Reznor MASA Unit User Manual

Form I-COND (Version C.2)

Obsoletes I-COND (Version C.1)

Installation/Operation/Maintenance

Applies to: Model MASA

Air Cooled Condensing Unit

Designed for Reznor Split Systems

P

R

O

Y

C

C

N

E

G

O

A

C

C

U

S

T

O

M

CQS

E

Q

R

U

A

P

R

O

D

U

E

S

R

E

G

V

N

L

I

T

C

S

E

N

T

P

U

-

T

R

A

T

S

M

Y

E

T

T

S

N

Y

Y

S

A

R

R

A

T

W

R-410A

Refrigerant

Only

IMPORTANT: Check, Test, and Startup MUST be followed, as documented in this manual.

A completed Condenser Startup Form (page 38) may be required for validation of any warranty

claims.

The factory reserves the right to deny warranty without completed Condenser Startup Form.

This booklet includes operation, maintenance, and service information. Before beginning any procedure, carefully

review the information, paying particular attention to the warnings. All installation procedures including handling of

refrigerant must be in compliance with all codes and requirements of authorities having jurisdiction.

Installer should complete information on page 40.

Condenser Startup Form on page 38 should be completed on initial startup.

Owner should keep this booklet for future reference.

Form I-COND, P/N 220746R6, Page 1

Table of Contents

1.0 General ..........................3

1.1 Hazard Labels and Notices ............3

1.2 General Information ..................4

1.3 Warranty ..........................4

1.4 Installation Codes ....................4

2.0 Location .........................5

3.0 Receiving, Moving, and Uncrating ....5

3.1 Receiving ..........................5

3.2 Moving ............................5

3.3 Uncrating ..........................5

3.3.1 Shipped-Separate Items ...........5

4.0 Clearances and Dimensions .........5

4.1 Clearances .........................5

4.2 Dimensions .........................6

5.0 Mounting .........................7

5.1 Weights............................7

5.2 Lifting .............................7

5.3 Mounting ..........................7

6.0 Mechanical .......................7

6.1 Refrigerant Piping ....................7

6.1.1 Location of Piping Connections at

the Condensing Unit ..............7

6.1.2 Location of Piping Connections at

the Split System Evaporator Coil.....8

6.1.3 Refrigerant Piping Guidelines

(R-410A Refrigerant) ............11

6.1.3.1 Type of Refrigerant Piping .....11

6.1.3.2 Refrigerant Piping Length

and Size ......................11

6.1.3.3 Liquid Line Piping ............13

6.1.3.4 Suction Line ................15

6.1.3.5 Optional Hot Gas Bypass Lines .15

6.1.3.6 Brazing Connections .........16

6.1.3.7 Piping Support and Insulation ...16

6.2 Leak Test the Refrigerant Circuits.......16

6.2.1 Leak Test the Condensing Unit ....16

6.2.2 Leak Test the Field-Installed Piping..17

6.3 Evacuate the Circuits ................17

6.4 Charge with R-410A Refrigerant .......17

7.0 Electrical and Wiring ..............18

7.1 General ...........................18

7.1.1 Wiring Diagram . . . . . . . . . . . . . . . . .18

7.2 Supply Wiring ......................18

7.2.1 Disconnect Switch...............18

7.2.2 Supply Voltage .................18

7.3 Unit Wiring Requirements ............19

7.4 Control Wiring ......................21

8.0 Controls and Operation ............21

8.1 Analog Control System ...............21

8.2 Digital Control System ...............21

8.3 Other Compressor and Refrigerant

Controls .........................22

8.3.1 High Pressure Cutoff .............22

8.3.2 Low Pressure Cutoff .............22

8.3.3 Hot Gas Bypass Valve (Option

CUG2 or CUG3) ................22

8.3.4 Compressor Protection (CUB1).....22

8.3.5 Crankcase Heaters ..............22

9.0 Final Checks and Start-Up.......... 23

9.1 General Comments ..................23

9.1.1 Checklist Prior to Start-up .........23

9.2 Start-up ...........................24

9.2.1 Power Supply Voltage Phasing .....24

9.2.2 Operating Sequence .............24

9.2.3 Refrigerant Charge ..............25

9.2.3.1 Check SUBCOOLING ........25

9.2.3.2 Determine SUPERHEAT .......25

9.2.4 Optional Hot Gas Bypass Valve ....26

10.0 Maintenance and Service..........26

10.1 General ..........................26

10.2 Maintenance Schedule ..............27

10.3 Condenser Fan(s) Maintenance .......27

10.4 Condenser Coil Maintenance .........28

10.5 Compressor Maintenance and

Replacement .....................28

10.6 Troubleshooting Chart...............34

APPENDIX

IMPORTANT Reminders about R-410A

Refrigerant and POE Oil ............36

Model MASA Technical Information ........36

Electrical Information....................37

Pressure/Temperature Chart for R-410A

Refrigerant for Checking Subcooling

and Superheat ....................37

CONDENSER STARTUP FORM ..........38

INDEX ..........................39

INSTALLATION RECORD - to be

completed by the installer .........40

Form I-COND, P/N 220746R6, Page 2

1.0 General

1.1 Hazard Labels and Notices

There are warning labels on the condensing unit and throughout this manual.

For your safety, read the denitions below and comply with all boxes labeled

CAUTION, WARNING, and DANGER during installation, operation, maintenance, and service of this system.

Denitions of Hazard Intensity Levels in this Manual

HAZARD INTENSITY LEVELS

DANGER: Failure to comply will result in severe personal injury

or death and/or property damage.

WARNING: Failure to comply could result in severe personal

injury or death and/or property damage.

CAUTION: Failure to comply could result in minor personal

injury and/or property damage.

WARNING

Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, personal injury, or

death. A qualied installer or service agency must perform

installation and service.

DANGER

This condensing unit is designed to use R-410A high pressure

refrigerant only. Hazards exist that could result in personal

injury or death. Installation, maintenance, and service should

only be performed by an HVAC technician qualied in R-

410A refrigerant and using proper tools and equipment. Due

to much higher pressure of R-410A refrigerant, DO NOT USE

service equipment or tools designed for R22 refrigerant.

DANGER

Never use oxygen to pressurize a refrigeration system.

Oxygen can explode on contact with oil and result in

personal injury or death. When using high pressure gas

such as nitrogen for pressurizing a refrigeration system,

ALWAYS USE A PRESSURE REGULATOR that can control

the pressure down to 1 or 2 psig.

SAFETY WARNINGS

For your safety, wear eye protection, gloves, and protective

clothing when handling R-410A refrigerant or POE oil

and when brazing. Have a re extinguisher nearby when

brazing.

Form I-COND, P/N 220746R6, Page 3

1.0 General

(cont’d)

1.1 Hazard Labels

and Notices

(cont’d)

WARNING

Before installing or servicing, always turn off the main

power to the system and install a lock out on the disconnect

switch.

CAUTION

Do not leave system open to the atmosphere any longer than

minimum required for installation. Exposure for more than

ve minutes may contaminate the system. POE oil in the

compressors is extremely susceptible to moisture absorption.

Always keep ends of tubing sealed during installation.

1.2 General Information

This booklet includes operation, maintenance, and service information. Before

beginning any procedure, carefully review the information, paying particular

attention to the warnings. All installations must be in compliance with all codes

and requirements of authorities having jurisdiction.

A Model MASA outdoor condensing unit operates on R-410A refrigerant and

has two independent refrigeration circuits congured in an approximate 1/3-

2/3 arrangement. The Model MASA condensing unit is designed for use with a

Reznor PreevA

indoor Models are PDH or SDH; outdoor Model is RDH. The Model MASA condensing unit may also be matched to a eld-supplied 1/3-2/3 two-circuit evaporator coil. An air handler used with a Model MASA condensing unit must be

properly matched; the evaporator coil must have freeze protection and must

be equipped with properly sized thermostatic expansion valves.

®

air handler unit with a 1/3-2/3 two-circuit cooling coil. PreevA®

Form I-COND, P/N 220746R6, Page 4

CAUTION

The condensing unit must be matched to an approximate

1/3-2/3 two-circuit, R-410A refrigerant evaporator coil with

properly sized thermostatic expansion valves. Failure to

properly match and/or equip the split system components will

prevent the system from operating correctly and will void the

manufacturer’s warranty. See Hazard Levels, page 3.

1.3 Warranty

Refer to limited warranty information on the Warranty Form in the “Literature

Bag” shipped with this system.

A completed Condenser Startup Form on page 39 may be required for validation of any warranty claim. Proper Check, Test, and Startup procedures MUST

be followed, as documented in this manual. The factory reserves the right to

deny warranty without a completed Condenser Startup Form.

1.4 Installation Codes

All installations must be in compliance with the National Electric Code ANSI/

NFPA No. 70 (latest edition) or, in Canada, the Canadian Electrical Code,

Part I-C.S.A. Standard C 22.l. Check any local ordinances or utility company

requirements that apply. The installation must be in compliance with all authorities having jurisdiction. Local code requirements supersede national requirements.

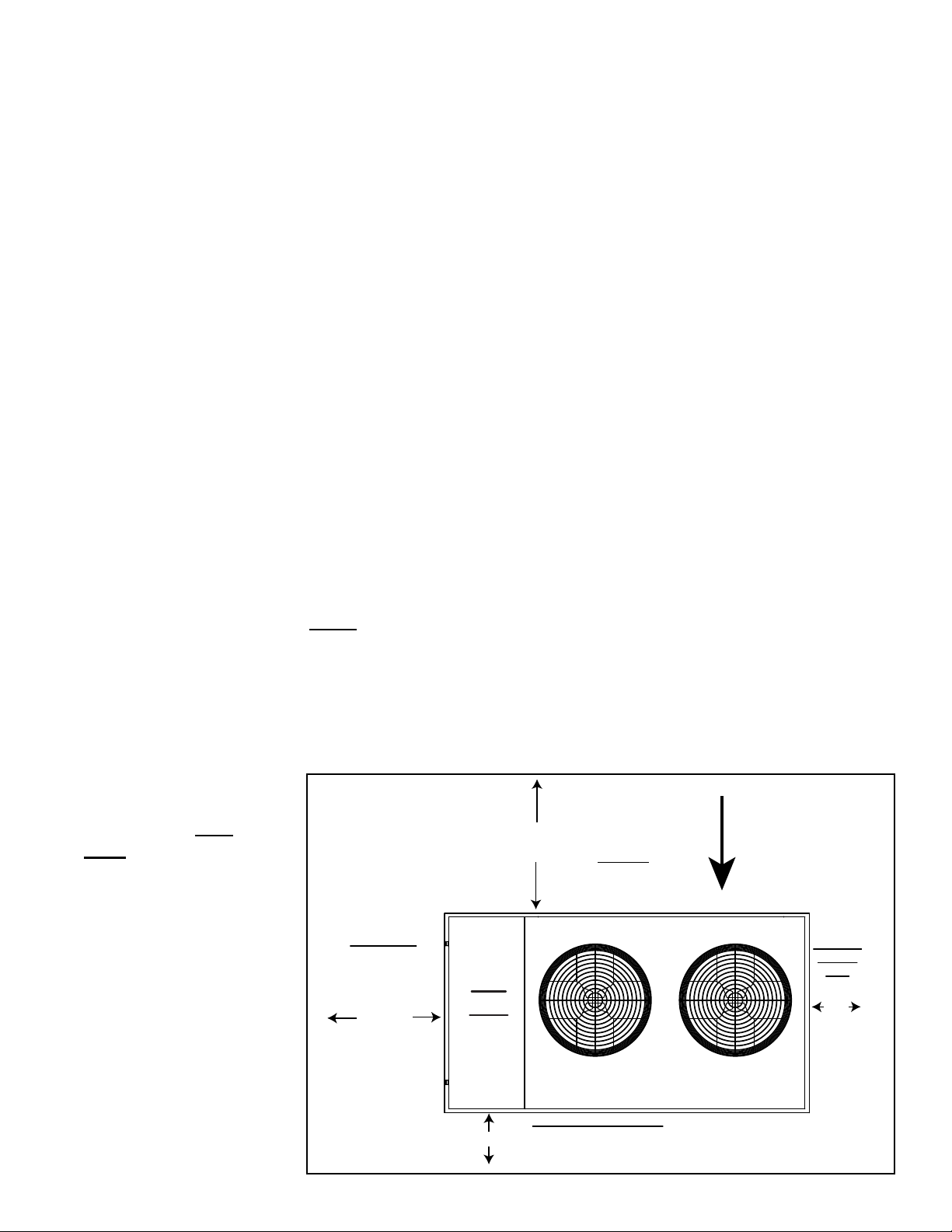

Coil Side

(Inlet airflow through

the condenser coil

must be unrestricted.)

Control Side

(Service

Clearance)

Opposite

Control

Side

Electrical Entrance Side

NOTE: Suggested side for installing disconnect switch;

see FIGURE 2, page 6. If disconnect switch is installed

on this side, minimum clearance is 36” (914mm).

Airflow

Top discharge airflow must be unrestricted.

Top clearance is 60” (1524mm).

36”

(914mm)

6”

(152mm)

6” (152mm)

48”

(1219mm)

Top

View

2.0 Location

Model MASA condensing unit must be mounted outdoors on a level surface.

The supporting structure must be able to support the operating weight of the

unit and maintain a level plane during continued operation. Water should drain

away from the unit. Location must comply with free space clearances for unre-

stricted airow (See Paragraph 4.1) and the refrigerant piping requirements

(See Paragraph 6.1.3). Avoid facing condenser coils into the prevailing wind.

3.0 Receiving,

Moving, and

Uncrating

3.1 Receiving

Check for any damage that may have been incurred during shipment. If damage is found, document the damage with the transporting agency and immediately contact your Reznor distributor. If you are an authorized Distributor, follow

the FOB freight policy procedures as published by Reznor for Reznor products.

3.2 Moving

The heavy gauge base of the condensing unit has forklift openings in both

sides. To move a unit, use a forklift with forks that have a minimum length of

24” (610mm).

3.3 Uncrating

Immediately upon uncrating, check the electrical characteristics to verify that

the unit is suitable for the installation site. This condensing unit is designed for

R-410A refrigerant only; verify that the split system air handler is for use with

R-410A refrigerant.

3.3.1 Shipped-Separate Items

Before beginning installation, be sure that all shipped-separate options ordered

are available at the site. Shipped-separate options could have been ordered

with the condensing unit or the matching PreevA® air handler.

NOTE: Two liquid line lter driers are shipped loose with the condensing unit

for eld installation.

4.1 Clearances

The condensing unit must

have unrestricted airow

FIGURE 1 - Minimum

Clearances (Top

View)

4.0 Clearances and Dimensions

on the coil side and above the unit. A service clearance is required on the control side of the cabinet.

Form I-COND, P/N 220746R6, Page 5

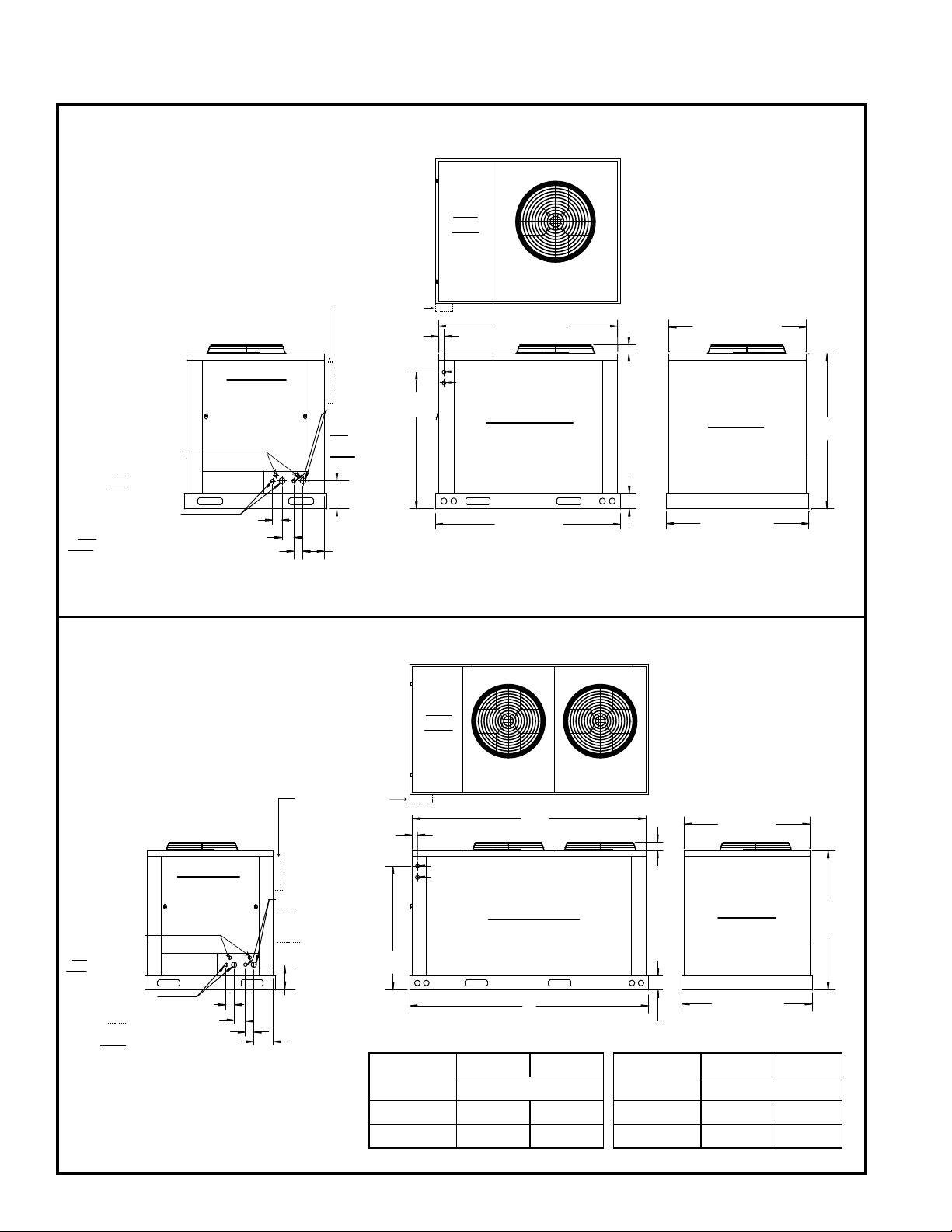

61” (1549mm)

59” (1499mm)

9-5/32”

(233mm)

47”(1194mm)

50-1/4”

(1273mm)

5-1/8”

(130mm)

7” (178mm)

3” (76mm)

3” (76mm)

4” (102mm)

45-7/32” (1149mm)

44-13/32”

(1128mm)

1-25/32”

(45mm)

3”

(76mm)

Supply Voltage Entrance

Control Voltage Entrance

Electrical Box

and Compressor

Compartment

Access Panel

CIRCUIT B

Connections

Left - 1/2”

Liquid Line;

Right - 7/8”

Suction Line

Optional Hot Gas

Bypass Connections

Left - Circuit A, 1/2”

Right - Circuit B, 1/2”

CIRCUIT A

Connections

Left - 1/2” Liquid Line;

Right - 7/8” Suction Line

Front View

Right Side View

(side opposite coil)

Rear View

Top

View

MASA Sizes

60 and 90

Suggested location

for field-installed

disconnect switch

(See FIGURE 1, page 5.)

4.0 Clearances and

4.2 Dimensions

Dimensions cont’d)

FIGURE 2A - Model MASA 60 and 90 Dimensions

FIGURE 2B - Model MASA 120, 150, and 180 Dimensions

Optional Hot Gas

Bypass Connections

Left - Circuit A, 1/2”

Right - Circuit B, 1/2”

CIRCUIT A

Connections

Liquid Line;

Suction Line

Form I-COND, P/N 220746R6, Page 6

120, 150, 180, 240

Electrical Box

and Compressor

3” (76mm)

Left - 1/2”

Right - 7/8”

4” (102mm)

MASA Sizes

Front View

CIRCUIT B Connections

Compartment

Access Panel

3” (76mm)

Left - Liquid Line, 1/2”

Sizes 120, 150, 180;

5/8” Size 240

Right - Suction Line,

7/8” Size 120; 1-3/8”

Sizes 150, 180, 240

9-5/32”

(233mm)

Suggested location

for field-installed

disconnect switch

(See FIGURE 1, page 5.)

1-25/32”

(45mm)

44-13/32”

(1128mm)

7” (178mm)

Top

View

Supply Voltage Entrance

Control Voltage Entrance

B

3”

(76mm)

45-7/32”

(1149mm)

Right Side View

Rear View

(side opposite coil)

MASA

Sizes

120, 150 86 84 120, 150 2184 2134

A B

Dimensions (inches) Dimensions (mm)

180, 240 110 108 180, 240 2794 2743

A

5-1/8”

(130mm)

MASA

Sizes

47” (1194mm)

A B

50-1/4”

(1273mm)

5.0 Mounting

5.1 Weights

Before installing, check the supporting structure to be sure that it has sufcient

load-bearing capacity to support the operating weight of the unit. Mounting is

the responsibility of the installer.

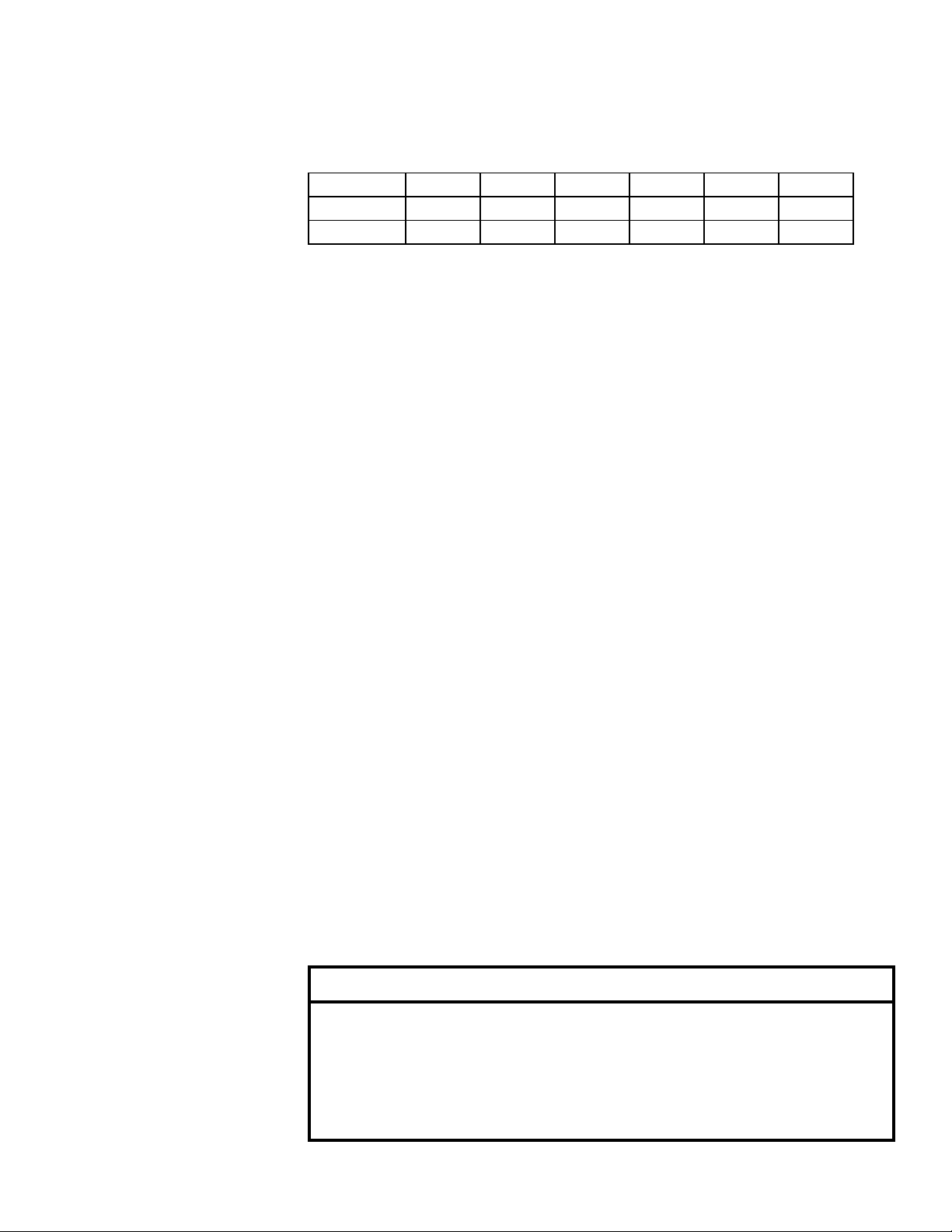

TABLE 1 - Weights

Approximate Operating Weight of Condensing Unit

MASA Size 060 090 120 150 180 240

lbs 440 461 632 699 749 771

kg 200 209 287 317 340 350

5.2 Lifting

The heavy gauge base of the condensing unit has fork lift holes and a pair of

lifting holes on each corner for rigging. If lifting with a forklift, forks must have

a minimum length of 24” (610mm). If attaching rigging, insert a clevis in each

set of holes for the rigging and lift using spreader bars. Lift the unit straight

up with vertical force.

Test lift the unit to be sure that it is secure and then lift slowly following safe

lifting procedures. Lifting and rigging are the responsibility of the installer.

5.3 Mounting

Condensing unit may be set directly on a roof or slab. Unit must be level. Be

sure to comply with clearances in FIGURE 1, page 5.

6.0 Mechanical

6.1 Refrigerant Piping

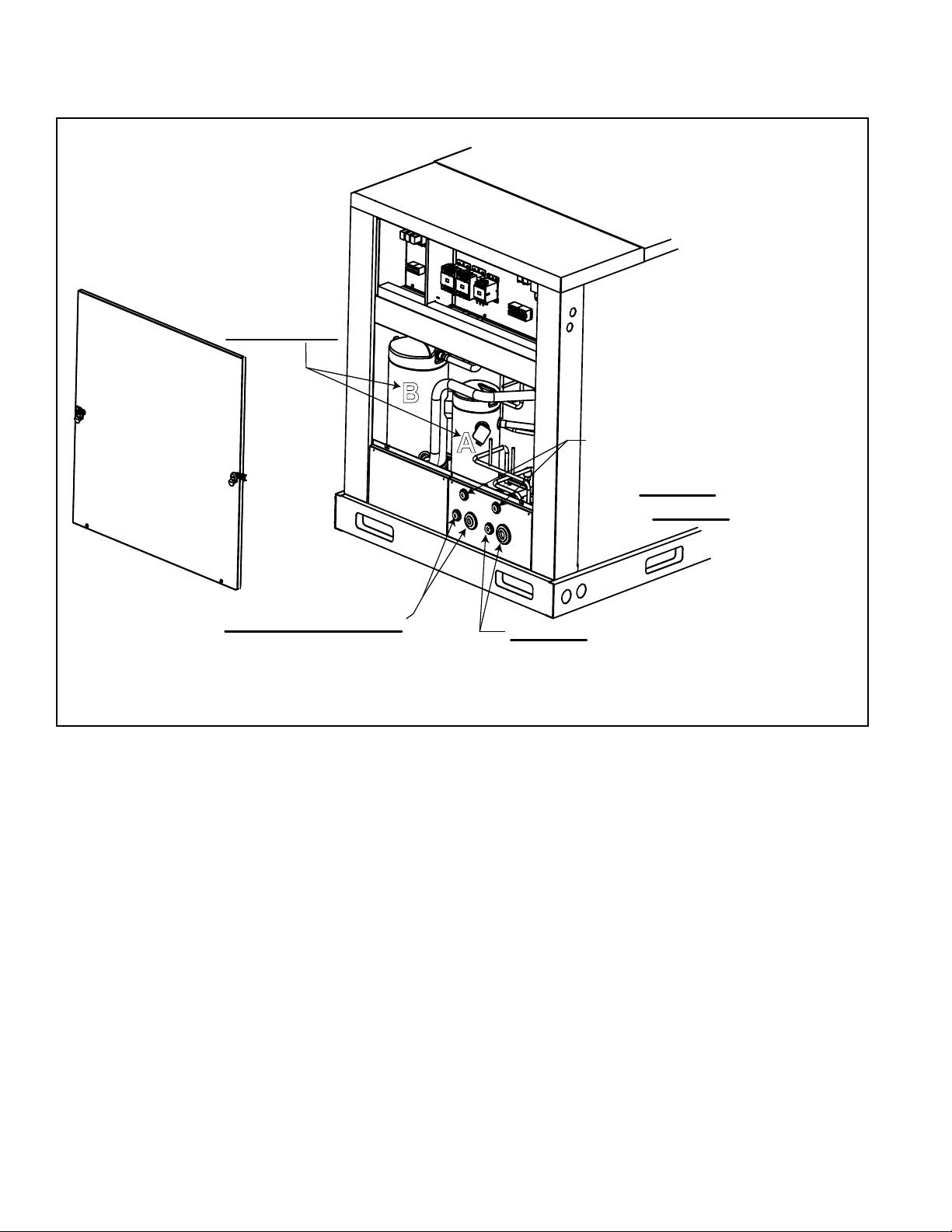

6.1.1 Location of Piping Connections at the Condensing Unit

Remove the control compartment door panel. Locate the refrigerant connections in the lower right corner. See FIGURE 3, page 8. Each circuit is shipped

with a nitrogen charge and has a shutoff valve. Do not open the valves until

after the lines are connected and the condenser circuits are leak tested.

The entrances for the two main refrigerant circuits are identied as Circuit A

and Circuit B (See FIGURE 3). Circuit A is the smaller (approximate 33%) con-

denser circuit; Circuit B is the larger (approximate 67%) circuit. Also indicated,

are the entrances for optional hot gas bypass circuits. If the condensing unit

is equipped with a hot gas bypass on only one circuit (Option CUG2), only

one entrance will be used. If equipped with a hot gas bypass on both circuits

(Option CUG3), both entrances will be used. When connecting refrigerant

lines to the condensing unit and the air handler, it is very important to

make all connections so that each individual circuit is maintained.

CAUTION

Do not remove seal caps from refrigerant connections or

open the service valves until ready to make permanent

connection. Exposure to the atmosphere for longer than

ve minutes may allow moisture and dirt to contaminate the

system. See Hazard Levels, page 3.

Form I-COND, P/N 220746R6, Page 7

6.0 Mechanical

Circuit A (1/3 circuit)

Piping Entrance Holes Liquid line on the left;

Suction line on the right

Electrical and

Compressor

Compartment

Access

Panel

Circuit B (2/3 circuit)

Piping Entrance Holes Liquid line on the left;

Suction line on the right

Entrances for Optional

Hot Gas Bypass Connections

Left - Circuit A;

Right - Circuit B

R-410A Compressors

(identified by

Circuit A & B)

B

A

Electrical

Compartment

(cont’d)

FIGURE 3 - Condensing

Unit Refrigerant Piping

Connection Locations

6.1.1 Location of Piping Connections at the Condensing Unit

(cont’d)

Form I-COND, P/N 220746R6, Page 8

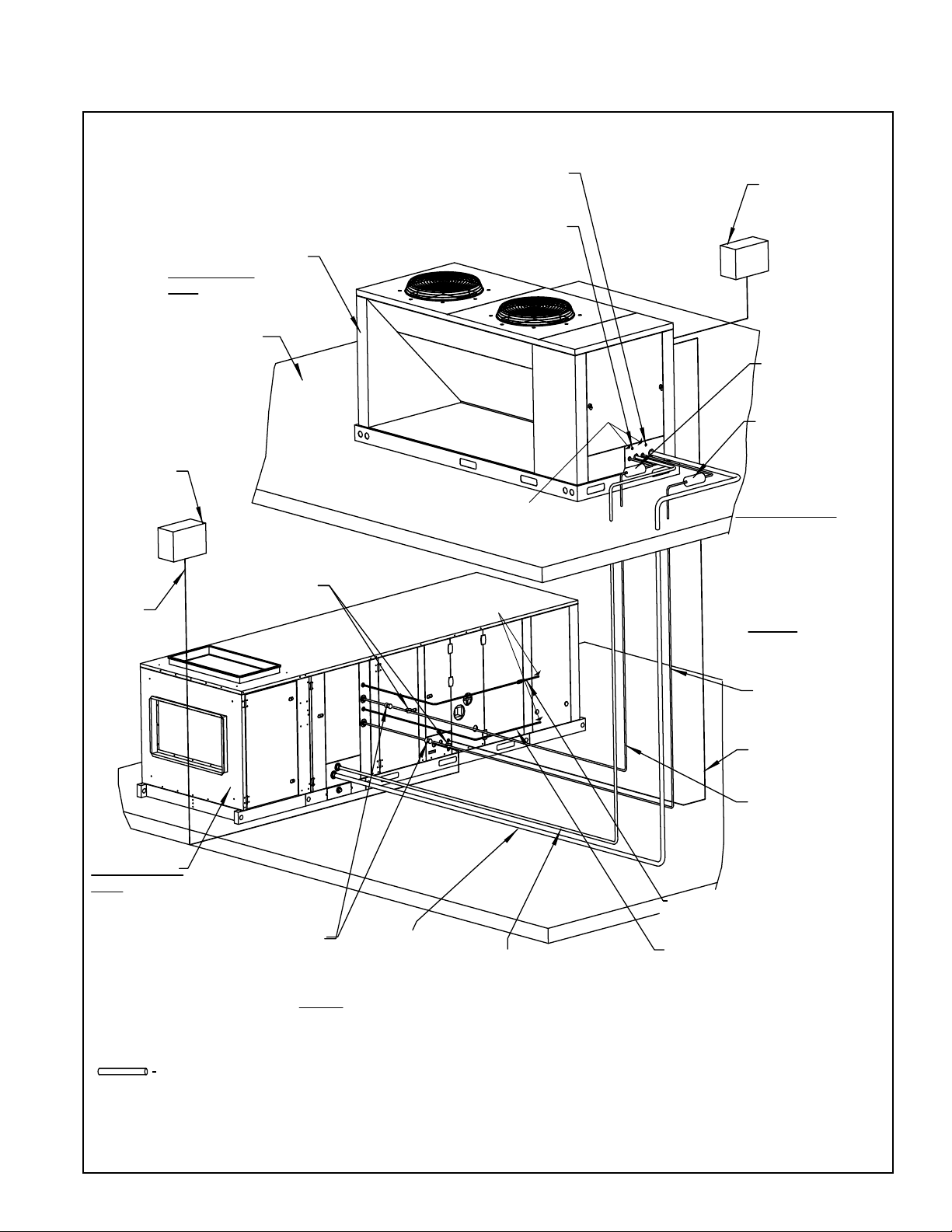

6.1.2 Location of Piping Connections at the Split System

Evaporator Coil

It is important to identify the Circuit A and Circuit B connections at the evaporator coil before running the refrigerant lines.

Circuit A on the condenser (FIGURE 3) is the smaller (33%) circuit and should

be connected to the 33% circuit of the evaporator coil. Circuit B on the condenser (FIGURE 3) is the larger (67%) circuit and should be connected to the

67% circuit of the evaporator coil.

On the evaporator coil, identify the liquid line connection at the distributor for

the smaller circuit (Circuit A). Force nitrogen into the Circuit A connection and

check which suction line connection corresponds to it. If the suction line connection is not identied, mark it as Circuit A. For verication, repeat the process with the larger circuit and mark the suction line connection as Circuit B.

Refer to FIGURE 4A or 4B for illustration of a split system refrigerant piping

system connecting a MASA condensing unit to a PreevA

FIGURE 4A, the condensing unit is higher than the evaporator coil. In FIGURE

4B, the condensing unit is lower than the evaporator coil.

®

evaporator coil. In

FIGURE 4A - Refrigerant Piping on a PreevA® Split System with the Condensing Unit

*Field-supplied per NEC.

**Field-supplied

SIGHT GLASS/

MOISTURE

INDICATOR **

CONDENSING UNIT INSTALLED ON THE ROOF

TO

CONDENSING

UNIT

FROM

AIR

HANDLER

Line Length NOTES:

1) MAXIMUM LIFT IS

45 FEET (13.7M).

2) MAXIMUM EQUIVALENT

LENGTH OF EACH

STANDARD LINE IS 60 FEET

(18.3M); SEE PARAGRAPH 6,

MECHANICAL.

3) CAUTION: MAXIMUM

EQUIVALENT LENGTH

OF AN OPTIONAL HOT GAS

BYPASS LINE IS 30 FT (9.1M).

TWO-CIRCUIT (1/3-2/3)

CONDENSING

UNIT FOR R-410A

REFRIGERANT

AIR HANDLER

UNIT WITH A

TWO-CIRCUIT (1/3-2/3)

COOLING COIL

FOR R-410A

REFRIGERANT

NOTES:

1. All piping must follow standard piping techniques for R-410A refrigerant. Refer to ASHRAE Guide and

ASME Informational Standards for piping information. Comply with CSA Mechanical Refrigeration Code

CSA B52, ASHRAE Guide Section 15, all municipal codes, and state or provincial requirements.

2. All wiring must comply with all applicable local and national codes.

3. Wiring and piping shown are general points-of-connection guides only and are not intended to apply

to or include all details for a specific installation. Refer to ASHRAE Guide Section 15 for piping details.

4. Internal factory-supplied TXV’s on PREEVA air handler unit are not shown. (Air handler must have

properly sized thermal expansion valves.)

5. Both condenser and evaporator must have two refrigerant circuits that are approximately 1/3-2/3.

6. Evaporative coil must have freeze protection.

ROOF

OPTIONAL “B” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

OPTIONAL “A” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

DISCONNECT

SWITCH *

DISCONNECT

SWITCH *

LIQUID LINE

FILTER DRIER

LIQUID LINE

FILTER DRIER

POWER

WIRE

“B” CIRCUIT

LIQUID LINE

24V CONTROL

WIRE

“A” CIRCUIT

LIQUID LINE

OPTIONAL “A” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

OPTIONAL “B” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

“A” CIRCUIT

SUCTION LINE

“B” CIRCUIT

SUCTION LINE

LIQUID LINE

SOLENOID

VALVE **

LEGEND

NEC - National Electric Code

TXV - Thermostatic Expansion

Valve

Piping

Installed at a Higher Level than the Air Handler Unit

Form I-COND, P/N 220746R6, Page 9

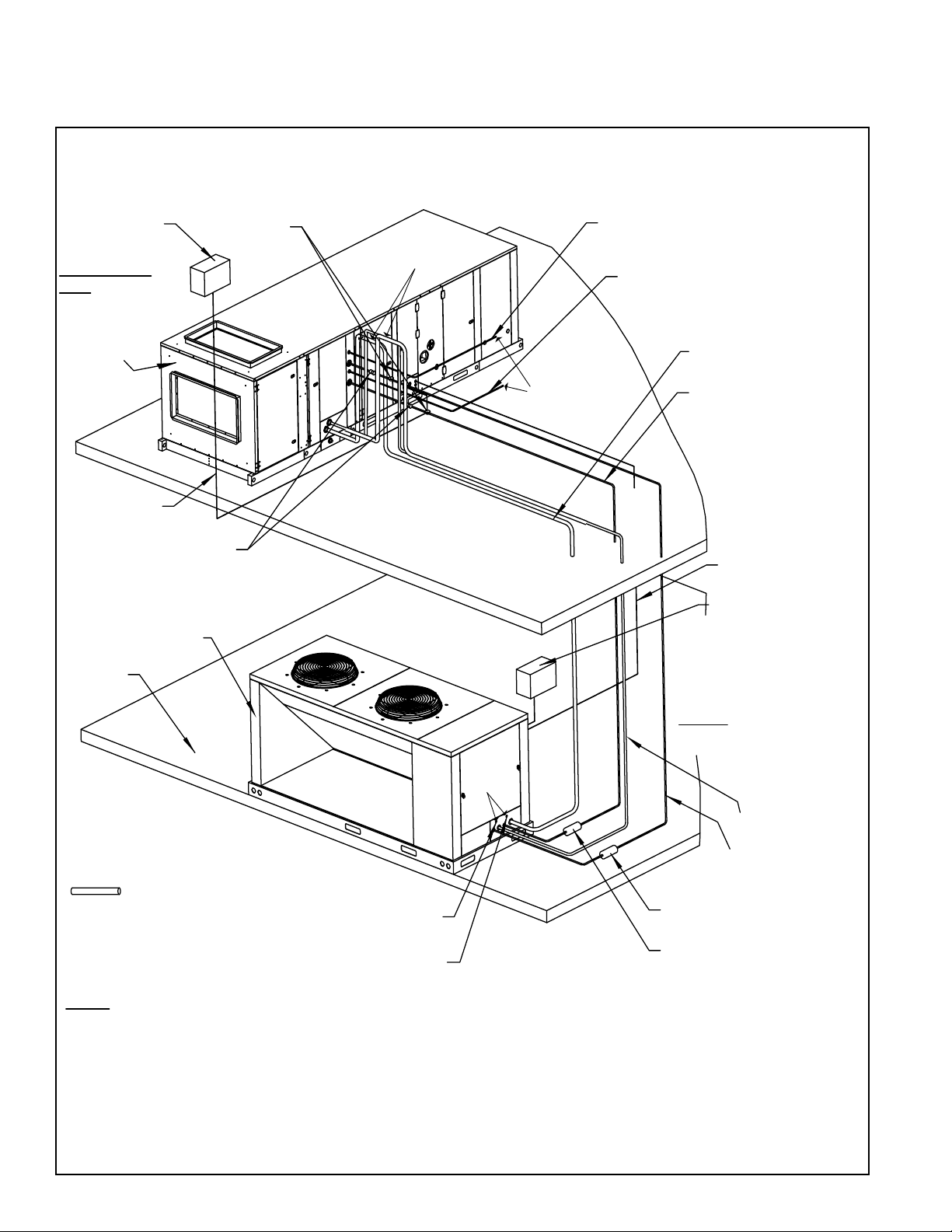

6.0 Mechanical

CONDENSING UNIT INSTALLED AT GROUND LEVEL

FROM

AIR

HANDLER

REPRESENTATIVE

TRAPS

*Field-supplied

per NEC.

**Field-supplied

SIGHT GLASS/

MOISTURE

INDICATOR **

AIR HANDLER

UNIT WITH A

TWO-CIRCUIT (1/3-2/3)

COOLING COIL

FOR R-410A

REFRIGERAN

T

NOTES:

1. All piping must follow standard piping techniques for R-410A refrigerant. Refer to ASHRAE Guide and ASME Informational Standards for

piping information. Comply with CSA Mechanical Refrigeration Code CSA B52, ASHRAE Guide Section 15, all municipal codes, and state or

provincial requirements.

2. All wiring must comply with all applicable local and national codes.

3. Wiring and piping shown are general points-of-connection guides only and are not intended to apply to or include all details for a specific

installation. Refer to ASHRAE Guide Section 15 for piping details.

4. Internal factory-supplied TXV’s on PREEVA air handler unit are not shown. (Air handler must have properly sized thermal expansion

valves.)

5. Both condenser and evaporator must have two refrigerant circuits that are approximately 1/3-2/3.

6. Evaporative coil must have freeze protection.

Line Length NOTES:

1) MAXIMUM LIFT IS 45 FEET (13.7M).

2) MAXIMUM EQUIVALENT LENGTH

OF EACH STANDARD LINE IS 60 FEET

(18.3M); SEE PARAGRAPH 6,

MECHANICAL.

3) CAUTION: MAXIMUM EQUIVALENT

LENGTH OF AN OPTIONAL HOT GAS

BYPASS LINE IS 30 FT (9.1M).

DISCONNECT

SWITCH *

OPTIONAL “A” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

OPTIONAL “B” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

“B” CIRCUIT

SUCTION LINE

“B” CIRCUIT

LIQUID LINE

24V CONTROL

WIRE

DISCONNECT SWITCH *

“A” CIRCUIT

SUCTION LINE

“A” CIRCUIT

LIQUID LINE

LIQUID LINE

FILTER DRIER

LIQUID LINE

FILTER DRIER

OPTIONAL “B” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

OPTIONAL “A” CIRCUIT HOT GAS

BYPASS (See Line Length NOTE 3)

POWER

LINE

LIQUID LINE

SOLENOID VALVE **

TWO-CIRCUIT (1/3-2/3)

CONDENSING UNIT

FOR R-410A

REFRIGERANT

GROUND

(PAD)

LEGEND

NEC - National Electric Code

TXV - Thermostatic Expansion Valve

- Piping

(cont’d)

FIGURE 4B - Refrigerant Piping on a PreevA® Split System with

the Condensing Unit Installed at a Lower Level than the Air

Handler Unit

Form I-COND, P/N 220746R6, Page 10

6.1.3 Refrigerant Piping Guidelines (R-410A Refrigerant)

The information in this section is a guideline and is not intended to provide

all of the instructions needed for designing and installing the R-410A refrigerant lines. The installer is responsible for designing the refrigerant connecting

system and for complying with standard refrigerant piping procedures. Refer

to ASHRAE Guide and ASME Informational Standards for piping information.

Comply with CSA Mechanical Refrigeration Code CSA B52, ASHRAE Guide

Section 15, all municipal codes, and state or provincial requirements.

Read all information in Section 6.1.3 before beginning installation of refrigerant

piping. In addition to the information in the following paragraphs, these general

requirements apply.

• IMPORTANT: Do not bury refrigeration lines.

• Pitch refrigerant lines in the direction of ow at approximately 1/2” per 10 ft

(12mm per 3 M).

• To prevent possible noise or line vibration, isolate refrigerant lines from

building structure and ductwork.

• Use long radius “L” for all 90° bends.

• Isolate suction and liquid lines from each other and from the unit cabinet.

CAUTION

Do not leave system open to the atmosphere any longer

than minimum time required for installation. POE oil in the

compressors is extremely susceptible to moisture absorption.

Keep ends of tubing sealed during installation. See Hazard

Levels, page 3.

6.1.3.1 Type of Refrigerant Piping

Refrigerant piping is eld supplied. Use only clean, dehydrated refrigeration

grade Type L scheduled or ACR Hard Drawn (ASTM B 280) copper tubing.

Size of refrigerant line segments depends on the condensing unit size and the

length and conguration of the lines. Do not determine the size of the piping

by the size of the connections at the condenser or evaporator; follow the line

sizing instructions in Section 6.1.3.2 below.

6.1.3.2 Refrigerant Piping Length and Size

Design the refrigerant circuit for a minimum pressure loss by keeping the actual

length to a minimum, with a minimum number of bends and ttings, and with

a minimum amount of line exposed to the outdoors. Excessive suction line

pressure drop will result in decreased thermal efciency and increased power

requirements. Excessive liquid line pressure drop can cause the refrigerant to

ash resulting in faulty expansion valve operation. Typically, each segment of

the refrigerant line should be sized for pressure loss of 2°F or less.

Lift must also be considered when determining location and piping length.

Maximum lift of the refrigerant circuit is 45 ft (13.7M).

Tubing size is determined separately for each of the four segments of the

refrigerant piping - Circuit A liquid line; Circuit A suction line; Circuit B liquid line;

and Circuit B suction line. The size of the tubing required for each segment is

determined by its equivalent length. The equivalent length is the actual length

of the line segment plus any ttings or accessories.

If accessories (see Paragraphs 6.1.3.3 and.4 for required accessories) have

equivalent lengths provided by the manufacturer, use that information. If

equivalent length is not provided and for ttings, use the equivalent lengths in

TABLE 2.

Form I-COND, P/N 220746R6, Page 11

6.0 Mechanical

(cont’d)

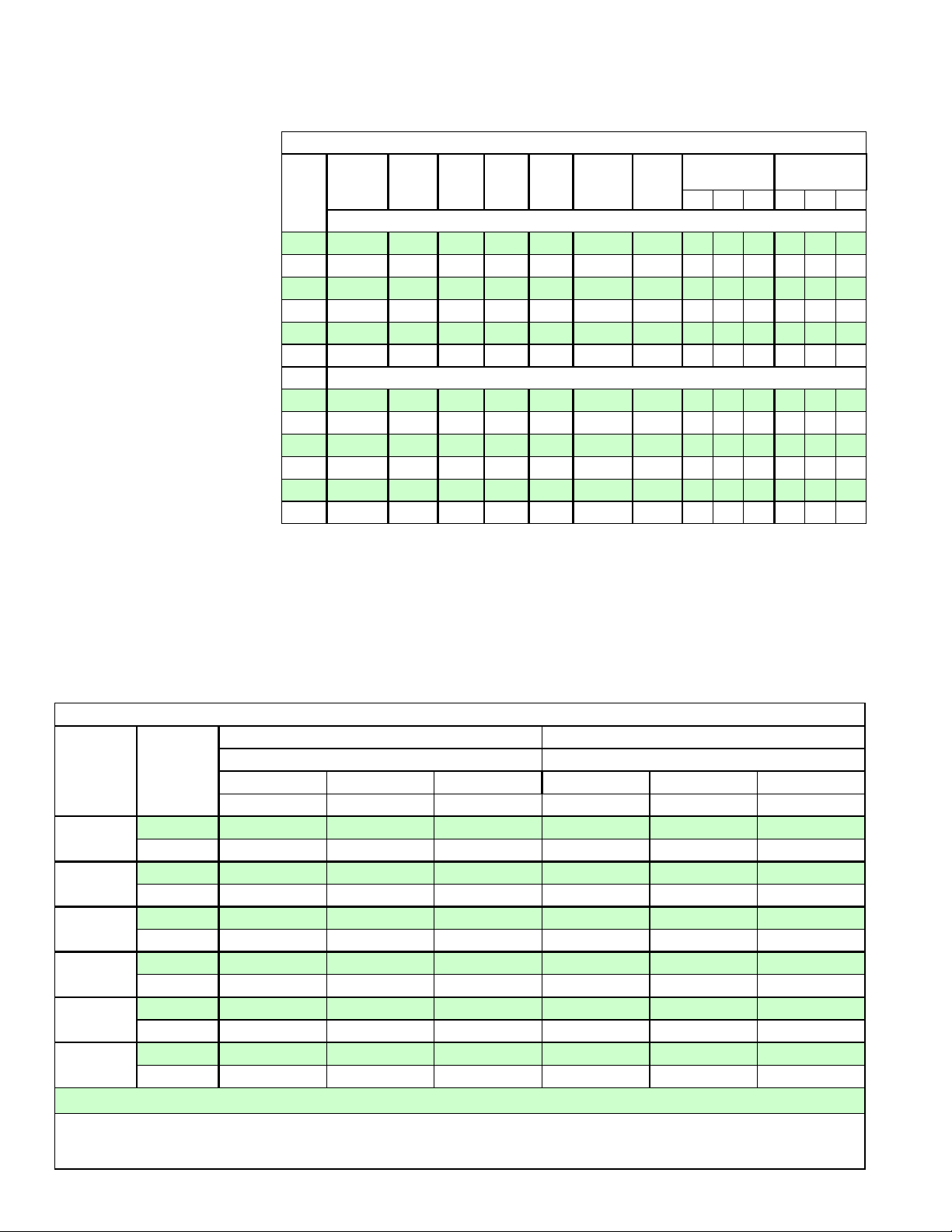

TABLE 2 - Fitting

Pressure Loss in

Equivalent Length

of Straight Copper

Tubing

NOTE: Liquid line lter

driers provided have 1/2”

connections. Add equil-

valent length for lter

driers plus, if liquid line is

not 1/2”, add equilvalent

for ttings.

6.1 Refrigerant Piping (cont’d)

6.1.3 Refrigerant Piping Guidelines (R-410A Refrigerant) (cont’d)

6.1.3.2 Refrigerant Piping Length and Size (cont’d)

Equivalent Length of Fittings and Accessories

Globe /

Line

Solenoid

Size

OD

Valve

1/2" 9 5 1.4 0.9 0.4 0.6 2.0 1.4 0.8 0.3 0.7 0.5 0.3

5/8" 12 6 1.5 1.0 0.5 0.8 2.5 1.8 1.1 0.4 0.8 0.7 0.4

3/4" 14 7 1.9 1.3 0.6 0.9 3.0 2.5 1.5 0.5 1.2 1.0 0.5

7/8" 15 8 2.3 1.5 0.7 1.0 3.5 3.2 2.0 0.7 1.6 1.2 0.7

1-1/8" 22 12 2.7 1.8 0.9 1.5 4.5 4.7 3.0 1.0 2.3 1.8 1.0

1-3/8" 28 15 3.6 2.4 1.2 1.8 6.0 5.8 3.6 2.9 2.9 2.2 1.2

1/2" 2.7 1.5 0.4 0.3 0.1 0.2 0.6 0.4 0.2 0.1 0.2 0.2 0.1

5/8" 3.7 1.8 0.5 0.3 0.2 0.2 0.8 0.6 0.3 0.1 0.2 0.2 0.1

3/4" 4.3 2.1 0.6 0.4 0.2 0.3 0.9 0.8 0.5 0.2 0.4 0.3 0.2

7/8" 4.6 2.4 0.7 0.5 0.2 0.3 1.1 1.0 0.6 0.2 0.5 0.4 0.2

1-1/8" 6.7 3.7 0.8 0.6 0.3 0.5 1.4 1.4 0.9 0.3 0.7 0.6 0.3

1-3/8" 8.5 4.6 1.1 0.7 0.4 0.6 1.8 1.8 1.1 0.9 0.9 0.7 0.4

Angle /

Check

Valve

90º SR

Elbow

45º

Tee Line

/ Sight

Glass

Tee

Branch

90º LR

Elbow

Elbow

Equivalent Length (in Feet of Pipe)

Equivalent Length (in Meters of Pipe)

Coupling to

Enlarge OD by

1/4" 1/2" 3/4" 1/4" 1/2" 3/4"

Coupling to

Reduce OD by

TABLE 3 Recommended Size

of Refrigerant Piping

for each Segment

determined by the

Equivalent Length

Use the worksheet on page 13, and the information in TABLE 2 and TABLE 3

to determine the line segment and circuit equivalent lengths and the size

of tubing required for each line segment.

IF AN APPLICATION REQUIRES MORE THAN 60 FEET (18.3M) OF EQUIVALENT LENGTH OF TUBING (LIQUID LINE OR SUCTION LINE) BETWEEN

THE CONDENSER AND THE AIR HANDLER, CONTACT REZNOR FOR

APPROVAL.

*Minimum Recommended Refrigerant Piping Size

Suction Line Tubing Size (OD) Liquid Line Tubing Size (OD)

MASA

Model

60

90

120

150

180

240

*Based on copper tubing type L; a 2°F loss; and a maximum of 65ºF suction line (return gas) temperature and liquid line temperature of 105ºF.

**Equivalent Line Segment Length = length of eld-installed tubing in line segment plus equivalent length of all eld-installed ttings and

accessories in line segment. For both liquid line and suction line segments, maximum recommended equivalent length is 60 ft (18.3M).

CAUTION: Maximum equivalent length of a hot gas bypass line is 30 ft (9.1M).

Circuit

A 1/2 5/8 3/4 1/2 1/2 1/2

B 3/4 3/4 7/8 1/2 1/2 1/2

A 5/8 3/4 3/4 1/2 1/2 1/2

B 7/8 7/8 1 1/8 1/2 1/2 1/2

A 3/4 3/4 7/8 1/2 1/2 1/2

B 7/8 1 1/8 1 1/8 1/2 5/8 5/8

A 7/8 7/8 1 1/8 1/2 1/2 1/2

B 1 1/8 1 1/8 1 3/8 1/2 5/8 5/8

A 7/8 7/8 1 1/8 1/2 1/2 1/2

B 1 1/8 1 1/8 1 3/8 1/2 5/8 5/8

A 7/8 1 1/8 1 1/8 1/2 5/8 5/8

B 1 1/8 1 3/8 1 3/8 5/8 3/4 3/4

**Equivalent Length of the Suction Line - Ft (M) **Equivalent Length of the Liquid Line - Ft (M)

Up to 25 Ft > 25 to 50 Ft > 50 to 60 Ft Up to 25 Ft > 25 to 50 Ft > 50 to 60 Ft

(Up to 7.6M) (> 7.6 to 15.2M) (> 15.2 to 18.3M) (Up to 7.6M) (> 7.6 to 15.2M) (> 15.2 to 18.3M)

Form I-COND, P/N 220746R6, Page 12

Loading...

Loading...