Page 1

Model PCD

Indirect-Fired, Vertical/Horizontal,

Indoor/Outdoor, Packaged,

Makeup Air Heating and Air

Conditioning System

Contents

MODELS PCD, HPCD

DESCRIPTION .............................................................................................. 2

STANDARD FEATURES .............................................................................. 2

OPTIONAL FEATURES - FACTORy INSTALLED ........................................ 3

OPTIONAL FEATURES - FIELD INSTALLED ............................................... 3

UNIT CONFIGURATION ................................................................................ 4

CONFIGURATION SELECTION ................................................................... 5

SIZE SELECTION ......................................................................................... 5

PERFORMANCE SPECIFICATION ..............................................................7

STATIC PRESSURE DROP FOR ACCESSORIES ..................................... 10

DIMENSIONS .............................................................................................. 11

PIPING DIAGRAMS .................................................................................... 27

AMPERAGE SPECIFICATIONS .................................................................. 28

SAMPLE SPECIFICATION .......................................................................... 29

REZNOR

®

PRODUCT LIMITED WARRANTy .............................................31

IMPORTANT: Specications are subject to change

without notice. This guide is intended to provide

specications and technical information only.

This guide is not intended to be an instruction

manual. When installing HVAC Equipment, you

must check and conform to all local and national

building codes. Improper installation of HVAC

Equipment could be dangerous. Consult manufacturer’s installation manual for instructions and

important warnings.

In keeping with our policy of continuous product improvement, we reserve

the right to alter, at any time, the design, construction, dimensions, weights,

etc., of equipment information shown here.

Page 2

Page Number _______ of ______

MODELS PCD, HPCD

Horizontal or Vertical, Indoor or Outdoor, Indirect Fired Power Burner, Makeup Air Heating,

Ventilating and Air Conditioning System.

DESCRIPTION

STANDARD FEATURES

The Reznor Model PCD Series units are indirect-red/makeup air system designed for either indoor or outdoor

installation. Units can be congured for either vertical, horizontal for oor mount, outdoor pad mount, rooftop or

suspended installation. Select from top, bottom or horizontal discharge supply air options. Model PCD systems

are available to operate on either natural gas, propane or fuel oil. This catalog details features and specications for heating capacities ranging from 200 to 6,000 MBH output. Larger sizes are available on special order

basis (contact your Reznor Representative for more more information) High cfm versions (Model HPCD) are

also available.

The basic cabinet is constructed of 18 gauge galvaneal with a grey enamel nish. Other nishes are available.

The standard cabinet is a single wall with 1” thick, 1.5 lb. neoprene coated insulation. High density (2 lb.) insulation or 2” thick insulation can be selected. A 22 gauge interior liner is standard on the burner section. Optional

solid (for cleaning) or perforated (for sound attenuation) liners are available on other sections.

Vertical units (Model PCDV) can be shipped with a 3’ or 5’ mounting stand for eld attachment. The mounting

stand can be screened, or it can be insulated with one or two anged inlets with or without dampers. A louvered

inlet plenum can be shipped separately with outdoor vertical or horizontal units.

Discharge air openings can be shipped with two position motorized discharge dampers - low leak dampers also

available. Other air distribution options include trapezoidal cowls with horizontal louvers; 4-sided (360 degrees)

louvered discharge plenum; or 90 degree discharge cowls.

A 409 stainless steel primary and secondary heat exchanger is standard on Model PCD. Optional 304 stainless

steel can be substituted for both heat exchangers or only the primary heat exchanger. Model PCD high can be

ordered with a standard gravity vent or induced draft vent.

Units can be arranged for 100% outside or return air, or a mixing box can be specied with 3-position motorized dampers. Other modules can be included with Model PCD and shipped separately for eld attachment

including an inlet louvered hood, evaporative cooling section, lter cabinet, service platform and/or cooling coil

cabinet.

Model PCD and HPCD meet ETL (ANSI) Standards for installation in the United States and CGA (CSA) Standards for installation in Canada.

All units are factory wired, piped and test red.

● Single wall cabinet (with interior 22 gauge liner on burner section)

● Gray enamel nish on 18 gauge Galvaneal cabinet construction

● 1” thick 1.5 lb. neoprene coated berglass insulation

● Natural gas operation

● 409 stainless steel primary and secondary heat exchangers

● Gravity vent exhaust

● 230/1/60 supply voltage

● Burner manifold meets ETL (ANSI) or CGA (CSA) standards

● 3:1 turndown ratio modulating power burner

Form S-PCD Page 2

Page 3

MODELS PCD, HPCD (cont’d)

Page Number _______ of ______

OPTIONAL FEATURES Factory Installed

OPTIONAL FEATURES - Field

Installed

● 22 gauge solid or perforated interior cabinet metal liner on blower, lter, mixing box, or inlet plenum sec-

tions.

● Special material cabinet coating

● 1” thick high density (2 lb.) or 2” thick cabinet insulation

● Propane or fuel oil operation

● Power vent exhaust

● 304 stainless steel primary and secondary heat exchangers (or 304 primary with a 409 secondary stainless

steel heat exchanger)

● 208/3/60, 230/3/60, 460/3/60, or 575/3/60 supply voltages

● Vibration isolation

▬ 1” deection motor/blower spring vibration isolation

▬ 2” deection motor/blower spring vibration isolation

▬ Motor/blower rubber-in-shear isolation

▬ 1” external spring isolation under unit channel base

▬ 2” external spring isolation under unit channel base

▬ Seismic isolation, pad type

▬ External spring hangers - 1” deection

▬ External spring hangers - 2” deection

▬ Seismic isolation, hanger type

● Left or right hand controls

● Extended lube lines

● Vertical or horizontal unit conguration

● Top, bottom or horizontal supply discharge air

● Two position motorized discharge air shutoff damper, spring return (also available with low leak airfoil type

dampers)

● Outdoor units

▬ Weather-housing covers the control section on outdoor units

▬ Roof slopes away from weather-housing on Model PCDH 125 and larger

● Manifold meets IRI and/or FM requirements

● Up to 15:1 turndown ratio modulating burner

● UV ame supervision

● Unit mounted discharge temperature sensor

● Premium efciency ODP motors or TEFC motors

● Variable frequency drive

● Convenience outlet

● Rain-tight safety disconnect switch

● Service Platform

● Discharge air attachments

▬ Trapezoidal, 3 facet cowl with horizontal louvers (also available with double deection louvers)

▬ 4-sided (360 deg.) louvered discharge plenum

▬ 90 deg. or 45 deg. louvered nozzles

● 3’ or 5’ stand for vertical indoor units

▬ Screened mounting stand

▬ Insulated stand with one or two anged inlet air openings

▬ Insulated stand with one or two inlet openings with dampers

● Filter section (with 2” permanent or pleated lters)

▬ Flat lter rack

▬ V-bank lter rack

● Mixing box with 3-position motorized dampers.

● Louvered inlet plenum (for outdoor units)

● DX or chilled water coil for downstream installation

● Evaporative cooling module

▬ Available with stainless steel cabinet

▬ 12” thick Glasdek

▬ 1” or 2” aluminum mesh, washable lters

▬ Louvered inlet or screened inlet hood

▬ Fill and drain options

● Steam or hot water coil cabinet

● Gas pressure safety switch

● Adjustable freezestat

● Post and/or pre-purge timer

● 16” or 26” roof curb

● Remote Console

®

or Celdek® media

Form S-PCD Page 3

Page 4

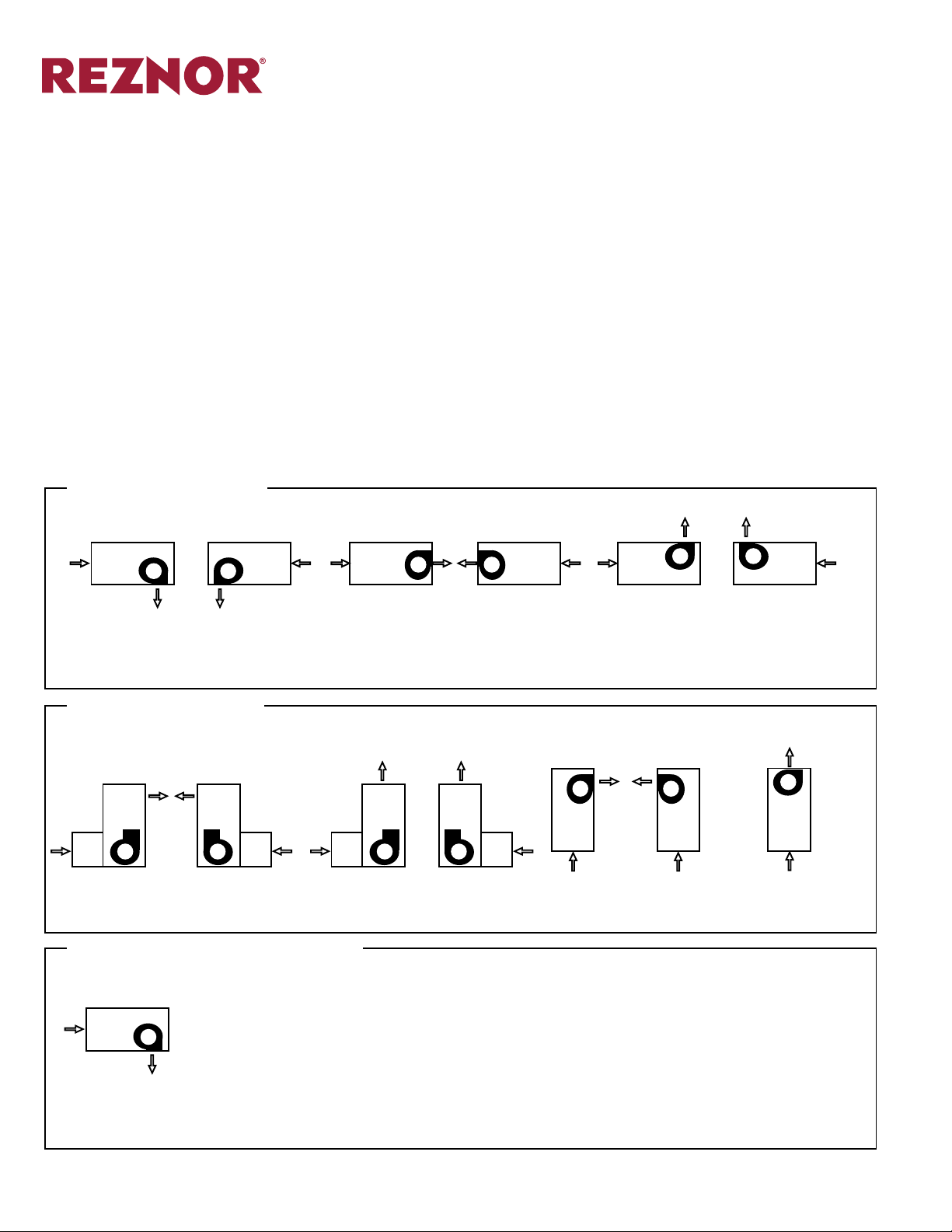

UNIT CONFIGURATION

Page Number _______ of ______

Control Side and Air

Arrangement Data

As previously mentioned, Model PCD can be arranged for horizontal air ow or vertical (up) airow conguration. There are a variety of air discharge arrangements for each conguration (top, bottom or horizontal air

ow). Units can also be congured for left-hand or right-hand controls.

There are a variety of discharge air louvers, cowls and nozzles for supply air openings.

The following table will show you each available conguration and arrangement and the option codes repre-

senting each.

Control Side

Option AJ1 Left side controls (when facing air stream)

Option AJ2 Right side controls (when facing air stream)

Discharge Air Arrangement

Option AQ1 Bottom Discharge (Model PCDH)

Option AQ2 Horizontal Discharge (Model PCDH)

Option AQ13 Top Discharge (Model PCDV without Mounting Base), “L” Conguration

Option AQ32 Horizontal Discharge (Model PCDV without Mounting Base), “L” Conguration

Option AQ33 Horizontal Discharge (Model PCDV with Mounting Base), “I” Conguration

AQ34 Top Discharge (Model PCDV with Mounting Base), “I” Conguration

Note: No difference between left-hand and right-hand controls for units with Option AQ34. Unit can be set in place with controls

on proper side.

(H)PCDH Configurations

Typical Rooftop, Curb Mounted, or Indoor Suspended Heating or Makeup Air System.

AQ1 - AJ1 AQ1 - AJ2 AQ2 - AJ1 AQ2 - AJ2 AQ13 - AJ1 AQ13 - AJ2

(H)PCDV Configurations

(H)PCDV Uflow “L” Configuration - Typical Indoor, Thru-Wall, or Outdoor Slab Mount

Upflow Heating or Makeup Air System

AQ32

AQ33

-AJ1

AQ32

AQ33

-AJ2

AQ13

AQ34

-AJ1

AQ13

AQ34

-AJ2

(H)PCDV Uflow “I” Configuration* - Typical Indoor or Outdoor

Air Turnover High Bay Heating/Cooling Makeup Air System

AQ32

AQ33

-AJ1

AQ32

AQ33

-AJ2

AQ13

AQ34

Example Configuration Nomenclature

Air flow directions and control side illustrations as seen when facing the unit from

the control side

PCDH (Horizontal Configuration)

AQ1 Option - bottom discharge

AJ1 Option - Left side controls when facing air flow.

-AJ1

*

If (H)PCDV is ordered with an AVA option, the AW6 or AW15 V-bank lter section will stack on top of the AVA base in an “I” conguration. Otherwise, the V-bank lter section will be in the “L” conguration

shown. For draw through coil cabinets in the “L” conguration, order option AU5 or AU6. For blow through upow A-Coil cabinets in the “I” conguration, order option AU2A or AU3A.

Form S-PCD Page 4

Page 5

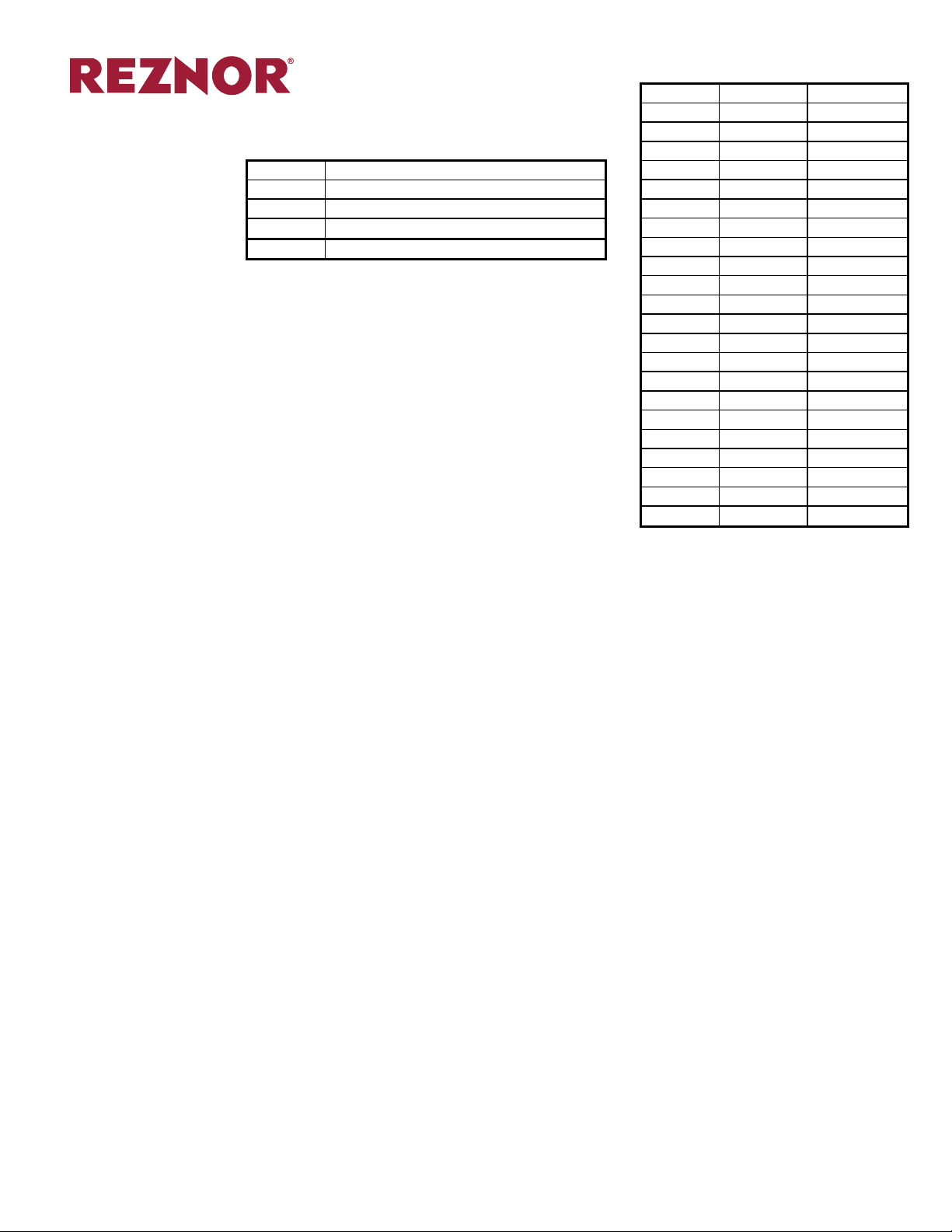

CONFIGURATION SELECTION

How to Specify a conguration

Model Description

PCDH Horizontal Indirect Fired Unit

HPCDH High CFM Horizontal Indirect Fired Unit

PCDV Vertical Indirect Fired Unit

HPCDV High CFM Vertical Indirect Fired Unit

Page Number _______ of ______

Size MBH Input MBH Output

20 250 200

25 312.5 250

35 437.5 350

40 500 400

45 562.5 450

55 687.5 550

65 812.5 650

75 937.5 750

85 1,062.5 850

100 1,250 1,000

125 1,562.5 1,250

150 1,875 1,500

175 2,187.5 1,750

200 2,500 2,000

250 3,125 2,500

275 3,437.5 2,750

300 3,750 3,000

325 4,062.5 3,250

350 4,375 3,500

400 5,000 4,000

500 6,250 5,000

600 7,500 6,000

SIZE SELECTION

How to determine the size of Model

PCD

Example 1: Make-Up Air

Model PCD are designated by their MBH output. Thus a PCD75 has 750 MBH output, or 750,000 BTUH.

● All PCD units are 80% efcient at high re, thus, output is BTUH input x 0.80

● Once you have chosen your required BTUH output, you can use BTUH output ÷ 0.80 to nd your required

input, or actual gas consumption. Using the desired output you can select your model.

● Choose your airow (this may be your rst step if the unit is applied in a make-up air situation)

● Calculate your TSP (add your ESP with your accessories – accessory pressure drops can be found after the

unit ESP table). With your airow and TSP selected you can nd your BHP from the performance table.

● Given the entering and leaving air dry bulb temperatures or temperature rise, the equation below can be

used to calculate the required MBH capacity

▬ MBH Capacity = (CFM x C x (LAT-EAT)) ÷ 0.80 ÷ 1000

▬ MBH capacity: BTUH/1000 (British Thermal Units per hour)

▬ CFM: Cubic Feet per Minute of air

▬ C: Gas constant of 1.08 based on air density at 75°F

▬ EAT: Entering air dry bulb temperature (°F)

▬ LAT: Leaving air dry bulb temperature (°F)

▬ 0.8: (80%) Series Efciency

A manufacturing facility needs pressurization via makeup air. A pressurization of 10% is deemed to be appropriate, and it is determined that 25,720 CFM exhaust is required. The design ambient is -20°F, and desired

discharge temperature is 70°F. Units will be roof mounted, down discharge, and will have an ESP of 0.60” w.c.

Select the appropriate size, and nd the BHP for the unit.

Selection:

● Since we are exhausting 25,720 CFM, and desire 10% pressurization, we can calculate that we need 28,300

CFM of supply air (25,720 x 110% = 28,300)

● We know our EAT = -20°F, and LAT = 70°F, thus we can calculate:

▬ MBH Output Capacity = (CFM x C x (LAT-EAT)) ÷ 1000

▬ MBH Output Capacity = (28,300 x 1.08 x (70 - (-20))) ÷ 1000

▬ MBH Output Capacity = 2,750.76

● The closest size available is the Model PCDH275 which has 2,750 MBH output, and 3,437.5 MBH input

We can now calculate our TSP:

● We are selecting the basic options – inlet lters and damper

● Inlet damper = 0.1” w.c.

● Inlet Filters = 0.3” w.c.

▬ TSP = ESP + Accessories

▬ TSP = 0.60 + 0.1 + 0.3

▬ TSP = 1.0” W.C.

● Consulting the chart for the PCD275 at 28,300 CFM and 1.0” W.C we nd our BHP = 16.28 BHP – Thus we

need a 20.0 HP motor minimum.

Form S-PCD Page 5

Page 6

How to Specify a conguration

Page Number _______ of ______

CONFIGURATION SELECTION (cont’d)

Example 2: Heat-Vent Unit

Selection:

Example 3: Heating Only Unit

A small warehouse needs a minimum of 20% fresh air in unoccupied (night time) mode and 100% fresh air in

occupied mode (during the day with forklift in the building). It has been calculated that at -30°F the room loses

1,000,000 BTUH. It has been determined that 11,000 CFM is required for the application. The outdoor air is

-30°F, and desired leaving air is 75°F. Return air will be 70°F. ESP is calculated to be 0.5” w.c. Select the appropriate model and nd the BHP for the unit.

Part 1 (Unoccupied mode)

● We only bring in 20% outside air in this mode, thus 2,200 CFM is outside air and 8,800 CFM is return air

● We know our EAT for outside air = -30°F, and LAT = 75°F, thus we can calculate:

▬ MBH Capacity = (CFM x C x (LAT - EAT)) ÷ 1000

▬ MBH Capacity = (2,200 x 1.08 x (75 - (-30))) ÷ 1000

▬ MBH Capacity = 249.48

● We also know that the room is losing 1,000 MBH, thus we need to add that to the calculation. Thus the total

Heat input capacity required = 1,250 MBH

● Before we select our model we must check the occupied mode to ensure we have sufcient heat capacity.

Part 2 (Occupied mode)

● We will be delivering 11,000 CFM of outside in this mode

● We know our EAT for outside air = -30°F, and LAT = 75°F, thus we can calculate:

▬ MBH Capacity = (CFM x C x (LAT - EAT)) ÷ 0.80 ÷ 1000

▬ MBH Capacity = (11,000 x 1.08 x (75 - (-30))) ÷ 0.80 ÷ 1000

▬ MBH Capacity = 1,247.40

● Thus to satisfy both options we need to use a PCDH125.

Note: In this example we are assuming there is an alternate source of heat that will be used during occupied

mode to make-up for the heat loss of the warehouse, which will not be used in unoccupied mode.

We can now calculate our TSP:

● We are selecting the basic options – inlet lters and damper

● Inlet damper = 0.1” w.c.

● Inlet Filters = 0.3” w.c.

▬ TSP = ESP + Accessories

▬ TSP = 0.50 + 0.1 + 0.3

▬ TSP = 0.9” W.C. (Round up to 1.0” w.c.)

● Consulting the chart for the PCDH125 at 11,000 CFM (use 11,574 CFM) and 1.0” w.c., we nd our BHP =

5.75 BHP – We can use a 7.5 hp motor.

A door heater for a large overhead door can potentially see 100% fresh air during times when the overhead

doors open frequently. Thus a durable Model PCD unit should be selected for this application. The appropriate

amount of air is determined to be 18,000 CFM at 0.5” w.c. for the vestibule, and 1,250 MBH is calculated to be

the appropriate amount of heat capacity required. Select the appropriate model and nd the BHP for the unit.

Selection:

● Since the heating load calculation has already been completed we simply need to use the heating capacity

and match it up with the appropriate Model PCD

● PCD125 is the appropriate model for 1,250 MBH

We can now calculate our TSP:

● We are selecting the basic options – inlet lters and damper

● Inlet damper = 0.1” w.c.

● Inlet Filters 0.3” w.c.

▬ TSP = ESP + Accessories

▬ TSP = 0.50 + 0.1 + 0.3

▬ TSP = 0.9” w.c. (Round up to 1.0” W.C)

● Consulting the chart for the PCD125 at 18,000 CFM (this value falls between 16,534 CFM and 19,290 CFM)

and 1.0” W.C we nd our BHP is between 9.59 BHP and 13.12 BHP. A 15 HP motor should be used.

Form S-PCD Page 6

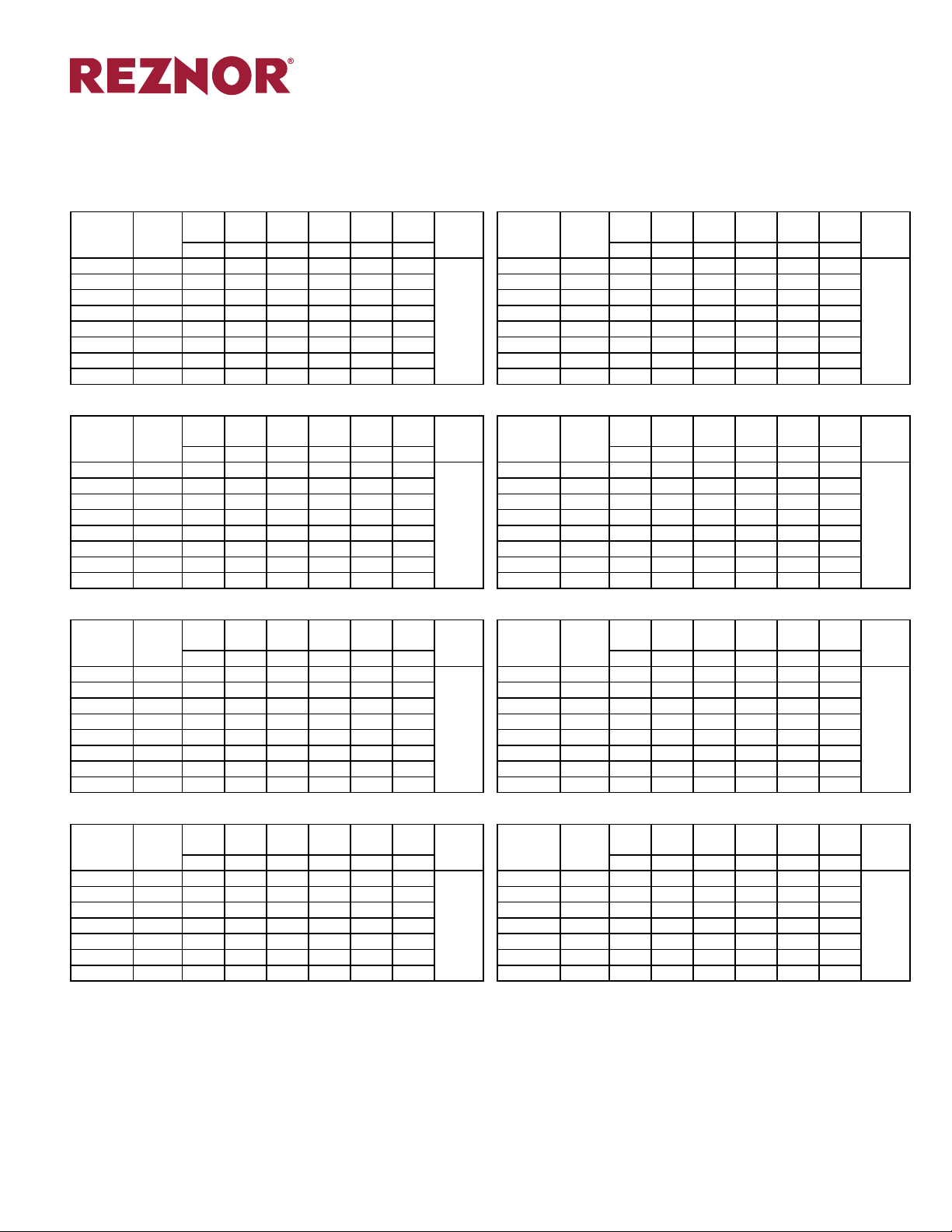

Page 7

Page Number _______ of ______

PERFORMANCE SPECIFICATION

Pressure Drop Table

Blower size will be determined by factory based on specied CFM and temperature rise requirements.

Note: The normal temperature rise for Model Series PCD is 71°-110°F; for Model Series HPCD it is 40°-70°F.

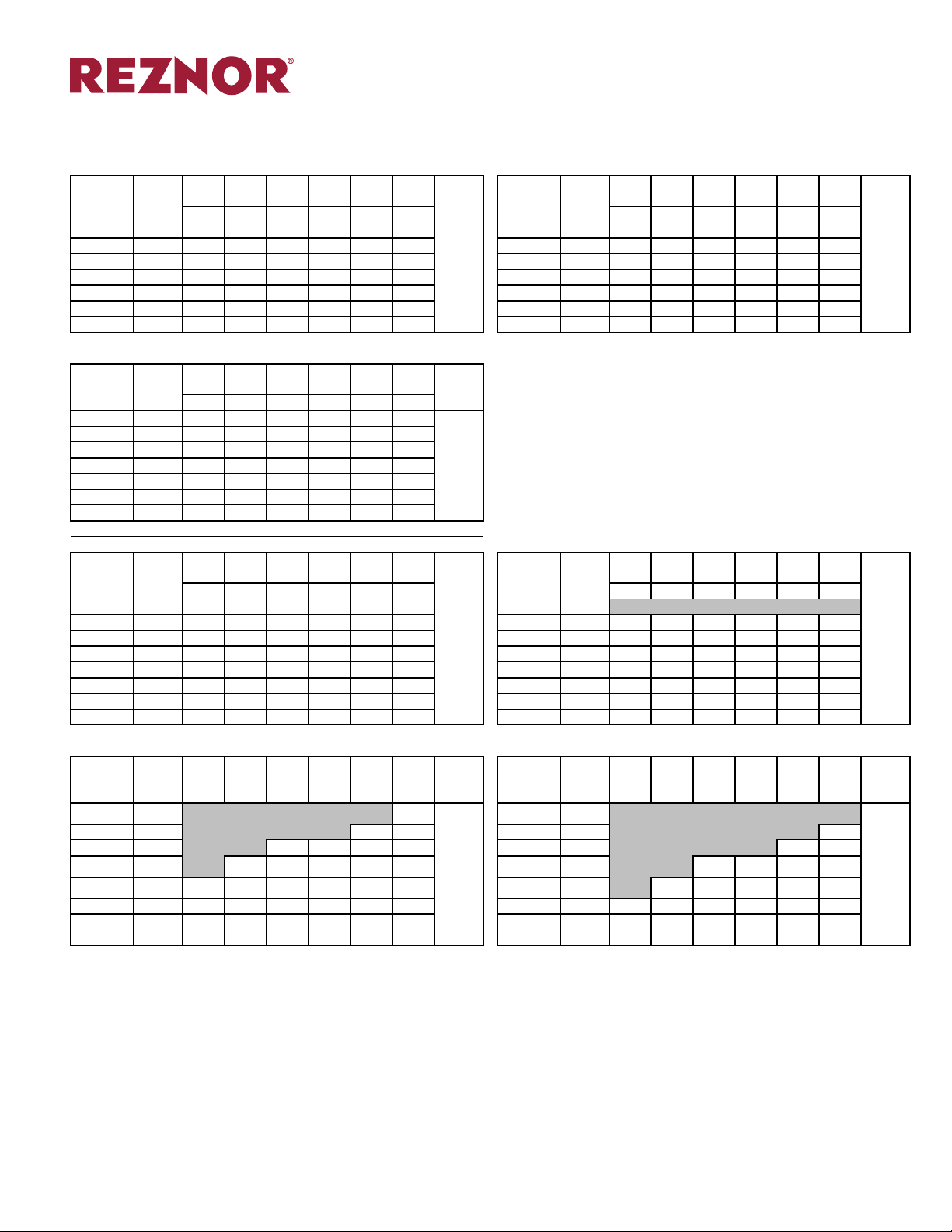

PCD20 - 250 MBH INPUT/200 MBH OUTPUT PCD25 - 312.5 MBH INPUT/250 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

Capacity

(CFM)

Temp.

Rise

W.C.

W.C.

W.C.

W.C.

W.C.

2.0”

W.C.

Inches

4630 40 1.70 1.94 2.17 2.42 2.94 4.28

3704 50 1.47 1.67 1.87 2.08 2.49 2.90 4630 50 1.70 1.94 2.17 2.42 2.94 4.28

3086 60 1.28 1.44 1.63 1.82 2.17 2.58 3858 60 1.62 1.82 2.02 2.24 2.67 3.09

2646 70 0.90 1.06 1.22 1.37 1.73 2.13 3307 70 1.53 1.66 1.87 2.08 2.46 2.83

2315 80 0.69 0.83 0.96 1.12 1.64 1.99 2894 80 1.09 1.27 1.44 1.61 1.95 2.37

2058 90 0.55 0.67 0.82 0.97 1.39 1.72 2572 90 0.85 1.01 1.16 1.3 1.67 2.27

1852 100 0.45 0.57 0.71 0.93 1.52 1.52 2315 100 0.69 0.83 0.96 1.12 1.64 1.99

1684 110 0.39 0.51 0.7 0.87 1.05 1.24 2104 11 0 0.58 0.69 0.84 0.99 1.43 1.79

PCD35 - 437.5 MBH INPUT/350 MBH OUTPUT PCD40 - 500 MBH INPUT/400 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

Capacity

(CFM)

Temp.

Rise

W.C.

W.C.

W.C.

W.C.

W.C

2.0”

W.C.

Inches

8102 40 4.49 4.93 5.37 5.82 6.73 7.66

6481 50 2.63 3.53 3.83 4.14 4.78 5.43 7407 50 3.59 4.00 5.22 5.56 6.27 7.00

5401 60 2.06 2.32 2.58 2.85 3.40 3.97 6173 60 2.35 3.14 3.43 3.73 4.34 4.97

4630 70 1.45 1.68 1.91 3.08 3.54 4.02 5291 70 1.96 2.21 2.47 2.73 3.28 3.84

4051 80 1.09 2.00 2.19 2.40 2.81 3.24 4630 80 1.45 1.68 1.91 2.15 2.64 3.99

3601 90 0.87 1.59 1.77 1.96 2.34 2.73 4115 90 1.12 1.33 1.54 1.76 2.80 3.26

3241 100 1.16 1.32 1.72 1.89 2.22 2.55 3704 100 1.36 1.53 1.72 1.93 2.34 2.74

2946 110 0.99 1.32 1.47 1.62 1.92 2.22

PCD45 - 562.5 MBH INPUT/450 MBH OUTPUT PCD55 - 687.5 MBH INPUT/550 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

Capacity

(CFM)

Temp.

Rise

W.C.

W.C.

W.C.

W.C.

W.C

2.0”

W.C.

Inches

10417 40 5.17 5.69 6.23 6.78 7.94 9.16

8333 50 4.13 4.57 5.02 5.48 6.40 8.31 10185 50 4.90 5.41 5.94 6.48 7.62 10.68

6944 60 2.68 3.06 3.44 4.46 5.12 5.81 8488 60 4.31 4.77 5.22 5.68 6.62 7.57

5952 70 1.90 2.66 2.94 3.22 3.81 4.42 7275 70 2.98 3.38 3.77 4.17 4.99 5.83

5208 80 1.75 1.99 2.24 2.50 3.03 3.58 6366 80 2.21 3.12 3.40 3.70 4.32 4.96

4630 90 1.34 1.57 1.80 2.03 2.52 3.04 5658 90 1.71 2.38 2.64 2.92 3.48 4.06

4167 100 1.07 1.28 2.09 2.32 2.77 3.24 5093 100 1.66 1.90 2.15 2.40 2.92 3.52

3788 110 1.39 1.54 1.74 1.93 2.37 3.39 4630 110 1.34 1.57 1.80 2.77 3.23 3.70

PCD65 - 812.5 MBH INPUT/650 MBH OUTPUT PCD75 - 937.5 MBH INPUT/750 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

Capacity

(CFM)

Temp.

Rise

W.C.

W.C.

W.C.

W.C.

W.C

2.0”

W.C.

Inches

12037 50 5.82 6.39 6.97 7.57 8.79 10.03

10031 60 3.73 4.22 4.72 7.31 8.31 9.32 11574 60 5.27 5.82 6.39 6.96 8.14 9.35

8598 70 2.64 4.47 4.89 5.32 6.19 7.09 9921 70 3.64 4.13 4.62 5.13 6.18 8.94

7523 80 2.00 3.36 3.74 4.12 4.91 5.72 8681 80 2.70 4.37 4.79 5.22 6.11 7.01

6687 90 2.34 2.67 3.53 3.87 4.56 5.24 7716 90 2.11 3.35 3.74 4.13 4.93 5.76

6019 100 1.91 2.59 2.90 3.21 3.83 4.53 6944 100 2.33 2.67 3.03

5471 110 1.89 2.17 2.45 2.73 3.29 4.85 6313 110 1.89 2.65 2.97 3.29 3.94 4.58

Gas

Conn.

Capacity

(CFM)

Air

Temp.

Rise

0.25”

W.C.

0.5”

W.C.

0.75”

W.C.

1.0”

W.C.

5787 40 2.91 3.19 3.48 3.77 4.37 4.99

1

0.25”

0.5”

0.75”

Gas

Conn.

Capacity

(CFM)

Air

Temp.

Rise

W.C.

W.C.

W.C.

1.0”

W.C.

9259 40 7.13 6.62 10.33 10.77 11.78 12.82

1

3367 110 1.08 1.26 1.44 1.63 1.99 2.81

0.25”

0.5”

0.75”

Gas

Conn.

Capacity

(CFM)

Air

Temp.

Rise

W.C.

W.C.

W.C.

1.0”

W.C.

12731 40 7.24 7.98 8.79 9.61 11.40 19.59

1

0.25”

0.5”

0.75”

Gas

Conn.

Capacity

(CFM)

Air

Temp.

Rise

W.C.

W.C.

W.C.

1.0”

W.C.

13889 50 8.39 9.02 8.82 10.35 11.72 13.12

1

3.39 4.13 5.39

1.5”

W.C

1.5”

W.C.

1.5”

W.C

1.5”

W.C

2.0”

W.C.

2.0”

W.C.

2.0”

W.C.

2.0”

W.C.

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

1

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

1

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

1

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

1

NOTES:

-All Static Values Include the Blower, Burner, and Casing

-Accesory Static Values Must be Added to Obtain the Total Static

-Brake Horsepower Does Not Include Drive Losses

Consult factory representative for:

-Higher Air Capacities or Special Applications

-Performance Data on Higher Statics than Listed

-Performance Data at Elevations Other Than Sea Level

Form S-PCD Page 7

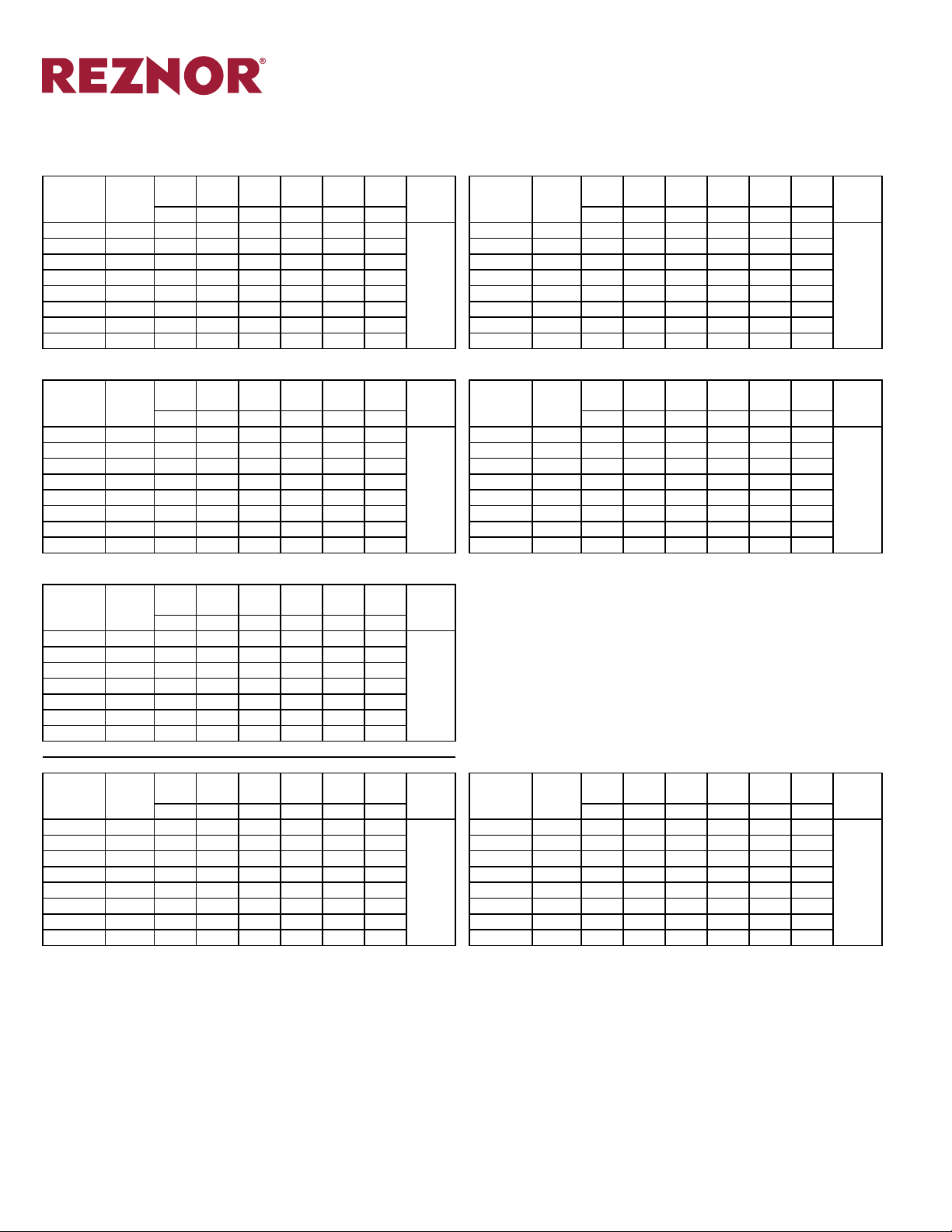

Page 8

Page Number _______ of ______

PERFORMANCE SPECIFICATION (cont’d)

Pressure Drop Table

PCD85 - 1062.5 MBH INPUT/850 MBH OUTPUT PCD100 - 1250 MBH INPUT/1000 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

W.C.

W.C.

W.C.

Capacity

(CFM)

Temp.

Rise

W.C.

19676 40 12.83 13.87 14.93 15.99 18.13 20.30

W.C.

2.0”

W.C.

Gas

Conn.

Inches

Air

Capacity

Temp.

(CFM)

23148 40 17.14 18.22 19.33 20.43 22.71 25.00

15741 50 7.35 8.20 9.05 9.91 11.67 13.45 18519 50 10.97 11.96 12.96 13.96 15.99 18.04

13117 60 4.82 5.54 7.36 7.98 9.25 10.56 15432 60 7.02 7.85 8.69 9.54 11.26 13.02

11243 70 3.46 4.75 5.29 5.84 6.96 8.13 13228 70 4.89 5.62 7.49 8.10 9.38 10.70

9838 80 3.10 3.57 4.05 4.54 5.56 8.49 11574 80 3.66 5.05 5.60 6.16 7.31 8.50

1

8745 90 2.41 2.84 4.74 5.16 6.04 7.95 10288 90 3.45 3.93 4.43 4.94 5.99 9.03

7870 100 1.94 3.55 3.84 4.23 5.04 5.87 9259 100 2.72 3.17 3.63 5.58 6.49 7.44

7155 110 1.61 2.86 3.21 3.58 4.33 5.68 8418 110 2.22 2.64 4.17 4.59 5.44 6.32

PCD125 - 1562.5 MBH INPUT/1250 MBH OUTPUT PCD150 - 1875 MBH INPUT/1500 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

W.C.

W.C.

W.C.

Capacity

(CFM)

Temp.

Rise

W.C.

28935 40 16.22 17.62 19.04 20.51 23.54 26.74

W.C.

2.0”

W.C.

Gas

Conn.

Inches

Air

Capacity

Temp.

(CFM)

34722 40 24.50 28.64 29.94 31.31 34.04 36.90

23148 50 10.76 11.82 12.91 14.02 16.35 18.79 27778 50 14.66 18.40 19.66 20.95 23.59 26.33

19290 60 6.92 7.84 12.09 13.12 15.20 17.30 23148 60 10.76 11.82 12.91 14.02 16.35 18.79

16534 70 4.90 7.81 8.70 9.59 11.39 13.23 19841 70 7.39 8.32 9.29 13.93 16.05 18.21

14468 80 5.10 5.87 6.65 7.45 9.05 10.70 17361 80 5.46 6.30 9.63 10.57 12.45 14.37

1-1/4”

12860 90 3.97 4.66 6.51 7.08 8.31 9.59 15432 90 4.23 6.72 7.55 8.39 10.09 11.82

11574 100 3.21 4.68 5.20 5.75

6.89 8.07 13889 100 4.68 5.43 6.18 8.34 9.63 10.98

10522 110 2.65 3.80 4.30 4.81 5.87 6.97 12626 110 3.81 4.49 6.24 6.81 8.03 9.28

PCD175 - 2187.5 MBH INPUT/1750 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

Capacity

(CFM)

Temp.

Rise

W.C.

W.C.

W.C.

W.C.

BHP BHP BHP BHP BHP BHP

W.C.

2.0”

W.C.

Gas

Conn.

Inches

32407 50 21.80 23.34 24.90 26.50 29.79 33.22

27006 60 13.62 17.11 18.35 19.61 22.19 24.88

23148 70 10.76 11.82 12.91 14.02 16.35 18.79

20255 80 7.77 8.72 9.70 10.72 12.86 15.14

1-1/2”

NOTES:

-All Static Values Include the Blower, Burner, and Casing

-Accesory Static Values Must be Added to Obtain the Total Static

-Brake Horsepower Does Not Include Drive Losses

Consult factory representative for:

-Higher Air Capacities or Special Applications

-Performance Data on Higher Statics than Listed

-Performance Data at Elevations Other Than Sea Level

18004 90 5.91 6.78 10.40 11.36 13.31 15.29

16204 100 4.70 7.48 8.35 9.22 11.00 12.80

14731 110 3.85 6.10 6.90 7.70 9.33 11.00

PCD200 - 2500 MBH INPUT/2000 MBH OUTPUT PCD250 - 3125 MBH INPUT/2500 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

W.C.

W.C.

W.C.

Capacity

(CFM)

Temp.

Rise

W.C.

46296 40 22.66 24.60 26.59 28.65 33.03 43.86

W.C.

2.0”

W.C.

Gas

Conn.

Inches

Air

Capacity

Temp.

(CFM)

57870 40 35.59 38.28 41.04 43.88 49.81 56.07

37037 50 16.18 17.89 19.64 21.46 25.24 29.26 46296 50 22.66 24.60 26.59 28.65 33.03 43.86

30864 60 10.50 11.98 18.83 20.30 23.32 26.48 38580 60 17.89 19.67 21.48 23.34 27.23 31.34

26455 70 7.48 12.13 13.40 16.70 19.16 21.73 33069 70 12.31 13.87 22.10 23.65 26.84 30.14

23148 80 7.95 10.46 11.52 12.60 14.84 17.21 28935 80 9.08 14.91 16.28 17.67 20.56 23.60

20576 90 6.12 8.05 9.01 10.01

12.10 14.33 25720 90 7.08 11.42 14.56 15.74 18.15 20.67

1-1/2”

18519 100 5.62 6.47 7.37 8.30 13.24 15.26 23148 100 7.95 10.46 11.52 12.60 14.84 17.21

16835 110 4.56 5.36 8.41 9.31 11.14 13.00 21044 110 6.43 8.46 9.44 10.45 12.56 14.82

Rise

Rise

Rise

0.25”

W.C.

0.25”

W.C.

0.25”

W.C.

0.5”

W.C.

0.5”

W.C.

0.5”

W.C.

0.75”

W.C.

0.75”

W.C.

0.75”

W.C.

1.0”

W.C.

1.0”

W.C.

1.0”

W.C.

1.5”

W.C.

1.5”

W.C.

1.5”

W.C.

2.0”

W.C.

2.0”

W.C.

2.0”

W.C.

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

1-1/4”

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

1-1/2”

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

2”

Form S-PCD Page 8

Page 9

Page Number _______ of ______

PERFORMANCE SPECIFICATION (cont’d)

Pressure Drop Table

PCD275 - 3437.5 MBH INPUT/2750 MBH OUTPUT PCD300 - 3750 MBH INPUT/3000 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

W.C.

W.C.

W.C.

Capacity

(CFM)

Temp.

Rise

W.C.

50926 50 25.65 27.71 29.79 31.90 36.30 40.99

W.C.

2.0”

W.C.

Gas

Conn.

Inches

Air

Capacity

Temp.

(CFM)

55556 50 28.02 30.52 33.08 35.71 41.22 47.07

42438 60 16.62 22.96 24.90 26.86 30.92 38.36 46296 60 20.61 22.51 24.44 26.43 30.62 35.17

36376 70 14.36 16.02 17.72 19.47 23.14 27.04 39683 70 14.12 19.58 21.41 23.27 27.15 31.23

31829 80 10.18 11.65 18.78 20.25 23.28 26.43 34722 80 12.89 14.48 16.12 17.82 21.40 25.22

2”

28292 90 8.08 9.44 14.93 16.28 19.10 22.07 30864 90 9.81 11.26 18.13 19.59 22.58 25.71

25463 100 6.52 10.76 11.98 15.01 17.39 19.87 27778 100 7.77 13.03 14.34 15.68 18.46 21.40

23148 110 7.65 8.75 11.22 12.30 14.52 16.87 25253 11 0 6.38 10.53 13.56 14.71 17.08 19.55

PCD325 - 4062.5 MBH INPUT/3250 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

Capacity

(CFM)

Temp.

Rise

W.C.

W.C.

W.C.

W.C.

BHP BHP BHP BHP BHP BHP

W.C.

2.0”

W.C.

Gas

Conn.

Inches

60185 50 34.40 37.07 39.79 42.58 48.37 54.48

50154 60 25.26 27.31 29.38 31.48 35.86 40.52

42989 70 17.13 18.91 20.73 27.59 31.68 35.96

37616 80 15.59 17.30 19.04 20.84 24.58 28.55

2-1/2”

NOTES:

-All Static Values Include the Blower, Burner, and Casing

-Accesory Static Values Must be Added to Obtain the Total Static

-Brake Horsepower Does Not Include Drive Losses

Consult factory representative for:

-Higher Air Capacities or Special Applications

-Performance Data on Higher Statics than Listed

-Performance Data at Elevations Other Than Sea Level

33436 90 11.78 13.32 14.92 23.37 26.55 29.85

30093 100 9.29 10.72 17.15 18.58 21.52 24.60

27357 110 7.55 12.62 13.91 17.52 20.03 22.64

PCD350 - 4375 MBH INPUT/3500 MBH OUTPUT PCD400 - 5000 MBH INPUT/4000 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

W.C.

W.C.

W.C.

Capacity

(CFM)

Temp.

Rise

W.C.

81019 40 48.29 51.64 55.00 58.39 65.33 72.56

W.C.

2.0”

W.C.

Gas

Conn.

Inches

Air

Capacity

Temp.

(CFM)

92593 40 CONSULT FACTORy

64815 50 29.42 32.21 35.04 37.92 43.92 54.90 74074 50 41.31 44.50 47.68 50.90 57.47 64.32

54012 60 21.86 24.20 26.59 29.04 34.15 39.61 61728 60 26.05 28.72 35.91 38.63 44.22 40.07

46296 70 15.21 20.08 21.98 23.90 27.90 32.21 52910 70 20.86 23.16 25.51 27.92 32.99 38.40

40509 80 13.18 14.84 20.55 22.41 26.24 30.27 46296 80 15.21 20.08 21.98 23.90 27.90 32.21

2-1/2”

36008 90 10.07 14.39 16.05 17.74 21.30 25.10 41152 90 13.69 15.37 21.28 23.16 27.04 31.11

32407 100 10.02 11.50 13.02 20.82 23.90 27.09 37037 100 10.72 15.30 16.99 18.72 22.34 26.19

29461 110 8.12 9.49 15.60 16.98 19.85 22.85 33670 11 0 10.90 12.43 14.00 15.62 25.81 22.73

PCD500 - 6250 MBH INPUT/5000 MBH OUTPUT PCD600 - 7500 MBH INPUT/6000 MBH OUTPUT

0.25”

0.5”

0.75”

1.0”

1.5”

Air

W.C.

W.C.

W.C.

Capacity

(CFM)

Temp.

Rise

W.C.

115741 40 CONSULT FACTORY, REQUIRES 139.7

W.C.

2.0”

W.C.

Gas

Conn.

Inches

Air

Capacity

Temp.

(CFM)

138889 40

92593 50 FAN SIZE GREATER THAN 77.06 84.76 111111 50 CONSULT FACTORY, REQUIRES 127.1

77160 60 2 - 36x36 42.40 49.27 55.92 62.71 92593 60 FAN SIZE GREATER THAN 77.06 84.76

66138 70 29.63 32.48 40.88 46.66 52.60 79365 70 2 - 36x36 45.35 52.60 59.43 66.37

57870 80 19.47 21.95 28.17 41.38 35.91 41.38 69444 80 30.61 36.18 37.17 45.24 51.58

3”

51440 90 14.86 19.69 21.95 28.06 32.30 36.69 61728 90 20.87 25.31 32.48 35.16 40.61 46.29

46296 100 13.76 15.77 20.61 28.34 32.55 36.87 55556 100 17.69 23.37 25.78 33.23 37.78 42.41

42088 110 11.13 15.11 16.84 23.11 27.01 31.07 50505 110 14.24 18.89 24.88 26.95 31.12 35.47

Rise

Rise

Rise

0.25”

W.C.

0.25”

W.C.

0.25”

W.C.

0.5”

W.C.

0.5”

W.C.

0.5”

W.C.

0.75”

W.C.

0.75”

W.C.

0.75”

W.C.

1.0”

W.C.

1.0”

W.C.

1.0”

W.C.

1.5”

W.C.

1.5”

W.C.

1.5”

W.C.

2.0”

W.C.

2.0”

W.C.

2.0”

W.C.

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

2-1/2”

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

3”

Gas

Conn.

InchesBHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP BHP

3”

Form S-PCD Page 9

Page 10

Page Number _______ of ______

PERFORMANCE SPECIFICATION (cont’d)

STATIC PRESSURE DROP FOR ACCESSORIES

ACCESSORIES

FLAT AND ANGULAR FILTER SECTION 0.4

V-BANK FILTER SECTION 0.6

INLET HOOD 0.1

INLET LOUVER 0.2

EVAPORATIVE COOLER 0.3

INLET DAMPER 0.1

DX PLENUM AND COIL 0.6

MIX BOX W/FILTERS 0.7

HORIZONTAL DISCHARGE HEAD 0.5

4-WAY DISCHARGE HEAD 0.5

NOTES: • Accessory Static Pressure Drops are Calculated at Maximum CFM Loads.

STATIC PRESSURE DROP

(w.c.)

Form S-PCD Page 10

Page 11

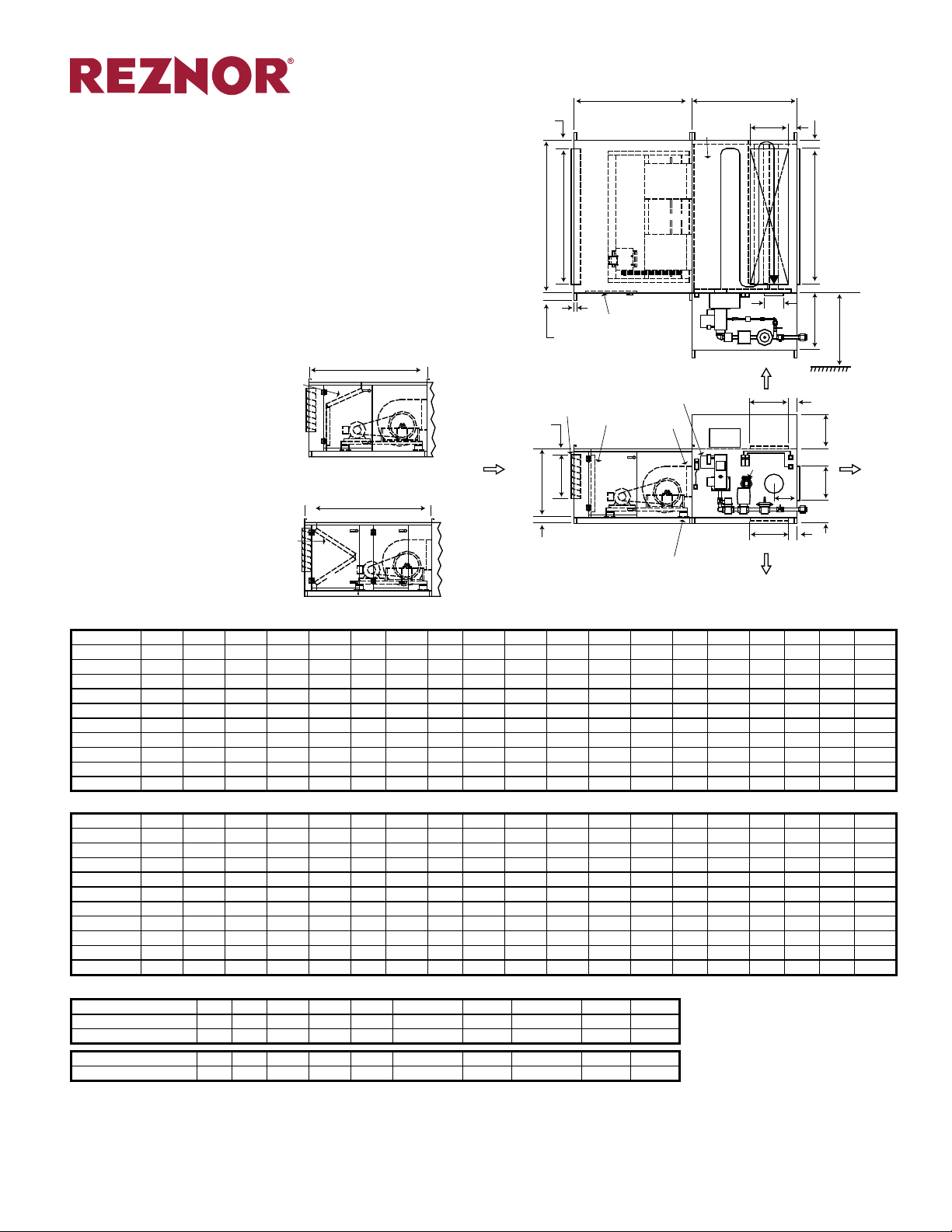

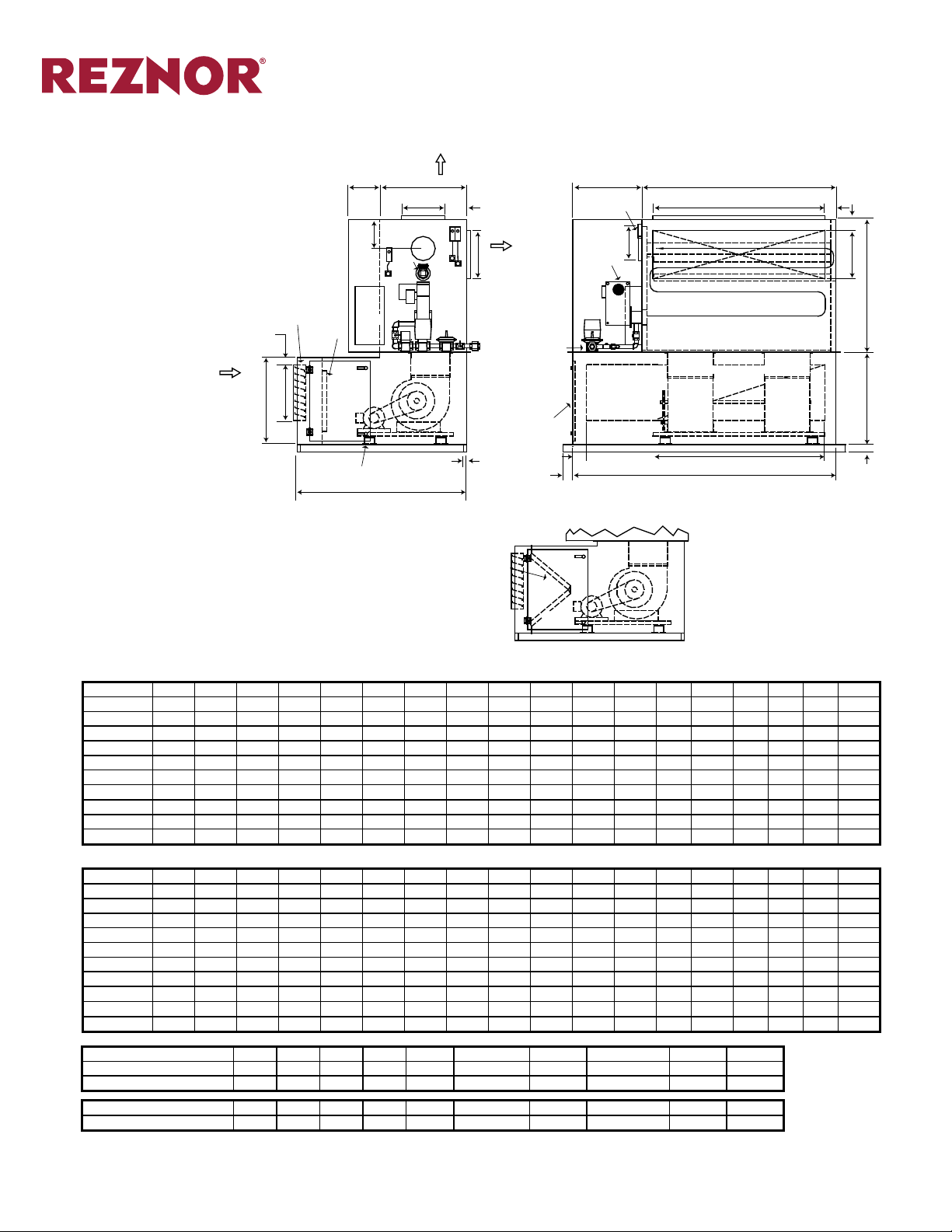

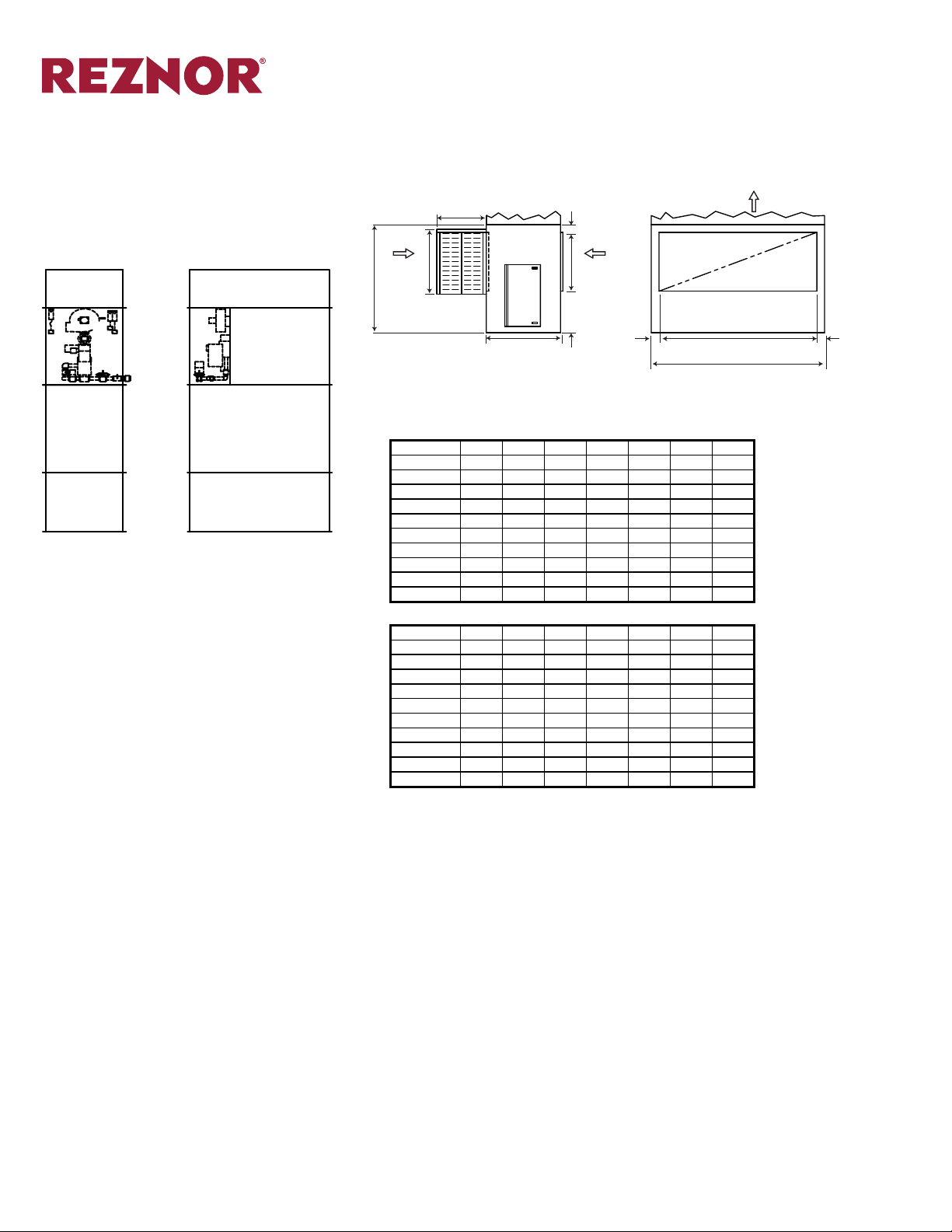

PCDH Basic Horizontal Unit

ANGLED

Burner Section and Blower/Filter Section only

±1/8” (3mm)

DIMENSIONS

U

BLOWER/FILTER

SECTION

1

A

Page Number _______ of ______

HEAT EXCHANGER

SECTION

B

FOUR PASS

COMBUSTION

CHAMBER

E

U

The illiustration to the right shows Model

PCDH. On the following pages are di-

C

L

BLOWERS

H

mension drawings for the high cfm horizontal unit, Model HPCDH, vertical unit,

Model PCDV, and the high cfm vertical

COMBUSTION PATH

unit, Model HPCDV.

Following those pages are dimension

data for modular options.

Dimensions are shown in inches and

(millimeters).

FILTER

V-BANK

FILTER

Dimensions ±1/8”

Sizes A

1

2

A

B C D E F G H K L M N P T U V W Z

BLOWER/FILTER

SECTION

1

A

MOTOR

BLOWER/FILTER

SECTION

2

A

MOTOR

Typ. 4”

(102mm)

OUTDOOR AIR

DAMPER

3”

(76mm)

FRESH AIR

FLOW

M

D

V

* Burner Section and Blower Section on Sizes 65 and greater

are split and shipped separately for eld attachment.

Z

FL AT

FILTER

SIDE VIEW

HINGED DOOR

ACCESS

HANDLE

TOP VIEW

MOTOR

SPRING

ISOLATOR

C/W

POWER

BURNER

FLEX

CONN.

SUPPLY AIR

CONTROL

PANEL

20/25 52 62 47 32 32 18 7 30 23 18 23 19 56 18 10 4 1/2 3 8 1 3/8

35/40 60 68 47 48 32 18 7 30 39 18 39 19 56 18 10 4 1/2 3 8 1 3/8

45/55 67 72 55 60 36 20 9 30 51 18 51 23 56 18 12 4 1/2 3 10 1 3/8

65/75 62 67 55 80 36 20 9 30 71 18 71 23 56 18 12 4 1/2 3 10 1 3/8

85/100 68 75 62 80 48 20 15 30 71 18 71 35 56 12 12 4 1/2 4 12 1 9/16

125/150/175 75 85 72 100 54 30 15 32 91 24 91 41 56 12 12 4 1/2 4 12 1 9/16

200/250 80 92 72 120 60 32 15 36 111 30 111 47 56 12 12 1/2 4 1/2 4 12 1 9/16

275/300/325 87 95 84 140 65 32 17 1/2 36 131 30 131 52 56 12 14 4 1/2 4 14 1 9/16

350/400 92 101 100 160 70 32 20 36 148 30 148 57 56 - 11 1/2 6 6 16 2

500/600 107 117 141 180 80 32 16 36 168 48 168 67 56 - 14 6 6 18 2

Dimensions (±3mm)

Sizes A

1

2

A

B C D E F G H K L M N P T U V W Z

20/25 (1,321) (1,575) (1,194) (813) (813) (457) (178) (762) (584) (457) (584) (483) (1,422) (457) (254) (114) (76) (203) (35)

35/40 (1,524) (1,727) (1,194) (1,219) (813) (457) (178) (762) (991) (457) (991) (483) (1,422) (457) (254) (114) (76) (203) (35)

45/55 (1,702) (1,829) (1,397) (1,524) (914) (508) (229) (762) (1,295) (457) (1,295) (584) (1,422) (457) (305) (114) (76) (254) (35)

65/75 (1,575) (1,702) (1,397) (2,032) (914) (508) (229) (762) (1,803) (457) (1,803) (584) (1,422) (457) (305) (114) (76) (254) (35)

85/100 (1,727) (1,905) (1,575) (2,032) (1,219) (508) (381) (762) (1,803) (457) (1,803) (889) (1,422) (305) (305) (114) (102) (305) (40)

125/150/175 (1,905) (2,159) (1,829) (2,540) (1,372) (762) (381) (813) (2,311) (610) (2,311) (1,041) (1,422) (305) (305) (114) (102) (305) (40)

200/250 (2,032) (2,337) (1,829) (3,048) (1,524) (813) (381) (914) (2,819) (762) (2,819) (1,194) (1,422)

(305) (318) (114) (102) (305) (40)

275/300/325 (2,210) (2,413) (2,134) (3,556) (1,651) (813) (445) (914) (3,327) (762) (3,327) (1,321) (1,422) (305) (356) (114) (102) (356) (40)

350/400 (2,337) (2,565) (2,540) (4,064) (1,778) (813) (508) (914) (3,759) (762) (3,759) (1,448) (1,422) - (292) (152) (152) (406) (51)

500/600 (2,718) (2,972) (3,581) (4,572) (2,032) (813) (406) (914) (4,267) (1,219) (4,267) (1,702) (1,422) - (356) (152) (152) (457) (51)

OPTION

PUFF

DOOR

W

U

E

T

E

U

SUPPLY AIR

OPTION

G

P

K

F

N

MINIMUM

CLEARANCE

SUPPLY AIR

OPTION

20/25 35/40 45/55 65/75 85/100 125/150/175 200/250 275/300/325 350/400 500/600

Base Weight Lbs. 1,510 1,900 2,375 3,055 3,810 5,335 6,700 8,590 10,280 15,170

with V-Bank Filter Rack 1,675 1,980 2,480 3,220 3,990 5,390 6,765 8,655 10,365 15,295

Base Weight (kg) (685) (862) (1077) (1386) (1728) (2420) (3039) (3896) (4663) (6881)

with V-Bank Filter Rack (760) (898) (1125) (1461) (1810) (2445) (3069) (3926) (4702) (6938)

Note: Dimension A1, Blower Section, includes standard at lter rack. Optional angled lter rack may

be substituted at manufacturer’s discretion. Angle lter rack section does not change unit dimensions.

Dimension A2 indicates length of blower cabinet with V-Bank Filters.

Form S-PCD Page 11

Page 12

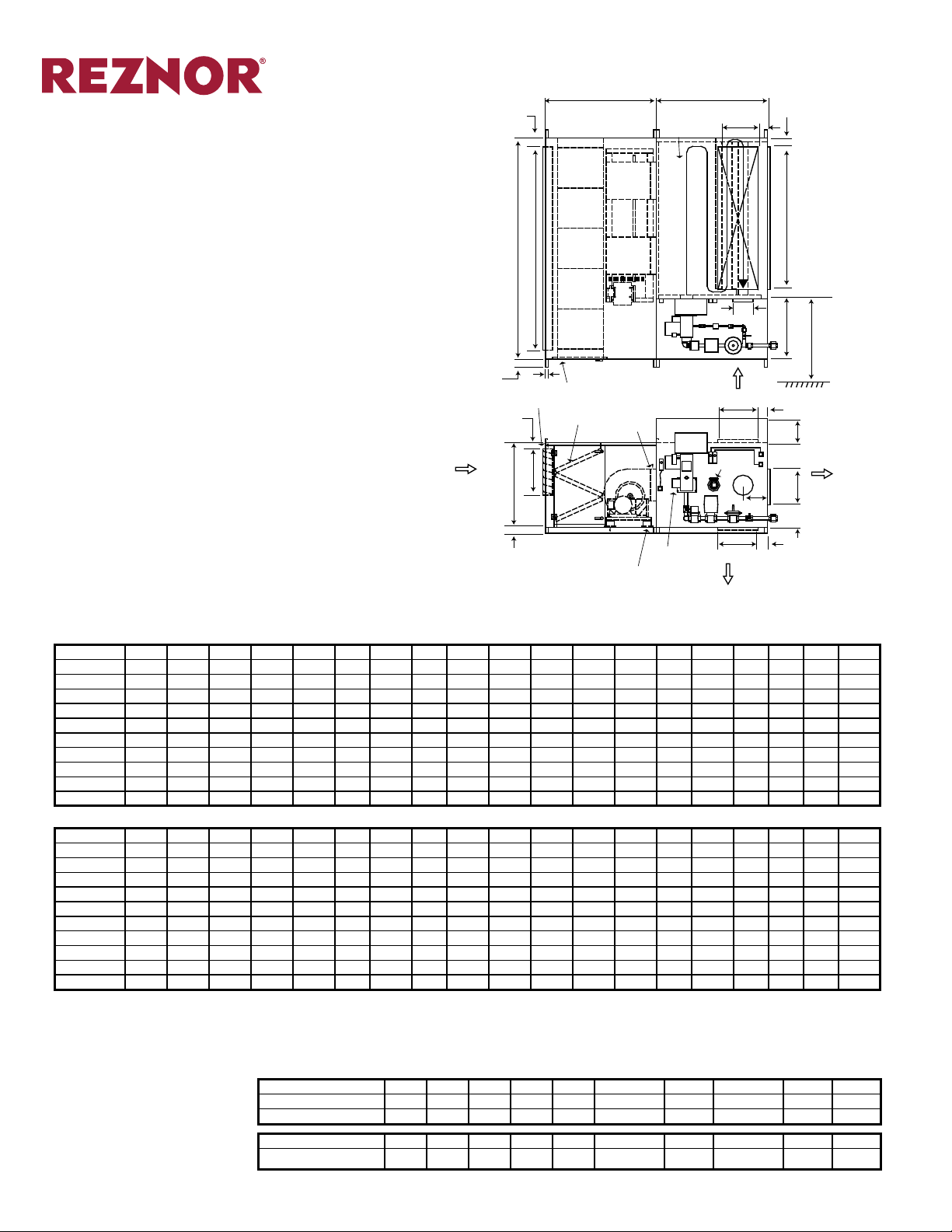

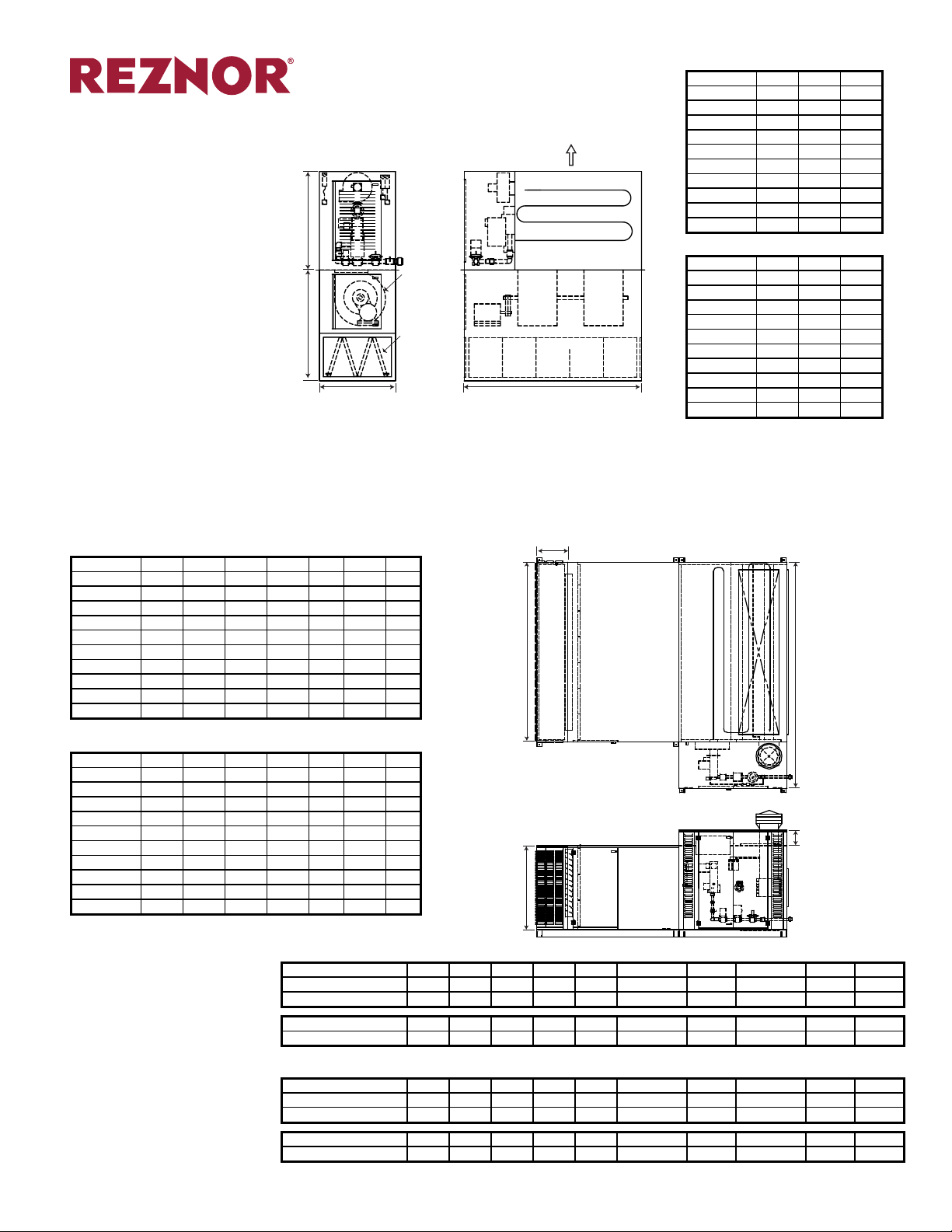

HPCDH Basic Horizontal Unit (Indoor Unit)

Burner Section and Blower/Filter Section only

±1/8” (3mm)

DIMENSIONS (cont’d)

U

C

L

BLOWER/FILTER

SECTION

2

A1, A

BLOWERS

TOP VIEW

FOUR PASS

COMBUSTION

CHAMBER

Page Number _______ of ______

HEAT EXCHANGER

SECTION

B

E

U

H

COMBUSTION PATH

MOTOR

W

G

N

MINIMUM

CLEARANCE

Typ. 4”

(102mm)

OUTDOOR AIR

OUTDOOR

AIR

FLOW

DAMPER

(76mm)

D

HINGED DOOR

C/W

ACCESS

Z

HANDLE

3”

FILTERS

FLEX

CONN.

M

SUPPLY AIR

OPTION

CONTROL

PANEL

PUFF

DOOR

E

U

P

SUPPLY AIR

K

T

OPTION

F

V

U

E

SUPPLY AIR

OPTION

Dimensions ±1/8”

Sizes A

SIDE VIEW

SPRING

ISOLATOR

* Burner Section and Blower Section on Sizes 65 and greater

are split and shipped separately for eld attachment.

1

2

A

B C D E F G H K L M N P T U V W Z

POWER

BURNER

20/25 37 52 47 62 38 18 9 30 23 18 53 19 56 12 10 4 1/2 3 8 1 3/8

35/40 40 55 47 78 38 18 9 30 39 18 69 19 56 12 10 4 1/2 3 8 1 3/8

45/55 47 60 55 90 42 20 11 30 51 18 81 23 56 12 12 4 1/2 3 10 1 3/8

65/75 47 55 55 110 42 20 12 30 71 18 101 23 56 8 12 4 1/2 3 10 1 3/8

85/100 50 60 62 110 54 20 18 30 71 18 101 35 56 4 12 4 1/2 4 12 1 9/16

125/150/175 57 84 72 132 60 30 18 32 91 24 123 41 56 6 12 4 1/2 4 12 1 9/16

200/250 60 90 72 156 66 32 17 1/2 36 111 30 147 47 56 6 12 1/2 4 1/2 4 12 1 9/16

275/300/325 65 95 84 176 71 32 20 36 131 30 167 52 56 6 14 4 1/2 4 14 1 9/16

350/400 68 98 100 196 76 32 27 1/2 36 148 30 184 57 56 - 11 1/2 6 6 16 2

500/600 77 102 141 216 86 32 21 36 168 48 204 67 56 - 14 6 6 18 2

Dimensions (±3mm)

Sizes A

1

2

A

B C D E F G H K L M N P T U V W Z

20/25 (940) (1,321) (1,194) (1,575) (965) (457) (229) (762) (584) (457) (1,346) (483) (1,422) (305) (254) (114) (76) (203) (35)

35/40 (1,016) (1,397) (1,194) (1,981) (965) (457) (229) (762) (991) (457) (1,753) (483) (1,422) (305) (254) (114) (76) (203) (35)

45/55 (1,194) (1,524) (1,397) (2,286) (1,067) (508) (279) (762) (1,295) (457) (2,057) (584) (1,422) (305) (305) (114) (76) (254) (35)

65/75 (1,194) (1,397) (1,397) (2,794) (1,067) (508) (305) (762) (1,803) (457) (2,565) (584) (1,422) (203) (305) (114) (76) (254) (35)

85/100 (1,270) (1,524) (1,575) (2,794) (1,372) (508) (457) (762) (1,803) (457) (2,565) (889) (1,422) (102) (305) (114) (102) (305) (40)

125/150/175 (1,448) (2,134) (1,829) (3,353) (1,524) (762) (457) (813) (2,311) (610) (3,124) (1,041) (1,422) (152) (305) (114) (102) (305) (40)

200/250 (1,524) (2,286) (1,829) (3,962) (1,676) (813) (445) (914) (2,819) (762) (3,734) (1,194) (1,422)

(152) (318) (114) (102) (305) (40)

275/300/325 (1,651) (2,413) (2,134) (4,470) (1,803) (813) (508) (914) (3,327) (762) (4,242) (1,321) (1,422) (152) (356) (114) (102) (356) (40)

350/400 (1,727) (2,489) (2,540) (4,978) (1,930) (813) (699) (914) (3,759) (762) (4,674) (1,448) (1,422) - (292) (152) (152) (406) (51)

500/600 (1,956) (2,591) (3,581) (5,486) (2,184) (813) (533) (914) (4,267) (1,219) (5,182) (1,702) (1,422) - (356) (152) (152) (457) (51)

Note: Dimension A1, Blower Section, includes at lter rack. Optional angled lter rack does not change

unit dimensions. Dimension A2 indicates length of blower cabinet with V-Bank Filters.

20/25 35/40 45/55 65/75 85/100 125/150/175 200/250 275/300/325 350/400 500/600

Base Weight Lbs. 1,770 2,265 2,865 3,565 2,548 5,880 7,365 9,275 11,070 16,025

with V-Bank Filter Rack 2,020 2,390 3,045 3,805 2,798 5,950 7,455 9,350 11,160 16,190

Base Weight (kg) (803) (1027) (1300) (1617) (1156) (2667) (3341) (4207) (5021) (7269)

with V-Bank Filter Rack (916) (1084) (1381) (1726) (1269) (2699) (3382) (4241) (5062) (7344)

Form S-PCD Page 12

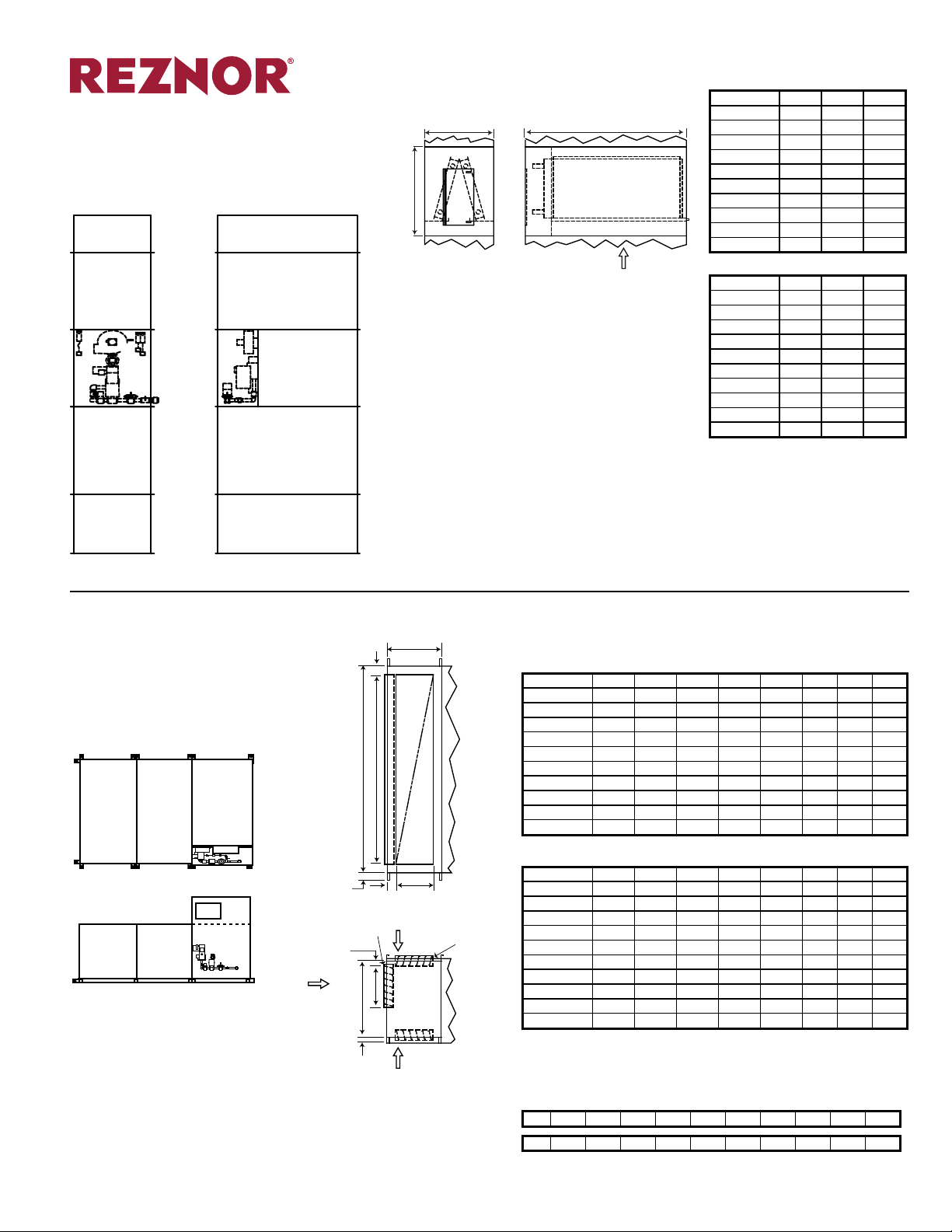

Page 13

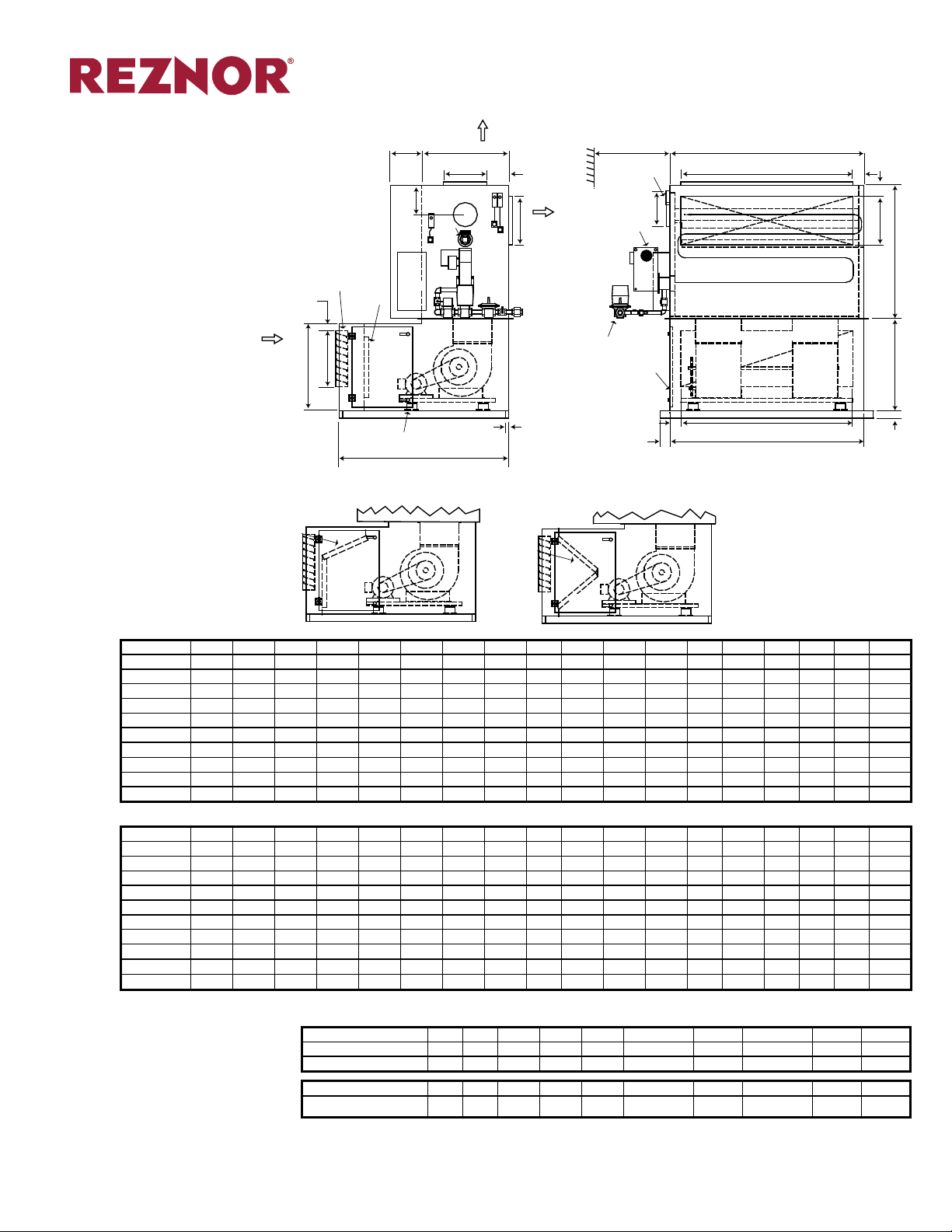

ANGLED

DIMENSIONS (cont’d)

Page Number _______ of ______

PCDV Basic Vertical Unit (“L” Conguration)

Burner Section and Blower Section only

±1/8” (3mm)

OUTDOOR AIR

DAMPER

3”

(76mm)

OUTDOOR

FLOW

FILTER

AIR

M

D

MOTOR

FILTER

MOTOR

SPRING

ISOLATOR

P

T

E

SUPPLY AIR

OPTION

F

PUFF

DOOR

N

MINIMUM

L

G

C

L

K

SUPPLY AIR

OPTION

CONNECTION

Z

CLEARANCE

GRAVITY VENT

CONNECTION

POWER

BURNER

GAS

HINGED DOOR

ACCESS

HANDLE

W

C/W

U

4”

(102mm)

C

H

COMBUSTION PATH

HEAT EXCHANGER

SECTION

BLOWER/FILTER

SECTION

BLOWERS

H

C

U

U

K

B

A

V

END VIEWSIDE VIEW

V-BANK

FILTER

MOTOR

Dimensions ±1/8”

Sizes A B C D E F G H K L M N P T U V W Z

20/25 34 47 32 32 64 18 7 23 18 32 19 56 15 10 4 1/2 3 8 1 3/8

35/40 34 47 48 32 64 18 7 39 18 32 19 56 15 10 4 1/2 3 8 1 3/8

45/55 38 55 60 36 70 18 9 51 20 36 23 56 10 12 4 1/2 3 10 1 3/8

65/75 38 55 80 36 70 18 9 71 20 36 23 56 10 12 4 1/2 3 10 1 3/8

85/100 50 62 80 48 82 18 15 71 20 48 35 56 10 12 4 1/2 4 12 1 9/16

125/150/175 56 72 100 54 90 24 15 91 30 54 41 56 10 12 4 1/2 4 12 1 9/16

200/250 62 72 120 60 95 30 15 111 32 60 47 56 10 12 1/2 4 1/2 4 12 1 9/16

275/300/325 67 84 140 65 96 30 17 1/2 131 32 65 52 56 - 14 4 1/2 4 14 1 9/16

350/400 72 100 160 70 107 30 20 148 32 70 57 56 - 11 1/2 6 6 16 2

500/600 82 141 180 80 117 48 16 168 32 80 67 56 - 14 6 6 18 2

Dimensions (±3mm)

Sizes A B C D E F G H K L M N P T U V W Z

20/25 (864) (1,194) (813) (813) (1,626) (457) (178) (584) (457) (813) (483) (1,422) (381) (254) (114) (76) (203) (35)

35/40 (864) (1,194) (1,219) (813) (1,626) (457) (178) (991) (457) (813) (483) (1,422) (381) (254) (114) (76) (203) (35)

45/55 (965) (1,397) (1,524) (914) (1,778) (457) (229) (1,295) (508) (914) (584) (1,422) (254) (305) (114) (76) (254) (35)

65/75 (965) (1,397) (2,032) (914) (1,778) (457) (229) (1,803) (508) (914) (584) (1,422) (254) (305) (114) (76) (254) (35)

85/100 (1,270) (1,575) (2,032) (1,219) (2,083) (457) (381) (1,803) (508) (1,219) (889) (1,422) (254) (305) (114) (102) (305) (40)

125/150/175 (1,422) (1,829) (2,540) (1,372) (2,286) (610) (381) (2,311) (762) (1,372) (1,041) (1,422) (254) (305) (114) (102) (305) (40)

200/250 (1,575) (1,829) (3,048) (1,524) (2,413) (762) (381) (2,819) (813) (1,524) (1,194) (1,422) (254) (318) (114) (102) (305) (40)

275/300/325 (1,702) (2,134) (3,556) (1,651) (2,438) (762) (445) (3,327) (813) (1,651) (1,321) (1,422) - (356) (114) (102) (356)

(40)

350/400 (1,829) (2,540) (4,064) (1,778) (2,718) (762) (508) (3,759) (813) (1,778) (1,448) (1,422) - (292) (152) (152) (406) (51)

500/600 (2,083) (3,581) (4,572) (2,032) (2,972) (1,219) (406) (4,267) (813) (2,032) (1,702) (1,422) - (356) (152) (152) (457) (51)

20/25 35/40 45/55 65/75 85/100 125/150/175 200/250 275/300/325 350/400 500/600

Base Weight Lbs. 1,510 1,900 2,375 3,055 3,810 5,335 6,700 8,590 10,280 15,170

with V-Bank Filter Rack 1,675 1,980 2,480 3,220 3,990 5,390 6,765 8,655 10,365 15,295

Base Weight (kg) (685) (862) (1077) (1386) (1728) (2420) (3039) (3896) (4663) (6881)

with V-Bank Filter Rack (760) (898) (1125) (1461) (1810) (2445) (3069) (3926) (4702) (6938)

Form S-PCD Page 13

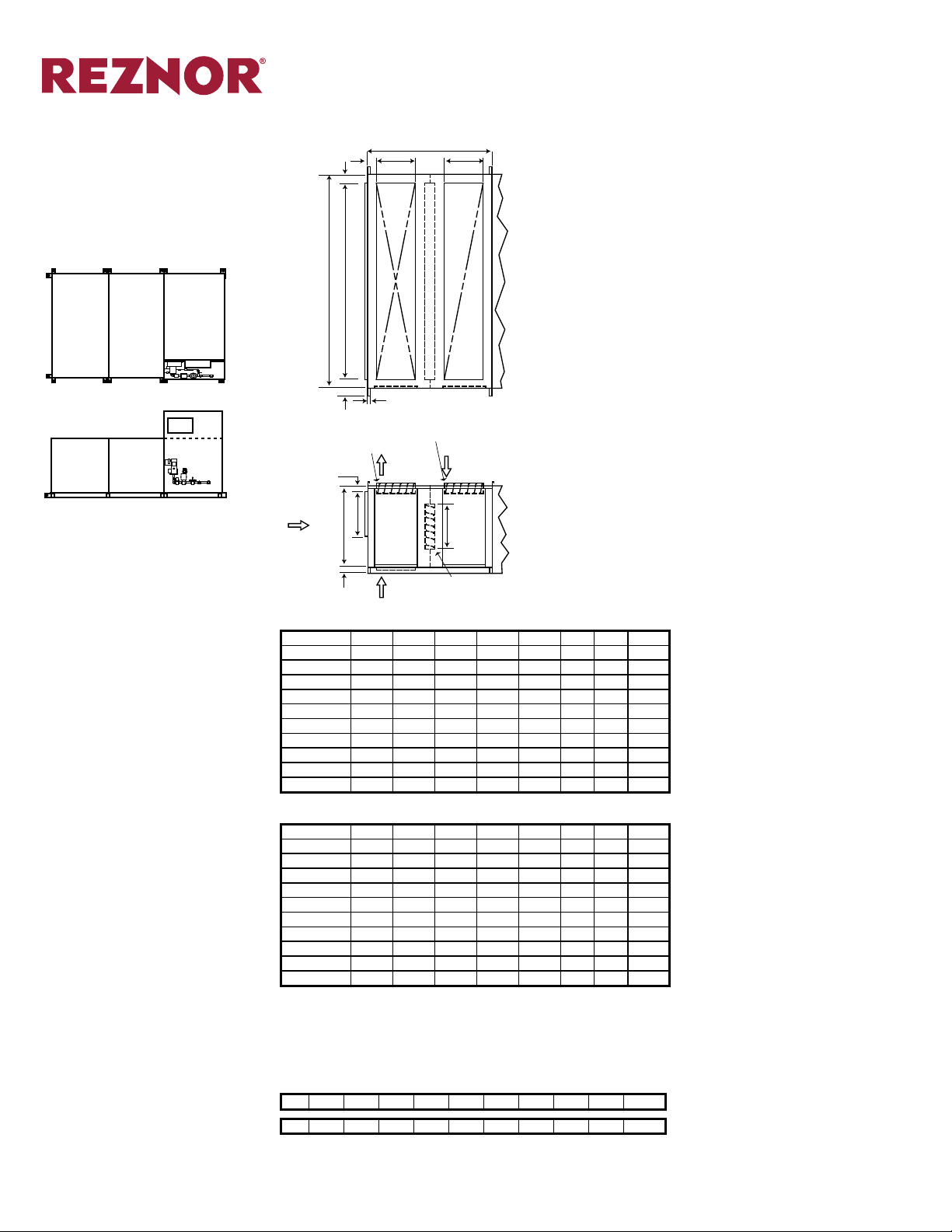

Page 14

HPCDV Basic Vertical Unit (“L” Conguration)

Burner Section and Blower Section only

±1/8” (3mm)

OUTDOOR AIR

DAMPER

3”

FILTER

M

MOTOR

SPRING

ISOLATOR

OUTDOOR

AIR

FLOW

(76mm)

D

DIMENSIONS (cont’d)

SUPPLY AIR

OPTION

P

T

E

PUFF

DOOR

L

F

G

C

L

K

SUPPLY AIR

OPTION

GAS

CONNECTION

HINGED DOOR

C/W

ACCESS

Z

HANDLE

(102mm)

GRAVITY VENT

CONNECTION

POWER

BURNER

U

4”

Page Number _______ of ______

N

W

C

H

COMBUSTION PATH

HEAT EXCHANGER

SECTION

BLOWER/FILTER

SECTION

BLOWERS

H

C

U

U

K

B

A

V

END VIEWSIDE VIEW

V-BANK

FILTER

MOTOR

Dimensions ±1/8”

Sizes A B C D E F G H K L M N P T U V W Z

20/25 40 47 62 38 64 18 10 23 18 38 19 56 15 10 4 1/2 3 8 1 3/8

35/40 40 47 78 38 64 18 10 39 18 38 19 56 15 10 4 1/2 3 8 1 3/8

45/55 44 55 90 42 70 18 12 51 20 42 23 56 10 12 4 1/2 3 10 1 3/8

65/75 44 55 110 42 70 18 12 71 20 42 23 56 10 12 4 1/2 3 10 1 3/8

85/100 56 62 110 54 82 18 18 71 20 54 35 56 10 12 4 1/2 4 12 1 9/16

125/150/175 62 72 130 60 90 24 18 91 30 60 41 56 10 12 4 1/2 4 12 1 9/16

200/250 68 72 150 66 95 30 18 111 32 66 47 56 10 12 1/2 4 1/2 4 12 1 9/16

275/300/325 73 84 170 71 96 30 20 1/2 131 32 71 52 56 - 14 4 1/2 4 14 1 9/16

350/400 78 100 190 76 107 30 23 148 32 76 57 56 - 11 1/2 6 6 16 2

500/600 88 141 210 86 117 48 19 168 32 86 67 56 - 14 6 6 18 2

Dimensions (±3mm)

Sizes A B C D E F G H K L M N P T U V W Z

20/25 (1,016) (1,194) (1,575) (965) (1,626) (457) (254) (584) (457) (965) (483) (1,422) (381) (254) (114) (76) (203) (35)

35/40 (1,016) (1,194) (1,981) (965) (1,626) (457) (254) (991) (457) (965) (483) (1,422) (381) (254) (114) (76) (203) (35)

45/55 (1,118) (1,397) (2,286) (1,067) (1,778) (457) (305) (1,295) (508) (1,067) (584) (1,422) (254) (305) (114) (76) (254) (35)

65/75 (1,118) (1,397) (2,794) (1,067) (1,778) (457) (305) (1,803) (508) (1,067) (584) (1,422) (254) (305) (114) (76) (254) (35)

85/100 (1,422) (1,575) (2,794) (1,372) (2,083) (457) (457) (1,803) (508) (1,372) (889) (1,422) (254) (305) (114) (102) (305) (40)

125/150/175 (1,575) (1,829) (3,302) (1,524) (2,286) (610) (457) (2,311) (762) (1,524) (1,041) (1,422) (254) (305) (114) (102) (305) (40)

200/250 (1,727) (1,829) (3,810) (1,676) (2,413) (762) (457) (2,819) (813) (1,676) (1,194) (1,422) (254) (318) (114) (102) (305) (40)

275/300/325 (1,854) (2,134) (4,318) (1,803) (2,438) (762) (521) (3,327) (813) (1,803) (1,321) (1,422) - (356) (114) (102) (356)

(40)

350/400 (1,981) (2,540) (4,826) (1,930) (2,718) (762) (584) (3,759) (813) (1,930) (1,448) (1,422) - (292) (152) (152) (406) (51)

500/600 (2,235) (3,581) (5,334) (2,184) (2,972) (1,219) (483) (4,267) (813) (2,184) (1,702) (1,422) - (356) (152) (152) (457) (51)

20/25 35/40 45/55 65/75 85/100 125/150/175 200/250 275/300/325 350/400 500/600

Base Weight Lbs. 1,770 2,265 2,865 3,565 4,245 5,880 7,365 9,275 11,070 16,025

with V-Bank Filter Rack 2,020 2,390 3,045 3,805 4,495 5,950 7,455 9,350 11,160 16,190

Base Weight (kg) (803) (1027) (1300) (1617) (1926) (2667) (3341) (4207) (5021) (7269)

with V-Bank Filter Rack (916) (1084) (1381) (1726) (2039) (2699) (3382) (4241) (5062) (7344)

Form S-PCD Page 14

Page 15

Page Number _______ of ______

DIMENSIONS (cont’d)

HPCDV Basic Vertical Unit (“I” Conguration)

Burner Section and Blower Section only (Requires Mounting Base)

±1/8” (3mm)

B

BLOWER

A

FILTER

C

MOTOR

AIR

FLOW

COMBUSTION PATH

HEAT EXCHANGER

SECTION

BLOWER BLOWER

BLOWER/FILTER

SECTION

D

END VIEWSIDE VIEW

Dimensions ±1/8”

Sizes A B C

20/25 42 38 62

35/40 48 38 78

45/55 54 42 90

65/75 60 42 110

85/100 60 54 110

125/150/175 70 60 132

200/250 100 66 156

275/300/325 100 71 176

350/400 100 86 196

500/600 120 86 216

Dimensions (±3mm)

Sizes A B C

20/25 (1,067) (965) (1,575)

35/40 (1,219) (965) (1,981)

45/55 (1,372) (1,067) (2,286)

65/75 (1,524) (1,067) (2,794)

85/100 (1,524) (1,372) (2,794)

125/150/175 (1,778) (1,524) (3,353)

200/250 (2,540) (1,676) (3,962)

275/300/325 (2,540) (1,803) (4,470)

350/400 (2,540) (2,184) (4,978)

500/600 (3,048) (2,184) (5,486)

PCDH/HPCDH (Outdoor Unit)

Outdoor units include a weatherhousing that covers the control section. Weatherhousing roof slopes away from controls on sizes 125 and larger.

Outdoor unit shown here with optional Louvered Inlet Air Hood.

Vertical (“L” Conguration) outdoor units have the same louvered inlet hood sizes. The weatherhousing conforms to the size of the controls section.

±1/8” (3mm)

Dimensions ±1/8”

Sizes A

20/25 32 38 32 62 10 62 18

35/40 32 38 48 78 10 78 18

45/55 36 42 60 90 10 90 18

65/75 36 42 80 110 10 110 18

85/100 48 54 80 110 10 110 12

125/150/175 54 60 100 132 24 132 12

200/250 60 66 120 156 24 156 12

275/300/325 65 71 140 176 24 176 12

350/400 70 76 160 196 24 196 -

500/600 80 86 180 216 24 216 -

Dimensions (±3mm)

Sizes A

20/25 (813) (965) (813) (1,575) (254) (1,575) (457)

35/40 (813) (965) (1,219) (1,981) (254) (1,981) (457)

45/55 (914) (1,067) (1,524) (2,286) (254) (2,286) (457)

65/75 (914) (1,067) (2,032) (2,794) (254) (2,794) (457)

85/100 (1,219) (1,372) (2,032) (2,794) (254) (2,794) (305)

125/150/175 (1,372) (1,524) (2,540) (3,353) (610) (3,353) (305)

200/250 (1,524) (1,676) (3,048) (3,962) (610) (3,962) (305)

275/300/325 (1,651) (1,803) (3,556) (4,470) (610) (4,470) (305)

350/400 (1,778) (1,930) (4,064) (4,978) (610) (4,978) -

500/600 (2,032) (2,184) (4,572) (5,486) (610) (5,486) -

Note: A1 and B1 are dimensions for Model PCDH. A2 and B2 are dimensions for

Model HPCDH

1

2

1

A

B

1

2

A

B

2

B

C D E

1

2

B

C D E

Weight PCDH - lbs. (kg)

20/25 35/40 45/55 65/75 85/100 125/150/175 200/250 275/300/325 350/400 500/600

Base Unit 1,750 2,140 2,645 3,325 4,110 5,685 7,125 9,090 10,930 15,845

with V-Bank Filter Rack 1,915 2,220 2,750 3,490 4,290 5,740 7,190 9,155 11,015 15,970

Base Unit (794) (971) (1200) (1508) (1864) (2579) (3232) (4123) (4958) (7187)

with V-Bank Filter Rack (869) (1007) (1247) (1583) (1946) (2604) (3261) (4153) (4996) (7244)

LOUVERED INLET

HOOD SECTION

C

B

A

D

E

HWeight PCDH - lbs. (kg)

20/25 35/40 45/55 65/75 85/100 125/150/175 200/250 275/300/325 350/400 500/600

Base Weight Lbs. 2,010 2,505 3,135 3,835 2,848 6,230 7,790 9,775 11,720 16,700

with V-Bank Filter Rack 2,260 2,630 3,315 4,075 3,098 6,300 7,880 9,850 11,810 16,865

Base Weight (kg) (912) (1136) (1422) (1740) (1292) (2826) (3534) (4434) (5316) (7575)

with V-Bank Filter Rack (1025) (1193) (1504) (1848) (1405) (2858) (3574) (4468) (5357) (7650)

Form S-PCD Page 15

Page 16

SIDE VIEW

DIMENSIONS (cont’d)

Page Number _______ of ______

PCD Accessories

Blower/Filter/Coil Section

±1/8” (3mm)

Displayed on the following pages are accessory modules for Model PCD.

The illustration on the left will show the relative location and size of the module. For example, this page

shows the Blower/Filter/Coil Section which replaces

the Blower/Filter section. Other optional sections will

be shown attached to the downstream air side of the

Blower Section

Dimensional drawings and a dimension table in inches (mm) are also shown.

BLOWER/

FILTER/

COIL

SECTION

HEAT

EXCHANGER

SECTION

BLOWER/

FILTER/

COIL

SECTION

HEAT

EXCHANGER

SECTION

PCDH Conguration HPCDH Conguration

CONTROL

BOX

CONTROL

BOX

(102mm)

OUTDOOR

AIR

FLOW

B

TYP. 4”

(76mm)

C

F

K

D

3”

E

FILTER

BLOWER/FILTER/COIL

H

J

HINGED DOOR

ACCESS

HANDLE

TOP VIEW

OUTDOOR AIR

DAMPER

G

DX

DRAIN

COIL

PAN

SECTION

A

C/W

MOTOR

SPRING

ISOLATOR

BLOWER

Dimensions ±1/8”

Sizes A

A

B

B

C

C

D

2

D

E F G

1

2

1

G

H

2

H

J K

1

2

1

2

1

2

1

20/25 82 67 32 62 32 38 23 53 19 3 23 29 22 47 1 3/8 4 1/2

35/40 90 70 48 78 32 38 39 69 19 3 23 29 23 63 1 3/8 4 1/2

45/55 97 77 60 90 36 42 51 81 23 3 27 33 45 75 1 3/8 4 1/2

65/75 92 72 80 110 36 42 71 101 23 3 27 33 65 95 1 3/8 4 1/2

85/100 98 80 80 110 48 54 71 101 35 4 39 44 65 95 1 9/16 4 1/2

125/150/175 102 87 100 132 54 60 91 123 41 4 45 51 85 117 1 9/16 4 1/2

200/250 100 90 120 156 60 66 111 147 47 4 51 57 102 141 1 9/16 4 1/2

275/300/325 102 95 140 176 65 71 131 167 52 4 56 62 125 161 1 9/16 4 1/2

350/400 102 98 160 196 70 76 148 184 57 6 61 67 145 181 2 6

500/600 108 102 180 220 80 86 168 204 67 6 71 77 165 201 2 6

Dimensions (±3mm)

Sizes A

A

B

B

C

C

D

2

D

E F G

1

2

1

G

H

2

H

J K

1

2

1

2

1

2

1

20/25 (2,083) (1,702) (813) (1,575) (813) (965) (584) (1,346) (483) (76) (584) (737) (559) (1,194) (35) (114)

35/40 (2,286) (1,778) (1,219) (1,981) (813) (965) (991) (1,753) (483) (76) (584) (737) (584) (1,600) (35) (114)

45/55 (2,464) (1,956) (1,524) (2,286) (914) (1,067) (1,295) (2,057) (584) (76) (686) (838) (1,143) (1,905) (35) (114)

65/75 (2,337) (1,829) (2,032) (2,794) (914) (1,067) (1,803) (2,565) (584) (76) (686) (838) (1,651) (2,413) (35) (114)

85/100 (2,489) (2,032) (2,032) (2,794) (1,219) (1,372) (1,803) (2,565) (889) (102) (991) (1,118) (1,651) (2,413) (40) (114)

125/150/175 (2,591) (2,210) (2,540) (3,353) (1,372) (1,524) (2,311) (3,124) (1,041) (102) (1,143) (1,295) (2,159) (2,972) (40) (114)

200/250 (2,540) (2,286) (3,048) (3,962) (1,524) (1,676) (2,819) (3,734) (1,194) (102) (1,295) (1,448) (2,591) (3,581) (40) (114)

275/300/325 (2,591) (2,413) (3,556) (4,470) (1,651) (1,803) (3,327) (4,242) (1,321) (102) (1,422) (1,575) (3,175) (4,089) (40) (114)

350/400 (2,591) (2,489) (4,064) (4,978) (1,778) (1,930) (3,759) (4,674) (1,448) (152) (1,549) (1,702) (3,683) (4,597) (51) (152)

500/600 (2,743) (2,591) (4,572) (5,588) (2,032) (2,184) (4,267) (5,182) (1,702) (152) (1,803) (1,956) (4,191) (5,105) (51) (152)

Note: A1, B1, etc. are dimensions for Model PCDH. A2, B2, etc. are dimensions for Model HPCDH

Form S-PCD Page 16

Page 17

HPCDV Accessories (“I” Conguration) (cont’d)

AIR FLOW

Cooling Coil Cabinet (Indoor/Outdoor)

±1/8” (3mm)

DISCHARGE AIR

SECTION

COOLING COIL

SECTION

BURNER

SECTION

BLOWER/FILTER

SECTION

DIMENSIONS (cont’d)

B

A

C

FLOW

END VIEWSIDE VIEW

AIR

Page Number _______ of ______

Dimensions ±1/8”

Sizes A B C

20/25 42 38 62

35/40 48 38 78

45/55 54 42 90

65/75 60 42 110

85/100 60 54 110

125/150/175 70 60 132

200/250 100 66 156

275/300/325 100 71 176

350/400 100 86 196

500/600 120 86 216

Dimensions (±3mm)

Sizes A B C

20/25 (1,067) (965) (1,575)

35/40 (1,219) (965) (1,981)

45/55 (1,372) (1,067) (2,286)

65/75 (1,524) (1,067) (2,794)

85/100 (1,524) (1,372) (2,794)

125/150/175 (1,778) (1,524) (3,353)

200/250 (2,540) (1,676) (3,962)

275/300/325 (2,540) (1,803) (4,470)

350/400 (2,540) (2,184) (4,978)

500/600 (3,048) (2,184) (5,486)

HPCDH Accessories (cont’d)

Mixing Box

±1/8” (3mm)

BOX

BLOWER/

FILTER

SECTION

HEAT

EXCHANGER

SECTION

CONTROL

BOX

MIXING

SECTION

INLET AIR

MOUNTING BASE

TYP. 4”

(102mm)

(76mm)

FLOW

B

DAMPER

3”

C

MIXING BOX

G

D

G

TOP VIEW

E

SECTION

A

F

AIR FLOW

OPTION

DAMPER

Dimensions ±1/8”

Sizes A B C D E F G H

20/25 27 62 38 53 19 3 4 1/2 18

35/40 27 78 38 69 19 3 4 1/2 18

45/55 29 90 42 81 23 3 4 1/2 20

65/75 29 110 42 101 23 3 4 1/2 20

85/100 29 110 54 101 35 4 4 1/2 20

125/150/175 39 132 60 123 41 4 4 1/2 30

200/250 41 156 66 147 47 4 4 1/2 32

275/300/325 41 176 71 167 52 4 4 1/2 32

350/400 44 196 76 184 57 6 6 32

500/600 44 216 86 204 67 6 6 32

Dimensions (±3mm)

Sizes A B C D E F G H

20/25 (686) (1,575) (965) (1,346) (483) (76) (114) (457)

35/40 (686) (1,981) (965) (1,753) (483) (76) (114) (457)

45/55 (737) (2,286) (1,067) (2,057) (584) (76) (114) (508)

65/75 (737) (2,794) (1,067) (2,565) (584) (76) (114) (508)

85/100 (737) (2,794) (1,372) (2,565) (889) (102) (114) (508)

125/150/175 (991) (3,353) (1,524) (3,124) (1,041) (102) (114) (762)

200/250 (1,041) (3,962) (1,676) (3,734) (1,194) (102) (114) (813)

275/300/325 (1,041) (4,470) (1,803) (4,242) (1,321) (102) (114) (813)

350/400 (1,118) (4,978) (1,930) (4,674) (1,448) (152) (152) (813)

500/600 (1,118) (5,486) (2,184) (5,182) (1,702) (152) (152) (813)

H

AIR FLOW

OPTION

SIDE VIEW

Weight - Mixing Box only (Add to base unit weight)

lbs 200 260 335 420 495 710 935 1055 1250 1555

(kg) (91) (118) (152) (191) (225) (322) (424) (479) (567) (705)

Form S-PCD Page 17

Page 18

PCDH/PCDV Accessories (cont’d)

Mixing Box

±1/8” (3mm)

BOX

BLOWER/

FILTER

SECTION

OR

BLOWER/

FILTER/

COIL

SECTION

EXCHANGER

SECTION

CONTROL

BOX

CONTROL

BOX

HEAT

MIXING

SECTION

TYP. 4”

(102mm)

(76mm)

AIR FLOW

OPTION

DIMENSIONS (cont’d)

MIXING BOX

SECTION

A

G

B

D

G

H

TOP VIEW

DAMPER

3”

C

F

E

SIDE VIEW

BURNER

SECTION

AIR FLOW

OPTION

AIR FLOW

OPTION

DAMPER

Page Number _______ of ______

Dimensions ±1/8”

Sizes A B C D E F G H

20/25 27 32 32 23 19 3 4 1/2 18

35/40 27 48 32 39 19 3 4 1/2 18

45/55 29 60 36 51 23 3 4 1/2 20

65/75 29 80 36 71 23 3 4 1/2 20

85/100 29 80 48 71 35 4 4 1/2 20

125/150/175 39 100 54 91 41 4 4 1/2 30

200/250 41 120 60 111 47 4 4 1/2 32

275/300/325 41 140 65 131 52 4 4 1/2 32

350/400 44 160 70 148 57 6 6 32

500/600 44 180 80 168 67 6 6 32

Dimensions (±3mm)

Sizes A B C D E F G H

20/25 (686) (813) (813) (584) (483) (76) (114) (457)

35/40 (686) (1,219) (813) (991) (483) (76) (114) (457)

45/55 (737) (1,524) (914) (1,295) (584) (76) (114) (508)

65/75 (737) (2,032) (914) (1,803) (584) (76) (114) (508)

85/100 (737) (2,032) (1,219) (1,803) (889) (102) (114) (508)

125/150/175 (991) (2,540) (1,372) (2,311) (1,041) (102) (114) (762)

200/250 (1,041) (3,048) (1,524) (2,819) (1,194) (102) (114) (813)

275/300/325 (1,041) (3,556) (1,651) (3,327) (1,321) (102) (114) (813)

350/400 (1,118) (4,064) (1,778) (3,759) (1,448) (152) (152) (813)

500/600 (1,118) (4,572) (2,032) (4,267) (1,702) (152) (152) (813)

Weight - Mixing Box only (Add to base unit weight)

lbs 200 260 335 420 495 710 935 1055 1250 1555

(kg) (91) (118) (152) (191) (225) (322) (424) (479) (567) (705)

MIXING BOX

SECTION

BLOWER/FILTER

SECTION

PCDH Accessories (cont’d)

Mixing Box w/Relief (Indoor)

±1/8” (3mm)

BOX

BLOWER/

FILTER

SECTION

HEAT

EXCHANGER

SECTION

CONTROL

BOX

MIXING

w/RELIEF

SECTION

(76mm)

RETURN AIR

FLOW

D

B

TYP. 4”

(102mm)

RELIEF AIR

DAMPER

3”

C

F

BLOWER/FILTER

SECTION

MIXING BOX w/RELIEF

G

G

H

RELIEF

AIR FLOW

E

RETURN AIR

OPTION

SECTION

TOP VIEW

FRESH AIR

DAMPER

SIDE VIEW

A

EE

OUTDOOR

AIR FLOW

E

RETURN AIR

DAMPER

Dimensions ±1/8”

Sizes A B C D E F G H

20/25 27 32 32 23 19 3 4 1/2 1 3/8

35/40 27 48 32 39 19 3 4 1/2 1 3/8

45/55 29 60 36 51 23 3 4 1/2 1 3/8

65/75 29 80 36 71 23 3 4 1/2 1 3/8

85/100 29 80 48 71 35 4 4 1/2 1 9/16

125/150/175 39 100 54 91 41 4 4 1/2 1 9/16

200/250 41 120 60 111 47 4 4 1/2 1 9/16

275/300/325 41 140 65 131 52 4 4 1/2 1 9/16

350/400 44 160 70 148 57 6 6 2

500/600 44 180 80 168 67 6 6 2

Dimensions (±3mm)

Sizes A B C D E F G H

20/25 (686) (813) (813) (584) (483) (76) (114) (35)

35/40 (686) (1,219) (813) (991) (483) (76) (114) (35)

45/55 (737) (1,524) (914) (1,295) (584) (76) (114) (35)

65/75 (737) (2,032) (914) (1,803) (584) (76) (114) (35)

85/100 (737) (2,032) (1,219) (1,803) (889) (102) (114) (40)

125/150/175 (991) (2,540) (1,372) (2,311) (1,041) (102) (114) (40)

200/250 (1,041) (3,048) (1,524) (2,819) (1,194) (102) (114) (40)

275/300/325 (1,041) (3,556) (1,651) (3,327) (1,321) (102) (114) (40)

350/400 (1,118) (4,064) (1,778) (3,759) (1,448) (152) (152) (51)

500/600 (1,118) (4,572) (2,032) (4,267) (1,702) (152) (152) (51)

Weight - Mixing Box only (Add to base unit weight)

lbs 220 290 380 480 580 825 1100 1270 1500 1875

(kg) (100) (132) (172) (218) (263) (374) (499) (576) (680) (851)

Form S-PCD Page 18

Page 19

DIMENSIONS (cont’d)

Page Number _______ of ______

PCDH Accessories (cont’d)

Mixing Box w/Relief (Outdoor)

±1/8” (3mm)

RELIEF

AIR HOOD

RETURN

AIR

BLOWER

SECTION

MIXING

w/RELIEF

SECTION

FRESH

AIR HOOD

BOX

BLOWER/

FILTER

SECTION

EXCHANGER

SECTION

CONTROL

BOX

HEAT

TYP. 4”

(102mm)

RETURN AIR

OPTION

RELIEF

HOOD

B

INLET

HOOD

(102mm)

C

H

4”

E

MIXING BOX

w/RELIEF

SECTION

A

RELIEF

AIR FLOW

D

(DxE)

RETURN AIR DAMPER

D

OUTDOOR

AIR FLOW

TOP VIEW

SIDE VIEW

G

F

F

G

Dimensions ±1/8”

Sizes A B C D E F G H

20/25 29 32 32 20 24 4 1/2 28 3

35/40 39 48 32 30 24 4 1/2 28 3

45/55 45 60 36 36 28 4 1/2 31 3

65/75 59 80 36 50 28 4 1/2 31 3

85/100 51 80 48 42 40 4 1/2 39 4

125/150/175 69 100 54 60 46 4 1/2 53 4

200/250 73 120 60 64 52 4 1/2 59 4

275/300/325 79 140 65 70 57 4 1/2 64 4

350/400 90 160 70 78 62 6 69 6

500/600 102 180 80 90 72 6 79 6

Dimensions (±3mm)

Sizes A B C D E F G H

20/25 (737) (813) (813) (508) (610) (114) (711) (76)

35/40 (991) (1,219) (813) (762) (610) (114) (711) (76)

45/55 (1,143) (1,524) (914) (914) (711) (114) (787) (76)

65/75 (1,499) (2,032) (914) (1,270) (711) (114) (787) (76)

85/100 (1,295) (2,032) (1,219) (1,067) (1,016) (114) (991) (102)

125/150/175 (1,753) (2,540) (1,372) (1,524) (1,168) (114) (1,346) (102)

200/250 (1,854) (3,048) (1,524) (1,626) (1,321) (114) (1,499) (102)

275/300/325 (2,007) (3,556) (1,651) (1,778) (1,448) (114) (1,626) (102)

350/400 (2,286) (4,064) (1,778) (1,981) (1,575) (152) (1,753) (152)

500/600 (2,591) (4,572) (2,032) (2,286) (1,829) (152) (2,007) (152)

Weight - Mixing Box only (Add to base unit weight)

lbs 220 290 380 480 580 825 1100 1270 1500 1875

(kg) (100) (132) (172) (218) (263) (374) (499) (576) (680) (851)

Form S-PCD Page 19

Page 20

DIMENSIONS (cont’d)

Page Number _______ of ______

HPCDH Accessories (cont’d)

Mixing Box w/Relief

±1/8” (3mm)

BOX

BLOWER/

FILTER

SECTION

HEAT

EXCHANGER

SECTION

CONTROL

BOX

MIXING

w/RELIEF

SECTION

(102mm)

(76mm)

RETURN AIR

FLOW

B

TYP. 4”

RELIEF AIR

DAMPER

3”

C

G

G

D

E

MIXING BOX w/RELIEF

SECTION

A

EE

TOP VIEW

H

FRESH AIR

DAMPER

RELIEF

AIR FLOW

OUTDOOR

AIR FLOW

E

F

RETURN AIR

OPTION

SIDE VIEW

RETURN AIR

DAMPER

Dimensions ±1/8”

Sizes A B C D E F G H

20/25 60 62 38 53 19 3 4 1/2 1 3/8

35/40 60 78 38 69 19 3 4 1/2 1 3/8

45/55 69 90 42 81 23 3 4 1/2 1 3/8

65/75 69 110 42 101 23 3 4 1/2 1 3/8

85/100 93 110 54 101 35 4 4 1/2 1 9/16

125/150/175 105 132 60 123 41 4 4 1/2 1 9/16

200/250 117 156 66 147 47 4 4 1/2 1 9/16

275/300/325 127 176 71 167 52 4 4 1/2 1 9/16

350/400 137 196 86 184 57 6 6 2

500/600 151 216 86 204 67 6 6 2

Dimensions (±3mm)

Sizes A B C D E F G H

20/25 (1,524) (1,575) (965) (1,346) (483) (76) (114) (35)

35/40 (1,524) (1,981) (965) (1,753) (483) (76) (114) (35)

45/55 (1,753) (2,286) (1,067) (2,057) (584) (76) (114) (35)

65/75 (1,753) (2,794) (1,067) (2,565) (584) (76) (114) (35)

85/100 (2,362) (2,794) (1,372) (2,565) (889) (102) (114) (40)

125/150/175 (2,667) (3,353) (1,524) (3,124) (1,041) (102) (114) (40)

200/250 (2,972) (3,962) (1,676) (3,734) (1,194) (102) (114) (40)

275/300/325 (3,226) (4,470) (1,803) (4,242) (1,321) (102) (114) (40)

350/400 (3,480) (4,978) (2,184) (4,674) (1,448) (152) (152) (51)

500/600 (3,835) (5,486) (2,184) (5,182) (1,702) (152) (152) (51)

Form S-PCD Page 20

Weight - Mixing Box only (Add to base unit weight)

lbs 390 500 505 785 880 1185 1550 1705 1940 2385

(kg) (177) (227) (229) (356) (399) (538) (703) (773) (880) (1082)

Page 21

HPCDV Accessories (“I” Conguration) (cont’d)

A

Screened Mounting Base (Indoor)

±1/8” (3mm)

DISCHARGE AIR

SECTION

BURNER

SECTION

BLOWER/FILTER

SECTION

INLET AIR

MOUNTING BASE

A

DIMENSIONS (cont’d)

AIR

FLOW

B

C

END VIEWSIDE VIEW

Page Number _______ of ______

Dimensions ±1/8”

Sizes A B C

20/25 24 38 62

35/40 24 38 78

45/55 30 42 90

65/75 30 42 110

85/100 36 54 110

125/150/175 36 60 132

200/250 42 66 156

275/300/325 42 71 176

350/400 48 86 196

500/600 48 86 216

Dimensions (±3mm)

Sizes A B C

20/25 (610) (965) (1,575)

35/40 (610) (965) (1,981)

45/55 (762) (1,067) (2,286)

65/75 (762) (1,067) (2,794)

85/100 (914) (1,372) (2,794)

125/150/175 (914) (1,524) (3,353)

200/250 (1,067) (1,676) (3,962)

275/300/325 (1,067) (1,803) (4,470)

350/400 (1,219) (2,184) (4,978)

500/600 (1,219) (2,184) (5,486)

Screened Discharge Plenum (Indoor)

±1/8” (3mm)

DISCHARGE AIR

BLOWER/FILTER

MOUNTING BASE

SECTION

BURNER

SECTION

SECTION

INLET AIR

Dimensions ±1/8”

Sizes A B C

20/25 24 38 62

35/40 24 38 78

45/55 30 42 90

65/75 30 42 110

85/100 36 54 110

125/150/175 36 60 132

200/250 42 66 156

B

C

275/300/325 42 71 176

350/400 48 86 196

500/600 48 86 216

Dimensions (±3mm)

Sizes A B C

AIR

FLOW

END VIEWSIDE VIEW

20/25 (610) (965) (1,575)

35/40 (610) (965) (1,981)

45/55 (762) (1,067) (2,286)

65/75 (762) (1,067) (2,794)

85/100 (914) (1,372) (2,794)

125/150/175 (914) (1,524) (3,353)

200/250 (1,067) (1,676) (3,962)

275/300/325 (1,067) (1,803) (4,470)

350/400 (1,219) (2,184) (4,978)

500/600 (1,219) (2,184) (5,486)

Form S-PCD Page 21

Page 22

ISOLATOR

DIMENSIONS (cont’d)

Page Number _______ of ______

PCDH Accessories (cont’d)

Return Air Blower and Mixing Box w/Relief

±1/8” (3mm)

RETURN

AIR

BLOWER

SECTION

MIXING

w/RELIEF

SECTION

BOX

BLOWER/

FILTER

SECTION

HEAT

EXCHANGER

SECTION

CONTROL

BOX

Dimensions ±1/8”

Sizes A B C D E F G

20/25 61 32 32 23 19 3 4 1/2

35/40 68 48 32 39 19 3 4 1/2

45/55 72 60 36 51 23 3 4 1/2

65/75 75 80 36 71 23 3 4 1/2

85/100 100 80 48 71 35 4 4 1/2

125/150/175 109 100 54 91 41 4 4 1/2

200/250 117 120 60 111 47 4 4 1/2

275/300/325 122 140 65 131 52 4 4 1/2

350/400 127 160 70 148 57 6 6

500/600 137 180 80 168 67 6 6

Dimensions (±3mm)

Sizes A B C D E F G

20/25 (1,549) (813) (813) (584) (483) (76) (114)

35/40 (1,727) (1,219) (813) (991) (483) (76) (114)

45/55 (1,829) (1,524) (914) (1,295) (584) (76) (114)

65/75 (1,905) (2,032) (914) (1,803) (584) (76) (114)

85/100 (2,540) (2,032) (1,219) (1,803) (889) (102) (114)

125/150/175 (2,769) (2,540) (1,372) (2,311) (1,041) (102) (114)

200/250 (2,972) (3,048) (1,524) (2,819) (1,194) (102) (114)

275/300/325 (3,099) (3,556) (1,651) (3,327) (1,321) (102) (114)

350/400 (3,226) (4,064) (1,778) (3,759) (1,448) (152) (152)

500/600 (3,480) (4,572) (2,032) (4,267) (1,702) (152) (152)

(102mm)

RETURN AIR

OPTION

B

TYP. 4”

(76mm)

C

F

RETURN AIR BLOWER

G

G

D

3”

E

RETURN AIR

OPTION

SECTION

A

E

MOTOR

TOP VIEW

SIDE VIEW

BLOWER

HINGED DOOR

ACCESS c/w

HANDLE (TYP)

SPRING

Form S-PCD Page 22

Page 23

DIMENSIONS (cont’d)

Page Number _______ of ______

HPCDH Accessories (cont’d)

Return Air Blower and Mixing Box w/Relief

±1/8” (3mm)

RETURN

AIR

BLOWER

SECTION

MIXING

w/RELIEF

SECTION

BOX

BLOWER/

FILTER

SECTION

HEAT

EXCHANGER

SECTION

CONTROL

BOX

(102mm)

RETURN AIR

OPTION

B

TYP. 4”

(76mm)

F

RETURN AIR BLOWER

SECTION

A

E

G

G

D

BLOWERS

MOTOR

TOP VIEW

3”

E

C

RETURN AIR

OPTION

SIDE VIEW

HINGED DOOR

ACCESS c/w

HANDLE (TYP)

SPRING

ISOLATOR

Dimensions ±1/8”

Sizes A B C D E F G

20/25 61 62 38 53 19 3 4 1/2

35/40 68 78 38 69 19 3 4 1/2

45/55 72 90 42 81 23 3 4 1/2

65/75 75 110 42 101 23 3 4 1/2

85/100 100 110 54 101 35 4 4 1/2

125/150/175 109 132 60 123 41 4 4 1/2

200/250 117 156 66 147 47 4 4 1/2

275/300/325 122 176 71 167 52 4 4 1/2

350/400 127 196 86 184 57 6 6

500/600 137 216 86 204 67 6 6

Dimensions (±3mm)

Sizes A B C D E F G

20/25 (1,549) (1,575) (965) (1,346) (483) (76) (114)

35/40 (1,727) (1,981) (965) (1,753) (483) (76) (114)

45/55 (1,829) (2,286) (1,067) (2,057) (584) (76) (114)

65/75 (1,905) (2,794) (1,067) (2,565) (584) (76) (114)

85/100 (2,540) (2,794) (1,372) (2,565) (889) (102) (114)

125/150/175 (2,769) (3,353) (1,524) (3,124) (1,041) (102) (114)

200/250 (2,972) (3,962) (1,676) (3,734) (1,194) (102) (114)

275/300/325 (3,099) (4,470) (1,803) (4,242) (1,321) (102) (114)

350/400 (3,226) (4,978) (2,184) (4,674) (1,448) (152) (152)

500/600 (3,480) (5,486) (2,184) (5,182) (1,702) (152) (152)

Form S-PCD Page 23

Page 24

DIMENSIONS (cont’d)

Page Number _______ of ______

HPCDV Accessories (“I” Conguration) (cont’d)

Insulated Enclosed Mounting Base (Indoor/Outdoor)

±1/8” (3mm)

A

OUTDOOR

AIR FLOW

D D

B

RETURN

AIR FLOW

5”

(127mm)

FLOW

END VIEWSIDE VIEW

AIR

Dimensions ±1/8”

Sizes A B C D E

20/25 30 38 62 20 52

35/40 30 38 78 20 68

45/55 36 42 90 26 80

65/75 36 42 110 26 100

85/100 42 54 110 32 100

125/150/175 48 60 132 38 122

200/250 70 66 156 60 146

275/300/325 70 71 176 60 166

350/400 80 86 196 70 186

500/600 90 86 216 80 206

Dimensions (±3mm)

Sizes A B C D E

20/25 (762) (965) (1,575) (508) (1,321)

35/40 (762) (965) (1,981) (508) (1,727)

45/55 (914) (1,067) (2,286) (660) (2,032)

E

C

5”

65/75 (914) (1,067) (2,794) (660) (2,540)

(127mm)

85/100 (1,067) (1,372) (2,794) (813) (2,540)

125/150/175 (1,219) (1,524) (3,353) (965) (3,099)

200/250 (1,778) (1,676) (3,962) (1,524) (3,708)

275/300/325 (1,778) (1,803) (4,470) (1,524) (4,216)

350/400 (2,032) (2,184) (4,978) (1,778) (4,724)

500/600 (2,286) (2,184) (5,486) (2,032) (5,232)