Reznor FSV, FSH, FSV Mk 2, FSH Mk 2 Installation Servicing & Operating Instructions

Floorstanding

Oil Fired Heaters

FSV - FSH

(Mk 2)

0210-FS0GBEN

Installation

Servicing

&

Operating Instructions

Please read this document carefully before commencing the installation & leave it

with the user or attached to the appliance after installation.

Reznor U.K. Limited – Park Farm Road – Folkestone – Kent CT19 5DT – Tel 01303-259141 – fax 01303-850002

INDEX

1.0 Introduction

1.1 General Information

1.2 Quality Products

1.3 CE Approved European Directives

1.4 Product Information

1.5 Warning

2.0 Technical Specifications

2.1 Data Sheets

2.2 Dimensions

3.0 Mechanical/Electrical Services

3.1 Oil supply

3.2 Oil pipework

3.3 Electrical Connection

3.4 Ventilation Requirement

3.5 Electrical timer

4.0 Installation

4.1 Location

4.2 Heater Clearances

4.3 Flue

4.4 Nozzled Heaters

4.5 Ducted Heaters

4.6 Filters

4.7 Controls

5.0 Commissioning

5.1 Pre-Commissioning Checks

5.2 Commissioning Procedure

5.3 Commissioning Outlets

5.4 User Instructions

6.0 Instructions for Servicing

6.1 Frequency

6.2 Procedures

6.3 Re-Commissioning

7.0 Fault Finding

8.0 Spare Parts

8.1 3D Drawing

8.2 Parts List

9.0 Reference Standards

2/31

1.0 Introduction

1.1 General

1.1.1 Before installation check that the appliance as

described on the packaging label is in

accordance with the correct type and model

specified on the data plate and complies with

your customer order.

1.1.2 The heater is delivered wrapped in heavy duty

polythene and should be checked to ensure

that it has been delivered undamaged.

1.1.3 Please read this document before commencing

installation. The onus rests with the installer to

ensure that all relevant manuals are read and

understood, especially with regard to any

safety instructions stipulated by the

manufacturer.

1.1.4 These instructions are only valid for the country

of use indicated on the appliance, i.e. GB - IE.

If these symbols are not shown it is necessary

to obtain appropriate technical instructions

which will provide information concerning the

necessary modification of the appliance for use

in the country concerned. Such instructions

may be obtained from your supplier upon

request.

1.1.5 Check that the local distribution conditions of

electricity supply, type of oil and pressure and

adjustment of the appliance are compatible.

1.1.6 When installed in Great Britain the total

installation must comply with the requirements

and recommendations of the relevant British

Standards & local laws. The installation must

also be in accordance with the relevant

electrical regulations and I.E.E. regulations.

1.1.7 Warning! Unauthorised modification of this

appliance or departure from use in the manner

for which it was intended by the manufacturer,

or installation in a manner contrary to these

instructions may constitute a hazard and

jeopardise all warranties. Deviations should

only be carried out after formal consent has

been obtained from the manufacturer.

1.1.8 Caution! Ensure that the environment in which

the air heater is to be installed will not create a

hazard, i.e. where excessive (volatile) dust,

flammable or corrosive substances and/or

vapours and combustible materials may be

present. Suitable protection should be given to

prevent damage to the appliance, for example

from fork lift trucks.

1.1.9 These appliances have been tested and set

according to the data plate before leaving the

factory.

1.2 Quality Products

1.2.1 The Reznor range of oil fired floorstanding

heaters is manufactured in the EC and

supplied in accordance with BS EN 9002: 1994

Quality Assurance System.

1.2.2 Certificates of conformity are available from the

Quality Control department at Reznor Limited.

1.3 CE-Approval-European

Directives

1.3.1 Reznor floorstanding heaters have been fully

assessed and tested and meet the following

EC Directives:

- Machinery Directive (89/392/EEC)

- Low Voltage Directive (73/23/EEC &

93/68/EEC)

- Electromagnetic Compatibility Directive

(89/336/EEC & 91/36 EEC)

- Product Liability Directive (65/379/EEC)

1.3.2 In addition Reznor oil fired floorstanding

heaters are conform to the following

harmonised standards:

BS EN 292 - Part 1 :Safety of Machinery Basic Concepts, General Principles for

terminology, methodology

BS EN 292 - Part 2 :Safety of Machinery Basic Concepts, General Principles for Design

Technical Principles and Specifications.

BS EN 60204 - Part 1 :Safety of Machinery Electrical Equipment for Machine Specification

for General Requirements.

BS EN 60335 - Part 1 :Safety of Household

and Similar Electrical Appliances General

Requirements.

BS EN 55014 :Limits and methods of

measurement of radio disturbance

characteristics of electrical motor-operated and

thermal appliances for household and similar

purposes, electric tools and similar electric

apparatus.

prEN 50165 :Electrical equipment of nonelectric heating appliances for household and

similar purposes, safety requirements.

1.4. Product Information

1.4.1 Reznor floorstanding heaters are available with

burner outputs from 30kW to 293kW and can

be floor mounted (FSV units) or suspended

(FSH units).

Floorstanding heaters can be used in free

blowing or ducted applications. Each heater

must have its own individual open flue.

1.4.2 All floorstanding heaters are fitted with a pretested and set forced draught burner. A

sequential control box is fitted to each burner

to provide safety. Note: No asbestos or

soldered joints are present in the construction

of the heater.

1.4.3 All the materials selected can withstand the

range of chemical, mechanical and thermal

demands expected during the foreseen and

normal use of the product, as stipulated by

manufacturers' instructions and

recommendations.

1.4.4 Before final location of the product the following

criteria should always be considered in placing

the heater:-

• Flue outlet access

• Placing for efficient distribution of warm air

• Oil supply

• Electrical services

• Fresh air supply (when applicable)

• Service access and maintenance

requirements

1.5 Warning

Heaters should not be installed in a corrosive

or solvent atmosphere

(i.e. near plating or degreasing plants), in areas

where there is a fire risk, or any other

environment which is detrimental to the heater

or its operation. Consult BS 6230 for further

information on hazardous areas.

3/31

4/31

2.00

4.50 AND

2.00

3.50 AND

RL28.1 RL28.1 RL28.1

head ref

3000771

40 G20S ext.

1.50

3.00 AND

S+S

S+SS+S

29 44 60 88 117 150 175 205 235 293

psi 174 174 189 174 160 203 174 181 174 145

kW 38.0 57.1 76.1 114.2 152.2 190.2 228.3 257.5 304.4 336.5

Frame Size 1 2 3 4 5

2.0 Technical Specifications

FSV/FSH Model

2.1 Class D Oil (table 1a)

kW 35.5 53.4 71.1 106.7 142.2 177.8 213.4 241.6 284.5 315.6

Btu/h 129777 195007 259895 390013 519790 649567 779685 879409 1039580 1149208

Heat Input Gross

kW 31.0 44.1 60.5 87.9 119.3 148.0 178.0 202.9 234.4 268.9

Btu/h 121239 182371 242819 364400 485638 607219 728799 825107 971618 1077830

Heat Input Net

Btu/h 105871 150609 206618 300194 407431 505446 607902 692940 800518 918342

Heat Output

Burner Type Riello 40 G5 40 G5 40 G10 40 G10 40 G20 40 G20S

bar 12.0 12.0 13.0 12.0 11.0 14.0 12.0 12.5 12.0 10.0

Pump Pressure

Oil Consumption kg/hr 2.89 4.34 5.78 8.67 11.56 14.45 17.34 20.36 23.12 26.60

Size 0.65 1.00 1.35 2.00 2.75 2.75 4.00

Angle 60° 60° 60° 60° 45° 45° 60° 45° x 2 45° x 2 45° x 2

Shape SSSSSS S

Number FIXED FIXED 2.0 4.8 2.0 4.0 6.0 6.0 6.0 6.0

Number 2.25 3.75 3.4 5.0 5.5 4.5 5.5 2.1 2.8 3.0

Smoke No. 0-1 0-1 0-1 0-1 0-1 0-1 0-1 0-1 0-1 0-1

Nozzle

Head Setting (at 0 flue

resistance)

Air Setting (at 0 flue

resistance)

Air Setting Start Number n/a n/a n/a n/a n/a 3.5 4.0 n/a n/a n/a

°C 230 310 330 375 325 355 325 345 380 335

CO2 (1) % 11.1 11.5 11.7 11.5 12.0 11.9 12.6 12.0 11.7 12.8

Gross Flue Temperature

(20∞C ambient)

(1): CO2 figure can be subject to fluctuations in different installations on site (see § 5.2.1 /g)

17330

10315

8393

14100

7619

12800

6250

10500

8750

5208

7140

4250

30

25

30

25

25

20

98

82

98

82

82

66

49

49

47

50

50

49

5/31

88

87

84

89

90

88

21

69

50

69

59

59

ft

34

52

36

°K

89

61

93

65

°F

dB(A) 52 52 53 53 59 61 61 65 63 67

5180

3083

5180

3083

2500

1488

2500

1488

m³/h

ft³/min

Pa 95 95 130 130 125 150 200 250 160 250

21

18

18

m

FRAME size I II III IV V

table 1b

FSV/FSH model 29 44 60 88 117 150 175 205 235 293

Nominal air flow

Available outlet pressure

(ducted outlet)

Air throw (approx) (1)

Temperature rise through heater

(nominal)

Sound level (2) (for guidance

only)

Flue spigot outside diameter mm 125 125 150 178 178 178 178 223 223 223

Minimum flue height m 2 22222222 2

Main fan motor size kW 0.55 0.55 0.736 0.736 1.5 2.2 3 4 4 5.5

Total absorbed electric power kW 0.91 0.91 1.60 1.60 2.41 2.76 4.60 5.80 5.47 8.39

Electrical supply 230/240V – 1N E 50Hz 400/415V – 3N E 50Hz

Inlet oil connection ins BSP 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Weight (without burner) kg 190 190 225 225 280 292 300 320 360 380

(1) : unobstructed in still air with a terminal velocity of 50ft/min.

(2) : Condition R=5m; Q=2; A=160; louvres in neutral position

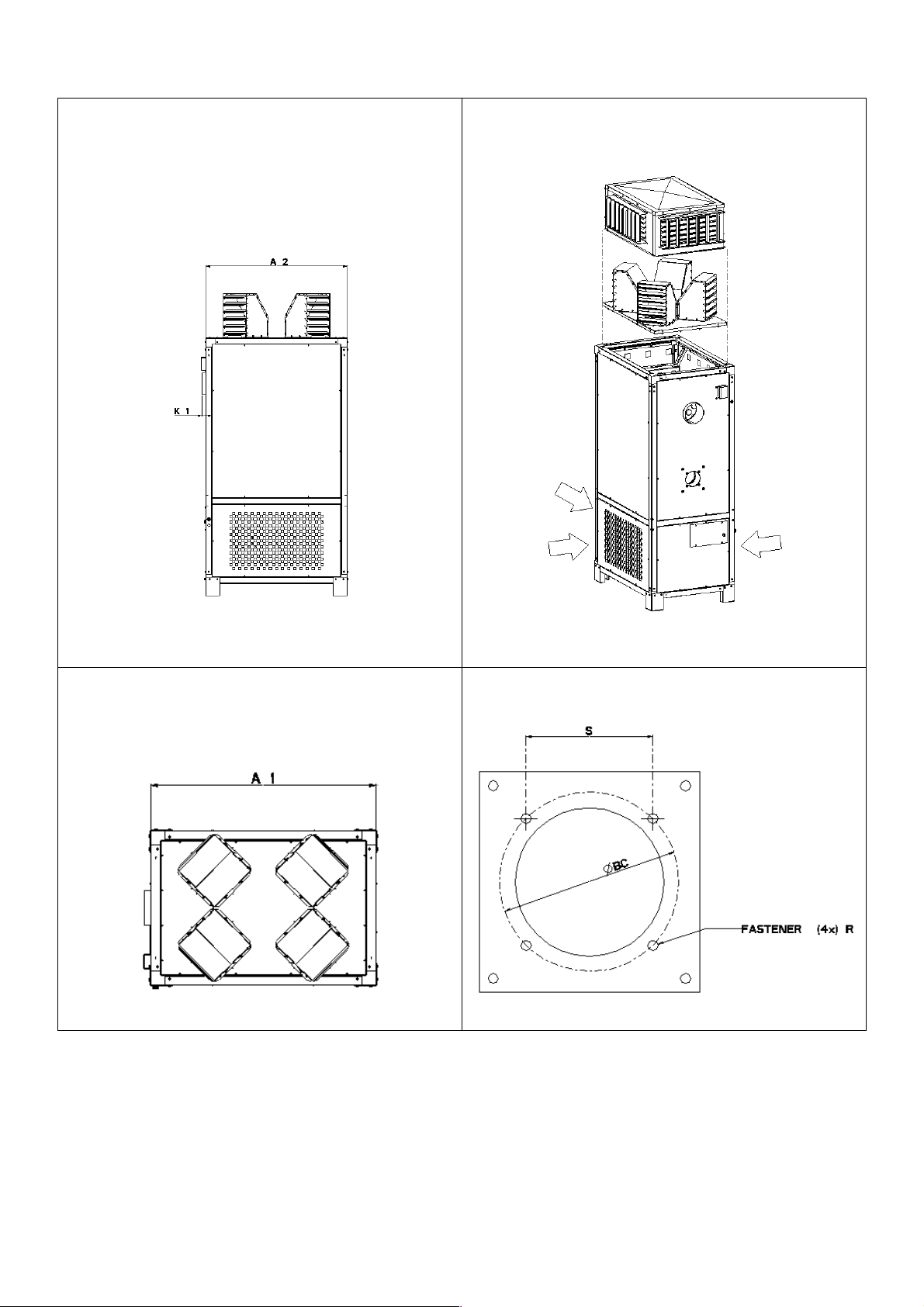

2.2 Dimensions

Figure 1a : unit with discharge nozzle

Vertical heater range

Front view

Figure 1b : unit with discharge plenum

Front view

6/31

Figure 1c – Side view

Figure 1d

Figure 1e

air inlet

Figure 1f : burner mounting flange

air inlet

7/31

Figure 2a – Side view

Horizontal heater range

Figure 2b – Front view

Remark :

The fixation eyes (4x dia 22.5) may only be used to put the unit into horizontal position after delivery. It is strictly forbidden

to use the fixation eyes for suspending the unit.

8/31

Dimensions (mm) (table 2)

FSV/FSH 29 44 60 88 117 150 175 205 235 293

Frame size I II III IV V

A1/A2 613 613 859 859 1158 1158 1305 1305 1504 1504

C1/C2/C3 865 865 865 865 795 795 1186 1186 1186 1186

D1/D2/D3 1007 1007 1019 1019 1041 1041 1184 1184 1111.5 1111.5

E1/E2/E3 1441 1441 1465 1465 1637 1637 1750 1750 1677.5 1677.5

outside dia 2

(flue outlet)

125 125 150 150 178 178 178 223 223 223

F1/F2/F3 1804 1804 1804 1804 2012 2012 2073 2073 2012 2012

inside dia 1

(burner inlet)

110 110 120 120 140 140 155 155 155 155

H1 2088 2088 2168 2168 2376 2378 2477 2477 2466 2466

H2 2164 2164 2114 2114 2400 2400 2395 2395 2334 2334

K1/K2 35.5 35.5 107.5 35.5 32 32 105.5 33.5 32.7 32.7

L 520 520 591 591 675 675 786 786 675 675

M 1284 1284 1213 1213 1337 1337 1287 1287 1337 1337

P1 284 284 364 364 364 366 404 404 454 454

P2 360 360 310 310 388 388 322 322 322 322

dia BC 142 142 145 145 162 162 180 224 180 224

R M8M8M8M8M8M8M8M8M8M8

S 100.4 100.4 102.5 102.5 114.5 114.5 127.3 158.4 127.3 158.4

2.3 Number of nozzles on heaters (figure 3)

29 - 44 60 - 88 117 - 293

9/31

3.0 Mechanical/Electrical Services

3.1 Oil supply

3.1.1 Connection to an oil supply may only be

carried out by suitably qualified persons.

The oil installation must comply with the

rules in force using materials appropriate for

oil installations.

3.2.7 All pipework must be adequately sealed

using approved sealing compounds suitable

for oil.

GALVANISED PIPEWORK AND FITTINGS

MUST NOT BE USED.

The pipework must be effectively sealed so

as to eliminate the ingress of air which will

ultimately stop the flow of oil.

3.1.2 Check that the oil grade is in accordance

with the data described on the air heater.

3.1.3 An adequate oil line sized to provide the

dynamic pressure for the volume required

by the air heater(s) is essential to maintain

the nominal heat input.

3.1.4 A shut off tap and, to facilitate servicing, a

disconnect union fitting must be provided

adjacent to the appliance.

3.1.5 Ensure that the installations a filter and has

been tested and purged in accordance with

prescribed practice prior to commissioning

and taking the air heater into service.

3.2 Oil Pipework

3.2.1 The burners fitted to the Reznor air heaters

are suitable for Class D (35 sec) oil via a

suitable oil pipeline and filter to a storage

tank installed externally to the building.

3.2.2 The pipework can be constructed for use on

either a single pipe, or two-pipe system.

Whether a gravity feed or pumped system is

required is determined by the parameters of

the installation i.e. number of heaters and

length of pipeline.

3.2.3 Please refer to the burner manual as to the

limitations of the oil line and most suitable

pipe diameters after deciding on which

pipework system to adopt.

3.2.4 The storage tank and heater are to be

installed with the appropriate safety/service

components as shown by the following

figures.

Tank and single pipe system

Pressure ring main.

3.3 Electrical connection

3.3.1 The electrical installation may only be

carried out by suitably qualified persons

observing the rules in force.

3.3.2 Check that the electrical specification is in

accordance with the specified data on the

air heater. A unique appliance wiring

diagram is supplied as a separate document

attached to this one, plus an additional copy

attached to the air heater.

3.3.3 These appliances must be earthen.

3.3.4 A lockable main switch must be installed

adjacent to each appliance and in view

when facing the service compartment. The

isolator must have a contact separation of at

least 3.0mm on all poles.

3.3.5 Ancillary controls (option 910.2) may be

included with the heater to provide timed

heat cycles, room comfort temperature

level, frost protection, override air

circulation, etc.

3.3.6 Ensure when planning the external

appliance control circuitry that power will be

supplied at all times to the air heater, even

when it is control switched in the ‘heat-off’

mode. This is necessary to ensure that the

fan can operate independently of the

heating control. Therefore never incorporate

automatic controls that electrically isolate

the appliance.

Figure 4 : Option 910.2

3.2.5 Any external piping from the tank or filter

should be adequately lagged to avoid

waxing during the winter.

Always ensure the correct grade of fuel is

used and especially ensure winter grade is

used for the winter period, as this will be

suitable down to –12°C whereas summer

grade will wax and plug the filter at –4°C.

3.2.6 When using a pumped ring main ensure that

correct pressure regulating valves are used

prior to each heater and a ring main

pressure below 0.4bar is used to avoid

aeration and consequential ‘air locks’.

Legend

1 frost stat 4 fan control

2 room stat 5 burner control

3 programmable clock 6 fuse

10/31

Loading...

Loading...