Reznor R6GN-150 User Manual

TECHNICAL

SPECIFICATIONS

R6GN Series

SinglePackagedGas/ElectricUnits

R6GN 10.8 EER Commercial System

12½ and 15 Ton Units

These units offer flexibility in the replacement market.

The 12½ and 15 ton units are designed specifically for

retrofit applications and are compatible with most standard

footprints. They take less time to install and retrofit as they

directly replace Carrier 48DP & 48DR series, making the

contractor's job more profitable.

FEATURES and BENEFITS

• Baserails: Provide lifting points for ease of installation.

• ConvertibleAirDelivery: Fits most standard applications

and easily converts to horizontal airflow with horizontal

roof curb.

• Fully Insulated Bottom Pan: Helps ensure quiet

operation and prevents condensation.

• Quick-Release Filter Access Panels: Requires no

special servicing tools.

• Hi/LowPressureSwitches:Ensures long compressor

life.

• 18-Gauge Precoated Paint: Promotes corrosion

resistance and long life.

• Two-Stage Cooling: Offers cooling ranges from

78,000/148,000 to 94,000/180,000 Btu/h. Dual

refrigeration circuits.

• Two-StageHeating: Offers heat ranges from 180,000

to 315,000 Btu/h.

• ForEasyService: Hi/low ser vice ports allow quick access

without disrupting operation. Proven, industry standard

components for service and availability.

• Crankcaseheater: Prevents damaging flooded starts

and future compressor failures.

• PlasticMesh HailGuard: A guard that will never rust

and protects the units coil from being damaged.

• Compatibility: Fits most standard rooftop applicationscan be easily adapted for exceptions. Footprint

database available for cross-reference at http://www.

rooftopsystems.com under the "Adapter Quote" tab.

• Freeze protection thermostat: Provides reliable

compressor operation.

Model R6GN-150 Shown

FIELDINSTALLEDACCESSORIES

• LowAmbientKit

• HorizontalReturnAirKit

• Economizer

• FreshAirKit

• CO2Sensor

• DuctSmokeDetector

• LPGas/HighElevationConversionKit

• Nat.Gas/HighElevationConversionKit

• DifferentialEnthalpyControl

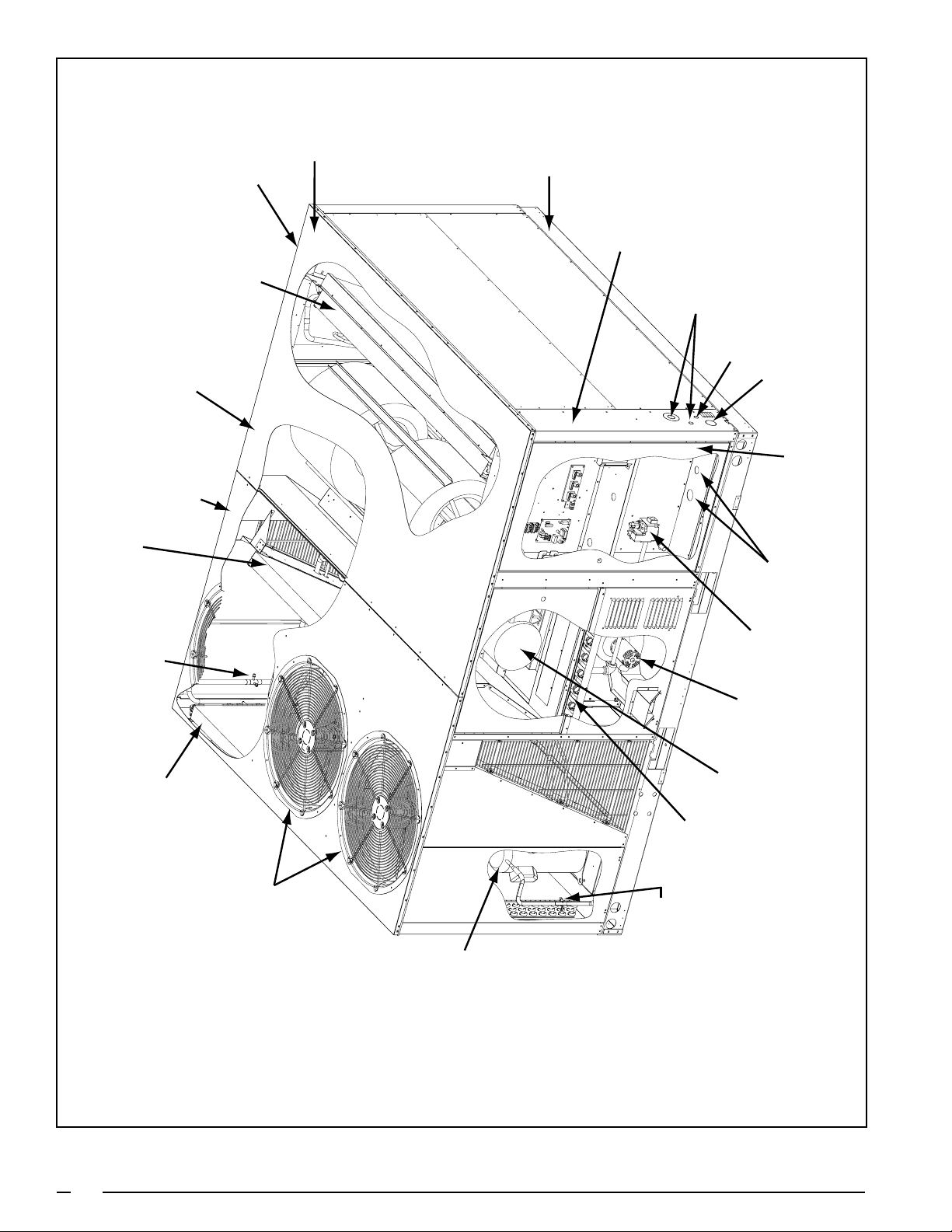

Condenser Coil

Stage 1

Condenser Coil

Stage 2

Heavy Gauge

BaseRails

For Lifting

Evaporator

Coil

Aluminized Steel

Tu bular Heat

Exchanger

Liquid Line

Filter Driers

High/Low Pressure

Switch Protection

Stage 1

High/Low Pressure

Switch Protection

Stage 2

Gas

Valve

Electrical Disconnect

Mounting Panel

(Field Supplied)

Durable

Pre-Coat Paint

Easy Access

Filter Panel

Knockouts

For Bottom

Power/Gas

Entry

Easy Access

Control Panel

Gas Supply Entry

Control Wiring Entry

Burner

Assembly

Inducer

Motor

Belt Drive

Blower

Motor

High Effciency

Scroll Compressors

with Crankcase Heaters

(one opposite side)

Condenser Fan

Assemblies

Power Wiring Entry

Model R6GN-180C270C Shown

2

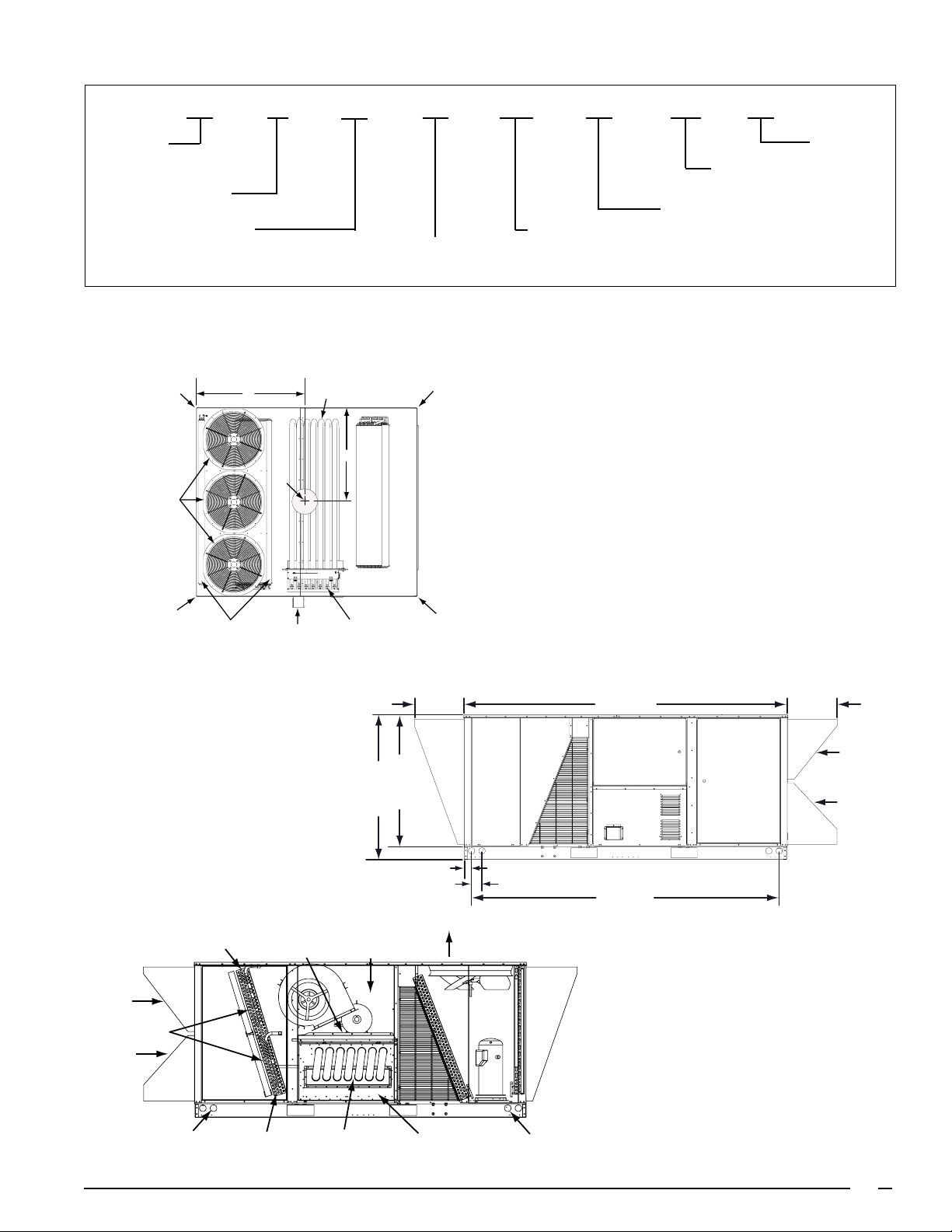

MODEL IDENTIFICATION CODE

102 (2590)

15.50

(394)

43 (1092)

47 (1194)

2 (51) TYP

3 (76) TYP

96 (2438)

OPTIONAL

FRESH

AIR INTAKE

HOOD

†

OPTIONAL

RELIEF

HOOD

†

ELECTRICAL

PANEL

ACCESS

BLOWER

MOTOR

ACCESS

BURNER

ACCESS

COMPRESSOR

ACCESS

15.50

(394)

OPTIONAL HAIL

GUARD HOOD

†

R 6 G N - 150 C 180 C

Application

R = Rooftop

Packaged Unit

Series

Gas

N = 10 - 10.99

R6GN-150/180 SERIES – PHYSICAL DATA

Dimensions shown in inches (mm)

CORNER “D”

CONDENSER

FANS (3)

“A”

CG

HEAT EXCHANGER

“B”

EVAPORATOR COIL

CORNER “C”

Cooling Capacity

(000) Btu

TOP VIEW

C = U.S./Can.

Heating Capacity

(000) Btu

Electrical Code

C = 208/230-60-3

D = 460-60-3

N = 575-60-3

OPTIONAL

FRESH AIR

RELIEF HOOD

†

HOOD

OPTIONAL

CORNER “B”

FILTERS (8)

†

HOISTING

CONNECTION

CONDENSER

COILS

STAGE 2

EVAPORATO R

FILTER

ACCESS

INDUCER/BURNER

VENT

HOOD

R6GN-180 Series

FRONT

VIEW

UPPER

SECONDARY

LIMIT

STAGE 1

EVAPORATO R

HEAT EXCHANGER

TUBE ACCESS

ASSY

BLOWER/HEAT

EXCHANGER

ACCESS

CORNER “A”

MAIN AIR

LIMIT

AIRFLOW

†

OPTIONAL HAIL

GUARD HOOD

HOISTING

CONNECTION

REAR VIEW

3

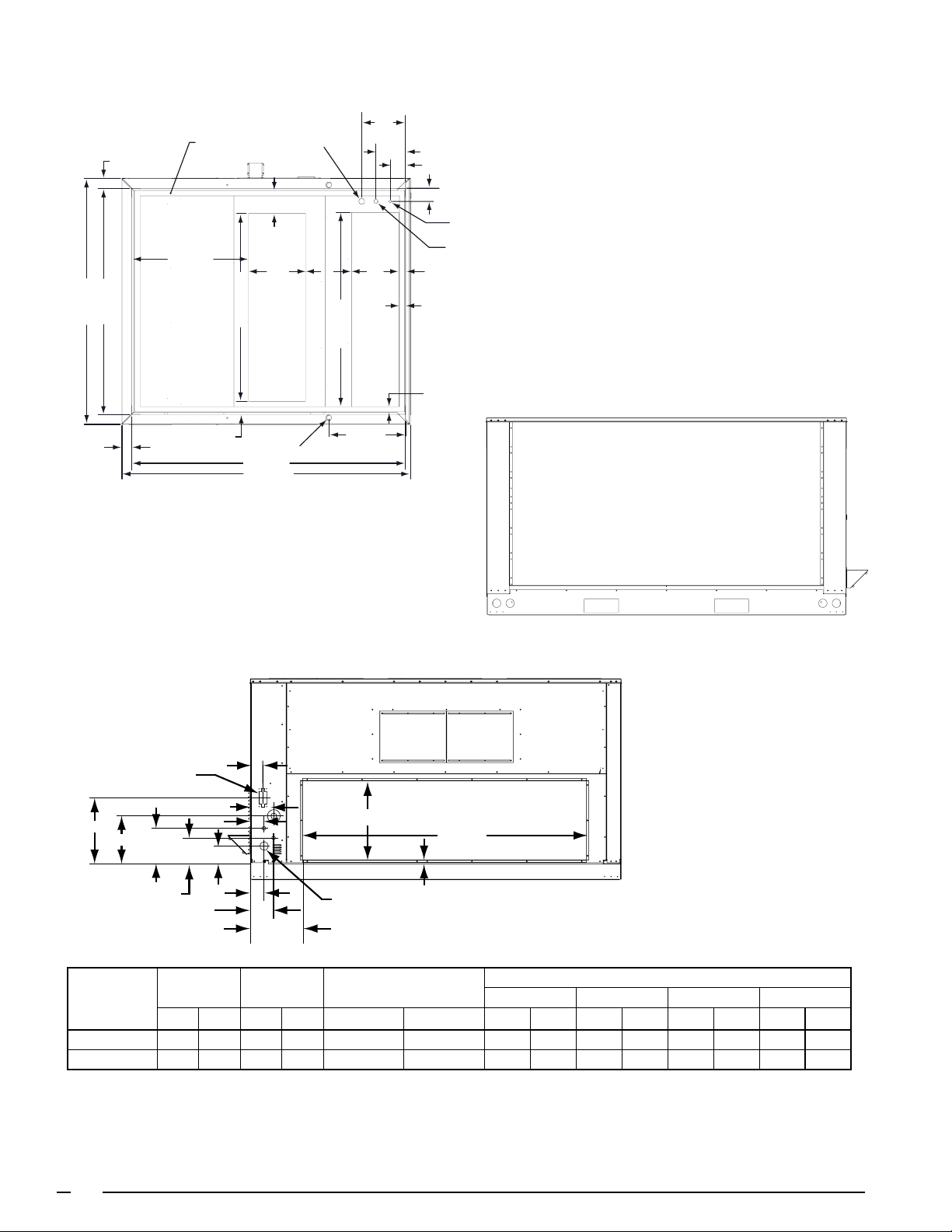

R6GN-150/180 SERIES – PHYSICAL DATA

15.31

Dimensions shown in inches (mm)

3.5 (89) TYP

ROOF CURB

OUTLINE

2" K.O. BOTTOM

GAS SUPPLY

ENTRY

(389)

10.31 (262)

5.31 (135)

87 (2210)

3.5 (89)

79 (2007)

8.5 (216)

41 (1041)

4.5 (114)

CONDENSATE DRAIN ACCESS (2)

20

(508)

65.5 (1664)

SUPPLY

AIR

OPENING

96 (2438)

102 (2590)

BOTTOM VIEW

16

(406)

16.5

(419)

RETURN

AIR

68 (1727)

OPENING

27 (686)

4.5 (114)

BOTTOM CONTROL

WIRING ENTRY

BOTTOM POWER

WIRING ENTRY

2.5 (64)

2 (51) TYP

2 (51) TYP

CONDENSER END

15.5 (394)

11 (279)

Model No.

ELECTRICAL SUPPLY

ENTRIES

3 (76)

115V

†

GFCI

5.5 (140)

3 (76)

8.5

(216)

6 (152)

4 (210)

3 (76)

5.5 (140)

Unit Weight ‡

GAS SUPPLY

12.5 (318)

Shipping

Weight

MANUAL

FRESH

AIR PANELS

18 (457)

1 (25)

ENTRY

Center of Gravity

Inches (mm)

†

HORIZONTAL RETURN

AIR OPENING

66 (1676)

†

A B C D

EVAPORATOR / FILTER END

Corner Weights

Lbs. Kg. Lbs. Kg A B Lbs. Kg. Lbs. Kg. Lbs. Kg. Lbs. Kg.

R6GN-150 1,730 786 1,944 884 48.75 (1,238) 44.5 (1,130) 430 195 460 209 405 184 435 198

R6GN-180 1,830 832 2,044 929 47.75 (1,213) 44.75 (1,137) 445 202 501 228 415 189 468 213

* Baserails are not intended to be removed. Information provided is total unit height for horizontal duct applications or height dimension

added to selected roof curb height for vertical duct applications.

† Field installed accessories required. ‡ Unit weight without packaging or field installed accessories.

4

Loading...

Loading...