Reznor BE-200 Service Manual

NOTICE:

The information contained on the following page(s) was produced

prior to May 1, 2014. On that date Reznor became part of

Nortek, Inc.

References to any other company afliations are no longer valid.

©2014 Reznor, LLC. All Rights Reserved.

Trademark notice: Reznor is registered in at least the United States.

0514 PDF Form Cover1

Model FE and BE

Gas-Fired, Power-Vented

Unit Heaters

®

Installation and Operation ........................ Paragraph 1-24 ...... Pages 1-19

Check Installation and Start-Up ................. Paragraph 25 ........... Page 20

Optional Equipment .................................. Paragraph 26-32 .... Pages 21-23

Service/Maintenance/Troubleshooting ...Paragraph 33-43 ....Pages 23-28

Index by Page

Belt Tension............................................. 17

Blower/Filter Cabinet (Optional) ............ 23

Blower Motor .......................................... 17

Blower Rotation ...................................... 18

Blower Speed Adjustment ....................... 17

Bottom Access......................................... 24

Burners .............................................. 19, 24

Burner Air Adjustment ............................ 19

Burner Rack Removal .............................. 24

Carryover, Flash ...................................... 25

Check Installation and Start-Up .............. 20

Clearances .................................................. 6

Combustion Air Proving Switch .............. 19

Combustion Air ......................................... 6

Confined Space Installation ....................... 6

Dimensions ................................................ 3

Disconnect Switch ................................... 12

Duct Flange (Blower Model Option) ...... 21

Electrical Supply and Connections.......... 12

Fan Blade ................................................. 25

APPLIES TO: Installation/Operation/Service

Table of Contents

Index by Page

Fan Control........................................ 18, 26

Fan Motor ............................................... 17

Gas Piping and Pressures ........................ 10

Guard Options (Blower Model).............. 22

Hanger Kits (Optional).............................. 7

Hazard Intensity Levels ............................ 2

Heat Exchanger ........................................ 25

High Altitude Combustion Air

Pressure Switch .......................... 5, 11

High Altitude Operation ............................ 5

Ignition System.................................. 19, 25

Installation Codes ...................................... 2

Limit Control ..................................... 18, 26

Location (Heater)....................................... 5

Louvers, V ertical (Optional) .................... 21

Maintenance ............................................ 23

Maintenance Schedule ............................. 23

Manifold Pressure ................................... 11

Multiple Heater Control Option ............. 23

REFERENCES: Replacement Parts, Form RZ-NA 726

Gas Conversion, Form RZ-NA 434/436-GC

INSTALLA TION FORM RZ-NA-I-FE/BE

Obsoletes RGM 436 (Version B)

Index by Page

Nozzles, Downturn Air (Optional) ......... 21

Optional Equipment ................................ 20

Operating Sequence ................................. 19

Orifices, Burner and Pilot ........................ 25

Pilot ................................................... 19, 25

Polytube Adapter (Blower Model

Option) .......................................... 21

Service ...................................................... 23

Spark Gap................................................ 25

Suspending the Heater ............................... 6

Thermostat and Connections................... 12

Troubleshooting....................................... 27

Uncrating and Preparation ......................... 2

V alve, Gas .......................................... 19, 26

Venter Motor and Relay .......................... 26

Venting ................................................. 8, 25

Warranty .................................................... 2

Wiring Diagrams .................................13-16

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier .

FOR YOUR SAFETY

The use and storage of gasoline or other

flammable vapors and liquids in open

containers in the vicinity of this appliance is

hazardous.

WARNING: Gas-fired appliances are not

designed for use in hazardous atmospheres

containing flammable vapors or combustible

dust, in atmospheres containing chlorinated

or halogenated hydrocarbons, or in applications with airborne silicone substances. See

Hazard Levels, Page 2.

WARNING: Improper installation, adjustment,

alteration, service, or maintenance can cause property

damage, injury or death. Read the installation,

operation, and maintenance instructions thoroughly

before installing or servicing this equipment.

GENERAL

Installation should be done by a

qualified agency in accordance with

the instructions in this manual and

in compliance with all codes and requirements of authorities having jurisdiction. The instructions in this

manual apply to the unit heater models listed below .

Model Fuel Vent Air Delivery

FE

BE

G as-Fired Power Propeller Fan

Gas -Fired Po wer

Form RZ-NA-I-FE/BE, Mfg P/N 98807 Rev 10, Page 1

C e ntrifugal Bl ower (heater may

be attached to ductwork)

Model

FE

Model

BE

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or death and/or property

damage.

2. WARNING: Failure to comply could result in

severe personal injury or death and/or property damage.

3. CAUTION: Failure to comply could result in

minor personal injury and/or property damage.

1. Installation Codes

The gas-fired unit heaters covered in this manual are design-certified by

the Canadian Standards Association (CSA) to ANSI Z83.8a and CGA

2.6a for industrial/commercial installations in the United States and

Canada. All heaters are available for use with either natural or propane

gas. The type of gas, the firing rate, and the electrical characteristics are

on the unit rating plate.

These units must be installed in accordance with local building codes. In

the absence of local codes, in the United States, the unit must be installed in accordance with the National Fuel Gas Code (latest edition).

A Canadian installation must be in accordance with the CAN/CGA

B149.1 and B149.2 Installation Code for Gas Burning Appliances and

Equipment. These codes are available from CSA Information Services,

1-800-463-6727. Local authorities having jurisdiction should be consulted before installation to verify local codes and installation procedure requirements.

Special Installations (Aircraft Hangars/

Garages)

Installations in aircraft hangars should be in accordance with ANSI/

NFP A No. 409 (latest edition), Standard for Aircraft Hangars; in public

garages in accordance with ANSI/NFPA No. 88A (latest edition), Standard for Parking Structures; and for repair garages in accordance with

ANSI/NFPA No. 88B (latest edition), Standard for Repair Garages.

ANSI/NFPA-88 (latest edition) specifies overhead heaters must be

installed at least eight feet above the floor. In Canada, installations in

aircraft hangars should be in accordance with the requirements of the

enforcing authorities, and in public garages in accordance with CAN/

CGA B149 codes.

ANSI/NFP A 409 (latest edition) specifies a clearance of ten feet to the

bottom of the heater from the highest surface of the top of the wing or

engine enclosure of whatever aircraft would be the highest to be housed

in the hangar, and a minimum clearance of eight feet from the floor in

other sections of aircraft hangars, such as the offices, and shops which

communicate with areas used for servicing or storage. The heaters must

be located so as to be protected from damage by aircraft or other objects

such as cranes and movable scaffolding. In addition, the heaters must be

located so as to be accessible for servicing, adjustment, etc.

2. Warranty

Refer to limited warranty information on the warranty card in the

"Owner's Envelope".

W ARRANTY: W arranty is void if......

a. Unit Heaters are used in atmospheres containing flammable

vapors or atmospheres containing chlorinated or halogenated

hydrocarbons or airborne silicone substances.

b. Wiring is not in accordance with the diagram furnished with

the heater.

c. Unit is installed without proper clearances to combustible ma-

terials or located in a confined space without proper ventilation and air for combustion. (See Paragraphs 7 and 8.)

d. Fan-type unit heater is connected to a duct system.

3. Uncrating and Preparation

This unit was test operated and inspected at the factory prior to crating

and was in operating condition. If the heater has incurred any damage in

shipment, document the damage with the transporting agency and immediately contact your Reznor Distributor.

Check the rating plate for the gas specifications and electrical characteristics of the heater to be sure that they are compatible with the gas and

electric supplies at the installation site. Read this booklet and become

familiar with the installation requirements of your particular heater. If

you do not have knowledge of local requirements, check with the local

gas company or any other local agencies who might have requirements

concerning this installation. Before beginning, make preparations for

necessary supplies, tools, and manpower.

Check to see if there are any field-installed options that need to be

assembled to the heater prior to installation. Each of the option packages includes a list of components and step-by-step instructions. For a

brief description of optional hanger kits, refer to Paragraph 9. For a

brief explanation of other frequently specified field-installed options,

see Paragraphs 26-32. After becoming familiar with the instructions,

assemble and install the options that are required for your heater.

If the heater was ordered with a vent cap, it will be shipped in a

separate carton.

Unless the crate bottom has been removed for option installation, leave

it attached until after the heater has been suspended. If the crate bottom

has been removed, the bottom of the heater must be supported with

plywood or appropriately placed boards. Without adequate support,

the bottom access panel could be damaged.

To protect the unit during shipping, the blower model has special

supports that must be removed before installation. Follow these instructions to remove:

Blower Support Legs -- Remove the two blower support legs and

screws.

Motor Shipping Block - Remove the wooden block located under the

motor bracket. Find the two rubber pads shipped in the instruction

envelope. Place these pads on the ends of the motor bracket bolts.

Motor Shipping Plate -- Blower models that are equipped with mo-

tors of 3/4 HP or less have a metal shipping plate attached between

the motor and the blower housing. Remove and discard the shipping

plate. Note: On units factory equipped with an optional belt guard,

the belt guard must be removed in order to reach the shipping plate.

Form RZ-NA-I-FE/BE, Mfg P/N 98807, Rev 10, Page 2

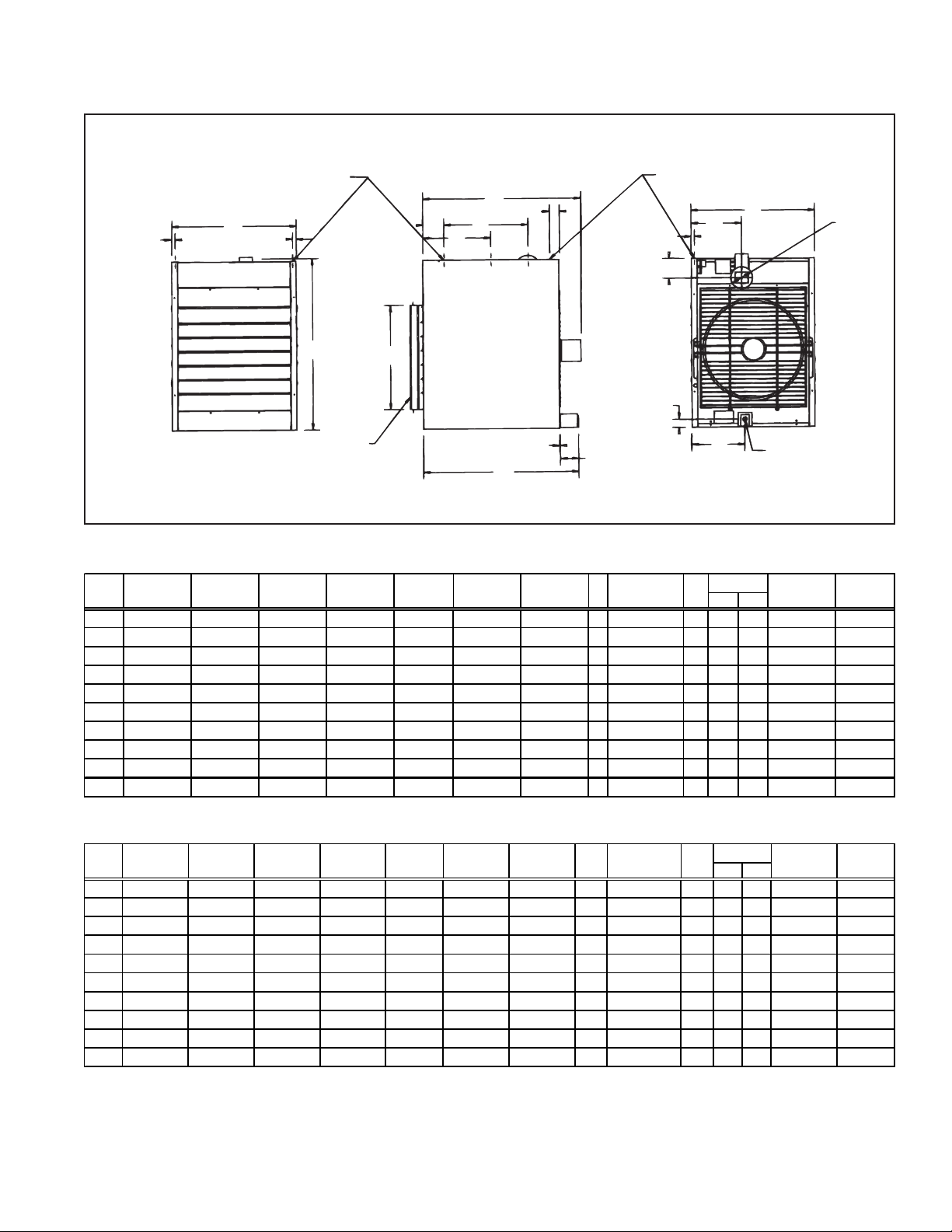

4. Dimensions

Fan-Type, Power-Vented Unit Heater

Figure 1A - Model FE Dimensions - inches (mm)

Female Thread - See Note at bottom of page

Suspension Points (2) or (4) 3/8-16

B

13/16

(21)

13/16

(21)

FRONT

A

Optional

Vertical

Louvers

C

E

K

2-1/4 (57)

F

G

D

RIGHT SIDE

1-11/16 (43)

1/8 (3)

4-1/4 (108)

Electrical Supply Connection

B

M

3/4 (19)

N

J

REAR

H = O.D.

Venter

Outlet

L = Gas connection

(not supply line size)

Dimensions (inches)

SizeABCDEFGHJKLMN

Nat Pro

29-25/32 13-9/16 27-1/16 31-7/16 5-27/32 14-7/16 14-1/32 4 10-9/32 16 1/2 1/2 9-13/16 3

25

29-25/32 13-9/16 27-1/16 31-7/16 5-27/32 14-7/16 14-1/32 4 10-9/32 16 1/2 1/2 9-13/16 3

50

29-25/32 15-9/16 27-1/16 31-7/16 5-27/32 14-7/16 14-1/32 4 10-17/32 16 1/2 1/2 10-7/16 3

75

29-25/32 17-9/16 30-7/16 31-7/16 5-27/32 14-7/16 14-1/32 4 12-29/32 16 1/2 1/2 10-7/16 3

100

29-25/32 23-5/16 30-7/16 31-7/16 5-27/32 14-7/16 14-1/32 5 14-7/16 16 1/2 1/2 11-9/16 2-5/8

125

39-15/16 20-5/16 35-7/16 35-15/16 4-7/8 19-15/32 15-23/32 5 14-9/32 24 1/2 1/2 11-11/16 4-19/32

165

39-15/16 23-5/16 36-3/16 35-15/16 4-7/8 19-15/32 15-23/32 5 14-13/32 2 4 1/2 1/2 11-11/16 4- 19/32

200

39-15/16 28-13/16 36-3/16 35-15/16 4-7/8 19-15/32 15-23/32 5 12-11/32 24 1/2 1/2 11-11/16 4-19/32

250

39-15/16 28 -13/16 36-11/16 35-15/16 4-7/8 19-15/32 15-23/32 6 12-11/32 24 3/4 1/2 11-11/16 3-19/32

300

39-15/16 37-1/16 37-5/16 35-15/16 4-7/8 19-15/32 15-23/32 6 13 24 3/4 1/2 11-11/16 3-19/32

400

Dimensions (mm)

SizeABCDEFGHJKLMN

Nat Pro

25

50

75

100

125

165

200

250

300

400

Suspension Notes: Use Dimension "G" for two-point suspension and "E" and "F" for four-

756 344 687 799 148 367 356 102 261 406 13 13 249 76

756 344 687 799 148 367 356 102 261 406 13 13 249 76

756 395 687 799 148 367 356 102 267 406 13 13 265 76

756 446 773 799 148 367 356 102 328 406 13 13 265 76

756 592 773 799 148 367 356 127 367 406 13 13 294 67

1014 516 900 913 124 498 399 127 363 610 13 13 297 117

756 592 919 913 124 498 399 127 366 610 13 13 297 117

756 732 919 913 124 498 399 127 314 610 13 13 297 117

756 732 932 913 124 498 399 152 314 610 19 13 297 91

756 941 948 913 124 498 399 152 330 610 19 13 297 91

point suspension. (Two-point suspension is standard; four-point is optional. Four-point suspension is available either factory or field installed.)

Form RZ-NA-I-FE/BE, Mfg P/N 98807 Rev 10, Page 3

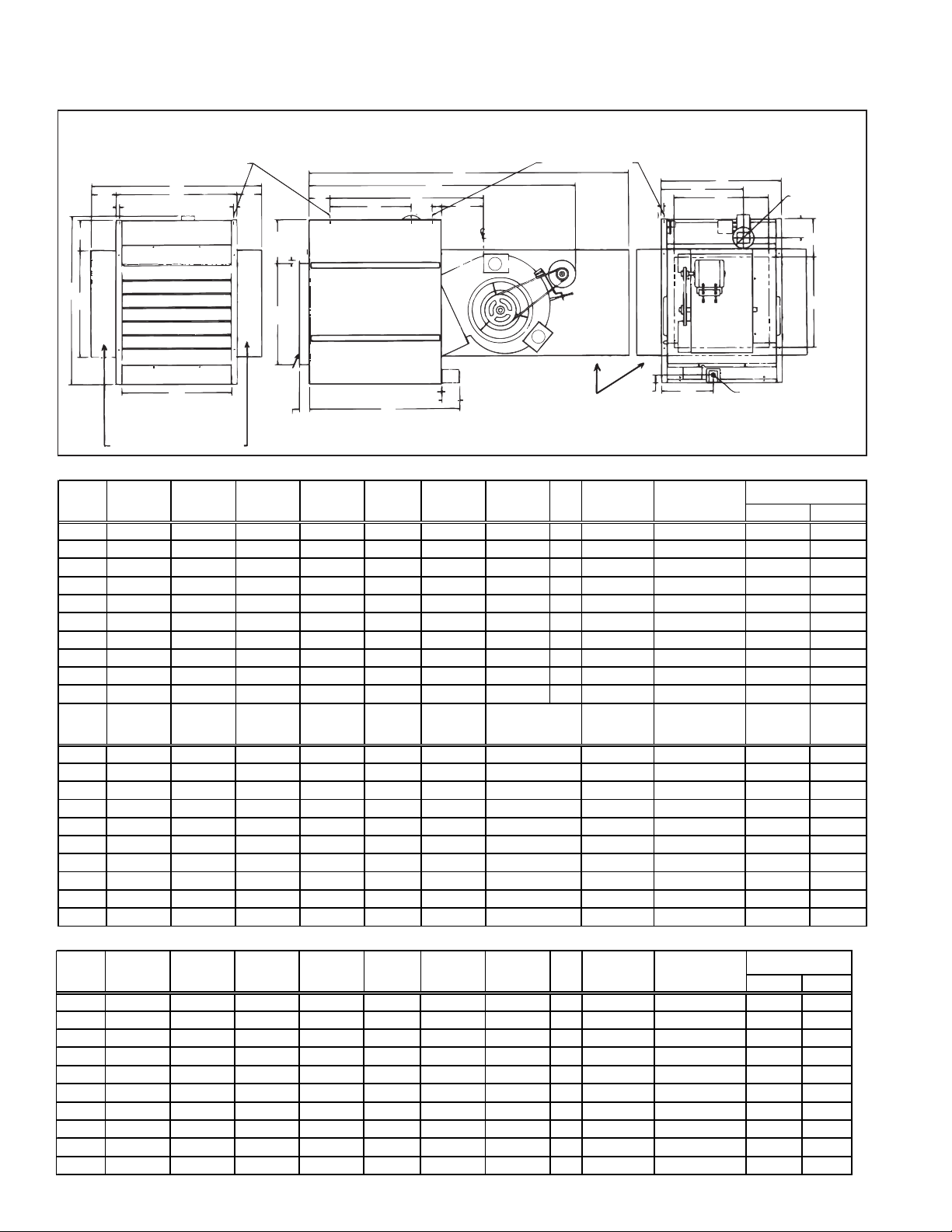

4. Dimensions (cont'd)

Blower-Type, Power-Vented Unit Heater

Figure 1B - Model BE Dimensions - inches (mm)

(4) Suspension Points

3/8-16 Female Thread

N

13/16 (21)

FRONT

B

13/16 (21)

S

T

K

Optional

Duct

Flange

2 (61)

E

3/4 (19)

F

D

RIGHT SIDE

M

R

A

P

Optional Blower Cabinet

X

2-1/4

(57)

1/8 (3)

C

G

10

(254)

4-1/4 (108)

Cabinet

Hanger

Location

6

Electrical Supply

Connection

7

Optional

Blower

Cabinet

1-11/16

(43)

3/4

(19)

Y

J

REAR

B

U

Gas connection

L =

(not supply line size)

H

= O.D.

Venter Outlet

Z

W

K

Dimensions (inches)

Size

25

50

75

100

125

165

200

250

300

400

Size

25

50

75

100

125

165

200

250

300

400

ABCHDEFDG

29-25/32 13-9/16 43-3/8 31-7/16 5-27/32 14-7/16 61-3/8 4 10-9/32 16 1/2 1/2

29-25/32 13-9/16 50 31-7/16 5-27/32 14-7/16 61-3/8 4 10-9/32 16 1/2 1/2

29-25/32 15-9/16 50 31-7/16 5-27/32 14-7/16 61-3/8 4 10-17/32 16 1/2 1/2

29-25/32 17-9/16 50 31-7/16 5-27/32 14-7/16 61-3/8 4 12-29/32 16 1/2 1/2

29-25/32 23-5/16 47-1/2 31-7/16 5-27/32 14-7/16 65-29/32 5 14-7/16 16 1/2 1/2

39-15/16 20-5/16 61 35-15/16 4-7/8 19-15/32 76-1/8 5 14-9/32 24 1/2 1/2

39-15/16 23-5/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 5 14-13/32 24 1/2 1/2

39-15/16 28-13/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 5 12-11/32 24 1/2 1/2

39-15/16 28-13/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 6 12-11/32 24 3/4 1/2

39-15/16 37-1/16 66-1/2 35-15/16 4-7/8 19-15/32 76-1/8 6 13 24 3/4 1/2

A

M

3-23/32 20-15/16 17-3/4 5-1/4 10-3/4 8-7/16 14-3/4 6-3/16 31-7/32 9-13/16 3

3-23/32 20-15/16 17-3/4 5-1/4 10-3/4 8-7/16 14-3/4 6-3/16 31-7/32 9-13/16 3

2-23/32 20-15/16 17-3/4 5-1/4 12-3/4 8-7/16 14-3/4 6-3/16 31-7/32 10-7/16 3

1-23/32 20-15/16 17-3/4 5-1/4 14-3/4 8-7/16 14-3/4 6-3/16 31-7/32 10-7/16 3

1-11/32 20-15/16 17-3/4 5-1/4 20-1/2 8-7/16 20-1/2 6-3/16 35-3/4 11-9/16 2-5/8

2-27/32 25-15/16 25-1/4 7-1/4 17-1/2 11-7/16 20-1/2 7-15/16 36-11/16 11-11/16 4-19/32

1-11/32 25-15/16 25-1/4 7-1/4 20-1/2 11-7/16 20-1/2 7-15/16 36-11/16 11-11/16 4-19/32

5-29/32 40-9/16 25-1/4 7-1/4 26 11-7/16 26 7-15/16 36-11/16 11-11/16 4-19/32

5-29/32 40-9/16 25-1/4 7-1/4 26 11-7/16 26 7-15/16 36-11/16 11-11/16 3-19/32

6-25/32 50-9/16 25-1/4 7-1/4 34-1/4 11-7/16 34-1/4 7-15/16 36-11/16 11-11/16 3-19/32

N

A

P

A

R

A

Dimensions (mm)

Size

25

50

75

100

125

165

200

250

300

400

Form RZ-NA-I-FE/BE, Mfg P/N 98807, Rev 10, Page 4

ABCHDEFDG

756 344 1102 799 148 367 1559 102 261 406 13 13

756 344 1270 799 148 367 1559 102 261 406 13 13

756 395 1270 799 148 367 1559 102 267 406 13 13

756 446 1270 799 148 367 1559 102 328 406 13 13

756 592 1207 799 148 367 1674 127 367 406 13 13

1014 516 1549 913 124 495 1934 127 363 610 13 13

1014 592 1689 913 124 495 1934 127 366 610 13 13

1014 732 1689 913 124 495 1934 127 314 610 13 13

1014 732 1689 913 124 495 1934 152 314 610 19 13

1014 941 1689 913 124 495 1934 152 330 610 19 13

S

A C

HJ K

Hanger

B

B

T

A

U

W

A

A B

E

X

L

Nat Pro

YZ

Hanger

Hanger

A C

HJ K

A B

L

Nat Pro

Size

25

50

75

100

125

165

200

250

300

400

NOTES

M

A

N

A

P

A

R

A

S

B

B

T

A

U

W

A

E

X

YZ

Hanger

94 532 481 133 273 214 375 157 793 249 76

94 532 481 133 273 214 375 157 793 249 76

69 532 481 133 324 214 375 157 793 265 76

44 532 481 133 375 214 375 157 793 265 76

34 532 481 133 521 214 521 157 908 294 67

72 659 641 184 445 291 521 202 932 297 117

34 659 641 184 521 291 521 202 932 297 117

150 1030 641 184 660 291 660 202 932 297 117

150 1030 641 184 660 291 660 202 932 297 91

172 1284 641 184 870 291 870 202 932 297 91

A

When equipped with optional blower cabinet.

B

When equipped with optional duct flange.

C

Dimension includes a 3/4" flange on the rear of the blower

cabinet.

D

Use with 4-point suspension without blower cabinet. If

installing hanger kit Option CK19, suspension points

change; see Paragraph 9.

E

Use with 4-point suspension with blower cabinet.

F

Contactor is standard on Models 300 and 400; optional on other

sizes.

G

Contactor location with optional three phase motors on Sizes 50,

75, 100 and 125.

H

Deduct 6-5/8" (168mm) on Sizes 50, 75, and 100 when equipped

with direct drive motor.

5. High Altitude Operation

If the heater is being installed in an altitude above 2000 ft (610M),

check the rating plate to determine what must be done to prepare the

heater for high altitude operation.

NOTE: A heater equipped with a two-stage valve must be factorybuilt for high altitude installation.

Check the rating plate, determine which circumstance below applies,

and follow the instructions.

• If the altitude range on the rating plate agrees with the altitude

at the site, no further action is required. Proceed with the installation.

• If the altitude range on the rating plate reads "Sea Level" and

the altitude at the site is between 2000 ft and 6000 ft (610M

to 1830M) and the heater has a single-stage gas valve, install

the heater and follow the instructions in Paragraph 11 to derate by

manifold gas pressure adjustment.

• If the altitude range on the rating plate reads "Sea Level" and

the altitude at the site is above 6000 ft (1830M) and the

heater has a single-stage gas valve, in addition to adjusting the

manifold pressure, it will be necessary to replace the combustion

air pressure switch. Order the listed below and replace the switch

before suspending the heater.

After the heater is installed, follow the instructions in Paragraph

11 to derate by adjusting the manifold gas pressure.

High Altitude Combustion Air Pressure Switch

P/N Description

159180 #PPS10027-2733

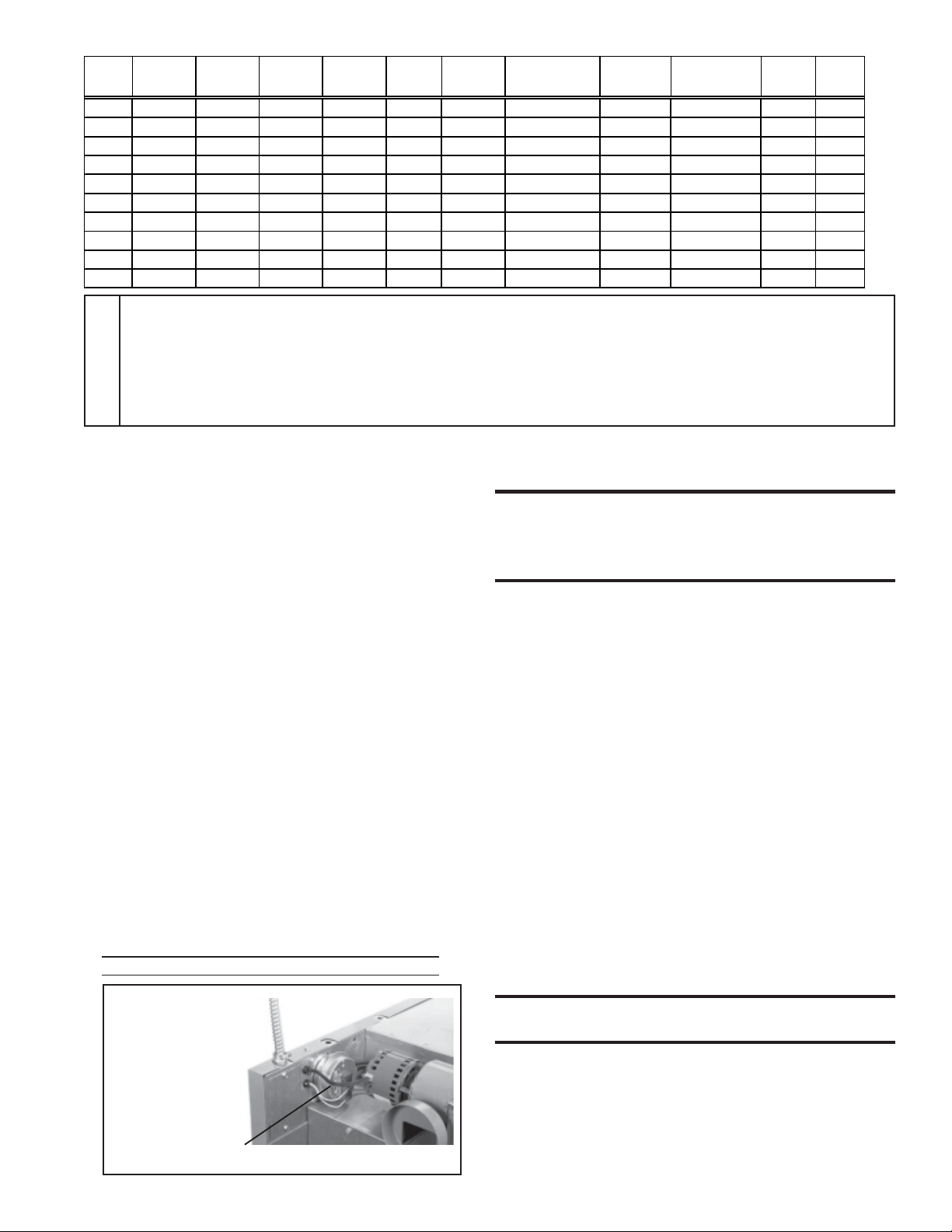

Figure 2Pressure Switch

Location (above

6000 ft, replace

with a pressure

switch set for high

altitude operation)

6. Unit Heater Location

CAUTION: Avoid installing a unit heater in

extremely drafty areas. Extreme drafts can shorten

the life of the heat exchanger and/or cause safety

problems.

For best results, the heater should be placed with certain rules in mind. In

general, a unit should be located from 8 to 12 feet (2.4-3.7M) above the

floor. Units should always be arranged to blow toward or along exposed

wall surfaces, if possible. Where two or more units are installed in the

same room, a general scheme of air circulation should be maintained for

best results.

Suspended heaters are most effective when located as close to the working zone as possible, and this fact should be kept in mind when determining the mounting heights to be used. However, care should be exercised to

avoid directing the discharged air directly on the room occupants.

Partitions, columns, counters, or other obstructions should be taken into

consideration when locating the unit heater so that a minimum quantity of

airflow will be deflected by such obstacles.

When units are located in the center of the space to be heated, the air

should be discharged toward the exposed walls. In large areas, units should

be located to discharge air along exposed walls with extra units provided

to discharge air in toward the center of the area.

At those points where infiltration of cold air is excessive, such as at

entrance doors and shipping doors, it is desirable to locate the unit so that

it will discharge directly toward the source of cold air from a distance of

15 to 20 feet (4.6-6.1M).

Units should not be installed closer than 18 inches (457mm) from any

wall.

CAUTION: Do not locate the heater where it may

be exposed to water spray , rain or dripping water .

Pressure Switch

Form RZ-NA-I-FE/BE, Mfg P/N 98807 Rev 10, Page 5

7. Clearances and Combustion

Air

Units must be installed so that the following clearances are provided for

combustion air space, service and inspection, and for proper spacing

from combustible construction. Clearance to combustibles is defined as

the minimum distance from the heater to a surface or object that is

necessary to ensure that a surface temperature of 90°F above the surrounding ambient temperature is not exceeded.

Model Required Clearances (inches and mm)

Size Top Flue Sides Bottom Rear

Collector

25-400 6"(152) 6"(152) 18"(457) 12"(305) * 24" (610)**

* When supplied with optional downturn nozzle, bottom clearance is

42"(1067mm). For service purposes, on standard units, bottom

clearance exceeding minimum (12" or 305mm) is not required but

may be desirable.

** For servicing purposes only, rear must remain full open.

All fuel-burning equipment must be supplied with the air that enters

into the combustion process and is then vented to the outdoors. Sufficient air must enter the equipment location to replace that exhausted

through the heater vent system. In the past, the infiltration of outside

air assumed in heat loss calculations (one air change per hour) was

assumed to be sufficient. However, current construction methods utilizing more insulation, vapor barriers, tighter fitting and gasketed doors

and windows or weather-stripping, and mechanical exhaust fans may

now require the introduction of outside air through wall openings or

ducts.

The requirements for combustion and ventilation air depend upon

whether the unit is located in a confined or unconfined space. An "unconfined space" is defined as a space whose volume is not less than 50

cubic feet per 1000 BTUH of the installed appliance. Under all condi-

tions, enough air must be provided to ensure there will not be a negative

pressure condition within the equipment room or space. For specific

requirements for confined space installation, see Paragraph 8.

W ARNING: These power -vented unit heaters are

designed to take combustion air from the space in

which the unit is installed and are not designed for

connection to outside combustion air intake ducts.

Connecting outside air ducts voids the warranty

and could cause hazardous operation. See Hazard

Levels, Page 2.

8. Combustion Air Requirement s

for a Heater Located in a

Confined Space

Do not install a unit in a confined space without providing wall openings leading to and from the space. Provide openings near the floor and

ceiling for ventilation and air for combustion as shown in Figure 3,

depending on the combustion air source as noted in Items 1, 2, and 3

below the illustration.

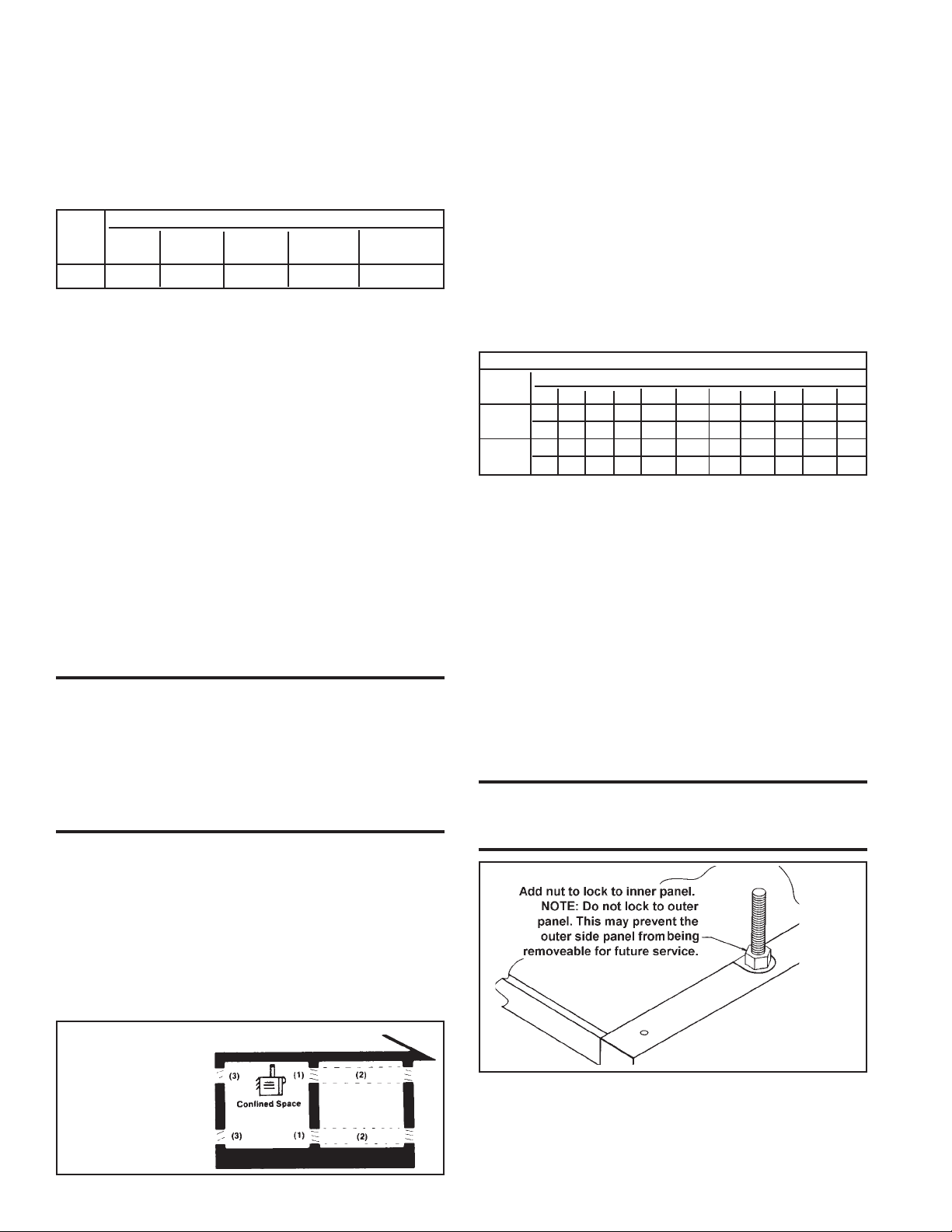

Figure 3 Confined Space: A

space whose volume is

less than 50 cubic feet

per 1000 BTUH of the

installed appliance

input rating

Form RZ-NA-I-FE/BE, Mfg P/N 98807, Rev 10, Page 6

Add total BTUH of all appliances in the confined space and divide by

figures below for square inch free area size of each (top and bottom)

opening.

1. Air fr om inside the building -- openings 1 square inch free area per

1000 BTUH. Never less than 100 square inches free area for each

opening. See (1) in Figure 3.

2. Air fr om outside thr ough duct -- openings 1 square inch free area

per 2000 BTUH. See (2) in Figure 3.

3. Air dir ect from outside -- openings 1 square inch free area per 4000

BTUH. See (3) in Figure 3.

NOTE: For further details on supplying combustion air to a confined

space, see the National Fuel Gas Code ANSI Z223.1a (latest edition ).

9. Suspending the Heater

Before suspending the heater, check the supporting structure to be

used to verify that it has sufficient load-carrying capacity to support

the weight of the unit.

Net Weight (lbs and kg)

Model Size

Type 25 50 75 100 125 165 200 250 300 400

Fan lbs 7 6 83 9 2 101 132 154 175 209 226 281

kg 34 38 42 46 60 70 79 95 103 127

Blower lbs 9 7 104 118 130 180 206 240 278 301 395

kg 44 47 54 59 82 93 109 126 137 179

NOTE: If the installation includes an optional stepdown transformer

kit (Option CF or CG), the stepdown transformer bracket is part of the

heater suspension and must be installed prior to hanging the heater.

Follow the instructions on the installation sheet included with the option kit.

A fan-type unit heater is equipped with standard two-point suspen-

sion. A 3/8-16 threaded hanger bracket assembly is located on each side

of the heater. If a fan-type unit has been ordered with optional, factoryinstalled, four-point suspension (Option BJ6), it will have two threaded

hanger brackets on each side.

A blower-type heater is equipped with standard four-point suspen-

sion. Two 3/8-16 threaded hanger bracket assemblies are located on

each side of the unit. Each hanger bracket assembly is designed for

threaded rod attachment.

For both "standard" and "optional" suspension point dimensions, see

Dimension Tables in Paragraph 3. (Note: If installing Option CK19

hanger kit, suspension points change; see Figure 7.)

WARNING: Suspend the heater only from the

threaded hanger brackets. Do not suspend from

the heater side panel.

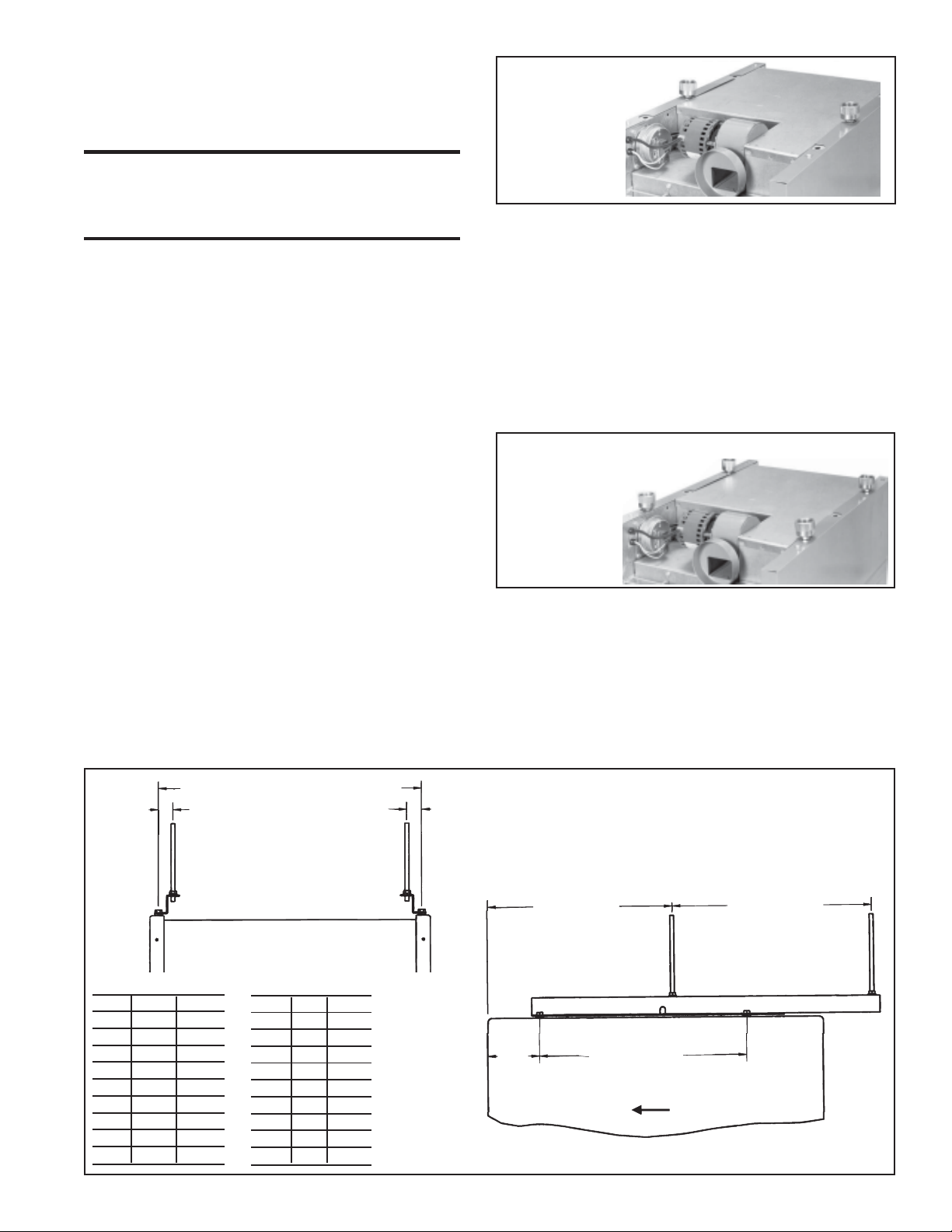

Figure 4 -

Suspension

When the heater is lifted for suspension, the bottom must be protected.

If the wooden crate bottom has been removed, the bottom of the heater

will have to be supported with plywood or other appropriately placed

material. If the bottom is not supported, the bottom access panel could

be damaged. Also, when lifting a blower unit, support the blower and

motor to prevent the unit from tipping.

All blower models have legs that support the blower assembly during shipping. After the unit is suspended, these legs should be removed.

Be sure that the threaded hanger rods are locked to the heater as

shown in Figure 4.

WARNING: Unit must be level for proper

operation. Do not place or add additional weight

to the suspended heater. See Hazard Levels, page

2.

If an optional downturn air nozzle is used, the unit must be suspended from four points to ensure level suspension. Two hanger

brackets are included in the downturn option package and must be

field-installed on fan-type units with standard two-point suspension. For additional information, refer to Paragraph 27 and the instructions that are furnished with the option package.

When blower-type units are equipped with an optional blower/

filter cabinet, there are two suspension points on the blower cabinet hanger bar. Suspend a unit equipped with a blower/filter cabinet

from four points, using the two heater hanger bracket assemblies

closest to the front of the heater and the two suspension points on

the blower/filter cabinet.

If one of the optional, field-installed hanger kits has been ordered for

your heater, it will have been shipped separately. Each option package includes a list of components and complete, step-by-step assembly instructions.

Optional, Field-Installed Hanger Kits:

1) Four-Point Suspension (fan models only) - Option CK7

This option kit is designed to convert a fan-type heater from standard two-point suspension to four-point suspension. The kit contains two additional hanger brackets.

2) Two-Point Swivel Connectors (fan models only) - Option

CK8 (See Figure 5)

The purpose of this option kit is to adapt the standard hanger bracket

so that the heater can be suspended from 1", threaded, stationary

pipe. The swivel connector screws "into" the threaded hanger bracket

on the heater and "onto" the 1" threaded pipe used for hanging the

heater. The kit includes two swivel hanger connector assemblies and

two lock washers.

Figure 5 - T woPoint Suspension

with Swivel

Connections

(fan models

only)

3) Four-Point with Swivel Connectors (fan-models only) - Option

CK9 (See Figure 6)

This option package is designed to convert a fan-type heater from standard two-point suspension to four-point suspension with swivel connectors. By installing this kit the standard fan-type heater can be hung

from four 1", threaded, stationary pipes. The kit includes two hanger

bracket assemblies, four swivel hanger connector assemblies and four

lock washers.

4) Four-Point Swivel Connectors - Option CK10 (See Figure 6)

This option package is used on a heater that is already equipped with

four-point suspension to adapt it for suspension from four 1", threaded,

stationary pipes. The kit includes four swivel hanger connector assemblies and four lock washers.

Figure 6 - Four-Point Suspension with Swivel

Connections (Applies to both

fan and blower models)

5) Special Four-Point Suspension with Nearly Equal Loading

(applies to blower models only) - Option CK19

This suspension option is designed for special applications when a suspension system is needed that has nearly equal loading at all four suspension points. Use this option in installations with spring isolation designed for seismic protection or when threaded rod hangers are longer

than twelve inches.

Suspension points change with the addition of hanger kit Option CK19;

see Figure 7.

(See Figure 7)

A (Standard suspension points/hanger bars)

1-3/8

(35)

B (Suspension points with Option CK19)

Front View of Model B with Option CK19

Dimensions (inches)

Size A B

25-50 11-7/8 9-1/8

75 13-7/8 11-1/8

100 15-7/8 13-1/8

125 21-5/8 18-7/8

165 18-5/8 15-7/8

200 21-5/8 18-7/8

250 27-1/8 24-3/8

300 27-1/8 24-3/8

400 35-3/8 32-5/8

Dimensions (mm)

Size A B

25-50 302 232

75 352 283

100 403 333

125 549 479

165 473 403

200 549 479

250 689 619

300 689 619

400 899 829

1-3/8

(35)

Figure 7 - Suspension Dimensions for Model B Heater

with Hanger Kit Option CK19

18-3/4 (476)

4-7/8

(124)

17-3/8 (441)

19-15/32 (495)

Side View of Model B with Option Ck19

Airflow

Form RZ-NA-I-FE/BE, Mfg P/N 98807 Rev 10, Page 7

10. V enting

These power-vented unit heaters are designed to operate safely and efficiently with either a horizontal or vertical vent. (Horizontal vent run is

recommended for maximum fuel savings.)

W ARNING: Units installed in multiples r equire individual vent pipe runs and vent caps. Manifolding of

vent runs is not permitted due to possible recirculation of combustion products into the building and possible

back pressure effects on the combustion air proving switch.

Specific Venting Requirements (read all before installing)

1. Venter (Flue) Outlet

Venter Outlet Size:

Model Size Outlet Diameter

25-100 4"

125-250 5"

300-400 6"

Venter Outlet Attachment Requirements:

• If the pipe used in the vent run is larger than the diameter of the

venter outlet (See Vent Length Table 2), Make the transition at

the venter outlet.

• A minimum of 12" (305mm) of straight pipe is required at the

venter outlet (or transition fitting) before installing an elbow in

the vent system. An elbow should never be attached directly to

the venter. An elbow attached to the straight pipe can be in any

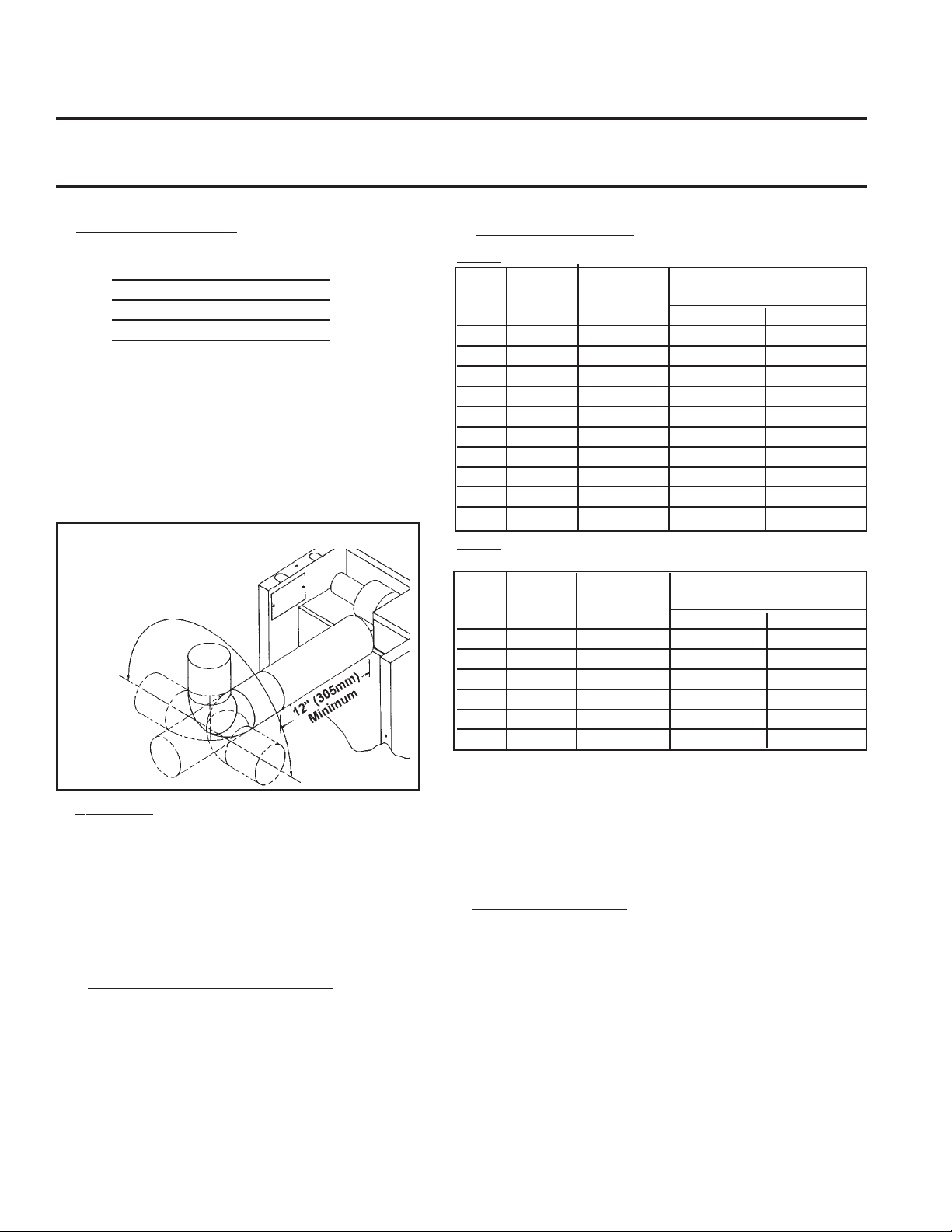

position at or above horizontal. See Figure 8.

Figure 8 - Alternate V ent Dir ections (vent in any

position above horizontal;

minimum of 12" (305mm)

of straight pipe is

required before an

elbow)

2. Vent Pipe

If installed with a horizontal vent run, use either vent pipe approved for a Category III heater or appropriately sealed 26-gauge

galvanized steel or equivalent single-wall pipe.

If at least half of the equivalent length of the vent system is vertical, vent pipe approved for a Category I heater may be used.

Single-wall pipe or double-wall (Type B) vent pipe are suitable for

use with a Category I heater.

Use only one of the flue pipe diameters listed in the Vent Length

Tables for the furnace size being installed.

2A. Vent Pipe Diameter Reduction

If at least half of the equivalent length of the vent system is vertical, the vent pipe diameter may be reduced one inch from the

standard diameter listed in Vent Length Table 1. Only single-wall

pipe is suitable for use when reducing the pipe diameter. A tapertype reducer must be used. The maximum allowable vent length

remains the same. If required, double-wall pipe may be used at the

terminal end as shown in Figures 9 and 10. (Use the equivalent

length for elbows as shown in V ent Length T able 1 for the standard

vent pipe diameter. All elbows used in the vent system must be

considered.)

Form RZ-NA-I-FE/BE, Mfg P/N 98807, Rev 10, Page 8

3. Vent Length Tables

Table 1: Maximum Permissible Vent Lengths

Vent Maximum Equivalent Straight

Model Pipe Vent Length* Length** - ft (M)

Diameter ft (M ) 90° Elbows 45° Elbows

25 4" 30 ft (9.1 M) 3.5' (1 M) 1.8' (.5 M)

50 4" 40 ft (12.2 M) 5' (1.5 M) 2.5' (.8 M)

75 4" 50 ft (15.2 M) 7' (2.1 M) 3.5' (1.1 M)

100 4" 50 ft (15.2 M) 7' (2.1 M) 3.5' (1.1 M)

125 5" 50 ft (15.2 M) 5' (1.5 M) .5' (.8 M)

165 5" 50 ft (15.2 M) 9' (2.7 M) 4.5' (1.4 M)

200 5" 50 ft (15.2 M) 8' (2.4 M) 4.0' (1.2 M)

250 5" 50 ft (15.2 M) 10' (3.0 M) 5' (1.5 M)

300 6" 50 ft (15.2 M) 11' (3.4 M) 5.5' (1.7 M)

400 6" 50 ft (15.2 M) 15' (4.6 M) 7.5' (2.3 M)

Table 2: Optional Maximum Permissible Vent Lengths

(Requires an increase in vent pipe diameter.)

Vent Maximum Equivalent Straight

Model Pipe Vent Length* Length** - ft (M)

Diameter ft (M) 90° Elbows 45° Elbows

100 5" 60 ft (18.3 M) 8' (2.4 M) 4.0' (1.2 M)

165 6" 60 ft (18.3 M) 10' (3.0 M) 5.0' (1.5 M)

200 6" 60 ft (18.3 M) 12' (3.7 M) 6.0' (1.8 M)

250 6" 70 ft (21.3 M) 8' (2.4 M) 4.0' (1.2 M)

300 7" 70 ft (21.3 M) 13' (4.0M) 6.5' (2.0 M)

400 7" 90 ft (27.4 M) 14' (4.3M) 7.0' (2.1M)

*Note 1: If the system contains all vertical pipe or a combination of

horizontal and vertical vent pipe, the Maximum Permissible Vent Length

shown in Tables 1 and 2 may be increased one foot for each foot vertical

rise up to a maximum increase of 10 feet for Model sizes 25 thru 100 and

up to 20 feet for Model sizes 125 thru 400.

**Reduce the maximum vent length by the amount indicated for each

elbow.

4. Vent System Joints

Vent system joints depend on the installation and the type of pipe being

used.

• If using single wall, 26-gauge or heavier galvanized pipe, secure slip-fit

connections using sheet metal screws or rivets. Seal pipe joints either

with tape suitable for 550°F (such as Option FA1, P/N 98266) or hightemperature silicone sealant.

• If using Category III vent pipe, follow pipe manufacturer's instructions

for joining pipe sections. When attaching Category III pipe to the venter

outlet or the vent cap, make secure, sealed joints following a procedure

that best suits the style of Category III pipe being used.

• If using double-wall (Type B) vent pipe (allowed only if 1/2 of the

equivalent vent length is vertical), follow pipe manufacturer's instructions for joining pipe sections. For joining double-wall pipe to the venter

outlet collar, single-wall pipe, and/or the vent cap, follow the instructions below.

Loading...

Loading...