Page 1

INSTALLATION

INSTRUCTION

I - SHIP PING AND PACK ING LIST

Package 1 of 1 contains:

1 - Economizer Assembly

1 - Fresh Air Hood w/ Filter

1 - Control Package

1 - Barometric Relief Hood

1 - Filter Access Panel

2 - Wire Nut (For Mixed Air Sensor)

16 - #10 x ½ x 16 Hex Tec

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

FORM# 571C-0411 (571C-0610)

ENTHALPY SENSOR

DAMPER MOTOR

Check contents for shipping damage. Contact the last carrier

immediately if any shipping damage is found.

II - AP PLI CA TION

Economizers are used with Q5SN/Q6SP/P6/R6 units for automatic sensor-controlled introduction of outdoor air into the

system through an electro-mechanically controlled damper. Outdoor air is mixed with the buildings return air to

economically improve indoor air quality and aide in reducing energy costs.

Economizer slides into horizontal return air opening. Mixed air sensor, TB11, and enthalpy control board relay are shipped

in economizer and must be relocated to the unit's filter section. Intake and exhaust hoods are packaged with economizers

and installed according to instructions below.

III - ECONOMIZER IN STAL LA TION

1. Disconnect all power to unit.

2. Cut and discard wire tie securing wire bundle to the damper motor

Important - DO NOT cut other wires. Inspect for damaged connections or loose wires.

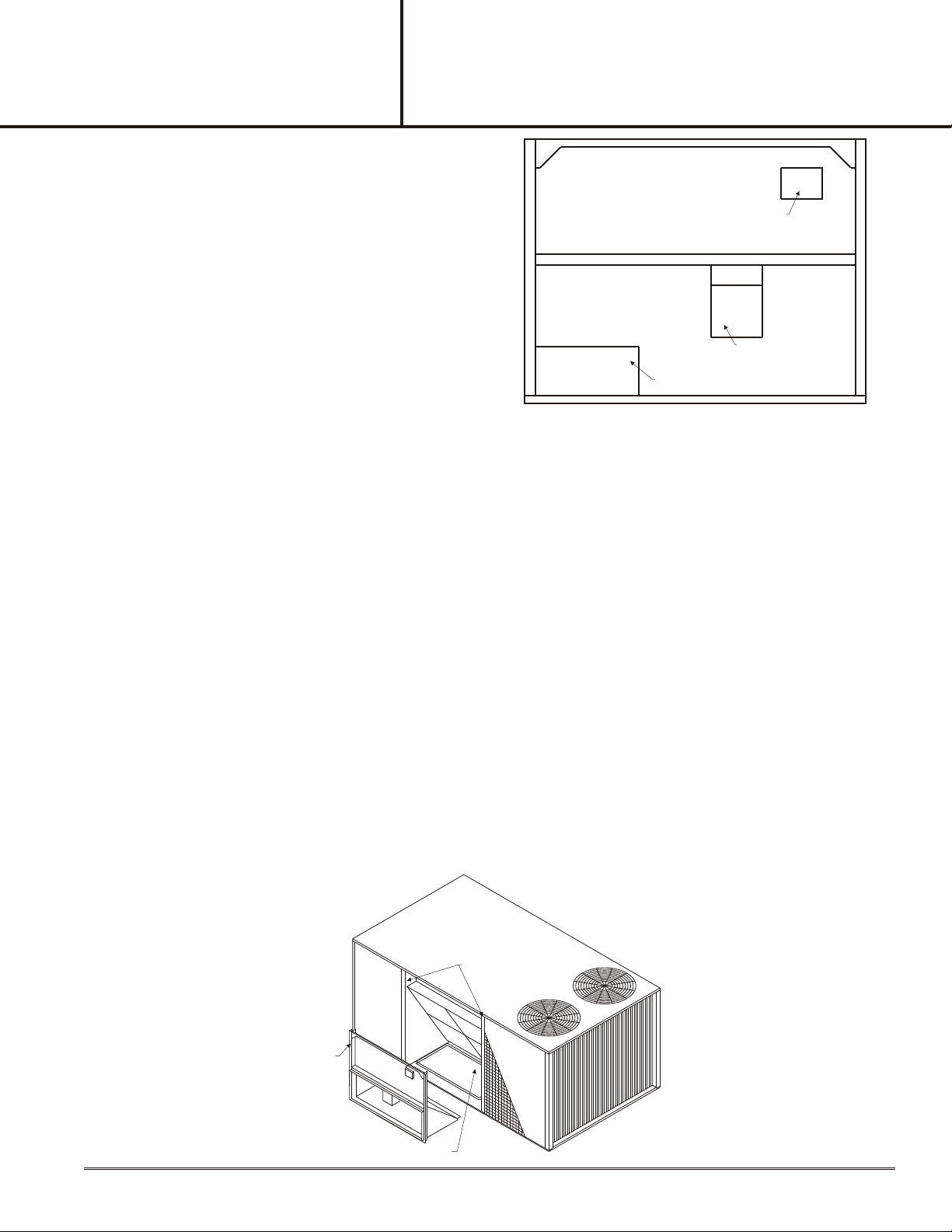

3. Remove box of controls to be installed over the assembly containing the logic control board and mixed air sensor. See

Figure 1.

4. Remove from box the logic control board and wire bundle. Cut wire tie securing the bundle of wires to logic control

board and mixed air sensor.

5. Locate S1, the unit's economizer connection and remove the installed dummy plug. See Figure 3.

6. Connect economizer jack S2 to economizer plug P2 on the economizer assembly.

7. Route wiring to the right side of the economizer and slide it into the unit. Insert economizer side flanges into the unit

standing seams. Using existing screws from bottom of discarded panel to secure economizer bottom flange to unit.

See Figure 2.

CONTROL PACKAGE (STEP 3)

Fig ure 1

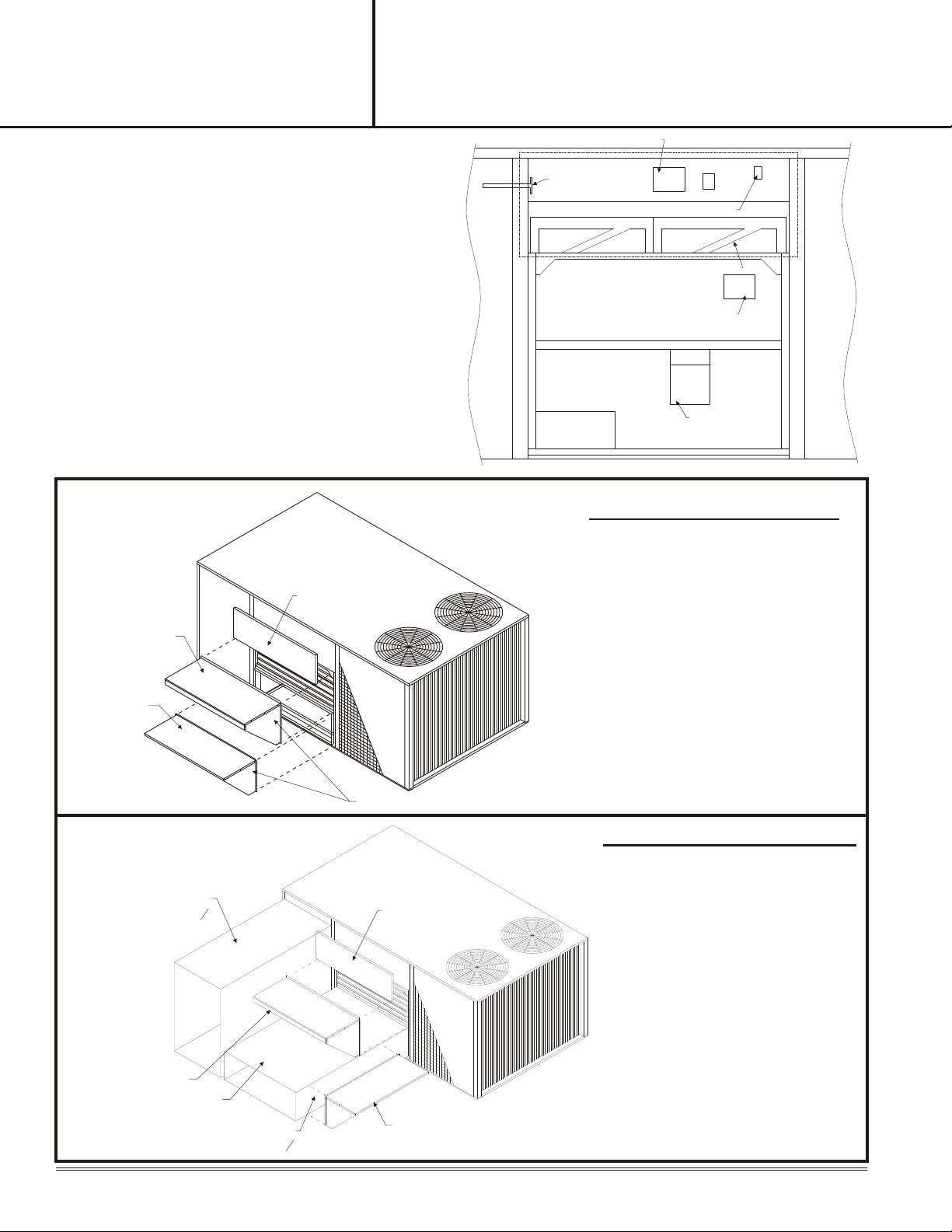

INSERT THE SIDE FLANGES INTO

THE UNIT STANDING SEAMS

RETURN AIR OPENING

MULLIONS

Figure 2

1

Page 2

INSTALLATION

INSTRUCTION

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

8. Position logic control board in filter access area as

shown in Figure 3. Secure control board with two

#10-16 x ½ screws.

9. Insert mixed air sensor tube through the mounting

hole into the supply air compartment. Secure using

two #10-16 x ½ screws. See Figure 3.

10. Connect economizer plug P1 to unit jack S1 on units

economizer control panel.

11. Verify that wire harnesses are secure and will not

interfere with economizer vane and linkage

operation, or with a filter change out

Note: Leave unit dummy plug (from Step 5) in the

unit control panel for later use if the

economizer needs to be by passed.

FILTER ACCESS

TB11 BOARD AND LOGIC CON TROL

MIXED AIR SENSOR

INTAKE AIR

EXHAUST AIR

ENTHALPY SENSOR

DOWN FLOW APPLICATION

12. Install barometric relief hood in front

of exhaust air opening.

13. Install fresh air hood in front of intake

opening.

S1 UNIT JACK

FIL TERS

DAMPER MOTOR

Figure 3

FRESH AIR HOOD

BAROMETRIC

RELIEF HOOD

Figure 4

NOTE: FOR THIS APPLICATION, HORIZONTAL

DUCT KIT #547881 IS REQUIRED.

SUPPLY DUCT

FRESH AIR HOOD

RETURN DUCT

Figure 5

3

30 x 16

8

31 x 18 ¾

559374 - 31" x 18

CUT HOLE

3

8

SCREW TO SIDE MULLIONS

FILTER ACCESS

BAROMETRIC RELIEF HOOD

14. Slide filter access panel underneath

top of unit and secure to mullions.

a. For heatpump units refer to

Section IV before restoring the

unit power.

15. Restore power to unit and check for

proper damper operation (See

System Check section).

HORIZONTAL APPLICATION

12. Install barometric relief hood to

return duct over the opening in

duct.

13. Install fresh air hood in front of

intake opening.

14. Slide filter access panel

underneath top of unit and

secure to mullions.

a. For heatpump units refer to

Section IV before restoring

the unit power.

15. Restore power to unit and check

for proper damper operation

(See System Check section).

2

Page 3

INSTALLATION

INSTRUCTION

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

IV – HEAT PUMP SET UP PRO CE DURES

A. Q5SN Series

Notice to Installer: Proper operation of this

economizer when used on Q5SN Series 7.5 and 10 Ton

Package Heat Pump systems is dependent on the type

thermostat installed with the unit. Identify which type

thermostat is connected to unit before making any

wiring changes if needed.

Ther mo stat Type 1 – Sep a rate "O" and "B" ter mi nals

for se lect ing Re vers ing Valve Con trol

Q5SN Series Heat Pump units are factory pre-wired for

economizers connected in conjunction with a 2 Stage Heat

/ 2 Stage Cool thermostat that utilize the "O" terminal to

energize the reversing valve(s) when the thermostat

"System Switch" is set in the "Cool" mode and has a

separate "B" terminal supplied with 24 VAC when the

thermostat "System Switch" is in the Off, Heat, or

Emergency Heat” mode. With "B" energized the

economizer is automatically locked out during heating

operation. It holds the outdoor fresh air damper at the

minimum position setting only.

Ther mo stat Type 2 –Sin gle "O/B" ter mi nal for

se lect ing Re vers ing Valve Con trol

If the thermostat has only one terminal, "O/B", for

determining if Heat or Cool mode energizes the Reversing

Valve(s), the following heat pump unit low voltage wiring

changes MUST

for identification)

1. DISCONNECT MAIN POWER TO THE UNIT.

2. Thermostat - Select the "Cool" mode to energize the

Heat Pump unit’s reversing valve(s).

3. Heat Pump Relay - Located to the left of the Defrost

Board in the unit’s main control panel.

l Reverse connections of the Orange and Yellow

wires on Heat Pump Relay terminals 1 and 4.

l Reverse connections of the White and Blue wires

on Heat Pump Relay terminals 3 and 6.

be made: (Refer to the unit wiring diagram

V - SYS TEM CHECK AND START UP PRO CE DURES

1. Disconnect main power to unit.

2. Install jumper on auxiliary contacts of blower contactor

in main unit control box.

3. Turn thermostat control to “OFF” position.

4. Install jumper on damper motor terminals T and T1.

See Figure 8.

5. Restore power to unit. Damper should drive to fully

opened position (requires 1 ½ minutes for full travel).

Observe travel for proper damper operation.

6. Disconnect power to unit. Damper should spring

return to closed position.

7. Remove T and T1 jumper on damper motor, then

restore power to unit. Adjust minimum vent position on

potentiometer on damper motor. See Figure 8.

8. Set the outdoor air enthalpy change overpoint. Refer

to Figure 6 and the instructions on Page 4.

9. Disconnect power to unit and remove jumper on

auxiliary contacts of blower contactor in main unit

control box. Restore power to unit.

10. Set the minimum damper position. See instructions on

Page 5 and 6 and the chart on the last page.

VI - MAIN TE NANCE

1. Damper motor is prelubricated and does not require

further lubrication.

2. Make visual inspection of dampers and linkage

assemblies during routine maintenance.

3. Filters should be checked periodically and cleaned

when necessary.

4. The washable filters supplied with the economizer can

be cleaned with water and a mild detergent.

5. Take note of "Air Flow Direction" marking on filter

frame when reinstalling.

4. Low Voltage Terminal Board - Jumper "O" and "B"

terminals. Located in the Electric Heat Section of unit.

B. Q6SP Series

The Q6SP Series heatpumps are factory wired for use with

an"O" terminal that is energized in cooling mode. These

units do not require or utilize a "B" terminal signal. Do not

alter the factory wiring of the Q6SP units for use with this

economizer

6. If filter must be replaced, filter of like kind and size must

be used. DO NOT replace permanent filters with

throwaway type filters.

3

Page 4

INSTALLATION

INSTRUCTION

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

OP ER A TION

A. Cool ing Mode

1. On a call for cooling, with ambient temperature and

humidity above enthalpy control setpoint, damper will

open to minimum vent position.

2. On a call for cooling, with ambient temperature and

humidity suitable for cooling, enthalpy control will shift

stage one control to outside air and shift stage two

thermostat to first stage compressor. Damper will

modulate to control supply air temperature at 55° F

(13° C). If additional cooling is required, compressor

one may be energized through second stage of

thermostat.

B. Heat ing Mode

1. On a call for heat damper will open to the minimum

vent position only.

4

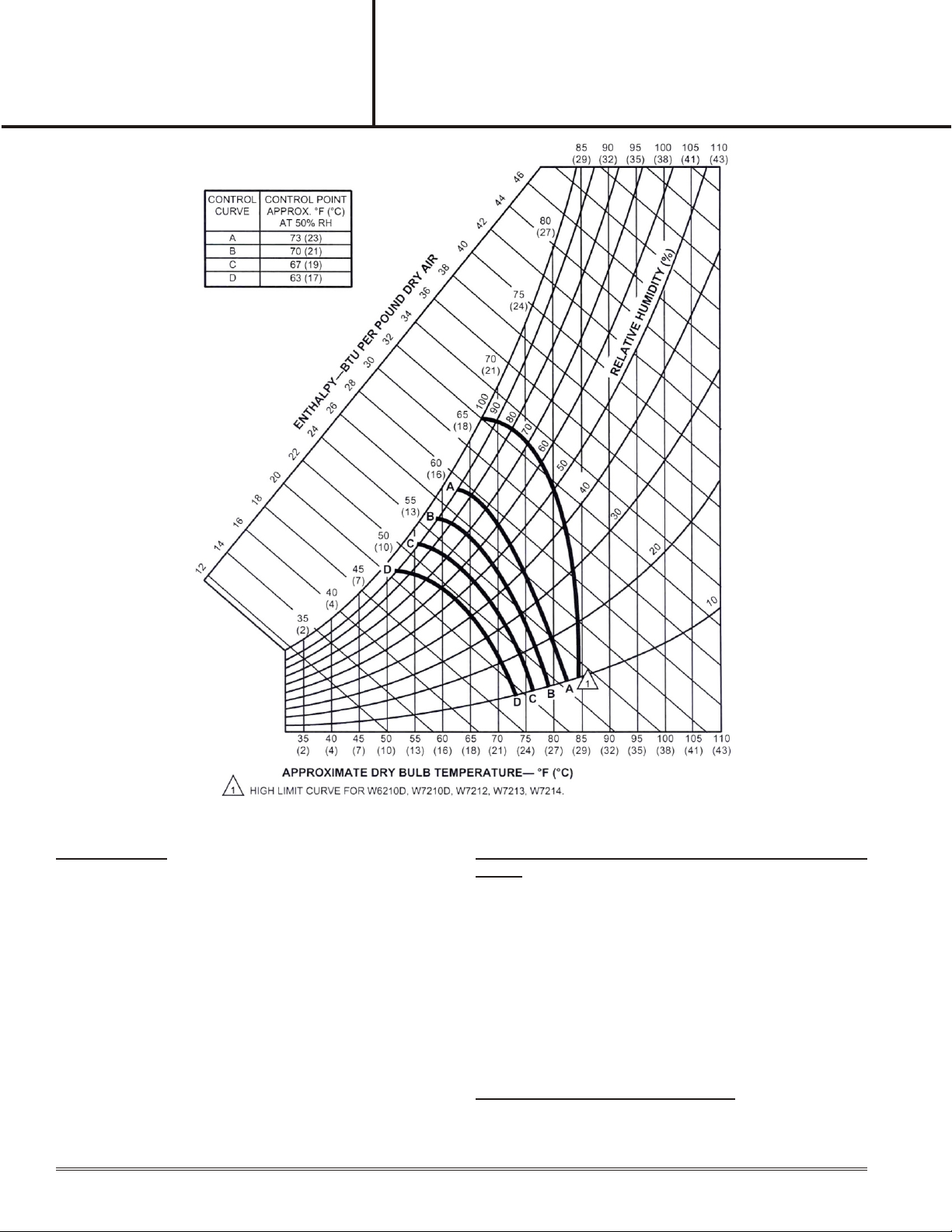

Figure 6

Set ting the Out door Enthalpy Change over

Point

The enthalpy control senses both temperature and

humidity or the heat content of the outside air. It controls

the amount of outdoor air brought into the system. When

the heat content of the outside air is below control setpoint,

the control modulates outdoor dampers to meet cooling

needs of the building. When the heat content rises above

control setpoint, the control closes outdoor dampers to

minimum position. The recommended setpoint is “A”. If

Economizer is allowing air which is too warm or too humid

to enter the system, control may be changed to a lower

setpoint (B, C, or D). Refer to Figure 6.

Differential Enthalpy Settin gs

For units equipped with a differential enthalpy sensor, refer

to the instructions include in the 920233 accessory kit.

Page 5

INSTALLATION

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

INSTRUCTION

Ad just ing Min i mum Damper Po si tion

The minimum position potentiometer keeps outdoor air

damper from closing completely during system operation

to provide ventilation.

Min i mum Po si tion Ad just ment

W7459A

1. Disconnect mixed air sensor from terminals T and T1.

2. Make sure either factory-installed jumper is in place

across terminals P and P1 or if remote damper

positioner is required, that it is wired according to

Figure 7 and turned fully clockwise.

3. Connect 24 Vac across terminals TR and TR1.

4. Adjust potentiometer on face of W7459 with

screwdriver to desired minimum position.

Op tional Ap pli ca tions

Re mote Min i mum Po si tion Con trol

Remote control of outdoor air dampers is desirable when

potential exists for temporary additional ventilation. The

potentiometer in W7459 controls damper minimum

position. Adding S963B1128 Remote Manual

Potentiometer allows occupants to open dampers beyond

minimum position for additional ventilation. Connect

potentiometer as shown in Figure 7.

INSTALLATION INSTRUCTIONS FOR

559374

P6 / R6 120 UNITS

This chart can also be used for measuring the percentage

of outside air on an air handler. The same three

temperatures are measured per the formulas on the

preceding page. Lines are drawn on the chart using a ruler.

As with the formulas this chart is most effective if there is at

least a 10 degree F difference between the return and

outside air. This will typically require either a warm or cold

day rather than moderate weather. It is more accurate to

measure outside air percentage on a day when the outside

temperature is 10°F (-12°C) rather than on a day when it is

70°F (21°C). If the temperature difference between the

return and outside air is only a few degrees, a small error in

measurements can alter the results by as much as 50%

using this method. If the temperature difference is 40 or

50°F (22 or 28°C) small errors in measurement do not

substantially affect the results of the calculations. A full

size chart is provided on the last page of these

instructions.

For detailed instructions on the use of this

chart, refer to Honeywell publication #

63-8594, Honeywell Economizers. Pages

12-13.

Figure 7

S963B1128 Remote Minimum Position Potentiometer

used with W7459 for remote damper control.

Re turn Air

Tem per a ture

For design requirements for CFM per person for all building types, refer to ASHRAE standard 62.1 section 6 and/or local or

state building codes.

x x

% of

Re turn Air

Formula for Adjusting the Minimum Position Control

+

Out side Air

Tem per a ture

% of

Out side Air

Tem per a ture

of Mixed Air

=

5

Page 6

INSTALLATION

INSTRUCTION

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

1. Measure the return air temperature.

2. Measure the outside air temperature.

3. Draw a line from the return air temperature to the

outside air temperature.

4. Measure the mixed air temperature in multiple

locations and determine the average.

5. Draw a line down from the mixed air temperature to the

point where it intersects the first line.

6. Draw a line from the point of intersection to the outside

air percentage on the left side of the chart.

6

According to the results from this chart this air handler is

supplied with 26% outside air. If the total supply volume is

20,000 cubic feet per minute (cfm) (566 m3/min) then:

0.26 X 20,000 cfm of total supply air equals 5,200 cfm of

outside air (147 m3/min).

This indicates that when the measurements were done on

this air handler the total volume of outside air in the mixed

air was 5,200 cfm of outside air (147 m3/min).

Page 7

INSTALLATION

INSTRUCTION

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

CHECK OUT AND TROU BLE SHOOT ING

Check the W7459 for proper operation. Table 1 describe how to

simulate various environmental conditions. Make necessary minor

adjustments to the minimum position until desired operation is

obtained.

If the economizer system does not operate properly, check individual

components of the system according to the instructions provided with

each device.

If the other components operate properly when disconnected from the

W7459, but the system (as a whole) does not, replace the W7459.

Check out Procedure Proper Response

1. a. Dis con nect power at TR and TR1. ---b. Dis con nect Jumper P to P1.

c. Jumper TR to 1.

d. Jumper T1 to T.

e. If con nected, re move C7400 Solid State

Enthalpy Sen sor from ter mi nals SO and +.

En sure fac tory-in stalled 620 ohm re sis tor is

connected to terminals SR and +.

f. Apply power (24 Vac) to terminals TR and TR1. Motor is in closed position.

2. a. Disconnect factory-installed 620 ohm resistor

from terminals SR and +.

3. a. To simulate high and low enthalpy (single

enthalpy sensor), reconnect factory- installed

620 ohm resistor from terminals SR and +.

Connect 1.2K ohm 4074EJM Checkout

Resistor across terminals SO and +

b. Turn enthalpy setpoint potentiometer to "A". LED turns on, indicating low enthalpy.

c. Turn enthalpy setpoint potentiometer to "D". LED turns on, indicating high enthalpy.

d. Disconnect the 1.2K ohm checkout resistor. ----

4. a. To verify sensor operation, reconnect the + lead

of outdoor enthalpy sensor to the + terminal of

W7459

b. Connect a DC milliammeter between terminal

SO of the W7459A and terminal S of the

enthalpy sensor. (Positive meter lead to

terminal S of the enthalpy sensor.)

c. When using differential enthalpy, check the

return air enthalpy sensor by connecting a DC

milliammeter between terminal SR of the

W7459A and terminal S of the return air

enthalpy sensor. (Positive meter lead to

terminal S of the enthalpy sensor.)

LED is off.

LED turns on (A model only, for D model,

go to step 3).

Motor drives toward open.

----

Motor drives toward open.

Motor drives toward closed.

----

Milliammeter indication is between 3 and

25 mA if sensor is operating properly.

If milliammeter indicates zero, the sensor

may be wired backwards.

Milliammeter indication is between 3 and

25 mA if sensor is operating properly.

If milliammeter indicates zero, the sensor

may be wired backwards

DAMPER ACTUATOR

Figure 8 - M7415A

Figure 9 - W7459A

7

Page 8

INSTALLATION

INSTRUCTION

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

C7046C Air Temperature Sensors

resistance versus temperature.

Approximate dimensions of C7046C Air Temperature Sensor in in. (mm).

C7400A Sensor output current

vs. relative humidity

Approximate dimensions of C7400A Solid State Enthalpy Sensor

C7650A Solid State Temperature Sensor in in. (mm)

8

Page 9

Re vi sion Change Date

Changed wire lengths 06-07-10

A Changed mixed air sensor 11-07-07

B

C Added S2/P2 plugs back in 06-18-10

P1 - (303908) PLUG & (303912) PIN

CONNECTOR & CONTACT CONFIGURATION

Date: June 22, 2010

Supersedes: 06-07-10

Drawn by: MGL

P6 / R6 120 (559374)

Q5SN / Q6SP 090-120

Mod u lat ing Economizer

Unit #: 47-314-11

Di a gram#: 4731411W

Ap proved by:

WIRE COLOR CODE

BLK Black

BLU Blue

BRN Brown

GRN Green

ORN Orange

RED Red

COMPONENT CODE

C7046C Mixed Air Sensor

C7400A Fresh Air Sensor

M7415A Damper Actuator 24V

P1/S1 Plug/Cap Economizer

P2/S2 Plug/Cap Economizer

TB-11 Terminal Board

VIO Violet

YEL Yellow

WHT White

W7459A Logic Module

PLUG

S2/P2 - (303903/303904) CAP/PLUG & (303913/303912) SOCKET/PIN

See Unit Wiring Diagram for Connections at S1

HARNESS DETAIL

E# = WIRE END DESIGNATION

E2 STUD #6 18 Ga. Wire

E3 Female ¼ Quick Disc.

(P1) ECONO MIZER

HAR NESS ENDS AT

E4 Male ¼ Quick Disc. Insul

E6 Wire Nut Size 73B

on the the W7459A Logic Mod ule.

Notes:

1. Y2 must be en er gized for Stage 1 com pres sor to op er ate dur ing economizer op er a tion.

2. Re lays 1K and 2K ac tu ate when the out door air enthalpy is higher than the enthalpy set point A-D

Enthalpy Sen sor is added to SR and + for dif fer en tial enthalpy con trol.

3. 1S is an elec tronic switch which closes when pow ered by a 24 VAC in put.

4. Fac tory in stalled 620 Ohm, 1 Watt, 5% re sis tor should be re moved only when a sec ond C7400

Page 10

INSTALLATION

INSTRUCTION

Outside Air Percentage Chart

INSTALLATION INSTRUCTIONS FOR

559374

ECONOMIZERS USED WITH Q5SN / Q6SP 090-120

P6 / R6 120 UNITS

SUPERSEDES 06-21-10

MAY 18, 2011

NEIEC11

10

Loading...

Loading...