Page 1

1. Always include complete heater model and serial number so that

IMPORTANT

any specification change can be considered for parts shipment. It

can save time and expense.

2. Specifications are subject to change without notice.

3. We reserve the right to substitute functional replacements.

4. Order by Part No.; not Heater Option Designation.

®

Model FT and Model SFT

Unit Heaters

INST ALLATION FORM RZ-NA -P-FT/SFT

Obsoletes Form RZ-728

APPLIES TO: Replacement Parts

Index of Parts

Model FT Model SFT

by Page No.

Burner Rack 7 9

Cabinet Parts 6 10

Downturn Air Outlet Nozzles 14 14

(same as Options CD 2, 3, 4)

Electrical Components 2-5 8-9

Fan and Components 7 10

Fan Guard 7 10

Gas Conversion Kits 12 12

Heat Exchangers 7 11

Ignition Control Board 4-5 8

Ignitor 4-5 8

Limit Control 4-5 8

Louvers, Horizontal 6 10

Louvers, Vertical (same as 13 13

Option CD1)

Manifold 7 9

Motor, Fan 7 10

Motor, Venter 2-5 8

Orifices, Burner 12 12

Rating Plate 1 1

Serial Number 2 2

Switch, Flame Rollout 4 9

Switch, Pressure 4-5 9

Thermostat 15 15

Transformer 4-5 9

Valve 4-5 8

Vent Cap (same as Option CC1) 7 -Vent/Combustion Air Kits (same -- 11

as Option CC2 and CC6)

Vent Tape (same as Option FA1) 15 15

Venter Parts 2-5 8

Additional References (use Form RZ designation to

order literature; not the P/N)

Description/Application................................... Form RZ ....... P/N

Parts/Service - Replacement Gas Valves and

Ignition Control Boards by Serial No. Code. P-VALVES .......N/A

Service - Converting to Other Gases ............ FT/SFT-GC ..148066

Installation/Operation - Model FT Heaters .............. I-FT ..173473

Installation/Operation - Special Model

FT-CV or FT-LN Unit Heaters ................. I-FT-CV/LN ..177854

Installation/Operation - Model SFT Heaters .......... I-SFT ..173474

Installation Instructions - Optional

Vertical Louvers, Models FT and SFT ..... I-FT/SFT-VL..160807

Installation Instructions - Optional

Downturn Nozzle, Models FT and SFT. I-FT/SFT-DN..160808

Rating Plate and Serial No.

Example of a Rating Plate

REZNOR

MERCER, P A. USA 1 613 7

MADE IN USA

UNIT HEATER

CATEGORY

ANSI Z83.8 [ A ] CG A 2.6- M [ A' ] UNIT HEATER

CSA .10.96 U. S. (2nd Ed.) UNIT HEATERS FOR RESIDENTIAL INSTALLATION

MODEL [ B ] [ C ]

SERIAL NO .

[ D ] VOLTS [ D ] PH [ D ] H Z MAXIMUM TOTAL INPUT [ D ] AMPS

TYPE OF GAS: [ E ]

FOR USE AT [ F ] FEET [ G ] METERS O F ALTI TUDE.

ORIFICE SIZE [

NORMAL I NPU T

THERM AL OUTPUT CA P A CITY

NORMAL MANIF O L D PRE S S URE

MIN. PERM ISSIBLE GAS SU PPLY PRESSURE

FOR PURPO S E OF INPUT ADJUST ME N T .

CLE ARANCES TO CO MBU S T I BLE CONS TRUCTI O N: TOP-1 ", FL UE

CONNE CTION-6 ", CO NTRO L S I DE - 1 8 ", OPP. SIDE-1 ", BOTTO M-1"

FOR ALTERNATE INSTALLATIONS USE THE LA TEST EDITIONS OF THE

APPROPRIATE STAND AR D LI STED BELOW:

FOR AI R CRAFT HANGARS U S E STANDARD ANSI /NFPA 409

FOR PARKI NG S TRUCTU RE S U S E S TANDARD ANSI/NFPA 88A

FOR RE PAI R GARAGE S U S E STANDARD ANSI/NF PA 88B

THIS UNIT IS NOT FOR USE WITH DUCTS.

THIS UNIT IS NOT FOR USE WITH FILTERS.

CONSTRUCTION WALL THICKNES S FOR PU RPOSE O F V E NTING:

1" M IN., 30" MAX.

Rating Plate Key:

A = Date of ANSI Standard

1

= Date of CGA Standard

A

B = Model No.

C = Month and Year of

Manufacture

D = 115V, 1 Phase, 60 Hertz,

Maximum Total Input Amps

E = Natural or Propane Gas

F/G = Elevation (Feet/Meters)

H = Orifice Size

I = BTU Input Sea Level

III

H ] DRIL L HAS BEEN F ACTORY ADJUSTED

SEA LEVEL ALT. ADJUSTED

[

I ] [ J ]BTU/HR.

[

K ] [ L ]BTU/HR.

[

[

J = BTU Input Altitude Adjusted

K = BTU Thermal Output Sea

Level

L = BTU Thermal Output

Altitude Adjusted

O = Manifold Pressure (3.5 w.c.

Natural Gas; 10 w.c.

Propane Gas)

P = Minimum Gas supply

Pressure (5.0 w.c. Natural

Gas; 11.0 w.c. Propane Gas)

Form RZ-NA-P-FT/SFT, Page 1

O ] IN.W.C.

P ] IN.W.C.

Page 2

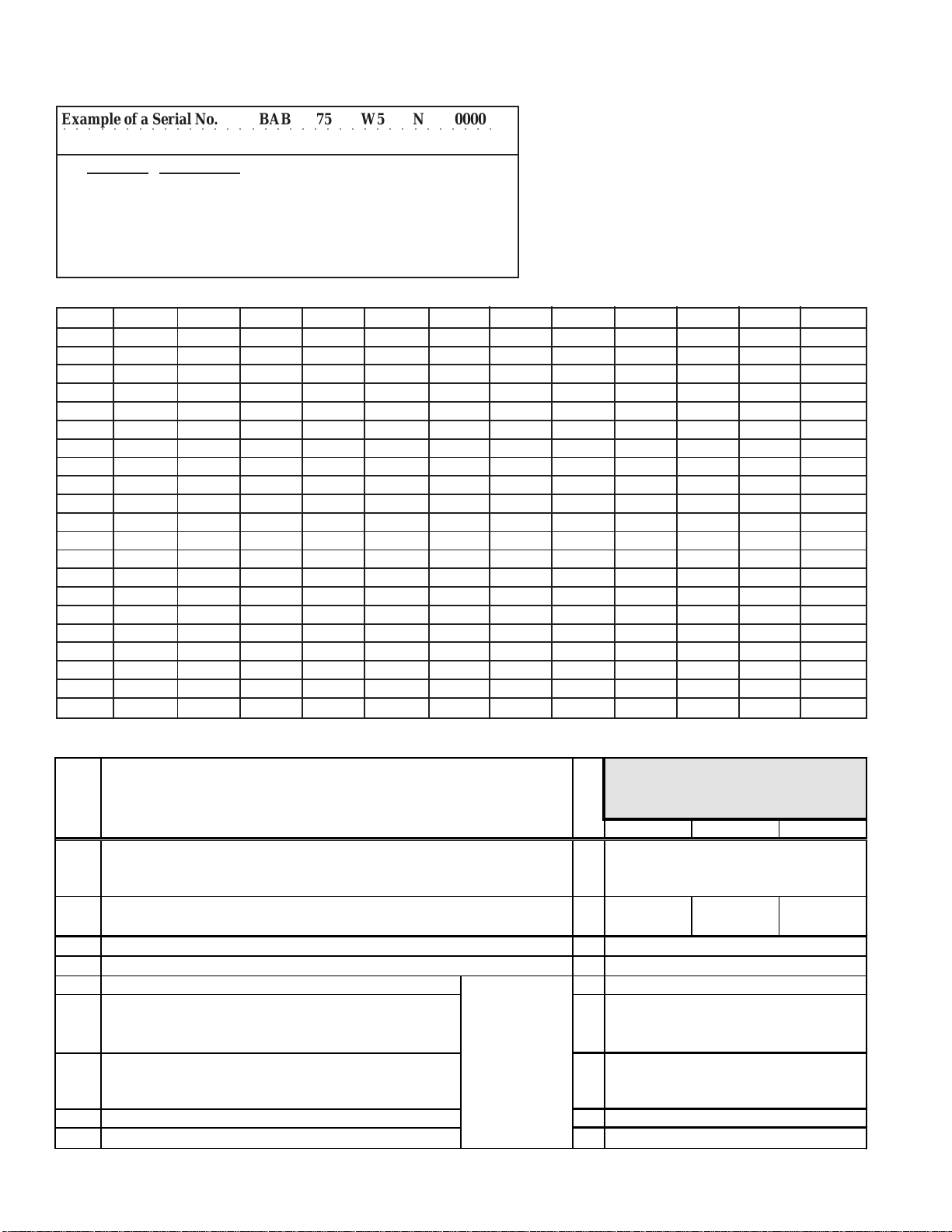

Rating Plate and Serial No. (cont'd)

Decoding a Serial No.

Example of a Serial No. BAB 75 W5 N 00000

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Code Nos. 1234 5

Code No. Explanation

1 Date of manufacture (see below)

2 Type of pilot system (see Form RZ 714)

3 Type of gas valve (see Form RZ 714)

4 Gas (N = natural; L = propane)

5 Consecutive number (identification only)

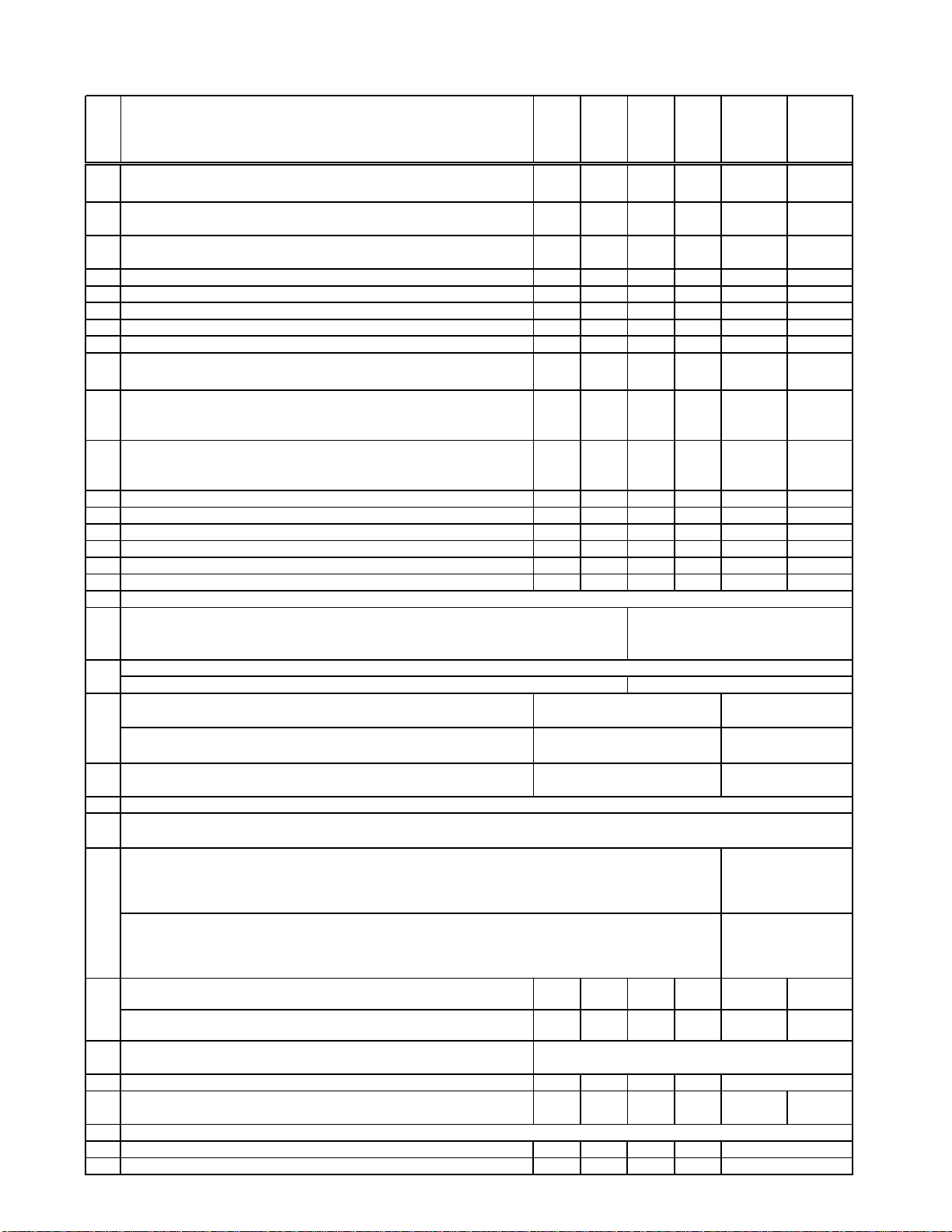

First Element of the Serial Number - Date of Manufacture

Year Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec

1995 AUA AUB AUC AUD AUE AUF AUG AUH AUI AUJ AUK AUL

1996 AVA AVB AV C AVD AVE AVF AVG AVH AV I AVJ AV K AVL

1997 AWA AWB AWC AWD AWE AWF AWG AWH AWI AWJ AWK AWL

1998 AXA AXB AXC AXD AXE AXF AXG AXH AXI AXJ AXK AXL

1999 AYA AYB AYC AYD AYE AYF AYG AYH AYI AYJ AYK AYL

2000 AZA AZB AZC AZD AZE AZF AZG AZH AZI AZJ AZK AZL

2001 BAA BAB BAC BAD BAE BAF BAG BAH BAI BAJ BAK BAL

2002 BBA BBB BBC BBD BBE BBF BBG BBH BBI BBJ BBK BBL

2003 BCA BCB BCC BCD BCE BCF BCG BCH BCI BCJ BCK BCL

2004 BDA BDB BDC BDD BDE BDF BDG BDH BDI BDJ BDK BDL

2005 BEA BEB BEC BED BEE BEF BEG BEH BEI BEJ BEK BEL

2006 BFA BFB BFC BFD BFE BFF BFG BFH BFI BFJ BFK BFL

2007 BGA BGB BGC BGD BGE BGF BGG BGH BGI BGJ BGK BGL

2008 BHA BHB BHC BHD BHE BHF BHG BHH BHI BHJ BHK BHL

2009 BIA BIB BIC BID BIE BIF BIG BIH BII BIJ BIK BIL

2010 BJA BJB BJC BJD BJE BJF BJG BJH BJI BJJ BJK BJL

2011 BKA BKB BKC BKD BKE BKF BKG BKH BKI BKJ BKK BKL

2012 BLA BLB BLC BLD BLE BLF BLG BLH BLI BLJ BLK BLL

2013 BMA BMB BMC BMD BME BMF BMG BMH BMI BMJ BMK BML

2014 BNA BNB BNC BND BNE BNF BNG BNH BNI BNJ BNK BNL

2015 BOA BOB BOC BOD BOE BOF BOG BOH BOI BOJ BOK BOL

Model FT Control Compartment and Electrical Components

Qty

Code

1A

Vent er Housing Assy - standard heater (does not apply to Model FT with suffix CV

or LN ; see Code 1B)

Vent er Housing Assy - Size 30 or 45 heater with suffix CV (Option AV6) or LN

1B

(Option AL2B)

Venter Gasket (not illustrated)

2

Static Pressur e Tap

3

Venter Motor & Wheel Assy (includes Codes 4A-4D) 1

*4

Vent er M otor 1

*4A

(**Sizes 150-200 is an assembly including motor, P/N 148053;

capacitor, P/N 1638 94; and capacitor boot, P/N 103182)

Venter Wheel 1

*4B

Vent er M otor Plate 1

*4C

Venter Fan Blade 1

*4D

*11/97 is Serial No. Date Code AWK; but always verify actual type of approval stated on the rating plate.

Form RZ-NA-P-FT/SFT, Page 2

Description

Apply to standard

Model FT (go to

page 5, Codes 5

and 6, for venter

parts for special

Model FT-CV or

FT-LN)

For heaters mfgd

approval (approx. 11/97*- verify on rating

1

1------

1

1

PRIOR TO

plate)

30 45 60

147357

147793

116043

147359

97738

Magnetek #JA1M156N

135979

Revcor B506-1005

135981

68005

residential

Page 3

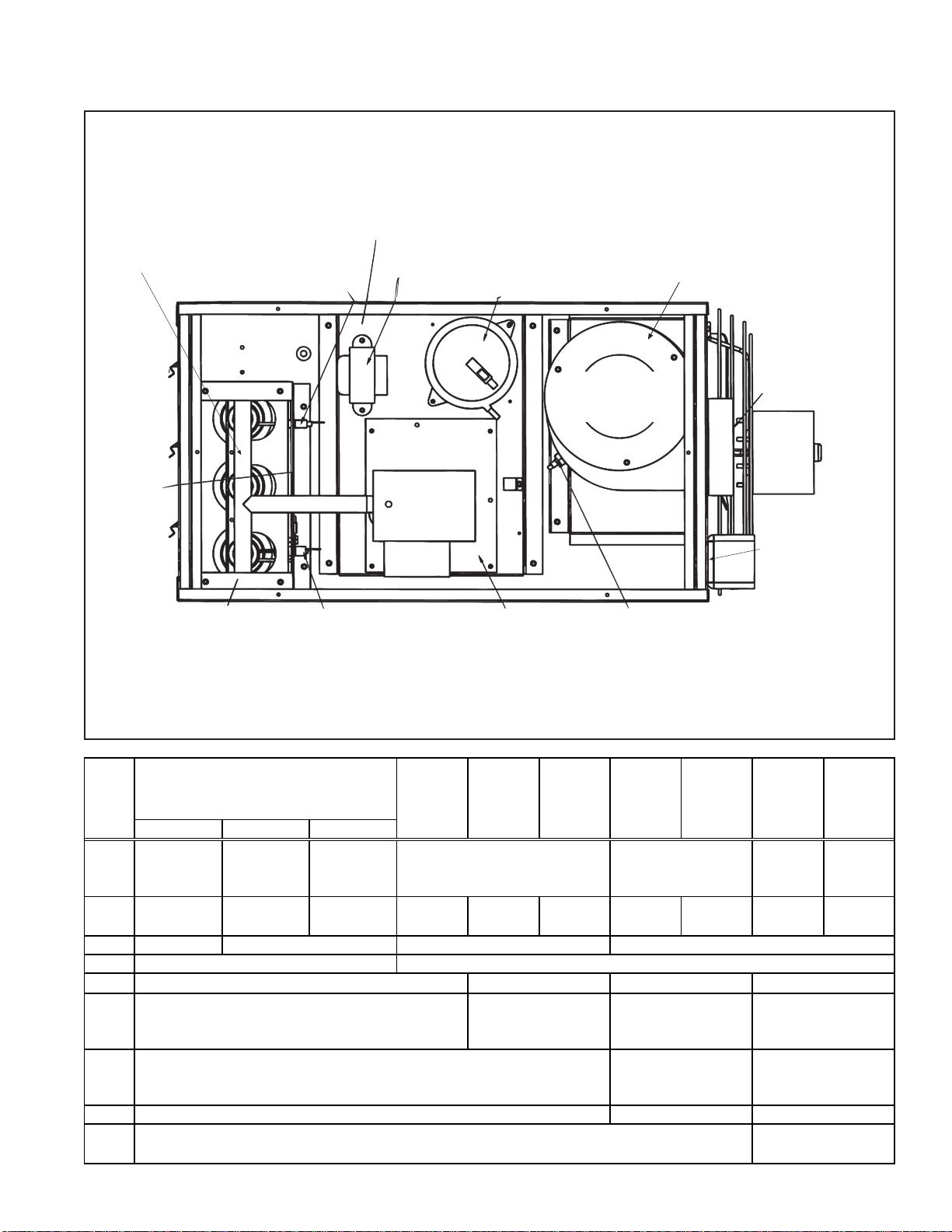

Model FT

-

)

Control Compartment and Electrical Components - see P/N listings, pages 2-5

Model FT Control Compartment (A Size 30 is illustrated; locations are approximately the same for

other sizes but may appear out of proportion.)

11 - Limit Control Sizes 30-75 (Located

in the heat exchanger

compartment; remove

louvers to access.)

8 - Flame Sensor

11 - Lmit Control - Sizes 100-300

12 - Transformer

14 Pressure Switch

1 - Venter Housing

4, 5, 6 -

Venter Motor

Flue Outlet

& Wheel Assy

18 Fan

Motor

17 -

Flame

Rollout

10 - Gas

Valve

Switch -

Sizes

30-60

16 - Auxiliary

Limit - Sizes

250-300 only

(remove fan

Burner/Manifold

Assembly

9 - Spark

Electrode

with Ignition

13 - Circuit Board

(Ignition Module)

3 - Static

Pressure Tap

guard to access)

Cable

NOTE: If the heater has been changed so that the controls are on the left side, their locations will appear inverted. On Sizes 60-300,

the ignitor must still be toward the bottom of the heater with the flame sensor toward the top.

Code

1A

1B

For heaters

beginning approx 11/97* - verify on rating

30 45 60

164689

(replaces

158435)

176809 176309 -- -- -- -- -- -- -- --

residential app roval (mfgd

WITH

plate

164690

(replaces

158436)

164691

(replaces

158448)

147357

147657

200

250 30075 100 125 150

149164 149165

2

3

*4

*4A

*4B

*4C

*4D

147793

P/N 116043 is p art of Vntr Housing, Code 1A

Magnetek #JA1M213N (replaces P/N 97738, Magnet ek

continued on the next page

#JA1M156N)

Revcor B506-1005 Brookside #FE-400- 200

14779344695

116043

148056

Magnetek #JA1M213N Includes P/N 148053,

135979 97724

135981

68005

148057

**148980148055 148055

Magnetek #JE1E024N

2

97301 164380

97300

149160147359

150771

Magnetek #JE1F022

135980

Brookside #FE610-200-

1

141570 (replaces 68005

on 250/300)

Form RZ-NA-P-FT/SFT, Page 3

Page 4

Model FT Electrical Components (cont'd) - Refer to the illustration on page 3

)

P

Fo r heaters mfgd

residential approv al (approx.

Code

5

Venter Mtr & Wheel Assy (includes Codes 5A-5G) - Size

30 or 45 heater with suffix CV (O ption AV6) only

Vent er Motor 1 -- -- -- --

5A

Venter Wheel 1 -- -- -- --

5B

Venter Motor Plate 1 -- -- -- --

5C

Vent er Motor Plate Gasket 1 -- -- -- --

5D

Secondary M otor Plat e 1 -- -- -- --

5E

Spacers 4 -- -- -- --

5F

Venter Fan Blade 1 -- -- -- --

5G

Vntr Mtr & Wheel Assy (includes Codes 6A-6G) - Size 45

6

heater with suffix LN (Option AL 2B) only

Venter Motor 1 -- -- -- -- 175987 --

6A

Venter Wheel 1 -- -- -- -- 135979 --

6B

Vent er Motor Plate 1 -- -- -- -- 176311 --

6C

Vent er Motor Plate Gasket 1 -- -- -- -- 155651 --

6D

Isolator, rubbe r w/brass insert 4 -- -- -- -- 113498 --

6E

Isolator Plate 1 -- -- -- 176310 --

6F

Venter Fan Blade 1 -- -- -- -- 68005 --

6G

Vntr Inlet Ring - Size 45 with suffix CV or LN only

7

Flame Sensor, Channel Products #1259-85 1

8

Sp ark Ignitor with Cable - applies only to heaters with

9A

Johnson Controls G861 Ignition Control Board, P/N 174260

(Code 13)

Spark Ignitor 1

9B

Ignition Cable 1

Gas Valve Natural 1

10

Identify the valve on the

NOTE:

heater by manuf acturer's no. and the

Serial No. code on page 2.

Limit Control, Thermodisc #36T 1

11

(access by removing louvers)

Transformer, 30 VA, #4000-01M04BB80 1

12

Ignition Contr ol Board , J/C G861 1

13

Pressure Switch - applies to

14A

standard heater (for Size 30 or 45

with suffix CV or LN, see Code 14B

Pressure Switch - applies to Sizes

14B

30 and 45 with Suffix CV or LN only

Silicone Rubber Tubing for Pressure 1 147905 147905

15

Sensing (not illustrated) 7 " long 9" lg 7 " lon g 9" long

Au xiliary Limit Control (remove fan guard to acces s) 1 -- -- -- -- -- --

16

Flame Rollout Switch (manual reset) Std FT & suffix CV 1 -- -- -- 121275, 275°F 112752, 225°F 121275, 275°F

17

Fan Moto r - See Code 39C for standard Model FT or Model FT with suffix CV; see Code 40C for Model FT with suffix LN

18

Outlet Box , 2x4, Steel City #58361 1 -- -- 17782 -- -- --

19

Outlet Box Cover 1 -- -- 17 800 -- -- --

20

Form RZ-NA-P-FT/SFT, Page 4

Description (cont'd)

Apply to Model FT

with s uffix CV

(Option AV6)

Apply to Model FT

with s uffix LN

(Option AL2B)

use w/RAM 3MC4

ignition cntrl board

Propane 1

up to 4000 ft 1 164672

4001-9000 ft 164674

up to 4000 ft 1 -- -- -- --

4001-9000 ft -- -- -- --

Model FT45-LN only -- -- -- -- 121275, 275°F --

Qty

11/97*- ver ify on rating plate)

30 45 60 30 45 60

1-- -- -- --

1 -- -- -- -- 176329 --

1-- -- -- -- 62594 --

1

172552, M/H VR8105M2187

Gas

Gas

(replaces 147133, Robertshaw #7222 DER; field-supplied pip ing is r equired)

172553, M/H VR8105M2825

(replaces 147134 , Rober ts haw #7222 DERLP; field- supplied piping is required)

174260 (replaces P/N 147102 and may be used with either Code 9 A or 9B; if

TDI #PPS10027-2228

TDI #PPS10027-2355

147904 147904

RIOR TO

147165

159956 (assembly replaces both 147166 and 14 7167)

147166

147167

45602

180°F

147356

replacing board and ignitor, order Code 9A)

148072

149879

Fo r heaters

approx. 11/97* - verify on rating plate)

Magnetek #JA2N297

Revc o r B5 06 -1005

TDI #PPS10027-

2731 (replaces

159180)

TDI #PPS10027-

2733 (replaces

159181

TD I #PPS10027-2731

TD I #PPS10027-2733

residential approv al (beginning

WITH

177148

175987

135979

176311

155651

176810

98872

68005

Magnetek

#JA2N297

Revcor B506-

1005

147165

147166

147167

172552, M/H VR8105M2187

172553, M/H VR8105M2825

45602

180°F

147356

164673, TDI #PPS10027-2732

(replaces

148072)

164675, TDI #PPS10 027-2734

(replaces

148072)

164672

164674

(replaces

149879)

(replaces

159179)

Page 5

Code

75 100 125 150 200 250 300

5A

5B

5C

5D

5E

5F

5G

6A

6B

6C

6D

6E

6F

6G

9A

5

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

6

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

-- -- -- -- -- -- --

7

8

159 956 (assembly replaces both 147166 and 147167)

-- -- -- -- -- -- -147165

159957 (assembly replaces both 147166

and 148085)

9B

147167

10

172552, M/H VR8105M2187

(replaces 147133, Robertshaw #7222 DER; field-supplied piping is required) M/H #VR8305- M 4009

172553, M/H VR8105M2825

(replaces 147134, Robertshaw #7222 DERLP; field-s upplied piping is required) M/H #VR8305M 4017

11

45602

147166

147830 150839

M/H #VR8205M1130

147560

M/H #VR8205M1148

155764 (r ep laces 96512)

148085

155 765 (r ep laces (85449)

180°F 220°F, Blue Dot 200°F, Yellow Dot

12

13

14A

174260 (replaces P/N 147102 and may be used w i th either Code 9A or 9B; if repl acing board and ignitor, order Code 9A)

148072 150837

147356

TDI #PPS10027-2228 TDI # PPS10027-2392

149879 151372

14B

TDI #PPS10027-2355

-- -- -- -- -- -- --

TDI # PPS10027-2406

-- -- -- -- -- -- --

15

147905

148251

9" long 12" long

16

17

-- -- -- -- --

-- -- -- -- -- -- --

100799, 150°F

150840

18

19

20

-- -- -- -- --

-- -- -- -- --

17782

17800

Form RZ-NA-P-FT/SFT, Page 5

Page 6

Model FT -

P

Cabinet and

Heat Exchanger

Parts

30A

Code

55

36

35

35

34

52

51

50

49

31

31

41

44

32

Location of

37

Code 16 on

Sizes 250 and 300

38 (Mount only;

does not include

fan guard)

Fan Sizes

150-300

39, 40

Fan Sizes

30-125

Vent

Cap

*Item 49 - Limit control location shown is for

33

30B

Sizes 100-300. On Sizes 30-75, the limit control

is located between the first and second heat

exchanger tube and is accessible from the heat

exchanger compartment.

For heaters mfgd

residential approval

C

Descri ption

o

d

e

Top Outer Mfgd after 3/99 1 147225

30A

Panel Mfgd before 3/99 1 175833

Bottom Outer Mfgd after 3/99 1 147226

30B

Panel Mfgd before 3/99 1 175834

Top/Bot tom Retainer Panel 2 147223 -- --

31A

Small Top/Btm Retainer Panel 2 -- -- -- -- -- -- -- -- -- -- --

31B

Large Top/Btm Retainer Panel 2 -- -- -- -- -- -- -- -- -- -- --

31C

Left Side Panel Assembly (Outer

32

Panel & Retainer)

Access Panel 1 147116 147116 147116

33

Right Front Mfgd after 3/99 1 -- -- -- 147113 147837 147114 147838

34

Panel M fgd before 3/99 1 175829 175830 175835 175829 175830 175835 175836

Top/Bot tom Front Panels 2 -- -- -- -- -- -- -- 147847 146476 147848 146477 150992 148682

35

Louver

36

Assembly

Fan Back M fgd after 3/99 1 -- 158734 147586

37

Mfgd before 3/99 1 175831 175831 175832

Fan Guard M ount Assembly

38

Form RZ-NA-P-FT/SFT, Page 6

TO

(approx. 11/97*- verify

Q

on rating plate)

t

y

30 45 60 30 45 60

147105

175827

147106

175828

147155

1 147575

147574

147115 147115 146490

1 147427 147850 131803

147426 147426 147427 94865

-- 147108

175826 175826

1-------- -- --------

RIOR

For heaters

residential approval (mfgd

beginning approx. 11/97* -

verify on rating plate)

147105

175827

147106

175828

147155

147574

WITH

147225

175833

147226

175834

147223 146615

75 100 125 150 200 250 300

146455

146455 148680

147816147575

146479

146492

148924

147158

147835 150990

148680

148591

148616

150977147817

148681146493

151595

148685

Page 7

C

o

d

e

39

39A

39B

39C

40

40A

40B

40C

41A

41B

42

43

44

45

46

47

49

50

51

51A

51B

51C

52

53

54

55

Description

(includes Codes 39A-39C) -

applies to standard Model FT

and Model FT with CV suffix

(for heater with LN suffix, see

Code 40)

Fan Guard 1 151992

Fan Blade - applies to

standard FT or Model Ft with

CV suffix (for heater with LN

suffix, see Code 40B)

Fan Motor - applies to

standard FT or Model Ft with

CV suffix (for heater with LN

suffix, see Code 40C)

Fan, Fan Guard, and Mt r

Assy (includes Codes 40A40C) - applies to Model FT

with LN suffix only

Fan Guard 1 -- -- -- -- 151991 -- -- -- -- -- -- -- -Fan Blade - applies to Model

FT with LN suffix only

Fan Motor - applies to Model

FT with LN suffix only

Flue Wrapper Assy -

standard Model FT and

Model FT with suffix LN (for

Size 30 and 45 with CV suffix,

see 41B)

Flue Wrapper Assy - applies

to heaters with CV suffix only

Top/Btm Flue Gasket 2 147395

Side Flue Gasket 2 147227 147228 147229 147227 147228 147882 147652 147855 147653 147855 147653

Heat Ex changer/Turbulator/

Inner Panel Assy

Mid-Tube

Support (heat

exchanger)

Mid-Tube

Support Bracket

Tube Clamp 1 -- -- -- -- -- -- -- -- -- -- -Limit Control Bracket 1 -- -- -- -- -- -- -- -Burner Box 1 147057 147058 147063 158441 158424 158425 147064

Burner Rack Assy (includes

51A, 51B, and 51C)

Burner

Not

illustrated see SFT

illustration

on page 10.

Burner Support Slot 1 147566 147567 147568 147566 147567 147568 147569

Burner Clamp 1 150184 105185 150153 150184 105185 150153 149595

Manifold (less orifices) 1 147003 147004 147136 147003 156094 156095 156096 151785 151786 151787 151788 151787 151788

Burner Orifices - See Table on page 12.

Hanger Angle Sub-Assembly2-- -- -- -- -- -----------Vent Cap (S ame as Option

CC1)

For heaters mfgd PRIOR TO

residential approval (approx.

Q

11/97*- verify on r ating plate)

t

y

30 45 60 30 45 60

1 147181 147182 147183 147181 147182

151991 (replaces

147185

1 125566

Revcor #01005-34

1 147103 147104 150332 147103 147104

Magnetek

1 -- -- -- -- 176490 -- -- -- -- -- -- -- --

1 -- -- -- -- 129853,

1 -- -- -- -- 175988,

1 147444 147445 147446 158433 158434 158442 147447 147911 147649 147880 147650 150995 150996

1 -- -- -- 176817 158434 -- -- -- -- -- -- -- --

1 148067 148068 148069 148067 148068 148069 148070 157939 157940 157941 157942 157943 157944

1-- -- -- -- -- ------------

2------------------

1 147577 147578 147579 147577 147578 147579 147580 147822 147823 147824 147825 150783 150784

Qty > (2) (3) (4) (2) (3) (4) (5) (5) (6) (8) (10) (8) (10)

1 111850

Magnetek

#JA2N

#JA2R

147394 147394 147395 147651

147132

Beckett #X783

111848 111848 111849

(rep laces

147157)

F07H07

15.75-31

1/20HP

(rep laces

4" diameter

For heaters WITH residential

approval (mfgd beginning

approx. 11/97* - verify on

151991 (replaces

147185

129853 125566

Lau

Revcor #01005-34 Lau #610257-01 Revcor T2004-33Lau Y10S08A

Magnetek

Smith

#F42A

53A13,

95547)

#JA2N

rating plate)

Magnetek

#JA2R

#01005-

34

Magnetek

2E3C002

75 100 125 150 200 250 300

147183 147672 147673Fan, Fan Guard & Mtr Assy

151992

(replaces

147157)

Lau F07H07

15.75-31

150332 147908

A. O. Smith

#F42A53A13,

1/20HP

(replaces 95547)

-- -- -- -- -- -- -- --

-- -- -- -- -- -- -- --

147230

147221

Beckett #X783

136949, 18"

round (replaces

45616)

141598129853

A. O. Smith

#F42C81A13,

1/6HP

146473 146474

147132 150836

104818, 20" square, flat

150155 150838

147913

A. O. Smi th

#F48H01A13,

1/4HP

155264

HE4T005, 1/2HP

148619

Beckett #10924X

146482 146484

146481 146483

4" diameter 5" diameter 6" dia

* 11/97 is Serial No. Date Code AWK (see page 1); but always verify actual typ e of approval stated on the rating plate before selecting replacement parts.

150997

2436

156275

Magnetek

(rep laces

100589)

148618

148684

150991

Form RZ-NA-P-FT/SFT, Page 7

Page 8

Model SFT - Electrical and Burner Box Components

Control

Compartment Model SFT

68 - Limit Control - Sizes

100-300 (located in heat

exchanger compartment)

65 -Flame Sensor

Combustion Air Collar

(flex hose removed for clarity)

72 Transformer

70 - Pressure

Switch

60 - Venter Housing/

63 - Venter Motor and

Wheel Assembly

Venter Outlet

(Flue) Collar

71 - Flame Rollout

Switch - Sizes 45-75

(located on the burner

box cover behind

the collar; disconnect

hose to access)

74 Fan

68 - Limit Control

Location - Sizes 45-75

(located in heat

67 - Gas

Valve

Motor

exchanger compartment;

remove louvers to access)

Burner/Manifold

Assembly (see page 9)

66 - Ignitor

Code Qty 45 60 75 100 125 150 200 250 300

Venter Housing Assembly 1 156854 156856 157289

60

Venter Gasket (not illustrated) 1 147793

61

Flow Sensing Probe Assy (not illustrated) 1

62

Venter Motor & Wheel Assy (includes Codes 1 156472

63

63A-63H) Venter Motor 1

63A

Capacitor, 4MFD @ 370V 1 - - - -

63B

Capacitor Boot 1 - - - -

63C

Venter Wheel 1 135979

63D

Venter M otor Plate

63E

Venter Fan Blade 1

63F

Spiral Spacer 4

63G

Nut #8- 3 2 4

63H

Venter Motor Plate Gasket 1 155651

64

Flame Sensor - Channel #1259-85 1

65

Spark Ignitor with Cable - applies only to heaters

66A

with Johnson Controls G861 Ignition Control

Board, P/N 174260 (Code 69)

Spark Ignitor 1

66B

Ignition Cable 1

Gas Valve Natural Gas 1

67

NOTE: Identify the valve on the

heater by the manufacturer's no. and

the Serial No. code on page 1.

Limit Control & Bracket Assy (includes 68A) 1

68

Snap Disk Limit Control 1

68A

Ig nition Control Board, J/C G861 1

69

Form RZ-NA-P-FT/SFT, Page 8

Description

Code 64 required with 63)

(Code 64 required with 63E)

RAM 3MC4

control board

Revcor

B506-

1 135981

1

use with

ignition

(repla ces 147133, Robertshaw #7222DER; field-

Propane Gas 1

(repla ces 147134, Robertshaw #7222DERLP;

174260 (replaces P/N 147102 and may be used with either Code 66A or 66B; if replacing

69 - Ignition

Control Module

148980 150771

Includes motor P/N 148053, Magnetek

#JE1E024N, and Codes 63B & 63C

163894

103182

Brookside #FE610-119-1

68005, 2.25" dia, 5/16" bore 141570, 2.25" dia., 3/8" bore

97722 - #8 x 15/16" long 97721 - #8 x 3/4" l ong

159956 (assembly replaces both 147166 and

147167)

147167 148085

172552, M/H

#VR8105M2187

supplied piping is required)

172553, M/H

#VR8105M2825

field-sup plied piping is required)

155985 147670 151516

45602 - 180°F 155764 - 220°F 155765 - 200°F

TOD 60T11-201614 TOD 36TV21-13878

73 Terminal

Block

156855 156857

155650 155649

155980 155981

155271 135980

147830, M/H

#VR8205M1130

147560, M/H

#VR8205M1148

board and ignitor, order Code 66A)

Flow Sensor (for

tubing connection

to the pressure switch)

148978

Magnetek #JE1F022N

Brookside #FE610-200-3

151515

31522

155652

147165

159957 (assembly replaces both 147166

147166

147830, M/H

#VR8205M1130

147560, M/H

#VR8205M1148

Inlet

Collar

and 148085)

150839, M/H

#VR8305M4009

150840, M/H

#VR8305M4017

TOD 36TV21-13879

Page 9

Code Qty 45 60 75 100 125 150 200 25 0 300

)

(rep

)

)

Pressure Switch, T DI #FS6210A 1

70A

High Altitude Pressure Switch (above 4000 ft) 1

70B

71

Flame Rollout Swit ch, T OD #36T26-662, 180

Transformer, 30VA, Products 4000-01-M04BB80 1

72

Terminal Board , Dor an 1

73

Fan Motor - See Code 113C

74

T u bing from pressu re switch to pressure tap 1

75

Tubing from pressure switch to probe 1 133117 - 11" 155377 - 15"

76

Description

173312, -0.60 w.c. (replaces

173316, -0.55 w.c. (r ep laces

o

1 - - ----

F

156302

157278)

157282

174399 - 13" 151564 - 17"

173311, -0.40 w.c.

laces 1563 01

173315, -0.35 w.c.

(replaces 157277 )

147356

151600

173313, -0.65 w.c. (replaces

156303

173312, -0.60 w.c. (replaces

156302)

Burner Box

Components -

87 - Burner Rack Assembly

Model SFT

To remove the burner rack/manifold

assembly, lift up and then pull out.

1/4-20

Hex Nut

Gas

Valve

80 - Burner

Box Cover

86 - Static

Pressure Tap

84 -

Manifold

Cover

Plate

Locating

Burner Box

Assembly

Pins (hidden)

85 - Manifold

Seal Plate

Code Description Qty 45 60 75 100 125 150 200 250 300

Burner Box Cover Assy (includes flue col lar) 1 157286 157287 157288

80

Neoprene Gas kets Side 1 155607 155606 156605

81

inside Burner Box T op/Bt m 2

82

(not illustrated) Middle 1 155612 155611 155610

83

Manifold Cover Plate 1

84

Manifold Cover Plate Gasket (not illus trated) 1

84A

Manifo ld Seal Plate 1

85

Static Pressure Tap, TD #AA3743 (on Code 80) 1

86

Burner Rack Assy (located behind Code 80) 1 155851 155852 155853 155855 155856 160506 160507 155858 155859

87

155340 151828 155340

157008 157007 157008

156029 156030

155608 155609

155617 155618155615 155616

155613 155614

157162

116043

(Includes Codes 87A, 87B, 87C - not illustrated)

87A

Burner

Qty

(3) (4) (5) (5) (6) (8) (10) (8) (10)

→

147132 150836

Beckett #X783 Beckett #10924X

Burner S upport Slot 1 150187 150154 149596

87B

Burner Clamp 1 150185 150153 149595

87C

Igniter/F lame Sensor Cover with Viewports 1 156018 156019 156020 156011 156021 156022 156023 156024 156025

88

Manifold (less orifices) - behind Code 80 1 156094 156095 156096 151785 151786 151787 151788 151787 151788

89

Burner Orifices - See Table on page 10.

90

Fiberglass Gaskets for between Burner Box Sides 2 155619 155620 155621

91

146482 146484

146481 146483

155622 155623

& Heat Exchanger Assy Panel (not illustrated)

Fiberglass Gaskets fo r betwe en Burner Box Top & 2

92

155624 155625

Btm & Heat Exchanger Assy Panel (not illustrated)

Flexible Combustion Air Hose - 18" long 1 155408

93

155409 155410 155411

(not illustrated) 3" dia.

Worm Clamp s for Code 93 (not illustrated) 2 155319

94

120716 155320 155321

Form RZ-NA-P-FT/SFT, Page 9

156031

6" diameter4" diameter 5" diameter

Page 10

Model SFT Cabinet

and Heat Exchanger

Parts

106

105

100

107

Inner Panel/Heat

Exchanger Assy

102A

102B

102C

120

119

123

Heat Exchanger

Support/Hanger

Bracket Assembly

120

103

NOTES: The fan and motor

assembly is not exploded;

the fan guard mount (Code

112) is not part of the

assembly identified as Code

113. Turbulators (Code

118) slide into the heat

exchanger tubes as illustrated. The heat exchanger

support/hanger bracket

assembly is shown here as a

subassembly . Parts are

identified separately (Codes

119, 120, 123 and 102D).

102D

Burner

Box

Assembly

102A

104

114

Venter Motor and

Wheel Assembly

Code Qty 45 60 75 100 125 150 200 250 300

Top Outer Units mfgd beginning 10/00 1 147105

100

Panel Units mfgd prior to 10/00 1 155286

Bottom Outer Units mfgd beginning 10/00 1 1471 06

101

Panel Units mfgd prior to 10/00 1 155287

Top/Bottom Retainer Panel 2 147155 - -

102A

Large Top/Bottom Retainer Panel 2 - ------

102B

Small Top/Bottom Retainer Panel 2 - ------

102C

Bott om Support (Hanger) Angle 1 - - - - - - -

102D

Left Side Panel Assy (Outer Panel, Air

103

Deflector, and Retainer)

Access Panel Units mfgd beginn ing 10/00 1 1 47115

104

Hin ged Door

Assembly

Right Front Units mfgd beginning 10/00 1 147837 147114 147838

105

Panel Units mfgd prior to 10/00 1 155283

Top/Bottom Front Panel 2 - - - 147847 146476 147848 146477 150992 148682

106

Louver Units mfgd beginning 10/00 1

107

Assembly Units mfgd prior to 10/00 1

Fan Back Assy Units mfgd beginning 10/00 1 156246 156005 156006

108

(includes collar) Units mfgd prior to 10/00 1 178422 178430 178431

Fan Guard Mount Assem bly 1 - - - - -

112

Fan, Fan Guard & Mtr A ssy (113A-C) 1 147182

113

Fan Guard 1 151991, 10"

113A

Fan Blade 1 129853

113B

Form RZ-NA-P-FT/SFT, Page 10

Description

Units mfgd prior to 10/00,

Includes Latch,

P/N 156245

102B

101

1 157010

1 178422 178430 178431

147426 147850

Revcor #01005-

34

102C

108

112

147225

151832

147226 146455 148680

151833

147223

157011

147116

178423 178428 178429

151829

156082

147427

156247 156003 156004

178423 178428 178429

147183 147672 147673 150997

151992, 16" 136949, 18" 104818, 20" square, flat

125566 141598 150155 150838

Lau F07H07

15.75-31

157013 157014 150977

146490

146492

155095

131803

Lau #610257-01

Sizes

45-125

113

Sizes

150-300

146455 148680

151760 155128

155339155289

146615

148616

148591

148617

146479

146493 148681

151761 155275

94865

147835 157912

Revcor #T2004-33Lau Y10S08A

151595

2436

Page 11

Code Qty 45 60 75 100 125 150 200 250 300

Fan Motor 1 147104

113C

Flue Wrapper Assembly 1 156840 156841 156843 156845 156847 156849 156851 156852 156853

114

Top/Bottom Flue Wrapper

115

Gasket

Si de Flue Wrapper Gasket 2 147228 147229 147230 147882 147652 147855 147653 147855 147653

116

Heat Exchanger/Inner Panel Assembly 1 157936 157937 157938 157939 157940 157941 157942 157943 157944

117

Turbulators (Size 45, 60 & 75

118

turbulator are "square" assemblies) Qty

Mid-Tube Support (heat exchanger) 1 - - - - - - -

119

Mid-Tube Support Bracket 2 - - - - -

120

Tube Clamp 1 - 155388 155108 - - - -

121

Tube Clamp Bracket 2 - 155348 155101 - - - -

122

Hanger Angle Sub-Assem b ly 2 - - - - - - -

123

Description

(not

illustrated)

(not

illustrated)

150332 147908 147913

Magnetek

#JA2R

2 147394 147395 147395 147651 147651 147651 147651 147651 147651

(3) (4) (5) (5) (6) (8) (10) (8) (10)

>

A. O. Smith

#B42A53A13,

1/20HP

155090 146452

A. O. Smith

#F42C81A13,

1/6HP

A. O. Smith

#F48H01A13,

1/4HP

148619

155264

-

156275

1/2HP, Mag netek

HE45005

(replaces 100589)

148618

150991

Model SFT Separated-Combustion Venting and Combustion Air System Parts

Codes 130A

and 131A Concentric

Adapter Box

Assembly

Collar for

attaching the

combustion air

pipe from the

heater

Code 130B - Exhaust

T erminal (V er tical

Kit)

View of Heater Connection

Side

Opening for vent pipe

from the heater. Seal

with rubber gasket.

The vent pipe extends

through the box.

Code 130C -

Combustion Air

Inlet (V ertical

Kit)

(NOTE: Concentric adapter boxes manufactured prior to 2/01 had a collar on the "heater

connection side" to attach the vent pipe. There was a factory-installed length of vent pipe

through the box. If replacing a concentric adapter box manufactured prior to 2/01, the fieldsupplied vent pipe must be extended through the new box. Code 130E or 131F, rubber

gasket, is required to seal the opening around the vent pipe as it extends into the box.

View of Vent Terminal Connection Side

Collar for attaching the outside portion

of the combustion air pipe (the vent

pipe runs concentric through the

outside portion of the combustion air

pipe)

Code 131B - Screened

Exhaust Assembly

(Horizontal Kit)

Code 131C -

Inlet Guard

(Horizontal

Kit)

Code 130 - Vertical Vent Terminal/Combustion Air

Package (Option CC2) includes:

Code Qty SFT P/N Description

1 45-125

130

150-250

300

130A 1 45-125 155118

150-250 155392

300 68404

130B 1 45-250 155631, 4" Exhaust Terminal Cap

300 53326, 5"

130C 1 45-250 155635, 6" Combustion Air Inlet

300 53330, 8"

130D 1 45-300 53335 3 oz Tube of High

130E 1 45-250 164492, 4"

300 164493, 5"

157155

157156

54444

Comp lete Vertical Vent

Kit (Same as Option

CC2)

Concentric Adapter Box

Assembly

Temperature (450°F)

Silicone Sealant

Rubber Seal (blue) for

Exhaust Pipe

Code 131 - Horizontal Vent Terminal/Combustion Air

Package (Option CC6) includes:

Code Qty SFT P/N Description

131 1 45-125

150-250

300

131A 1 45-125 155118

150-250 155392

300 68404

131B 1 45-250 155096, 4"

300 53316, 5"

131C 1 45-250 151755, 6" Inlet Guard

300 124940, 8"

131D 4 45-300 376 61 #10-16 x 1/2" Screws (for

131E 1 45-300 53335 Tube of High Temperature

131F 1 45-250 164492, 4"

300 164493, 5"

157157

157158

82131

Complete Horizontal Vent

Kit (Same as Option CC6)

Concentric Adapter Box

Assembly

Screened Exhaust

Assembly

at tachin g inlet guard)

Silicone R ubber Sealant

Rubber Seal (blue) for

Exhaust Pipe

Form RZ-NA-P-FT/SFT, Page 11

Page 12

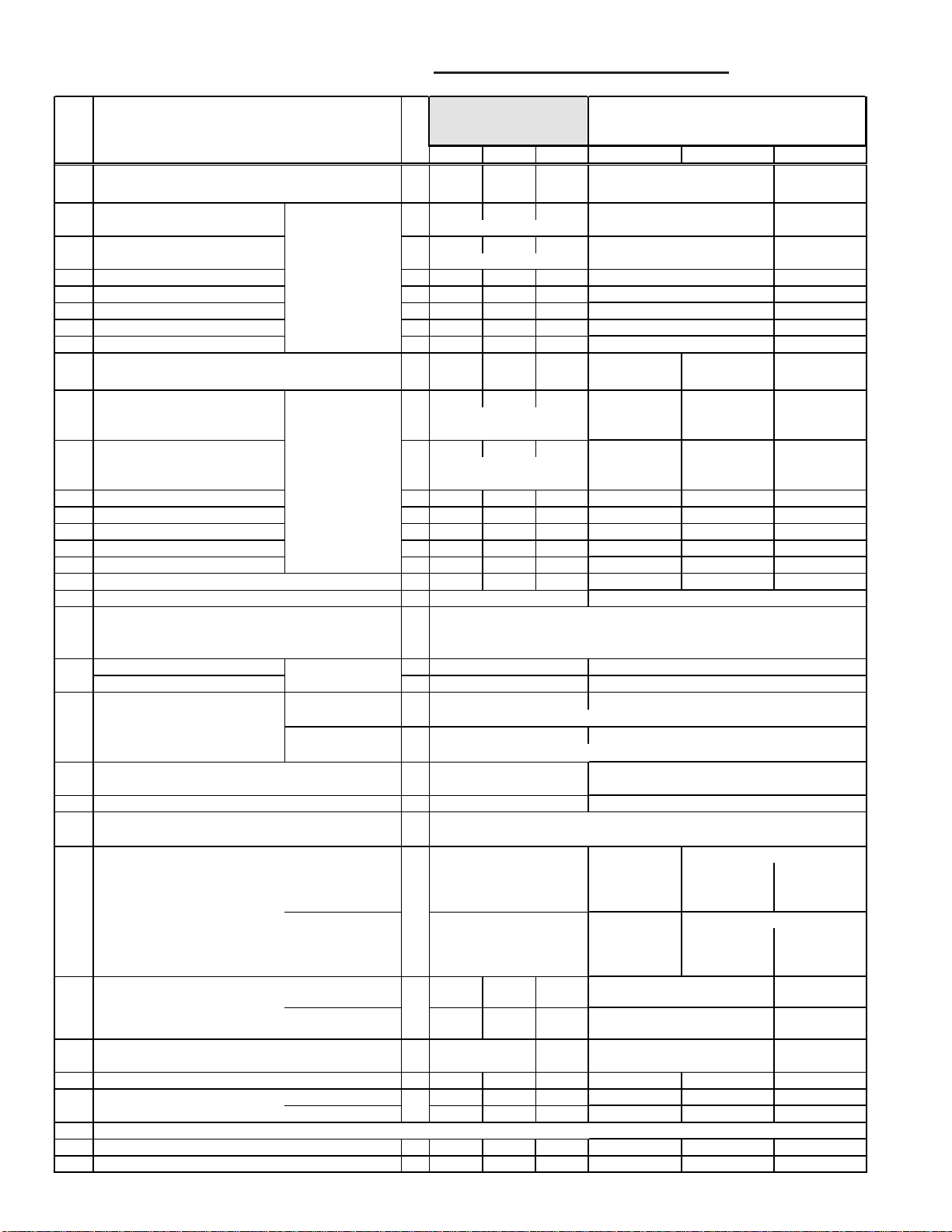

Burner Orifice Chart - Models FT and SFT

IMPORTANT NOTE: If the manifold pressure has been adjusted at the valve for high altitude operation, the standard sea level burner orifices

apply. The high altitude orifices in the table apply only to units purchased with a factory installed high altitude option. Check the rating plate to

determine at what altitude the unit was manufactured to operate.

Models FT an d SF T 30 45 60 75 100 125 150 200 250 300

BURNE R ORIFICES

Natural Gas, 0-2000 ft,

installed in U.S. or Canada Size

Propane Gas, 0-2000 ft,

installed in U.S. or Canada Size

Installed Natural 2001in Canada Gas 4500 Size

Propane ft

Gas Size

Installed Natural 2001in U.S. Gas 3000 Size

Propane ft

Gas Size

Natural 3001-

Gas 4000 Size

Propane ft

Gas Size

Natural 4001-

Gas 5000 Size

Propane ft

Gas Size

Natural 5001-

Gas 6000 Size

Propane ft

Gas Size

Natural 6001-

Gas 7000 Size

Propane ft

Gas Size

Natural 7001-

Gas 8000 Size

Propane ft

Gas Size

Natural 8001-

Gas 9000 Size

Propane ft

Gas Size

Quantity 234556810810

40414 40414 40414 40414 11833 11833 38678 11833 97362 97362

P/N

#48 #48 #48 #48 #4 4 #44 #45 # 44 #36 #36

63922 63922 63922 63922 11830 11830 64676 11830 96344 51284

P/N

1.15mm 1.15mm 1.15mm 1 .15mm #55 #55 1.3mm #55 1.65mm #52

39651 39651 39651 39651 38678 38678 84853 38678 45870 45870

P/N

#49 #49 #49 #49 #4 5 #45 #47 # 45 #38 #38

39659 39659 39659 39659 11830 11830 97359 11830 61653 9789

P/N

#58 #58 #58 #58 #5 5 #55 1.25mm #55 1.55mm #53

39651 39651 39651 39651 38678 38678 16590 38678 11835 11835

P/N

#49 #49 #49 #49 #4 5 #45 #46 # 45 #37 #37

63922 63922 63922 63922 11830 11830 97359 11830 51284 51284

P/N

1.15mm 1.15mm 1.15mm 1.15mm #55 #55 1.25mm #55 #52 #52

39651 39651 39651 39651 38678 38678 84853 38678 45870 45870

P/N

#49 #49 #49 #49 #4 5 #45 #47 # 45 #38 #38

63922 63922 63922 63922 11830 11830 97359 11830 61653 9789

P/N

1.15mm 1.15mm 1.15mm 1.15mm #55 # 55 1.25mm #55 1.55mm #53

39651 39651 39651 39651 38678 38678 84853 38678 45870 45870

P/N

#49 #49 #49 #49 #4 5 #45 #47 # 45 #38 #38

39659 39659 39659 39659 11830 11830 97359 11830 61653 9789

P/N

#58 #58 #58 #58 #5 5 #55 1.25mm #55 1.55mm #53

39652 39652 39652 39652 16590 16590 84853 16590 45871 45871

P/N

#50 #50 #50 #50 #4 6 #46 #47 # 46 #39 #39

39659 39659 39659 39659 39658 39658 63003 39658 9789 9789

P/N

#58 #58 #58 #58 #5 6 #56 1.2mm #56 #5 3 #53

39652 39652 39652 39652 84853 84853 40414 84853 87391 87391

P/N

#50 #50 #50 #50 #4 7 #47 #48 # 47 #40 #40

39659 39659 39659 39659 39658 39658 63003 39658 9789 9789

P/N

#58 #58 #58 #58 #5 6 #56 1.2mm #56 #5 3 #53

39652 39652 39652 39652 84853 84853 40414 84853 11792 11792

P/N

#50 #50 #50 #50 #4 7 #47 #48 # 47 #41 #41

95936 95936 95936 95936 39658 39658 63922 39658 9789 9789

P/N

#60 #60 #60 #60 #5 6 #56 1.15mm #56 #53 #53

39650 39650 39650 39650 40414 40414 39656 40414 11792 11792

P/N

#51 #51 #51 #51 #4 8 #48 #49 # 48 #41 #41

95936 95936 95936 95936 39658 39658 63922 39658 61652 11834

P/N

#60 #60 #60 #60 #5 6 #56 1.15mm #56 1.45mm #54

Gas Conversion Kits - Models FT and SFT

NOTE: Gas Conversion include standard burner orifices.

Model FT or SFT 30, 45, 60, 75 100, 125, 200 150 250 300

Natural to Propane Kit 179315 179317 179318 179327 179328

Propane to Natural Kit 179316 179319 179320 151180

Form RZ-NA-P-FT/SFT, Page 12

Page 13

Optional Vertical Louvers - Models FT and SFT

V ertical louvers are designed to direct the dischar ge air to provide a wider throw pattern. These vertical louver option packages apply to models and

sizes as listed in the table below.

The vertical louver option packages include:

Model FT and SFT FT SFT FT and SFT

Size 30 & 45 60 & 75 60 & 75 100 125 15 0 200 250 3 0 0

Option Package P/N 160850 160818 160819 160820 160821 160822 160823 160824 160825

Components: (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N

Vertical Louver Top (2) 159443 (2) 159443 (2) 159443 (2) 159444 (2) 160889 (2) 160889 (2) 160889 (2) 160890 (2) 160890

/Bottom Member

Vertical Louver (4) 160500 (4) 160504 (4) 160501 (6) 160501 (6) 160502 (6) 160503 (6) 160505 (10) 160503 (10) 160505

#10-16 x 1/2" lg screw (32) 149563 (32) 149563 (32) 149563 (32) 149563 (32) 149563 (32) 149563 (32) 149563 (32) 149563 (32) 149563

Vertical Louvers

Top Member

Sheetmetal

Screws

Vertical Louver

(left side)

Bottom Member

Sheetmetal

Screws

Vertical Louver

(right side)

NOTE: Do not use vertical louvers above with downturn nozzle Option CD3 on

page 14; vertical louvers are included in downturn nozzle Option CD4.

Form RZ-NA-P-FT/SFT, Page 13

Page 14

Optional Downturn Nozzles for Models FT and SFT 75-300

Description:

Option CD2 is a downturn nozzle with a 25-65° variable air deflection range.

Option CD3 is a downturn nozzle with a 50-90° variable air deflection range.

Option CD4 is a downturn nozzle with a 25-65° variable air deflection range and vertical louvers (same as the vertical louvers on page 13)

Option packages include:

Model FT SFT FT and SFT

Size 75 75 100 125 150 200 250 300

Option CD2 Package P/N 160826 160827 160828 160829 160830 160831 160832 160833

Components: (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N

Nozzle Side (2) 149578 (2) 159059 (2) 159063 (2) 159060 (2) 159067 (2)159065 (2) 159067 (2) 159065

Nozzle Top (1) 149580 (1) 149580 (1) 159062 (1) 159062 (1) 159066 (1) 159066 (1) 159068 (1) 159068

#10-16 x 1/2" lg screw (20) 149563 (20)149563 (20) 149563 (20) 149563 (20) 149563 (20) 149563 (20) 149563 (20) 149563

Option CD3 Package P/N 160834 160835 160836 160837 160838 160839 160840 160841

Components: (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N

Nozzle Side (4) 149578 (4) 159059 (4) 159063 (4) 159060 (4) 159067 (4)159065 (4) 159067 (4) 159065

Nozzle Top (2) 149580 (2) 149580 (2) 159062 (2) 159062 (2) 159066 (2) 159066 (2) 159068 (2) 159068

#10-16 x 1/2" lg screw (34) 149563 (34)149563 (34) 149563 (34) 149563 (34) 149563 (34) 149563 (34) 149563 (34) 149563

Option CD4 Package P/N 160842 160843 160844 160845 160846 160847 160848 160849

Components: (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N (Qty) P/N

Nozzle Side (2) 149578 (2) 159059 (2) 159063 (2) 159060 (2) 159067 (2)159065 (2) 159067 (2) 159065

Nozzle Top (1) 149580 (1) 149580 (1) 159062 (1) 159062 (1) 159066 (1) 159066 (1) 159068 (1) 159068

Vertical Louver Top/Bottom (2) 159443 (2) 159443 (2) 159444 (2) 159444 (2) 159444 (2) 159444 (2) 159445 (2) 159445

Member

Vertical Louver (4) 160504 (4) 160501 (6) 160501 (6) 160502 (6) 160503 (6) 160505 (10) 160503 (10) 160505

Nozzle Angle Clip (2) 149581 (2) 149581 (2) 159061 (2) 159061 (2) 159064 (2) 159064 (2) 159064 (2) 159064

#10-16 x 1/2" lg screw (44) 149563 (44)149563 (44) 149563 (44) 149563 (44) 149563 (44) 149563 (44) 149563 (44) 149563

Downturn Nozzle Parts

Nozzle Top,

CD 2, 3, 4

Nozzle Side,

CD 2, 3, 4

Nozzle Side,

Nozzle Side,

CD 2, 3, 4

Nozzle Side,

CD 3

Nozzle Top, CD 3

CD 3

Horizontal louvers (must be removed

from the heater and re-installed in the

outlet of the downturn nozzle.)

Form RZ-NA-P-FT/SFT, Page 14

Page 15

Miscellaneous - Models FT and SFT

P/N 91919, Thermostat,

1-stage, 24-volt, 40-80°F

(same as Option CL1)

P/N 91926, Locking Cover

for 1-stage thermostat

(same as Option CM1)

P/N 39581, Thermostat,

2-stage, 24-volt, 40-90°F

(same as Option CL3)

P/N 98266, High temperature

tape suitable for 550°F (for

vent pipe), 1" x 10 yards

(same as Option FA1)

Form RZ-NA-P-FT/SFT, Page 15

Page 16

Form RZ-NA-P-FT/SFT, Page 16

(800) 695-1901 ww w . Rez Spec.com

©2004 Thomas & Betts Corporation, All rights reserved. Printed in U.S.A.

MANUFACTURER OF GAS, OIL, ELECTRIC HEATING AND VENTILATING SYSTEMS

Trademark Note: Reznor® is registered in the United States and other countries.

804 OG POD Form RZ-NA-P-FT/SFT

Loading...

Loading...