Reznor RBL User Manual

NOTE: After installation, keep this

booklet with the makeup air system

installation/operation manual.

OPTIONS AS3, AS4, AS5, AND AS8

EVAPORATIVE COOLING MODULE

INSTALLATION/OPERATION/MAINTENANCE

FORM RZ/NA I-OPT-EC

OBSOLETES FORM 400EC

1. Description/

Application

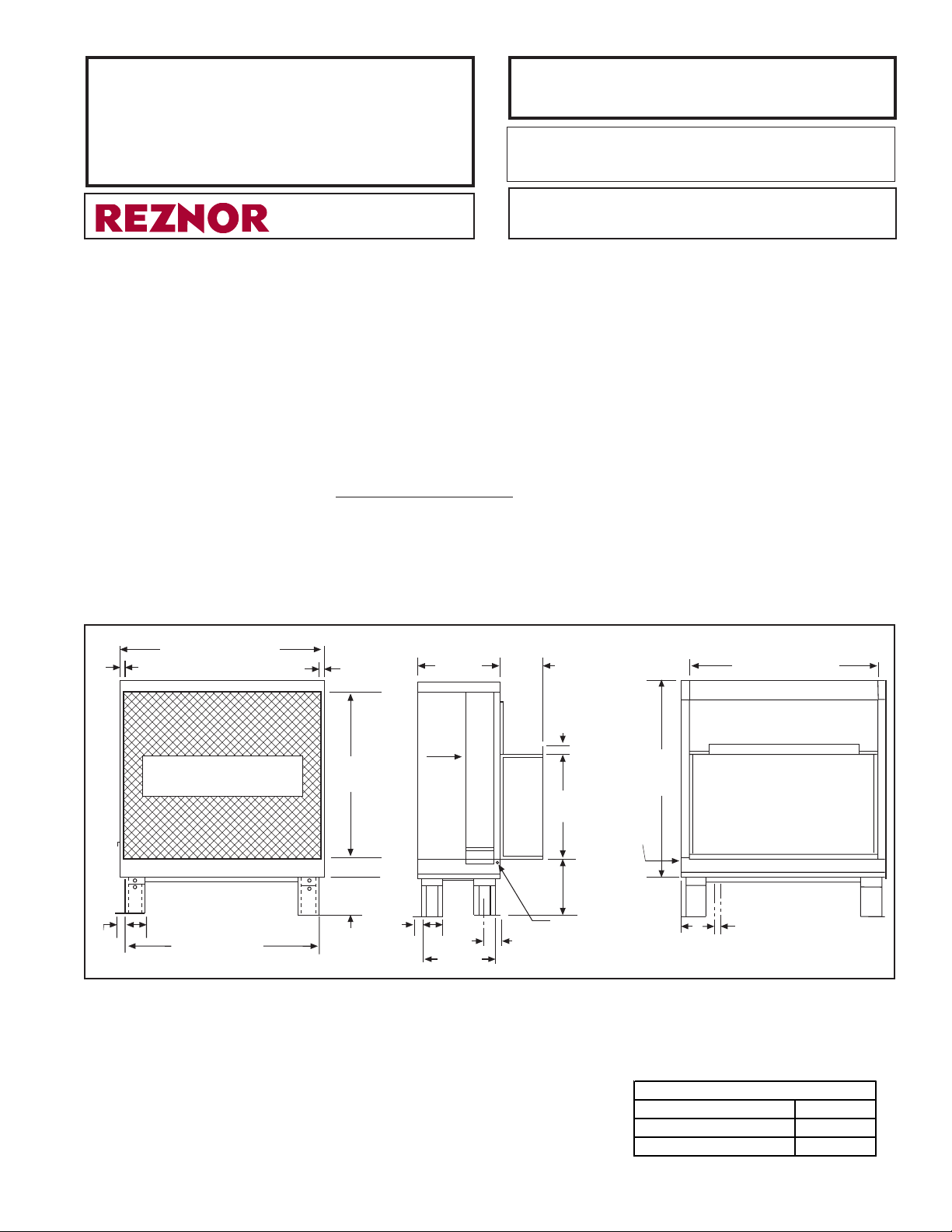

2. Dimensions

58-3/4 (1492mm)

1 (25mm)

1 (25mm)

®

APPLIES TO: Models RGBL,RPBL,SSCBL,PGBL;

Models ADF/ADFH 700/1200; Model RBL

The optional evaporative cooling module for packaged indirect-fired system Model

Series RGBL, RPBL, SSCBL, PGBL, blower cabinet Model RBL, and direct-fired

makeup air Models ADF/ADFH 700/1200 is factory assembled but requires field

installation. Evaporative cooling module Option AS3 includes 6” rigid cellulose

media; Option AS4 includes 12" rigid cellulose media; Option AS5 includes 6"

rigid glass fiber media; and Option AS8 includes 12" rigid glass fiber media. The

base parts for supporting the evaporative cooling module and the transition duct for

connecting it to the unit are shipped with the module for field assembly and installation. If optional moisture elimination pads, a drain and fill kit, and/or a water

hammer arrestor are to be included in the installation, they also require field installation.

Indoor Installation Note: The evaporative cooling module cannot be suspended;

it must be placed on a platform. If the installation is not conducive to providing a

platform for the optional evaporative cooling module to attach directly to the cabinet, install a compatible Reznor ® Model REC evaporative cooling module which

also must be mounted but requires a field-fabricated transition duct and can be

located further away. All evaporative cooling modules require outside air.

24

(610)

12

(305)

54-1/16 (1373)

Opening Size

56-3/4 (1441) x 48 (1219)

Inlet View

2(51)

6 (152)

47-3/4 (1213)

3. Installation

Preparation

Check List:

3 (76)

29-3/4

(756)

Adjustable

21-9/16 (548)

maximum

14-9/16 (370)

minimum

Water Connection

(1/4 tubing)

5-1/32

Drain/Overflow Connection

)

(128

(centerline)

56-5/8

(1438)

Water

Connection

(Control

Side)

Transition Duct Opening

for Reznor Model Series

RGBL, RPBL, SSCBL, and

PGBL; Blower Model RBL;

and Model ADF/ADFH

Sizes 700 and 1200.

Outlet View

9-1/2

(241)

2(51)

Drain/Overflow

Connections

47-3/4

(1213)

5-1/2 (140)

Adjustable Legs

16 (406) maximum

9 (229) minimum

2(51)

AIR

FLOW

Control

Side

View

6 (152)

21-1/2

(546)

Control Pump

Access Panel

o Make certain the installation complies with all local, utility and federal build-

ing and safety codes and regulations.

o Check module for shipping damage. If damage is found, document the damage

with the transporting agency and immediately contact your Reznor Distributor.

o Check fabricated parts in the duct kit

package against parts list shown in

FIGURE 2, page 3. The package

also includes the hardware listed

here.

Transit ion D uct Hard w are Pack age

#10x1/2” Screws (58) 11813

1/4 - 20 Hex Head Bolts

(10) 16246

1/4 - 20 Nuts (10)16050

Mfg No. 160202, Page 1

3. Installation

Preparation

Check List

(cont’d):

In addition, the following parts for making electrical and water connections are

shipped in the bottom pan of the evaporative cooling module.

Qty P/N Descrip ti on

1 105945 1/4" Hose I.D. x 1/2" N.P.T. Bleed Line Fitting (not used

with optional timed metering AquaSaver® system)

2 16835 Bushings, Heyco #SR-7W-2

o If the evaporative cooling module is being installed indoors (Model SSCBL,

PGBL, or ADF/ADFH 700/1200), outside makeup air must be provided.

o If optional shipped-separate equipment will be included (Drain and Fill Kit,

Freeze Protection Kit, Moisture Elimination Pads, and/or Water Hammer

Arrestor), check to be sure that these parts are available for installation.

o Make certain the roof or platform is capable of handling the additional load of

a cooling module with a full reservoir.

Weights of Evaporative Cooling Module - With Wet Media & Full Reservoir

Module with 6" rigid cellulose media (Opt AS3) ............... 379 lbs (172 kg)

Module with 12" rigid cellulose media (Opt AS4) ............ 431 lbs (195 kg)

Module with 6" rigid glass fiber media (Opt AS5) ............. 420 lbs (191 kg)

Module with 12" rigid glass fiber media (Opt AS8) ........... 514 lbs (233 kg)

o Make certain the surface is level and free of debris where cooling module will

be mounted.

o Do not mount directly on soft tar roofs where the legs could sink and tilt the

cooler. Provide a weather-resistant, solid wood or metal base under the cooling

module support base.

o Make certain that there will be adequate clearance between the bottom of the

reservoir and the roof or platform to allow for drain and overflow pipe connections.

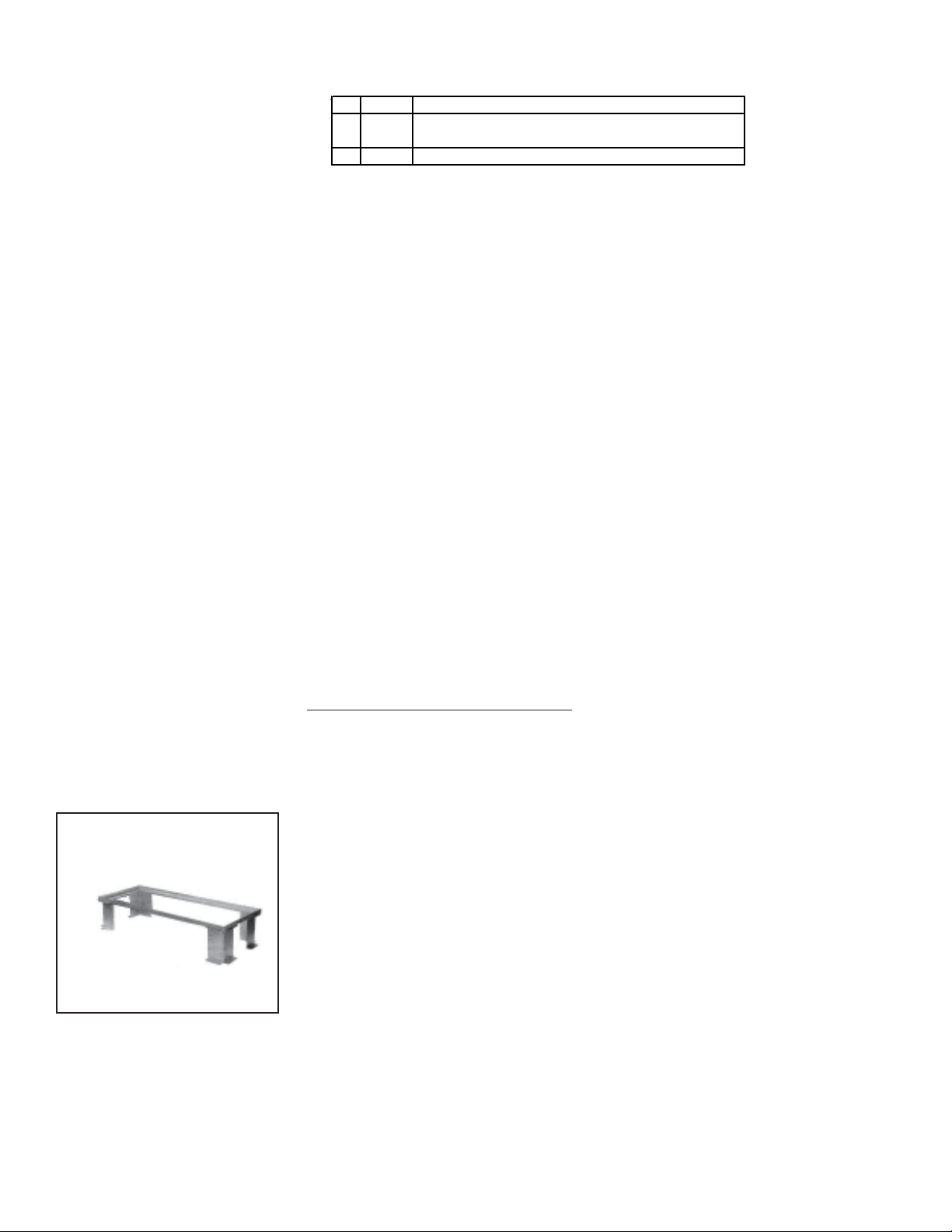

4. Base and

Transition

Duct

Installation

Instructions

FIGURE 1- Assembled

Base for Evaporative

Cooling Module

Adjustable Leg

Height

16” (406mm) Maximum

9” (229mm) Minimum

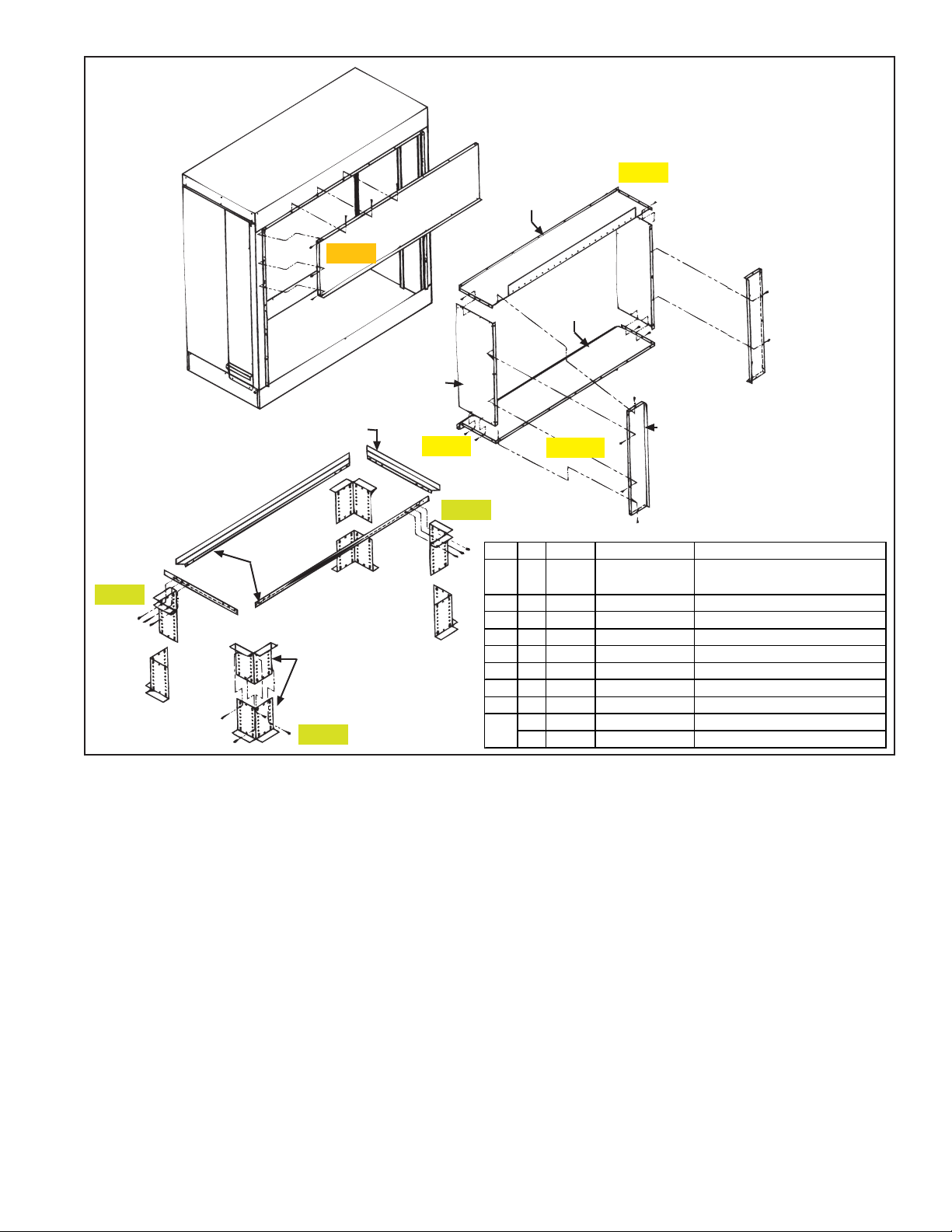

Attach the evaporative cooling module after the makeup air unit is in its permanent

location. Do not install the evaporative cooling module and connecting duct while

the blowers are in operation. Steps 2-11 are illustrated on FIGURE 2, page 3.

Steps 12-20 are illustrated in FIGURE 4, page 4.

FOLLOW EACH STEP IN ORDER.

STEP 1:

1) Be sure all preparations have been made. Review Preparation Checklist, pages

1 and 2.

Assembling Base, FIGURE 1 & STEPS 2-5, FIGURE 2:

2) Using four bolts and nuts per leg, fasten the two leg halves (ITEM 4) together.

See FIGURE 2, Step #2. The top flange of the assembled legs should be level

with the bottom of the system cabinet. Adjust legs to proper height and tighten

bolts securely. Assemble all four legs.

3) Approximately two feet (610mm) from the air inlet side of the cabinet, posi-

tion the four assembled legs in a rectangular pattern corresponding to the size

of the cooler. Depending on the type of surface, it may be necessary to set the

legs on a weather-resistant, solid wood or metal base. Check again to be sure

that the top of the legs are level with the bottom of the makeup air system

cabinet.

4) Place rail sides (ITEM 3) on the inside of the top flanges of the leg assemblies.

Using the bolts and nuts provided, bolt the side rail to the top three holes

located on the legs just below the top flange. Repeat on the remaining three

legs. Tighten nuts securely.

5) Place the rail ends (ITEM 2) on the inside of the top flange of the leg assem-

blies. Bolt the end rail to the top three holes located on the legs just below the

top flange. Repeat on the remaining three legs. Tighten nuts securely.

Form I-OPT-EC, Page 2

Cooling Module

FIGURE 2 - Parts List and Illustration for

Assembling Base and Transition Duct for

Optional Evaporative Cooling Module

Cooling Module

Base (must

be field

assembled)

Step 4

ITEM 1

ITEM 3 (2)

ITEM 2

(2)

ITEM 4

(4 sets)

Step 2

Step 7

ITEM 7 (2)

ITEM 5

Step 9

Step 5

Step 8

ITEM 6

Transition Duct

(connects cooling

module to makeup

air system)

ITEM 8

ITEM 9 (2)

Step 11

Item Qty P/N Description Where Us ed:

1 Evaporative

1

Cooling Module

2 107235 Support Ends Base Assembly

2

2 107227 Support Sides Base Assembly

3

8 107236 Leg Halves Base Assembly

4

1 107228 Front Top Cover Cooling Module

5

1 107229 Duct Top Transition Duct

6

2 107231 Duct Side Transition Duct

7

1 107230 Duct Bottom Transition Duct

8

2 107233 Duct Extensions “BL” Models 500 and 600

9

2 107234 Duct Extensions “BL” Models 700 and 1050

Used on BL

Sizes 500, 600,

700, & 1050 only.

Not required on

other Models

and Sizes.

Factory-assembled for field

attachment to a makeup air system

Attaching

Cover and

Assembling

Transition

Duct

(FIGURE 2,

STEPS 7-11)

6) Carefully lift the evaporative cooling module (ITEM 1) from both ends and place it on the

completed base assembly. Be certain that the cooling module is level and all base assembly bolts are secure.

7) Attach front top cover (ITEM 5) to cooling module, as shown in STEP #7 using 13 of the

# 10 x 1/2" long sheetmetal screws. There will be three screws per side and seven screws

across the top.

8) Attach transition duct sides (ITEM 7) to duct top (ITEM 6) using eight, #10 x 1/2"

long sheetmetal screws. As shown in STEP #8, there will be four screws per side.

9) Fasten the duct bottom (ITEM 8) to the transition duct sub-assembly begun above

by following STEP #9, using eight of the #10 x 1/2" long sheetmetal screws

provided. Again, there will be four per side.

10)If the packaged heating system is a “BL” 500, 600, 700 or 1050 size, the duct

extensions (ITEM 9) must also be installed on the transition duct. If the packaged

heater is a “BL” 400, 800, or 1200 size, an RBL, or an ADF/ADFH, skip STEP

11 and continue with STEP 12.

11)There are two sizes of the duct extensions. One is used to fit the “BL” 500 or 600

size heaters; one fits the 700 and 1050 size heaters. To fasten the duct extension

(ITEM 9) to the transition duct assembly, use 14 #10 x 1/2" long metal screws as

shown in STEP #11. Five screws will be used on each side of the extension and

one up through the bottom of the extension.

Mfg No. 160202, Page 3

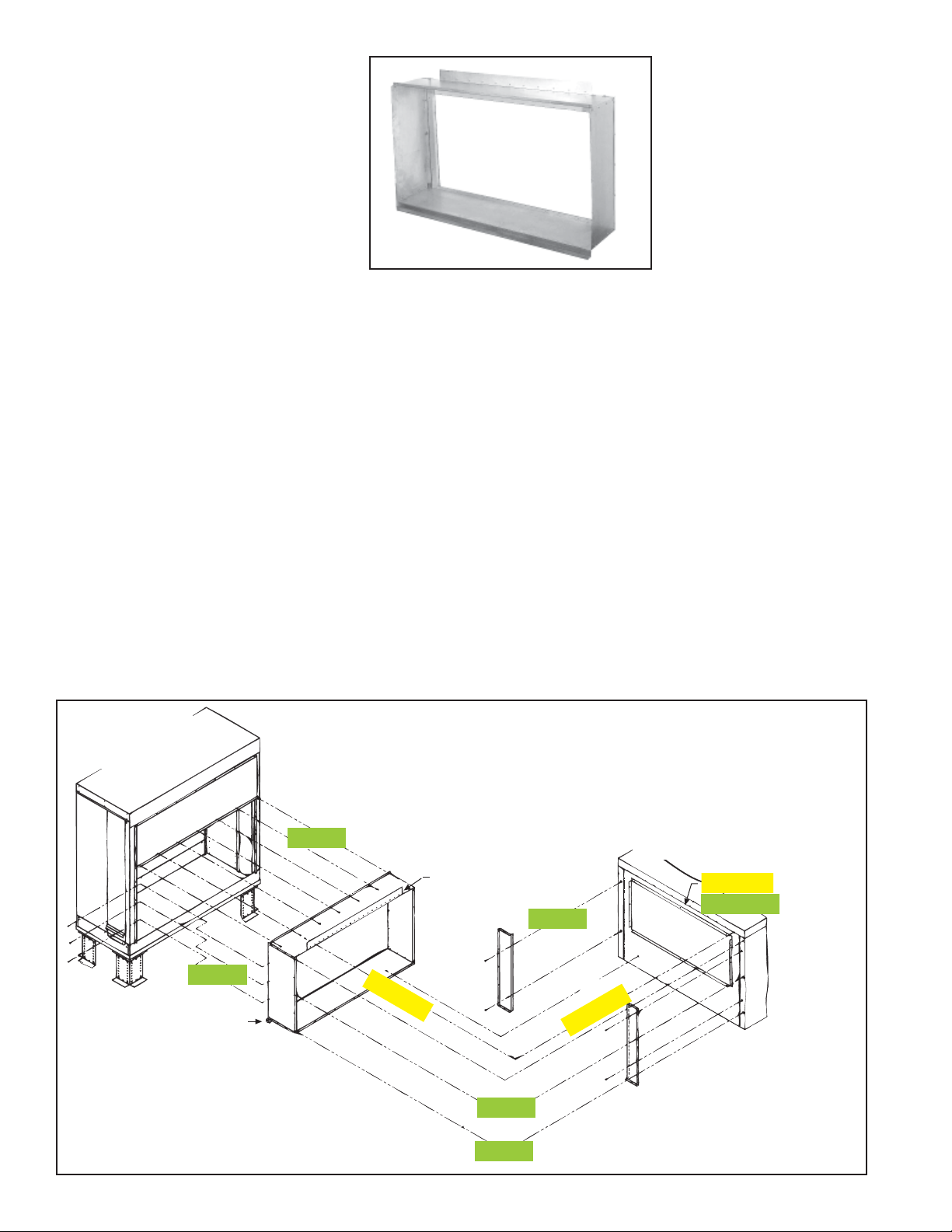

Assembling

Transition

Duct (cont’d)

Attaching

Transition

Duct and

Cooling

Module to

System

Cabinet

(FIGURE 4,

STEPS 12-

21):

FIGURE 3 Assembled

Transition Duct

12)Following Step #12A, remove the screws from along the top rear lip of the blower

cabinet panel. Slip the transition duct flange underneath the cabinet top edge and

loosely insert two screws through the top edge, through the transition duct flange, and

into the cabinet end panel. Follow STEP #12B.

13)If the transition duct has duct extensions (FIGURE 2, ITEM 9), insert the duct extension

mounting flanges into the slots on the cabinet end panel.

14)With the transition duct attached to the cabinet, carefully tilt the transition duct upward

enough to clear the cooler reservoir pan and slide the evaporative cooling module

underneath the catch pad mounting trough. Squeeze the cooling module and transition

duct assembly into the system cabinet until a tight fit is obtained.

15)Following STEP #15, line up the holes in the cooling module corner leg with the holes in

the transition duct sides. Using five #10 x 1/2" long sheetmetal screws per side, fasten

the transition duct sides to the cooling moduler.

16)Following STEP #16, fasten the transition duct top lip to the front top cover of the

cooling module with seven of the #10 x 1/2" long sheetmetal screws provided.

17)With the cooling module and transition duct properly positioned on the blower cabinet,

tighten the two screws loosely inserted in STEP 12B. Insert and tighten screws in the

remaining holes along top edge of cabinet.

NOTE: When attaching the transition duct to the cabinet (STEP 18 or 19), you may find

it easier with the media pads removed. See FIGURES 5 and 7 and the corresponding

Evaporative

Cooling

Module

Front Top Cover

Catch Pad

Mounting Trough

Step 15

Step 16

FIGURE 4 - Illustration for attaching Transition Duct and

Evaporative Cooling Module to the System Cabinet

(illustration is angled for clarity; actual connections will be

in a straight line)

Makeup Air

Transition

System Cabinet

Duct

Flange (must go under

edge of cabinet top)

Step 12A

& Step 17

Step 19

Step 12B

Step 12B

Duct extensions (if used)

Step 18

are attached to the transition

duct. Duct extension flanges

go into slots on the cabinet.

Step 20

Form I-OPT-EC, Page 4

Loading...

Loading...