Page 1

Form O-MAPSIII&IV Cabinets A/B/C (Version B.4)

CQS

Obsoletes O-MAPSIII Cabinets A/B/C (Version B.3)

®

Operation / Maintenance / Service

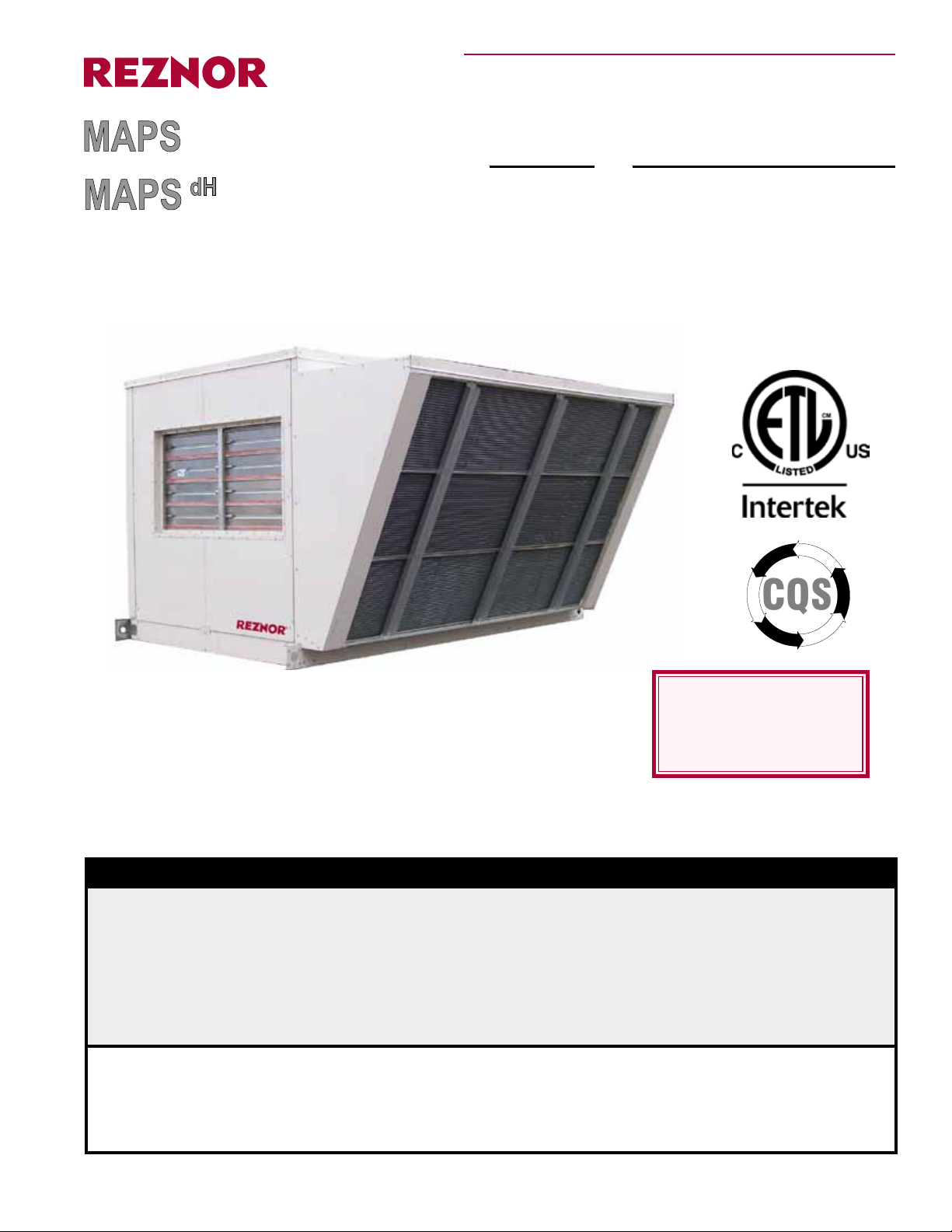

Applies to: Cabinet Sizes A, B, and C

®

™

of MAPS®III Models RCB, RDB,

RDCB, RDDB, RECB, REDB and

MAPS®IV Models RCC, RDC,

RDCC, RDDC, RECC, REDC

P

R

O

Y

C

C

N

E

G

A

C

C

U

S

T

O

M

CQS

E

Q

R

U

P

R

O

D

E

S

R

E

G

S

V

E

N

N

O

T

P

U

-

T

R

A

T

S

M

Y

E

A

L

I

T

U

C

T

T

S

N

Y

Y

S

A

R

R

A

T

W

MAPS® Cabinet

Sizes A, B, and C

R-410A

Refrigerant

DANGER

This unit contains R-410A high pressure refrigerant. Hazards exist that could

result in personal injury or death. Installation, maintenance, and service should

only be performed by an HVAC technician qualied in R-410A refrigerant and

using proper tools and equipment. Due to much higher pressure of R-410A

refrigerant, DO NOT USE service equipment or tools designed for R22

refrigerant.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service

procedures include the adding or removing of refrigerant, the service technician

must comply with all federal, state and local laws. The procedures discussed

in this manual should only be performed by a qualied HVAC technician.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 1

Page 2

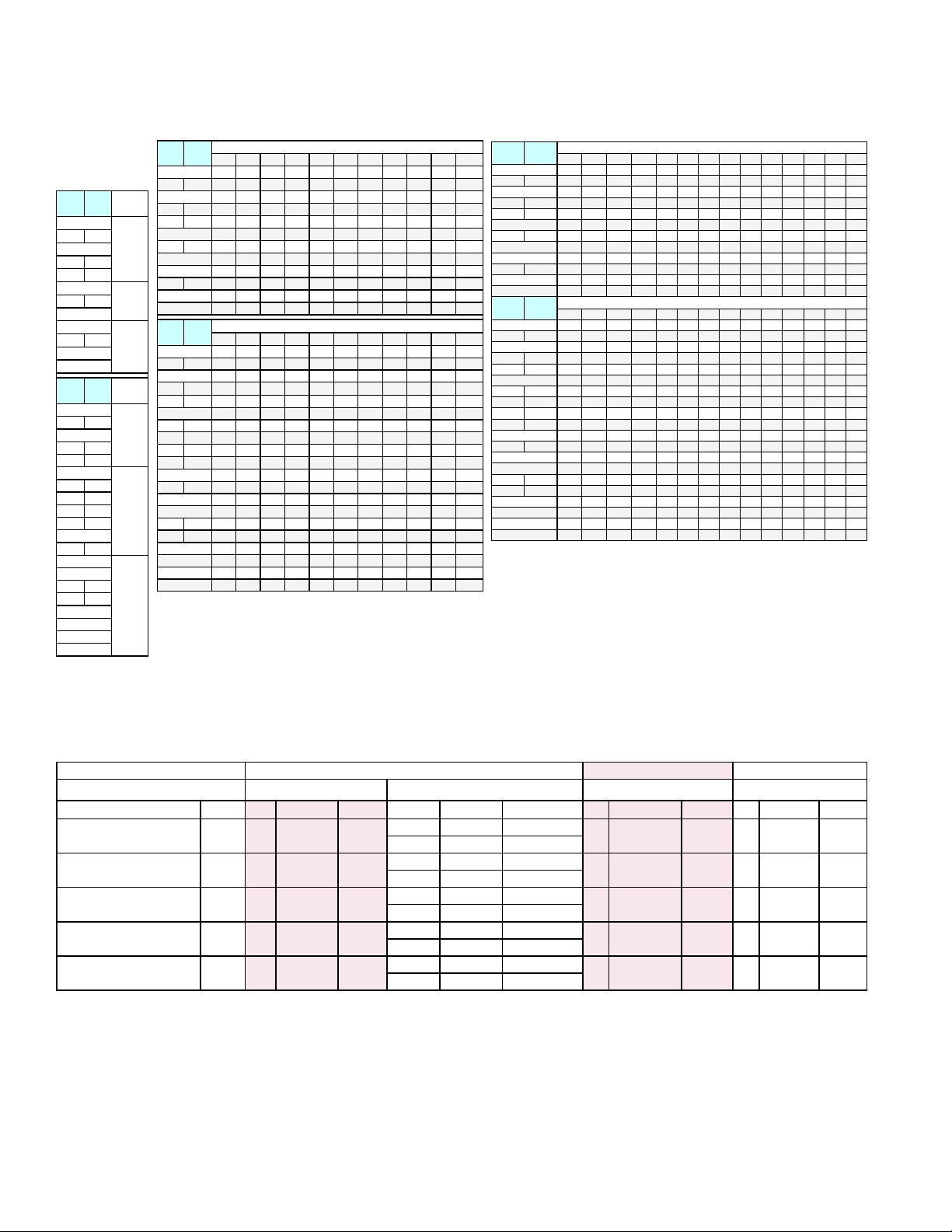

Table of Contents

1.0 General ....................................................2-3

2.0 Maintenance Requirements ..................3-6

2.1 Maintenance Schedule.....................................4

2.2 Control Locations ............................................. 5

2.3 Cross-Reference of Models and

Cabinet Sizes A, B, and C ..............................6

3.0 Maintenance & Service Procedures ...6-21

3.1 Filters ..............................................................6

3.2 Drive Components ...........................................7

3.3 Condenser Fans...............................................8

3.4 Coil Maintenance .............................................8

3.5 Check Refrigerant Pressure & Temperatures

(subcooling and superheat) ............................. 9

3.6 Compressor Operation, Maintenance, and

Replacement.................................................. 11

3.7 Thermostatic Expansion Valves ..................... 19

3.9 Other Controls ................................................ 20

3.8 Optional Dampers and Damper Controls ....... 20

1.0 General

This booklet includes operation, maintenance, and service information for Cabinet

Sizes A, B, and C of the MAPS® III and MAPS® IV Models listed below. Before beginning any procedure, carefully review the information, paying particular attention to the

warnings. Handling of refrigerant should only be performed by a certied HVAC technician with knowledge of the requirements of R-410A refrigerant and in compliance with

all codes and requirements of authorities having jurisdiction.

The instructions in this manual apply to the following MAPS® Models in Cabinet A, B,

and C Sizes and Model JHUP 250 and 300 duct furnace curb option.

4.0 Gas Heat Section Maintenance -

RDCB, RDCC, RDDB, RDDC .............21-30

4.1 Heat Exchanger, Burner, and Venter..............21

4.2 Heat Section Controls .................................... 25

4.3 Gas Train........................................................26

4.4 Other Gas Heat Section Controls / Sensors ..30

5.0 Electric Heat Section Maintenance -

RECB, RECC, REDB, REDC ..............30-31

6.0 Energy Recovery Module,

Option ER1 ..............................................31

7.0 Troubleshooting .................................32-39

7.1 Troubleshooting - Refrigeration (All Models) ..32

7.2 Compressor Digital Controller

Troubleshooting - all MAPS® IV Models.........33

7.3 Troubleshooting the Heat Section .................34

INDEX .............................................................40

NOTE: To conrm that this

booklet is applicable, see

list of Model and Cabinet

Sizes in Paragraph 2.3,

page 6.

Form O-MAPSIII&IV Cabinets A/B/C, Page 2

MAPS

Model

®

III MAPS®IV

RCB RCC

RDCB RDCC

RECB RECC

RDB RDC

RDDB RDDC

REDB REDC

JHUP

System Description (MAPS®III models have

staged cooling; MAPS®IV models have modulating

cooling.)

Makeup Air Cooling Packaged System, 1500-9000

CFM

Makeup Air Cooling Packaged System, 1500-9000

CFM, with Gas Heat Section (100-700 MBH)

Makeup Air Cooling Packaged System, 1500-9000

CFM, with Electric Heat Section (10- 88 kw)

Makeup Air Cooling and Re-heat Pump Reheat Cycle

Packaged System, 1500-9000 CFM

Makeup Air Cooling and Re-heat Pump Reheat Cycle

Packaged System, 1500-9000 CFM, with a Gas Heat

Section (100-700 MBH)

Makeup Air Cooling and Re-heat Pump Reheat Cycle

Packaged System, 1500-9000 CFM, with Electric Heat

Section (10 - 88 kw)

Optional Curb Section with 250 or 300 MBH Gas-Fired

Duct Furnace installed with a Model RDCB, RDCC,

RDDB or RDDC with a Size 250 or 700 Heat Section to

provide 500 or 1000 MBH heating

Page 3

Denitions of Hazard

Intensity Levels used

in this Manual

There are warning labels on the unit and throughout this manual. For your safety,

comply with all warnings during installation, operation, and service of this system. See

denitions of Hazard Intensity Levels of warnings below.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal

injury or death and/or property damage.

2. WARNING: Failure to comply could result in severe

personal injury or death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal

injury and/or property damage.

2.0 Maintenance

Requirements

To ensure long life and satisfactory performance, a system that is operating under normal conditions should be inspected according to the Maintenance Schedule in Paragraph 2.1. If in an area where an unusual amount of dust or soot or other impurities are

present in the air, more frequent inspection is recommended.

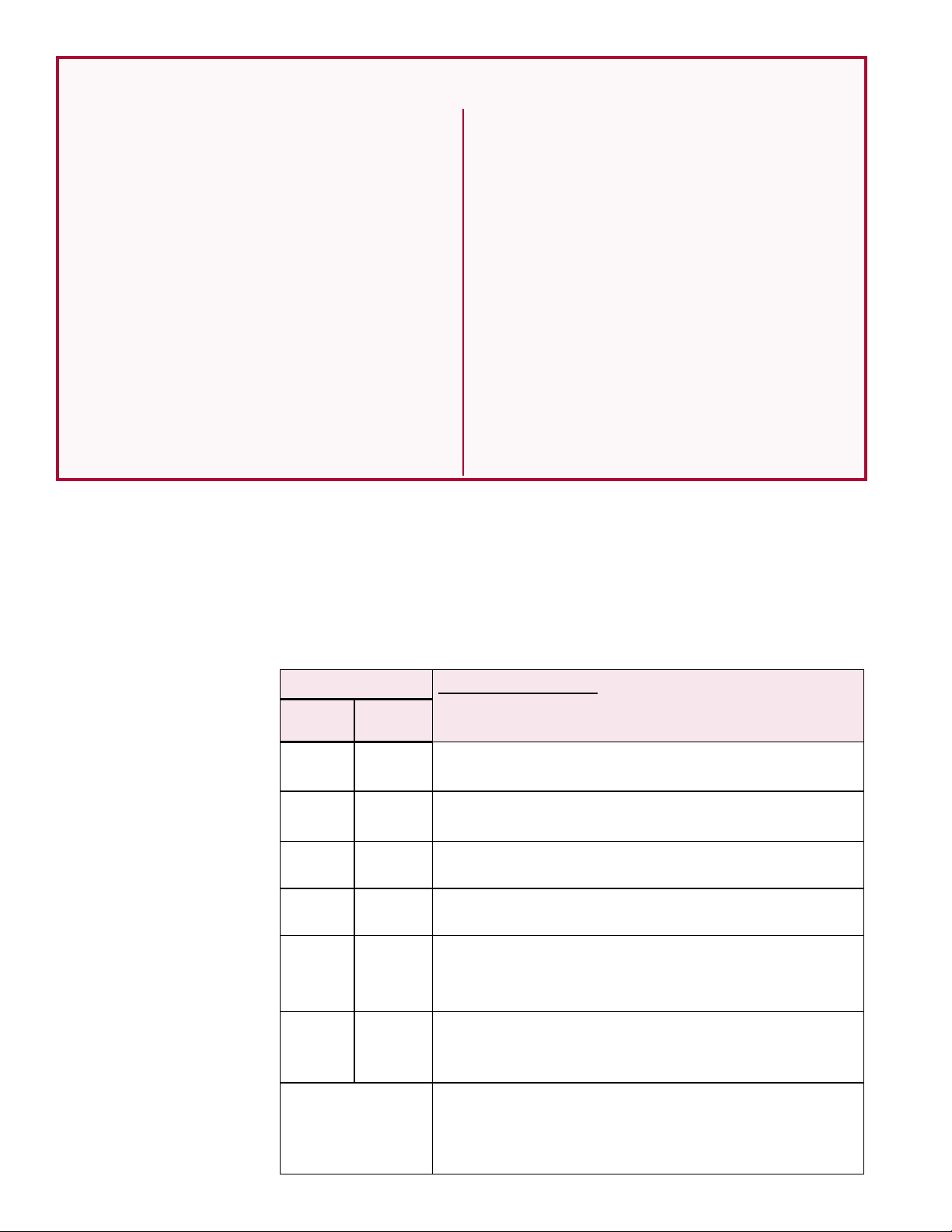

Refer to the illustration in FIGURE 1 and follow the instructions in the referenced paragraphs to maintain this equipment. Maintenance requirements apply to all Models and

Sizes unless noted.

IMPORTANT: Do not release refrigerant to the

atmosphere! If required service procedures include the

adding or removing of refrigerant, the service technician

must comply with all federal, state and local laws. The

procedures discussed in this manual should only be

performed by a qualied HVAC technician familiar with

R-410A refrigerant.

WARNING

Lock power OFF before performing any maintenance

procedure (except where power is required such as

checking refrigerant pressure and temperature). Lock

disconnect switch in OFF position. If the system has a

gas heat section, when you turn off the power supply,

turn off the gas. See Hazard Levels above.

If replacement parts are required, use only factory-

authorized parts. For information, go to

www.ReznorHVAC.com or call (800)-695-1901.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 3

Page 4

2.0 Maintenance

Requirements

(cont'd)

2.1 Maintenance

Schedule

Important NOTE:

If equipped with an

optional energy recovery

module, refer to Form

I-MAPSIII&IV-ER

for enthalpy wheel

maintenance instructions

Monthly

□ Inspect lters; clean or replace as needed. See Paragraph 3.1.

□ Inspect the condensate drain; clean as needed. For information, see the

installation manual, Form I-MAPSIII&IV, Paragraph 6.2.

Semi-Annually

□ Inspect the unit blower and belts. Check belts for tension, wear, and alignment.

Adjust or replace as needed. Clean dirt from blower and motor. See Paragraph

3.2.

Annually

NOTE: Redo the cooling startup procedures when the cooling season begins. Refer

to Startup instructions in the installation manual, Form I-MAPSIII&IV, Paragraph 10.0.

All Models - Beginning of the cooling season or more frequently

in year-round cooling climate:

□ Inspect the wiring for any damaged wire. Replace damaged wiring.

□ Inspect the condensate drain pan. Clean the coil cabinet, clean the drain pan,

and ll the trap.

□ Inspect/clean condenser fans. See Paragraph 3.3.

□ Inspect/clean all coils. See Paragraph 3.4.

□ Check compressor operation. See Paragraph 3.6.

□ Check refrigerant pressure and temperatures (superheat and subcool). These

checks are done when the system is operating. See Paragraph 3.5.

Models RDCB, RDCC, RDDB, & RDDC with a gas heat section

(beginning of the heating season) - See Paragraph 4.0:

NOTE: A MAPS® B cabinet with 500 MBH of heat is a Size 250 gas heat section

plus an optional Model JHUP curb duct furnace. A MAPS® C cabinet with 1000

MBH of heat is a Size 700 gas heat section plus an optional Model JHUP curb duct

furnace. The same maintenance procedures apply to the duct furnaces.

□ Clean all dirt and grease from the combustion air openings and the venter

assembly.

□ Check the heat exchanger, burner, and venter for scale, dust, or lint

accumulation. Clean as needed.

□ Check the gas valves to ensure that gas ow is being shutoff completely.

Models RECB, RECC, REDB, & REDC with an electric heat section

(beginning of the heating season) - See Paragraph 5.0:

Form O-MAPSIII&IV Cabinets A/B/C, Page 4

□ Check wiring connections.

□ Check the heat section and elements for dust or lint accumulation. Carefully

clean as needed.

Page 5

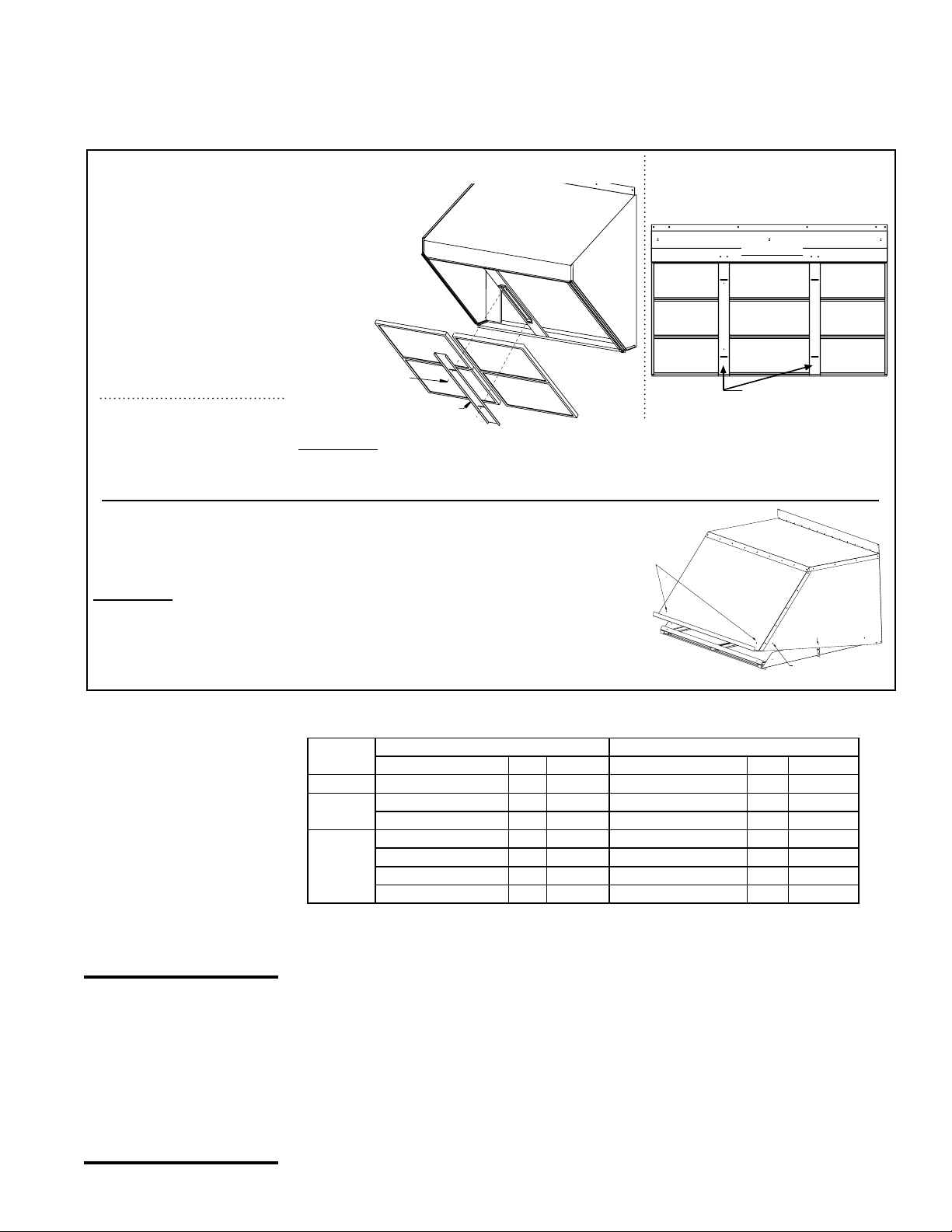

2.2 Control Locations

Controller

Display

(BacView)

IQ

Controller

Reheat

Board

Combustion

Air Proving

Switch

(RDCB/RDCC/

RDDB/RDDC)

Air

Proving

Switch

Power Supply

Ignition

Board

(RDCB/RDCC/

RDDB/RDDC)

Relay or

Sequencer

(RDCB/RDCC/

RDDB/RDDC)

Control

Expander

Option BHB6

Dirty Filter

Switch or

Differential

Pressure

Gauge

Low Voltage Panel - Cabinet C

Optional

Control

Block(s)

FIGURE 1 - Showing Access (panels removed) and High and Low Voltage Control Locations

(including control options)

Condenser Section

Compressors

Tubing

Access

Heat Section

(Gas illustrated)

High Voltage Panels

Cabinets A & B

Digital Controller

- MAPS IV only

Control

Transformers

Contactor,

Condenser Fan

Contactor,

Compressor A

Fuse & Fuse

Holder

Contactor,

Compressor B

Contactor, Compressor C

(below “B”, behind the transformer)

Cabinet C

Contactor,

Compressor B

Optional

Transformer

Control

Transformers

Digital Controller

- MAPS IV only

Fuse & Fuse

Holder

Contactor, Compressor DH

Phase Monitor or Motor Saver

Dampers

Blower Section

with Bottom Discharge

Two Low Voltage Panels A&B Cabinets (top right)

or Low Voltage Panel -

C Cabinet (bottom right)

Phase Monitor

or Motor Saver

Distribution

Blocks

Grounding

Lug

Contactor or

Starter and

Overload,

Blower Motor

Contactor,

Compressor DH

Optional Transformer

Contactor, Compressor A

Contactor,

Condenser Fan

Contactor,

Compressor C

Contactor or

Starter and

Overload,

Blower Motor

Distribution

Blocks

Grounding

Lug

Optional Transformer

Slide-out

Filter Rack

Reheat

Compressor

Evaporator Coil

Section (with slide

out drain pan)

Primary Low Voltage Layout - Cabinets A & B

Controller

Display

(BacView)

IQ

Controller

Optional

Plugin Card

Optional

Differential

Pressure

Switch

Combustion

Air Proving

Switch

(RDCB/RDCC/

RDDB/RDDC)

Air Proving

Switch

Venter Motor

Capacitor

(RDCB/RDCC/

RDDB/RDDC)

Secondary Low

Voltage Layout -

Cabinets A & B

Optional

Control

Expander

Optional

Reheat

Board

Sequencer

(RDCB/RDCC/

RDDB/RDDC)

Ignition

Board

(RDCB/RDCC/

RDDB/RDDC)

Optional

Control

Block(s)

Power

Supply

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 5

Page 6

2.0 Maintenance Requirements (cont'd)

2.3 Cross-Reference of Models and Cabinet Sizes A, B, and C

DX Cooling

Models RCB

and RCC and

DX with Reheat

Models RDB

and RDC

Model

Model

RCB

RCC

060

078 --

090

118 120

136 --

160

186 --

200

190

216 --

298

410

Model

Model

RDB

RDC

084

102 --

114

142 144

162 --

184

-- 196

210 --

222 --

224 --

236

-- 257

248

262

272 --

288 --

354

370

468

482

3.0 Maintenance

and Service

Procedures

Cabinet Size A B C

Model Sizes 060/078/084/102 090/114/11//120/136/142/144/162 All Cabinet B All Cabinet C

Filter Description Opt Qty Size P/N Qty Size P/N Qty Size P/N Qty Size P/N

2” Pleated Disposable AW 11 1 20x25x2 104113

4” Pleated Disposable,

MERV 8

4” Pleated Disposable,

MERV 13

2” Permanent Aluminum AW9 1 20x25x2 101623

4” Permanent Aluminum AW20 2 20x25x2 101623

Model RDCB, RDDB, RDCC, and RDDC by Cabinet Size

and Gas Heat Section Size

Model

Model

RDCB

RDCC

-100 -150 -200 -250 -300 -400 -500 -600 -700 -800 -1000

060

Cabinet

Cabinet

078 --

Size

118 120

136 --

186 --

A

216 --

B

Model

RDDB

C

102 --

142 144

Size

162 --

-- 196

A

210 -222 --

224 --

-- 257

B

272 -288 --

* A MAPS® B Cabinet with 500 mbh of gas heat is a Size 250 mbh heat section plus an Option JH25 curb with a 250 mbh

C

duct furnace.

A A A -- -- -- -- -- -- -- --

A A A B B B* -- -- -- --

090

A A A B B B* -- -- -- --

A A A B B B* -- -- -- --

A A A B B B* -- -- -- --

160

-- -- -- B B B* -- -- -- --

-- -- -- B B B* -- -- -- --

200

-- -- -- B B B* -- -- -- --

190

-- -- -- -- -- C C C C -- C**

-- -- -- -- -- C C C C -- C**

298

-- -- -- -- -- C C C C -- C**

410

-- -- -- -- -- C C C C -- C**

Model

RDDC

-100 -150 -200 -250 -300 -400 -500 -600 -700 -800 -1000

084

A A A -- -- -- -- -- -- -- -A A A B B -- -- -- -- -- --

114

A A A B B -- -- -- -- -- --

A A A B B -- -- -- -- -- --

-- A A B B -- -- -- -- -- --

184

-- -- -- B B -- -- -- -- -- --

-- -- -- B B -- -- -- -- -- --

-- -- -- B B -- -- -- -- -- --

-- -- -- B B -- -- -- -- -- --

-- -- -- B B -- -- -- -- -- --

236

-- -- -- B B -- -- -- -- -- --

-- -- -- B B -- -- -- -- -- --

248

-- -- -- -- -- C C C C -- C**

262

-- -- -- -- -- C C C C -- C**

-- -- -- -- -- C C C C -- C**

-- -- -- -- -- C C C C -- C**

354

-- -- -- -- -- C C C C -- C**

370

-- -- -- -- -- C C C C -- C**

468

-- -- -- -- -- C C C C -- C**

482

-- -- -- -- -- C C C C -- C**

Gas Heat Section Size

Gas Heat Section Size

Model RECB, REDB, RECC, and REDC by Electric Heat Module

and Cabinet Size

Model

RECB

060

078 --

090

118 120

136 --

160

186 --

200

190

216 --

298

410

Model

REDB

084

102 --

114

142 144

162 --

184

-- 196

210 -222 -224 --

236

-- 257

248

262

272 -288 --

354

370

468

482

Model

RECC

-10S -15S -20S -24S -15 -20 -25 -30 -35 -39 -50 -60 -75 -88

A A A A A A A A A A -- -- -- --

-- A A A A B A A B A B B B --

-- A A A A B A A B A B B B B

-- A A A A B A A B A B B B B

-- A A A A B A A B A B B B B

-- -- -- -- B B B B B B B B B B

-- -- -- -- B B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

Model

REDC

-10S -15S -20S -24S -15 -20 -25 -30 -35 -39 -50 -60 -75 -88

A A A A A B A A B A B B B --

-- A A A A B A A B A B B B B

-- A A A A B A A B A B B B B

-- A A A A B A A B A B B B B

-- -- -- -- A B A A B A B B B B

-- -- -- -- B B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- B B B B B B B B B

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

-- -- -- -- -- -- -- -- -- C C C C C

Electric Heat Section

Electric Heat Section

** A MAPS® C Cabinet with 1000 mbh of gas heat is a Size 700 mbh heat section plus an Option JH30 curb with a 300

mbh duct furnace.

3.1 Filters

The lter section is equipped with a slide out lter rack and 2 or 4 inch, pleated disposable or permanent aluminum lters. To remove lters, open the door and slide lters

out. Replacement lters are listed in the table below. Do not use any other type of

lters.

AW21 1 20x25x4 205791

AW24 1 20x25x4 256663

If equipped with permanent aluminum lters, remove the lters, wash, rinse, allow to

dry, and slide them back in the cabinet.

If equipped with pleated disposable lters, replace dirty lters. Exposure to humid

makeup air can accelerate lter degradation. Systems with disposable lters require

more frequent lter inspection.

2 16x20x2 104110

2 20x20x2 104111

2 16x20x4 211127

2 20x20x4 205790

2 16x20x4 256665

2 20x20x4 256662

2 16x20x2 101620

2 20x20x2 101621

4 16x20x2 101620

4 20x20x2 101621

4 20x25x2 104113 6 20x25x2 104113

4 20x25x4 205791 6 20x25x4 205791

4 20x25x4 256663 6 20x25x4 256663

4 20x25x4 101623 6 20x25x2 101623

8 20x25x2 101623 12 20x25x2 101623

Dirty Filter Switch

(Options BE16 and

BE18)

If equipped with a dirty lter switch or gauge, check the condition of the sensing tubes

to be sure that they are not blocked. Check the wiring connections. To set a new switch

(Option BE18), see Installation Form I-MAPSIII&IV, Paragraph 8.3, Replacement

switch is P/N 105507.

Form O-MAPSIII&IV Cabinets A/B/C, Page 6

Page 7

Filter

Clamp

Filter

Filter

Wing Screw,

P/N 205707,

and Retainer,

P/N 205709

(2 each)

Filter

Filter

Filter Clamps attach

with Wing Screws

P/N 205707

Filter

16x20x1

Filter

16x20x1

Filter

16x20x1

Filter

16x25x1

Filter

16x25x1

Filter

16x25x1

Filter

16x20x1

Filter

16x20x1

Filter

16x20x1

Inlet View

Permanent Filters in

the Outside Air Hood

If equipped with an outside air hood, there are 1" permanent, aluminum lters at the

entrance of the hood. The lters act as a moisture eliminator and bird screen. See FIG-

URE 2A or 2B. When inspecting the inlet air lters, inspect the outside air hood lters.

If cleaning is needed, remove the lters, clean, rinse, dry and re-install.

NOTE: If it is more convenient to keep an extra clean set of lters, lter sizes and part numbers are shown in the illustration.

FIGURE 2A -

Removing Filters

from Outside

Air Hood

1" Permanent

Aluminum Filters

for Outside Air

Cabinet Sizes A and B with Option AS16

Outside Air Hood

(Does not apply if

system includes

Option PE

power exhaust;

see below.)

All Cabinet Size C with

either Outside Air Hood

Option AS16 or AS19

Hood are listed by

Cabinet Size A, B, or C

(see cross-reference, page 6)

*A - (4) 16 x 20, P/N 101607

*B - (4) 16 x 25, P/N 101609

C - (3) 16 x 25, P/N 101609;

(6) 16 x 20, P/N 101607

* Apply only to Cabinet

Size A and B with outside

air hood Option AS16

.

Instructions: Remove lters by loosening the wing screws and sliding the lter

clamp(s). Clean with soap and water, allow to dry, and replace. If it is more convenient

to keep an extra clean set of lters, quantities, lter sizes, and part numbers are listed.

FIGURE 2B - Removing Filters from Option AS19 Outside Air

Hood Installed on a Cabinet Size A or B with power exhaust

Option PE1 or PE2

Instructions: 1) Remove the four screws as illustrated. Lower the tray.; 2) Pull out

lters. Clean with soap and water. Allow to dry.; 3) Slide clean dry lters into tray.;

4) Re-position tray and replace screws.

1" Aluminum Filters: **A - (4) 18 x 20, P/N 194903; **B - (4) 20 x 25, P/N 101610

** Apply only to Cabinet Size A and B with outside air hood Option AS19.

Filters in an Optional

Energy Recovery

Module

*See cross-reference of

MAPS® Models by Cabinet

Size A, B, or C on page 6.

3.2 Drive

Components

CAUTION: If the

blower is unused

for more than three

months, bearings

with a grease tting

should be purged

with new grease

prior to startup.

If equipped with an energy recovery module (Option ER1A, ER1B, or ER1C), check

both inlet and exhaust lters. Replace as needed.

Cabinet

Size *

A Pleated 20x25x2 2 104113 Pleated 20x25x2 2 104113

B

C

Inlet Air Filters (Merv 8) Exhaust Air Filters (Merv 8)

Filter Type & Size Qty P/N Filter Type & Size Qty P/N

Pleated 16x25x2 2 104112 Pleated 16x25x2 2 104112

Pleated 12x25x2 2 114320 Pleated 12x25x2 2 114320

Pleated 16x25x2 2 104112 Pleated 16x25x2 2 104112

Pleated 20x25x2 2 104113 Pleated 20x25x2 2 104113

Pleated 16x16x2 1 104109 Pleated 16x16x2 1 104109

Pleated 16x20x2 1 104110 Pleated 16x20x2 1 104110

Bearings - Bearings with a grease tting should be lubricated twice a year with a high

temperature, moisture-resistant grease. (Type NLGI-1 or -2 standard grease is recom-

mended.) Be sure to clean the grease tting before adding grease. Add grease with a

handgun until a slight bead of grease forms at the seal. Be careful not to unseat the

seal by over lubricating. NOTE: If unusual environmental conditions exist (temperatures below 32°F or above 200°F; moisture; or contaminants), more frequent lubrication is required.

Setscrews - Check all of the setscrews (bearing/blower hubs and pulleys). Torque pulley setscrews a minimum of 110 in-lb to 130 in-lb maximum.

A bearing hub setscrew for a 1-3/8" to 1-3/4" shaft requires a 5/16" socket and a tightening torque of 165 in-lbs.

Belts - Check belt for proper tension and wear. If needed, follow instructions to adjust

belt tension. Replace worn belts.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 7

Page 8

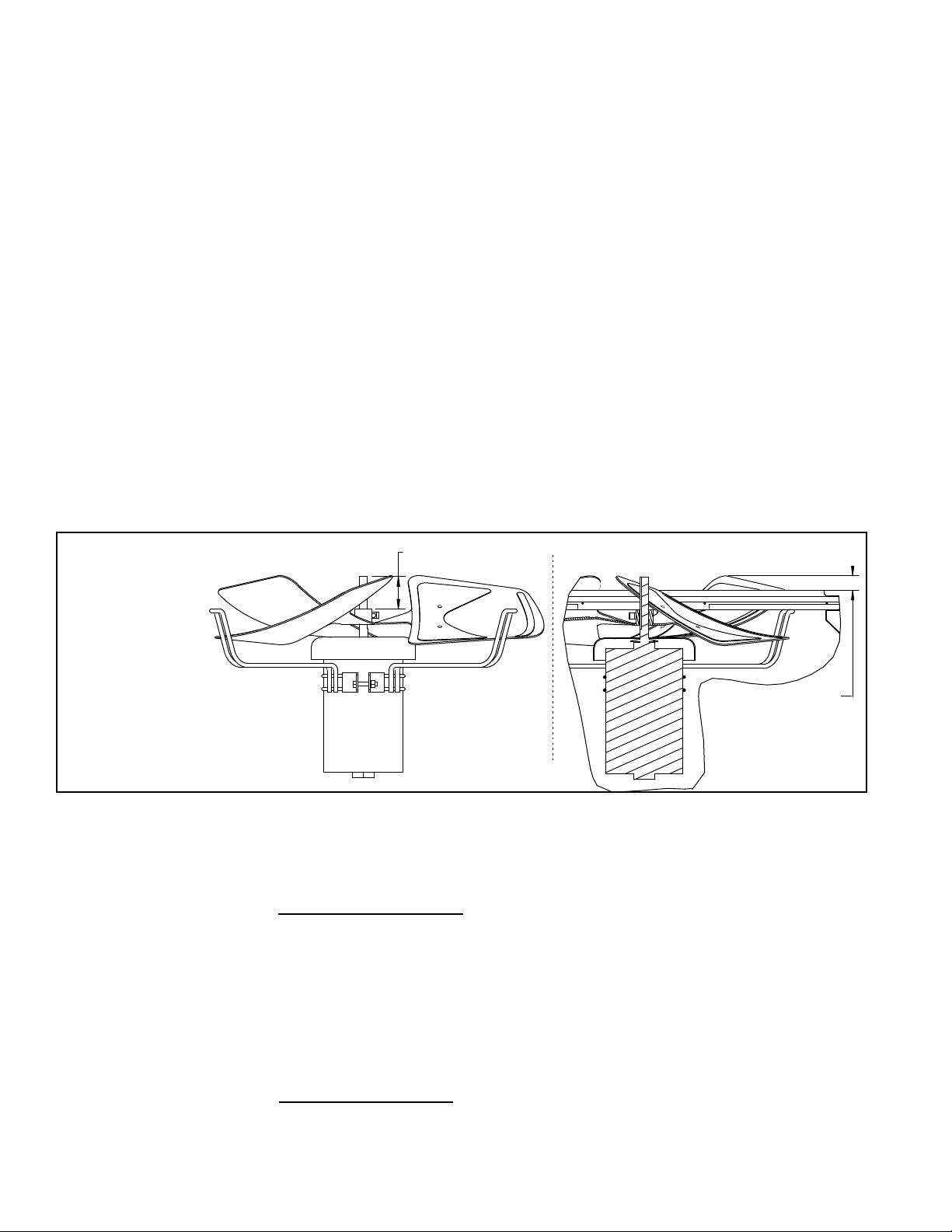

2-1/2” (63.5mm)

Fan and Motor Assembly

showing Fan Blade Position

Cross-section of Installed Fan and Motor

Assembly showing Cabinet Top

1.76” (44.7mm)

Top of Fan Blade

to Top of the

Cabinet Top Panel

Fan rotation is

clockwise.

3.0 Maintenance

and Service

Procedures

(cont'd)

3.2 Drive

Components

Cont'd)

Belts (cont'd) - Blower systems are equipped with either Power Twist Plus

blower belt or a solid belt. The linked belts are designed in sections allowing for easy

sizing and adjustment. The belt is sized at the factory for the proper tension. If the belt

needs adjustment, the recommended method of shortening the belt length is to count

the number of links and remove one link for every 24. (A link is made up of two joining

sections of belt. For easier removal of links, turn the belt inside out. But be sure to turn

it back before installing.)

If equipped with a solid belt, adjust the belt tension by turning the adjusting screw on

the motor base until the belt can be depressed 1/2" (13mm) on each side. After correct

tension is achieved, re-tighten the locknut on the adjustment screw.

Proper belt tension is important to the long life of the belt and motor.

Be sure belts are aligned in the pulleys. If a belt is removed or replaced, be sure the

directional arrows on the belt match the drive rotation.

Motor and Blower - Inspect the motor mounts periodically. Remove dust and dirt accu-

mulation from the motor and wheel.

The blower has cast iron, pillowblock, sealed bearings. Under most operating condi-

tions, re-lubrication is unnecessary. If lubrication is required, use a lubricant compatible to Shell Alvania #2 (lithium base - Grade 2). Operating temperature range is -30

to 230°F.

If any drive parts need to be replaced, use only factory-authorized replacements

designed for the application.

®

linked

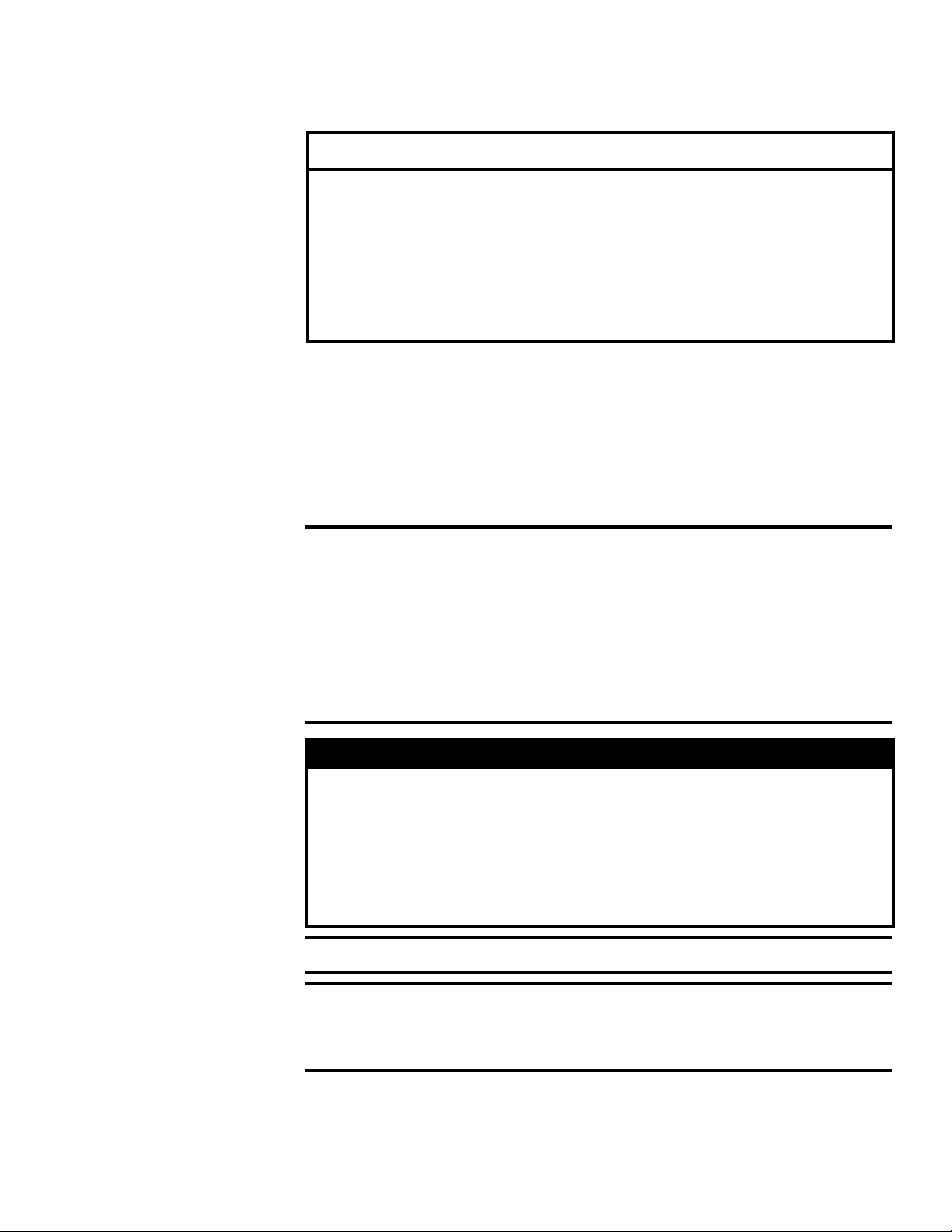

3.3 Condenser Fans

FIGURE 3 -

Condenser

Fan Assembly

Dimensions

and Rotation

3.4 Coil

Maintenance

Condenser

Coil Cleaning

Instructions:

Form O-MAPSIII&IV Cabinets A/B/C, Page 8

Depending on the size, there are two, three, or four fans in the condenser section. If

parts need to be replaced, use only factory authorized replacement parts. See FIGURE

3 for assembled dimensions and proper fan rotation.

The MAPS® cooling system is equipped with space-saving MACROCHANNEL

Inspect all cooling system coils at the beginning of the cooling season or more often if

needed. Follow the cleaning instructions below. If additional cleaning is required or if a

coil must be removed for any reason, consult the factory. Be prepared to provide rating

plate and specic installation information.

Condensing Coil Access - The condensing coils are visible on the side of the unit

(below the condenser fans). For additional access for inspection and maintenance,

remove the tubing access panel (See FIGURE 1, page 5.).

1. Verify that the electrical power has been turned off and the disconnect switch locked.

2. Use a soft brush to remove any dirt and debris from the coils.

3. Spray with cold or warm (not hot) water and a cleaning solution (non-acid based coil

4. When clean, rinse with cool, clean water.

Evaporator Coil Access - The evaporative coils can be accessed by opening the coil

cabinet door.

Inspect coils for debris, dirt, grease, lint, pollen, mold, or any element which would

obstruct heat transfer or airow. Inspect coils and tubing for physical damage. Inspect

®

coils.

cleaner is recommended). Due to possible damage to the coil, DO NOT use high

pressure spray.

Page 9

feeders, piping connections, coil headers, and return bends for signs of fatigue, rubbing, and physical damage.

Clean the coils annually, or more often if needed. Use the proper tools and follow the

instructions carefully to avoid damaging the coil. Use of a non-acid based coil cleaner is

recommended. Due to possible damage to the coil, DO NOT use high pressure spray.

Evaporator

Coil Cleaning

Instructions:

3.5 Check

Refrigerant

Pressure and

Temperatures

(subcooling

and superheat)

1. Verify that the electrical power has been turned off and the disconnect switch

locked.

2. Open the access panels.

3. Use a soft brush to remove any dirt and debris from both sides of a coil.

4. Spray with cold or warm (not hot) water and a cleaning solution (non-acid based

coil cleaner is recommended). Due to possible damage to the coil, DO NOT use

high pressure spray. First spray the leaving airow side, then the inlet airow side.

As much as possible, spray the solution perpendicular to the face of the coil.

Follow the instructions on the cleaning solution. When cleaning process is

complete, rinse both sides with cool, clean water.

DANGER

These refrigeration circuits are high pressure systems.

Hazards exist that could result in personal injury or death.

Removal, installation, and service of this scroll compressor

must be performed by a technician qualied in R-410A

refrigerant. DO NOT USE service equipment or tools designed

for R22 refrigerant. See Hazard Levels, page 3.

Two important requirements before checking superheat and subcooling:

1) This unit has fully intertwined refrigerant circuits and each circuit MUST be isolated before measuring its

temperature. Another active circuit will inuence the reading and make it impossible to determine accurate superheat

and subcooling.

2) If the circuit is equipped with an optional hot gas bypass valve, the valve must be disabled before measuring

superheat and subcooling. Method of disabling depends on the model and date of manufacture.

All MAPS®IV Models & any MAPS®III Models with a shutoff valve in the line between the compressor discharge and

the hot gas bypass valve - Locate the shutoff valve. Disable the hot gas bypass valve by closing the shutoff valve.

When measurements are complete, be sure to open the valve.

MAPS®III Models without a shutoff valve in the line between the compressor discharge and the hot gas bypass valve

- Disable the hot gas bypass valve by removing the cover and adjusting the spring tension counterclockwise until the

spring tension is relieved. Count and record the number of turns required so that you can return the bypass valve

to its original setting. To check setting, refer to Paragraph 3.9.5.

Check SUBCOOLING

Measure and record temperature and pressure of the liquid line at the condenser coil outlet.

STEP 1) Record Measurements: Temperature = ________°F (°C) and Pressure = ________ psig

STEP 2) From Temperature/Pressure Conversion Chart (page 10), convert Measured Pressure (STEP 1) to

________°F (°C)

STEP 3) Subtract Measured Temperature (STEP 1) from Temperature from Conversion Chart (STEP 2)

________°F (°C) - ________°F (°C) = ________°F (°C) degrees of Subcooling

Recommended subcooling with outdoor temperature range of 70 to 95°F (21 to 35°C)

is 10 to 12 degrees F (5.6 to 6.7 degrees C).

Too much subcooling indicates a refrigerant overcharge. To reduce the subcooling, remove excess refriger-

ant. Too little subcooling indicates a refrigerant undercharge. To increase subcooling, slowly add R-410A

refrigerant.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 9

Page 10

3.0 Maintenance and Service Procedures (cont'd)

3.5 Check

Refrigerant

Pressure and

Temperatures

(cont'd)

WARNING

Do not release refrigerant to the atmosphere. When adding or

removing refrigerant, the qualied technician must comply

with all national, state/province, and local laws.

Determine SUPERHEAT

Measure and record temperature (insulate probe from surrounding air temperature)

and pressure in the suction line at the compressor inlet.

STEP 1) Record Measurements: Temperature = _______°F (°C) and

Pressure = _______ psig

STEP 2) From Temperature/Pressure Conversion Chart (below), convert

Measured Pressure (STEP 1) to ________°F (°C)

STEP 3) Subtract Measured Temperature (STEP 1) from Temperature from

Conversion Table (STEP 2)

________°F (°C) - ________°F (°C) = ________°F (°C) degrees of

Superheat

Recommended superheat range is 8 to 12 degrees F (4.5 to 6.7

degrees C).

Typically, too much superheat indicates that the evaporator coil is undercharged.

Too little superheat typically indicates that the evaporator coil is overcharged and

may potentially ood liquid refrigerant to the compressor. To reduce the superheat,

adjust the thermal expansion valve by turning the adjusting stem counterclockwise. To increase the superheat, adjust the thermal expansion valve by turning the

adjusting stem clockwise.

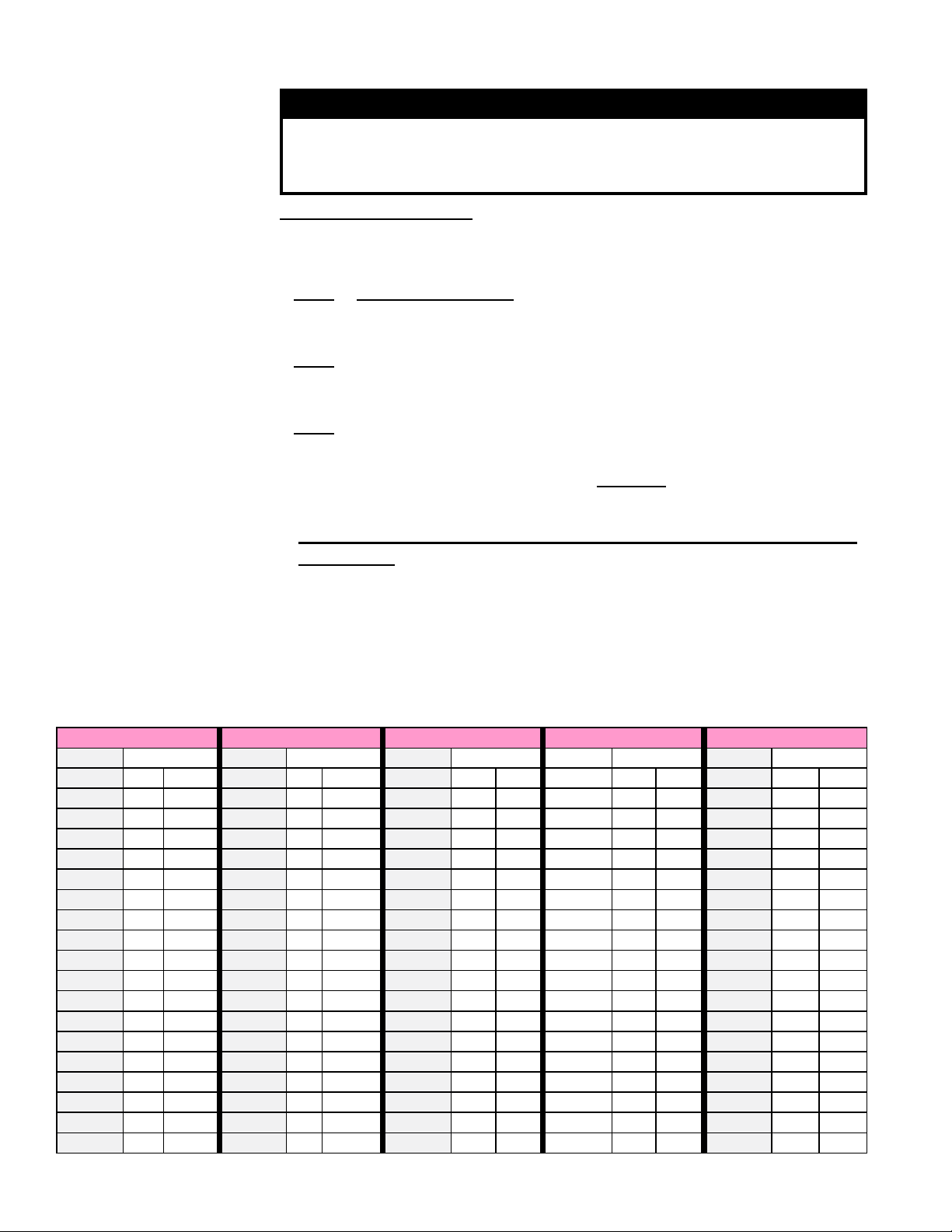

Temperature/Pressure Conversion Chart

R-410A Refrigerant R-410A Refrigerant R-410A Refrigerant R-410A Refrigerant R-410A Refrigerant

Pressure Temperature Pressure Temperature Pressure Temperature Pressure Temperature Pressure Temperature

PSI °F °C PSI °F °C PSI °F °C PSI °F °C PSI °F °C

1.8 -55 -48.3 49.5 1 -17.2 77.0 19 -7.2 112.2 37 2.8 218.2 75 23.9

4.3 -50 -45.6 50.9 2 -16.7 78.7 20 -6.7 114.4 38 3.3 235.9 80 26.7

7.0 -45 -42.8 52.2 3 -16.1 80.5 21 -6.1 116.7 39 3.9 254.6 85 29.4

10.1 -40 -40.0 53.6 4 -15.6 82.3 22 -5.6 118.9 40 4.4 274.3 90 32.2

13.5 -35 -37.2 55.0 5 -15.0 84.1 23 -5.0 121.2 41 5.0 295.0 95 35.0

17.2 -30 -34.4 56.4 6 -14.4 85.9 24 -4.4 123.6 42 5.6 316.9 100 37.8

21.4 -25 -31.7 57.9 7 -13.9 87.8 25 -3.9 125.9 43 6.1 339.9 105 40.6

25.9 -20 -28.9 59.3 8 -13.3 89.7 26 -3.3 128.3 44 6.7 364.1 11 0 43.3

27.8 -18 -27.8 60.8 9 -12.8 91.6 27 -2.8 130.7 45 7.2 389.6 11 5 46.1

29.7 -16 -26.7 62.3 10 -12.2 93.5 28 -2.2 133.2 46 7.8 416.4 120 48.9

31.8 -14 -25.6 63.9 11 -11.7 95.5 29 -1.7 135.6 47 8.3 444.5 125 51.7

33.9 -12 -24.4 65.4 12 -11.1 97.5 30 -1.1 138.2 48 8.9 474.0 130 54.4

36.1 -10 -23.3 67.0 13 -10.6 99.5 31 -0.6 140.7 49 9.4 505.0 135 57.2

38.4 -8 -22.2 68.6 14 -10.0 101.6 32 0.0 143.3 50 10.0 537.6 140 60.0

40.7 -6 -21.1 70.2 15 -9.4 103.6 33 0.6 156.6 55 12.8 571.7 145 62.8

43.1 -4 -20.0 71.9 16 -8.9 105.7 34 1.1 170.7 60 15.6 607.6 150 65.6

45.6 -2 -18.9 73.5 17 -8.3 107.9 35 1.7 185.7 65 18.3 645.2 155 68.3

48.2 0 -17.8 75.2 18 -7.8 110.0 36 2.2 201.5 70 21.1

Form O-MAPSIII&IV Cabinets A/B/C, Page 10

Page 11

3.6 Compressor

Compressor B

Compressor C

Compressor A

Compressor

Dh (Reheat)

Operation,

Maintenance,

and

Replacement

DANGER

The refrigeration circuits are high pressure systems.

Hazards exist that could result in personal injury or death. It

is therefore required that the removal and installation of this

scroll compressor be performed by a technician qualied in

R-410A refrigerant. See Hazard Levels, page 3.

DANGER

Never use oxygen to pressurize a refrigeration system. Oxygen

can explode on contact with oil and could result in personal injury

or death. When using high pressure gas such as nitrogen for

this purpose, ALWAYS USE A PRESSURE REGULATOR that can

control the pressure down to 1 or 2 psig. Failure to use a regulator

will result in extremely high pressure which could exceed the

burst pressure of the compressor or other system components

and result in personal injury or death. See Hazard Levels, page 3.

WARNINGS

For your safety, wear eye protection, gloves, and protective

clothing when handling refrigerant and oil and when brazing.

Have a re extinguisher nearby. See Hazard Levels, page 3.

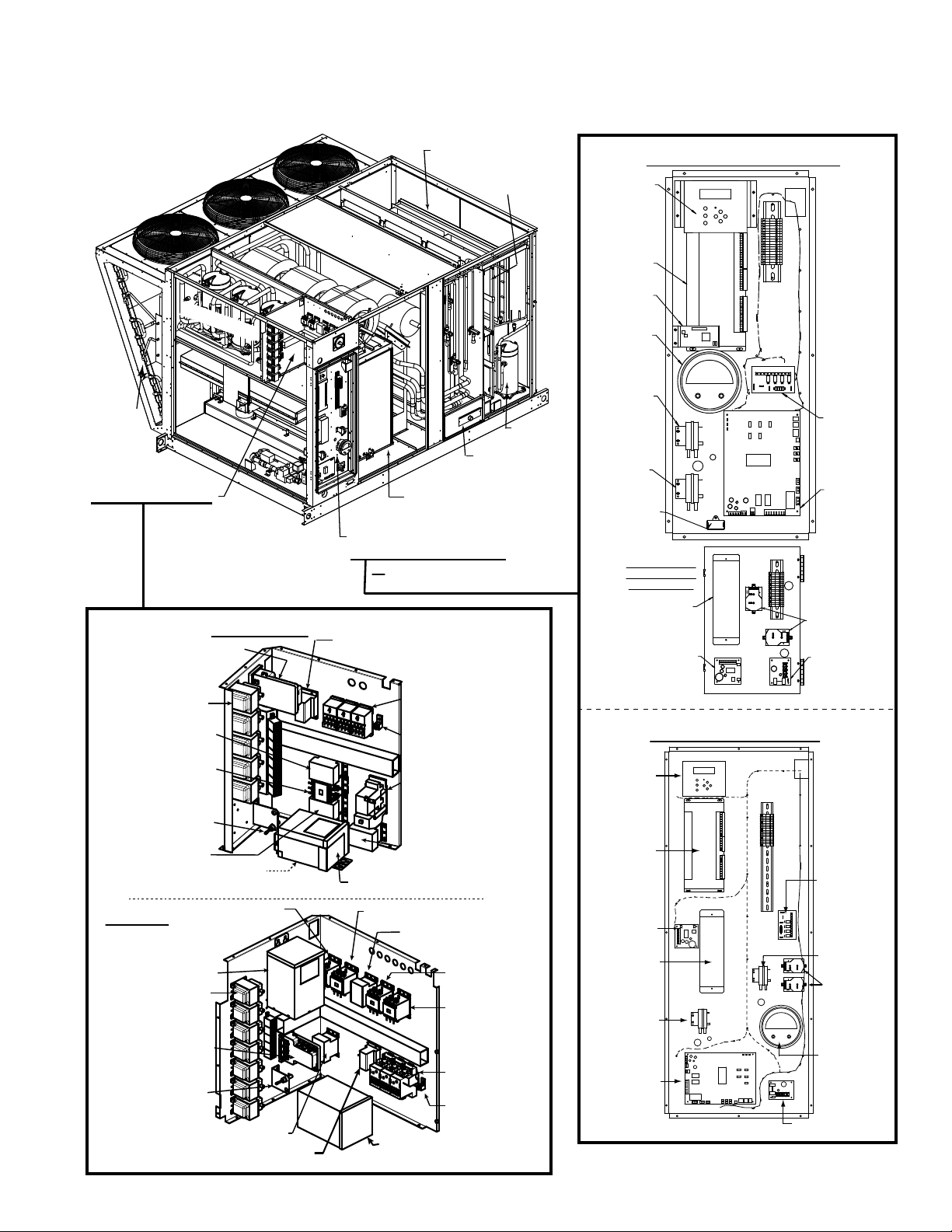

Compressor Staging

(Cooling) - applies to

all MAPS®III Models

Each MAPS®III system leaves the factory with the compressor staging sequence

shown here for that Model and Size. The compressor will start based upon a call for

cooling to maintain the discharge air temperature setpoint. There is a minimum 240

second ON and OFF time for each stage (not compressor).

FIGURE 4 - Identication of

Compressors by Circuit and

Staging for MAPS®III Models

Cabinet

Size

A

A or B

B

C

Cooling

Size

(RCB)

060

078

090

118

136

160 184 B A A+B A+B+C --

186

200

190

216

298

410

Cooling/

Reheat Size

(RDB)

084 B A A+B -- -102 B A A+B -- -114 B A A+B -- -142 B A A+B -- -162 B A A+B -- --

210 A B A+C A+B A+B+C

222 A B A+C A+B A+B+C

224 A B A+B B+C A+B+C

236 A B A+B B+C A+B+C

248 A B A+B -- -262 A B A+B -- -272 B B+C A+B+C -- -288 B B+C A+B+C -- -354 B A+B B+C A+B+C -370 B A+B B+C A+B+C -468 B A+B A+B+C -- -482 B A+B A+B+C -- --

Cooling Staging by Compressor

Circuit

1st 2nd 3rd 4th 5th

Compressor

NOTE: Staging listed by cooling only Models RCB/RDB also

applies to Models RDCB /RDDB with gas heat and Models RECB/

REDB with electric heat.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 11

Page 12

3.0 Maintenance/Service Procedures (cont'd)

Alarm Light

(Red LED) - See

Paragraph 7.2.

Compressor

Modualting

Solenoid Valve

Energized Light

(Yellow LED)

Power Light

(Green LED)

3.6 Compressor Operation, Maintenance, and Replacement (cont'd)

Compressors and Crankcase Heater P/N's by Voltage on MAPS®III Models

208-240/3/60 480/3/60 575/3/60

Compressor

Model P/N Model P/N Model P/N

ZP24K5E 235095 216434 ZP24K5E 235097 216436 ZP24K5E 235099 216437

ZP36K5E 235096 216398 ZP36K5E 235098 216400 ZP36K5E 235100 216401

ZP54K5E 235008 216398 ZP54K5E 235012 216400 ZP54K5E 235016 216401

ZP57K3E 216686 216398 ZP57K3E 216687 216400 ZP57K3E 216688 216401

ZP72KCE 235009 216398 ZP72KCE 235013 216400 ZP72KCE 235018 216401

ZP83KCE 216689 216398 ZP83KCE 216690 216400 ZP83KCE 216691 216401

ZP137KCE 235010 216398 ZP137KCE 235014 216404 ZP137KCE 235019 216405

ZPT144KCE 235011 216398 ZPT144KCE 235015 216400 ZPT144KCE 235020 216401

ZP154KCE 220260 216402 ZP154KCE 220261 216404 ZP154KCE 220262 216405

Crankcase

Heater P/N

Compressor

Crankcase

Heater P/N

Compressor

Crankcase

Heater P/N

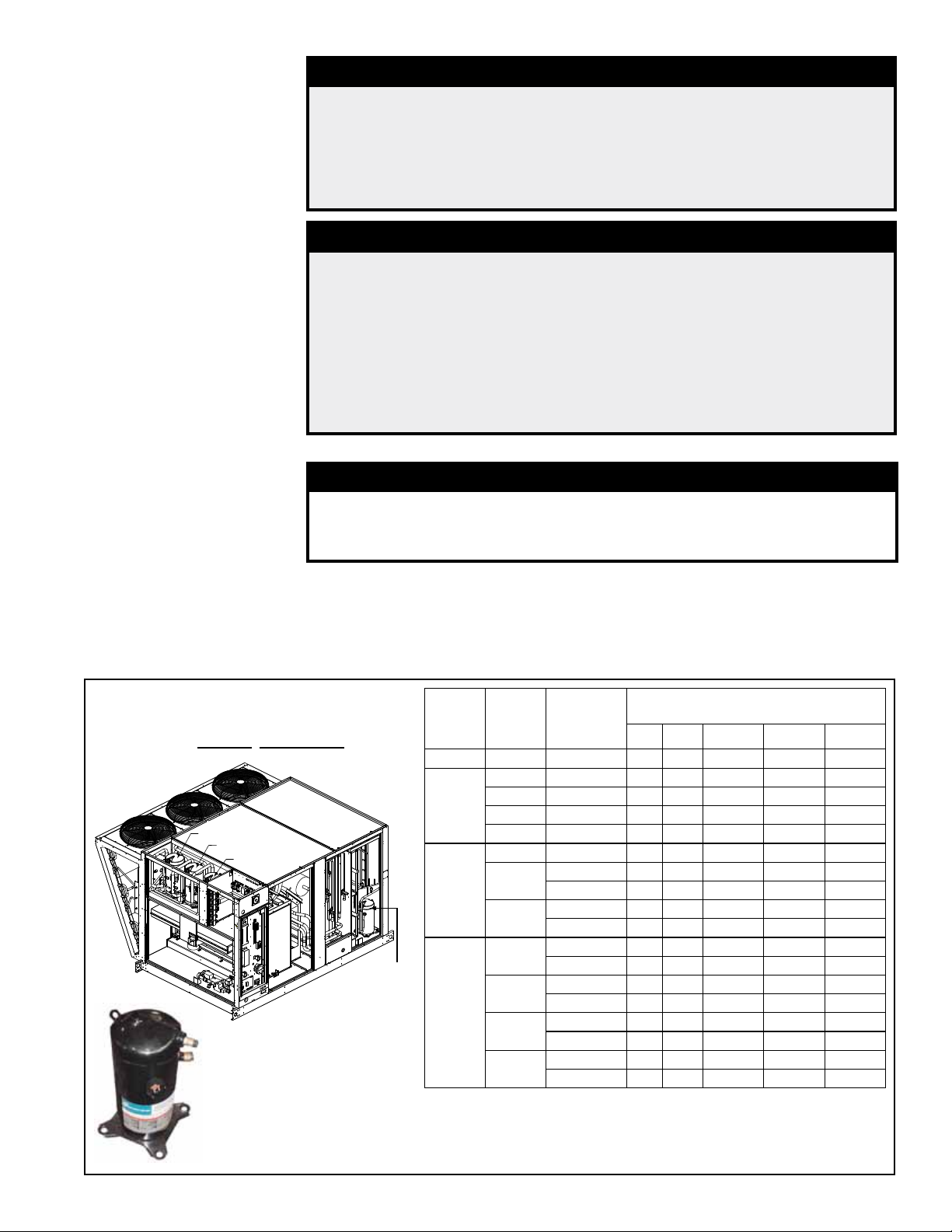

Modulating Cooling -

®

MAPS

IV Models

MAPS®IV units are equipped with a modulating capacity compressor and a digital con-

troller to provide cooling modulation. The digital controller in the control compartment

(See FIGURE 1, page 5) is the electronic interface between the compressor and the

NOTE: To identify MAPS®IV

Models, see Paragraph 1.0.

system controller. The compressor controller is connected to the unit controller to provide protection and diagnostics for modulating compressor operation.

After a compressor shutdown, a two-minute anti-short cycle timer in the compressor

controller delays the compressor restart. The unit controller has a ve-minute compressor on/off time. The delay times are concurrent so total delay time is ve minutes.

FIGURE 5 - Compressor Digital Controller

located in the control compartment

interfaces the modulating capacity

compressor with the unit controller.

LED

Color

Green Solid

Green Flashing Anti-short cycle timer is active

Yellow Solid

Red Not lit No abnormal operation alerts

NOTE: See Troubleshooting, Paragraph 7.2.

LED

State

Indicates

Power (24VAC present at power

terminals)

Unloader (Solenoid valve is

energized; compressor capacity is 0.)

Compressor and Crankcase Heater P/N's by Voltage on MAPS®IV Models

208-240/3/60 480/3/60 575/3/60

Compressor

Model P/N Model P/N Model P/N

ZP24K5E 235095 216434 ZP24K5E 235097 216436 ZP24K5E 235099 216437

ZP36K5E 235096 216394 ZP36K5E 235098 216396 ZP36K5E 235100 216397

ZP54K5E 235008 216394 ZP54K5E 235012 216396 ZP54K5E 235016 216397

ZP57K3E 216686 216398 ZP57K3E 216687 216400 ZP57K3E 216688 216401

ZP61KCE 261235 216398 ZP61KCE 261236 216400 ZP72KCE 235018 216401

*ZPD61KCE 261145 216398 *ZPD61KCE 261146 216400 ZP83KCE 216691 216401

ZP72KCE 235009 216398 ZP72KCE 235013 216400 *ZPD83KCE 261149 216401

ZP83KCE 216689 216398 ZP83KCE 216690 216400 ZP137KCE 235019 216405

*ZPD83KCE 261147 216398 *ZPD83KCE 261148 216400 *ZPD137KCE 261155 216405

ZP137KCE 235010 216402 ZP137KCE 235014 216404 *ZPD61KCE 268531 216401

*ZPD137KCE 261153 216402 *ZPD137KCE 261154 216404 ZP61KCE 268532 216401

ZP154KCE 220260 216402 ZP154KCE 220261 216404 *ZPDT14MCE 268533 216401

*ZPDT14MCE 262656 (2)216398 *ZPDT14MCE 262657 (2)216400 * Modulating capacity compressor

Form O-MAPSIII&IV Cabinets A/B/C, Page 12

Crankcase

Heater P/N

Compressor

Crankcase

Heater P/N

Compressor

Crankcase

Heater P/N

Page 13

Compressor

Replacement

WARNINGS

For your safety, wear eye protection, gloves, and protective clothing

when handling refrigerant and oil and when brazing. Have a re

extinguisher nearby. See Hazard Levels, page 2.

Compressor

Handling

Do not lift compressor by copper tubing. To prevent internal damage, compressors

must ALWAYS be held upright.

The following instructions include major points of consideration that will ensure proper

installation and protect you from potential personal injury. Please use the following 13

steps as a checklist, taking each item in order before proceeding to the next. If more

information is required, contact the Reznor HVAC Service Department for Reznor

products.

®

WARNING

To avoid electrical shock, power to the compressor(s) MUST REMAIN

OFF during performance of Steps 1 through 9 below. LOCK DISCONNECT

SWITCH OFF (open).

□ Step 1. Verify Proper Application

Verify that the replacement compressor is identical to the model being replaced.

All system components are matched to the compressor. Replacing a compressor

with a model other than the Reznor® specied replacement will void the product

warranty. See part numbers for R-410A compressors in the tables on page 12.

□ Step 2. Determine Cause of Initial Failure and Remove the Compressor

In order to prevent a second failure, the cause of the original failure must be

determined. Identify the cause and make the necessary repairs.

CAUTION: DO NOT LIFT compressor by copper tubing; damage will

occur. Compressor must remain upright.

WARNING

Wear eye protection and gloves when handling refrigerant or oil and

when brazing.

a) BEFORE REMOVING THE FAULTY COMPRESSOR, remove refrigerant

charge using proper recovery procedures. Call 1-800-441-9450 for the name

of the nearest Dupont authorized distributor or 1-800-ASK-KLEA (IGI) for

information on their refrigerant reclaim programs.

b) Disconnect wires. All compressor wiring is connected using a black molded

plastic plug. Remove the plug from the compressor.

c) Open access ports so that pressure does not build up in the system. Before

unbrazing stubs from the compressor, cut suction and discharge tubing with a

tubing cutter.

WARNING

Have a re extinguisher near. The compressor contains oil. There is a

risk of re when unbrazing stubs.

Use a high temperature torch to disconnect the suction line and the discharge line from

the compressor.

d) Remove the mounting bolts and the compressor. Save the mounting hardware

to attach the grommets and sleeves shipped with the replacement compressor.

e) To test for acid and to assure excess oil does not remain in the circuit, remove

oil from the failed compressor. Measure the amount of oil.

CAUTION: In addition to the required eye protection and gloves, care

should be taken in handling POE oil because it may cause damage to

certain plastics and roong materials. See Hazard Levels, page 3.

If the oil taken from the compressor and measured is found to be signicantly

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 13

Page 14

3.0 Maintenance/

Service

Procedures

(cont'd)

3.6 Compressor

Maintenance

(cont'd)

lower than listed in the table on page 14, clean the excess oil through use

of suction and liquid line lter driers. Beginning in Step 4, follow the same

procedure as for burnout cleanup.

Use an acid test kit to check the oil for acid. If acid is found, beginning in Step

Compressor Oil Charge (POE Oil)

Compressor Model cc oz

ZP24K5E 621 21

ZP36K5E 1124 38

ZP54KCE 1242 42

ZP57K3E 1715 58

ZP61KCE 1538 52

ZPD61KCE 1774 60

ZP72KCE 1774 60

ZP83KCE 1656 56

ZPD83KCE 1656 56

ZP137KCE 3253 110

ZPD137KCE 3135 106

ZPT144KCE 3312 112

ZP154KCE 3253 110

ZPDT14MCE 3135 106

4, follow procedures indicated for burnout cleanup.

Dispose of oil and compressor using an approved environmentally safe

disposal method.

Important NOTES: These R-410A

compressors use a polyolester (POE)

lubricant. Types of recommended POE

oil are Copeland Ultra 22 CC, Copeland Ultra

32 CC, Copeland Ultra 32-3MAF, Mobil EAL,

Arctic 22 CC, Uniqema Emkarate RL32CF, or

Uniqema RL32-3MAF.

POE oil absorbs moisture much quicker

and to a greater degree than standard

mineral oil. The compressor must not

be left open longer than 15 minutes

during replacement. During installation

the system must be swept with an

inert gas such as dry nitrogen to keep

moisture from entering the compressor

and prevent the formation of oxides.

• Step 3. Mount the Replacement Compressor

• Step 4. Install New Filter Driers (Select procedure that applies.)

Form O-MAPSIII&IV Cabinets A/B/C, Page 14

Do not remove the dust cover or rubber shipping plugs until all other system

connections are complete (i.e. new liquid line lter drier(s) installed and all tubing

changes made - see Steps 4 and 5). The amount of time the compressor is open

to the atmosphere must be kept to a minimum.

Use the new mounting grommets and sleeves that are shipped with the

compressor to mount it. The sleeves will prevent over compression of the

grommets. Re-use the mounting bolts from the compressor that was removed. The

mounting bolts will bottom out when tight.

IF the oil measured in Step 2 was not signicantly less than the amount shown in

the table above or the test for acid in Step 2 did NOT indicate burnout , install

a new R-410A refrigerant liquid line lter drier. The lter drier must be rated for

no less than 600 psig and be the proper size for the circuit. Because R-410A

refrigerant requires POE oil which absorbs moisture quickly, it is important to

change the lter drier any time the circuit is opened.

It is recommended to use a tubing cutter when cutting out a lter drier as the

desiccant absorbs and holds moisture better when it is cool. Heat from a torch

may cause moisture to leave the lter and be absorbed in the oil. Be careful to

keep dirt, lings, and other contaminants out of the system.

Continue to Step 5.

IF the oil measured in Step 2 was signicantly less than shown in the table above

or the test for acid in Step 2 did indicate compressor burnout, do the following:

a) Install a liquid line lter drier. If there is acid, install an acid removing lter

drier. Size the acid-removing lter drier at least one capacity size larger than

normally required for the circuit.

b) Install a temporary lter drier in the suction line. When there is acid, a 100%

activated alumina suction lter drier is recommended. The suction line drier

should be sized properly for the circuit and have a service access tting to

monitor pressure drop across the drier. (NOTE: Suction line lter drier must be

removed after 72 hours of operation.)

Page 15

Step 12 includes the remaining procedures required for cleanup of a burnout.

Continue to Step 5.

• Step 5. Braze on Suction and Discharge Lines

CAUTION: Do not leave system open to the atmosphere any longer

than minimum required for installation. POE oil in the compressors

is extremely susceptible to moisture absorption. Always keep ends

of tubing sealed during installation. See Hazard Levels, page 3.

Brazing materials must be able to withstand the high pressure of R-410A

refrigerant. A high temperature, silver phosphate type brazing with 5% or greater

alloy is recommended.

To prevent oxidation, purge tubing with 2-3 psig of regulated dry nitrogen while it

is being brazed. Open the service valve as needed to release the nitrogen. Do not

allow moisture to enter the system.

The installer is responsible for brazing and for complying with appropriate standard

refrigerant piping procedures.

CAUTION: All brazing should be done using a 2-3 psig dry nitrogen

purge owing through the pipe being brazed.

CAUTION: When brazing, protect all painted surfaces and

components from excessive heat. Wet wrap all valves but do not

allow moisture to enter the tubing. See Hazard Levels, page 3.

• Step 6. Check System for Leaks

After installation is complete, pressurize the circuit with helium or dry nitrogen to

approximately 150 psi (maximum pressure is 450 psi). Check for leaks using soap

bubbles or other leak-detecting methods.

• Step 7. Evacuate the Circuit

Evacuate one circuit at a time. Use a vacuum pump and micron gauge. Each

circuit must be evacuated to hold a 500 micron vacuum. Vacuum must be pulled

on both the discharge (high) and suction (low) side. Do the suction side rst; and

the compressor discharge side second. To establish that a circuit is leak-free

and moisture-free, a standing vacuum test is recommended. Close off the valve

to the vacuum pump and observe the micron gauge. If the vacuum gauge does

not rise above 500 microns in one minute, the evacuation should be complete.

If the vacuum gauge does rise above 500 microns in one minute, evacuation

is incomplete or the circuit has a leak. Repeat as needed until evacuation is

complete. The evacuation process must be done on each circuit.

NOTE: Evacuation will not remove moisture from POE oil. Moisture must be

prevented from getting in the oil.

Continue and/or repeat Steps 6 and 7 until evacuation is complete.

CAUTION: Do not use the replacement compressor as an

evacuation assist and never apply voltage to a compressor while

it is in a vacuum. See Hazard Levels, page 3.

Moisture and air are harmful to the system because they increase the condensing

temperature, raise the discharge gas temperature, cause formation of acids, and

cause oil breakdown.

CAUTION: Do not leave a circuit open to the atmosphere any longer

than minimum required for installation. POE oil in the compressor

is extremely susceptible to moisture absorption. Evacuation will

not remove moisture from POE oil.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 15

Page 16

Compressor B

Compressor C

Compressor A

Compressor

Dh (Reheat)

3.0 Maintenance/

Service

Procedures

(cont'd)

3.6 Compressor

Maintenance

(cont'd)

CAUTION:

Crankcase heaters

must be allowed

to warm up for

at least 24 hours

prior to startup.

Disable cooling

controls before

turning on power

to warm up

crankcase heaters.

• Step 8. Check the Electrical System

After the system has been evacuated, reconnect the electrical plug to the

compressor or the wires to the compressor terminals. It is a normal practice to

replace all starting components any time a compressor is changed.

WARNING

Do not apply voltage to the compressor when the plug is

removed or terminals disconnected.

Crankcase Heater - Connect the crankcase heater. The crankcase heater is

energized continuously and is extremely important to proper compressor operation

and long life. NOTE: See crankcase heater P/N's on page 12.

The crankcase heater must be energized for at least 24 hours before starting

the unit or after a power outage of more than 8 hours. Be sure to disable cooling

controls before turning on power to warm up crankcase heaters.

• Step 9. Charge the System (Use R-410A refrigerant only.)

Refer to the applicable table (either MAPS®III or MAPS®IV) for the approximate

amount of refrigerant required. Follow the instructions below to charge the circuit.

R-410A refrigerant MUST BE charged as a LIQUID.

NOTE: Outdoor temperature must be between 70-95°F (21-35°C) for verifying

superheat and subcooling. If temperature is not within this range, consult the

factory service department before charging.

If equipped with an optional hot gas bypass, disable the hot gas bypass valve

before charging. Method of disabling depends on the model and date of

manufacture.

All MAPS®IV Models & any MAPS®III Models with a shutoff valve in the line

between the compressor discharge and the hot gas bypass valve - Locate the

shutoff valve. Disable the hot gas bypass valve by closing the shutoff valve.

When measurements are complete, be sure to open the valve.

MAPS®III Models without a shutoff valve in the line between the compressor

discharge and the hot gas bypass valve - Disable the hot gas bypass valve by

removing the cover and adjusting the spring tension counterclockwise until the

spring tension is relieved. Count and record the number of turns required so

that you can return the bypass valve to its original setting. To check setting, refer

to Paragraph 3.9.5.

Liquid charge the high side to 80%. With the system running, add the balance of

the charge to the correct superheat and subcooling values. Refer to Step 11, page

17, and the instructions in Paragraph 3.5, page 9.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service

procedures include the adding or removing of refrigerant, the qualied HVAC service

technician must comply with all federal, state or provincial, and local laws.

Approximate R410-A Refrigerant Charge

(lbs) for MAPS®IV Models by Size and

Compressor for Each Circuit

Form O-MAPSIII&IV Cabinets A/B/C, Page 16

Cabinet

A 060 084 N/A 8.0 N/A 4.2

A or B

B

C

RCC/

RDCC/

RECC

090 114 N/A 10.5 N/A 4.2

120 144 8.0 8.0 N/A 4.2

160

200

190

298

410

RDC/

RDDC/

REDC

R410-A Charge (lbs) by Compressor Circuit

A B C

184

196 4.2

236

257 6.0

248

262 10.0

354

370 10.0

468

482 10.0

9.5 9.5 N/A

5.5 6.0 5.5

9.0 10.5 N/A

11.0 11.0

10.5 10.5 10.5

DH

(Reheat)

4.2

6.0

10.0

10.0

10.0

Page 17

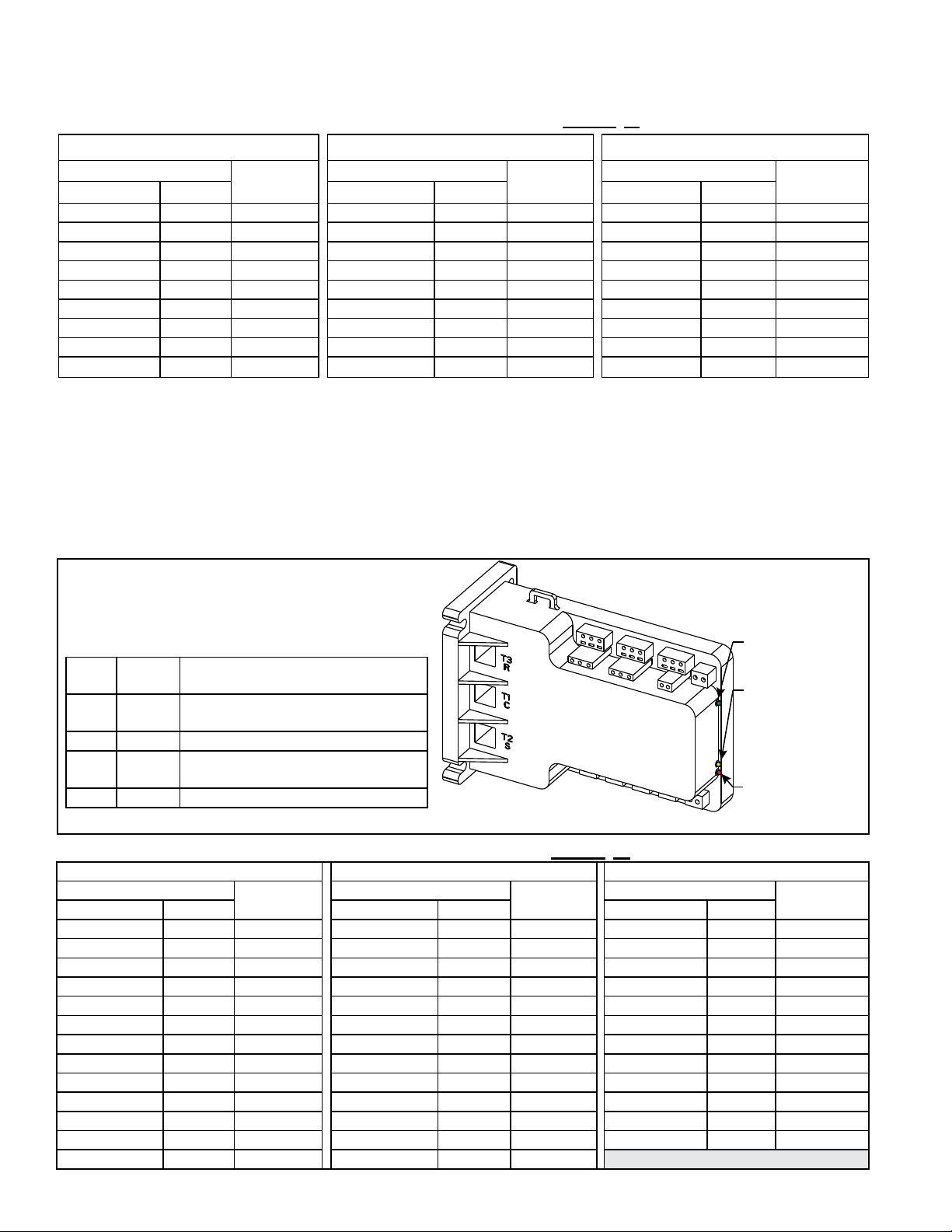

Approximate R410-A Refrigerant

Compressor B

Compressor C

Compressor A

Compressor

Dh (Reheat)

Charge (lbs) for MAPS

®

III Models

by Size and Compressor for Each

Circuit

• Step 10. System Startup

Assure voltage to compressor does not drop below minimum allowable voltage

(e.g. 187 volts for 230/208-3-60, 415 volts for 460/3/60, 518 volts for 575/3/60)

during the period the compressor is trying to start. If a low voltage or voltage

imbalance condition exists, the electrical problem must be determined and

corrected prior to operating the unit.

Voltage Imbalance - Voltage imbalance is becoming a more common problem.

In a 3-phase system, excessive voltage imbalance between phases will cause

motors to overheat and compressors to fail. Maximum allowable imbalance is

2%. To determine voltage imbalance, measure and record the voltage of all three

phases. Take the measurements at the compressor terminals with the compressor

operating.

Voltage Imbalance Formula:

Key:

Formula:

If the imbalance is within the 2% tolerance, voltage imbalance is not a problem and

the system may be operated. If the imbalance exceeds the 2% tolerance, follow

the procedures below.

Solutions to Voltage Imbalance:

The cause for a voltage imbalance problem can originate at the power company or

can be caused inside the building. Try the following on-site solution to determine if

the problem can be easily resolved.

Roll the connections at the compressor terminals one forward. Connect the wire

now on Terminal 1 to Terminal 2, 2 to 3, and 3 to 1. Re-measure and re-calculate

the voltage imbalance. If the imbalance is within 2%, the system may be operated.

If the imbalance is not within tolerance, roll the connections one more forward.

Re-measure and re-calculate the voltage imbalance. If the imbalance is within

2%, the system may be operated. If the voltage imbalance still exceeds 2%, do

not start the system. Contact the building owner or person responsible to have an

electrician analyze the buildings's power supply and load distribution.

Power Supply Voltage Phasing - Connect refrigerant pressure gauges to the

suction and discharge lines of the compressors and an electric meter to the power

supply.

Cabinet

A 060 084 4.3 4.0 N/A 4.2

A or B

B

C

RCB/

RDCB/

RECB

078 102 5.2 4.0 N/A 4.2

090 11 4 5.7 4.8 N/A 4.2

118 142 6.5 4.8 N/A 4.2

136 162 6.5 5.7 N/A 4.2

160 184 6.5 4.8 4.2 4.2

186

200

190

216

298

410

RDB/

RDDB/

REDB

210

222 6.0

224

236 6.0

248

262 10.0

272

288 10.0

354

370 10.0

468

482 10.0

R410-A Charge (lbs) by Compressor Circuit

A B C DH (Reheat)

5.2 6.0 5.2

5.2 6.0 6.0

8.0 10.5 N/A

11.0 8.5

11.0 11.0

10.5 10.5 10.5

4.2

4.2

9.5

9.5

9.5

9.5

V1, V2, V3 = line voltages as measured

VA (Average )= (V1 + V2+ V3) / 3

VD = Line Voltage (V1, V2, or V3 that deviates farthest from average (VA)

% of Voltage Imbalance = [100 (VA - VD)] / VA

CAUTION: Be sure to connect pressure gauges to the suction and discharge lines before

system startup so that compressor rotation can be checked immediately. Scroll compressors

will be destroyed if allowed to operate in the wrong direction. See Hazard Levels, page 3.

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 17

Page 18

3.0 Maintenance/

Service

Procedures

(cont'd)

3.6 Compressor

Maintenance

(cont'd)

• Step 10. System

Startup (cont'd)

NOTE: To identify MAPS

and MAPS®IV Models, see

Paragraph 1.0.

IMPORTANT: Do not

release refrigerant

to the atmosphere!

If required service

procedures

include the adding

or removing of

refrigerant, the

qualied HVAC

service technician

must comply with

all federal, state or

provincial, and local

laws.

®

Record the ambient temperature. Adjust the system controller so that a call for

cooling exists.

NOTE: Outdoor ambient lockouts may prevent mechanical cooling. Temporarily

override lockouts by lowering the cooling setpoint. When testing is complete, reset

the controller.

Because it is possible to unknowingly connect 3-phase power in such a way

as to cause the scroll compressor or blower to rotate in reverse, it is very

important to check this on startup.

Check Compressors - Immediately at startup, observe the gauges. If the

suction pressure rises and discharge pressure drops, the compressor is

operating in reverse and must be shut down. Turn off the power and switch

the 3-phase line voltage wiring connections before restarting the unit.

Important: If allowed to operate for several minutes in reverse, the compressor’s

internal protector will trip. If a compressor is repeatedly allowed to restart and run

in reverse, the compressor will be permanently damaged.

• Step 11. Check Subcooling and Superheat

Superheat is the verication that the evaporator coil is properly using the

refrigerant supplied. Too much superheat indicates that the coil is undercharged.

Too little superheat indicates that the coil is overcharged and potentially ooding

liquid refrigerant to the compressor.

Subcooling is the measurement of liquid refrigerant stored in the condenser

coil. Too much subcooling indicates a system overcharge. Too little subcooling

indicates a system undercharge and may not provide the thermal expansion valve

with a full column of liquid refrigerant for proper operation.

Two important requirements before checking superheat and subcooling:

1) This unit has fully intertwined refrigerant circuits and each circuit MUST be

isolated before measuring its temperature. Another active circuit will inuence the

reading and make it impossible to determine accurate superheat and subcooling.

2) If the circuit is equipped with an optional hot gas bypass valve, the valve must

be disabled before measuring superheat and subcooling. Method of disabling

depends on the model and date of manufacture.

III

All MAPS®IV Models & any MAPS®III Models with a shutoff valve in the line

between the compressor discharge and the hot gas bypass valve - Locate the

shutoff valve. Disable the hot gas bypass valve by closing the shutoff valve. When

measurements are complete, be sure to open the valve.

MAPS®III Models without a shutoff valve in the line between the compressor

discharge and the hot gas bypass valve - Disable the hot gas bypass valve by

removing the cover and adjusting the spring tension counterclockwise until the

spring tension is relieved. Count and record the number of turns required so

that you can return the bypass valve to its original setting. To check setting, refer

to Paragraph 3.9.5.

Follow the procedures in Paragraph 3.5 to check subcooling and superheat.

• Step 12. (Select the procedure that applies.)

IF the oil measured in Step 2 was signicantly less than in the table on

page 14 or the acid test in Step 2 indicated a burnout, do the following:

a) Operate the unit for several hours. Check the pressure drop through the

temporary suction line lter drier. If the pressure drop exceeds 8 psig, recover

the refrigerant, replace the suction line lter drier with the same type as

removed, replace the liquid line lter drier, evacuate the circuit, and re-charge

with the recovered refrigerant.

Continue to monitor the pressure drop through the suction line lter drier and

repeat the process above until the pressure does not exceed 8 psig after

several hours of operation. (NOTE: System must be allowed to run no more

than 72 hours with a suction line lter drier.)

b) Allow the system to operate for 4-8 hours. Recover the refrigerant and take an

oil sample. Retest the oil for acid.

Form O-MAPSIII&IV Cabinets A/B/C, Page 18

Page 19

c) If the test for acid is negative, remove the suction line lter drier, replace

Compressor B

Compressor C

Compressor A

Compressor

Dh (Reheat)

the liquid line drier, evacuate, and re-charge the system with the recovered

refrigerant.

If the test indicates acid, replace both the liquid line lter drier and the suction

line lter drier and repeat b) and c).

CAUTION: After cleanup is complete, remove the suction line lter

drier. See Hazard Levels, page 3.

d) Verify subcooling and superheat (refer to Step 11).

e) When the system is operating properly, remove the gauges.

Or, IF the oil measured in Step 2 was not signicantly less than that

shown in the table on page 14 or the acid test in Step 2 did not indicate

a compressor burnout, continue to the review in Step 13.

• Step 13 . Review ALL Steps to ensure that nothing was overlooked.

3.7 Thermostatic

Expansion

Valves

All refrigeration circuits have a thermostatic expansion valve. Thermostatic expansion

valves do not have replaceable parts. If a replacement valve is required, it must be

for R410-A refrigerant and must be sized correctly for the application. All refrigerant

service should be performed by a service technician qualied in R410-A refrigerant.

Replacement valve P/N's by Model, size, and circuit are listed in the following tables.

FIGURE 6 - Thermostatic Expansion

Valve

Cabinet

Size

A or B

Cabinet

Size

A or B

RCB/

RDCB/

RECB

A 060 084 220553 220552 -- 220552

078 102 220554 220552 -- 220552

090 114 220554 220553 -- 220552

118 142 220555 220553 -- 220552

136 162 220555 220554 -- 220552

160 184 220555 220554 220552 220552

186

B

200

190

216

C

298

410

RCC/

RDCC/

RECC

A

B

C

RDB/

RDDB/

REDB

210

222 220553

224

236 220553

248

262

272

288

354

370

468

482

RDC/

RDDC/

REDC

060

090

120 144 220554 220554 N/A 220552

160

200

190

298

410

084 N/A 220554 N/A 220552

114 N/A 220555 N/A 220552

184

196 220553

236

257 234967

248

262 234987

354

370 234987

468

482 234987

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 19

Thermostatic Expansion Valve P/N's by

Compressor Circuit

A B C DH (Reheat)

220554 220555 220554

220554 220555 220555

234987 220558 N/A

220558 220555

220558 220558

220558 220558 220558

Thermostatic Expansion Valve P/N's

by Compressor Circuit

A B C DH (Reheat)

220555 220555 N/A

220554 220556 220554

234967 261175 N/A

261175 261175

261175 261175 261175

220552

220552

234987

234987

234987

234987

234987

234987

234987

234987

220552

220553

234987

234987

234987

Page 20

3.0 Maintenance/

Service

Procedures

(cont'd)

FIGURE 7 - Damper

Motor

3.8 Optional Dampers and Damper Controls

Inlet Air Dampers

Location: Dampers and damper motors are located in the inlet air opening.

Function: Dampers operate in response to a variety of controls (GF Options).

Service: Clean dampers and controls of dust and dirt.

2-Position Damper Motor (Options AR8, AR2D, AR2L)

Function: The 2-position damper motor opens and closes the dampers in response to

unit operation or a eld-supplied time clock. The motor closes the dampers on heater

shutdown.

Modulating Motor (Options AR25, AR2G, AR2H, AR2K)

Function: The modulating damper motor actuates the dampers in response to the

selected control with actuation from input switch settings.

The motor closes the inlet dampers on heater shutdown.

Service: Other than external cleaning, there is no service required on the dampers or

the damper motor. If the damper, control, or motor need to be replaced, replace with a

factory-authorized replacement.

For additional information on damper controls (Options GF 1-9), see the system installation manual Form I-MAPSIII&IV.

3.9 Other Controls

FIGURE 8 - I/Q

System Programmable Controller

and Unit Module

Interface with Display

Refer to Control

Instruction Form

CP-MAPS D15/16/17/18

for information on the

programmable controller.

3.9.2 Air Proving

Switch

3.9.1 Programmable Digital Controller and Sensors

All MAPS® systems have a unit-mounted,

BACview

Display

I/Q System

Controller

Some sensors are standard and others will depend on option selection.

Service: If a sensor needs to be replaced, use only a factory authorized replacement

part designed for the purpose. Refer to the digital wiring requirements in Paragraph 7.4

of Installation Form I-MAPSIII&IV.

If a controller needs to be replaced, it must be replaced with the same controller and

software.

Function: The airow proving switch is a pressure switch that veries

to the main controller that the blower is operating.

Service: If the switch needs to be replaced, use a factory-authorized

replacement designed for the application.

24-volt I/Q programmable controller.

Depending on how it was ordered, the

system is equipped for either neutral air/

discharge air control (Option D15) or

space control with discharge air reset

(Option D16). In addition, MAPS®IV electric heat Model RECC for process applications may have neutral air/discharge

air control (Option D17) or space control

with discharge air reset (Option D18). The

controller is factory programmed to match

the selection. See the control instruction

manual, Form CP-MAPS D15/16/17/18, for

more details.

3.9.3 Motor Starter

(Option AN10) or

Variable Frequency

Drive (Option VFD2)

Form O-MAPSIII&IV Cabinets A/B/C, Page 20

Function: When the main controller calls for blower operation, either an IEC type

starter with a contactor or a variable frequency drive (VFD) module responds to operate the motor.

The starter is in the high voltage control compartment. The VFD was eld installed in

a location that is no more than 50 feet (15M) away where the minimum temperature

is 18°F (-9°C). Control of the variable frequency drive module is coordinated with the

main controller, and depending on what was ordered, can function in response to temperature, CO2, or pressure controls.

Service: If a starter or contactor need replaced, use only the identical replacements

that are designed to match the motor and voltage of the system.

Page 21

If a VFD needs to be replaced, contact the factory service department. Be prepared to

provide the model, serial, and wiring diagram number.

3.9.4 Voltage

Protection,

Option PL4

3.9.5 Hot Gas Bypass

Valve (Option AUC9)

FIGURE 9 - Hot

Gas Bypass Valve

3.9.6 Modulating

Reheat (Option

AUR1) - RDB, RDC,

RDDB, RDDC, REDB,

REDC

Function: Phase loss and low or high voltage can cause damage to electrical com-

ponents. This safety control monitors phase loss and voltage and shuts down the unit

when its limits are exceeded. The device is auto reset and allows the unit to restart

when the power conditions are corrected.

Function: The hot gas bypass valve allows some of the refrigerant gas from the suction line to be re-routed directly to the evaporator coil providing for expanded compressor modulation at low outside air temperatures.

Service: To check the hot gas bypass valve setting, connect a pressure gauge to the

suction line and block the entering air to the evaporator coil. Suction pressure will drop,

and the hot gas bypass valve should begin to open at a approximately 115 psi and will

be fully open at 95 psi. When the valve begins to open it will be hot to the touch (see

caution below).

CAUTION: Touching the operating hot gas bypass valve can cause

a burn. Use caution when checking and adjusting the valve. See

Hazard Levels, page 3.

If a hot gas bypass valve needs to be replaced, use only a factory-authorized replace-

ment for R410-A refrigerant. All refrigerant service should be done by a qualied R410-A

service technician.

Function: Units with modulating reheat control (Option AUR1) have a temperature

control board with a potentiometer, an air temperature sensor, and an electric discharge bypass valve. When reheat is active, the sensor monitors the air temperature

as it leaves the reheat coil. Based on the potentiometer setpoint, the board will open

or close the bypass valve. If the leaving air temperature is higher than the setpoint, the

board will open the valve adding refrigerant hot gas to the refrigerant liquid before it

enters the pre-cool coil. This reduces the coil's ability to absorb the heat, and thus, the

reheat coil's ability to reject. If the leaving air temperature is lower than the setpoint,

the opposite occurs.

Service: Check the wiring connections at the board. The board is polarity sensitive;

positive connects to terminal 1 and negative to terminal 2.

The valve may be tested by measuring the resistance of the leads. Remove the power

and the leads from the board before testing. Resistance between the black and white

leads should be about 75 Ohms. Resistance between the green and red leads should

be within 5% of the white and black.

Use only factory-authorized replacement parts.

4.0 Gas Heat

Section

Maintenance Models RDCB,

RDCC, RDDB,

and RDDC

This gas heater will operate with a minimum of maintenance. To ensure long life and

satisfactory performance, a heater that is operated under normal conditions should be

inspected and cleaned at the start of each heating season. If the heater is operating in

an area where an unusual amount of dust or soot or other impurities are present in the

air, more frequent maintenance is recommended.

When any service is completed, be careful to reassemble correctly to ensure that no

unsafe conditions are created. When re-lighting, always follow the lighting instructions

on the furnace.

WARNING

Turn off the power before performing maintenance procedures. Lock disconnect switch in

OFF position. When you turn off the power supply, turn off the gas at the external manual

valve. See Hazard Levels, page 2.

2

4.1 Heat Exchanger,

Burner,

and Venter

This gas heat section is equipped with a

Inspect the gas heat section annually to determine if cleaning is necessary. If there is

an accumulation of dirt, dust, and/or lint, clean the compartment.

TCORE

®

style heat exchanger and burner.

Maintenance

Form O-MAPSIII&IV Cabinets A/B/C, P/N 257004R8, Page 21

Page 22

Venter Motor

and Wheel

Assembly

Venter Side Supports

Venter

Housing

and Support

Flue Collection

Box Assembly

Venter Support

Venter

Housing

Venter

Housing

Gasket

Motor and

Wheel Assy

OR, depending on the Cabinet size

and date of manufacture, venter

components may look more like

the one shown below.

4.0 Gas Heat Section Maintenance - RDCB, RDDC, RDDB and RDDC (cont'd)

4.1 Heat Exchanger, Burner, and Venter Maintenance (cont'd)

4.1.1 Instructions for

Inspecting/Cleaning

the Heat Exchanger

and Burner

CAUTION: Use of

eye protection is

recommended.

NOTE: If the installation

includes a Model JHUP

curb duct furnace, the

inspection and cleaning

procedures described in

Paragraph 4.1 also apply

to the duct furnace. For

illustration of a curb duct

furnace, see the installation

manual, Form I-MAPSIII&IV