Reznor RHC 4000(M) DJL, RHC 4000(M) RJL User Manual

®

1307RHC4DJL/RJL--EN

Gas-Fired, Balanced-Flue or Power-Vented Unit Heaters

RHC 4000(M) DJL for indoor use

RHC 4000(M) RJL for outdoor use

NSTRUCTION DOCUMENT APPLIES FOR:

Installation

Commissioning

Servicing

Applies to

Austria,Belarus, Bulgaria, China, Czech Republic, Croatia, Cyprus, Denmark,

England, Estonia, Finland, Germany, Greece, Hungary, Iceland, Latvia, Lithuania,

Montenegro, New Zealand, Norway, Poland, Romania, Russian Federation, Serbia,

Slovakia, Slovenia, Spain, Sweden, Turkey, Ukraine

These appliances meet the following EC Directives

Dir 2009/142/EC: GAD

Dir 2004/108/EC: EMC

Dir 2006/95/EC: LVD

Dir 2006/42/EC: MD (annex II, sub B)

WARNING

Please read this document carefully before commencing installation commissioning and/or

servicing. Leave it with the user or attached to the appliance or gas service meter after installation

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or

death. All work must be carried out by appropriately qualified persons.

The manufacturer does not take any responsibility in the event of non-observance of the regulations

concerning the connection of the apparatus causing a harmful operation possibly resulting in damage to the

apparatus and/or environment in which the unit is installed.

Reznor Europe N.V. – J&M Sabbestraat 130 – B 8930 Menen

Tel : +32 56/52 95 11 - Fax : +32 56/52 95 33

Subject to modifications

P 1/24-1307RHC4DJL/RJL—EN,

TABLE OF CONTENTS

1.0 INTRODUCTION

1.1 Basic Information

1.2 Warranty

2.0 TECHNICAL DATA

3.0 GENERAL REQUIREMENTS

3.1 General

3.2 Specific heater location

3.3 Minimum airflow duty

3.4 Compartment dimensions

3.5 Maximum airflow conditi ons

3.6 Combustion air supply & flue system (applies

only to DJL models)

3.7 Air Supply (applies only to DJL models)

3.8 Electrical supply

3.9 Gas supply

4.0 INSTALLATION

4.1 Uncrating and preparation

4.2 Fitting the combustion air inlet/flue system

(applies only to DJL)

4.3 Electrical Connection

4.4 Room Thermostat Siting

5.0 COMMISSIONING AND TESTING

5.1 Electrical Check

5.2 Gas Connection

5.3 Lighting the Heater

5.3.1 To Turn the Heater ON

5.3.2 To Turn the Heater OFF for Short Periods

5.3.3 To Turn the Heater OFF for Long Periods

5.4 Heater Pipework

5.5 Adjustments

5.6 Options

5.6.1 2 stage burner control

5.6.2 Modureg V7335A 2000 series modulation

system

5.7 Air heater controls & operation

5.8 Handing Over

6.0 SERVICING INSTRUCTIONS

7.0 REMOVAL AND REPLACEMENT OF PARTS

7.1 Main Burner Removal

7.2 Main Burner Injectors

7.3 Ignition System

7.4 Gas control valve

7.5 Limit Controls

7.6 Combustion Air Control Switch

7.7 Combustion Air Fan

8.0 FAULT FINDING

9.0 PARTS LIST

10.0.GAS CONVERSION

11.0 USERS INSTRUCTIONS

12.0 HEALTH & SAFETY STATEMENT

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe

personal injury or death and/or property damage.

2. WA RNING

personal injury or death and/or property damage.

3. CAUTION

personal injury and/or property damage.

: Failure to comply could resul t in severe

: Failure to comply could result in minor

WARNING:

The electrical isolator should only be used in an

emergency and should not be used for closing

down the main burner, as it switches off the fan

prematurely and may damage the heat exchanger,

invalidating the warranty.

This appliance is not intended for use by persons

(including children) with reduced sensory or

mental capabilities or lack of experience and

knowledge unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance

1.0 INTRODUCTION

1.1 BASIC INFORMATION

The instructions in this manual apply to the following gasfired/fan-assisted warm air heaters:

RHC 4000(M) DJL

only (when installed where the height above floor level is

greater than 1,8 meters measured to the underside of the

appliance they may be used as a garage air heater).

Model RHC 4000(M) DJL heaters are approved for:

Type C12 - horizontal vent for balanced-flue heaters;

Type C

Type B

(through the wall)

RHC 4000(M) RJL

handlers built for outdoor

Model RHC 4000 RJL heaters are approved for outdoor or

rooftop application.

Category : see table 2A.

All models & sizes are available for use with either natural,

propane or butane gas with operating temperatures between

-15°C and 40°C.

These instructions are only valid for the country of use as

indicated on the appliance. If these symbols are not shown,

it is necessary to obtain appropriate technical instructions.

Such instructions may be obtained upon request from your

supplier.

Check that the local distribution conditions of electricity

supply, type of gas and pressure of the appliance are

compatible with the data plate.

- vertical vent for balanced-flue heaters;

32

– vertical vent (through the roof) or horizontal vent

22

model suitable for indoor air handlers

model suitable for incorporation in air

installation only.

P 2/24-1307RHC4DJL/RJL—EN,

The installation

must comply with the requirements and

recommendations of all relevant national and local

standardisations.. The installation must also be in

accordance with the relevant el ectrical and IEE regul ations.

When the external control calls for heat, an electronic control

begins the ignition sequence to provide for a safe start.

Under normal conditions the fan motor runs constantly and

after a call for heat it switches the heater on thr ough a room

or duct stat. However, in some applications, about 30

seconds after the call for heat, the fan control relay will

activate the fan motor of the air ha ndler.

The electronic control will supervise the flame during the

entire heating cycle to ensure safe operation.

When the required room temperature is reached, the main

burner will shut down leaving the fan running to cool down

the heat exchanger

In some applications, after approximately 45 seconds, the

fan delay relay will turn off the fan (if wired).

2.0 TECHNICAL DATA

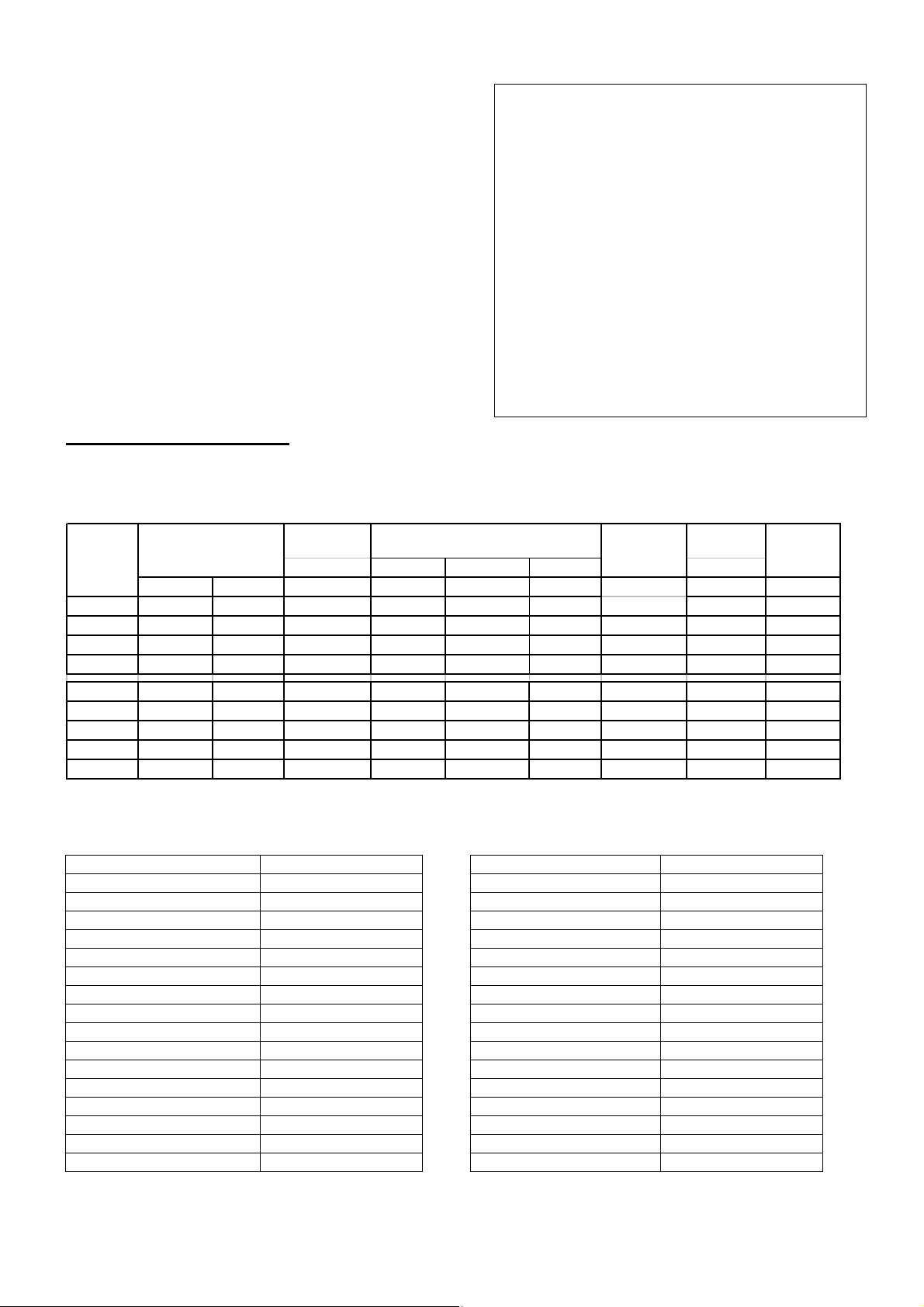

2.1 SPECIFICATIONS

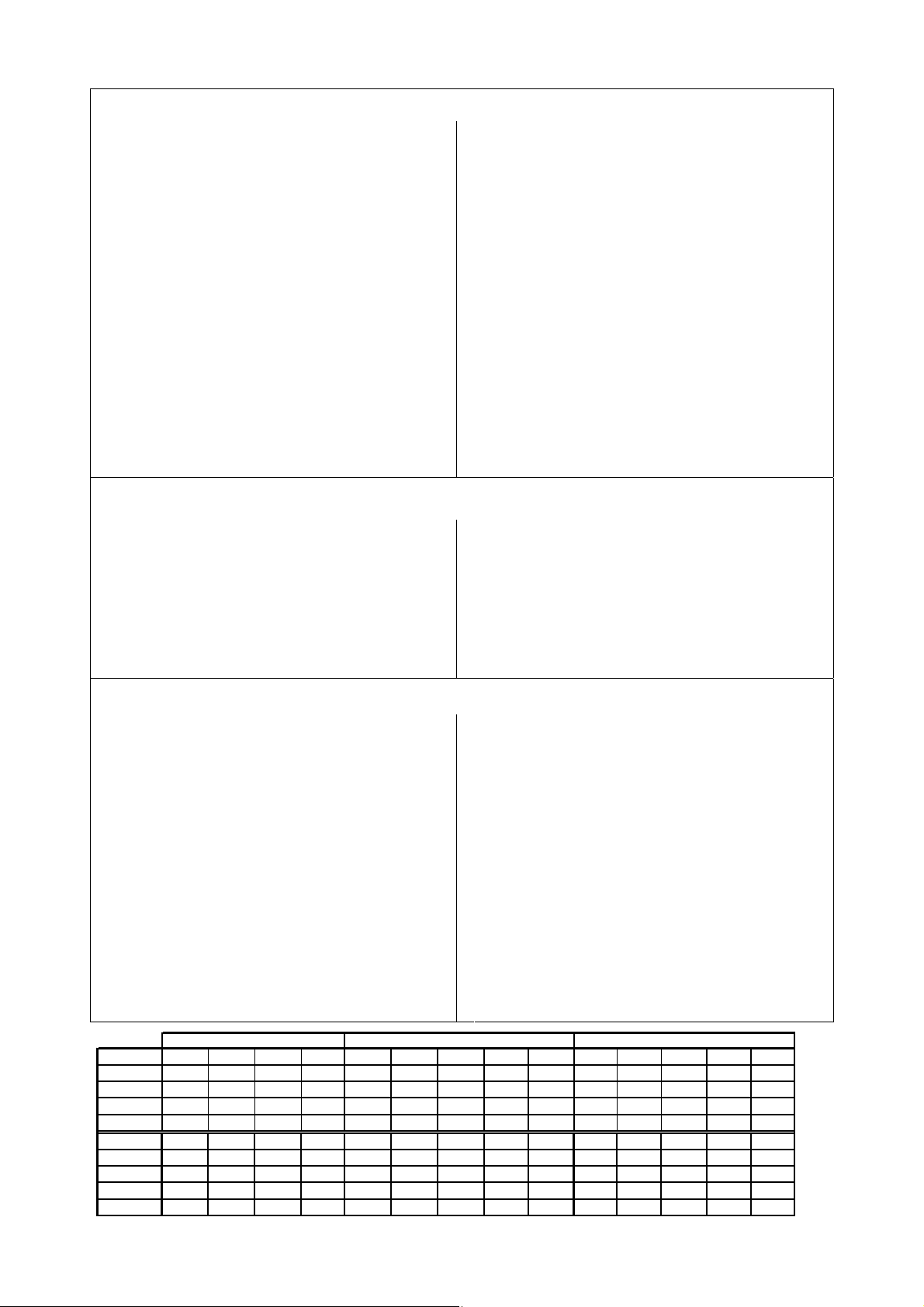

Table 1 – Specifications

1.2 WARRANTY

Warranty is void if:

a) Model RHC 4000(M) DJL/RJL heaters are installed in

atmospheres containing flammable vapors or

atmospheres containing chlorinated or halogenated

hydrocarbons or atmospheres containing any silicone,

aluminum oxide, etc., that adheres to spark ignition

flame sensing probes.

b) The installation is not in accordance with these

instructions.

c) The maximum airflow through the heat exchanger tubes

is not respected (see section 3.5).

d) The required minimum air delivery is not respected (see

table 3a).

e) The duct dimensions do not comply with the prescribed

dimensions (see table 3b).

f) The inlet tem perature (meas ured at the heat exc hanger

inlet) is lower than the value st at ed o n t he ch a rt (s ee f ig.

5 : dew point occurrence chart).

Heat output

Model

4050 06 62.00 55.90 50.80 5.90 4.50 4.40 0.15 24.00 24.00

4060 07 74.60 67.20 61.20 7,10 5.40 5,20 0.15 28.60 28.60

4075 09 91.50 82.40 75.00 8,70 6.70 6,60 0.15 36.00 36.00

4100 12 120.00 108.40 100.00 11,40 8.80 8,60 0.15 47.00 47.00

4110M.13 136.60 123.00 112.30 13.00 -- 9.60 0.28 51.20 51.20

4125M.15 153.50 138.30 126.30 14.60 -- 10.80 0.28 51.00 51.00

4150M.18 182.90 164.80 151.30 17.40 -- 12.80 0.28 75.80 75.80

4175M.21 211.80 190.80 175.00 20.20 -- 14.90 0.28 99.40 99.40

4200M.24 240.60 216.80 198.70 22.90 -- 16.90 0.65 99.40 99.40

1. GCV (Hs) 3. Heat output depends on airflow – heat output H2 only for airflows above V2

2. NCV (Hi) 4. Natural gas G20 gross calorific value 10.48 kWh/m

Table 2A - Gas category

Heat input

kW gros1KW net

Butane gas G30 gross calorific value 13.7 kWh/kg

Propane gas G31 gross calorific value 14.0 kWh/kg

2

H2

3

100%

kW m³/h kg/h kg/h kW kW kW

G20 G30 G31 2 sta ge

Gas rate

4

Pow er

Consumption

3

@ 15 °C, 1013.25 mbar

Heat output

50%

3

Minimum

modulating

output

Country Gas category Country Gas category

Austria II2H3P

Belarus II2H3+ Germany I2ELL or I3P

Bulgaria I2H or I3B/P Montenegro II2H3+

China II2H3+ New Zealand II2H3+

Czech republic II2H3+ Norway II2H3 B/P

Croatia II2H3P Poland II2E3P

Cyprus II2H3+ Portugal II2H3+

Denmark II2H3 B/P Romania II2H3P

Estonia II2H3+ Russian Federation I2H or I3P

England II2H3+ Serbia II2H3+

Finland II2H3 B/P Slovakia II2H3+

Greece II2H3+ Slovenia II2H3+

Hungary II2HS3P Spain II2H3+

Iceland II2H3+ Sweden II2H3 B/P

Latvia II2H3+ Turkey II2H3+

Lithuania II2H3+ Ukraine I2H or I3P

P 3/24-1307RHC4DJL/RJL—EN,

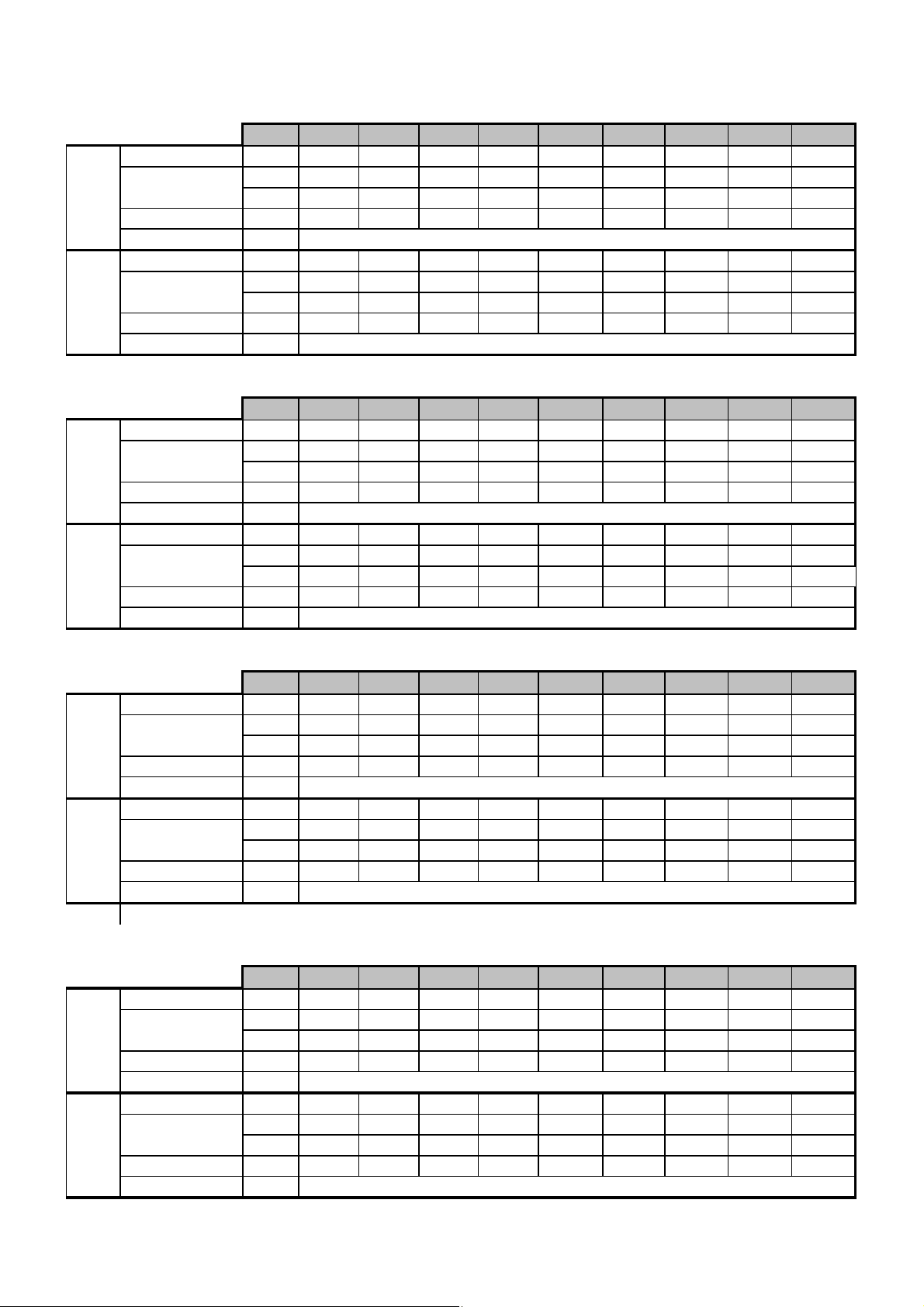

Table 2B :Injector size and burner pressure

Belarus, China Croatia, Czech Republic, Cyprus, England, Estonia, Greece, Iceland, Latvia, Lithuania,

Montenegro, New Zealand, Portugal, Serbia, Slovenia, Slovakia, Spain , Turkey

Mo d el 4050 06 4060 07 4075 09 4100 12 4110M,13 4125M,15 4150M, 18 4175M,21 4200M,24

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G20

Burner pressure (1) mbar 7,00 7,50 7,50 7,50 7,70 7,40 7,50 7,70 7,70

Nat. Gas

Inlet pressure mbar

mm 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00

marking 300 300 300 300 300 300 300 300 300

20

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G31

Burner pr essure (1) mbar 35,50 35, 50 33,90 33,60 35,20 34,80 34,90 35,30 34,40

Prop. Gas

Inlet pressure mbar

mm 1,55 1,55 1,55 1,55 1,55 1,55 1,55 1,55 1,55

marking 155 155 155 155 155 155 155 155 155

37

Romania, Poland

Mo d el 4050 06 4060 07 4075 09 4100 12 4110M,13 4125M,15 4150M, 18 4175M,21 4200M,24

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G20

Burner pressure (1) mbar 7,00 7,50 7,50 7,50 7,70 7,40 7,50 7,70 7,70

Nat. Gas

Inlet pressure mbar

mm 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00

marking 300 300 300 300 300 300 300 300 300

20

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G31

Burner pr essure (1) mbar 28,90 28, 44 27,90 26,80 28,20 28,20 27,90 28,40 26,50

Prop. Gas

Inlet pressure mbar

mm 1,65 1,65 1,65 1,65 1,65 1,65 1,65 1,65 1,65

marking 165 165 165 165 165 165 165 165 165

30

Germany,Hungary, Russian Federation, Ukraine, Austria

Mo d el 4050 06 4060 07 4075 09 4100 12 4110M,13 4125M,15 4150M, 18 4175M,21 4200M,24

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G20

Burner pressure (1) mbar 7,00 7,50 7,50 7,50 7,70 7,40 7,50 7,70 7,70

Nat. Gas

mm 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00

marking 300 300 300 300 300 300 300 300 300

Inlet pressure mbar

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G31

Burner pr essure (1) mbar 35,50 35, 50 33,90 33,60 35,20 34,80 34,90 35,30 34,40

Prop. Gas

mm 1,55 1,55 1,55 1,55 1,55 1,55 1,55 1,55 1,55

marking 155 155 155 155 155 155 155 155 155

Inlet pressure mbar

(* ): Inlet pressure for Hungary = 25mbar

Bulgaria, Denmark, Finland, Norway, Sweden

Mo d el 4050 06 4060 07 4075 09 4100 12 4110M,13 4125M,15 4150M, 18 4175M,21 4200M,24

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G20

Burner pressure (1) mbar 7,00 7,50 7,50 7,50 7,70 7,40 7,50 7,70 7,70

Nat. Gas

mm 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00 3,00

marking 300 300 300 300 300 300 300 300 300

Inlet pressure mbar

Injector quantity 6 7 9 12 13 15 18 21 24

Injector size

G31

Burner pr essure (1) mbar 27,60 27, 50 25,40 27,30 27,69 27,28 27,35 27,67 29,96

Prop. Gas

mm 1,55 1,55 1,55 1,55 1,55 1,55 1,55 1,55 1,55

marking 155 155 155 155 155 155 155 155 155

Inlet pressure mbar

(1) : with open service door

20(*)

50

20

30

P 4/24-1307RHC4DJL/RJL—EN,

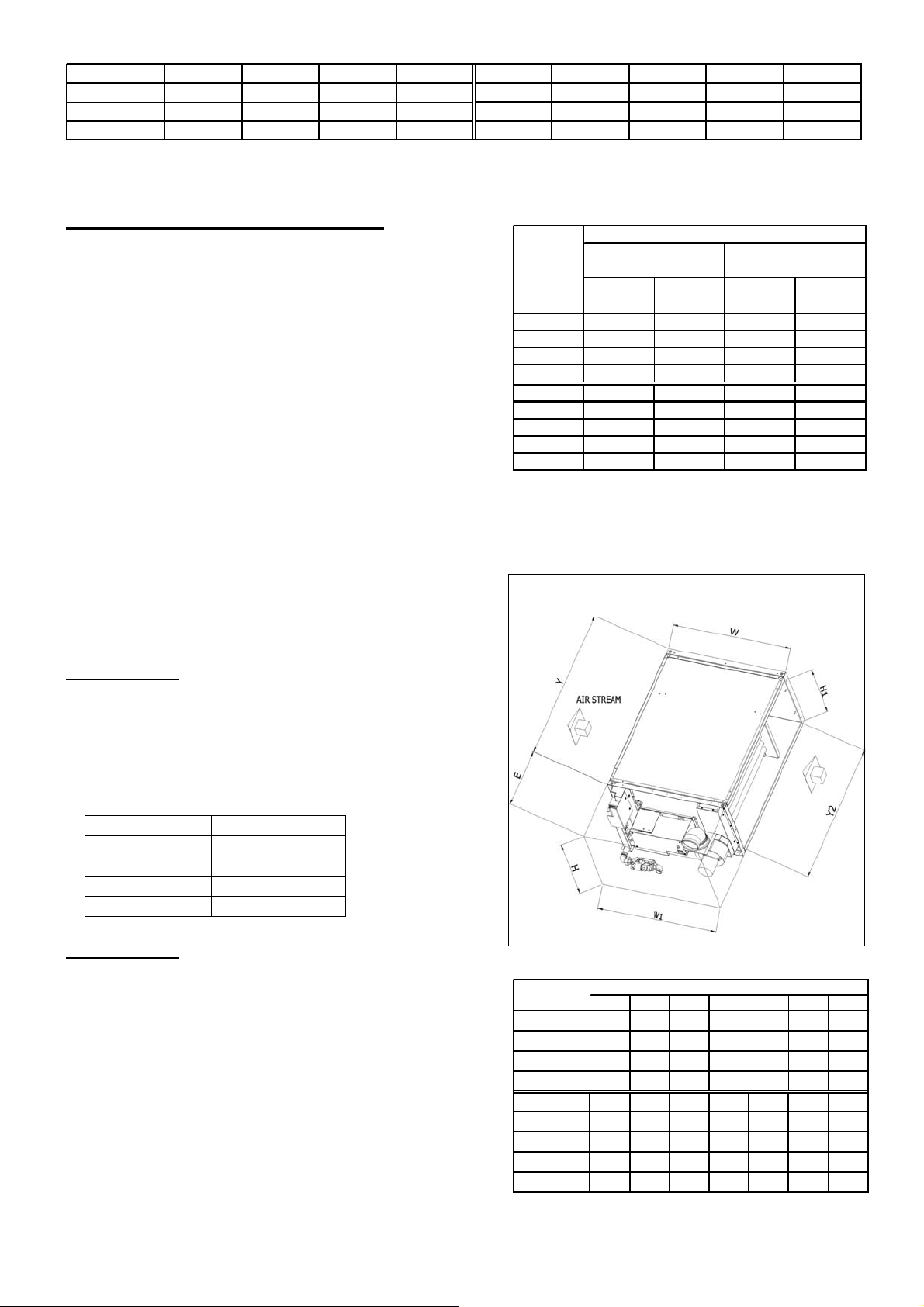

2.2. MOUNTING FLANGE & MAIN DIMENSIONS

RHC 4000 DJL/RJL

1.Gas connection ¾”

2.Flue outlet

3.Electrical connection

Figure 1 : Side view

Figure 2 : Top view

RHC 4000(M) DJL/RJL

Figure 3 : Front view

TYPE A B B1 B2 A1 A2 C C1 E A1 A2 C C1 E

4050 06 531 800 613 187 85 466 224 268 118 85 446 291 268 118

4060 07 601 800 613 187 160 441 224 268 118 85 516 291 268 118

4075 09 741 800 613 187 160 581 224 268 118 85 656 291 268 118

4100 12 950 800 613 187 160 790 224 268 118 85 865 291 268 118

4110M.13 1132 930 778 152 190 942 361 348 188 190 942 364 351 191

4125M.15 1272 930 778 152 190 1082 361 348 188 190 1082 364 351 191

4150M.18 1481 930 778 152 190 1291 361 348 188 190 1291 364 351 191

4175M.21 1691 930 778 152 190 1501 361 348 188 190 1501 364 351 191

4200M.24 1900 930 831 99 139 1761 352 445 179 139 1761 354 447 181

DJL/RJL DJL RJL

P 5/24-1307RHC4DJL/RJL—EN,

2.3 W

/

/

EIGHTS

Weights (kg) 4050 06 4060 07 4075 09 4100 12 4110M.13 4125M.15 4150M.18 4175M.21 4200M.24

unit 90 100 120 149 200 220 250 279 313

packaging 292929295858585858

total 119 129 149 178 258 278 308 337 371

3.0 GENERAL REQUIREMENTS

3.1 GENERAL

It is important that all gas appliances are installed in

accordance with the rules in force and by appropriately

qualified persons. Failure to install appliances correctly could

lead to prosecution. It is in your own interest and that of

safety to ensure co mpli an ce wi th the law.

Caution : Air heaters should not be installed in corrosive

atmospheres, i.e. near plating spray or de-greasing

plants or in areas where there is a fire risk.

Care should be exercised when designing ducting systems

especially with regard to the application of restriction and

direction turning fittings, i.e. elbows directly on to the air

heater, doing so can cause a n uneven and turbul ent air flo w

across the heat exchanger resulting in heat exchanger spots

and nuisance shut down of the gas burner due to localized

overheating, thus activating thermal over-heat controls.

The location must als o provide sufficient spa ce to allow the

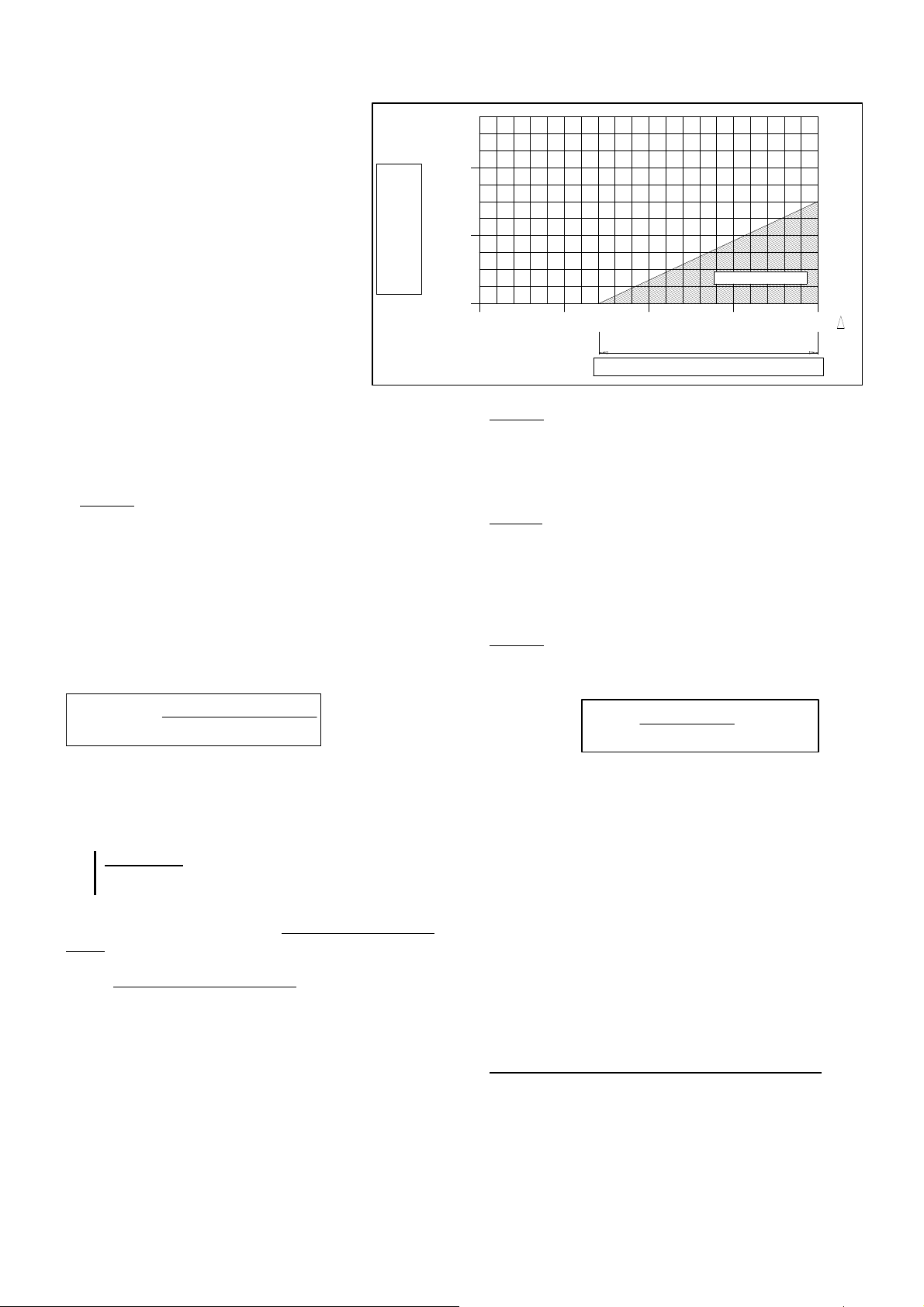

Table 3a

Min. air volume required

With heat output

Model

4050 06 3900 1.

4060 07 4700 1.31 7150 1.99

4075 09 5700 1.

4100 12 7500 2.08 11700 3.25

4110M.13 --- --- 13600 3,80

4125M.15 --- --- 15600 4,30

4150M.18 --- --- 12300 3,40

4175M.21 --- --- 14100 4,00

4200M.24 --- --- 16300 4,50

(*) : cfr. table 1

H1 (*)

V1 V1 V2 V2

3

m

h

m³/s

08 5950 1.65

58

COMPARTMENT DIMENSIONS

3.4

Figure 4

With heat output

3

m

h

8800 2.

H2 (*)

m³/s

44

heater to be serviced.

Horizontal airflow

SPECIFIC HEATER LOCATIONS

3.2

DJL installation :

Do not locate the air heater where it may be e xposed to

water spry, rain, etc.

The location chosen for the air heater must permit the

provision of a satisfactory flue system venting to outdoor

atmosphere and adequately ventilated to provide for

combustion air.

Installation clearances (mm) (towards combustible

materials)

Top 150

Flue connector 150

Access panel 600

Non-access side 150

Bottom 50

RJL installation :

A minimum distance of 1500mm must be maintained on the

control side of the appliance.

When installed at ground level a fence to guard against

damage and to protect the public fro m possi ble injur y shoul d

protect the entire installation.

Ensure that the air heater is installed in a level plain and that

the surface onto which it is installed is vibration free.

MINIMUM AIRFLOW REQUIREMENT

3.3

The minimum airflow duty through the heating section

enclosure (see figure 4) must be observed as indicated in

table 3a.

Table 3b (dim. expressed in mm)

Model

4050 06 531 461 1049 975 800 800 400

4060 07 601 531 1049 975 800 800 400

4075 09 741 671 1049 975 800 800 400

4100 12 950 880 1049 975 800 800 400

4110M.13 1132 1062 1049 975 930 930 420

4125M.15 1272 1202 1049 975 930 930 420

4150M.18 1481 1411 1049 975 930 930 420

4175M.21 1691 1621 1049 975 930 930 420

4200M. 24 1900 1830 1049 975 930 930 470

Duct channel & controls compartment

H1

H

YY2WW1E

P 6/24-1307RHC4DJL/RJL—EN,

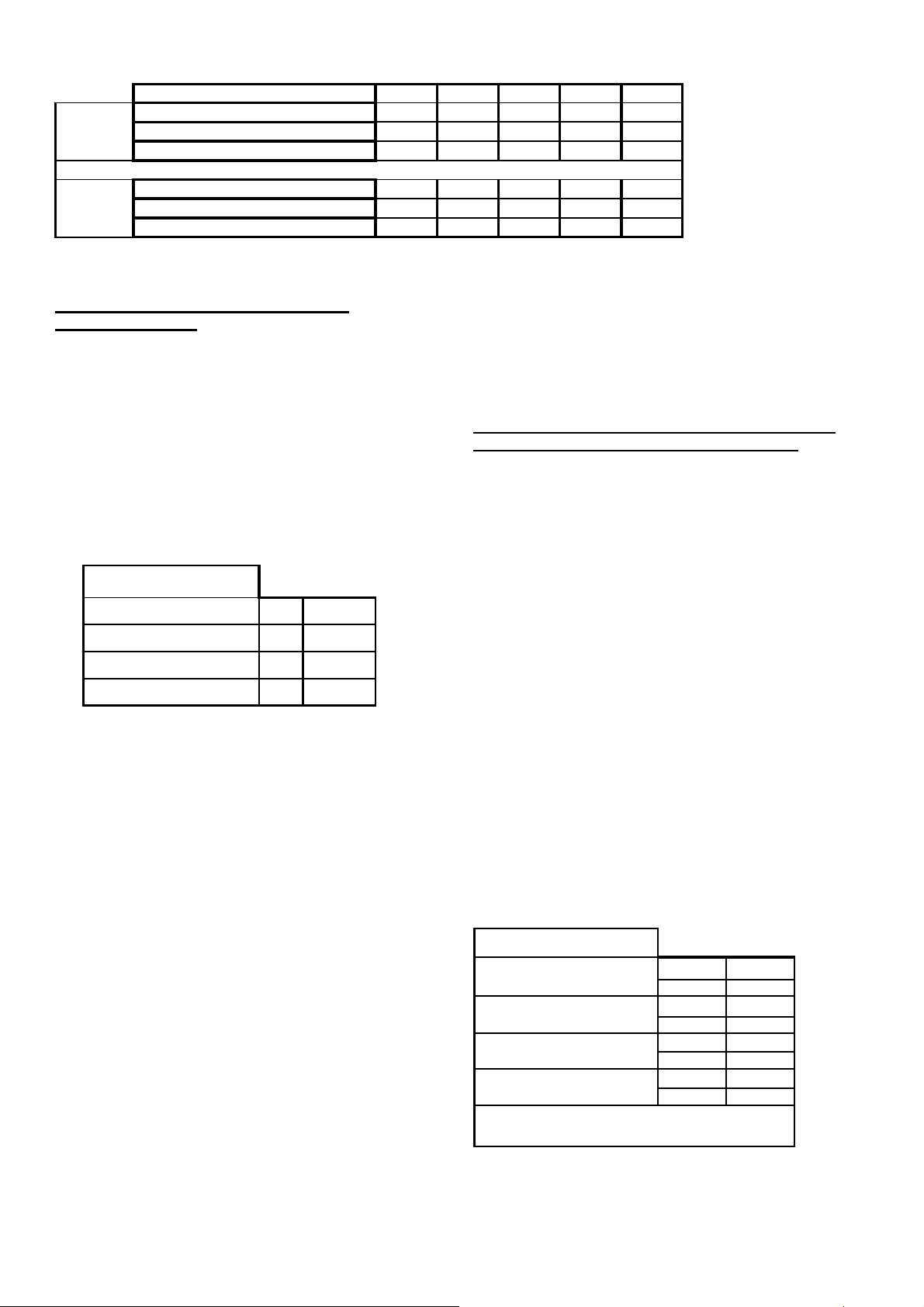

3.5

MAXIMUM AIRFLOW CONDITION

Special attention must be given to ensure Figure 5 : Dew point occurrence chart (condensation zone)

that the temperature rise of the a ir, passing

through the enclosure (duct channel) around

the heat exchanger tubes, is high enough to

20°C

T

avoid condensation forming within the tubes.

This condensation forming could occur by

super cooling of the products of combustion.

Such condensation can be the source of

severe corrosion and damage to tubes or

part of the tubes.

Figure 5 indicates the probability of

condensation forming within the tubes

reference :

- the temperature rise of the air through the

20 ░ C

0°C

E

R

R

E

U

G

T

N

A

A

R

H

C

X

E

T

A

E

H

E

H

T

T

A

0 ░ C

-20°C

-20 ░ C

40K 20K 0K

30K

E

P

M

E

T

R

I

A

T

E

L

N

I

enclosure (around the tubes)

- the inlet air temperature passing over the

heat exchanger

TEMPERATURE RISE OVER THE HEAT EXCHANGER

In function of the expected minimum inlet air

temperature, the minimum required temperature rise (to

avoid condensation) must be derived from the chart

below (figure 5).

Example

expected minimum inlet temperature = -5°C

minimum required temper ature rise sho wn on the chart

= +13°K

Table 1 indicates the heat output (kW) of the different

models.

The maximum allowable airflow through the enclosure

(duct channel) around the tubes can be calculated as

follows :

V

max

(m³/h)

T

Δ

minimum

0.3423

1000(kW)outputheat

Example :

△T

= 13K (with min. inlet temp. = -5°C)

min

model 4075 09 at 100% heat output : 75.00kW results into

V

= 16850m³/h

max

Remark

:

For air heaters with the option 2 stage gas valve (50%

minimum heat input) or the option modulating gas valve

(30% minimum heat input) attention must be given to

determine the maximum allowable airflow in function of the

appropriate heat input.

Example :

△T

= 13K (with min. inlet temp. = -5°C)

min

model 4075 09 at 50% modulation (see table 1 ‘output’) :

36W

results into :

V

max

3.6 COMBUSTION AIR SUPPLY & FLUE SYSTEM

ATTENTION : this section only applies to DJL

models !

The air heater may be installed as a ba lanced flue (Type C)

heater, requiring both a combustion air inlet duct and a

combustion flue outlet duct (use a s eamless alumi nium pipe )

or as a power vented (Type B) heater

flue pipe exhausting to outdoors and takes combustion air

directly from the space to be heated.

The center distance between th e combustion air inlet soc ket

and the flue outlet socket is 225mm for all models.

Each appliance requires it’s own individual flue system.

When several appliances are installed, o ne common flue and

combustion air system, thus combining several heaters, is

not allowed.

, which requires only a

IMPORTANT:

The flue must be installed in accordance with national

and local regulations. Failure to provide proper fluing

could result in death, serious injury and/or property

damage.

The air heater must be installed with a flue to the outside

of the building. Safe operation of any power vented gas

apparatus requires a properly operating flue system,

correct provision for combustion air, and regular

maintenance and inspection.

Use of flue restriction rings (Only for 4000M units !!)

To ensure the efficiency of the units, eventually a flue

restriction ring needs to be fitted in the outlet collar of the

venter housing. The diameter of the restriction ring will be

determined by the flue pipe length and the type of appliance

(combustion air from environment (appliance B) or

combustion air from outside (appliance C)).

CONDENSATION ZONE

10K

1000(kW)36

0.342313

T

h/³m8090

P 7/24-1307RHC4DJL/RJL—EN,

Table 5 : Diameter flue restrictors for DJL

Combustion out and inlet application 4110M.13 4125M,15 4150M.18 4175M.21 4200M.24

2X1m pipe length till 2X3m pipe length 99mm 95mm 93mm 95mm 102mm

C Appliance

B appliance

2X4m pipe length till 2X6m pipe length 107mm 107mm 99mm 107mm 114mm

2X7m pipe length till 2X9m pipe length open open open open open

1X1m pipe length till 1X3m pipe length 90mm 86mm 90mm 90mm 92mm

1X4m pipe length till 1X6m pipe length 93mm 90mm 93mm 95mm 97mm

1X7m pipe length till 1X9m pipe length 96mm 93mm 95mm 99mm 102mm

3.6.1 Flues for power vented instal lations

(Type B appliances)

If the air heater is to be in stalled as a type B a ppliance, air

for combustion will be taken from within the space where

the heater is installed. Ensure that an adequate air supply

for combustion and ventilation is provided within the building

in accordance with the regulations & rules in force.

The combustion air inlet socket at the appliance must be

foreseen with an inlet grill of class IP20 (dia 130 = PN 06

22786 134 (for all types))

Table 5 below shows flue pipe sizes and maximum vent

lengths. The minimum flue length is 0.5 meters.

Model RHC 4000(M) DJL

Heater socket & pipe dia mm 130

Center distance B mm 225

Maximum straight length mm 9

Equivalent length of 90° elbow mm 1.5

To avoid leakage use single wall flue pipes of seamless

aluminium. All joints must be seal ed to prevent products of

combustion from leaki ng into th e building. A n approv ed flue

terminal (installed through the roof or the wall) i s requ ired .

If the flue passes through a combustible element of the

building it must be enclosed by a sleeve of non-combustible

material and separated from the sleeve by at least a 25 mm

air break.

The temperature of any combustible material near to the

flue must not exceed 65 °C when the heater is in operation .

The flue must be at least 50 mm away from any

combustible material.

Single wall flue pipe exposed to cold air or run through

unheated areas must be insulated. Where condensation is

unavoidable, provision must be made for the condensation

to flow freely to a point to which it can be released, i.e. a

drain or gully.

The condensation drain from the flue must be constructed

from non-corrodible material not less than 20 mm diameter.

Copper or copper-based alloys must not be used for

condensation drains.

3.6.2 Combustion air inlet pipe & flue pipe for

balanced flue installation (Type C appliances)

Balanced flue air heaters are designed to be fitted with a

combustion air inlet duct that obtains outdoor air and a flue

pipe that exhausts flue products to outdoors.

The heaters must be installed with an appropriate

concentric vertical or horizontal vent terminal. The

heaters are only approved for u se when installed with

the appropriate approved co ncentric vent terminal (see

table 6.)

Both the flue and combustion air pipes must be sealed. Use

seamless aluminum pipe.

The flue pipe may include a re-sealable test port to allow

good average sampling of the fl ue gas mixture for testing,

the port must be at least 450 mm away from the air heater

flue connection socket.

Follow any flue pipe manufacturers installation instructions

for making joints, includin g conn ections t o th e air heat er, fo r

passing through a building element and for support

requirements. If more than one air heater is being installed

in the same place each heat er must have a separate flue

system.

Table 6 Combustion air inlet & flue pipe requirements

Model RHC 4000(M) DJL

Heater socket & pipe dia mm

Max. straight length m

Equivalent length of 45 ° elbow m

Equivalent length of 90 ° elbow m

Concentric vertical/horizontal vent or wall terminal: types :

Mugro or Burfix dia130

Flue pipe 130

Inlet pipe 130

Flue pipe 9

Inlet pipe 9

Flue pipe 0.75

Inlet pipe 0.50

Flue pipe 1.5

inlet pipe 1.5

P 8/24-1307RHC4DJL/RJL--EN

Loading...

Loading...