IMPORTANT

V

1. Always include complete heater model and serial number so

that any specification change can be considered for parts shipment. It can save time and expense.

2. Specifications are subject to change without notice.

3. We reserve the right to substitute functional replacements

4. Order by Part Number. Do not order by Option Number.

NOTE: Replacement parts manual for Models RIH and TRP

has been revised to Form RZ-NA-P-VR/TRP/RIH

INFRARED

HEATERS

Replacement Parts Form RZ-NA-P-TR

Obsoletes Form 709 (Version B)

APPLIES TO: INFRA-REZTM Heater Models

TR/TR-H and TRP

and Models RIH/RIHV

INDEX by M odel TR/TR-H TRP RIH/RIH

Replacement parts on pages 4-8, 13- 14 9-14 15- 16

Burner Assembly 5 11 16

Burner/Control Box and Components 4 9 -Capacitor 5 9 -Chains for Hanging 13 11 15

Combustion Cham b er Tube 7 -- -Connector, Flexible Gas 13-14 13-14 15

Conversion Kit, Altitude 8 -- -Conversion Kit, Gas 8 12 -Cord, Power 6 11 -Door Assembly (Burner Box) 4 9 -Electric Components 6 10-11 15

Heat Exchanger/Reflector Assembly -- 11 -Heat Exchanger Tube (5-ft) (Same as Option UA1) 7 -- -Heat Exchanger Tube (10-ft) 7 -- -Ignition Controller 6 10 15

Inlet Air Kit (Combustion Air, Same as Option DE2) 13 -- -"L" Heat Exchanger Tube (Same As Option UC2) 8 -- -Light (Burner Indicator) 6 -- -Manifold 5 11 16

Motor 5 9 -Multiple Heater Control (Same as Options CL31/32) 13-14 -- -Orifice, Air (Combustion Air Restrictor Plate) 4 -- -Orifice, Gas 5 12 16

Pilot 7 -- 15

Rating Plate/Model Convers ion Label 2 & 3 2 & 3 -Reflector 7 11 16

Reflector End Cap 7 -- -Reflector Gap Cover 7-8 -- -Reflector Retainer Kit 7 -- -Relay, Time Delay 6 -- -Replacement Parts Tag 3 3 -Restrict or Plate 4 -- -Screen, Protective (Same as Option DN3) -- -- 16

Separated Combustion Combustion Air/Vent

Terminal Kits (Same as Options CC2 & CC6)

Serial No. 2 & 3 2 & 3 -Shield, Heat (Same as Option DO3) -- -- 16

Shield, Side (Same as Options CD13-20, 30-31) 13-14 13-14 -Switch, Door 6 -- -Switch, Air Pressure 6 10 -Transformer 6 10 -Thermostat/Thermostat Accessories 13 13 15

Tube Connection Hardware 7 11 -Tube Packages 7 -- -Turnbuckle 13 13 -"U " Heat Exchanger Tube (Same as Option UB3 ) 7-8 -- -Valve 6 10 15

Vent Cap 4 -Vent Kit for Dual Vent (Same as Option CC5) 13 13 -Wire Grid (Same as Option DN2) -- -- 16

-- 12 --

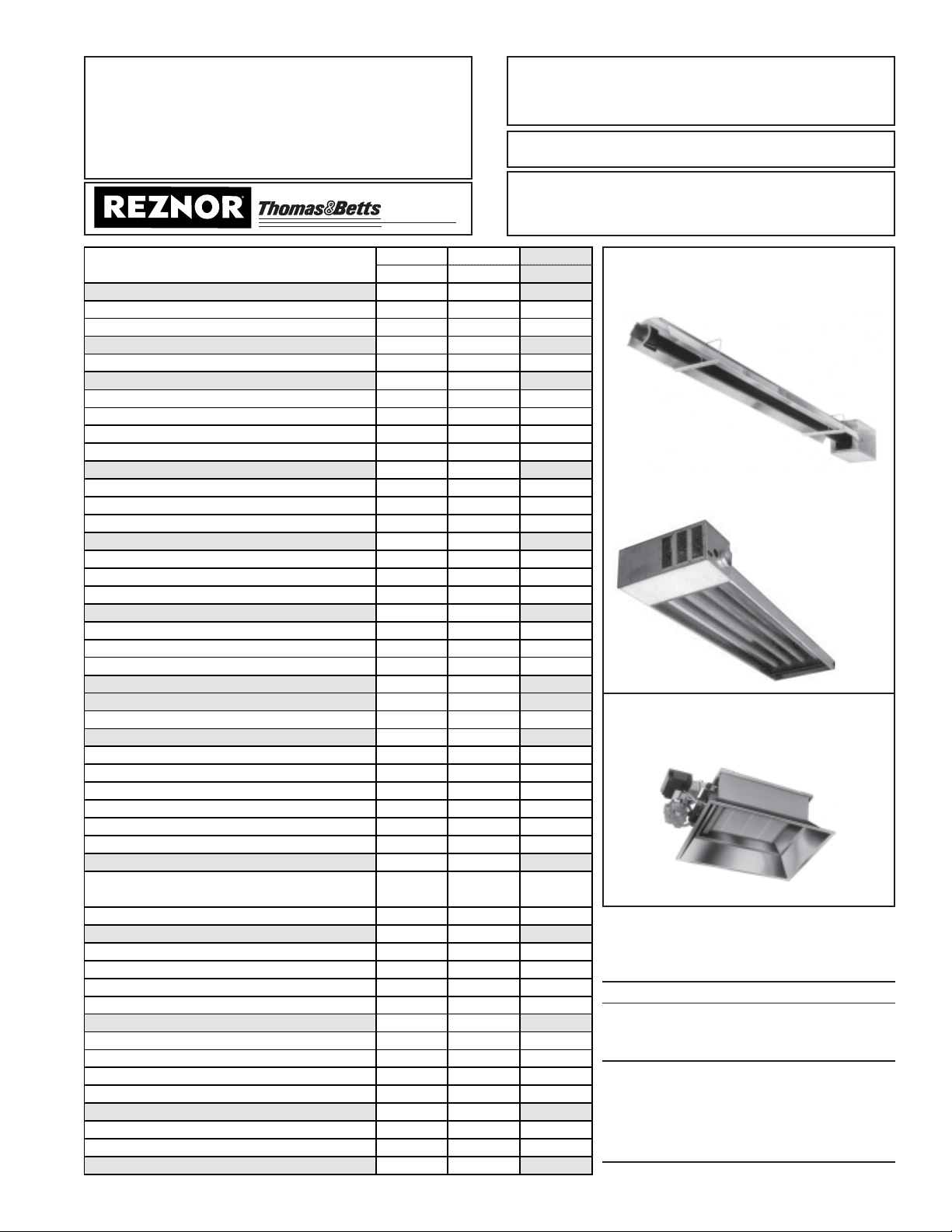

INFRA-REZTM Model, Low-Intensity,

Tubular, Infrared Heaters

TR/TR-H T ubular

Radiant Heaters

TRP Tubular Radiant

Packaged Heater

Models RIH/RIHV High-Intensity

Infrared Heaters

REFERENCES:

Form RGM

450, Model RIH/RIHV Installation/Maintenance

452, Model TRP Installation/Operation/Mainte-

nance

452-GC, Model TRP Gas Conversion

456, Model TR/TR-H Installation

456-OMS, Model TR/TR-H Maintenance and

Service

456-GC, Model TR Gas Conversion

456-HA, Model TR High Altitude Conversion

Form 709, page 1

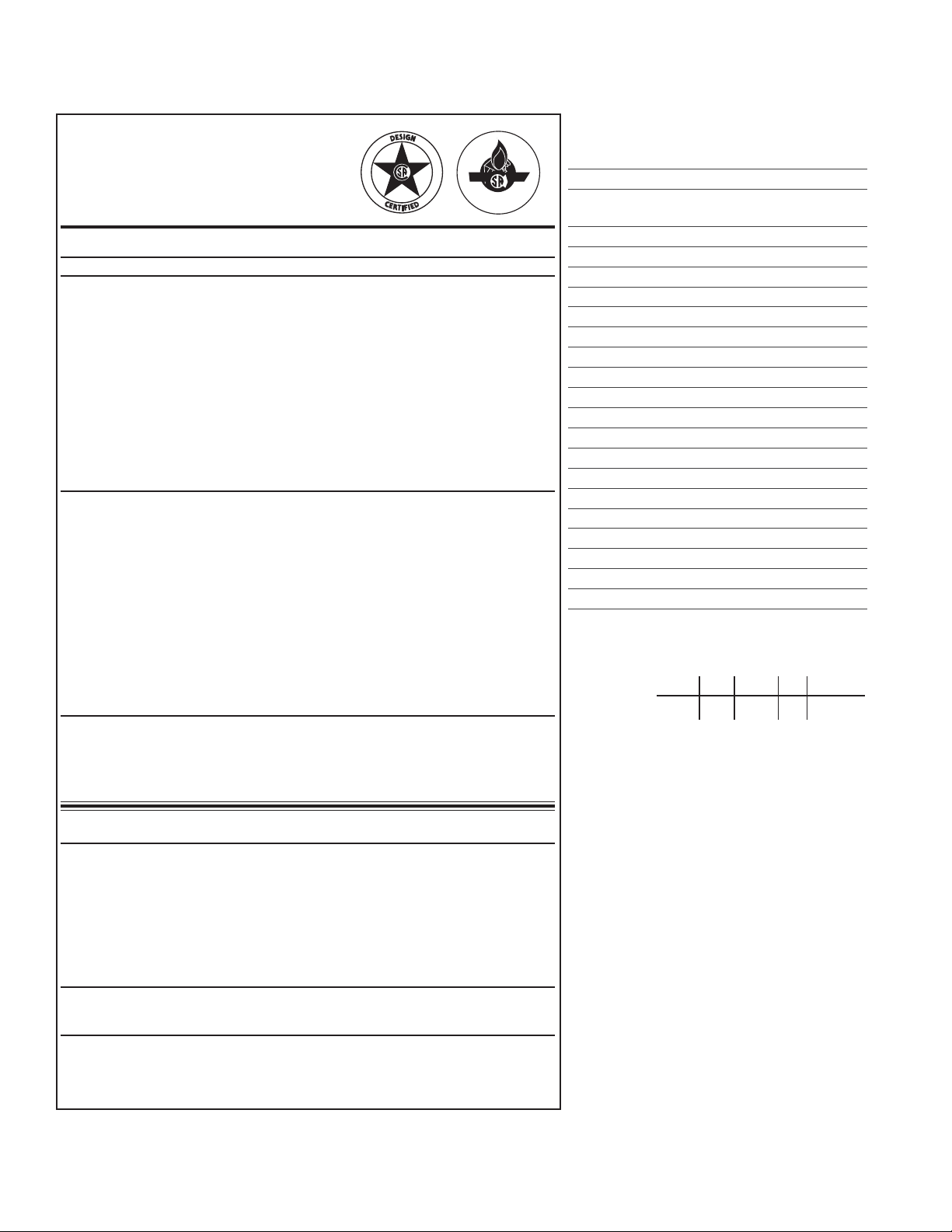

Rating Plate and Serial No.

(Example is a Model TRP)

REZNOR

MERCER, PA. USA 16137

MADE IN MEXICO / FABRIQUÉ AU MEXIQUE

TUBULAR INFRARED HEATER

FOR INDUSTRIAL / COMMERCIAL USE ONLY

POUR USAGE INDUSTRIEL / COMMERCIAL SEUL

ANSI Z83.6b- [ A ] CAN/CGA-2.16-M [ A1 ] INFRARED HEATER

MODEL/DATE MODÈLE/DATE [ B ] [ C ]

SERIAL NO. #DE SÉRIE [ ]

TYPE OF GAS TYPE DE GAZ [ E ]

VOLTS/PH/HZ VOLTS/PH/HZ [ D ]

MAX. TOTAL AMPS TOTALE MAX. DE AMPERAGE [ K ]

ALTITUDE ALTITUDE [ F ] FEET [ G ] METERS

GAS ORIFICE SIZE DIMENSION DE GAZ L’ORIFICE [ H ]DRILL/FORET

NORMAL INPUT ENTRÉE NORMALE [ I ]BTUH

ALT. ADJ. NORMAL INPUT ALT. ADJ. ENTRÉE NORMALE [ Q ]BTUH

MANIFOLD PRESSURE PRESSION DE LA TUB [ O ]IN. W.C./PO/COL D’EAU

MIN. PERMISSIBLE GAS SUPPLY PRESSURE FOR PURPOSE OF INPUT ADJUST-

MENT: [ P ] IN. W.C.

CLEARANCES TO COMBUSTIBLE CONSTRUCTION:

TOP- [ X ] INCHES; SERVICE SIDE- [ Y ] INCHES; OPPOSITE SIDE [ Z ] INCHES;

FLUE CONNECTION - 6 INCHES; BELOW- [ W ] INCHES

REFLECTOR MAX. MOUNTING ANGLE BELOW FRONT/REAR

STANDARD 0 DEGREES [ W ]” [ S ]”

STANDARD 45 DEGREES [ W ]” [ T ]”

STANDARD W/SIDE [ R ] DEGREES [ W ]” [ U ]”

SHIELDS

* 24" IF UNVENTED

THIS UNIT IS FOR USE WITH NATURAL OR PROPANE GAS. A CONVERSION KIT, AS

SUPPLIED BY THE MANUFACTURER, SHALL BE USED TO CONVERT THIS HEATER

TO THE ALTERNATE FUEL.

FOR ALTERNA TE INST ALLATIONS USE THE LATEST ADDITIONS OF THE APPROPRIATE STANDARDS LISTED BELOW:

STANDARD ON AIRCRAFT HANGARS: ANSI/NFPA 409

STANDARD ON PARKING STRUCTURES: ANSI/NFPA 88A

STANDARD ON REPAIR GARAGES: ANSI/NFPA 88B

PRES. D’ALIM MIN. ACCEPT ABLE DE GAZ POUR DES FIN DE RÉGLAGE DE L ’ENTRÉE:

[ P ] PO/COL D’EAU

DÉGAGEMENT ENTRÉE LES CONTSRUCTIONS COMBUSTIBLES:

EN HAUT- [ X ] PO; CÔTÉ ENTRETIEN [ Y ]PO; CÔTÉ OPPOSÉ [ Z ] PO;

EN BAS- [ W ] PO; RACCORD DE TUYAUX- 6 PO

CET APPAREIL POUR UTILISATION AVEC LE GAZ NATUREL OU LE PROPANE.

UNE TROUSSE DE CONVERSION FOURNIE PAR LE FABRICANT DOIT ÉNTRE

UTILISÉ POUR

PASSER D’UN COMBUSTIBLE À L’AUTRE.

L’INSTALLTION DE L’UNITÉ DANS DES GARAGES D’AVIONS DOIT SE CONFORMER

AUX

CONDITIONS DES AUTORITÉS CHARGÉE DE FAIRE APPLIQUER LA LOI.

L’INSTALLATION DANS DES GARAGES PUBLICS DOIT SE CONFORMER AU CODE

CAN/CGA-B149 (.1 OU .2).

SEPARATED COMBUSTION UNITS MUST USE THE CONCENTRIC ADAPTER

ASSEMBLY LISTED IN THE MANUFACTURER’S INSTALLATION INSTRUCTIONS.

CONSTRUCTION WALL THICKNESS FOR PURPOSE OF VENTING: 1" MINIMUM, 30"

MAXIMUM

C E R T I F I E D

Key:

A Design Standards (ANSI Z83.6B and CGA

2.16-M)

B Model No.

(Model Suffixes: H - High altitude; DP Separated combustion; WP - Outdoor unit)

C Mfg Date (month and year)

D Supply Voltage

E Type of Gas (Natural or Propane)

F Altitude (feet)

G Altitude (meters)

H Orifice Size

I Normal Sea Level Input (BTUH)

K Maximum Total Amps

O Normal Manifold Pressure ("w.c.)

P Minimum Gas Supply Pressure

Q High Altitude Input (BTUH)

R Maximum Mounting Degrees with Side Shield

S Front/Rear Clearances (Horizontal Mounting)

T Front/Rear Clearances (Angled up to 45°)

U Front/Rear Clearances with Side Shield

W Clearance Below

X Clearance Above

Y Clearance on Service Side

Z Clearance on Other Side

Serial No.

Example: AZA 71 T9 N 12345

1234 5

Codes:

1 = Date of manufacture (see chart on page 3)

2 = Type of ignition

3 = Type of valve

4 = Type of gas (N= Natural; L= Propane)

5 = Consecutive number (for identification

purposes only)

Form 709, page 2

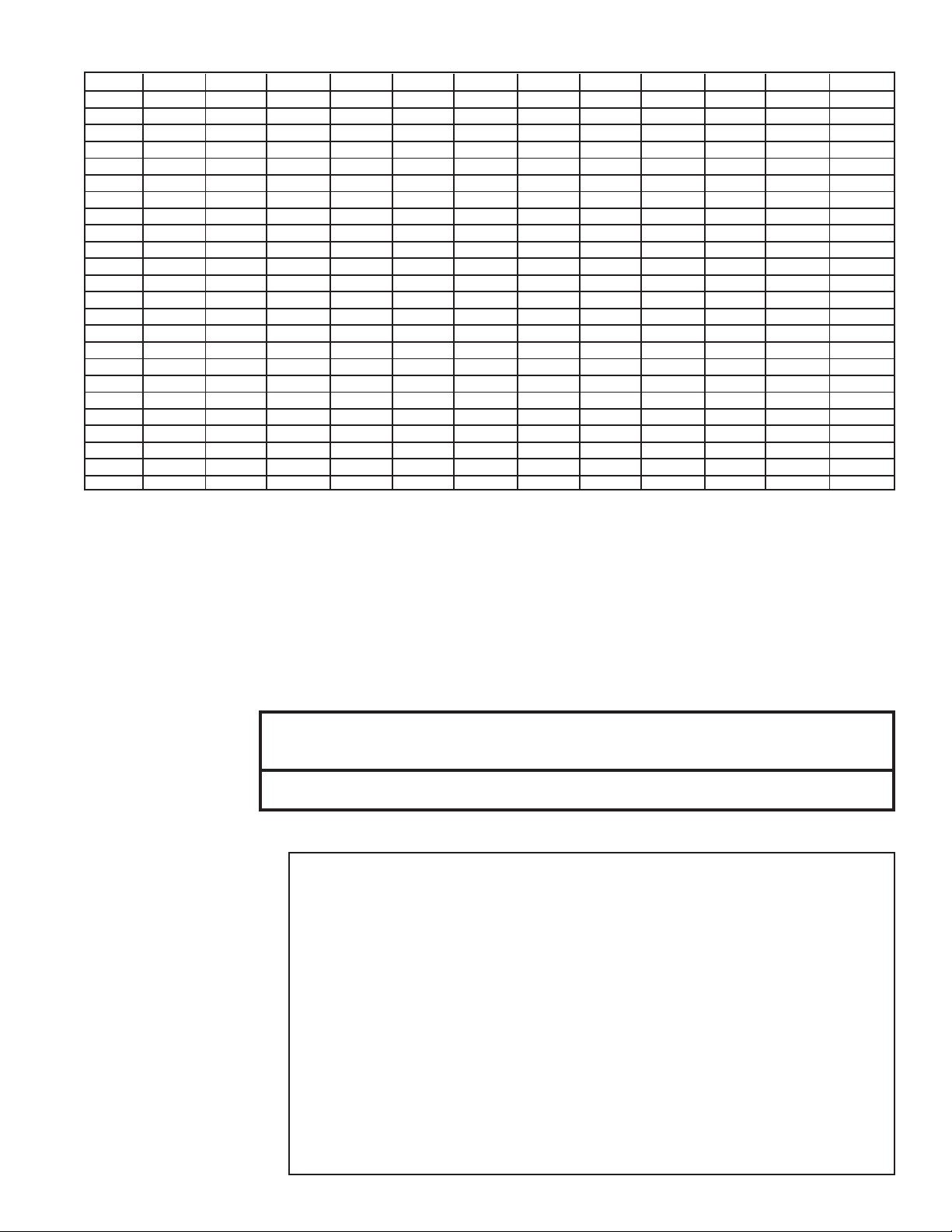

First Element of the Serial Number - Date of Manufacture

Year Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec

1992 ARA ARB ARC ARD ARE ARF ARG ARH ARI ARJ ARK ARL

1993 ASA ASB ASC ASD ASE ASF ASG ASH ASI ASJ ASK ASL

1994 ATA ATB ATC ATD AT E ATF ATG ATH ATI ATJ ATK ATL

1995 AUA AUB AUC AUD AUE AUF AUG AUH AUI AUJ AUK AUL

1996 AVA AV B AV C AV D AV E AVF AV G AVH AVI AV J AV K AVL

1997 AWA AWB AWC AWD AWE AWF AWG AWH AWI AWJ AWK AWL

1998 AXA AXB AXC AXD AXE AXF AXG AXH AXI AXJ AXK AXL

1999 AYA AYB AYC AYD AYE AYF AYG AYH AYI AYJ AYK AYL

2000 AZA AZB AZC AZD AZE AZF AZG AZH AZI AZJ AZK AZL

2001 BAA BAB BAC BAD BAE BAF BAG BAH BAI BAJ BAK BAL

2002 BBA BBB BBC BBD BBE BBF BBG BBH BBI BBJ BBK BBL

2003 BCA BCB BCC BCD BCE BCF BCG BCH BCI BCJ BCK BCL

2004 BDA BDB` BDC BDD BDE BDF BDG BDH BDI BDJ BDK BDL

2005 BEA BEB BEC BED BEE BEF BEG BEH BEI BEJ BEK BEL

2006 BFA BFB BFC BFD BFE BFF BFG BFH BFI BFJ BFK BFL

2007 BGA BGB BGC BGD BGE BGF BGG BGH BGI BGJ BGK BGL

2008 BHA BHB BHC BHD BHE BHF BHG BHH BHI BHJ BHK BHL

2009 BIA BIB BIC BID BIE BIF BIG BIH BII BIJ BIK BIL

2010 BJA BJB BJC BJD BJE BJF BJG BJH BJI BJJ BJK BJL

2011 BKA BKB BKC BKD BKE BKF BKG BKH BKI BKJ BKK BKL

2012 BLA BLB BLC BLD BLE BLF BLG BLH BLI BLJ BLK BLL

2013 BMA BMB BMC BMD BME BMF BMG BMH BMI BMJ BMK BML

2014 BNA BNB BNC BND BNE BNF BNG BNH BNI BNJ BNK BNL

2015 BOA BOB BOC BOD BOE BOF BOG BOH BOI BOJ BOK BOL

Size Conversion Label - Models TR 75, 125, 175

When servicing a heater with a rating plate reading Model TR75, TR125, or TR175, always look for a Size Conversion label.

• Rating Plate reads Model TR75/ Size Conversion Label reads TR100 - Burner/control boxes originally ordered as Model TR-A or Model

TR75/100 include a factory-built Model TR75 and a field kit to convert to a Model TR100. A heater with Model TR75 rating plate and a Field

Conversion Label converting it to a Model TR100 is the same as a factory-built Model TR100.

• Rating Plate reads Model TR125/ Size Conversion Label reads TR150 - Burner/control boxes originally ordered as Model TR-C or Model

125/150 include a factory-built Model TR125 and a field kit to convert to a Model TR150. A heater with Model TR125 rating plate and a Field

Conversion Label converting it to a Model TR150 is the same as a factory-built Model TR150.

• Rating Plate reads Model TR175/ Size Conversion Label reads TR200 - Burner/control boxes originally ordered as Model TR-K or Model

TR 175/200 include a factory-built Model TR175 and a field kit to convert to a Model TR200. A heater with Model TR175 rating plate and a

Field Conversion Label converting it to a Model TR200 is the same as a factory-built Model TR200.

Example of a

Size Conversion

Label

Example of a

Replacement

Parts Tag

Replacement parts tags on Model

TR/TR-H and TRP heaters are for

your convenience in identifying replacement part numbers. Always

give the complete Model No., Serial No., and P/N with description

when ordering replacement parts.

This appliance has been converted at the time of installation to a Model 100 with Kit No.

120096 by __________________________________________________________________

who accepts the responsibility for the correctness of this conversion.

ORIFICE SIZE - #12 drill

NORMAL INPUT - 100,000 btu/hr

Minimum permissible gas supply pressure

for purposes of input adjustment - 4.5" w.c.

COMMON REPLACEMENT P ARTS FOR: REZNOR

MODEL TR75

SERIAL NUMBER ARI66M4N44585

WHEN ORDERING PART, ALWAYS GIVE THE FULL MODEL NUMBER AND SERIAL NUMBER

TRANSFORMER ....................................102709

PILOT .....................................................097534

SPARK IGNITION ..................................097782

TIME DELA Y RELAY..............................116044

BLOWER MOTOR .................................097738

BLOWER WHEEL .................................097724

PRESSURE SWITCH ............................120031

BURNER DOOR SWITCH .....................116023

BURNER ON LIGHT ..............................116045

OPTIONAL REPLACEMENT P ARTS:

4" INLET AIR CAP .................................120724

-- WARNING --

ALL PARTS ARE FOR USE WITH THE FUEL IDENTIFIED ON THE UNIT RATING PLATE. IF THE UNIT

HAS BEEN CONVERTED TO OTHER FUELS, CHECK WITH DEALER FOR PROPER FUEL-CARRYING

PARTS. INSTALLATION OF IMPROPER PARTS CAN CAUSE DEATH OR INJURY OR PROPERTY LOSS.

Form 709, page 3

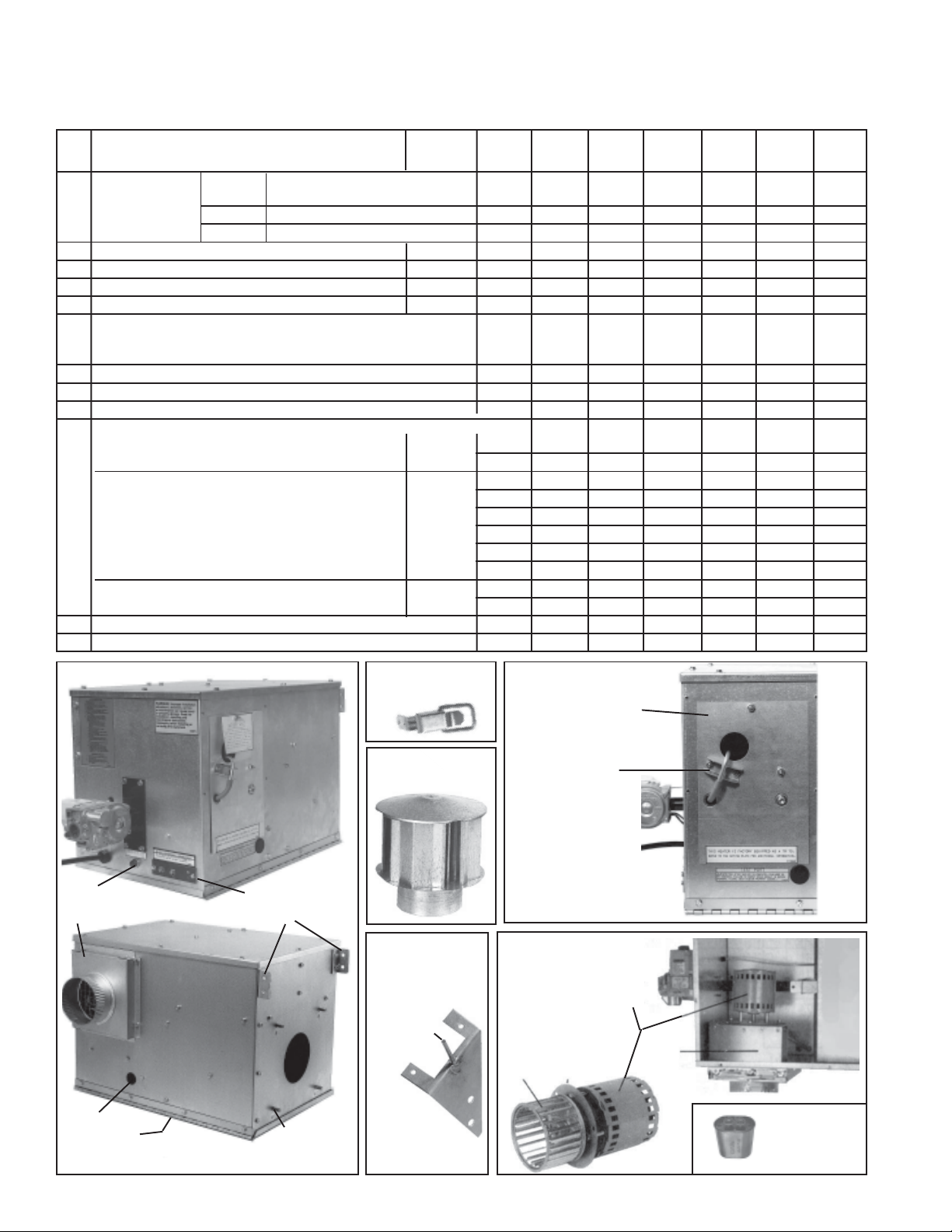

Burner/Control Box - Models TR/TR-H (Model TR-H is a for operation at elevations above

2000 ft. Unless specified, replacement parts apply to Both Model TR and TR-H)

Burner/Control Box and Non-Operating Components

Code Description Qty (other 50 7 5 100 125 150 175 200

than 1)

Gas Ignition System

1 Burner Natural Recycling Spark 125791 115953 120521 120297 120523 133246 133248

Control Box Natural Spark with Lockout 150000 150001 150002 150003 150004 150005 150006

Propane Spark with Lockout 125797 115997 120522 120298 120524 -- --

2 Burner Box Hanger 2 116030 116030 116030 116030 116030 116030 116030

3 Burner Box Door Assembly 125794 115964 115964 115964 115964 115964 115964

4 Draw/Pull Door Latch, Guden #832-02 2 120735 120735 120735 120735 120735 120735 120735

5 Combustion Air Inlet Cover Assembly 116040 116040 116040 116040 116040 133253 133253

6 Hardware Bag for attaching Burner/Control Box and Combustion 120348 120348 120348 120348 120348 120348 120348

Chamber Tube (includes 4 lockwashers, 4 nuts, 3 “S” hooks, 1

gasket (Code 6A), 2 bolts, 4 screws)

6A Combustion Chamber/Burner Box Gasket 116029 116029 116029 116029 116029 116029 116029

7 Hole Plug for Testing Port, Heyco #DP-875 (replaces P/N 120350) 16452 16452 16452 16452 16452 16452 16452

8 Vent Cap, 4" 110051 110051 110051 110051 110051 110051 110051

9 Combustion Air Restrictor Plate (also referred to as an air orifice plate)

Natural Gas, 0-2000 Ft Elevation (Model TR) U.S. & 125795 120354 120546 120355 120547 133166 133167

Propane Gas, 0-2000 Ft Elevation (Model TR) Canada 125795 120529 120546 120355 120547 -- --

Natural, 2001-4000 Ft (Model TR-H) 126072 120381 120382 120383 120384 133802 133803

Propane, 2001-4000 Ft (Model TR-H) U.S. 126072 120381 120382 120383 120384 -- - Natural, 4001-6000 Ft (Model TR-H) (ANSI 126075 120981 120982 120983 120984 133807 133808

Propane, 4001-6000 Ft (Model TR-H) Std) 126075 120981 120982 120983 120984 -- - Natural, 6001-8000 Ft (Model TR-H) 126081 120985 120986 120987 120988 133810 - Propane, 6001-8000 Ft (Model TR-H) 126081 120985 120986 120987 120988 -- - Natural, 2001-4500 Ft (Model TR-H) Canada 126072 120381 120382 120383 120384 133802 133803

Propane, 2001-4500 Ft (Model TR-H) (CGA Std) 126072 120381 120382 120383 120384 -- --

10 Sensing Tube with Bracket 115969 115969 115969 115969 115969 115969 115969

11 Pilot Mounting Bracket with Sensing Rod 120675 120675 120675 120675 120675 120675 120675

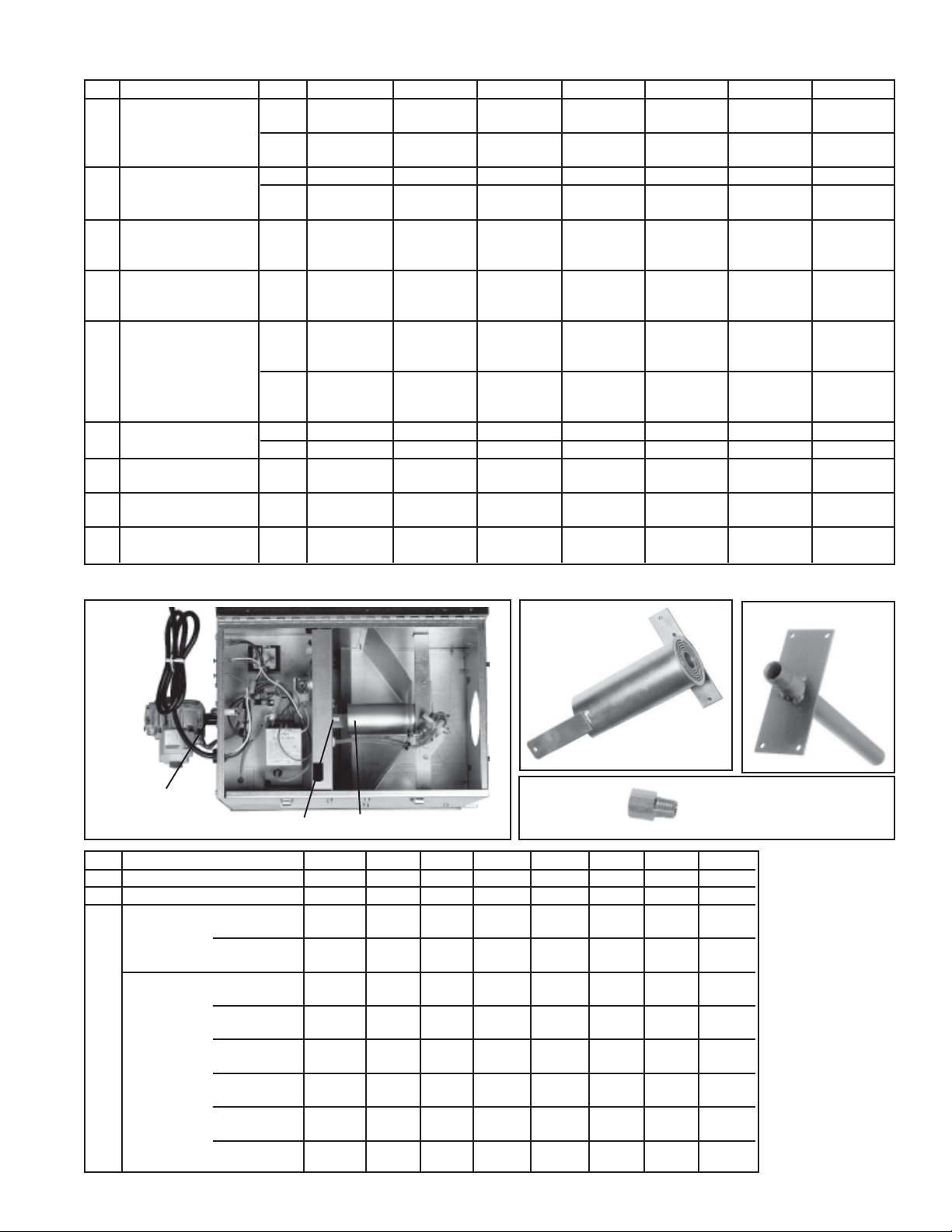

Code 1 - Burner/Control Box

22 (page 6)

5

7

3

gasket fits over the four studs; gasket

is not shown in this illustration.

Form 709, page 4

23 (page 6)

2

6A Square

Code 4 - Door

Latch

Code 8 - 4" Vent

Cap

Code 11 - Pilot

Mounting

Bracket with

Ground Rod

Ground

Rod

Codes 9 and 10

9 - Combustion

Air Restrictor

Plate

10 -

Combustion

Air Flow

Sensor

Bracket and

Tube

Burner/Control Box

Top View (with Top

Panel Removed)

14A/B -

Combustion Air/

Venter Motor and

Wheel Assembly

14D

14C

13

Code 14E Capacitor

Combustion Air/Venter Blower and Motor (Model TR operates at 0-2000 ft elevation; Model TR-H above 2000 ft)

Code Description Model 50 75 100 125 150 175 200

13 Blower Housing TR 120999 120999 120999 120999 121861 132006 132006

Hi-Tech #360 Hi-Tech #360 Hi-Tech #360 Hi-Tech #360

TR-H 120999 120999 120999 121575 121575 132006 132006

Hi-Tech #360 Hi-Tech #360 Hi-Tech #360

14 Combustion Air/Venter TR 116002 116002 116002 116003 116003 132009 132009

Mtr & Wheel Assy TR-H 116002 116002 116002 121052 121052 132009 132009

(includes Codes 14A-G)

14A Motor - 115Volt TR & 97738 97738 97738 97741 97741 132058 132058

TR-H Universal Universal Universal Universal Universal Universal Universal

#JAIM156M #JAIM156M #JAIM156M #JEIE009N #JEIE009N #JE1F015N #JE1F015N

14B Motor - 208/230 Volt TR & 98157 98157 98157 98157 98157 98157 98157

TR-H Universal Universal Universal Universal Universal Universal Universal

#JEIE010N #JEIE010N #JEIE010N #JEIE010N #JEIE010N #JEIE010N #JEIE010N

14C Venter Wheel TR 97724 97724 97724 97724 97724 132007 132007

Brookside Brookside Brookside Brookside Brookside Brookside Brookside

#FE-400-200 #FE-400-200 #FE-400-200 #FE-400-200 #FE-400-200 #FE-610-216-1 #FE-610-216-1

TR-H 97724 97724 97724 120545 120545 132007 132007

Brookside Brookside Brookside Brookside Brookside Brookside Brookside

#FE-400-200 #FE-400-200 #FE-400-200 #FE-519-119-2 #FE-519-119-2 #FE-610-216-1 #FE-610-216-1

14D Motor Plate TR 97301 97301 97301 97301 97301 132019 132019

TR-H 97301 97301 97301 120997 120997 132019 132019

14E Motor Capacitor - TR & -- -- -- 163894 163894 163894 163894

4MFD @ 370V TR-H

14F Capacitor Boot - TR & -- -- -- 103182 103182 103182 103182

Syntex #M-78 TR-H

14G Spacers - #8 Spirol TR & (4)97721 (4)97721 (4)97721 (4)97722 (4)97722 (4)97722 (4)97722

TR-H 3/4"lg 3/4"lg 3/4"lg 15/16"lg 15/16"lg 15/16"lg 15/16"lg

Burner, Manifold and Orifices

Burner

Control

Box

16 -

Manifold

17- Burner Orifice

Code Description Model 50 75 100 125 150 175 200

15 Main Burner Assembly TR/TR-H 115973 115973 115973 115973 115973 132022 132022

16 Manifold & Manifold Bracket TR/TR-H 115981 115981 115981 115981 115981 115981 115981

17 Burner Natural TR 120146 120153 120157 120161 120165 120164 136200

Orifice 0-2000 ft 3.4mm #20 #12 #1 D C 6.75mm

Propane TR 124966 120137 120141 120145 120149 -- -0-2000 ft #45 #40 # 32 3.3mm #27

Natural TR-H 120147 120154 120158 131581 120166 120165 136201

Burner 2001-4000 ft #29 #19 #10 5.9mm E D 6.8mm

Orifice Propane TR-H 124967 120138 120142 120145 120150 -- -(Do not 2001-4000 ft 2.1mm #39 #3.0mm 3.3mm #26

use for Natural TR-H 124969 131579 120159 120162 120167 120166 136202

high altitude 4001-6000 ft #28 4.25mm 5.0mm A F E 7.0mm

conversion; Propane TR-H 124968 120139 120143 120146 120151 -- -high altitude 4001-6000 ft 2.15mm #38 #31 3.4mm 3.8mm

kits are on Natural TR-H 120149 120155 131580 120164 120168 120167 -page 8.) 6001-8000 ft #27 #18 #8 C G F

Propane TR-H 131578 120140 120144 120148 120152 -- --

6001-8000 ft 2.2mm #37 3.1mm 3.5mm #23

15 - Burner Assembly

Code 15 Main

Burner

Assembly

Code 17 Burner

Orifice

Select burner

orifice carefully .

Do not ream.

Code 16 - Manifold

Form 709, page 5

Loading...

Loading...