensor?

Is there

minimum flame current

at the control

module?

Replace control

module.

Check connections to flame

sensor and/or moisture in the

burner assembly.

Is the flame

sensor corroded?

Clean flame

sensor.

Is the sensor

located in flame

correctly?

Replace flame

sesnsor.

Reposition

flame sensor.

Is gas

flowing?

Is the ignitor

position correct in the

gas flow?

Check gas pressure

and supply voltage.

If either are low,

correct and repeat

startup.

Reposition

spark ignitor.

Is there

24VAC at the gas

valve?

Is there 24VAC

from gas valve output on

control module to

chassis?

Check wiring and

connections to

gas valve.

Replace

ignition

control

module.

Replace gas

valve.

Is there

spark voltage at

control?

Check high

voltage wire

continuity.

Is there 24V P1-2

to power control?

Replace

control

module.

Check wiring

and/or 24VAC

transformer output.

YES NO

YES NO

YES NO

YES

NO

YES

NO

YES

NO

YES NO

YES

NO

NO

YES

YES NO

YES

NO

YES

NO

10.2.13 Disconnect

Switch—Separated

Combustion model

only

10.2.14 Vent or Vent/

Combustion Air

System

10.3 Troubleshooting

Check the Lights on

the DSI Integrated

Control Module

(Circuit Board)

IMPORTANT: When using

a multimeter to troubleshoot

the 24 volt circuit, place the

meter’s test leads into the 5

or 9 pin connectors located

on the ignition control. Do

not remove connectors or

terminals from the electrical components. Doing so

can result in misinterpreted

readings due to the ignition

control board’s fault mode

monitoring circuits.

See FIGURE 18, page 30, for location. Use a voltmeter to verify that

there are 24 volts output from the transformer. If the transformer is not

functioning, it must be replaced. Use a replacement transformer identi-

cal to the factory-installed model.

If it is determined that the disconnect switch needs replacing, use only the

factory-authorized replacement part that is designed for the heater. Always

replace electrical box cover.

Check the complete system at least once a year. Inspection should include all joints,

seams, concentric adapter box (Separated Combustion), inlet air guard or inlet air cap

(Separated Combustion), and the vent terminal cap. Clean openings. Replace any

defective parts.

The integrated circuit board monitors the operation of the heater and includes two

LED signal lights that indicate normal operation and various abnormal conditions. If

the heater fails to operate properly, check this signal to determine the cause and/or

to eliminate certain causes. LED is visible through viewport on Separated Combustion models. Remove access panel on Standard Power Vent models. See operating

sequence in Paragraph 9.

Do not attempt to repair the DSI integrated control module (circuit board); the only eld

replaceable component is the fuse.

Control Status—Green LED Codes

Steady ON Normal Operation, No call for heat

Fast Flash . Normal Operation, Call for heat

1 Flash ...... System Lockout, Failed to detect or sustain ame

2 Flashes .. Pressure Switch Did Not Close within 30 Seconds of Venter Motor

3 Flashes .. High Limit or Flame Rollout Switch Open

4 Flashes ....Pressure Switch is Closed Before Venter Motor is Energized

Steady OFF Blown fuse, No Power, or Defective Board

Flame Status—Yellow LED Codes

Steady ON ..Flame is sensed

Slow Flash ..Weak ame (current below 1.0 microamps ± 50%)

Fast Flash ...Undesired Flame (valve open and no call for heat)

DSI Integrated Control Module (Circuit

Board) Trial Troubleshooting Flowchart

D300519A (04-18) I-UDA&APD Series, Page 35

Page 3

10.3 Troubleshooting (cont’d)

General Troubleshooting

PROBLEM PROBABLE CAUSE REMEDY

Venter motor will not

start

Burner will not light 1. Manual valve not open. 1. Open manual valve.

Burner cycle on and o1. Gas pressure too high or too low. 1. Supply pressure should be 5–14" w.c. for natural gas or 11–14" w.c. for pro

1. No power to unit. 1. Turn on power, check supply fuses or circuit breaker.

2. No 24 volt power to integrated circuit board. 2. Turn up thermostat; check control transformer output.

3. Integrated circuit board fuse blown. 3. Correct cause. Replace fuse (type ATC or ATO, 32VDC, 3A).

4. No power to venter motor. 4. Tighten connections at circuit board and/or motor terminals.

5. Integrated circuit board defective. 5. Replace integrated circuit board.

6. Defective venter motor. 6. Replace venter motor (see Paragraph 29).

2. Air in the gas line. 2. Bleed gas line (initial startup only).

3. Gas pressure too high or too low. 3. Supply pressure should be 5–14" w.c. for natural gas or 11–14" w.c. for

4. No Spark:

a) Loose wire connections a) Be certain all wire connections are solid.

b) Transformer failure.

c) Incorrect spark gap. c) Maintain spark gap at 1/8".

d) Spark cable shorted to ground. d) Replace worn or grounded spark cable.

e) Spark electrode shorted to ground. e) Replace if ceramic spark electrode is cracked or grounded.

f) Burner not grounded. f) Make certain integrated circuit board is grounded (Terminal P1-9).

g) Circuit board not grounded. g) Make certain integrated circuit board is grounded to furnace chassis.

h) Unit not properly grounded. h) Make certain unit is properly eld grounded to earth ground and properly

i) Integrated circuit board fuse blown. i) Correct cause. Replace fuse (type ATC or ATO, 32VDC, 3A).

j) Faulty integrated circuit board. j) If 24 volt is available to the integrated circuit board and all other causes have

5. Lockout device interrupting control circuit by

above causes.

6. Combustion air proving switch not closing. 6.

7. Faulty combustion air proving switch. 7. Replace combustion air proving switch.

8. Main valve not operating. 8.

a) Defective valve. a) If 24 volt is measured at the valve connections and valve remains closed,

b) Loose wire connections b) Check and tighten all wiring connections.

9. Integrated circuit board does not power main

valve.

a) Loose wire connections. a) Check and tighten all wiring connections.

b) Flame sensor grounded. b) Be certain ame sensor lead is not grounded or insulation or ceramic is not

c) Incorrect gas pressure. c) Supply pressure should be 5–14" w.c. for natural gas or 11–14" w.c. for pro

d) Cracked ceramic at sensor. d) Replace sensor.

2. Burner not grounded 2. Make certain integrated circuit board is grounded (Terminal P1-9).

3. Circuit board not grounded. 3. Make certain integrated circuit board is grounded to furnace chassis.

4. Faulty integrated circuit board 4. If 24 volt is available to the integrated circuit board and all other causes have

5. Combustion air proving switch not closing. 5.

6. Faulty combustion air proving switch. 6. Replace combustion air proving switch.

7. Flame sensor grounded. 7. Be certain ame sensor lead is not grounded or insulation or ceramic is not

8. Cracked ceramic at sensor. 8. Replace sensor.

9. Incorrect polarity. 9. Reverse line volt leads to integrated circuit board.

10. Pin terminal loose on 9 pin plug. 10. Replace wire harness.

:

propane.

4.

b) Be sure 24 volts is available.

phased (L1 to hot lead L2 to neutral).

been eliminated, replace board.

5. Reset lockout by interrupting control at the thermostat or main power.

a) Make sure unit is properly vented.

b) Remove obstructions from vent.

c) Replace faulty tubing to pressure switch.

replace valve.

9.

cracked. Replace as required.

pane.

pane.

been eliminated, replace board.

a) Make sure unit is properly vented.

b) Remove obstructions from vent.

c) Replace faulty tubing to pressure switch.

cracked. Replace as required.

-

-

Page 36, D300519A (04-18) I-UDA&APD Series

Page 4

No heat (Heater Operating)

Fan or venter motor

will not run

Fan or venter motor

turns on and o while

burner is operating

Fan or venter motor

cuts out on overload

1. Incorrect valve outlet pressure or orice. 1. Check valve outlet pressure (see Rating plate for manifold pressure).

2. Cycling on limit control. 2. Check air throughput.

3. Improper thermostat location or adjustment. 3. See thermostat manufacturer's instructions.

1. Circuit open. 1. Check wiring and connections.

2. Defective integrated circuit board. 2. Replace board.

3. Defective motor or starter. 3. Replace motor or starter.

1. Motor overload device cycling on and o. 1. Check motor load against motor rating plate. Replace motor if needed.

1. Low or high voltage supply. 1. Correct electric supply.

2. Defective motor. 2. Replace motor.

3. Poor airow. 3. Clean motor, fan, fan guard, lter, and coils.

D300519A (04-18) I-UDA&APD Series, Page 37

Page 5

APPENDIX

TECHNICAL DATA—Sizes 30–125 (Data applies to all Models unless noted otherwise)

Size 30 45 60 75 100 125

Input Heating Capacity

Thermal Eciency (%) 82 83 83 83 83 83

Output Heating Capacity

Gas Connection (inches)

Vent Connection (inches diameter)

A

B

C

Combustion Air Inlet (inches diameter)—Separated Combustion only

Control Amps (24 volt) 1.0 1.0 1.0 1.0 1.0 1.0

Full Load Amps (115 volt) 1.9 2.4 2.4 3.3 3.9 5.1

Maximum Over Current

Protection

D,E

Normal Power Consumption (watts) 109 155 155 217 276 354

Discharge Air Temperature Rise (°F) 50 55 60 60 60 60

Air Volume

Discharge Air Opening Area

Output Velocity

Fan Motor HP

E

Fan Motor RPM 1550 1550 1550 1550 1050 1050

Fan Diameter (inches) 10 10 12 12 16 16

Sound Level dba @ 15 ft 40 40 40 49 54 55

TECHNICAL DATA—Sizes 150–400 (Data applies to all Models unless noted otherwise)

Size 150 175 200 225 250 300 350 400

Input Heating Capacity

Thermal Eciency (%) 83 83 83 83 83 83 83 83

Output Heating Capacity

Gas Connection (inches)

Vent Connection

Combustion Air Inlet

A

B

C

(inches diameter) 5 5 5 5 5 6 6 6

C

(inches diameter)—Separated Combustion only 6 6 6 6 6 6 6 6

Control Amps (24 volt) 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0

Full Load Amps (115 volt) 3.8 3.8 7.5 7.5 7.5 10.7 10.7 10.7

Maximum Over Current

Protection

D,E

Normal Power Consumption (watts) 392 392 491 747 747 1086 1086 1086

Discharge Air Temperature Rise (°F) 60 60 60 60 60 60 60 60

Air Volume

Discharge Air Opening Area

Output Velocity

Fan Motor HP

E

Fan Motor RPM 1050 1050 1050 1050 1050 1050 1050 1050

Fan Diameter (inches) 18 18 18 20 20 24 24 24

Sound Level dba @ 15 ft 51 52 53 56 56 59 61 62

A

CSA ratings for altitudes to 2000 ft.

B

Size shown is for gas connection to a single-stage gas valve, not supply line size.

C

Smaller and/or larger vent and combustion air pipe diameters may be permissible. For Separated Combustion models refer to the Venting

Installation Manual for Separated Combustion Units. For Standard Power Vent models refer to the Venting Installation Manual for Power Vented

units. For a Standard Power Vent model with Option AV6, refer to the Venting Installation Manual for Common Venting.

D

MOCP = 2.25 × (largest motor FLA) + smallest motor FLA. Answer is rounded to the next lower standard circuit breaker size.

E

Except where indicated, information in this table is based on a heater equipped with a standard 115 volt open fan motor.

BTUH 30,000 45,000 60,000 75,000 105,000 120,000

kw 8.8 13.2 17.6 22.0 30.8 35.2

BTUH 24,600 37,350 49,800 62,250 87,150 99,600

kw 7.2 11.0 14.6 18.3 25.6 29.2

Natural 1/2 1/2 1/2 1/2 1/2 1/2

Propane 1/2 1/2 1/2 1/2 1/2 1/2

4 4 4 4 4 4

C

4 4 4 4 4 4

Standard 115V 15 15 15 15 15 15

Optional 208V or 230V 15 15 15 15 15 15

CFM 456 629 769 961 1345 1537

3

/minute 12.9 17.8 21.8 27.5 36.7 45.9

M

2

ft

2

M

1.0 1.0 1.2 1.2 2.0 2.0

0.1 0.1 0.1 0.1 0.2 0.2

FPM 475 656 616 770 668 763

M/minute 145 200 188 238 196 245

Standard Open 0.0 0.0 0.0 0.1 1/30 1/20

Optional Enclosed N/A N/A N/A N/A 1/4 1/4

BTUH 150,000 175,000 200,000 225,000 250,000 300,000 350,000 400,000

kw 43.9 51.2 58.6 65.9 73.2 87.8 102.5 117.1

BTUH 124,500 145,250 166,000 186,750 207,500 249,000 290,500 332,000

kw 36.4 42.5 48.6 54.7 60.8 72.9 85.1 97.2

Natural 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4

Propane 1/2 1/2 1/2 3/4 3/4 3/4 3/4 3/4

Standard 115V 15 15 15 15 15 20 20 20

Optional 208V or 230V 15 15 15 15 15 15 15 15

CFM 1921 2242 2562 2882 3202 3843 4483 5123

3

/minute 54.4 63.5 72.5 81.6 90.7 108.8 126.9 145.1

M

2

ft

2

M

2.6 2.6 2.6 3.5 3.5 4.8 4.8 4.8

0.2 0.2 0.2 0.3 0.3 0.5 0.5 0.5

FPM 752 877 1003 820 9 11 802 936 1069

M/minute 229 267 306 250 278 244 285 326

Standard Open 1/6 1/6 1/4 1/4 1/4 1/2 1/2 1/2

Optional Enclosed 1/4 1/4 1/4 1/4 1/4 1/2 1/2 1/2

Page 38, D300519A (04-18) I-UDA&APD Series

Page 6

INDEX

A

Abnormal Heat Cycle Functions 24

Aircraft Hangars 4

Control Amps 38

Full Load Amps 38

APPENDIX 38

B

Clean the Burner 31

Burner Maintenance 30

Burner Orice 31

Burner Removal 30

C

California Warning Label 4

Ceiling Suspension Kit 11

Certication 3

Check installation after startup 27

Check the installation prior to

startup 26

Check the Lights 35

Chlorine 6

Clearances 7

LED Codes 23, 35

Combustion Air 16

Combustion Air Inlet 38

Combustion Air Pressure Switch 34

Combustion Air Proving (Pressure)

Switch 20

Commissioning 26

Conned Space 16

Contact 40

Control Wiring 17

Conversion Kits 13

D

DDC Controls 22

Dimensions 8

Disconnect Switch 35

Door Switch 34

Door Switch—Separated Combustion

Model only 21

Downturn Nozzle Kits 7

DSI Integrated Control Module 23, 31

E

Thermal Eciency 38

Electrical Supply 16

F

Continuous Fan Operation 25

Fan/Blower O Delay 24

Fan/Blower On Delay 24

Fan Blades 32

Fan Motor 21

Fault Modes 25

Field-Installed Parts 6

Flame Rollout Switch 34

Flame Sensor 32

G

Garages 4

Gas Connection 38

Gas Connection Size 12

Gas Supply 11

Gas Supply Line 12

Gas Valve 21, 33

Gas Valve ON/OFF Control Knob 27

H

Hanger Kits 11

Hanging the Heater 10

HAZARD INTENSITY LEVELS 2

Hazard Labels and Notices 2

Heat Exchanger Maintenance 30

High Altitude Capacity 15

High Altitude Derate 14

High Altitude Kit 6, 7

I

Ignition System 23, 31

Ignition Trial Period 23

Ignitor 32

Input Heating Capacity 38

Installation Codes 4

L

Leak-test 12

Lifting 10

LED lights 23

Limit Control 20, 34

Limit Switch 24

Literature Bag 28

Location 5

Unit Heater Location 4

Location of Controls 29

Lockout 25

Optional vertical louvers 6

M

Maintenance Procedures 30

Maintenance Schedule 29

Massachusetts Requirement 4

Fan Motor 32

Venter Motor 33

Motor HP 38

Multiple Heater Control 22

N

Normal Heat Cycle 23

O

Operating Sequence 27

Option CC1 6

Option CC2 or CC6 3, 6

Option CD 2, 3, or 4 7

Option CK8, CK10, and CK22 11

Option CL31 22

Option CL32 22

Option CM3 21

Option DJ20 or DJ21 6

Options D10 and D14 22

Orice Pressure 13

Output Heating Capacity 38

P

Plug the unused suspension points 10

Post Purge 24

Power Interruption 25

Preparing for Installation 6

Prepurge 23

Pressure Switch 24

Pressure Switch Settings 20

PRESSURE TESTING SUPPLY

PIPING 11

S

Mounting the Sensor 22

Sound Level 38

Spark Gap 32

Startup 26

Stepdown transformer 6

Supply Wiring 17

Suspending 10

Suspending the Heater with Rods 11

Suspend the Heater from 1ʺ Pipe 11

Swivel Connectors 11

T

TECHNICAL DATA 38

Thermostat 21

Unit Mounted Thermostat 21

Throw 4

Transformer 35

Troubleshooting 35, 36

Troubleshooting Flowchart 35

TURN OFF GAS TO THE APPLI-

ANCE 27

U

Uncrating and Inspecting 6

V

Valve Outlet Pressure 13

Vent 35

Vent/Combustion Air 35

Vent/Combustion Air Kit 3

Vent/combustion air kit 6

Vent cap 6

Vent Connection 38

Venter Wheel 33

Venting Manual 3, 5

Vent System Testing Procedure—Stand

Power Vent Model 27

W

Warranty 4

Weights 10

WHAT TO DO IF YOU SMELL GAS 26

Wiring Connections 17

Wiring Diagram for all Single Stage

Models 18

Wiring Diagram for all Two Stage Gas

Valve 19

Wiring Diagrams 18

D300519A (04-18) I-UDA&APD Series, Page 39

Page 7

INSTALLATION RECORD—to be completed by the installer:

Installer:

Name ________________________________________________________

Company ________________________________________________________

Address ________________________________________________________

________________________________________________________

________________________________________________________

Phone _________________________________

Distributor (company from which the unit was purchased):

Company ________________________________________________________

Contact ________________________________________________________

Address ________________________________________________________

________________________________________________________

________________________________________________________

Phone _________________________________

Model ________________ Serial No.______________________________Date of Installation ____________

SPECIFIC INSTALLATION NOTES: (i.e. Location, Amps, Gas Pressure, Temperature, Voltage, Adjustments,

Warranty, etc.)

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

BUILDING OWNER OR MAINTENANCE PERSONNEL:

For service or repair

• Contact the installer listed above.

• If you need additional assistance, contact the Distributor listed above.

• For more information, contact your Local Representative.

Page 40, D300519A (04-18) I-UDA&APD Series

Specications & illustrations subject to change without notice of incurring obligations.

©Nortek Global HVAC, LLC 2018. All rights reserved.

All marks are the property of their respective organizations.

O’Fallon, MO I Printed in U.S.A. (04-18)

Document No. D300519A (04-18) I-UDA&APD Series

Loading...

Loading...