Page 1

Art No 9343 A

OPERATION MANUAL

Revent Incorporated

100 Ethel Road West

Piscataway, NJ 08854

Phone #800-822-9642

www.revent.com

Modular Deck Oven

THE MANUAL SHOULD STAY WITH THE OVEN

Page 2

2

Oven identification

Modular Deck Oven Operation Manual, October 2011

Page 3

Modular Deck Oven Operation Manual, October 2011

3

CONTENTS

Oven identification Oven identification 2

Preface Important information 4

Chapter 1: Introduction 6

General How the Revent Modular Deck Oven works 6

Information Standard features 6

Options 7

Dimensions and weights 7

Wiring diagram 7

LCD Screen 7

Chapter 2: Regarding installation 8

Installation

Chapter 3: Introduction 12

Operating Key components 13

Instrumentation 14

Baking 16

Baking with steam 18

More Baking instructions 19

Overheating 20

Cool down 20

Burners 21

Chapter 4: Cleaning 23

Routine Mechanical maintenance 24

Maintenance Lubrication needed 26

Oven safety checks 26

Chapter 5: Troubleshooting 28

Troubleshooting

Appendices: A Technical specifications

B Spare parts and Wiring diagram

C Oven components

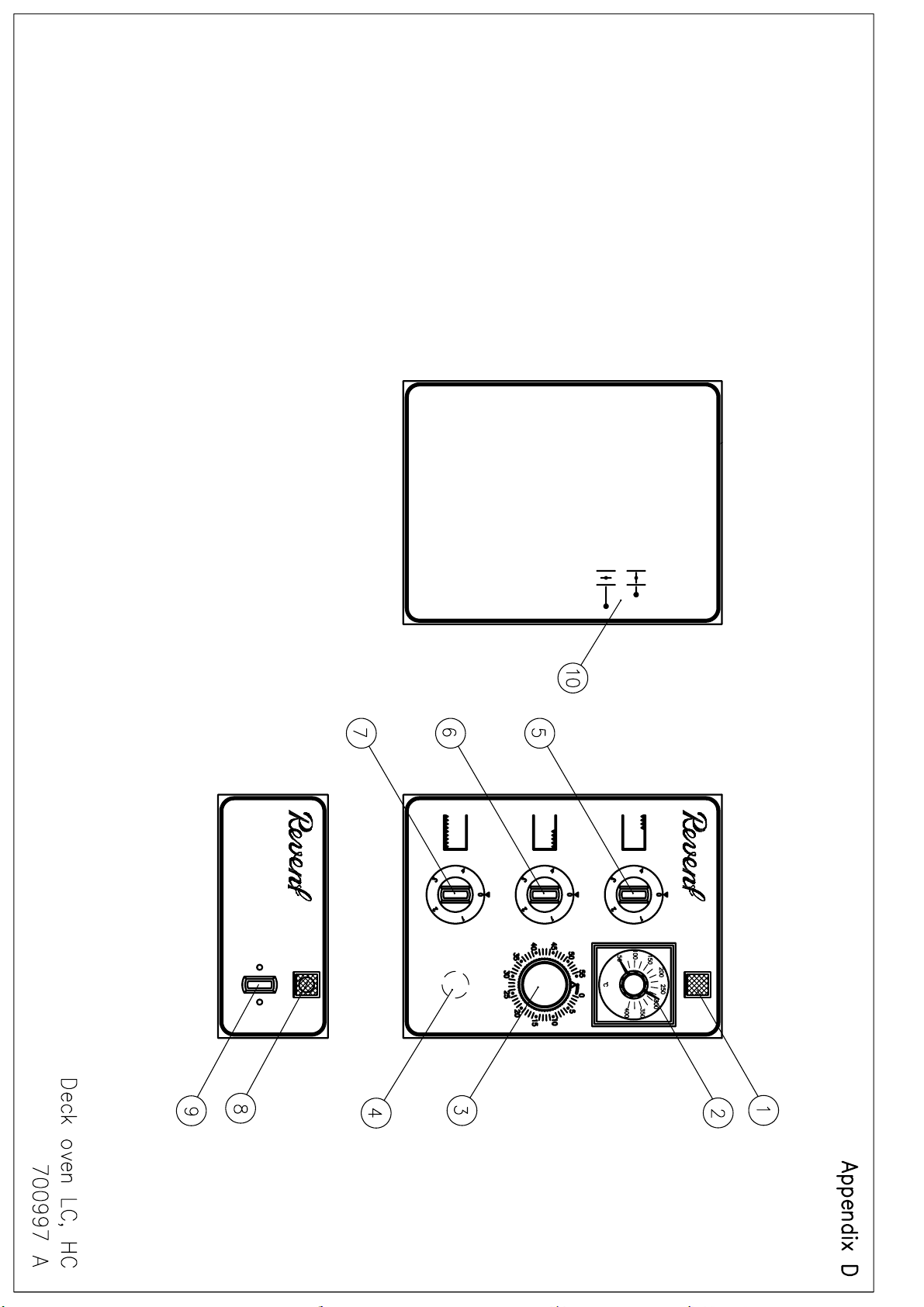

D Control panel and control box

F Measurement diagram

Page 4

Modular Deck Oven Operation Manual, October 2011

4

General informat ion to the owner/operator:

Read this manual prior to first use or if you are uncertain of how to use this product.

servicing and cleaning the oven hav e the appropriate knowledge of how to handle the oven. It

laws.

FOR YOUR SAFETY – IF YOU SMELL GAS OR IF YOU SUSPECT A GAS LEAK:

• Open windows.

Natural gas is lighter than air and propane is heavier t han air!

FOR YOUR SAFETY

Do not store or use gasoline or other flam m able vapors or liquids in the vicinity of this

appliance.

Remember, improper use or installation of this product may void warranty.

This oven is to be used for food products only, except for those containing vol atile and/or

flammable ingredients. Racks and trays should not be used outside the bakery environment

or for other products than for food products.

It is the responsibilit y of the oven owner/operator to make sure that all per sonnel using,

is important that they know the contents of all warnings in this manual. It is generally t he

responsibility of the oven owner/operator to take precautions to protect people or animals

from getting hurt.

It is the responsibilit y of the owner/oper ator to make sure that this oven i s m aintained and

serviced according to the instructions in this manual and according to applicable codes and

DANGER

• Evacuate people in risk zone.

• Do not try to light any appli a nce .

• Don’t touch electrical switches or any other equipment that might cause sparks

(including phones or cel l phones) in your b uilding.

• Extinguish any open flame.

• Immediately call your gas supplier. Follow the gas supplier’s instructions

• If you cannot r ea ch your gas supplier – call the fire department.

• Never use flame or any kind of spark for gas leak detection. This could cause fire

and/or explosion.

REMEMBER!

DANGER

Page 5

Modular Deck Oven Operation Manual, October 2011

5

IMPORTA NT INFORMATION CONCERNING BURNER (IF USED) IN THIS OVEN

• WARNING! Only allow an AUTHORISED SERVICE COMPANY to adjust the burner.

maintenance of the burner.

WARNING

Special instruments and training are required.

• WARNING! Carbon monoxide poisoning hazard. Carbon monoxide is a col orless,

odorless gas that can kill. Do not use the burner in an un-vented, enclosed area. Carbon

monoxide may accumulate.

• WARNING! Do not adjust the pressure regulator. A high pressure produces carbon

monoxide. Any adj ustment of the burner must be performed by an AUTHORISED

SERVICE COMPANY.

• WARNING! Check flue gases for carbon monoxide before use (requires special

equipment).

• WARNING! Do not attempt to use a gas valve set for natural gas on LP gas, or a gas

valve set for LP gas on natural gas.

• WARNING! Any modifications to the burner wil l void warranty and will invalidate Safety

Agency Certification.

• WARNING! Damage to ignition control could result in fatal accidents. Do not attempt to

repair or disassemble the ignition control. Ignition control that has been wet must be

replaced.

• WARNING! Calling for burner service and maintenance of safety devices in this oven is

the sole responsibility of the owner/operator.

• WARNING! All installations must be made in accordance with all local codes, which may

differ from instructions given i n this manual.

• WARNING! Improper negative pressure in the heating unit of the oven might damage the

heating unit, burner, ov en and the property and al so cause per sonal injuries or death.

Improper negative pressure will void warranty.

• WARNING! Electric shock hazard. High voltages are present in this equipment. Follow

these rules to avoid electric shock: Use only a properl y grounded circuit. A ground fault

interrupter is recommended. Do not spray water directly on the burner. Turn off power

before servicing.

• WARNING! Overheating hazard. Should overheating occur: Shut off the manual valve to

the appliance. Do not shut off the control switch to the pump or blower .

The installer should inform and demonstrate to the user the correct operation and

This Instruction Handbook follows:

European Norm: SS-EN 1673:2000E

Revent ISO 9001 Document Routine.

Page 6

Modular Deck Oven Operation Manual, October 2011

6

Chapter 1

GENERAL INFORMATION

INTRODUCTION

The Revent Modular Deck Oven is delivered so that the decks can be parted for easier

intake and moving (splitable oven).

The Revent Modular Deck Oven is suitable for small to medium size bakeries. It is

available up to five decks in height and up to three trays in width. (See Brochure)

HOW THE REVENT MODULAR DECK OVEN WORKS

The Revent Modular Deck Oven transfers heat to the baked goods by the means of

conduction from the bottom and radiation from the top of the baking chamber.

The electric heaters transferring the heat to the pr oducts in the oven chamber ar e located

in three zones: The bottom zone, located immediately under the ov en chamber floor , the

top zone, just below the oven chamber ceiling and the door heating zone just below the

oven chamber ceiling close to the door.

The controls (provided on the c ontrol panel) allow y ou to easily regulate temperat ure, heat

generation from the three zones (top/ bottom/door), steam (optional), and baking time.

FEATURES

- Each deck individually heated, controlled and operated

- Fast continuous operation

- All stainless steel outside lining

- Heavily insulated all over to prevent heat loss

- Glass doors

- Easy to use oven chamber temperature regulator

- Steam damper fitted on each deck

OPTIONS

- Built-in steam generator (one per deck)

- Stone soles

- Oven stand with tray storing supports

- Under built prover

- Tray grid for oven chamber bottom

- Retractable tray rest in stand

DIMENSIONS AND WEIGHTS

See appendix A for all product dimensions and weights.

WIRING DIAGRAM

See appendix B for wiring diagram.

Page 7

Modular Deck Oven Operation Manual, October 2011

7

The information in this section is for the owner/operator and user(s) to understand basic

requirements for a successful installation.

To meet the product requirements, local codes, product warranty etc, Revent recommends

• How to operate the oven.

Keep everyone clear fr om the risk of getting hurt from oven parts that are moved or lift ed.

The oven should be installed on a non-combustible floor surface equal to the oven foot-print.

Water temperature at wat er inlet must not exceed maxi mum 140°F. The oven should not be

fitted with a w ater softener, since it can cause seri ous damage to the oven. A filter should be

Chapter 2

INSTALLATION

IMPORTANT POINTS ABOUT INSTALLATION

that a REVENT AUTHORISED DEALER/DISTRIBUTOR is used for installation and service.

A REVENT AUTHORISED DEALER/DISTRIBUTOR is trained in:

• How to install an oven.

• How to service an oven.

WARNING

PREPARE THE INSTALLATION SITE

To assemble a Revent oven in the most effective way, it i s important to first find:

-a suitable place to unload the oven.

-a bay or place where a forklift truck can manoeuvre.

-how to get to the spot where the oven will be inst alled.

-if you will need to go up or down steps or around tight corners?

THE CONDITION OF THE FLOOR

WARNING

The floor where the oven is to be erected shoul d be level and non-combustible. The slope of the

floor can be no greater than 0.04” per foot in any direction. B e careful that the floor does not

slope downwards toward the back or side wall (if instal led in a corner).

WATER AND DRAINS

Water pressure should be at least 64psi for optimum steam system results. If lower

water pressure is causing poor steam system results, a booster pump should be

installed.

CAUTION

Page 8

Modular Deck Oven Operation Manual, October 2011

8

installed just in front of the solenoid valve if there is any doubt regarding the water quality.

Water or the water connection from the steam drain outlet is extremely hot and may cause

serious burns.

All electrical connections are t ightened at the Revent factory prior to delivery according to t he

retightened if necessary during installation.

CAUTION

Before the oven is put into place, the drainage pipes must be planned. Drainage pipes must be

planned according to local plumbing regul ations. Note that the pipes must dr op off for proper

drainage.

ELECTRICAL

The ovens shall be connected with separate fuses, with future servicing in mind. A

lockable circuit-breaker should be installed to allow easier servicing.

Plan the electrical connections in advance. It is easier to install the electrical feed to the oven

before the oven is in place rather t han aft er.

WARNING

manufacturers stipulated torque r equirement.

However, during tr ansport electrical connections as well as any connection can become

loose. For this reason we recommend that all electrical connections are checked and

VENTILATION

The oven combined damper duct has a dia of 2.75” and should be fitted to a properly

insulated stack.

INSTALLATION

It is important to have the site ready for the installation to avoid unnecessary delays.

Survey the site. Check all intake openings and tig ht corners to be sure that it is possible to

take the oven in. Find a suitable place to unload the oven, preferably somewhere that a

forklift truck or other lifting device can manoeuvre.

If you place the oven against the left-hand side wall (as you stand facing the oven front),

the space between the wall and the oven side panel should be a minimum of 0.4”.

If you intend to place the oven, contr arily, ag ainst the right-hand side wall, the s pace must

only exceed 2” if the oven can be pushed in after assembly and likewi se be pulled out for

future service. How ever, if it cannot, you must all ow a minimum of 31.5” between the ov en

panel and the right wall of premises.

If the oven contains the optional built-in steam generator and cannot be pulled out from the

Page 9

Modular Deck Oven Operation Manual, October 2011

9

wall for future service, you must also allow 31.5” clearance on the left-hand side as well.

Minimum distance between the rear premises wall and the rear part of the oven body

(including the damper outlet cover) must exceed 4”.

UNPACKING THE REVENT MODULAR DECK OVEN

The oven is crated on a wooden pallet. Optional equipment, such as oven stand, is

packed on top of the oven. Stone soles and or spacer g r i d( s) for t he deck floor is packed

inside the oven chamber. Retractable tray rest is shipped in separate package(s).

Before unpacking the oven check the pac kage completel y for any transp ortat ion da mages.

Unpack the oven and make a thorough inspection for transport damages.

SPLITTING THE DECKS

A modular oven is delivered as one unit but can be split to enable easier intake.

To split the oven:

Open the right-hand side cover panel to disclose electrical connections. Disconnect all

cables between the decks obser ving the colours of the w ire leads. Unscre w the appli cable

bolts in this section between all decks that you wish to split.

Dismantle the smoke hood on the back side of the oven. Unscrew the scr ews holding the

thin sheet metal deck fixator.

Unscrew the two socket head cap screws (just above the oven door, in two separate

holes).

Lift the oven deck - gently - straight up. If the deck is too heavy, it is possible to lift the

deck enough to fit tubes under it and then roll it on to a lift or forklift.

REASSEMBLING THE DECK

To reassemble the deck oven after it has been spl it, simply rever se the above procedure s.

INSTALLING THE REVENT MODULAR DECK OVEN

Place the oven in a position that allows you to conveniently complete the installation.

Allow a minimum of 0.4” space between the oven side panel ( to y our lef t as y ou fac e the

front of the oven) and nearest object. Likewise, the space on the r ight hand si de m ust be

no less than 2” for the cooli ng of electrical components . We recommend space to be 31. 5”

on this side to facilitate eas y servicing, unless the oven can be pulled out for this purpose.

Space between rear wall and oven should be no less than 4”.

Level the oven off. No more than 0.04” per foot in any direction is permitted.

Connect the damper outlet to the stack (appendix F item 4). T he oven combined dam per

outlet has a dia of 2.75” mm and should be fitted to a pr operly i nsulated s tack. T he oven

combined damper outlet should also be insulated. If the stack is connected to a

ventilation/fan system, a draft by-pass should be used.

Page 10

Modular Deck Oven Operation Manual, October 2011

10

Connect water and drains (appendix item 1). If the ov en or ov en deck s ar e or der ed wit h

steam function (optional) the solenoid valve is for 1/4" connection.

Electrical connections (appendix F i tem 7) should be carri ed out by a qualified elec trician.

Suitable wire area should be selected to sui t rated current. Rem ember to all ocate enough

wire length to allow for oven being pulled out for servicing. A separate "service circuitbreaker" should be installed so that the power can be disconnected during service.

Remember to place this breaker so it can be easily seen by the service engineer when

working on the oven. This is a safety measure.

Make sure that the circuit -breaker is in the "zero" posi tion. Connect the power supply cable

to the terminal block.

Page 11

Modular Deck Oven Operation Manual, October 2011

11

This oven is to be used for food products only, except for those containing volatil e flammable

products other than food products.

Before first bake the oven must be broken-in by the installer as per inst ructions in the

installation manual.

When the oven door is opened, hot air and steam are released f rom the bake chamber. To

the oven door are hot. Use your oven gloves!

If you have a product fire in the oven, turn off the power and wait until the fire has gone out .

oven

Humidity from the products or steam system can cause slippery conditions on the oven

chamber floor and adjacent fl oor. Be cautious!

Chapter 3

OPERATING

INTRODUCTION

CAUTION

ingredients. Racks and trays should not be used outside the bakery environment or for

CAUTION

CAUTION

avoid burns open the oven door slowly and leave an opening gap of 2” mm for a couple of

seconds, then open the door. Please, observe that interior surfaces of the bake chamber and

WARNING

To avoid personal injuries and propert y damage, do not remove a product on fire from the

CAUTION

Page 12

Modular Deck Oven Operation Manual, October 2011

12

KEY COMPONENTS

The key components of the oven are shown in appendix C.

(item B) Control box

(item C) Control panel

(item E) Manual Damper

(item F) Damper exhaust

(item G) Solenoid valve

(item H) Temperature limit control

(item M) Drain

(item O) Electrical heaters

(item P) Electrical heaters (for steam generator)

(item U) Control switch

Page 13

Modular Deck Oven Operation Manual, October 2011

13

The main power source (not t he oven main switch) to the oven must be turned off prior to

service.

Before first bake the oven must be broken-in by the installer as per inst ructions in the

installation manual.

INSTRUMENTATION

All item numbers below refer to appendix D, control panel and control box.

Control panel

(Item 1) Red pilot lamp. The red pilot lamp is lit when elements are in operation.

(item 2) Temperature regulator (max 572ºF). The temperature regulator displays the

set oven temperature. Temperature is set by turning the knob to desired

temperature according to the scale and it is indicated by the red pointer.

Current temperature is indicated by the white pointer. The temperature can

be changed during baking. IMPORTANT! If the temperature rises above

599°C, the temperature limit control will trip. This must be reset manually.

(Item 3) Baking time. The baking time is set by turning the knob clockwise to

desired time. An alarm will sound to signal the end of the bake. The baking

time can be changed during baking.

(Item 4) Steam push button. As long as this button is pushed the steam will be

transferred to the oven chamber.

(Item 5, 6, 7) Heat regulation sw itches . Each deck has thr ee controls for bottom heat, t op

heat and oven door zone heat, respectively, offering you the ability to use

individual settings for different products. Each control has setting s marked 0,

1, 2, 3 and 4 (0 (0% power) – 4 (100% power)).

(Item 8) Green pilot lamp means power on.

(Item 9) Control switch. Oven is in stop position when switch points upwards.

WARNING

CAUTION

Page 14

14

Be cautious!

and by becoming hot these items may also be a safety hazard.

Modular Deck Oven Operation Manual, October 2011

CAUTION

When opening the oven door one may get exposed to hot air and steam . The oven door

glass, inside of door, oven inter ior panels, racks, trays/pans and baked products coul d be

very hot. Prevent people and animal s from burning themselves on hot oven surfaces.

Remember, that items placed or stored close to a hot oven may be damaged and heated up

THE FIRST START-UP - BREAK IN

All position (item) numbers below refer to Appendix D.

- To minimize odour remove all visible excess grease and plastic.

- Open the dampers (item 10) on all decks.

- Turn all switches and thermostats (item 2, 3, 5, 6, 7 and 9) to "zero" position.

Switch on the main power supply (item 9) to the oven.

Break-in Step 1 (Includes both standard modular deck ovens and those with optional

stone sole)

- Set the thermostat to 150°C (item 2) on al l decks. Turn the bottom heat swi tch ( item

7), the upper heat switch ( item 6) and the door zone heat sw itch (item 5) to position

"4". The green pilot lamp (item 8) w ill turn on. Leav e the heat on for approximately

2 hours. The green pilot lamp (item 8) will go off when desired temperature is

reached.

Break-in Step 2 (Standard model only)

- Set the thermostat (item 2) at 482°F. Leave the oven heat on for tw o more hours .

Break-in Step 2 (Ovens equipped with optional stone sole only)

- Set the thermostat (item 2) at 392°F. Leave the oven heat on for two more hours.

Break-in Step 3 (Ovens equipped with optional stone sole only)

- Set the thermostat (item 2) at 527°F. Leav e the oven heat on for three more hours.

Final Step (applicable to all ovens)

- Let the oven cool off. Clean the oven chamber w ith a soft brush and clean the ov en

door window.

The oven is now ready to be used.

Page 15

Modular Deck Oven Operation Manual, October 2011

15

BAKING

Before first bake the oven must be broken-in as per instruction “ The First Start-Up - Break

In”.

- Select the baking temperature by turning the thermostat knob clockwise to the

desired temperature. Turn all heat controls (item 5, 6 and 7) to position 4. Wait

until the oven has reached set temperature (30-45 minutes), and the red pilot

lamp (item 1) goes out.

- Select appropriate settings for the heat controls (item 5, 6 and 7) on each deck

depending on type of bread being baked.

- Open the door and load the products. Close the door and give steam (item 4),

immediately, if needed.

- Select baking time with the timer (item 2).

- After the baking time has completed the buzzer will sound. Turn off the alarm by

turning the baking timer knob (item 3) counter clockwise as far as possible. Open

the door and remove the products.

BAKING WITH STEAM

Steam must be added to the oven chamber at the beginning of the baking process for

some kinds of bread. The steam has three important functions to serve:

- To make the surface of the dough smooth and pliable in order to avoid cracking.

- To increase the heat transmission to the unbaked bread at the beginning of the

baking process.

- To give the crust of the bread the right surface structure.

Steam must be added directly after the ov en door has been closed, so that the steam can

condense on the surface of the unbaked bread before it starts drying and heating up.

COOL DOWN

For cooling dow n the oven decks it is r ecommend that the heat controls are turned off and

that the damper is completely opened.

If you cool down the oven by opening the doors there is a slight risk that the doors may

warp. However, they will return to normal condition 5 to 10 minutes after being closed

again.

- Energy demanding products The heat capacity, steam capacity and their recovery (in Revent ovens) are designed to

enable baking of the most energy demanding bread products.

(Some of our oven models can be equipped with heating sections capable of supplying

more energy). Please, contact your authorized Revent dealer for more information.)

Page 16

Modular Deck Oven Operation Manual, October 2011

16

It is absolutely prohibit ed to cool down the oven by using water. This may damage the oven

chamber, oven door window and also cause personal injury.

Remember not to leave a warm oven with the door open unattended (or without warning

signs) People or animals m ight get hurt.

OVERHEATING

When the overheat protection device trips out for electric heated ovens, the heat

contactor will be shut off. To reset the high limit control the oven must first be cooled

down approx. 140°F, when the oven has cooled down the high limit switch has to be

reset.

CAUTION

CAUTION

Page 17

Modular Deck Oven Operation Manual, October 2011

17

Revent recommends the use of a REVENT AUTHORISED DEALER for all serv ice and

When cleaning the oven do not spray water, especially not with a high pressure wat er gun,

e or outside the oven. Using water on hot oven surfaces may damage the oven chamber ,

ROUTINE MAINTENANCE & SERVICE

WARNING

maintenance work.

CAUTION

insid

oven door window and also cause personal inj ury.

Chapter 4

CLEANING

- Cleaning of oven The glass of the oven door is to be cleaned with hot water and liquid detergent (not on

hot oven). The oven floor must be swept regularly and burnt grimy should be raked

away. Any non-chlorine detergent can be used for cleaning of stainless surfaces. Soda,

borax and sodium perborate are good detergents. The detergent should always be

wiped away using a wet cloth.

Greasy spots on the outside surfaces can be removed with Vienna lime. The Vienna

lime is applied with a cloth and the surface is polished in the grinding direction of the

stainless steel surface. Steel wool should never be used as it will scratch the surface.

Furthermore, non-stainless steel wool can cause corrosion on the surface. For internal

cleaning, non-metallic sponges, type Scotch Brite, can be used. The instrument panel is

cleaned with a moist cloth and liquid detergent.

MECHANICAL MAINTENANCE

- Heat unit, electric heated ovens The electric heat unit normally does not require any service. However, check the fuses

regularly. Blown fuses cause longer heating time and the oven cannot hold the right

temperature. Once a year an electrician should check the function and contact surfaces

of the contactor(s).

Page 18

Modular Deck Oven Operation Manual, October 2011

18

A worn out or damaged contactor can cause seri ous dam age to the oven and lead to related

problems.

It is very important that you follow the instruct ions for service of the burner given i n the burner

instruction handbook in the document compartment within the heat section door. If the oven is

instruction handbook.

Heat exchangers must be cold when sweepi ng is performed.

WARNING

WARNING

instructions. If the oven i s equipped with a burner from Revent you will find the burner

equipped with a burner purchased locall y, please ask the local supplier for a burner

WARNING

- Steam generator -

Steam is produced by sprinkling water over a number of flat bars. If the steam capacity

decreases, there might be lime or other deposits in the sprinkler tube. The tube should

be cleaned. In areas with high lime content in the water, it may pay off to install a

softening filter to avoid production stops. (Please, ask us for information on softening

filters.)

OVEN SAFETY CHECKS

Other safety checks

At least once a year the right hand side panel should be removed to enable cleaning

around the electrical connections. Disconnect the power with the service circuit-breaker

and vacuum clean carefully around all the connections.

Revent recommends that a REVENT AUTHORISED DEALER makes a check once a

year of the following safety device/function on the ovens oven: temperature high limit

control.

Page 19

Modular Deck Oven Operation Manual, October 2011

19

Revent recommends the use of a REVENT AUTHORISED DEALER for all serv ice and

All trouble shooting and service mentioned below could be associated with personal danger

To be safe, please contact your REVENT AUTHORISED DEALER.

The main power source to the oven must be turned off prior to service.

SYMPTOM

MEASURE

If measures 1-4 do not help, call a REVENT AUTHORISED DEALER.

The oven is slow to

1. Check the heat regulation switches and increase the settings.

COMPANY. Measures 4-6 demand a REVENT AUTHORISED DEALER.

Uneven heat

oven chamber.

1. Check the heat regulation switches and increase settings.

3. Check all heaters.

Chapter 5

TROUBLESHOOTING

WARNING

maintenance work.

WARNING

and also be of lethal risk. Some of the measures below could also be illegal if not carri ed out

by authorised personnel . Improper service and repair may void warranty.

DANGER

Oven does not heat

up

1. Check that the oven main switch is on.

2. Check the main fuse.

3. Check the (service) contactor.

4. Check that the temperature is set (red pointer) higher than actual

temperature (white pointer).

5. Check the thermostat. Turn the thermostat clockwise and check that

the red pilot lamp (item 6) is on. If it is not, the connections to the

thermostat should be checked. The thermostat may need replacing. If

the red pilot lamp is activated, the heat contactor or the elements

needs to be replaced.

6. Check that the red pilot lamp is activated.

heat up.

distribution in the

2. Check that all three phases have power.

3. Check the thermostat settings and function.

4. The temperature limit control has tripped and should be reset.

5. The heat contactor is defective and should be replaced.

6. One or many electric heaters are out of order and should be replaced.

If measures 1-4 do not help, call a REVENT AUTHORISED DEALER

2. Check all fuses.

Page 20

Modular Deck Oven Operation Manual, October 2011

20

SYMPTOM

MEASURE

Measure 3 demands a REVENT AUTHORISED DEALER.

Insufficient or no

1. Check that all valves and filters are open.

Measures 2-4 demand a REVENT AUTHORISED DEALER.

Measures 1-2 demand a REVENT AUTHORISED DEALER.

No light in the oven.

1. Unscrew the glass lamp cover in the oven chamber, unscrew the light

If measure 1 does not help, call a REVENT AUTHORISED DEALER.

The oven door falls

1. The spring needs to be replaced. Unscrew the right hand panel and

If measure 1 does not help, call a REVENT AUTHORISED DEALER.

If measures 1-2 do not help, call a REVENT AUTHORISED DEALER.

steam.

Water on the oven

floor.

down.

2. The sprinkler tube is clogged and should be cleaned.

3. The solenoid valve is defective and should be cleaned or replaced.

4. The water pressure is too low (below 4.5 kg\m²) and a booster pump

has to be installed.

If measure 1 does not help, call a REVENT AUTHORISED DEALER.

1. The outlet water pipe is clogged and should be cleaned.

2. The solenoid valve is leaking and should be cleaned or replaced.

bulb and replace it (heat resistant 300°C (572°F), E14, 40W.

the spring cover and replace the spring.

Page 21

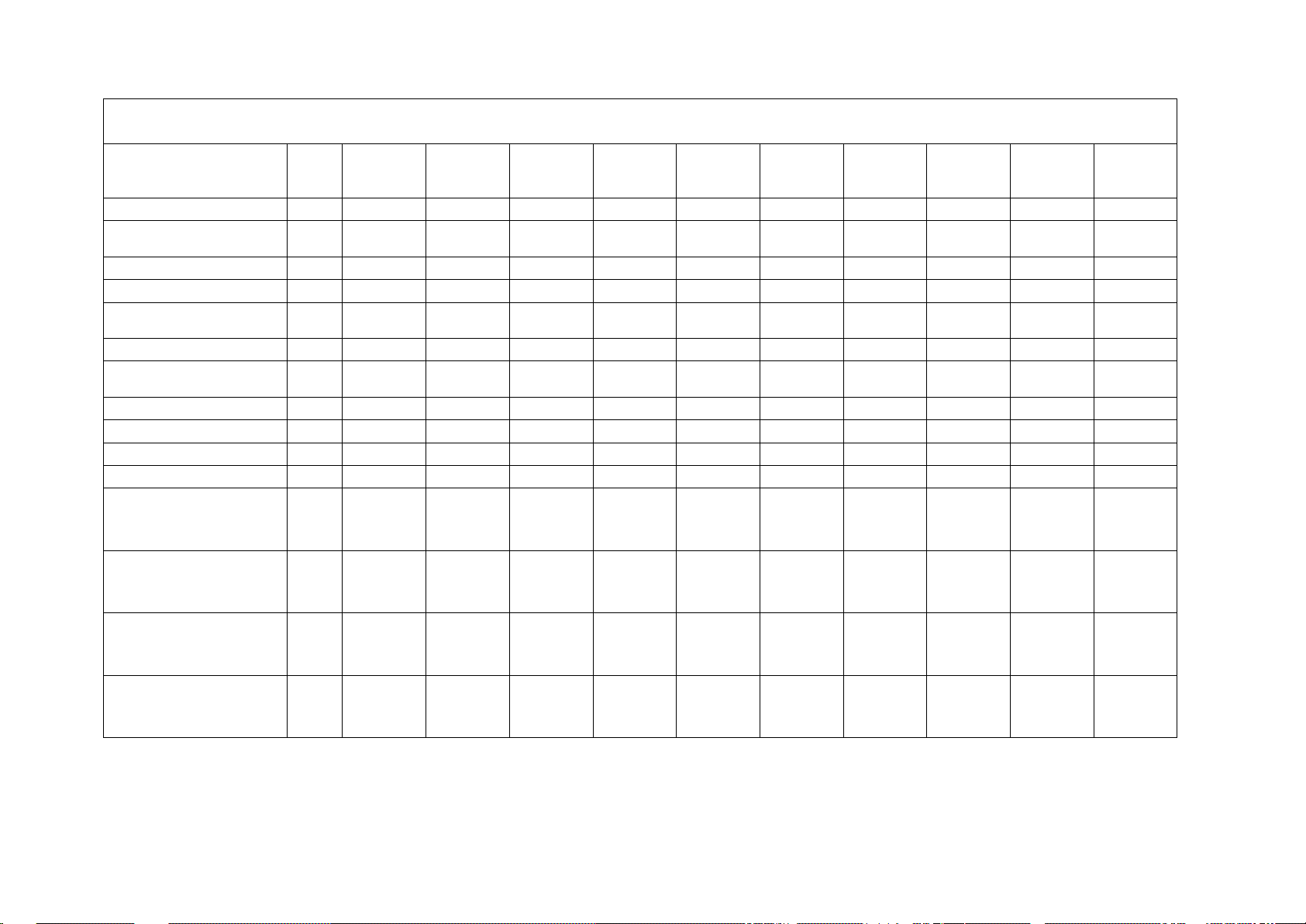

Technical specification Appendix A

Chamber interior dimensions (inch) Exterior dimensions (inch)

Module No of pans kW Width Depth Height Width Depth Height Revent part no

PAN S IZE 18" x 26"

Deck LC * 2 4.7 37.8 26.6 5.9 61.9 37.4 12.6 649302xxxx

Deck HC ** 2 4.7 37.8 26.6 7.9 61.9 37.4 14.6 649312xxxx

Top 2 62.6 37.4 4.0 6493720000

Bottom 2 62.6 37.4 4.3 6493820014

Deck LC 3 6.9 56.7 26.6 5.9 80.8 37.4 12.6 649303xxxx

Deck HC 3 6.9 56.7 26.6 7.9 80.8 37.4 14.6 649313xxxx

Top 3 81.5 37.4 4.0 6493730000

Bottom 3 81.5 37.4 4.3 6493830014

OPTIONALS

Steam generator 2 ask factory

Stone soles ask factory

Legs (set of 4), length 4" 6497010000

Legs (set of 4), length 10" 6497020000

Legs (set of 4), length 15.8" 6497030000

Legs (set of 4), length 21.7" 6497040000

Legs (set of 4), length 27.6" 6497050000

Castors (set of 4), heigth 7.5" 6498210000

Grid for oven chamber sole 29.1" x 37.8" 6498410000

Grid for oven chamber sole 29.1" x 56.7" 6498420000

UTILITY REQUIREMENTS

Standard voltage 208V / 3 / 60Hz

Water connection 5 GPH, ½" NPT connection

Page 22

Page 23

B

SPARE PARTS 3PH200-240V+PE, 3PH380-415V+N+PE, 50/60 Hz

Mechanical

Pos.

2x

18”x26”

LC

3x

18”x26”

LC

2x

600x800

LC

2x

457x762

LC

3x

457x762

LC

2x

18”x26”

HC

3x

18”x26”

HC

2x

600x800

HC

2x

457x762

HC

3x

457x762

HC

Castor

1

50239976

50239976

50239976

50239976

50239976

50239976

50239976

50239976

50239976

50239976

Door with glass

2

50239992

50239995

50239993

50239992

50239995

50239990

50239996

50239994

50239990

50239996

Glass 3 50239997

50239998

50239963

50239997

50239998

50239991

50239999

50239962

50239991

50239999

Protection batch, Glass

4

50239946

50239946

50239946

50239946

50239946

50239946

50239946

50239946

50239946

50239946

Door springs

5

50239950

50239950

50239950

50239950

50239950

50239950

50239950

50239950

50239950

50239950

Door handle

6

50239972

50239972

50239972

50239972

50239972

50239972

50239972

50239972

50239972

50239972

Door sealing, side

7

50239965

50239965

50239965

50239965

50239965

50239965

50239965

50239965

50239965

50239965

Door sealing, sole

8

50239966

50239966

50239966

50239966

50239966

50239966

50239966

50239966

50239966

50239966

Door sealing, up and low

9

50239986

50239986

50239986

50239986

50239986

50239986

50239986

50239986

50239986

50239986

Knob (door handle, damper)

10

50239973

50239973

50239973

50239973

50239973

50239973

50239973

50239973

50239973

50239973

Oven light protection glass

14

50153203

50153203

50153203

50153203

50153203

50153203

50153203

50153203

50153203

50153203

Oven light gasket

15

50287101

50287101

50287101

50287101

50287101

50287101

50287101

50287101

50287101

50287101

Stone sole

16

50239952

50239952

50239979

50239984

50239984

50239952

50239952

50239979

50239984

50239984

Page 24

B

SPARE PARTS 3PH200-240V+PE, 3PH380-415V+N+PE, 50/60 Hz

Electrical

Control box, Panel

Pos.

2x

18”x26”

LC

3x

18”x26”

LC

2x

600x800

LC

2x

457x762

LC

3x

457x762

LC

2x

18”x26”

HC

3x

18”x26”

HC

2x

600x800

HC

2x

457x762

HC

3x

457x762

HC

Control Switch

1

50239915

50239915

50239915

50239915

50239915

50239915

50239915

50239915

50239915

50239915

Pilot lamp green

Pilot lamp green USA

2

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

Push button (Steam)

3

50239925

50239925

50239925

50239925

50239925

50239925

50239925

50239925

50239925

50239925

Knob (for timer)

4

50204501

50204501

50204501

50204501

50204501

50204501

50204501

50204501

50204501

50204501

Timer baking 50Hz

Timer baking 60Hz

5

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

50113601

50152200

Thermostat

6

50239902

50239902

50239902

50239902

50239902

50239902

50239902

50239902

50239902

50239902

Pilot lamp yellow

Pilot lamp green USA

7

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

50239908

50205401

Knob (for switch heat)

8

50239901

50239901

50239901

50239901

50239901

50239901

50239901

50239901

50239901

50239901

Switch heat regulation

9

50239903

50239903

50239903

50239903

50239903

50239903

50239903

50239903

50239903

50239903

Panel (lower)

10

10289602

10289602

10289602

10289602

10289602

10289602

10289602

10289602

10289602

10289602

Panel (top)

11

10289601

10289601

10289601

10289601

10289601

10289601

10289601

10289601

10289601

10289601

Element

208-220V

380V

400V

415V

12

50296201

50266203

50296205

50296207

50296201

50266203

50296205

50296207

Element

208-220V

380V

400V

415V

13

50296202

50266204

50296206

50296208

50296202

50266204

50296206

50296208

Element

208-220V

380V

400V

415V

12

50239953

50296222

50296224

50296226

50239953

50296222

50296224

50296226

Element

208-220V

380V

400V

415V

13

50239954

50296223

50296225

50296227

50239954

50296223

50296225

50296227

Page 25

B

SPARE PARTS 3PH200-240V+PE, 3PH380-415V+N+PE, 50/60 Hz

Electrical

Control box, Panel

Pos.

2x

18”x26”

LC

3x

18”x26”

LC

2x

600x800

LC

2x

457x762

LC

3x

457x762

LC

2x

18”x26”

HC

3x

18”x26”

HC

2x

600x800

HC

2x

457x762

HC

3x

457x762

HC

Element

208-220V

380V

400V

415V

12

50296215

50296217

50296219

50239961

50296215

50296217

50296219

50239961

Element

208-220V

380V

400V

415V

13

50296216

50296218

50296220

50239961

50296216

50296218

50296220

50239961

Element

208-220V

380V

400V

415V

12

50296209

50296211

50296213

50239957

50296209

50296211

50296213

50239957

Element

208-220V

380V

400V

415V

13

50296210

50296212

50296214

50239958

50296210

50296212

50296214

50239958

Element

208-220V

380V

400V

415V

12

50296228

50239955

50296230

50296232

50296228

50239955

50296230

50296232

Element

208-220V

380V

400V

415V

13

50296229

50239956

50296231

50296233

50296229

50239956

50296231

50296233

Light

Light USA

14-16

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

50239917

50153200

Light bulb

15

50153302

50153302

50153302

50153302

50153302

50153302

50153302

50153302

50153302

50153302

Buzzer

Buzzer USA

17

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

50239924

50296611

Contactor

208V

220V

380-415V

18

50294108

50239905

50239905

50294108

50239905

50239905

50294108

50239905

50239905

50294108

50239905

50239905

50294108

50239932

50239905

50294108

50239905

50239905

50294108

50239905

50239905

50294108

50239905

50239905

50294108

50239905

50239905

50294108

50239932

50293807

Page 26

B

SPARE PARTS 3PH200-240V+PE, 3PH380-415V+N+PE, 50/60 Hz

Electrical

Control box, Panel

Pos.

2x

18”x26”

LC

3x

18”x26”

LC

2x

600x800

LC

2x

457x762

LC

3x

457x762

LC

2x

18”x26”

HC

3x

18”x26”

HC

2x

600x800

HC

2x

457x762

HC

3x

457x762

HC

Terminal board

19-23

Contact dealer for detalis

Fuse

24

Fuse

25

Terminal board

27

Breaking protector

28

Shunt

29

Time relay

31

Terminal board

35-36

Fuse

37

Terminal board

38-40

Temp. limit controller

Temp. limit controller USA

2TAS

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

50239931

50232801

Page 27

B

SPARE PARTS 3PH200-240V+PE, 3PH380-415V+N+PE, 50/60 Hz

Mechanical, Electrical

Steam generator

Pos.

2x

18”x26”

LC

3x

18”x26”

LC

2x

600x800

LC

2x

457x762

LC

3x

457x762

LC

2x

18”x26”

HC

3x

18”x26”

HC

2x

600x800

HC

2x

457x762

HC

3x

457x762

HC

Steam generator

1

20583791

20583791

20583791

20583791

20583791

20583791

20583791

20583791

20583791

20583791

Element

2

50231701

50231701

50231701

50231701

50231701

50231701

50231701

50231701

50231701

50231701

Terminal board

3

Contact dealer for details

Terminal board

4

Terminal board

5

Thermostat

Knob

6

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

50232701

50232711

Temp. limit control

7

50232801

50232801

50232801

50232801

50232801

50232801

50232801

50232801

50232801

50232801

Pilot lamp green

Pilot lamp green USA

8

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

50239906

50205301

Switch

9

50239915

50239915

50239915

50239915

50239915

50239915

50239915

50239915

50239915

50239915

Panel

10

10289603

10289603

10289603

10289603

10289603

10289603

10289603

10289603

10289603

10289603

Solenoid valve

Solenoid valve USA

11

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

50149801

50149807

Steam trap

12

50123402

50123402

50123402

50123402

50123402

50123402

50123402

50123402

50123402

50123402

Pipe

13

Contact dealer for details

Drain pipe

14

Page 28

Page 29

Page 30

Page 31

Page 32

Loading...

Loading...