Page 1

Description

e

p

e

p

q

q

g

pp

g

p

p

p

p

g

)

and

Application

Option Pkg

Components

• Option CD57

• Option CD59

• Option CD58

Discharge Air Nozzles,

Options CD57, CD58, and CD59

Installation Form RZ-NA I-LDAP-N (Version A)

®

APPLIES TO: Model LDAP

Nozzles are designed to direct the flow of discharge air from each heat section of a

Reznor Model LDAP downflow heater. Nozzles are available in three configurations:

n Option CD57 - nozzle providing a 25-65° range of air deflection

n Option CD59 - same as CD57 plus 4-way louvers

n Option CD58 - nozzle providing a 50-90° range of air deflection

Model LDAP Size

tion CD57 Pkg P/N

O

Nozzle Section Right Side (1) 207932 (2) 207932 (3) 207932

Nozzle Section Left Sid

Nozzle Section To

Nozzle Section Bottom (1) 207935 (2) 207935 (3) 207935

Nozzle Side Filler (2) 208747 (4) 208747 (6) 208747

Screws, #8-18 x 3/8" long AB point, slotted indented serrated hex

washer head

#8 x 1/2" lon

O

tion CD59 Pkg P/N

Same components as Option CD57 above PLUS

Louver

Top Louver Frame Support

Btm Louver Frame Support

Louver Frame Side

Screws, #8-18 x 3/8" long, AB point, slotted indented serrated hex

washer head

Com

ression Springs (for louvers)

#8 x 1/2" lon

O

tion CD58 Pkg P/N

Nozzle Section Right Side (2) 207932 (4) 207932 (6) 207932

Nozzle Section Left Sid

Nozzle Section To

Nozzle Section Bottom (2) 207935 (4) 207935 (6) 207935

Nozzle Side Filler (4) 208747 (8) 208747 (12) 208747

Nozzle Bottom Filler (1) 208606 (2) 208606 (3) 208606

Screws, #8-18 x 3/8" long AB point, slotted indented serrated hex

washer head

#8 x 1/2" lon

(Read A

NOTE:

nozzle kit(s) as re

TEKS (self-drilling screws)

NOTE:

nozzle kit(s) as re

TEKS (self-drilling screws

NOTE:

nozzle kit(s) as required by the application.

TEKS (self-drilling screws)

NOTE

lication

Package for Size 400 includes parts

for one Option CD57 nozzle; Size 800

includes two nozzles; and Size 1200

includes three nozzles. Select and install

Package for Size 400 includes parts

for one Option CD59 nozzle; Size 800

includes two nozzles; and Size 1200

includes three nozzles. Select and install

for one Option CD58 nozzle; Size 800

includes two nozzles; and Size 1200

includes three nozzles. Select and install

in each Table.)

uired by the application.

uired by the application.

Package for Size 400 includes parts

Obsoletes Form RZ-NA I-LDAP-N

400 800 1200

208094 208886 208887

(1) 207933 (2) 207933 (3) 207933

(1) 207934 (2) 207934 (3) 207934

(20) 195638 (40) 195638 (60) 195638

(6) 195249 (12) 195249 (18) 195249

208100 208890 208891

(7)195578 (14)195578 (21)195578

(1) 207937 (2) 207937 (3) 207937

(1) 208637 (2) 208637 (3) 208637

(2) 207936 (4) 207936 (6) 207936

(18) 195638 (36) 195638 (54) 195638

(7) 195046 (14) 195046 (21) 195046

(12) 195249 (24) 195249 (36) 195249

208097 208888 208889

(2) 207933 (4) 207933 (6) 207933

(2) 207934 (4) 207934 (6) 207934

(46) 195638 (92) 195638

(12) 195249 (24) 195249 (36) 195249

(138)

195638

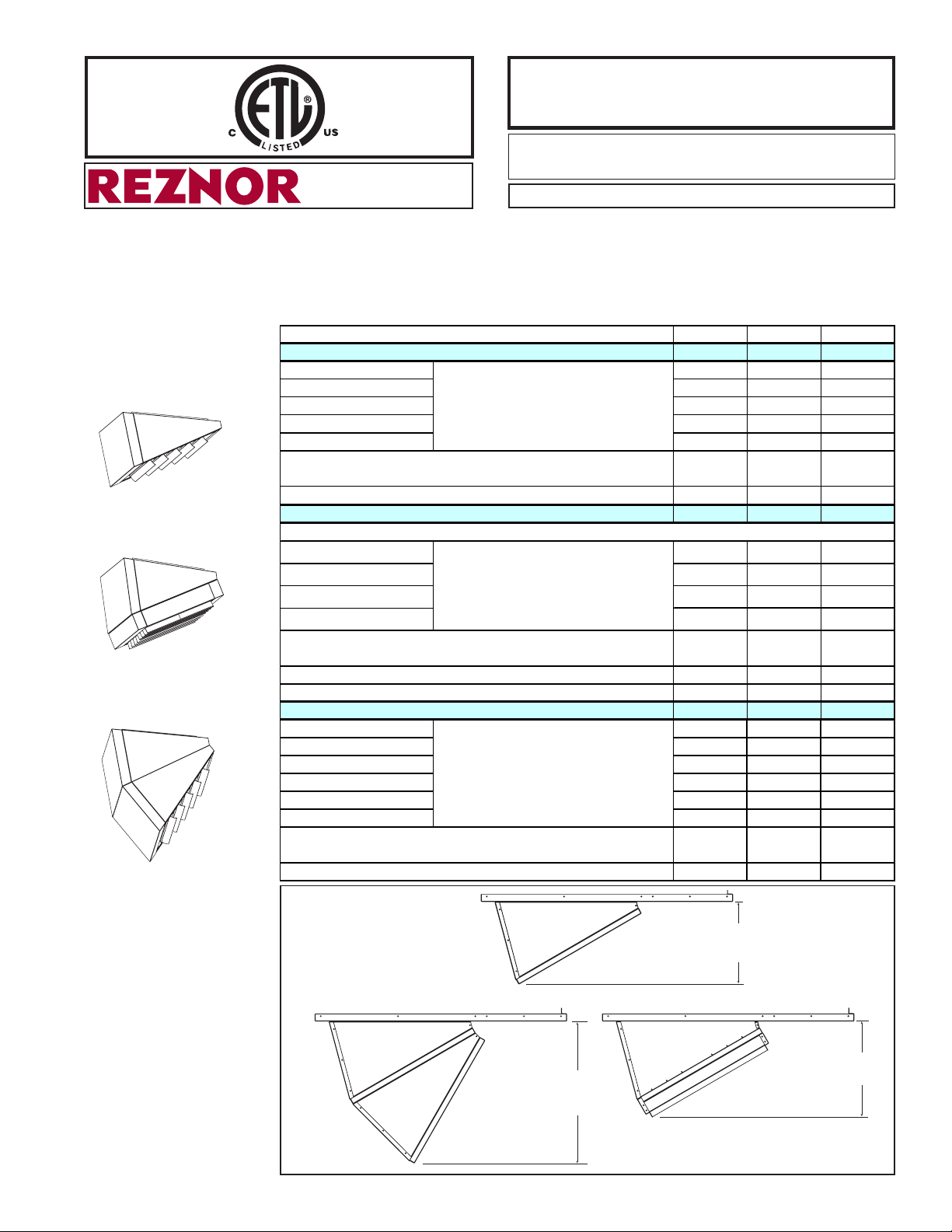

Nozzle

Dimensions

FIGURE 1 Dimensions

(inches/mm)

Option CD58,

60° Nozzle

Option CD57,

30° Nozzle

24-3/8

(618mm)

14-1/8

(360mm)

16-1/2

(419mm)

Option CD59, 30° Nozzle

with 4-Way Louvers

Form RZ-NA I-LDAP-N, P/N 208899 Rev 3, page 1

Page 2

Installation

WARNING: Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury or death. Read the

Instructions

installation, operation, and maintenance instructions thoroughly before

installing or servicing this equipment.

Installation should be done by a qualified agency in accordance with the instructions on this sheet and in compliance with all codes and requirements of authorities having jurisdiction.

n Option CD57 or CD58 ...... Follow instructions in SECTION A.

n Option CD59 .......................Follow instructions in both SECTIONS A and B.

All installations will also include the louvers that were shipped with the heater. Repeat the instructions to install a

nozzle on each heat section.

SECTION A

1. If the heater is installed, turn off the gas and the electric power.

Applies to

n Option CD57

n Option CD58

n Option CD59

FIGURE 3 If installing

Option

CD58,

assemble

the second

nozzle and

attach the

two nozzle

sections.

Nozzle side

fillers attached

in FIGURE 2.

3. If the louvers shipped with the heater have been installed in the heater discharge opening, remove them.

Save the louvers and the springs to be re-installed in the nozzle discharge.

4. Install the Assembled Nozzle in the Heater Outlet (FIGURE 4)

All Options - The discharge opening is square so the nozzle can be installed in any direction. Determine the

appropriate direction and position the assembled nozzle in the heater outlet so that the holes on each side are

lined up with the holes in the heater. Use the 3/8” screws in the kit to attach the nozzle sides to the heater.

Screw ends should be inside the nozzle.

Form RZ-NA I-LDAP-N, P/N 208899 Rev 2, page 2

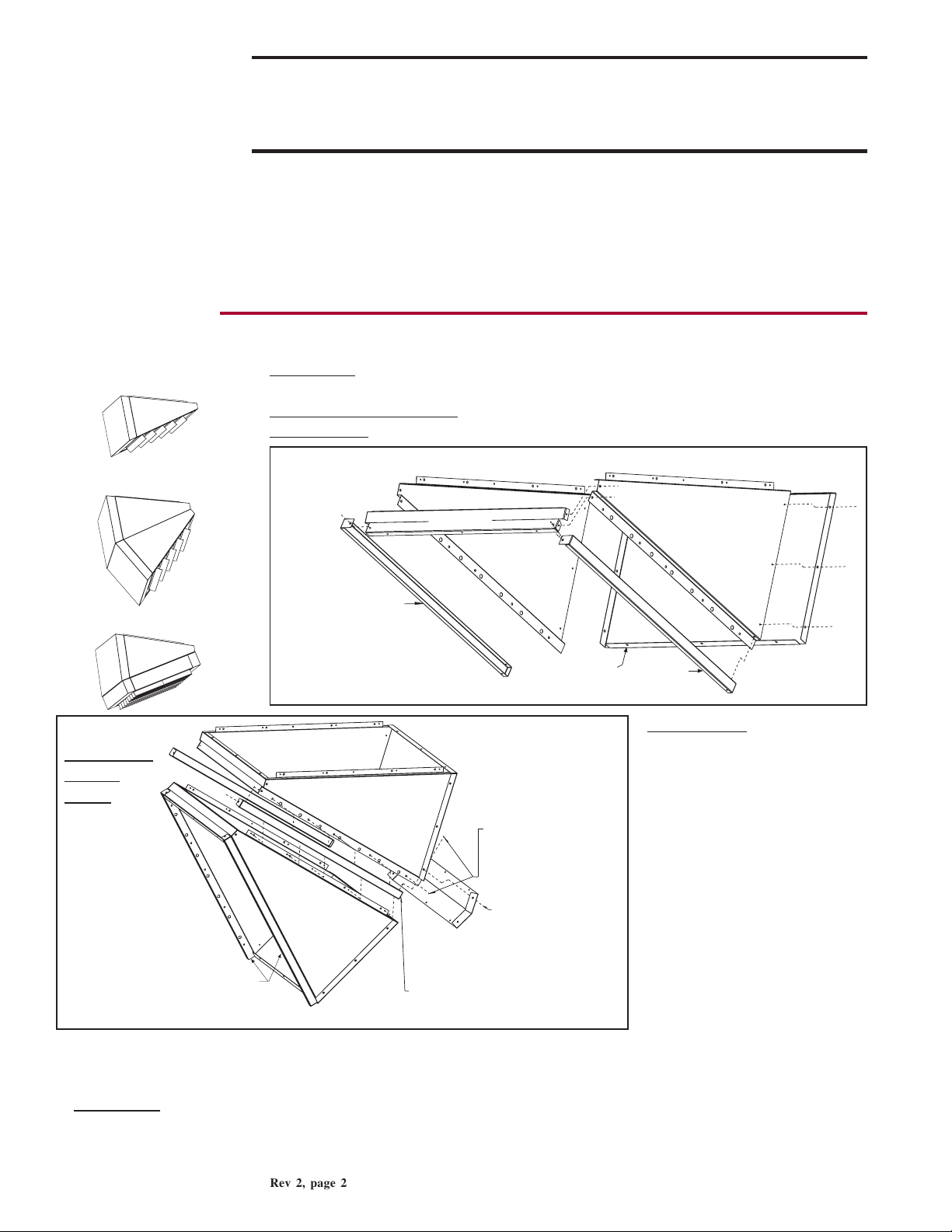

2. Assemble Nozzle

All Options - See FIGURE 2. Assemble a nozzle section. Use the 3/8” screws in

the kit to attach both sides to the top. Attach the bottom to both sides.

Options CD57 and CD58 - Use 3/8” screws to attach side fillers as shown.

Option CD59 - Do not attach side fillers; save to install later.

FIGURE 2 - Assemble a Nozzle Section

Nozzle Top

Nozzle

Side Filler

Use 3/8 screws

(P/N 195638) from the option

package to assemble top, sides,

and bottom. If installing CD57

or CD58, attach side fillers.

CD58 - Second

Nozzle Section

Assembly

CD58 - Nozzle

Section Assembled

in FIGURE 2.

Nozzle Side Fillers - Install these two

side fillers when joining the two

sections of an Option CD58 nozzle.

Nozzle

Right

Side

Nozzle

Bottom

Attach the two

assembled nozzles

and the side fillers

with the 3/8 screws

(P/N 195638).

Nozzle Bottom Filler After nozzle sections

are assembled, remove

appropriate screws and

reuse to attach nozzle

filler as illustrated.

Nozzle

Side Filler

Option CD58 - Assemble the

second nozzle section with-

out attaching the side fillers.

Attach the two nozzles and

the side fillers as shown to

create one nozzle with two

sections (See FIGURE 3).

Position the nozzle bottom

filler over the seam between

the two bottom nozzle sections. Remove the screws that

line up with the holes in the

nozzle bottom filler. Re-insert

the screws securing the filler

over the seam.

Nozzle

Left

Side

Page 3

FIGURE 4 - Fasten

Assembled Nozzle

to Heater Outlet

(NOTE: Option

CD57 is illustrated.

Procedure is the

same for all

options.)

Using the 1/2” self-drilling

screws in the kit, reach

inside the nozzle and

attach the nozzle top and

bottom to the heater outlet.

Use the holes in the nozzle

top and bottom to position

the screws.

(2) Attach nozzle top

and bottom with 1/2

self-drilling screws.

(1) Attach nozzle sides

inside heater outlet

with 3/8 screws.

5. Install the Louvers in the Nozzle Outlet

All Options - Before actually installing the louvers, note the louver curve and determine how the louvers

should be positioned to provide the optimal throw pattern. Louvers may be installed with the curve all the

same direction (either way) or the right half one way and left the other as illustrated in FIGURE 5. Follow

the instructions and refer to the illustration to install the louvers using the compression springs.

Louver Installation Instructions:

a) With the wider section of the louver facing out of the heater, place one of the compression springs over

the tab on the notched end of a louver. The end of the louver with the spring will fit in any direction in

the square opening. How the louver turns depends on which end of the louver is inserted first.

b) Depending on the airflow pattern selected, push the louver tab with the spring into a hole in the discharge

opening and insert the louver tab on the other end into the corresponding hole on the opposite side.

c) Continue installing until all louvers are in place. Adjust the louvers to provide the desired air throw

pattern.

FIGURE 5 - Installing

Airflow direction depends on how the louvers are installed.

Louvers in Nozzle Outlet

Compression Spring

CAUTION: To avoid

getting burned, adjust

louvers while heater is

Airflow direction;

springs are on

the upper end.

Wider side of the

louver blade must

always be facing

out of the heater.

Option CD57 or CD58 - Repeat nozzle installation as required for each heat section. If the heater is installed, turn

on the electric and the gas. Light the heater following the lighting instructions. Check for proper operation.

Option CD59 - Continue to SECTION B.

Airflow direction;

springs are on

the lower end.

not in operation. If

louvers are adjusted

while heater is in

operation, wear

protective gloves.

SECTION B

Applies to

n Option CD59

1. Option CD59 - Assemble the Frame for 4-Way Louvers (See FIGURE 6.)

Using the 3/8” long screws in the kit, attach both sides to the supports.

FIGURE 6 - Assemble the Louver Frame

Bottom Louver Frame

2-3/32 (53mm)

Support (P/N 208637)

(note height of support )

Top Louver Frame

Support (P/N 207937)

(note height of support)

2-31/32 (75mm)

Louver Frame

Side (P/N 207936)

Assemble louver frame with

screws provided (P/N 195638).

Form RZ-NA I-LDAP-N, P/N 208899 Rev 3, page 3

(sides are identical)

Page 4

SECTION B - CD59 Installation Instructions (cont’d)

©2014 Reznor, LLC. All rights reserved. Printed in the U.S.A.

Reznor® is registered in at least the United States.

0514 POD OG Form I-LDAP-N (Version A.2)

2. Install the Assembled Louver Frame in

the Nozzle Outlet (See FIGURE 7.

Note that standard louvers are not

shown but should already be installed

in the nozzle.)

Position the assembled louver frame in

the nozzle outlet so that the holes in the

tabs on each side are lined up with the

holes in the nozzle. The tabs in the louver frame fit between the louvers already

installed in the nozzle discharge. Using

the 3/8” screws (P/N 195638) from the

kit, attach the louver frame tabs to the

nozzle. Screw ends should be inside the

nozzle.

Use the 1/2” self-drilling screws (P/N

195249) to attach the other two sides of

the louver frame. Use the holes in the

louver frame as a template for inserting

the screws.

FIGURE 7 - Option CD59 - Install Louver Frame in

Nozzle Outlet

Nozzle Assembly already

attached to the heater and

with standard louvers (not

shown) in the nozzle outlet

Assembled Louver Frame

(FIGURE 6)

Attach assembled

louver frame to

nozzle assembly

using screws from

the option package.

Attach the two

Nozzle Side

Fillers (saved in

SECTION A,

Step 2.)

FIGURE 8 - Installing

Louvers in the Louver

Frame

Compression Spring

Wider side of the

louver blade must

always be facing

out of the heater.

3. Install the Louvers in the Louver Frame Using the Compression Springs

(See FIGURE 8.)

Before actually installing the louvers, note the louver curve and determine

how the louvers should be positioned to provide the optimal throw pattern.

Depending on the desired direction of airflow, louvers may be installed with

the curve all the same direction (either way) or the right half one way and the

left the other as illustrated in FIGURE 5, page 3.

a) With the wider section facing out of the heater, place one of the compres-

sion springs over the tab on the notched end of the louver.

b) Depending on the throw pattern selected, the end with the spring can go in

either direction. Slide the tab with the spring into one of the holes in either

of the sides. Push the louver, compressing the spring enough to place the

tab on the other end into the corresponding hole in the other side.

c) Continue installing until all louvers are in place.

4. Adjust the louvers to provide the desired throw pattern.

CAUTION: To avoid getting burned, adjust louvers while heater is

not in operation. If louvers are adjusted while heater is in operation,

wear protective gloves.

5. Repeat nozzle installation as required for each heat section. If the heater is in-

stalled, turn on the electric and the gas. Light the heater following the lighting

instructions. Check for proper operation.

Form RZ-NA I-LDAP-N, P/N 208899 Rev 2, page 4

(800) 695-1901; www.RezSpec.com

©2005 Thomas & Betts Corporation, All rights reserved.

MANUFACTURER OF HEATING, COOLING, AND VENTILATING SYSTEMS

Trademark Note: Reznor® is a trademark of Thomas & Betts Corporation

1/05 Form RZ-NA I-LDAP-N (Version A.1)

Loading...

Loading...