REVELL AV-8B Harrier User Manual [en, fr, nl, it, gr, da, no, fi, sv, es, pt, de, en, hr, et, fi, hu, lv, lt, nl, pl, ro, ru, sr, sk, sl, cs, tr, gr, bg, uk, ch, he, ar, ja, ch, ch, ko, hi, id, kk, ms, fa, pt, es, th, vi, sq, mk]

Page 1

KIT6878 85687800200

AV-8B HARRIER

The AV-8B Harrier traces its origins back to

a British designed vertical take-off and landing

(VTOL) aircraft. The first Harrier used by the U. S.

Marine Corps was the AV-8A which entered service

in the 1960s. The present AV-8B entered service

in the mid-1980s, and it is a much larger and more

powerful variant. The payload capability of the AV8B is twice that of the earlier AV-8A. Capable of

operating from amphibious assault ships or unimproved forward areas without runways, AV-8Bs

provide close air support to Marine forces on the

the latest Joint Direct Attack Munitions (JDAM) and

laser-guided bombs. For self defense, AIM-9M

Sidewinder missiles provide the Harrier with a good

air-to-air capability. AV-8Bs currently in operation

with the Marine Corps include the AV-8B II+, which

features an AN/APG-65 radar, and the Night Attack

AV-8B. During Operation Iraqi Freedom, seventy

Marine AV-8B II+ and Night Attack Harriers flew

from assault ships and shore bases to help overthrow the regime of Saddam Hussein and liberate

the people of Iraq.

ground. They can deliver a wide variety of conventional and precision guided weapons to include

* REPEAT SEVERAL TIMES

* A REPETER PLUSIEURS FOIS

READ THIS BEFORE YOU BEGIN LIRE CE QUI SUIT AVANT DE COMMENCER

* Study the assembly drawings.

* Each plastic part is identified by a number.

* In the assembly drawings, some parts will be

marked by a star (★) to indicate chrome

plated plastic.

* For better paint and decal adhesion, wash

the plastic parts in a mild detergent solution.

Rinse and let air dry.

* Check the fit of each piece before

cementing in place.

* Use only cement for polystyrene plastic.

* Scrape plating and paint from areas

to be cemented.

* Allow paint to dry thoroughly before

handling parts.

* Any unused parts may be discarded.

DECAL APPLICATION INSTRUCTIONS

1. Cut desired decal from sheet.

2. Dip decal in water for a few seconds.

3. Place wet decal on paper towel.

4. Wait until decal is movable on paper backing.

5. Place decal in position on model, face up and

slide backing away.

6. Press out air bubbles with a soft damp cloth.

7. Milkiness that may appear is for better decal

adhesion and will dry clear. Wipe away any

excess adhesive.

8. Do not touch decal until fully dry.

9. Allow the decals 48 hours to dry before

applying clear coat.

NOTE: Decals are compatible with

setting solutions or solvents.

* OPTIONAL PARTS

* PIECES EN OPTION

* DECAL

* DECAL COMANIE

* Etudier les schémas de montage.

* Chaque pièce en plastique est identifiée par un numéro.

* Sur les schémas de montage, certaines pièces sont

marquées d'une étoile (★) pour indiquer qu'elles sont en

plastique chromé.

* Pour une meilleure prise de la peinture et des autocollants,

laver les pièces en plastique avec une solution détergente

peu concentrée. Les rincer et les laisser sécher à l'air.

* Vérifier que chaque pièce s'ajuste bien avant

de la coller en place.

* N'utiliser que de la colle pour polystyrène.

* Gratter les parties à coller pour enlever le chrome et la peinture.

* Laisser la peinture bien sécher avant de manipuler les pièces.

* Toute pièce inutilisée peut être jetée.

DIRECTIVES D'APPLICATION DES AUTOCOLLANTS

1. Découper l'autocollant désiré de la feuille.

2. Tremper l'autocollant dans de l'eau pendant quelques secondes.

3. Placer l'autocollant mouillé sur une serviette en papier.

4. Attendez que l'autocollant puisse être déplacé sur son support

en papier.

5. Mettre l'autocollant en position sur le modèle face sur

le dessus et faire glisser le support pour l'enlever.

6. Appuyer avec un chiffon doux humide pour éliminer les bulles d'air.

7. La substance laiteuse qui peut apparaître est destinée à

améliorer l'adhésion de l'autocollant et devient incolore au

séchage. Essuyer pour enlever tout excédent d'adhésif.

8. Ne pas toucher l'autocollant tant qu'il n'est pas bien sec.

9. Laisser l'autocollant sécher pendant 48 heures avant

d'appliquer une couche transparente.

REMARQUE: Les autocollants sont compatibles avec

* ALTERNATIVE ASSEMBLY

* ENSEMBLAGE ALTERNATIVE

les solutions de fixage ou les solvants.

* CEMENT TOGETHER

* A COLLER

* REMOVE AND THROW AWAY

* A RETIRER ET JETER

This optional paint guide is provided if

you choose to detail paint your model.

Ce guide de peinture vous sera fourni si vous choisis-

sez de peindre votre modèle en détail.

Dark Ghost Gray

Dark Gray

Dark Gull Gray

Flat Black

Gloss Black

Gloss White

Gray

Gray-Green

Gunship Gray

Olive Drab

Red

Silver

Steel

Tan

Yellow

* DO NOT CEMENT

* NE PAS COLLER

Gris fantôme foncé

Gris foncé

Gris cendré foncé

Noir mat

Noir brilliant

Blanc brilliant

Gris

Vert-gris

Gris hélicoptère

Gris vert

Rouge

Argent

Acier

Havane

Jaune

If you have any questions or comments, call our hotline at: (800) 833-3570

or, please write to:

Revell-Monogram Consumer Service Department, 725 Landwehr Road, Northbrook, Illinois 60062

Be sure to include the plan number (85687800200), part number, description, your return address and phone number.

Visit our website: www.revell-monogram.com

REVELL-MONOGRAM, LLC Northbrook, IL. Copyright © 2003. All rights reserved.

Page 2

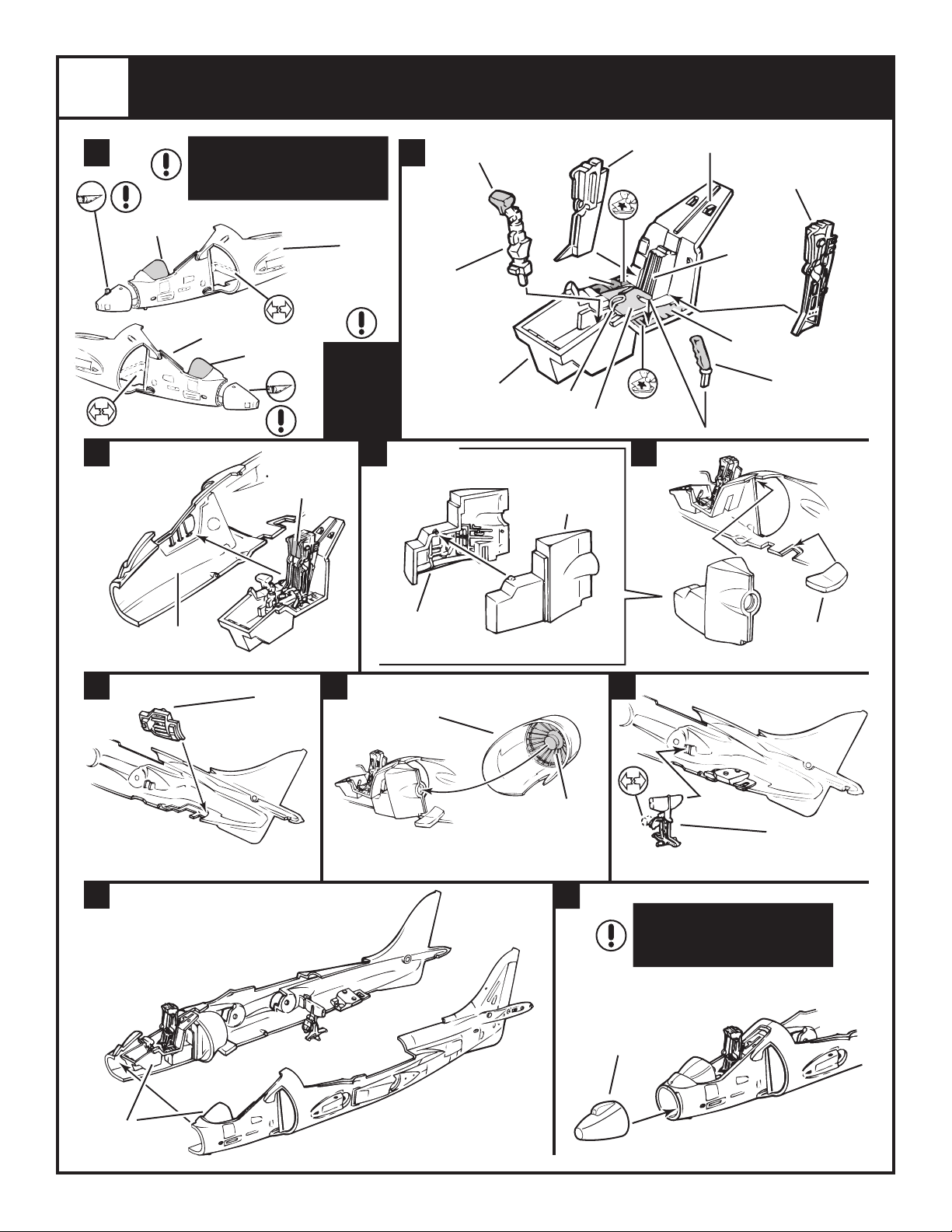

1

A B

C

COCKPIT AND FUSELAGE ASSEMBLY

NOTE: USE RESIN NOSE FOR NIGHT

ATTACK VERSION OF VMA-211.

USE THE STANDARD NOSE FOR

AIRCRAFT OF VMA-311

FLAT BLACK

FUSELAGE

2

FUSELAGE

HALF

FLAT BLACK

OLIVE DRAB

1

HALF

CUT OFF

FOR

VMA-211

NIGHT

ATTACK

VERSION

NOSE

D E

FLAT BLACK

74

CONTROL

STICK

DARK GULL

GRAY

DARK GULL GRAY

7

COCKPIT

INTERIOR

FLAT BLACK

YELLOW

OLIVE DRAB

26

WHEEL WELL

HALF

GLOSS WHITE

9

SEAT

SIDE

FLAT BLACK

4

1

FLAT BLACK

FLAT BLACK

OLIVE DRAB

FLAT BLACK

THROTTLE

FLAT BLACK

10

SEAT

SIDE

75

25

DARK GULL

GRAY

F

17

BRAKE WELL

GLOSS WHITE

G H

I

WHEEL WELL

HALF

GLOSS WHITE

15

COMPRESSOR

FAN

STEEL

J

RESIN NIGHT

ATTACK NOSE

MAIN

GEAR STRUT

GLOSS WHITE

NOTE: USE RESIN NOSE FOR NIGHT

ATTACK VERSION OF VMA-211.

USE THE STANDARD NOSE FOR

AIRCRAFT OF VMA-311

8

FENCE WELL

GLOSS WHITE

20

DARK GULL

GRAY INTERIOR

Page 3

2

11

INTAKE

ENGINE ASSEMBLY

35

BLAST SHIELD

BURNT STEEL

36

BLAST

SHIELD

BURNT STEEL

12

INTAKE

13

INLET

DOOR

33

NOZZLE HALF

STEEL

34

NOZZLE HALF

STEEL

REPEAT FOR

OTHER SIDE

56

FUEL VENT

55

ENGINE

VENT

4

STABILIZER

31

NOZZLE HALF

STEEL

TEMPERATURE

14

AIR

PROBE

13

INLET

DOOR

32

NOZZLE HALF

STEEL

3

STABILIZER

3

21

NOSE GEAR

STRUT HALF

GLOSS WHITE

19

MAIN WHEEL

HALF

FLAT BLACK

NOSE AND MAIN WHEEL ASSEMBLY

GLOSS WHITE

23

NOSE WHEEL

HALF

FLAT BLACK

MAIN WHEEL

FLAT BLACK

GLOSS WHITE

18

HALF

22

NOSE GEAR

STRUT HALF

GLOSS WHITE

18

MAIN WHEEL

HALF

FLAT BLACK

19

MAIN WHEEL

HALF

FLAT BLACK

GLOSS WHITE

Page 4

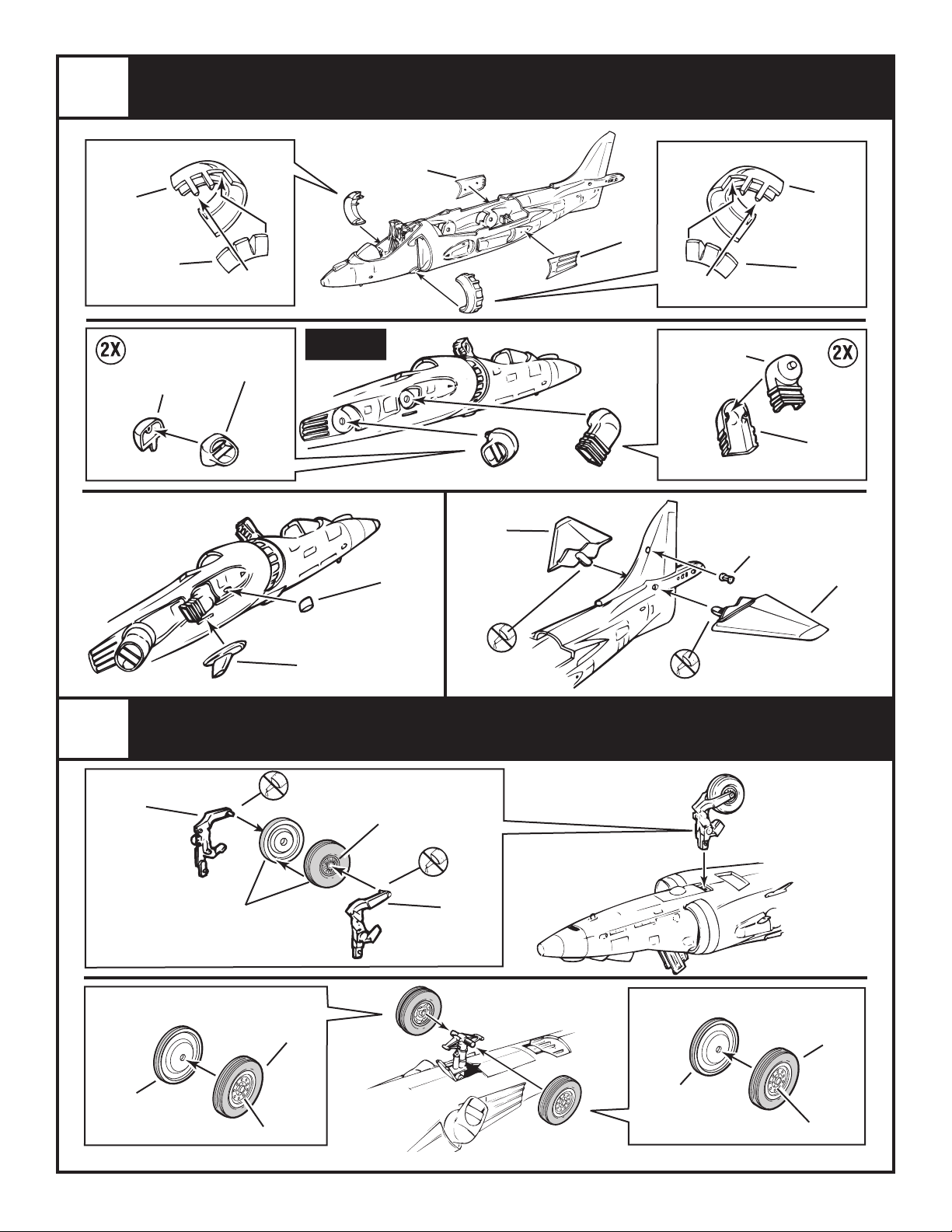

4

FUSELAGE AND GUN PACK ASSEMBLY

28

AMMO PACK

HALF

45

LIFT FENCE

GLOSS WHITE

16

SPEED BRAKE

GLOSS WHITE

79

BRAKE

CYLINDER

GLOSS WHITE

29

GUN PACK

HALF

5

5

WING TOP

27

AMMO PACK

HALF

GLOSS

WHITE

SILVER

30

GUN PACK

HALF

RIGHT

76

FUSELAGE

STRAKE

GRAY

LEFT

FUSELAGE

STRAKE

GRAY

GLOSS

WHITE

WING AND DROP TANK ASSEMBLY

6

WING

BOTTOM

77

39

DROP

TANK HALF

90

FIN

40

DROP

TANK HALF

37

DROP

TANK HALF

38

DROP

TANK HALF

90

FIN

Page 5

6

BOMB ASSEMBLY

61

BOMB HALF

OLIVE DRAB

STEEL

YELLOW

INNER PYLON

GRAY

7

61

BOMB HALF

OLIVE DRAB

60

BOMB HALF

OLIVE DRAB

42

STEEL

YELLOW

60

BOMB HALF

OLIVE DRAB

41

INNER PYLON

GRAY

MISSILE ASSEMBLY

NOTE: SEE PAINTING INSTRUC

TIONS AT THE END OF THIS

BOOKLET FOR INFORMATION ON

HOW TO PAINT THE MISSILES

AND WHERE TO APPLY DECALS

44

OUTER

PYLON

GRAY

-

SIDEWINDER

LIGHT GRAY

BLACK

58

FIN

LIGHT

GRAY

57

YELLOW

STEEL

STEEL

58

FIN

LIGHT GRAY

43

OUTER

PYLON

GRAY

Page 6

8

FINAL ASSEMBLY

A

GLOSS WHITE

(PAINT OLEO

PORTION SILVER)

FLAT BLACK

48

GEAR

COVER

B

72

PILOTS

ARM

GRAY-

GREEN

OLIVE

GREEN

FLAT BLACK

46

OUTRIGGER

GEAR

GLOSS WHITE

GRAY-GREEN

71

PILOT

DARK

GREEN

OLIVE

GREEN

OLIVE

DRAB

84

NOSE LENS

CLEAR

FLAT BLACK

49

GEAR

COVER

GLOSS WHITE

(PAINT OLEO POR

TION SILVER)

52

AIR SCOOPS

STEEL

(NOZZLE)

-

FLAT BLACK

47

OUTRIGGER

GEAR

78

REFUELING

PROBE

C

HEAD UP

DISPLAY

FLAT BLACK

9

D

82

2

3

73

INSTRUMENT

PANEL

FLAT BLACK

PAINTING NOTE:

GLOSS BLACK

INSTRUMENTS WITH

WHITE DETAILS AND

SILVER SWITCHES

93

YAW

INDICATOR

STEEL

54

PITOT TUBE

STEEL

NOTE: USE WATER

BASED WHITE GLUE

TO ATTACH CLEAR

TAN

80

WINDSHIELD

CLEAR

54

PITOT TUBE

STEEL

CANOPY ASSEMBLY

81

CANOPY

CLEAR

TAN

(PAINT MIRROR FACE SILVER

83

MIRRORS

FLAT BLACK

CLOSED

OPEN

70

CANOPY FRAME

CLEAR

83

MIRROR

FLAT BLACK

(PAINT MIRROR FACE SILVER

Page 7

10

DECAL PLACEMENT

Page 8

10

DECAL PLACEMENT

CONTINUED

85687800200

Loading...

Loading...