Page 1

TECHNICAL

SPECIFICATIONS

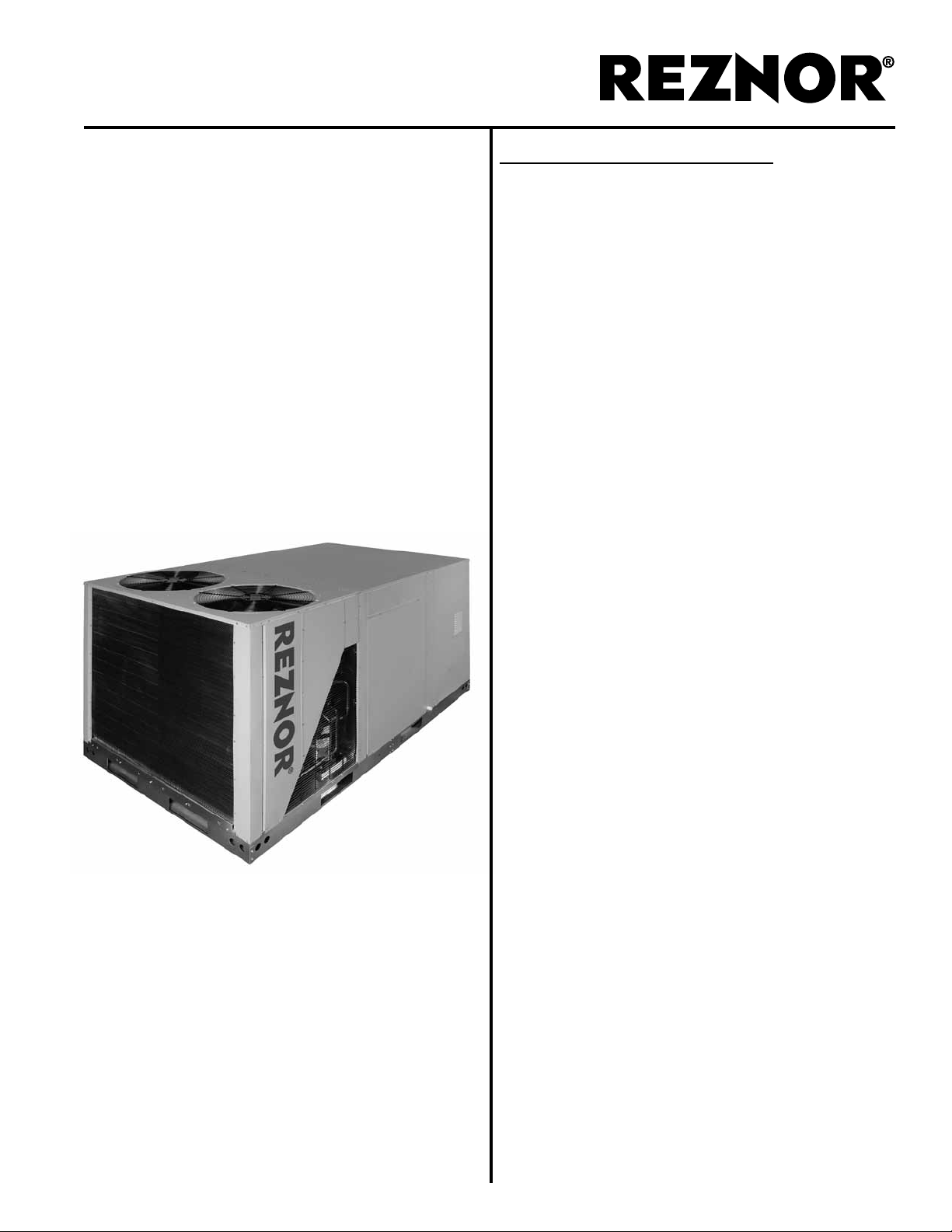

R6GP Series

6, 7½ and 10 Ton Packaged

Gas/Electric Units

11.2 EER Commercial System

80% Steady State Efficiency

with Optional Stainless Steel Heat Exchangers

These units are designed specifically for retrofit

applications and compatibility with most standard footprints.

They take less time to install and retrofit, making the

contractor's job more profitable. These units offer

flexibility in the replacement market.

FEATURES and BENEFITS

• QualityCompressor:State of the art scroll compressor is

standard equipment.

• 7½&10TonFeatureTwo-StageCooling

• 6TonFeaturesSingleStageCooling

• HighEfcientBlowerMotor:Meets the requirements of

NEMA 12/19/2010

• Hi/LowPressureSwitches:Ensure long compressor life.

Featuring manual reset high pressure control.

• CopperTube/AluminumFinCoils:Both indoor and outdoor

coils are designed to optimize heat transfer, minimize size

and cost, and increase durability and reliability.

• PlasticMeshHailGuard:A guard that will never rust and

protects the units coil from being damaged.

• ForEasyService:Hi/low service ports allow quick access

without disrupting operation.

• PermanentlyLubricatedCondenserFanMotors:A heavy

duty PSC motor for long lasting reliability and quiet operation.

Requires no maintenance and is completely protected from

rain and snow.

• 75VATransformer:Includes 4 Amp circuit breaker to protect

the low voltage circuit.

• LiquidLineFilterDriers:Factory installed for convenience.

• CrankcaseHeater:Protection from liquid flood back and

future compressor failures.

• Freeze Protection Thermostats: provide reliable

compressor operation.

• Easy Compressor and Control Access: Designed to

make servicing easier for the contractor, access panels are

provided to all controls and the compressor from the side of

the unit.

• 80%SteadyStateEfciency:Aluminized steel or stainless

steel heat exchanger tubes are available.

• Two-StageHeating:Provides High / Low fire operation

• Direct Spark Ignition Control:With 3 amp fuse, flame

sensing, and diagnostic LED

• ConvertibleAirDeliverywithKit:Converts to horizontal

airflow with side panels including duct flange and bottom

close off panels.

• Quick-ReleaseFilterAccessPanels:Requires no special

servicing tools.

• FullyInsulatedBottomPan:Helps ensure quiet operation

and prevents condensation.

• RemovableTopGrilleAssembly:Allows ease of service

to the fan motor.

• FullPerimeterBaseRailSystem:Base rails have rigging

holes and do not need to be removed for curb applications.

Base rails have fork truck slots on three sides.

• Durable,Attractive Cabinet: Designed using 20 gauge

galvanized steel with a polyester urethane finish. The 950

hour salt spray finish is 1.5 mil thick and resists corrosion

50% better than comparable units.

Page 2

2

Page 3

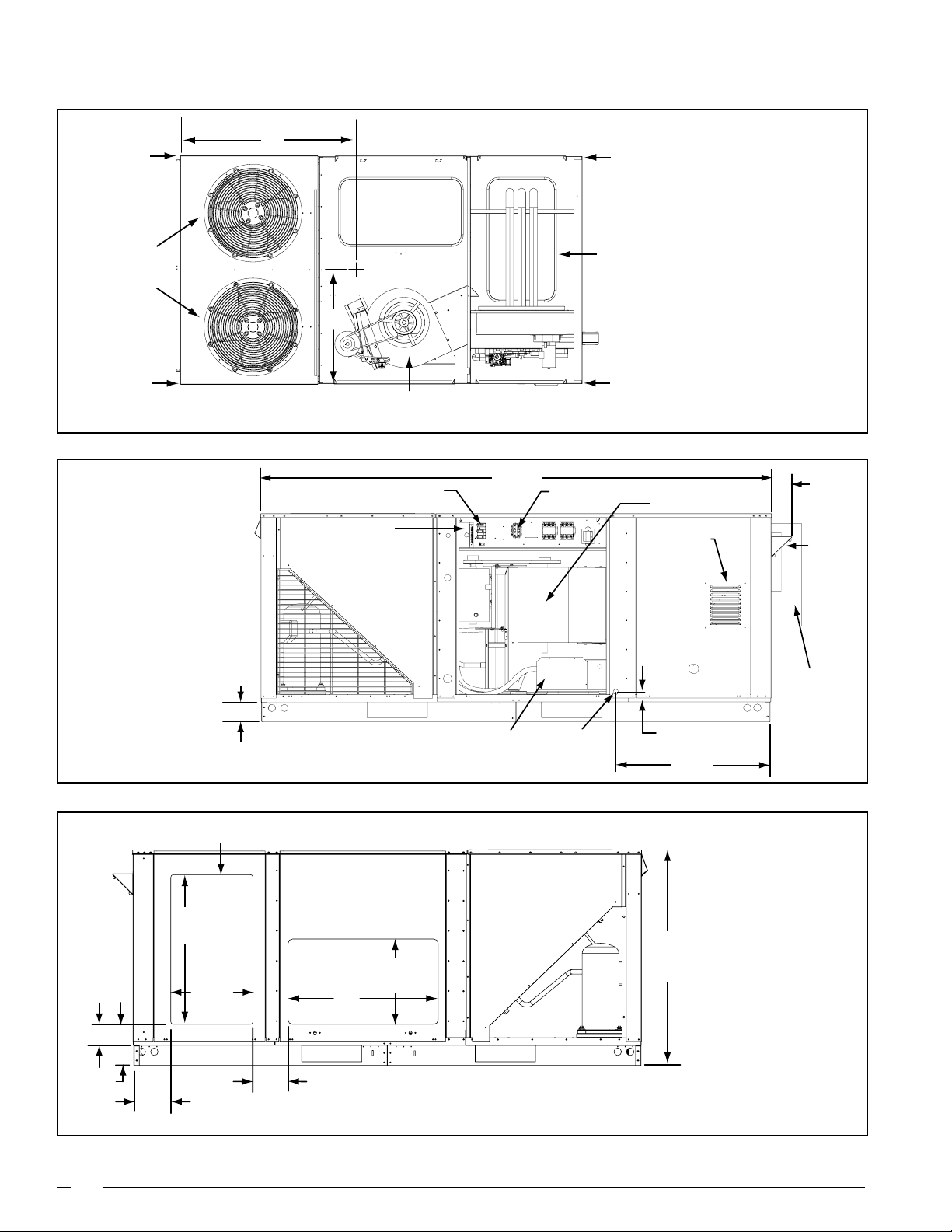

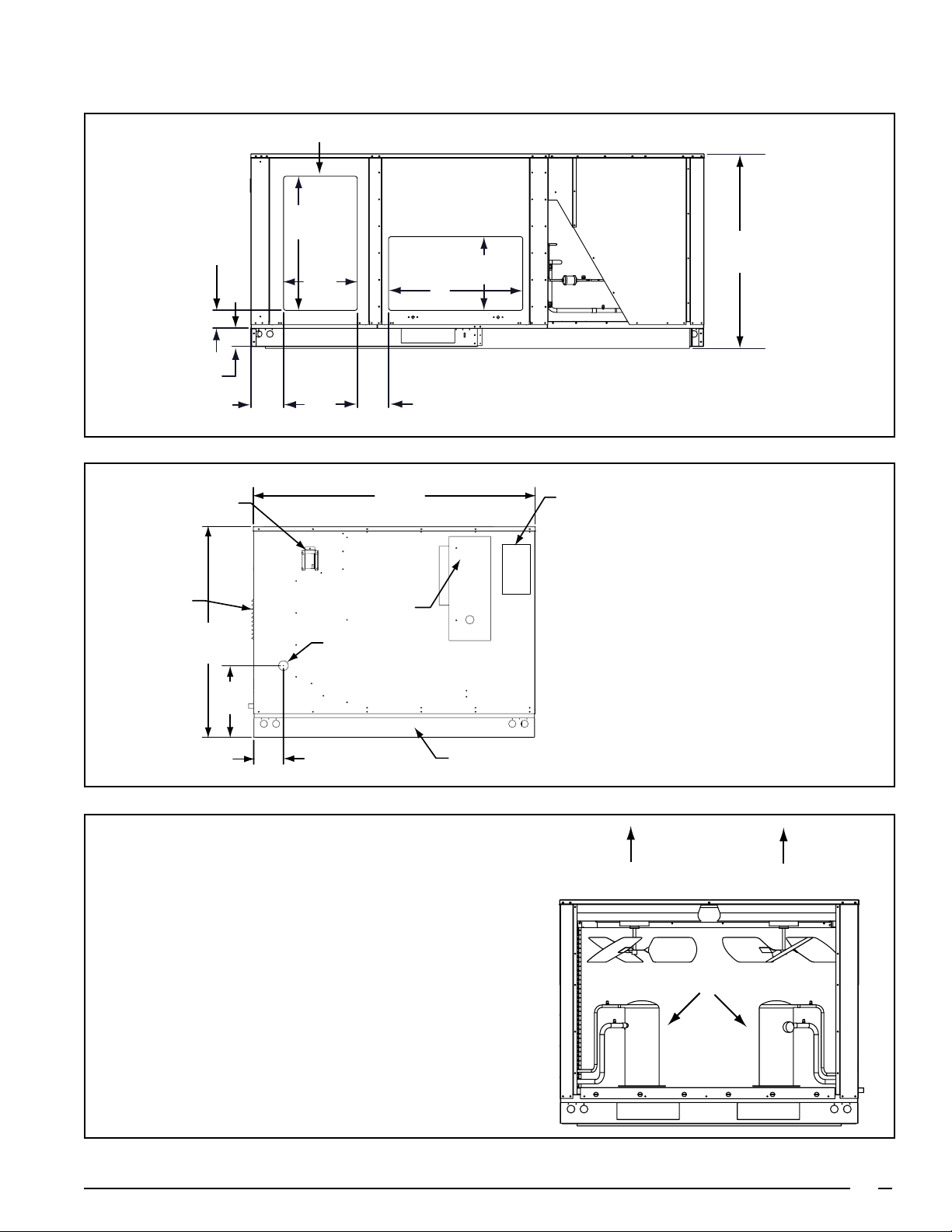

Model R6GP-120C235C Shown

Condenser Fan

Assemblies

High/Low

Pressure Switch

Protection

Liquid Line

Filter Driers

High Efficiency

Compressors

with Crankcase

Heaters

Belt Drive

Blower Motor

Knockout

for Bottom

Power Entry**

3/4” PVC

Condensate

Drain

Permament Baserail -

No Need for Removal

with Roof Curb

Knockout for

Bottom Power

Entry

Control Wiring Entry

Power Wiring Entry

Condenser Coils

Electrical

Disconnect

Mounting

Panel +

Easy Access

Control Panel

Durable Pre-Coat

Paint

Quick Release

Filter Panel

Evaporator Coils

Exhaust Vent

Gas Line Inlet

Flame

Observation

Combustion

Air Inlet

+ Field Supplied

** Field Installed Kit Required

3

Page 4

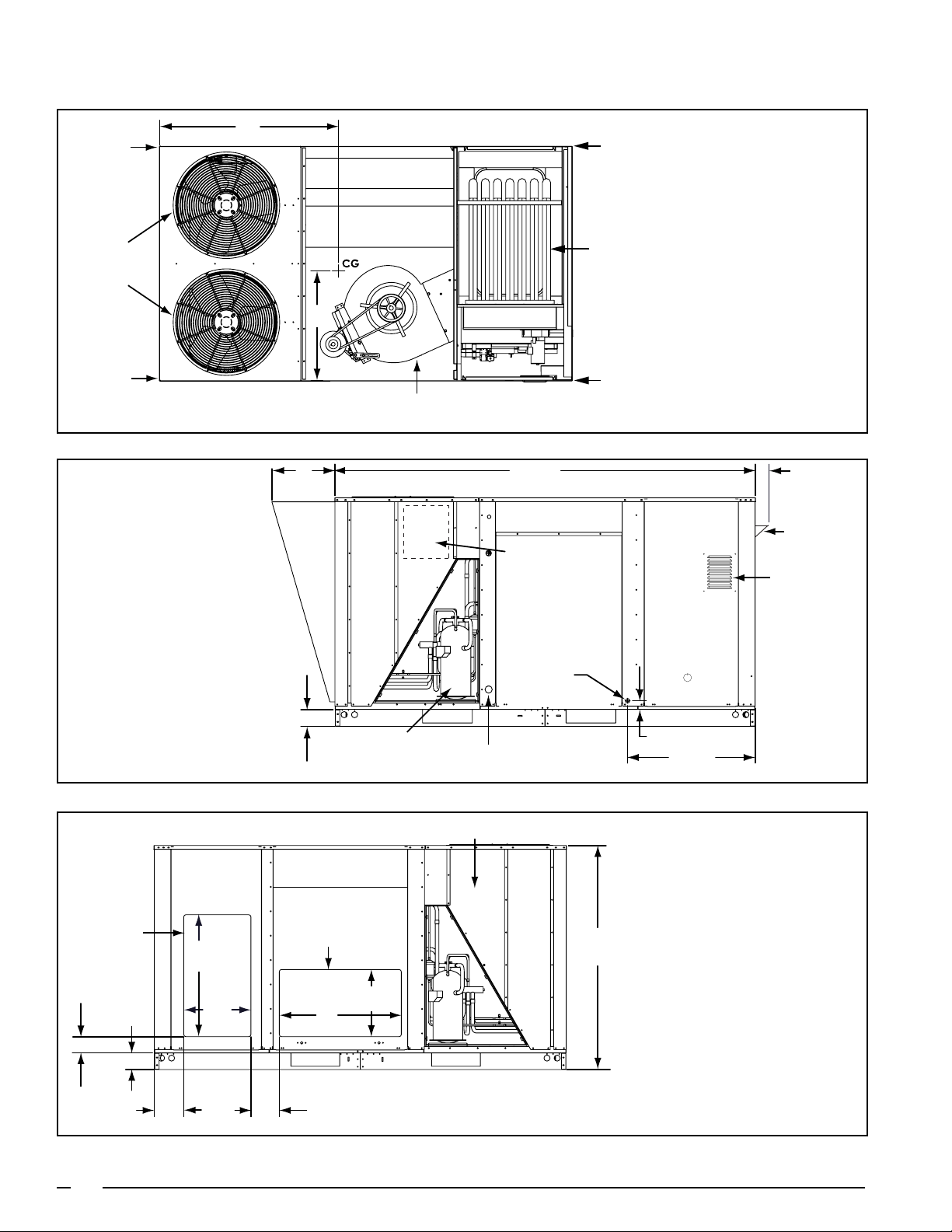

R6GP – PHYSICAL DATA

101 1/2

(2578)

2 (51)

30 3/4

4

(102)

FLAME

OBSERVATION

PORT

CONDENSAT E

DRAIN

BOTTOM POWER KIT

MOUNTING LOCATION

4 (102)

INDOOR BLOWER

COMBUSTION

AIR INLET

HIGH VOLTAGE

CONNECTIONS

OUTDOOR

COMPARTMENT

LOW VOLTAGE

CONNECTIONS

GROUND

CONNECTIONS

INDUCER

EXHAUST

RECOMMENDED

DISCONNECT

MOUNTING

LOCATION

Dimensions shown in inches (mm)

A

Corner “D”

Condenser Fans

CG

Corner “A”

Heat

Exchanger

Top View

Corner “C”

Front View

B

Corner weights and

center of gravity

see Table Page 9

Corner “B”

Blower

Assembly

Horizontal Discharge Air Opening*

30

(762)

4

(102)

16 1/2

(419)

4 (102)

7 1/4 (184)

4

Filter Access

Horz. Return Air Opening*

Condenser Coil

16 1/2

(419)

30

(762)

7 (178)

*Shown with optional horizontal duct panels

Physical Dimensions for R6GP-072 Series

43 1/2

(1403)

Rear View

Page 5

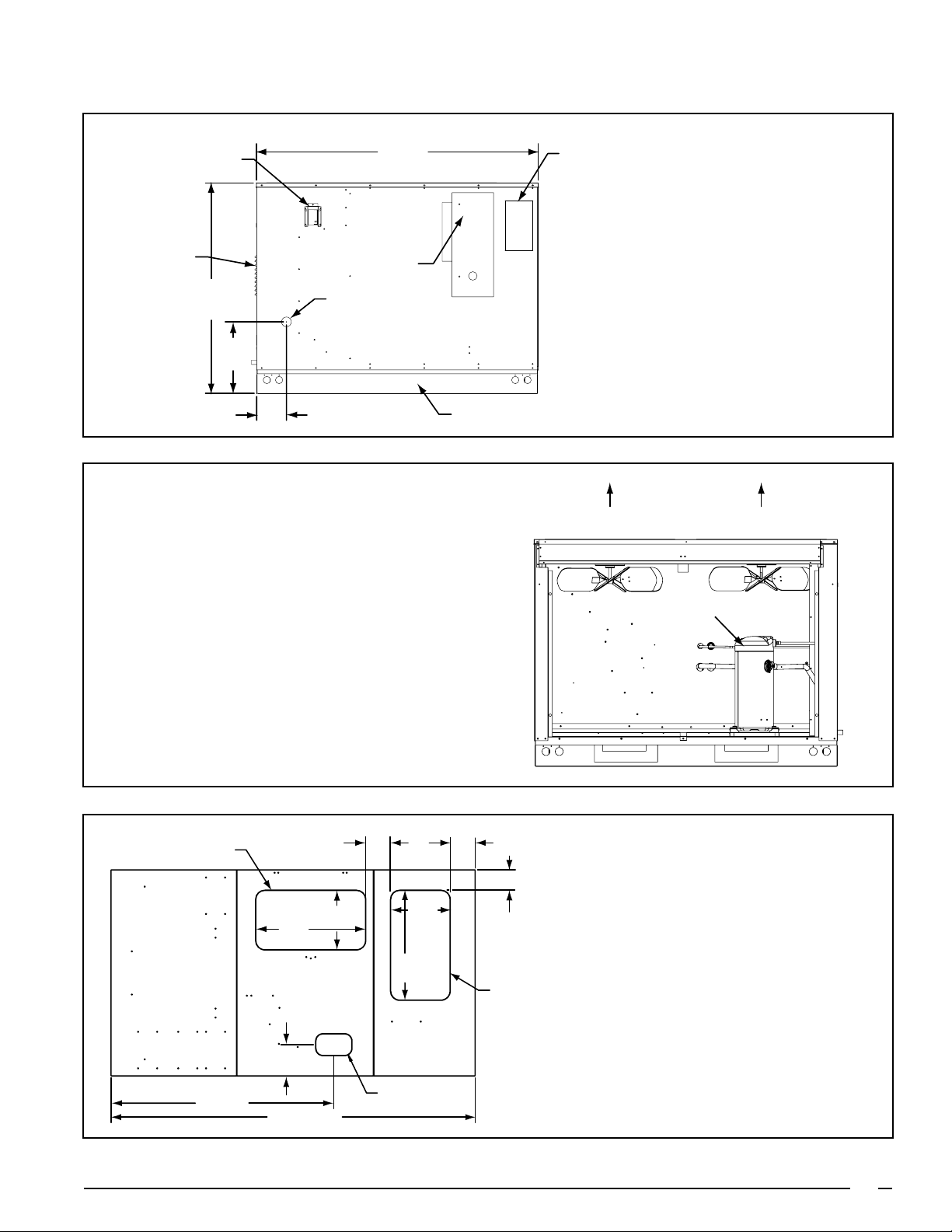

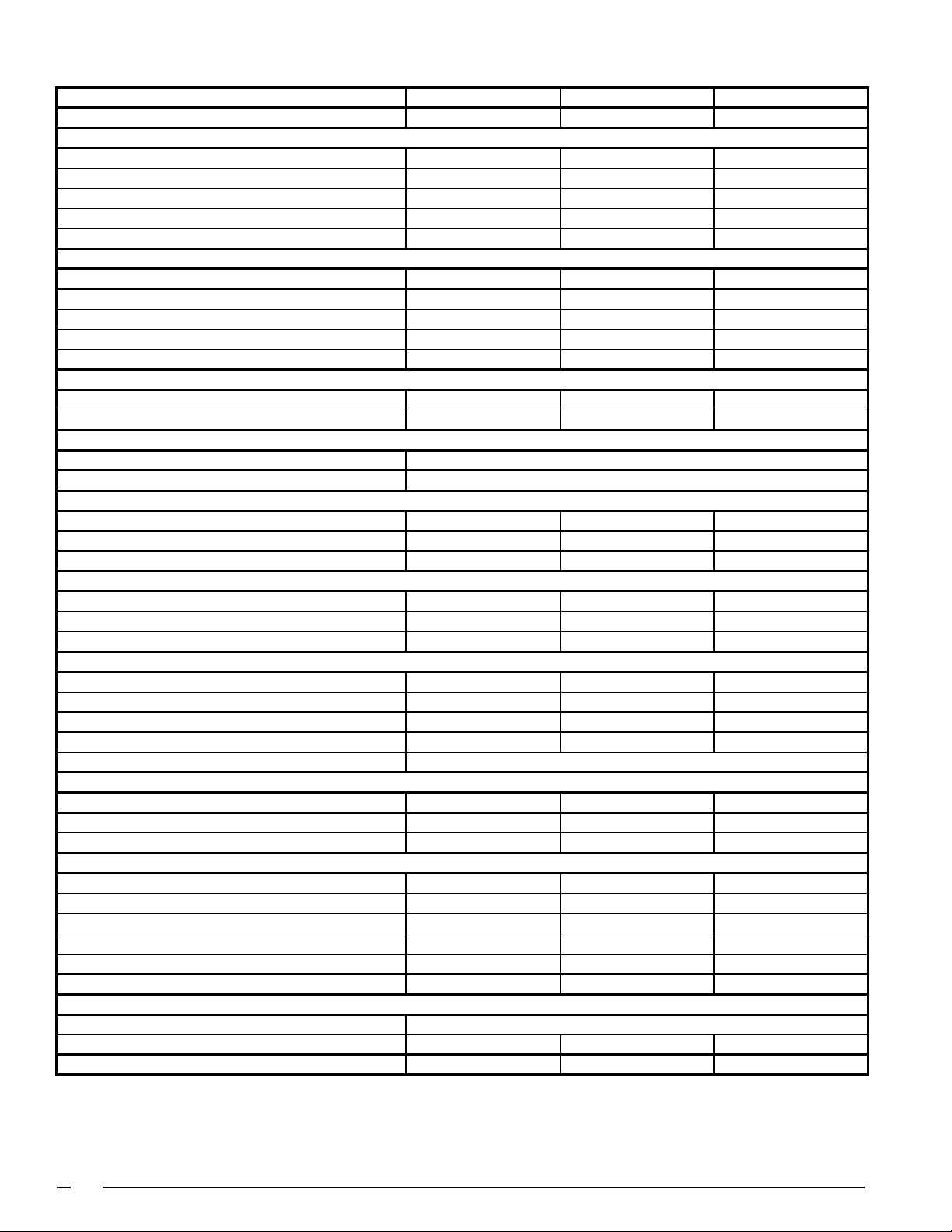

R6GP – PHYSICAL DATA (CONTINUED)

INDUCER

Dimensions shown in inches (mm)

EXHAUST

COMBUSTION

AIR LOUVERS

43

(1092)

14 5/8

(371)

57 1/2

(1460)

RECOMMENDED LOCATION

FOR UNIT DISCONNECT

GAS INLET

6 5/64 (154)

UNIT BASERAIL

RATING

LABEL

Heat Exchanger End

Airflow

Airflow

Return Air

Opening

62 (1575)

Condenser End

7 (178)

16 1/2

(419)

30 1/2

(775)

8 3/4

(222)

101 1/4 (2572)

30 1/2

Power

†

Entry

Compressor

7 (178)

5-3/4 (146)

16 1/2

(419)

Bottom Pan Top View

(072, 090, 120)

(775)

Discharge Air

Opening

Physical Dimensions for R6GP-072 Series Continued

5

Page 6

101 1/2

(2578)

16

(406)

2 (51)

30 3/4

(781)

4 (102)

Control Access

Blower Access

Condesate Drain

Field Wiring

(†)Electric Element

Access

Optional

Hail Guard

Hood

4

(102)

Corner “D”

Condenser

Fans

Dimensions shown in inches (mm)

A

CG

B

Corner “A”

Heat

Exchanger

Corner “C”

Top View

Blower

Assembly

Corner “B”

Corner weights and

center of gravity

see Table Page 9

6

Front View

Physical Dimensions for R6GP-090 Series

Page 7

Horizontal Discharge Air Opening

*

INDUCER

*Shown with optional horizontal duct panels

4 (102)

7 1/4 (184)

EXHAUST

COMBUSTION

AIR LOUVERS

4

(102)

43

(1092)

30

(762)

16 1/2

(419)

RECOMMENDED LOCATION

FOR UNIT DISCONNECT

GAS INLET

Horz. Return Air Opening

7 (178)

57 1/2

(1460)

Filter Access

16 1/2

(419)

30

(762)

Condenser Coil

*

43 1/2

(1403)

RATING

LABEL

Heat Exchanger End

Rear View

14 5/8

(371)

6 5/64 (154)

UNIT BASERAIL

Airflow

Airflow

Compressors (x2)

Condenser End

Physical Dimensions for R6GP-090 Series Continued

7

Page 8

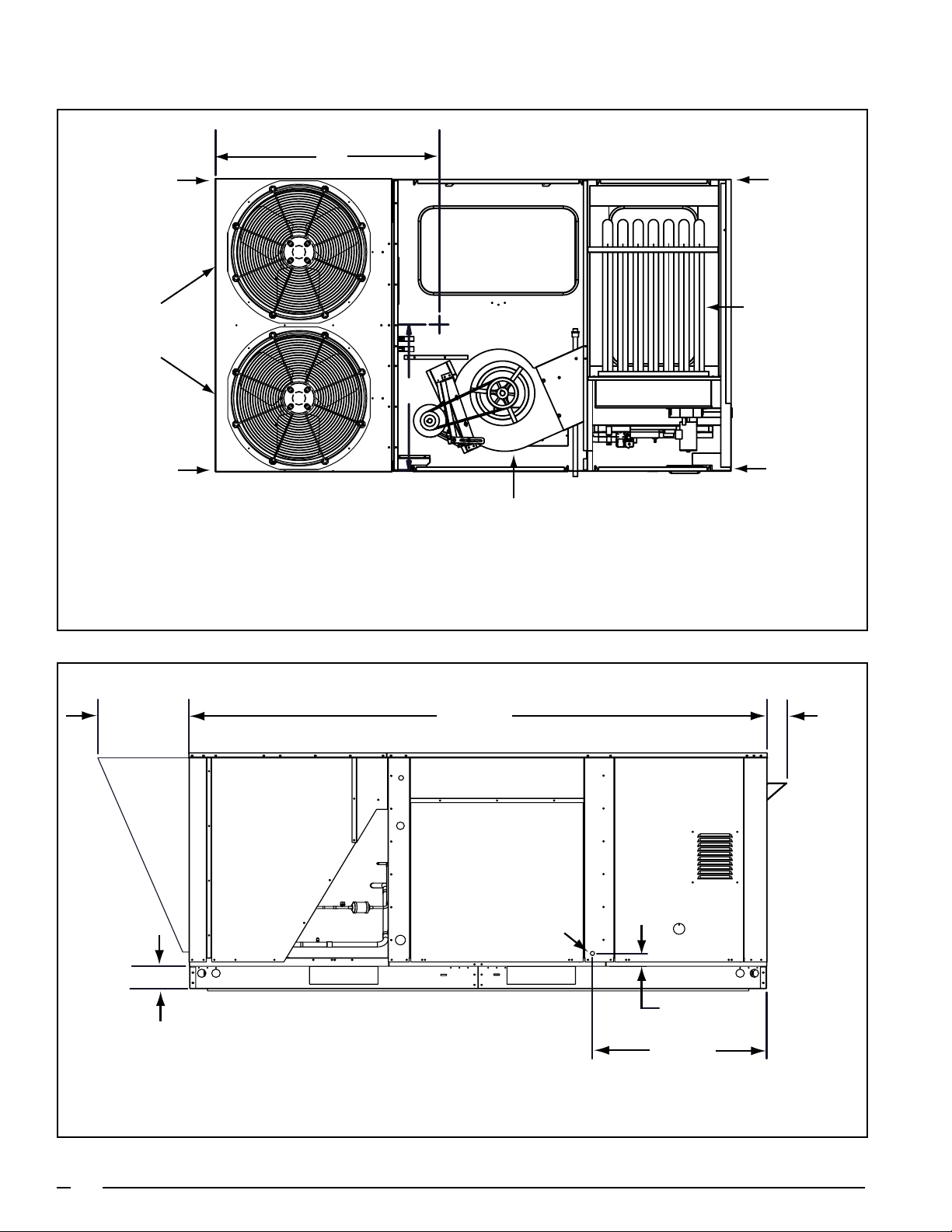

A

4

Dimensions shown in inches (mm)

Condenser

Corner “D”

Condenser

Fans

Corner “C”

Front View

B

16

(406)

Optional

Hail Guard

Hood

Filters (x4)

Evaporator

Assembly

Blower

Exchanger

101 1/2

(2578)

Control Access

Recommended Unit

Disconnect Mounting

Location

Blower Access

Corner “A”

Heat

Top View

Corner “B”

(102)

Inducer

Exhaust

Combustion

Air Inlet

Horizontal

Discharge

Air

Opening*

4 (102)

4 (102)

7 1/4 (184)

4 (102)

Compressor

*Shown with optional horizontal duct panels

Exchanger

Access

30

(762)

Heat

16 1/2

(419)

Filter Access

Horiz. Return

Air Opening*

30

(762)

7

(178)

16 1/2

(419)

Condensate

Electric

Supply Entries

Coils

Drain

55 1/4

(1403)

2 (51)

30 3/4

(781)

Rear View

Physical Dimensions for R6GP-120 Series

8

Page 9

18 1/2

(470)

Optional

Fresh Air

Intake

Hood

Optional

Relief

Hood

Airflow

Condenser Coil

Compressors (2)

Airflow

9 7/8 (250)

8 (203)

57 1/2

(1461)

Gas Inlet

4 (102)

Condenser End

Heat Exchanger End

Physical Dimensions for R6GP-120 Series Continued

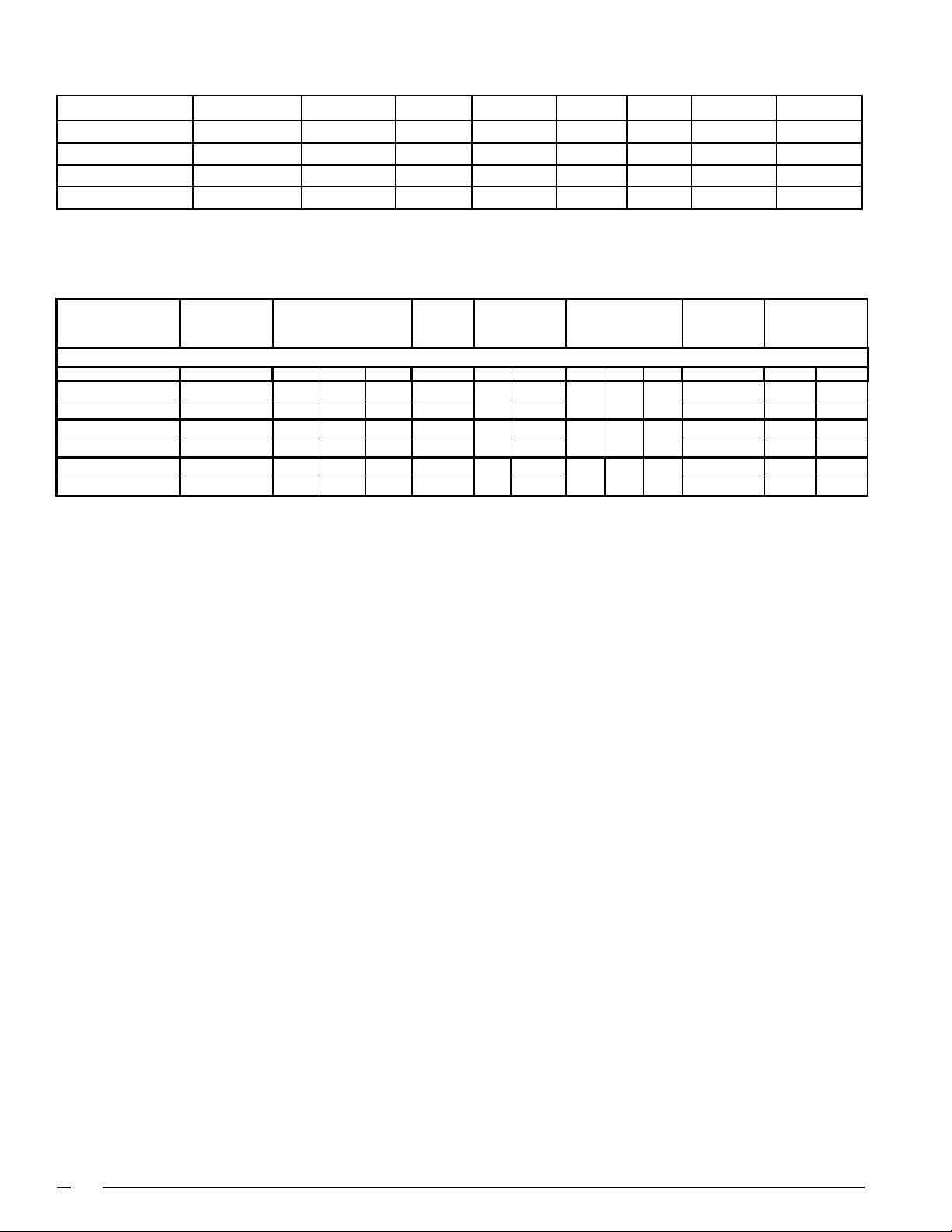

Model No.

Unit Weight ‡

Lbs. Kg. Lbs. Kg A B Lbs. Kg. Lbs. Kg. Lbs. Kg. Lbs. Kg.

R6GP-072*-100 934 425 1069 486

R6GP-072*-166 959 436 1094 497

R6GP-090*-200 983 446 1118 507

R6GP-120*-235 1301 590 1441 654

* Baserails are not intended to be removed. Information provided is total unit height for horizontal duct applications or height dimension added to selected roof curb

height for vertical duct applications.

‡ Unit weight without packaging or field installed accessories.

Shipping

Weight

Center of Gravity

Inches (mm)

48

(1219)

(1245)

55 3/8

(1407)28(711)

(1245)30(762)

25 5/8

(651)

49

25 5/8

(651)

49

A B C D

197 89 245 111 273 124 219 100

206 94 257 117 275 125 221 100

262 119 275 125 229 104 218 99

300 136 328 149 351 159 322 146

Corner Weights Unit Height*

Horizontal

Duct

Applications

43 1/2

(1105)

43 1/2

(1105)

43 1/2

(1105)

55-1/4

(1409)

Applications

Vertical

Duct

38 1/4

(972)

38 1/4

(972)

38 1/4

(972)

51

(1295)

Center of Gravity & Unit Shipping Weights

MODEL IDENTIFICATION CODE

R 6 G P - 090 C 045 C A

Application

R = Rooftop Packaged Unit

Series

Gas

P = 11.0 - 11.9 EER

Cooling

Nominal

Capacity

(000) Btu

Revision

C = U.S./Canada - Aluminized Steel Hx

S = U.S./Canada - Stainless Steel Hx

Heating Capacity

(000) Btu

Electrical Code

C = 208/230-60-3

D = 460-60-3

9

Page 10

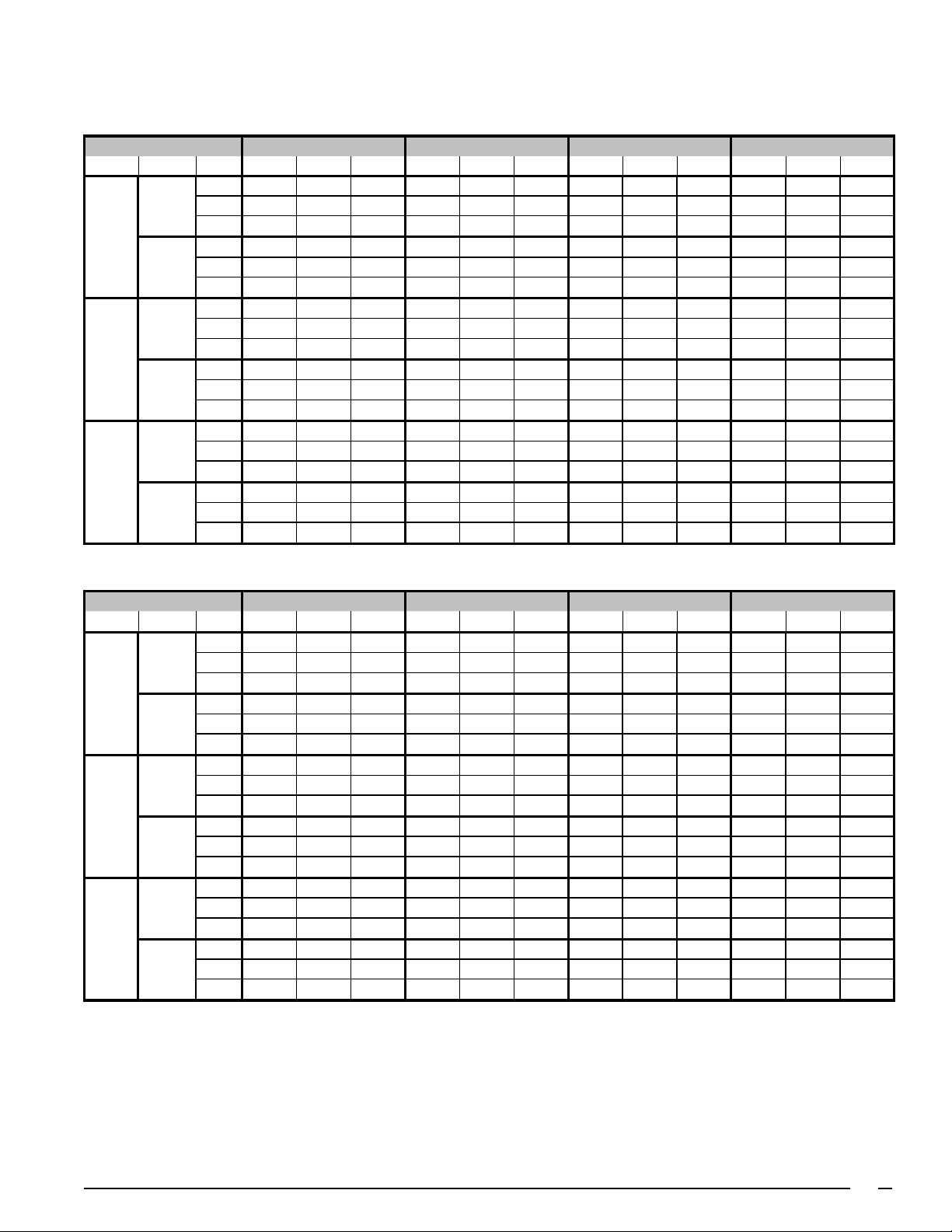

PHYSICAL SPECIFICATIONS DATA

Model R6GP- 072(C/D) 090(C/D) 120(C/D)

Nominal Capacity (tons) 6 7.5 10.0

Performance Data

Total Gross Cooling Capacity (Btuh) 73,300 93,500 125,000

Rated Net Cooling Capacity (Btuh) 72,000 90,000 119,000

E.E.R. - Cooling Efficiency (Btuh/Watt) 11.2 11.2 11.2

IEER - Part load Efficiency 12.6 12.3 11.5

Rated Airflow - CFM 2,400 3,000 4,000

Compressor Data

Compressor(s) Type Scroll Scroll Scroll

Quantity (number of refrigeration circuits) 1 2 2

Unit Capacity Steps (%) 100 50/50 50/50

Crankcase Heaters yes yes yes

POE Oil Charge (Ea.) 56 Oz. 42 Oz. 42 Oz.

Refrigerant Charge (R-410a)

Stage 1 Circuit 240 Oz. 168 Oz. 216 Oz.

Stage 2 Circuit - 168 Oz. 216 Oz.

System Pressure Switches

Manual Reset High Pressure Switch (PSIG) Cut Out: 650 +/- 10

Loss of Charge Switch (PSIG) Cut Out: 5 +/- 5, Cut In: 20 +/- 5

Outdoor Fan Data

Fan Diameter / Total Nominal CFM 20” / 7000 24” / 8200 24” / 8200

Motor - HP / RPM 1/3 - 1100 1/3 - 1075 1/3 - 1075

Quantity 2 2 2

Outdoor Coil Data

Rows / fpi 2 / 18 2 / 19 2 / 17

Type Cu Tube/Al Fin Cu Tube/Al Fin Cu Tube/Al Fin

Total Face Area (sq ft) 17.0 25.5 34.0

Indoor Coil Data

Rows / fpi 4 / 14 4 / 14 4 / 14

Type Cu Tube/Al Fin Cu Tube/Al Fin Cu Tube/Al Fin

Total Face Area (sq ft) 8.5 8.5 11.3

Expansion Device TXV TXV TXV

Freeze Protection Thermostat Opens (˚F): 28 +/- 5, Closes (˚F): 57 +/- 6

Indoor Blower Data

Blower Type Centrifugal Centrifugal Centrifugal

(Qty.) - Wheel Diameter (1) - 12 x 12 (1) - 12 x 12 (1) - 15 x 15

Drive Type Belt Belt Belt

Standard Blower Drive Motor 4

Motor - Hp / RPM 1 / 1725 1.5 / 1750 2/1800

Speeds 1 1 1

Frame Size 143T 143T 143T

NEMA Efficiency Premium Eff. Premium Eff. Premium Eff.

Blower RPM Range 715 - 971 777 - 1060 672 - 897

Blower ESP Range (in-WC) 0.1 - 1.0 0.1 - 1.3 0.1 - 1.0

Installed Filters

Style Disposable - 2” Pleated

Size[inches] (Qty.) 16x20 (4) 16x20 (4) 16x25 (4)

Sound Rating Number dBA

Notes:

1) Certified in accordance with AHRI Standard 340/360 at the rated airflow shown and the minimum external static duct pressure allowed by the standard. ARI Rating for

units with dual voltages are shown at highest rated unit voltage.

2) E.E.R. - Energy Efficiency Ratio: The EER and Net Capacity is determined @ 95˚F Outdoor DB and with air entering the evaporator at 80˚F DB / 67˚F WB

3) IEER - Intergrated Energy Efficiency Ratio: a measure of merit for part load performance of the unit.

4) Refer to Alternate Accessory Drive Table for other available motor/drive kits

1,2,3

83.5 85.2 85.8

10

Page 11

UNIT HEATING PERFORMANCE DATA

Model R6GP- 072(C/D) 090(C/D) 120(C/D)

Heater Model -100(c,s) -166(c,s) -200(c,s)a -235(c,s)b

High Heating Input (Btuh)

High Heating Output (Btuh) 80,000 132,800 160,000 188,000

Low Heating Input (Btuh)

Low Heating Output (Btuh) 52,000 86,400 104,000 120,000

Steady State Efficiency 80% 80% 80% 80%

Number of Capacity Stages 2 2 2 2

Ignition Type Spark Spark Spark Spark

Number of Burners 3 5 6 7

Gas Piping Connection (in) 1/2” NPT 1/2” NPT 1/2” NPT 3/4” NPT

Factory Configured

Notes:

1) Units with Heating inputs of 225,000 Btuh or greater are rated in accordance with DOE 10 CFR Part 431

2) Capacities shown represent use with Natural Gas, refer to Table 10 for LP gas capacities

3) Heat Exchangers are convertible to LP with Accessory Kit

1, 2

1, 2

3

100,000 166,000 200,000 235,000

65,000 108,000 130,000 150,000

Nat. Gas Nat. Gas Nat. Gas Nat. Gas

TEMPERATURE RISE/AIRFLOW

Heating

Unit

Model

R6GP-072*-100

R6GP-072*-166

R6GP-090*-200

R6GP-120*-235

* At Elevations of 2000 Ft or less

Gas

Type

Heating

Input

Heating

Output

Rise

Range CFM Range

SCFM 1950 2100 2250 2400 2550 2700

Natural Gas 100,000 80,000

Propane (LP) 85,000 68,000 32 30 28 26 25 23

15 - 45

Rise (ºF)*

38 35 33 31 29 27

SCFM 1950 2100 2250 2400 2550 2700

Natural Gas 166,000 133,000

Propane (LP) 141,000 112,800 54 50 46 44 41 39

35 - 65

Rise (ºF)*

63 59 55 51 48 46

SCFM 2425 2625 2800 3000 3188 3375

Natural Gas 200,000 160,000

Propane (LP) 175,000 140,000 53 49 46 43 41 38

30 - 60

Rise (ºF)*

61 56 53 49 46 44

SCFM 3250 3500 3750 4000 4250 4500

Natural Gas 235,000 188,000

Propane (LP) 205,000 164,000 47 43 40 38 36 34

25 - 55

Rise (ºF)*

54 50 46 44 41 39

ORIFICE OR DRILL SIZE FOR NATURAL AND PROPANE (LP) GASES.

Unit

Model

R6GP-072*-100

R6GP-072*-166

R6GP-090*-200

R6GP-120*-235

* Refer to Instructions for High Altitude Deration to determine heat-exchanger capacity at increased elevations.

Gas

Type

Natural Gas 100,000

Propane (LP) 85,000 53 54 54 55 55

Natural Gas 166,000

Propane (LP) 141,000 53 54 54 55 55

Natural Gas 200,000

Propane (LP) 175,000 51 52 52 52 53

Natural Gas 235,000

Propane (LP) 205,000 51 52 52 52 53

Heating

Input

Number

of

Burners

3

5

6

7

0-2,000 Ft 2,001-4,000 Ft 4,001-6,000 Ft 6,001-8,000 Ft 8,001-10,000 Ft

36 38 40 41 43

36 38 40 41 43

36 38 40 41 43

36 38 40 41 43

Table 10. Approximate Orifice or Drill Size for Natural and Propane (LP) Gases.

Orifice Size for Increased Elevation*

(Above Sea Level)

11

Page 12

ELECTRICAL DATA FOR POWER EXHAUST ACCESSORY KITS

Part #

Model

† Volts HP CFM FLA Fuse MCA MOP

R6GP-072 & 090 547867 230 1/2 2350 3.00 6A 3.75 6.75

R6GP-072 & 090 547868 460 1/2 2350 1.50 3A 1.88 3.38

R6GP-120 547876 230 3/4 4900 4.00 9A 5.00 9.00

R6GP-120 547877 460 3/4 4900 2.00 4A 2.50 4.50

† See Accessory List, pg 22

ELECTRICAL DATA

Outdoor

motors

(2) ea.

Indoor

Motor

4

Inducer Motor

Total Unit

RLA Unit Only Circuit

Model Number

Nominal Unit

2,3

Voltage

1

Compressors

Factory Unit Electrical Data:

R6GP QTY RLA LRA FLA Hp FLA Hp FLA LRA FLA MCA MOP

-072-(100/166) 208-230 V 1 ea. 19 123 1.5

-072-(100/166) 460 V 1 ea. 9.7 62 0.8 1.5 12.8 16 20

-090-200 208-230 V 2 ea. 13.1 83.1 2.3

-090-200 460 V 2 ea. 6.1 41 1.2 2.1 16.7 19 20

-120-235 208-230 V 2 ea. 16.0 110 2.3

-120-235 460 V 2 ea. 7.8 52 1.2 2.9 20.9 23 30

Notes:

1) To achieve the rated unit performance, unit voltage should be within 2% of

nominal.

2) For C series units:

Nominal Unit Input Voltage = 208-230 Volt, 60 Hertz, 3 Phase

Minimum allowed unit voltage = 187V

Maximum allowed voltage = 253V

3) For D series units:

Nominal Unit Input Voltage = 460 Volt, 60 Hertz, 3 Phase

Minimum allowed unit voltage = 414V

Maximum allowed voltage = 506V

4) Indoor Motors meet 2010 DOE requirements (Premium Efficient)

5) FLA = Full Load Amps MCA = Minimum Circuit Ampacity

RLA = Rated Load Amps MOP = Maximum Over-Current Protection

LRA = Locked Rotor Amps

1.5

3.2-3.1

1

4.4-4.2

6.0-5.8

2

1/12 0.5 0.76

1/12 0.5 0.76

1/12 0.5 0.76

25.2 30-30 45-45

35.2 39-39 50-50

42.6 47-47 60-60

12

Page 13

R6GP - EXPANDED RATINGS, COOLING MODE

R6GP-072-(100/166)

O.D.T 85°F 95°F 105°F 115°F

CFM E.D.B. E.W.B. T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW

62 68.4 52.3 5.64 63.1 49.9 6.24 57.7 47.6 6.85 52.4 45.2 7.46

75

2250

80

75

2400

80

75

2550

80

67 76.1 41.1 5.73 70.6 39.0 6.33 65.0 36.8 6.92 59.5 34.7 7.52

72 84.7 32.3 5.82 78.7 30.2 6.41 72.8 28.2 7.01 66.8 26.1 7.60

62 68.7 63.0 5.65 63.7 60.5 6.21 58.6 57.9 6.78 54.4 54.2 7.47

67 76.1 52.3 5.74 71.4 50.3 6.28 66.7 48.2 6.83 60.7 45.5 7.54

72 84.1 41.5 5.85 78.8 39.4 6.37 73.4 37.2 6.89 67.0 34.5 7.55

62 69.2 54.2 5.73 63.9 51.7 6.34 58.6 49.3 6.95 53.3 46.8 7.55

67 77.1 42.4 5.81 71.6 40.0 6.41 66.2 37.6 7.01 60.7 35.2 7.61

72 85.9 32.3 5.92 79.9 30.5 6.51 73.8 28.7 7.10 67.8 26.9 7.70

62 69.7 64.4 5.75 65.1 61.4 6.35 60.5 58.5 6.95 55.9 55.6 7.55

67 77.0 54.1 5.82

72 85.1 42.7 5.92 79.5 40.3 6.50 73.9 37.9 7.09 68.2 35.5 7.67

62 70.0 56.0 5.82 64.7 53.5 6.43 59.5 50.9 7.04 54.2 48.4 7.65

67 78.0 43.7 5.89 72.7 41.0 6.50 67.3 38.4 7.10 61.9 35.7 7.71

72 87.0 32.2 6.01 81.0 30.7 6.61 74.9 29.1 7.20 68.8 27.6 7.79

62 70.6 65.8 5.85 66.2 62.8 6.45 62.5 60.9 6.97 57.3 56.9 7.63

67 77.9 56.0 5.90 72.6 53.4 6.50 67.4 50.9 7.11 62.2 48.3 7.71

72 86.1 43.9 5.98 80.6 41.4 6.59 75.0 38.9 7.19 69.5 36.4 7.79

72.0 51.7 6.43

65.9 49.4 7.08 60.4 47.0 7.71

R6GP-072-(100/166)

O.D.T 55°F 65°F 75°F 85°F

CFM E.D.B. E.W.B. T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW

62 78.6 57.9 4.49 75.2 56.0 4.87 71.8 54.2 5.25 68.4 52.3 5.64

75

2250

80

75

2400

80

75

2550

80

Notes:

1) T.C. = Total (Net) Cooling Capacity, S.C. = Sensible Cooling Capacity, kW = Kilowatts

2) Expanded Ratings are based on 230 Volt - 60 Hz operation

3) Ratings based on Factory Standard Blower Drive

4) Bolded Values indicate ARI rating points

5) Energy Efficiency Ratio (EER) = T.C. / kW

67 86.8 46.7 4.59 83.2 44.8 4.97 79.7 43.0 5.35 76.1 41.1 5.73

72 95.0 36.1 4.70 91.6 34.8 5.07 88.1 33.6 5.45 84.7 32.3 5.82

62 79.2 68.9 4.47 75.8 66.9 4.85 72.8 65.5 5.21 68.7 63.0 5.65

67 87.3 58.2 4.57 83.8 56.3 4.95 80.6 54.9 5.31 76.1 52.3 5.74

72 95.0 45.6 4.69 91.6 44.3 5.06 88.8 43.5 5.41 84.1 41.5 5.85

62 79.6 59.7 4.58 76.1 57.8 4.97 72.6 56.0 5.35 69.2 54.2 5.73

67 87.6 48.0 4.68 84.1 46.1 5.06 80.6 44.3 5.44 77.1 42.4 5.81

72 95.6 36.0 4.79 92.4 34.8

62 80.2 70.6 4.57 76.7 68.7 4.95 73.6 67.3 5.31 69.7 64.4 5.75

67 88.1 59.5 4.66 84.6 57.6 5.03 81.5 56.2 5.39 77.0 54.1 5.82

72 95.6 45.5 4.78 92.4 44.2 5.15 89.8 43.4 5.50 85.1 42.7 5.92

62 80.5 61.5 4.68 77.0 59.6 5.06 73.5 57.8 5.44 70.0 56.0 5.82

67 88.3 49.3 4.77 84.9 47.4 5.15 81.5 45.6 5.52 78.0 43.7 5.89

72 96.2 35.9 4.88 93.1 34.7 5.26 90.1 33.4 5.64 87.0 32.2 6.01

62 81.1 72.4 4.66 77.6 70.5 5.04 74.5 69.2 5.40 70.6 65.8 5.85

67 88.8 60.8 4.75 85.5 58.9 5.12 82.4 57.5 5.48 77.9 56.0 5.90

72 96.2 45.4 4.88 93.2 44.1 5.24 90.8 43.4 5.60 86.1 43.9 5.98

5.17 89.1 33.5 5.54 85.9 32.3 5.92

13

Page 14

R6GP - EXPANDED RATINGS, COOLING MODE

R6GP-090 (Two Compressor Operation)

O.D.T 85°F 95°F 105°F 115°F

CFM E.D.B. E.W.B. T.C. S.C. K.W. T.C. S.C. K.W. T.C. S.C. K.W. T.C. S.C. K.W.

62 85.3 65.2 7.08 81.3 63.9 7.74 73.4 62.7 8.84 68.5 61.2 9.39

75

2825

80

75

3000

80

75

3188

80

67 93.3 52.4 7.19 88.8 51.2 7.84 80.1 50.0 8.94 74.8 48.6 9.46

72 101.9 39.3 7.31 97.3 38.0 7.97 87.7 36.7 9.06 82.0 35.3 9.59

62 86.0 76.5 7.09 82.2 75.5 7.75 74.3 74.5 8.85 69.8 73.6 9.40

67 92.9 64.4 7.18 88.6 63.4 7.84 80.0 62.4 8.94 74.7 61.2 9.46

72 101.7 51.4 7.31 97.0 50.4 7.96 87.5 49.3 9.06 81.6 48.1 9.58

62 86.8 69.4 7.27 82.7 68.1 7.93 74.5 66.8 9.05 69.5 65.3 9.57

67 94.6 55.2 7.38 90.0 54.0 8.03 80.9 52.7 9.14 75.3 51.3 9.64

72 103.5 40.4 7.51 98.6 39.1 8.17 88.8 37.8 9.27 82.9 36.3 9.78

62 87.9 81.9 7.29 84.3 81.8 7.96 76.6 80.3 9.08 72.2 76.4 9.60

67 94.5 68.5 7.38

72 103.1 54.2 7.51 98.2 53.1 8.16 88.4 52.0 9.26 82.5 50.9 9.78

62 87.9 73.3 7.46 83.7 72.0 8.12 75.3 70.7 9.24 70.2 69.1 9.75

67 95.3 57.8 7.57 90.3 56.5 8.22 81.2 55.1 9.32 75.7 53.6 9.82

72 104.6 41.4 7.71 99.5 40.1 8.36 89.6 38.7 9.46 83.5 37.3 9.95

62 90.3 88.4 7.50 86.7 86.3 8.16 78.7 78.3 8.49 74.0 73.7 9.80

67 95.6 72.5 7.57 91.1 71.4 8.23 82.0 70.4 8.56 76.6 69.2 9.83

72 104.1 56.8 7.70 98.9 55.7 8.35 88.9 54.7 8.68 82.4 53.4 9.95

90.0 67.5 8.04

81.2 66.5 9.14 75.6 65.3 9.65

R6GP-090 (One Compressor Operation)

O.D.T 55 °F 65 °F 75 °F 85 °F

CFM E.D.B. E.W.B. T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW

62 58.5 52.6 3.74 52.5 47.2 3.88 48.0 44.1 4.10 45.0 43.2 4.42

75

2825

80

75

3000

80

75

3190

80

Notes:

1 ) T.C. = total (Net) cooling in kBtuh; S.C. = Sensible Cooling in kBtuh; kW = Kilowatts

2 ) Ratings are based on the Factory Standard blower drive combination

3 ) For 208-230V Units, the ratings shown reflect 230V operation

4 ) Bolded Values indicate AHRI rating points

5 ) Energy Efficiency Ratio (EER) = T.C./kW

67 64.7 44.3 3.81 58.8 38.9 3.95 54.3 35.8 4.18 51.3 34.9 4.49

72 71.7 35.0 3.90

62 59.3 59.3 3.78

67 64.6 57.4 3.85 58.7 52.0 3.98 54.2 48.9 4.21 51.1 48.0 4.52

72 70.5 49.5 3.92 64.6 44.1 4.06 60.1 41.0 4.28 57.0 40.1 4.59

62 59.0 53.7 3.77 53.1 48.3 3.91 48.6 45.2 4.14 45.5 44.3 4.45

67 65.3 45.3 3.85 59.4 40.0 3.99 54.9 36.9 4.21 51.8 36.0 4.53

72 72.2 36.1 3.93 66.3 30.8 4.07 61.8 27.6 4.30 58.8 26.8 4.61

62 59.8 59.8 3.82 53.9 53.9 3.96 49.4 49.4 4.18 46.3 46.3 4.49

67 65.1 58.4 3.88 59.2 53.1 4.02 54.7 50.0 4.24 51.6 49.1 4.56

72 71.1 50.6 3.95 65.1 45.2 4.09 60.6 42.1 4.32 57.6 41.2 4.63

62 59.5 55.3 3.77 53.6 50.0 3.90 49.1 46.8 4.13 46.0 46.0 4.44

67 65.8 47.0 3.84 59.8 41.6 3.98 55.3 38.5 4.20 52.3 37.6 4.52

72 72.7 37.8 3.92 66.8 32.4 4.06 62.3 29.3 4.29 59.2 28.4 4.60

62 60.3 60.3 3.81 54.4 54.4 3.95 49.9 49.9 4.17 46.8 46.8 4.49

67 65.6 60.1 3.87 59.7 54.7 4.01 55.2 51.6 4.24 52.1 50.7 4.55

72 71.5 52.2 3.94 65.6 46.9 4.08 61.1 43.7 4.31 58.0 42.9 4.62

65.8

53.3

29.7 4.04 61.3 26.6 4.26 58.2 25.7 4.57

53.3 3.92 48.8 48.8 4.15 45.8 45.8 4.46

14

Page 15

R6GP - EXPANDED RATINGS, COOLING MODE

R6GP-120 (Two Compressor Operation)

O.D.T 85°F 95°F 105°F 115°F

CFM E.D.B. E.W.B. T.C. S.C. K.W. T.C. S.C. K.W. T.C. S.C. K.W. T.C. S.C. K.W.

62 112.7 86.5 9.36 107.5 84.9 10.24 97.0 83.3 11.68 90.5 81.3 12.41

75

3500

80

75

4000

80

75

4500

80

67 123.3 69.6 9.50 117.4 68.0 10.37 105.9 66.3 11.82 98.8 64.5 12.50

72 134.7 52.2 9.67 128.6 50.5 10.53 115.9 48.7 11.98 108.4 46.9 12.68

62 113.7 101.5 9.37 108.6 100.3 10.25 98.2 98.9 11.71 92.3 97.8 12.43

67 122.8 85.5 9.49 117.2 84.2 10.36 105.7 82.8 11.82 98.8 81.3 12.51

72 134.4 68.3 9.67 128.2 66.9 10.53 115.6 65.5 11.98 107.9 63.9 12.67

62 114.8 92.1 9.62 109.3 90.4 10.49 98.5 88.7 11.96 91.8 86.7 12.65

67 125.0 73.3 9.76 118.9 71.6 10.62 107.0 70.0 12.08 99.6 68.1 12.74

72 136.8 53.6 9.93 130.3 51.9 10.80 117.4 50.1 12.25 109.6 48.2 12.93

62 116.2 108.8 9.64 111.5 108.6 10.52 101.3 106.6 12.01 95.4 101.5 12.69

67 124.9 91.0 9.75

72 136.3 71.9 9.93 129.8 70.5 10.79 116.9 69.1 12.25 109.1 67.6 12.92

62 116.2 97.4 9.87 110.7 95.6 10.74 99.6 93.9 12.22 92.8 91.8 12.89

67 125.9 76.8 10.00 119.4 75.0 10.86 107.3 73.2 12.33 100.0 71.2 12.98

72 138.2 55.0 10.19 131.6 53.2 11.05 118.4 51.4 12.51 110.4 49.5 13.16

62 119.4 117.4 9.91 114.6 114.6 10.79 104.0 104.0 11.22 97.8 97.8 12.95

67 126.4 96.2 10.01 120.4 94.9 10.88 108.5 93.5 11.31 101.2 91.9 13.00

72 137.6 75.4 10.18 130.7 74.0 11.04 117.5 72.6 11.48 108.9 70.9 13.16

119.0 89.6 10.62

107.3 88.3 12.09 100.0 86.7 12.75

R6GP-120 (One compressor operation)

O.D.T 55 °F 65 °F 75 °F 85 °F

CFM E.D.B. E.W.B. T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW T.C. S.C. kW

75

3500

4000

4500

Notes:

1 ) T.C. = total (Net) cooling in kBtuh; S.C. = Sensible Cooling in kBtuh; kW = Kilowatts

2 ) Ratings are based on the Factory Standard blower drive combination

3 )For 208-230V Units, the ratings shown reflect 230V operation

4 ) Bolded Values indicate AHRI rating points

5 ) Energy Efficiency Ratio (EER) = T.C./kW

62 65.9 49.1 4.50 61.8 46.9 4.80 56.8 44.3 5.10 50.7 41.4 5.50

67 73.8 37.5 4.70 69.8 35.3 5.00 64.7 32.7 5.30 58.7 29.8 5.70

72 82.6 27.7 4.80 78.6 25.5 5.10 73.5 22.9 5.50 67.5 19.9 5.90

80

62 69.9 58.8 4.30 65.9 56.6 4.60 60.9 54.0 5.00 54.8 51.0 5.30

67 76.7 47.9 4.50 72.6 45.6 4.70 67.6 43.1 5.10 61.5 40.1 5.50

72 84.2 36.5 4.60 80.1 34.3 4.90 75.1 31.7 5.20 69.0 28.8 5.60

75

62 66.9 50.5 4.90 62.9 48.3 5.20 57.9 45.7 5.50 51.8 42.8 5.90

67 74.9 38.8 5.00 70.8 36.5 5.30 65.8 34.0 5.60 59.7 31.0 6.00

72 83.7 28.8 5.20 79.6 26.6 5.40 74.6 24.0 5.80 68.5 21.0 6.20

80

62 68.8 58.9 5.00 64.8 56.7 5.20 59.8 54.1 5.60 53.7 51.2 6.00

67 75.5 48.4 5.10 71.5 46.2 5.30 66.5 43.6 5.70 60.4 40.7 6.10

72 83.0 37.5 5.20 79.0 35.3 5.40 74.0 32.7 5.80 67.9 29.7 6.20

75

62 68.0 51.9 5.20 64.0 49.7 5.50 58.9 47.1 5.80 52.9 44.2 6.20

67 75.9 40.0 5.40 71.9 37.8 5.60 66.9 35.2 6.00 60.8 32.2 6.40

72 84.7 29.9 5.50 80.7 27.7 5.80 75.7 25.1 6.10 69.6 22.1 6.50

80

62 67.9 59.0 5.60 63.9 56.8 5.90 58.9 54.2 6.20 52.8 51.3 6.60

67 74.4 49.0 5.70 70.4 46.7 5.90 65.4 44.1 6.30 59.3 41.2 6.70

72 82.3 38.1 5.70 78.2 35.9 6.00 73.2 33.3 6.30 67.1 30.3 6.70

15

Page 16

BLOWER PERFORMANCE DATA

R6GP-072-100

Factory Standard: 1 Hp Down-flow Performance Chart

Extended

Unit Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Operating

@ 230 or

460 Volts

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

Fully

Closed

1/2 Turn

Open

1 Turn

Open

1.5 Turns

2528 2301 2074

936 912 888 866

0.97 0.86 0.76

2417 2220 2111

960 940 908

1.02 0.85 0.79

2105 1854

964 944

0.88 0.77

Open

2582 2399 2177

908 884 862 866

0.98 0.86 0.76

2588

Indicates a recommended

719

unit operational point

0.72

2793

715

0.77

Indicates a setting that is not permitted for unit operation

Adjustable Motor Sheave Setting

2 Turns

Open

2.5 Turns

Open

3 Turns

Open

2975 2828

824 800 775 749 722

0.98

2763

828 804 760 746 726

0.95

3.5 Turns

Open

0.88

2608 2453 2293 2110

0.84 0.72 0.63 0.57

2727 2582 2381 2180 1982

854 831 808 784 750

0.95 0.86 0.75 0.65 0.56

2680 2488 2295 2105

880 858 835 801 786

0.97 0.86 0.76 0.63

1913

0.68

1913

0.68

Indicates an allowable setting that is

not recommended for unit operation †

† These operational points should be carefully examined

by the installer for proper unit setup and heating operation

‡ Indicates Factory Sheave Setting

4 Turns

Open

2867 2728

771 745 719

0.85 0.78

2680 2528 2375

0.79 0.72 0.65

1860

0.54

4.5 Turns

Open

2946 2793

741 715

0.85

5 Turns

Open ‡

0.77

2588

0.72

R6GP-072-100

Factory Standard: 1 Hp Horizontal Performance Chart

Extended

Unit Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Operating

@ 230 or

460 Volts

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

Fully

Closed

1/2 Turn

Open

1 Turn

Open

1.5 Turns

2545 2353 2100

931 907 833 858

1.02 0.91 0.78

2414 2306 2046

959 936 912

1.04 0.92 0.79

2174 2013

964 941

0.90 0.81

Open

2563 2349 2165

903 879 855 833

1.00 0.87 0.77

‡ Indicates Factory Sheave Setting

Adjustable Motor Sheave Setting

2 Turns

Open

2626 2462 2298 2026

877 853 829 800 775

0.99 0.87 0.76 0.64

2.5 Turns

Open

3 Turns

Open

2812

821 795 769 745 721

0.96

3.5 Turns

Open

2881

792 766 745 723

0.92

2663 2514 2289 2085

0.85 0.74 0.68 0.56

2729 2590 2426 2261

850 826 799 772 746

0.97 0.85 0.77 0.68

2018

0.68

1862

0.68

4 Turns

Open

2955 2785

764 742 720

0.88 0.79

4.5 Turns

Open

2999 2848

740 717

0.86

5 Turns

Open ‡

2615

2738 2558 2377

0.81 0.72 0.64

1995

0.60

1957

0.58

0.76

0.69

1802

730

0.46

Values includes losses for: Unit Casing, 2" Disposable (Pleated) Filters & Dry Evaporator Coil

For approximate Cfm at 208V Deduct 0.5%

16

Page 17

BLOWER PERFORMANCE DATA

R6GP-072-166

Factory Standard: 1 Hp Down-flow Performance Chart

Extended

Unit Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Operating

@ 230 or

460 Volts

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

Fully

Closed

1/2 Turn

Open

1 Turn

Open

1.5 Turns

2525 2323 2120

937 915 892 868

1.01 0.89 0.77

2449 2216 2004

964 941 919

1.01 0.88 0.79

2160

971 946

0.92

1928

0.81

Open

2625 2395 2220

909 887 864 840

1.01 0.86 0.78

‡ Indicates Factory Sheave Setting

Adjustable Motor Sheave Setting

2 Turns

Open

2769

881 860 838 811 784

1.04

2.5 Turns

Open

2826

857 834 808 782 756

0.99

3 Turns

Open

2879

831 804 777 753 726

0.96

3.5 Turns

Open

2936 2788

802 776 751 725

0.94 0.85

2708 2537 2335 2132

0.87 0.79 0.68 0.57

2647 2437 2227

0.87 0.78 0.68

2544 2318 2107

0.90 0.77 0.67

2044

0.70

1920

0.68

4 Turns

Open

2989 2832

775 749 722

0.92

4.5 Turns

Open

3025 2872

721 719

0.88

0.83

5 Turns

Open ‡

2613 2437

0.76 0.68

2016

0.59

1895

0.57

0.80

2674

0.74

R6GP-072-166

Factory Standard: 1 Hp Horizontal Performance Chart

Extended

Unit Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

Operating

@ 230 or

460 Volts

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

CFM

RPM

kW

Fully

Closed

1/2 Turn

Open

2254 2043

971 945

0.96 0.85

1 Turn

Open

1.5 Turns

Open

2668 2474 2285 2095

912 888 865 842

1.05 0.92 0.80 0.69

2572 2386 2200

939 971 894 870

1.07 0.93 0.79

2303 2097

942 920

0.95 0.83

‡ Indicates Factory Sheave Setting

Adjustable Motor Sheave Setting

2 Turns

Open

2745

884 862 839 813 789

1.02

2.5 Turns

Open

3 Turns

3.5 Turns

Open

2879

833 807 781 757 732

0.97

2655 2457 2259

837 811 785 760

0.89 0.78 0.67

2569 2392 2169

0.89 0.77 0.59

1988

0.70

Open

2704 2529 2366 2203

0.86 0.75 0.68 0.60

4 Turns

Open

2771

778 755 731

0.84

4.5 Turns

Open

2620 2469

0.75 0.66

5 Turns

Open ‡

2060

0.59

1946

0.60

2914

724

0.80

2703

728

0.74

Values includes losses for: Unit Casing, 2" Disposable (Pleated) Filters & Dry Evaporator Coil

For approximate Cfm at 208V Deduct 0.5%

17

Page 18

BLOWER PERFORMANCE DATA

R6GP-090-200

Factory Standard: 1 Hp Down-flow Performance Chart

Extended

Unit Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

Operating

@ 230 or

460 Volts

CFM

RPM 867 843

kW

CFM

RPM 893 870

kW

CFM

RPM 895

kW

CFM

RPM 918

kW

CFM

RPM 943

kW

CFM

RPM 968

kW

CFM

RPM 993

kW

CFM

RPM 1010

kW

CFM

RPM

kW

CFM

RPM 1039

kW

CFM

RPM 1043

kW

CFM

RPM

kW

CFM

RPM

kW

Fully

Closed

2904

1.40

2693

1.30

1/2 Turn

Open

3164

1 Turn

Open

3255

1.54

3059 2903 2747

996 974 952 931

1.52

1.44 1.31 1.19

2962 2830

1014 1001 979

1.39 1.31

2754

2572

1018 1005

1.28

1.19

2528

1024

1.17

1.5

3312

2 Turns

Open

3332

1.49

3195 3039 2883 2727

Turns

Open

946 924 902 881 860

1.52

1.40 1.29 1.19 1.07

3128 3001 2825

971 949 927 905

1.42 1.31 1.19

2669

1.20

2508

956

1.08

Adjustable Motor Sheave Setting

2.5

Turns

Open

3 Turns

Open

3613 3496

3.5

Turns

Open

4 Turns

Open

3666 3549

1.49

1.36

3378 3316 3253 3137 3021

846 834 822 800 778

1.52

3439

1.40

1.28 1.25 1.21 1.11 1.01

3315 3190 3135 3080 2946 2811

872 849 836 823 802 780

3384

1.45

3267 3139 3010 2945 2879 2736

1.33 1.20 1.17 1.13 1.03 0.94

896 875 853 839 824 803 782

1.48

1.37 1.25 1.12 1.09 1.06 0.96

3213 3094 2943 2791

921 898 878 857 842

1.38 1.28 1.16 1.05

2571

0.95

2648

1.08

2469

885

0.97

2574

1.09

‡ Indicates Factory Sheave Setting

4.5

Turns

Open

5 Turns

Open ‡

5.5 Turns

Open

3495 3441 3325

832 820 799 777

1.33 1.29 1.18

2726

1.01

2479

845

0.92

2661 2503

826 805

0.98 0.88

6 Turns

Open

3209

1.07

2592

0.86

Values includes losses for: Unit Casing, 2" Disposable (Pleated) Filters & Dry Evaporator Coil

For approximate Cfm at 208V Deduct 0.5%

18

Page 19

BLOWER PERFORMANCE DATA

R6GP-120-235

Factory Standard: 2Hp Down-flow Performance Chart ‡ Indicates Factory Sheave Setting for Pre-configured Units

External

Unit

Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

Operat-

ing @

230 or

460

Volts

CFM 5061 4896 4731 4558 4384

RPM 736 715 694 673 651

kW 1.86 1.72 1.57 1.44 1.31

CFM 4849 4679 4508 4321 4134

RPM 737 716 696 674 653

kW 1.77 1.63 1.49 1.35 1.22

CFM 5005 4816 4627 4447 4267 4071 3875

RPM 781 760 738 718 697 676 655

kW 2.01 1.83 1.66 1.52 1.38 1.25 1.12

CFM 4773 4593 4413 4202 3990 3777 3564

RPM 782 762 741 720 698 678 657

kW 1.92 1.74 1.56 1.42 1.29 1.15 1.02

CFM 4719 4534 4336 4137 3923 3708 3477 3245

RPM 803 783 764 744 722 699 679 659

kW 1.98 1.79 1.61 1.43 1.30 1.18 1.05 0.92

CFM 4685 4479 4273 4059 3845 3603 3361

RPM 826 806 786 766 746 724 703

kW 2.04 1.85 1.66 1.50 1.33 1.19 1.05

CFM 4457 4236 4014 3773 3531 3243

RPM 828 808 788 768 747 727

kW 1.91 1.72 1.54 1.37 1.20 1.06

CFM 4601 4395 4188 3940 3692 3412

RPM 867 849 832 811 791 771

kW 2.15 1.97 1.78 1.59 1.40 1.22

CFM 4326 4110 3893 3609 3325

RPM 870 853 835 814 793

kW 2.01 1.82 1.63 1.44 1.26

CFM 4251 3998 3765 3531 3252

RPM 890 872 855 839 817

kW 2.03 1.82 1.64 1.45 1.28

CFM 3917 3675 3434 3192

RPM 894 874 858 842

kW 1.83 1.66 1.48 1.31

CFM 3845 3605 3358

RPM 910 897 878

kW 1.89 1.68 1.51

CFM 3551 3274

RPM 913 900

kW 1.73 1.53

CFM 3168

RPM 916

kW 1.56

Fully

Closed

1/2 Turn

Open

1 Turn

Open

1.5

Turns

Open

Adjustable Motor Sheave Setting

2 Turns

Open

2.5

Turns

Open

3 Turns

Open

3.5

Turns

Open

4 Turns

Open

4.5

Turns

Open

5 Turns

Open ‡

5.5

Turns

Open

6 Turns

Open

Values includes losses for: Unit Casing, 2" Disposable (Pleated) Filters & Dry Evaporator Coil

For approximate Cfm at 208V Deduct 0.5%

19

Page 20

BLOWER PERFORMANCE DATA

R6GP-120-235

Factory Standard: 2Hp Horizontal Performance Chart ‡ Indicates Factory Sheave Setting for Pre-configured Units

External

Unit Static

(in-Wg)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

1.4

Operating

@ 230 or

460 Volts

CFM 5020 4871 4722 4536 4350

RPM 736 717 697 675 653

kW 1.82 1.68 1.53 1.41 1.29

CFM 4783 4619 4454 4271 4087

RPM 738 718 698 676 655

kW 1.73 1.59 1.45 1.33 1.20

CFM 4986 4785 4584 4407 4229 4030 3831

RPM 779 760 740 720 699 678 656

kW 2.00 1.82 1.64 1.50 1.36 1.24 1.12

CFM 4720 4519 4317 4120 3922 3727 3532

RPM 783 762 742 722 701 680 659

kW 1.90 1.71 1.53 1.39 1.26 1.14 1.02

CFM 4661 4458 4265 4072 3858 3643 3436 3229

RPM 805 786 765 744 724 703 682 661

kW 1.94 1.76 1.59 1.42 1.29 1.15 1.04 0.92

CFM 4637 4445 4252 4037 3821 3569 3316

RPM 827 808 789 767 746 726 706

kW 1.99 1.82 1.64 1.48 1.32 1.18 1.05

CFM 4394 4191 3988 3745 3502 3238

RPM 830 811 792 770 747 728

kW 1.88 1.70 1.53 1.36 1.20 1.06

CFM 4350 4173 3916 3658 3422 3186

RPM 851 833 814 794 773 751

kW 1.93 1.76 1.57 1.39 1.23 1.07

CFM 4254 4058 3861 3601 3341

RPM 870 853 836 816 796

kW 1.97 1.80 1.62 1.44 1.26

CFM 4191 3982 3762 3542 3270

RPM 891 874 856 839 816

kW 1.99 1.81 1.64 1.47 1.30

CFM 3892 3685 3452 3218

RPM 894 877 860 843

kW 1.83 1.65 1.49 1.32

CFM 3861 3572 3362

RPM 913 897 883

kW 1.88 1.68 1.51

CFM 3500 3244

RPM 915 902

kW 1.70 1.52

CFM 3191

RPM 917

kW 1.55

Fully

Closed

1/2 Turn

Open

1 Turn

Open

1.5 Turns

Open

2 Turns

Open

Adjustable Motor Sheave Setting

2.5 Turns

Open

3 Turns

Open

3.5 Turns

Open

4 Turns

Open

4.5 Turns

Open

5 Turns

Open ‡

5.5 Turns

Open

6 Turns

Open

Values includes losses for: Unit Casing, 2” Disposable (Pleated) Filters & Dry Evaporator Coil

For operation at 208V: Deduct approximately 0.5% from Cfm

20

Page 21

ACCESSORIES - 6, 7 1/2 AND 10 TON R6GP

Part # Description Weight 072 090 120

559914 Horizontal Supply & Return Kit 39 X X

547881 Horizontal Supply & Return Kit 49 X

547860 Hinged Roof Curb 8” High - K/D 70 X X X

547861 Hinged Roof Curb 14” High - K/D 125 X X X

547862 Hinged Roof Curb 18” High - K/D 155 X X X

547863 Hinged Roof Curb 24” High - K/D 220 X X X

559411 Hooded Hail Guard 62 n/a X

558857 Hooded Hail Guard 62 X

547864 0-35% Manual Outside Air Damper 30 X X

547874 0-35% Manual Outside Air Damper 41 X

547865 0-35% Motorized Damper - Only (Requires 547864 OR 547874) 15 X X X

559375 Economizer - Modulating w/ Relief, Adapts Horizontal, Enthalpy Control 125 X X

559374 Economizer - Modulating w/ Relief, Adapts Horizontal, Enthalpy Control 181 X

920233 Sensor, Enthalpy, C7400A (For Economizer Differential Enthalpy Control) X X X

547848 CO2 Sensor for economizer control - 4-9v dc X X X

547867 Power Exhaust - Prop (208/230V - 3Ø), Adapts Horizontal See Note 143 X X

547868 Power Exhaust - Prop (460V - 3Ø), Adapts Horizontal See Note 143 X X

547876 Power Exhaust - Prop (208/230V - 3Ø), Adapts Horizontal See Note 152 X

547877 Power Exhaust - Prop (460V - 3Ø), Adapts Horizontal See Note 152 X

547869 20” Supply & Return Transition Round 38 X X

547870 20” Flush Mount Concentric Diffuser Round 154 X X

547871 20” Step Down Concentric Diffuser Round 157 X X

547878 18” x 28” Supply & Return Transition 36 X

547879 18” x 28” Flush Mount Concentric Diffuser 162 X

547880 18” x 28” Step Down Concentric Diffuser 193 X

558863 Duct Smoke Detector Photo Elect. 3 X X X

558866 Duct Smoke Detector, Remote Multi-signal control SSK 451 1 X X X

558864 Smoke Detector Sampling Tube DST3, 2-4 ft. X X X

558865 Smoke Detector Sampling Tube DST5, 4-8 ft. X X X

920463 Low Ambient Kit X X X

920612 Natural Gas - High Altitude Application Kit X X X

920610 LP Gas - Conversion & High Altitude Application Kit X X X

920465 Bottom Power Entry Kit 7 X X

917165 Bottom Power Entry Kit 7 X

920619 Thermostat-3 Stage Heat/2 Stage Cool X X X

920937 Flue Exhaust Extension Kit 10 X X X

Note:

Requires separate branch circuit, see table Electrical Data For Power Exhaust Accessory Kits, page 12.

Accessory Performance Data

R6GP

-072*

&

-090*

-120*

† Pressure drop data are approximate values to allow for use in all design conditions.

‡ The distance the air from the grille travels from the diffuser before it slows down to 50 ft. per minute. All sides open.

Air

Volume

(CFM)

2200 0.08 0.20 0.03 0.15 0.14 0.13 20-24 0.11 17-25

2400 0.10 0.25 0.04 0.16 0.16 0.13 22-27 0.13 18-26

2600 0.12 0.30 0.04 0.20 0.20 0.15 24-29 0.17 19-26

2800 0.14 0.35 0.04 0.25 0.25 0.20 25-30 0.20 20-28

3000 0.16 0.40 0.04 0.30 0.30 0.25 27-33 0.25 21-29

3200 0.18 0.45 0.05 0.40 0.38 0.30 28-35 0.31 22-29

3400 0.20 0.50 0.05 0.50 0.46 0.40 30-37 0.37 22-30

3600 0.22 0.55 0.05 0.60 0.55 0.50 32-39 0.43 23-31

3600 0.12 0.20 0.04 0.35 0.25 0.20 25-33 0.17 22-29

3800 0.13 0.22 0.04 0.40 0.30 0.25 27-35 0.18 22-30

4000 0.14 0.24 0.04 0.45 0.35 0.30 29-37 0.21 24-33

4200 0.16 0.27 0.05 0.50 0.40 0.35 32-40 0.24 26-35

4400 0.18 0.30 0.05 0.55 0.45 0.40 34-42 0.27 28-37

4600 0.20 0.33 0.05 0.60 0.50 0.45 36-44 0.30 30-39

Wet

Evaporator

Coil

Down Flow

Economizer

Horizontal

Economizer

Total Resistance (inches water column) †

Step Down Diffuser System Flush Mount

2 Ends

Open

2 Ends Open

w/1 Side Open

2 Ends Open

w/2 Sides Open

Throw ‡

(Ft)

Diffuser

System

Throw ‡

(Ft)

21

Page 22

22

Page 23

23

Page 24

For complete catalog information including submittals,

energy calculations, dimension drawings, and more go to

www.ReznorHVAC.com or call 800-695-1901.

© 2015 Reznor LLC.

Reznor is registered in at least the United States. All other trademarks are the property of their respective owners.

All rights Reserved. Printed in U.S.A.

268E-0315 Form S-R6GP

Note: In keeping with our policy of continuous

product improvement, we reserve the right to alter,

at any time, the design, construction, dimensions,

weights, etc., of equipment information shown here.

Loading...

Loading...