Reverberi Pratika B16-20 Service manual

COMPANY WITH CERTIFIED QUALITY SYSTEM

UNI EN ISO 9001 & EN 13485

MEDICAL APPLIANCE DIVISION

GB

Cod. 3915

Operation and maintenance manual

STEAM STERILIZERS

MODELS

PRATIKA S16 PRATIKA B16-20

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA |

|

|

|

Table of contents: |

|

1. INTRODUCTION ..................................................................................................................................................................... |

3 |

|

2. T E C H N I C A L S P E C I F I C A T I O N S ............................................................................................................... |

4 |

|

3. G E N E R A L R E C O M M E N D A T I O N S ............................................................................................................ |

6 |

|

3.1 |

Regulations for the operator ........................................................................................................................................... |

6 |

4. L O C A T I O N O F T H E C O N T R O L S .............................................................................................................. |

7 |

|

5. S T A R T I N G A N D S E T T I N G A T W O R K ................................................................................................. |

8 |

|

5.1 |

Removing the machine from the packing............................................................................................................................. |

8 |

5.2 |

Installation and preliminary inspections.............................................................................................................................. |

9 |

5.3 |

Using the SD Card………………………………………………………………………………………………………..10 |

|

6. G E N E R A L I N S T R U C T I O N S F O R U S E .............................................................................................. |

13 |

|

6.1 |

Directions for use ......................................................................................................................................................... |

13 |

6.2 |

How to drain the water from the tanks ......................................................................................................................... |

14 |

6.3 |

End of work...................................................................................................................................................................... |

14 |

7. H O W T O A R R A N G E T H E I N S T R U M E N T S F O R T H E S T E R I L I Z I N G |

|

|

P R O C E S S ............................................................................................................................................................................ |

14 |

|

7.1 |

Sterilizing table ................................................................................................................................................................. |

15 |

7.2 |

Notes and warnings ............................................................................................................................................................ |

15 |

7.3 |

Monthly inspection proposal .............................................................................................................................................. |

16 |

8. MESSAGES DISPLAYED...................................................................................................................................................... |

17 |

|

8.1 |

Alarm management ...................................................................................................................................................... |

17 |

8.2 |

Operating messages............................................................................................................................................................ |

17 |

8.3 |

Printed Messages................................................................................................................................................................ |

17 |

9.1 |

General maintenance .......................................................................................................................................................... |

18 |

9.2 |

Daily routine maintenance.................................................................................................................................................. |

18 |

9.3 |

Weekly routine maintenance .............................................................................................................................................. |

18 |

9.4 |

Monthly routine maintenance............................................................................................................................................. |

19 |

9.5 |

Periodic extraordinary maintenance ................................................................................................................................... |

19 |

9.6 |

Recommended inspections and replacements (after about 1000 cycles)............................................................................ |

20 |

9.7 |

Corrective actions to prevent faults.................................................................................................................................... |

20 |

ELECTRICAL SYSTEM PRATIKA: ......................................................................................................................................... |

21 |

|

HYDRAULIC CIRCUIT PRATIKA: ......................................................................................................................................... |

22 |

|

FORM TO FILL OUT WHEN APPLIANCES ARE RETURNED FOR REPAIRS............................................................... |

23 |

|

WARANTY CERTIFICATE…………………………………………………………………………………………………25 |

||

DECLARATION OF CONFORMITY……………………………………………………………………………………….27 |

||

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 2 di 27 |

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

1. INTRODUCTION

The machine described in this operation and maintenance manual is a steam sterilizer that has been specially designed to sterilize most of the materials and instruments used in dental surgeries, doctors' surgeries and hospitals in general.

The machine can either operate at a temperature of 134°C and a pressure of 2.1 Bar or 121°C and a pressure of 1.1 Bar. These parameters are monitored and kept at constant levels by three mechanical and electronic devices that ensure an optimal sterilizing process along with total safety.

The operating cycles can be visually checked on a display installed on the control panel of the machine, or by means of a printer supplied on request.

The machine has been built so that the work cycle will automatically stop and the situation be indicated by an error message on the display if the operator fails to carry out the loading operations correctly or if a fault occurs on printer.

SYMBOLS AFFIXED TO THE MACHINE

WARNING: IDENTIFIES A HEAT SOURCE. A PART COULD BE

DANGEROUSLY HOT

WARNING: IDENTIFIES A GENERIC DANGER. THERE COULD BE A POTENTIALLY DANGEROUS CONDITION

IDENTIFIES THE GROUND CONDUCTOR

Do not use the machine for purposes other than those for which it has been built.

To prevent the autoclave from being subjected to electrical disturbance, it is important to make sure that the earth resistance value is sufficient and well coordinated with the protections in your electrical system.

•This symbol it means the product is covered by the European Directive 2002/96/EC.

•Please inform yourself about the local separate collection system for electrical products.

•Please act according to your local rules and do not dispose of your old products with your normal household waste. The correct disposal of your old product will help prevent potential negative consequences for the environement and human healt.

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 3 di 27 |

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

2. T E C H N I C A L S P E C I F I C A T I O N S

PRATIKA are autoclaves designed and built in compliance with the operators' need for functionality, practical use and safety.

Are fully automatic. All functions are electronically servo-assisted, so the operator knows what the machine is doing at any given moment.

Have functional characteristics that make them unique, i.e.:

AUTOMATIC POWERING, thanks to which the electric heating element maintains the chamber at a temperature of 80°C for up to 60 min., after which it will automatically switch off if not used, if the “night” program is selected.

Gradual heating to obtain a more accurate temperature and a better sterilizing process.

AUTOMATIC WATER FILLING by means of an electric pump.

AUTOMATIC AIR EXHAUST to eliminate the air from inside the chamber at the beginning of the cycle, thus achieving the utmost steam saturation.

DOUBLE SAFETY VALVE to prevent overpressures.

DRYING CYCLE included: with thermodynamic system and vacuum pump

SAFETY THERMOSTAT to prevent overtemperatures.

Electronic DISPLAY for all functions, with message display and printout.

Press-moulded seamless 18/10 STAINLESS STEEL CHAMBER.

16 l. CAPACITY chamber which can be fitted with up to five trays.

Riscaldamento graduale al fine di ottenere una temperatura più precisa e una migliore sterilizzazione.

After each cycle, the PRATIKA autoclave, as required, triggers an anti-condensation system unless the door is opened within a few minutes.

Incorporated DRYING CYCLE: with thermodynamic system and vacuum pump

POSSIBILITY OF CONNECTING THE DRAIN to the sewage system or can provided.

POSSIBILITY OF CONNECTING UP the water supply to our WATER OK treatment unit.

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 4 di 27 |

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

Description |

Unit of measurement |

Values |

|

||

|

|

|

|

|

|

Power source voltage rating |

V |

|

230 V.a.c. ~ |

|

|

Power source frequency |

Hz |

|

50 |

|

|

Machine power rating |

W |

|

2300 |

|

|

Boiler volume |

mm |

|

Ø 240 x 340 |

Ø 240 x 440 (B20) |

|

Operating pressure |

Bar |

|

2.1 - 1.1 |

|

|

Machine dimensions X, Y, Z |

mm |

|

Prof. 540 x Larg. 480 x H 530 |

|

|

Gross weight |

Kg |

|

50 |

|

|

Pack dimensions |

mm |

|

Prof. 680 x Larg. 560 x H 670 |

|

|

Operating temperatures |

°C |

|

+ 3°C …… + 35°C |

|

|

Distance from walls |

cm |

|

8 - 10 |

|

|

X = depth |

Y = width |

Z = height |

|||

The electrical system is protected against the risk of over-currents installed inside the machine by two 15 A delayed action fuses ( T 15 A ).

The electronic control and powering boards protect the various users by means of 3 dedicated fuses: 2 quick-acting 1 A types (F 1 A) and one 100 mA delayed action type (T 100 mA) – (see enclosed wiring diagram).

Only have these fuses changed by a skilled electrician.

The noise level of the machine has been tested. The continuous equivalent weighted acoustic pressure level A is less than 70 dB (A) and the continuous equivalent weighted acoustic power level A does not exceed 85 dB (A). The measured noise level measured is therefore very low. For this reason, the operator need not take any particular measures (also in view of the fact that the machine operates automatically).

DATA AND SPECIFICATIONS OF THE PRESSURIZED VESSEL:

Serial N° of vessel, Serial N° of door |

Month N°, Year N° (see internal label) |

|

Max. operating pressure: |

2.2 Bar |

|

Max. operating temperature: |

160°C |

|

Min. operating pressure: |

-0.9 Bar |

|

Test pressure: |

8 Bar |

|

Reference standards: |

TRD 421 |

|

Volume of vessel: |

16 or 20l. |

|

DATA AND SPECIFICATIONS OF THE PRESSURIZED VESSEL: |

|

|

|

|

|

Serial N° of vessel, Serial N° of door |

Month N°, Year N° (see internal label) |

|

Max. operating pressure: |

3 Bar. |

|

Max. operating temperature: |

160°C |

|

Test pressure: |

12 Bar. |

|

Reference standards: |

TRD 421 |

|

Volume of vessel: |

1 lt. |

|

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 5 di 27 |

|

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

3. G E N E R A L R E C O M M E N D A T I O N S

3.1 Regulations for the operator

Always wear personal protective equipment in compliance with the directives that establish the current accident-preventing provisions.

Do not approach the machine with inflammable materials.

Do not carry out repairs or maintenance work whilst the machine is operating or plugged into the electricity main or when parts of it are hot.

Only responsible adults may use the machine in places inaccessible to children.

Use the machine in a dry place, sheltered from the rain.

Periodically inspect the power cable to make sure that it is in a good condition.

If there are several persons in the place of work, remember to keep at a safe distance from the machine to prevent accidental contact with hot parts.

Never ever operate the appliance unless the power cable is in a perfect condition and the structure undamaged.

It is advisable to keep the door half-open with switch (8) turned off in “0” position, when the appliance is not in use.

It is advisable to nominate a person responsible for the autoclave, as established by directive 626/94.

Pay the utmost attention to those parts of the appliance that become hot during operation and that still remain hot after it has been switched off. Keep your face well away from the top part of the machine when the door is opened to prevent it from being scalded by steam. Keep about 50 cm. away from the machine when opening the door.

As specified in the technical specifications, these autoclaves operate at a pressure that can reach 2.2 Bar at most. Do not use the autoclave in an improper way and do not carry out maintenance operations while the sterilizing cycles are in progress. Remember that the pressure is shown by the pressure gauge installed on the front of the machine itself.

Wait at least 20 minutes after the appliance has been switched off, to allow the boiler to completely cool.

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 6 di 27 |

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

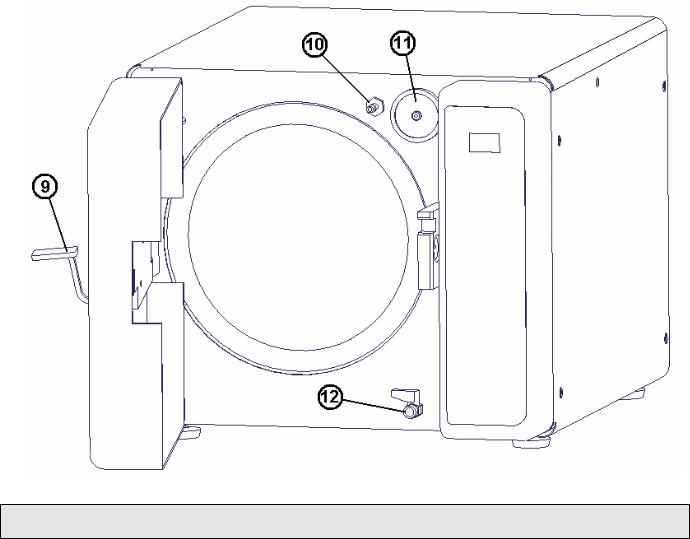

4. L O C A T I O N O F T H E C O N T R O L S

PRATIKA feature an elegant casing treated with scratch-proof epoxy powder paint in the RAL 9010 COLOUR. No particular preparations are required to operate the machines. Just fit the plug into a 230 V power socket.

CONTROL PANEL:

-1- INFO DISPLAY

-2- VALUE INCREASE / MENU’ -3- OK / ENTER

-4- VALUE DECREASE / MENU’

-5- FILL WATER / START-STOP CYCLE -6- PRESSURE AND VACUUM GAUGE -7- PRINTER CONNECTING SOCKET -8- MAIN SWITCH

-9- DOOR OPENING LEVER -10- WATER FILL UNION

-11- BACTERIOLOGICAL FILTER -12- WATER DRAIN UNION

-13- SD CARD

THE FOLLOWING ACCESSORIES ARE

SUPPLIED:

1 TRAY HOLDER, 4 TRAYS, 1 TOOL TO TAKE OUT THE TRAYS AND ADJUST THE DOOR, 1 PIPE WITH FILTER FOR WATER FILLING, 1 WATER DRAIN PIPE, 1 TRANSPARENT 6 TUBE TO DRAIN WATER INTO THE CAN, 1 SPONGE, 1 INSTRUCTION MANUAL, 1 10 LITER CAN, 1 LIFTING HANDLE.

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 7 di 27 |

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

5. S T A R T I N G A N D S E T T I N G A T W O R K

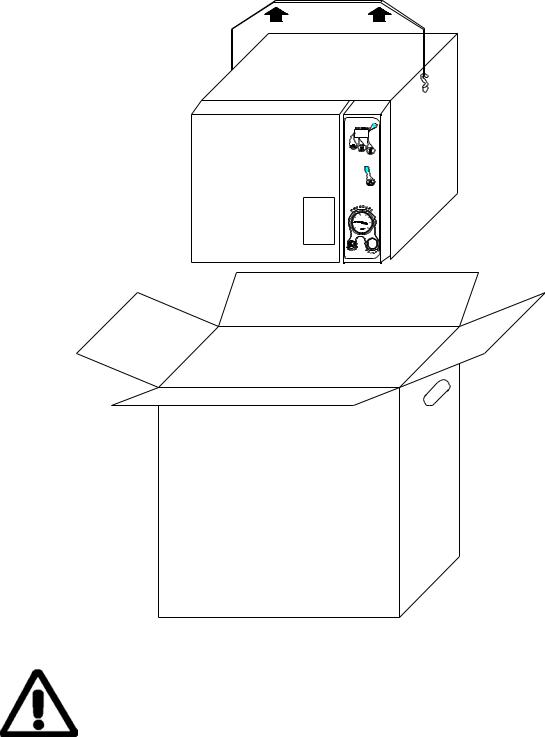

5.1 Removing the machine from the packing

The machine is consigned packed on a wooden pallet in a cardboard box: make sure that there are no dents and that the wrapping is in optimum conditions.

The machine must be stored in a dry place, sheltered from adverse weather conditions, at a temperature between +3°C and +35°C. The machine must be handled without jolting and using appropriate means. Open the pack without overturning it. Remove the polystyrene from the top and sides (the weight of the model is given in chap. 2, technical specifications).

Lift the machine out of the box in a vertical direction using the 2 hooks supplied in the bag inside the pack. These should be inserted into the two holes at the sides of the casing (see drawing on page 9). Remove the pluriball wrapping from around the machine and make sure that all parts of this latter are undamaged and complete with all the accessories indicated on the consignment note. Immediately notify our dealer if discrepancies are discovered.

Keep the packing materials for as long as the machine remains in use, not just for the warranty period. This is because the autoclave may need to be calibrated or regulated by the manufacturer's staff of by an after-sales center. Non-original packing is unable to ensure that the machine is correctly protected during transport.

The original packing comprises the following items:

-BIWALL BOX IN CARDBOARD WITH 3 CORRUGATIONS

-PLURIBALL POLYETHYLENE BAG

-SHAPED POLYSTYRENE FOAM

-PALLET INSIDE THE BOX

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 8 di 27 |

Operation and Maintenance Manual – Steam sterilizers mod. PRATIKA

DRAWING ILLUSTRATING HOW THE MACHINE MUST BE LIFTED FROM THE PACK

5.2 Installation and preliminary inspections

The installer is obliged to make sure that the place in which the sterilizer is installed is fit for that purpose (CEI 62/4).

Install the autoclave in a well ventilated place, well away from sinks, heat sources, grinders and from all other machines.

Comply with the following instructions to simply and efficiently check that the machine has been positioned correctly:

Fit the electric plug into a socket WITH A CAPACITY OF AT LEAST 16 Ampere AND EQUIPPED WITH AN EARTH CONNECTION. Make sure that the mains voltage rating corresponds to the value indicated on the label at the rear of the machine (230 Volts).PRATIKA must only be filled with DISTILLED WATER to ensure that the electrical and air-operated devices operate efficiently and are long lasting.

Rev. 01 del 03-01-2007 - C:\Documenti\Manuali di istruzione\PRATIKA GB-R01.doc |

Pag. 9 di 27 |

Loading...

Loading...