Retrotec DM32 User Manual

Retrotec Inc.

Pressure Gauge Operation Manual

For Model DM32

rev-2014-09-09

Page 2 of 94

©Retrotec Inc. 2014

Made by Retrotec Inc.

1060 East Pole Road

Everson, WA USA 98247

For support:

Call 1(888) 330-1345 in USA

+1 (360) 738-9835 outside USA support@retrotec.com or

Fax +1(360) 647-7724

Page 3 of 94

©Retrotec Inc. 2014

Copyright © 2012-2014 Retrotec Inc.

All rights reserved.

This document contains materials protected under International and Federal Copyright Laws. This book contains

material protected under International and Federal Copyright Laws and Treaties. Any unauthorized reprint or use of

this material is prohibited. No part of this book may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying, recording, or by any information storage and retrieval system

without acknowledging Retrotec Inc. as the original source.

Retrotec makes no warranties with respect to this documentation and disclaims any implied warranties of

merchantability, quality, or fitness for any particular purpose. The information in this document is subject to change

without notice. Retrotec reserves the right to revise this publication without obligation to notify any person or entity

of any such changes.

Infiltrometer, FanTestic, and DucTester are Trademarks of Retrotec Inc. Other Trademarks or brand names mentioned

herein are trademarks or registered trademarks of their respective owners.

Wireless communication is certified under Wi-Fi 802.11 with ASD Model Test Plan with Test Engine for IEEE 802.11a,

b, and g Devices (Version 1.0).

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of

the FCC Rules. These limits provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Caution: To satisfy FCC RF Exposure requirements for mobile and base station transmission devices, a separation

distance of 20 cm or more should be maintained between the antenna of this device and persons during operation.

To ensure compliance, operation at closer than this distance is not recommended.

The antenna(s) used for this transmitter must not be co-located or operating in conjunction with any other antenna or

transmitter.

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two

conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence.

L'exploitation est autorisée aux deux conditions suivantes: (1) l'appareil ne doit pas produire de brouillage, et (2)

l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est susceptible d'en

compromettre le fonctionnement.

Page 4 of 94

©Retrotec Inc. 2014

Table of Contents

Important equipment-related safeguards ..................................................................................................... 8

1. Introducing the Retrotec DM32 series of digital gauge .................................... 9

2. Gauge overview ............................................................................................ 10

2.1 Make connections to the gauge ..................................................................................................... 10

2.2 Charge the battery in the gauge ..................................................................................................... 11

2.3 Power the gauge on and off – press for 2 seconds ........................................................................ 12

2.4 Read Results and control the gauge from the Home screen.......................................................... 12

2.5 Observe icons on Top Bar to monitor gauge status ....................................................................... 14

2.5.1. What speed is being sent to the fan on the “Fan Speed” output? ........................................ 14

2.5.2. Over what time period is the Result being averaged? .......................................................... 14

2.5.3. Result display can be frozen to write down values ............................................................... 14

2.5.4. Is the gauge connected to a Network? .................................................................................. 14

2.5.5. How much battery life is left in the gauge? ........................................................................... 14

2.6 Use keys on the Home screen to control gauge operation ............................................................ 16

2.6.1. [Channel A] Pressure Reading ................................................................................................ 16

2.6.2. [Channel B] Pressure Reading or Result ................................................................................ 16

2.6.3. Set the [Range/Device] connected to the gauge ................................................................... 17

2.6.4. Estimate Results with [@ Pressure] ....................................................................................... 19

2.6.5. Setting “n value” for @Pressure extrapolation ..................................................................... 20

2.6.6. Capture and apply a Baseline using [Settings] ....................................................................... 20

2.7 Gauge compensates for sensor drift with Auto Zero ..................................................................... 20

3. Get Results directly from the gauge ............................................................... 21

3.1 Connect Speed Control Cable between the gauge and fan ............................................................ 21

3.2 Connect pressure tubes to gauge ................................................................................................... 21

3.3 Control the test and read Results on the Home screen ................................................................. 21

3.3.1. Tap [Range/Device] to match Range on Device in use .......................................................... 21

3.3.2. Tap [Range/Device] [Change Device] to change Device in use ......................................... 21

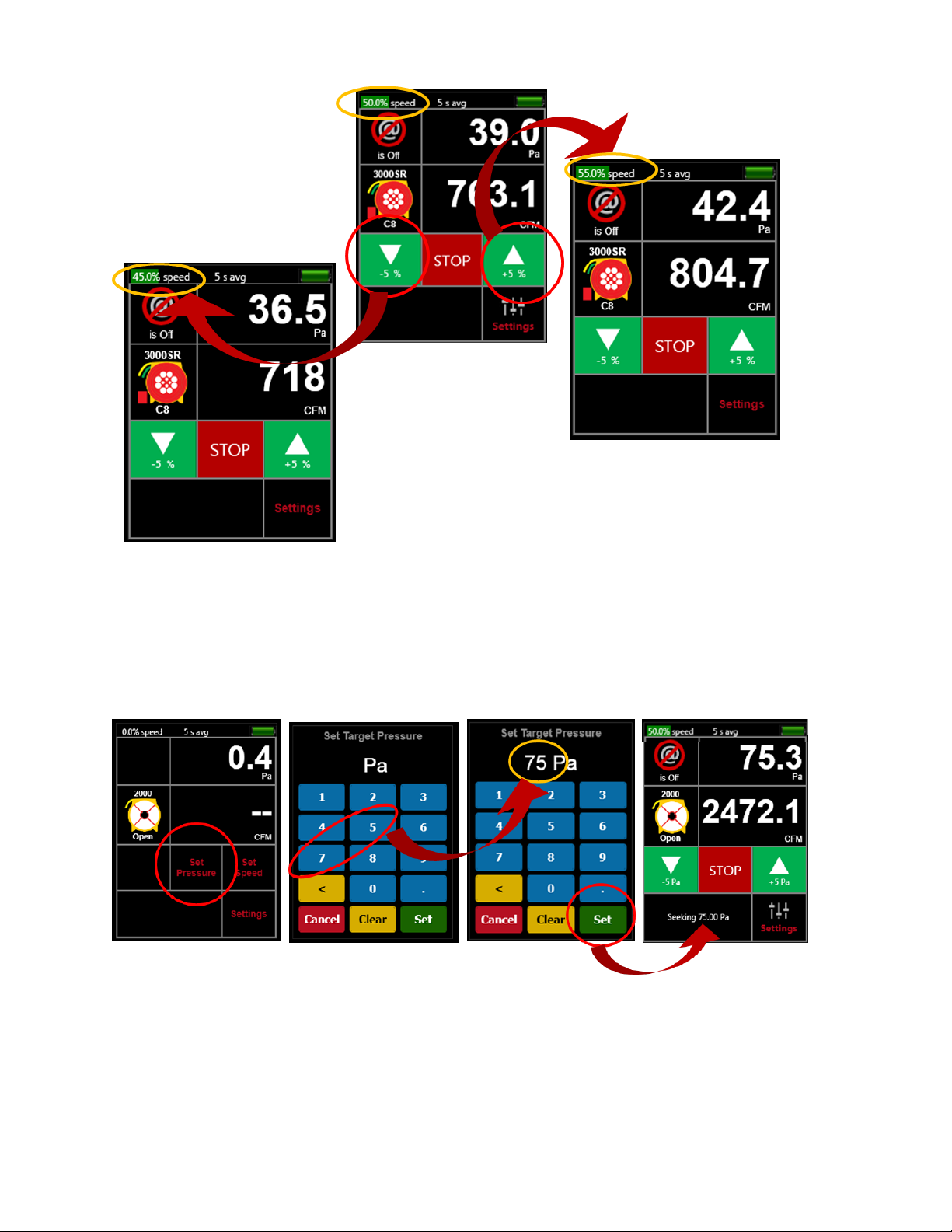

3.3.3. Tap [Set Speed] to run the fan at a particular speed ............................................................. 22

3.3.4. Tap [Jog] keys to adjust speed up or down 5% ...................................................................... 22

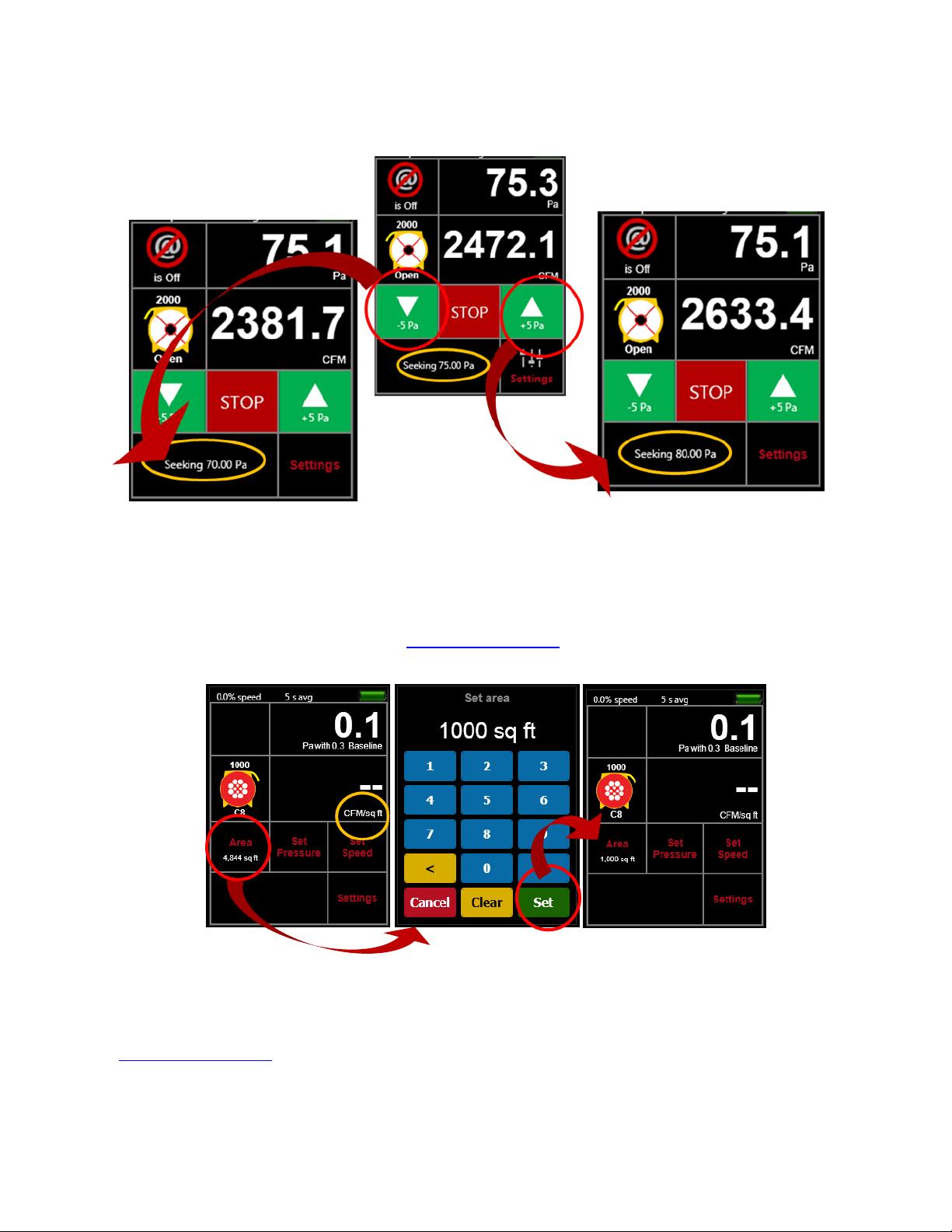

3.3.5. Tap [Set Pressure] to achieve a particular enclosure pressure ............................................. 23

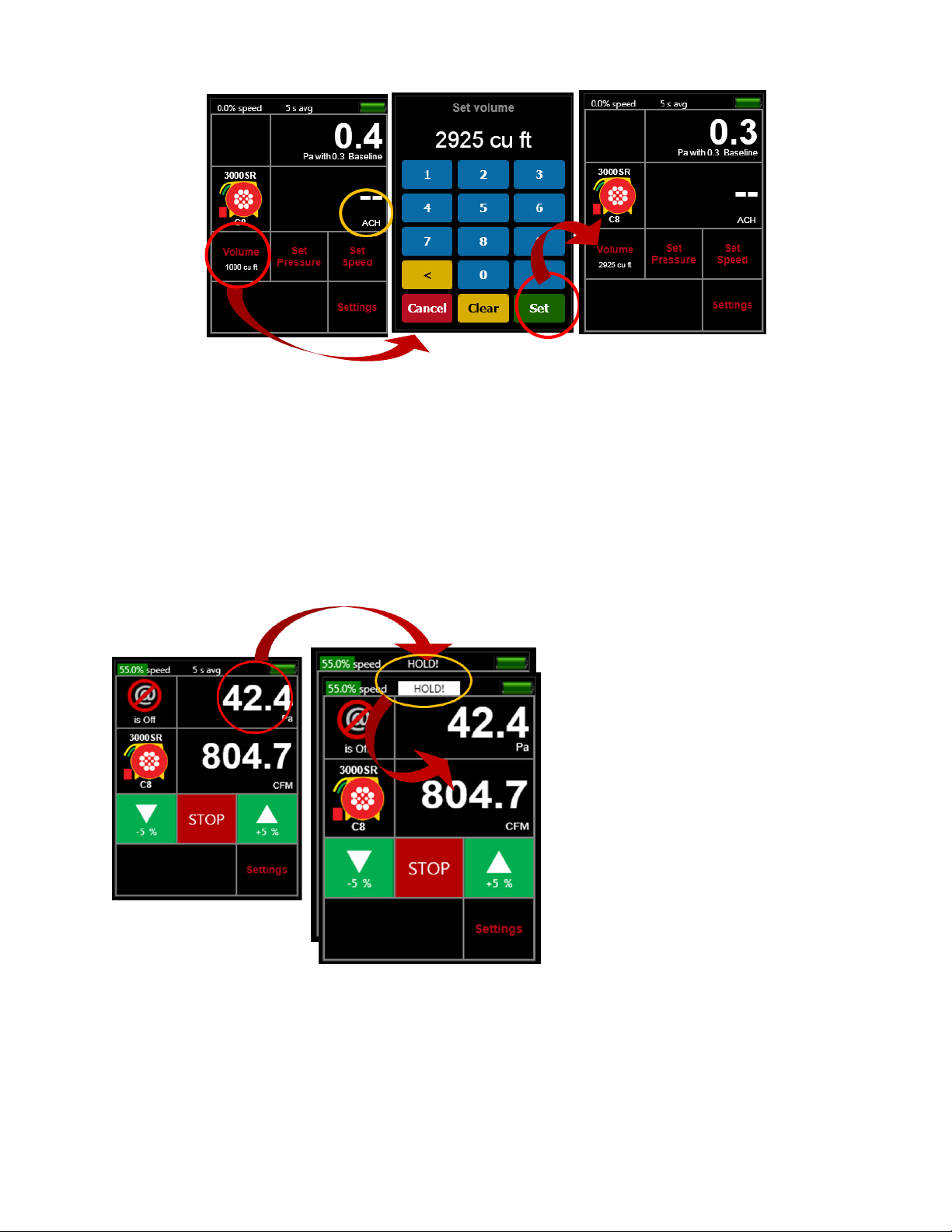

3.3.6. Tap [Jog] keys to adjust pressure up or down 5 Pa ............................................................... 24

3.3.7. Tap [Area] or [Volume] to enter dimension for particular Results ........................................ 24

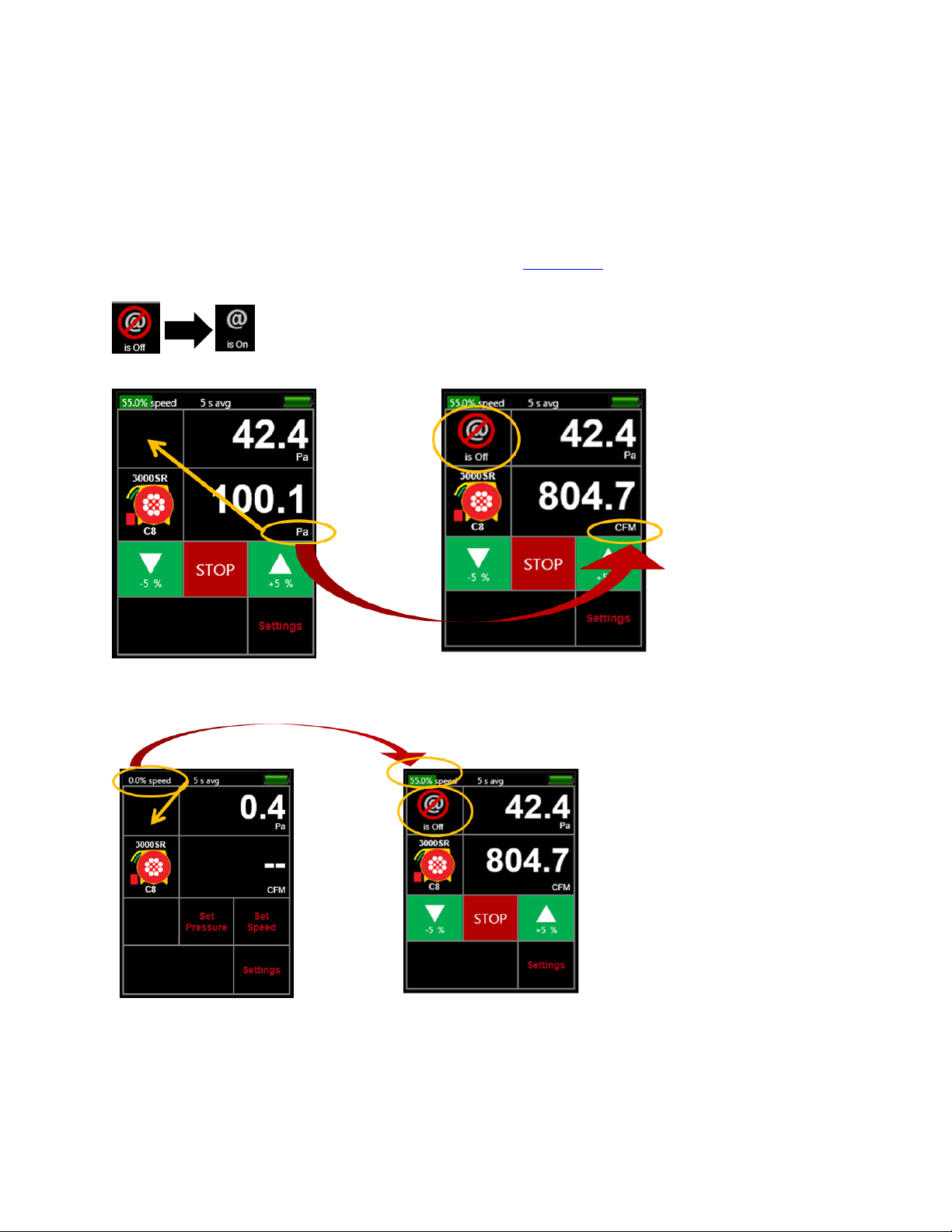

3.3.8. Tap [Channel A] to “Hold” readings and results .................................................................... 25

Page 5 of 94

©Retrotec Inc. 2014

3.3.9. Tap [Channel B] or [Settings] to change Result or units to be displayed .............................. 26

3.3.10. Tap [@ Pressure] to estimate Result at a different pressure ................................................ 27

4. Change [Settings] for gauge operating parameters ........................................ 32

4.1 Capture [Baseline] Pressure ........................................................................................................... 32

4.2 Set [Area] if using a Result per Area ............................................................................................... 33

4.3 Set [Volume] if using ACH ............................................................................................................... 34

4.4 Use metric units for dimensions ..................................................................................................... 35

4.5 Set the [Default @ Pressure] .......................................................................................................... 36

4.6 Set [Time averaging] period ........................................................................................................... 38

4.7 Change Result and units to be displayed........................................................................................ 39

4.8 Set up “Network” if using Ethernet connection ............................................................................. 41

4.9 View and update the [Firmware] version, check serial number .................................................... 42

4.10 Re-calibrate the touchscreen ......................................................................................................... 43

4.11 Reset button ................................................................................................................................... 44

5. Remotely run tests and save results with Retrotec software ......................... 45

5.1 Connecting gauges to a computer .................................................................................................. 45

5.2 Connect single gauge to a computer with Ethernet cable ............................................................. 45

5.3 Connect multiple gauges to a computer via “Wired” network ...................................................... 47

5.4 Connect computer or phone to the DM32 “WiFi” Hotspot ........................................................... 49

5.5 Make the DM32 join an existing “WiFi” network ........................................................................... 51

5.5.1. Set secure wireless credentials using DM32 Configurator software ..................................... 52

5.5.2. On DM32, verify wireless credentials after updating ............................................................ 52

6. Update gauge with new features ................................................................... 54

6.1 Connect the gauge to a computer via USB ........................................................................ 54

7. Verify your gauge accuracy between factory calibrations .............................. 56

8. What to do if you have trouble with the gauge ............................................. 59

8.1 Re-calibrate touchscreen if keys don’t respond well to taps ......................................................... 59

8.2 Gauge may get stuck running “Re-calibrate touchscreen” if the battery gets into a low state ..... 60

8.3 Reset if you need to clear the gauge to base settings .................................................................... 60

8.4 Flashing screen may appear as gauge recovers from deep discharge ........................................... 60

8.5 Pressing power button may not turn gauge On if battery is fully discharged................................ 60

8.6 Gauge will not reset (run splash screen) while gauge is plugged into power ................................ 60

8.7 Flashing yellow LED on front means gauge had an internal malfunction ...................................... 60

Page 6 of 94

©Retrotec Inc. 2014

8.8 Calculated Result will be wrong if the Range and Device installed on fan are different than those

selected on the gauge ................................................................................................................................. 61

8.9 Moving tubes might cause fluctuating pressure readings ............................................................. 61

8.10 Fans with a single tube have results adjusted by gauge ................................................................ 62

8.11 Pressure can overshoot when using the Set Pressure key ............................................................. 62

8.12 Check if large fixed errors are caused by pinched tubes ................................................................ 63

8.13 Check if large fixed errors are caused by water in the tube ........................................................... 64

8.14 Check if large fixed errors are caused by sun heating the tubes.................................................... 65

8.15 Check if wind is causing fluctuating pressure ................................................................................. 65

8.15.1. Use the [@ Pressure] key to reduce the effects of wind ....................................................... 65

8.15.2. Use Time Averaging feature to reduce the effects of wind ................................................... 65

8.15.3. Let Time Averaging take effect before making readings ....................................................... 65

8.15.4. Use Baseline feature to reduce the effects of a constant wind ............................................ 66

8.15.5. In extreme cases you can use a Wind Damping Kit designed to reduce wind-related

fluctuations ............................................................................................................................................. 66

9. Technical Specifications ................................................................................. 68

Appendix A: Understanding Pressures on the Gauge ........................................... 70

Differential Pressure .................................................................................................................................... 70

Positive vs. Negative Pressure ..................................................................................................................... 70

Why static and fluctuating pressures occur, causing bias ........................................................................... 71

Managing fluctuating pressures created by wind ....................................................................................... 72

Reduce uncertainty in results by taking lots of readings ............................................................................ 72

Appendix B: Flow Equations used with Devices ................................................... 74

Appendix C: Manually estimate Flow if required test pressure cannot be reached

............................................................................................................................ 79

Cannot Reach 50 Pa Factors ........................................................................................................................ 80

Cannot Reach 25 Pa Factors ........................................................................................................................ 81

Appendix D: Details about the @Pressure extrapolation function ....................... 82

“n value” for @Pressure extrapolation ....................................................................................................... 83

Errors occur in estimated flow if gauge and actual “n” don’t match .......................................................... 84

Appendix E: Tables to adjust Flow values for temperature difference ................. 87

Appendix F: Tables to correct Flow if range selected did not match the installed

range ................................................................................................................... 89

Appendix G: Measure Supply or Exhaust flow with a gauge and box .................. 90

Page 7 of 94

©Retrotec Inc. 2014

Glossary ............................................................................................................... 92

Page 8 of 94

©Retrotec Inc. 2014

Important equipment-related safeguards

Read and save these instructions

When using electrical appliances, basic safety precautions should always be followed. If Retrotec equipment is

used in a manner that does not follow the information provided in this manual, safety to the operator and

equipment performance may be impaired.

The risk of fire, electric shock, and injury to persons may result during cleaning of the gauge. To avoid these risks,

unplug or disconnect the gauge from the electrical power supply and turn the gauge off before cleaning. Clean

only by wiping with a soft dry cloth. There are no user serviceable parts on the gauge.

To protect against the risk of fire, electric shock, and injury to persons during gauge operation:

Do not operate any gauge with a damaged electrical cord. Discard gauge or return to an authorized service

facility for examination and/or repair.

Do not run cord under carpeting. Do not cover cord with throw rugs, runners, or similar coverings. Do not route

cord under furniture or appliances. Arrange cord away from traffic and where it will not be tripped over.

Do not place this equipment or power cord in water or other liquid.

Use only the included power plug to charge and/or operate the gauge.

Turn the unit off and unplug the charger (if in use) from electrical outlet before moving.

For use under indoor conditions only, where there is no exposure to water or dusty substances or explosive

materials or flammable materials.

Do not use equipment for other than its intended use.

Equipment is intended for diagnostic testing andmust be operated by a qualified operator.

Failure to follow these instructions carefully may result in bodily injury, damage to property and/or equipment

failure. Failing to operate equipment as intended may void warranty and compliance with CE mark and other

listings.

Page 9 of 94

©Retrotec Inc. 2014

1. Introducing the Retrotec DM32 series of digital gauge

The DM32 is the next generation digital manometer, with touchscreen and two digital pressure sensors. It

is a small, lightweight dual- channel pressure gauge with computer control options via USB or over a

network via Ethernet.

The DM32 series utilizes the latest in microcontroller technology allowing the unit to support a rich set of

capabilities including full color touchscreen display, pre-calibrated digital pressure sensors, high capacity

rechargeable Lithium Polymer battery, onboard charging and power management, USB connectivity, and

wired and optional wireless (WiFi) networking capabilities.

The DM32 includes a suite of software to maximize your use of the gauge. The DM32 Software Suite (for

PC) includes a Data Logger, Virtual Gauge for remote control, and the DM32 Configurator. DM32 gauge

internal software can be updated with new features as they get developed from time to time, using the

DM32 Configurator software and the USB connection on the DM32. WiFi enabled gauges also include the

GaugeRemote App for Android and iOS based smart phones and devices.

The gauge will conveniently control the speed of fans that create flow such as Blower Door Fans,

DucTesters and other flow devices. It will also calculate the flow rate going through these devices as well as

many passive devices such as flow grids. Results can be displayed in any series of units used anywhere

worldwide.

Words in square brackets indicate keys that must be tapped on the touchscreen to operate the gauge. The

ON- OFF key must be pressed and held for two seconds in order to actuate while all other Touch-Screen

functions are Tap and Release to actuate.

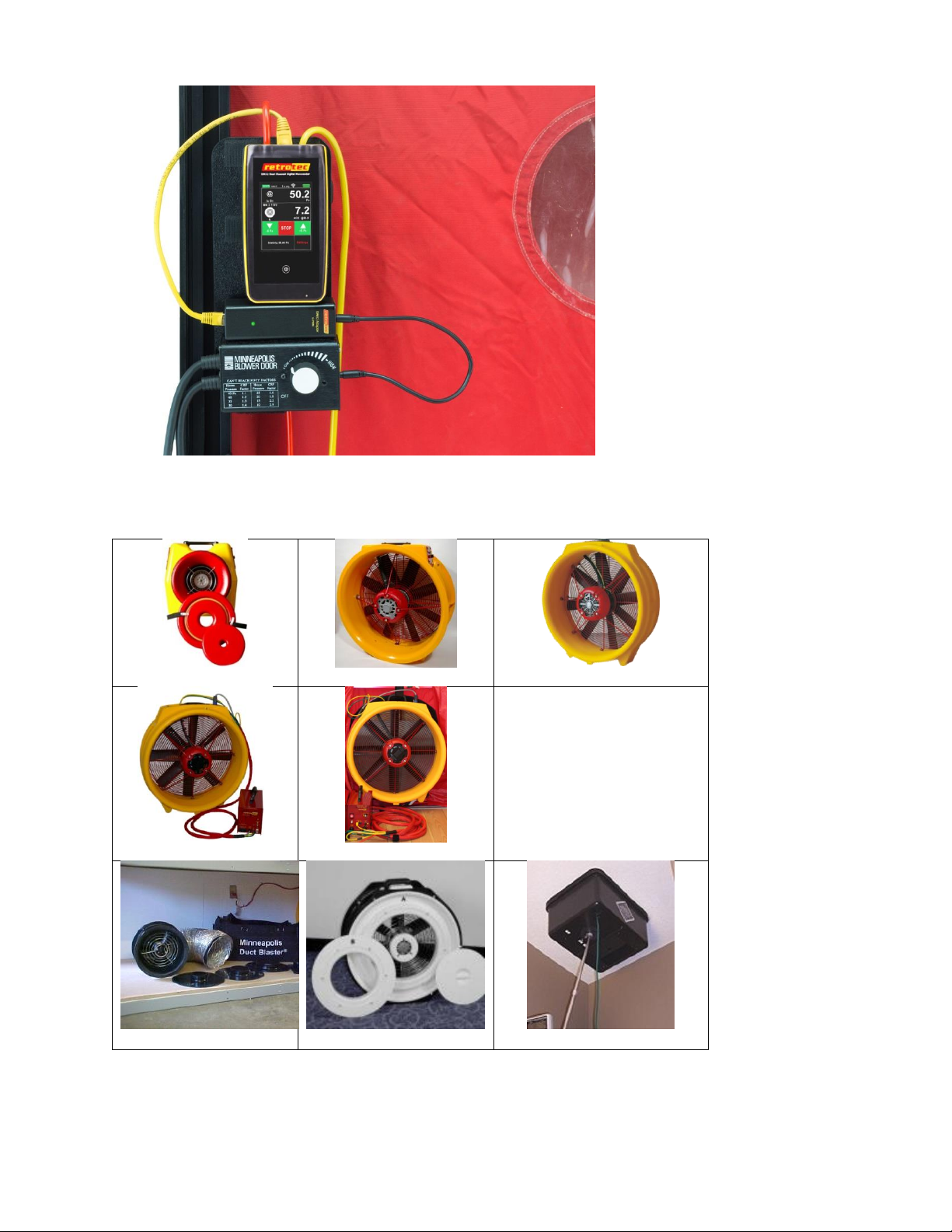

Figure 1: DM32 digital gauge has been turned on and is ready for action.

Page 10 of 94

©Retrotec Inc. 2014

2. Gauge overview

The front of the gauge has a resistive touchscreen, a touch-sensitive [Home] button , and a battery

charge indicator light. Because the screen is resistive, it can be operated when the user is wearing gloves,

and in most environmental conditions.

The top of the gauge has four color-coded pressure tube ports, and a Control output port (for fan speed)

The bottom of the gauge has an Ethernet network port (for gauge-computer communications), a USB port

(mainly for battery charging), and a Reset button (recessed, accessible using a paper clip).

The touchscreen serves as both the information display and the keypad for the gauge. The information

displayed depends on selections a user makes by tapping on the touch sensitive areas on the screen, called

“keys” in this manual and shown in square brackets [].

2.1 Make connections to the gauge

Physical connections from the gauge to a calibrated fan are on top of the gauge. Physical connections to a

computer or power adapter are on the bottom of the gauge.

An Ethernet-style cable from the fan speed output control port connects to a calibrated fan to control its

speed. The cable supplied for this purpose with Retrotec systems is yellow.

Pressure tube ports on the top of the gauge are color-coded to distinguish where pressure tubes are

connected. Retrotec has a specially designed pressure tube port that grips pressure tubes well, but

releases them without tearing after long-term use. This exclusive connector is designed by Retrotec to

make contact with the both tube internally and externally with a shallow taper.

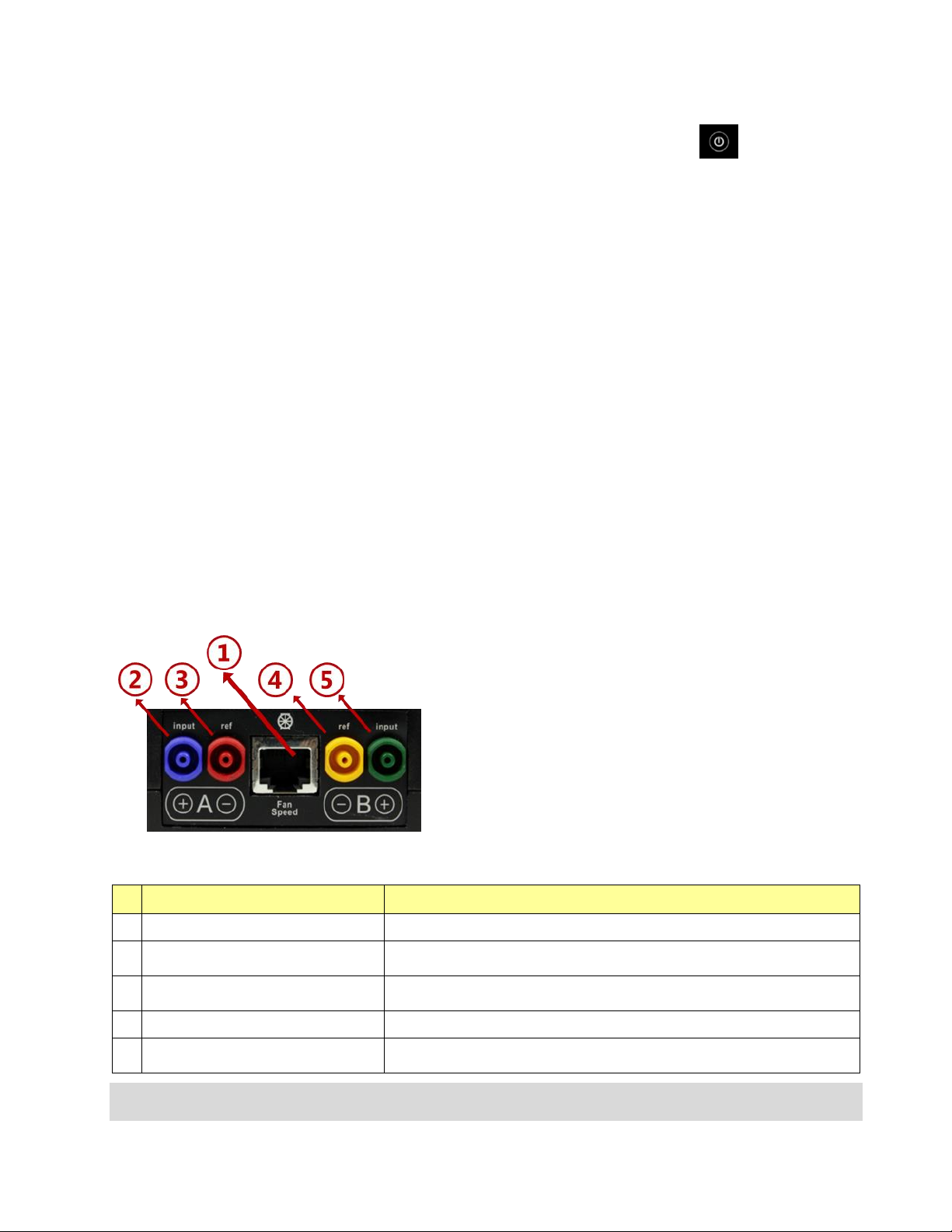

Figure 2: Connect tubes and Speed Control Cable

Table 1: Physical connections from gauge to fan are on top of gauge

gauge port

connection

1

“Fan Speed” control cable port

Connect the yellow Retrotec-proprietary Speed Control Cable

2

Blue pressure port: “input B (+)”

Often has no pressure tube connected. For duct testing, a blue pressure tube

leads from the gauge into the ducts.

3

Red pressure port: “ref B (-)”

Connect the red pressure tube from the gauge through the Door Panel to the

outdoors.

4

Yellow pressure port: “ref A (-)”

Connect the yellow pressure tube from gauge to yellow port on a Retrotec fan

5

Green pressure port: “input A (+)”

Connect green pressure tube to green port on Retrotec fan, if applicable. No

pressure tube will be here if Retrotec fan does not have a green pressure port

Pressure tubes should be clean and not stretched in order to make a proper connection. If a pressure tube is

damaged, simply slice a short piece of tube off the end to ensure a clean fit. Tubing can crack in cold weather, but can

Page 11 of 94

©Retrotec Inc. 2014

be heated in hot water before being handled. Be careful to dry all water from the tubing prior to connecting since

water in the tube is a major source of measurement error.

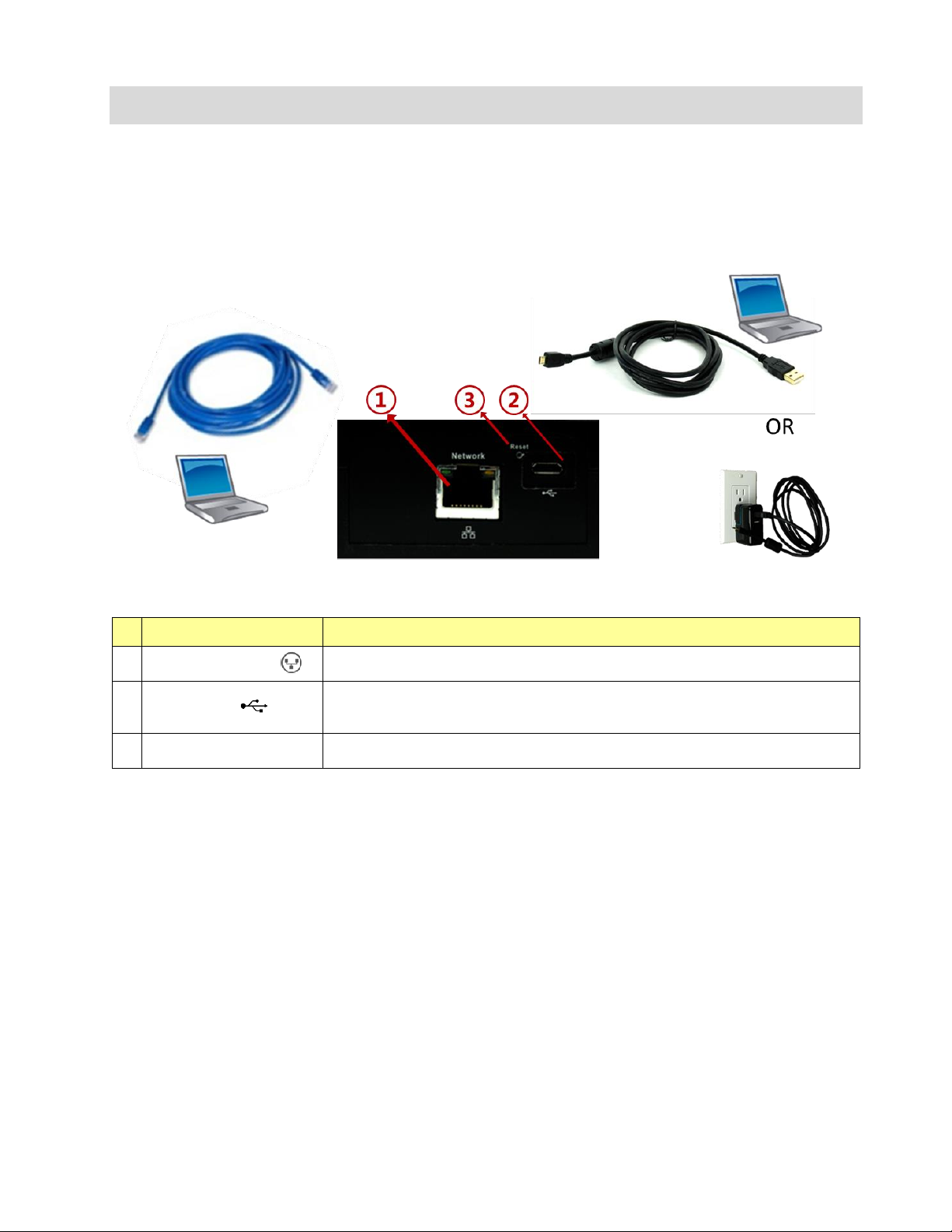

Connections on the bottom of the gauge provide a USB charging input and remote control port as well as

an Ethernet remote control port. An Ethernet cable of type Cat5e or Cat6 from the “Network” port can

connect the gauge directly to a PC, to an Ethernet switch, or to a router. Ethernet cables have a maximum

length of 328 ft (100 m); over longer lengths signal strength may be compromised.

Figure 3: Connect charger or remote computer control

Table 2: Physical connections from gauge to a computer or charger are on the bottom of gauge

gauge port

connection

1

“Network” cable port

A Cat5e or Cat6 Ethernet cable can connect the gauge to a computer, a switch, or a router,

in order to control fan and/or read the gauge measurements via the computer

2

USB cable port

Connect the USB “A”/“Micro-B” cable to a PC or the supplied AC power adapter in order to

charge the internal battery of the gauge.

Connect the USB to a computer to update the software internal to the gauge (firmware).

3

“Reset”

Press a paper clip into the hole to reset the gauge – forces the gauge to turn off and back

on again.

2.2 Charge the battery in the gauge

The gauge is charged at the factory, but you can plug it in to ensure a full charge before each test. Connect

the USB cable to the AC power adapter to charge the gauge battery. Charging using the AC power adapter

is the only way to fully charge the gauge. Plugging the gauge into a computer USB port will extend the

length of the charge but the gauge will eventually need to be recharged using the AC power adapter.

With the AC adapter, a full charge will be completed in about four hours. A fully charged gauge will last for

approximately 8 hours without a recharge. For details see 2.5.5

Page 12 of 94

©Retrotec Inc. 2014

Figure 4: Red light shows that gauge battery is charging

When connected to the computer USB port, the gauge still discharges very slowly. Connection to the

computer USB is just a way to extend the time available on a charge, so that you can run longer tests if you

have a computer nearby.

2.3 Power the gauge on and off – press for 2 seconds

Warning: Gauge does not turn on immediately. You don’t need

to press the screen overly hard. You may break the glass.

Figure 5: Gauge [Home] key and power on/off key

Press the power on/off key and remove your finger. After two

seconds, you will hear a click as the gauge starts up, then the Splash

Screen will be displayed. Press on/off for 2 seconds to power off.

The Splash Screen is visible until the user taps anywhere on the screen

or until the gauge self-check sequence finishes and automatically

displays the Home screen.

Information displayed on the Splash Screen during start up includes:

Internal gauge software (Firmware) Build and Version Number

Gauge Serial Number

Upon gauge start up, the Home screen will display the Device, Range, and Result to be displayed settings

that were set on the gauge before it was last powered off, so the user can immediately start testing if they

are using the same equipment.

2.4 Read Results and control the gauge from the Home screen

The Home screen is the main display that allows a user to control the gauge. The gauge includes

convenience functions to support operation of pressure measurement systems with calibrated fans, and

calculate results for air leakage testing.

In this manual, words that are in square brackets indicate keys that can be tapped to change something on

the gauge.

Figure 6: DM32 splash screen shows

while gauge starts up

Page 13 of 94

©Retrotec Inc. 2014

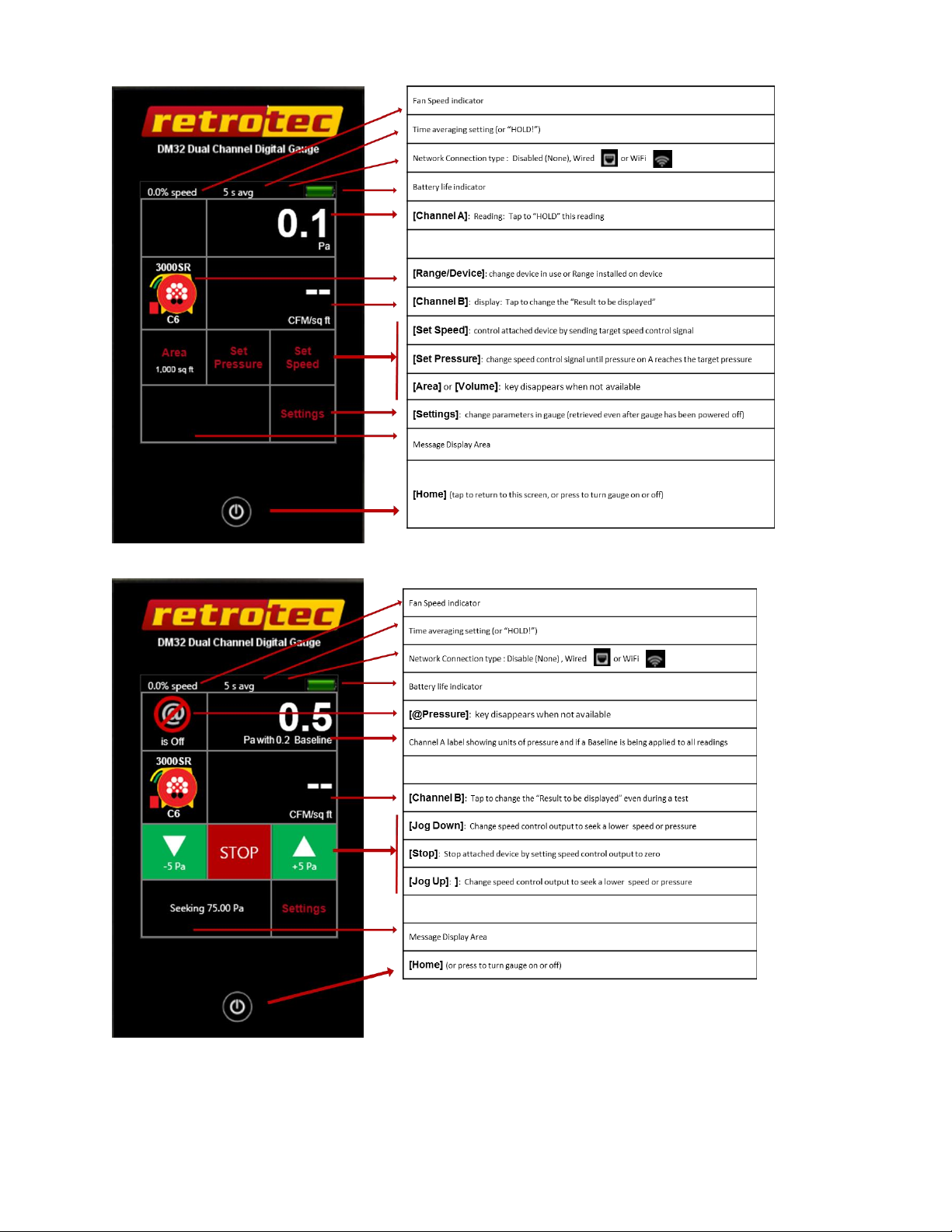

Figure 7: Home screen keys when the gauge is idle (not controlling a fan)

Figure 8: Home screen keys when gauge is seeking a target pressure

Page 14 of 94

©Retrotec Inc. 2014

2.5 Observe icons on Top Bar to monitor gauge status

Icons on the Top Bar indicate the current status and various settings on the gauge.

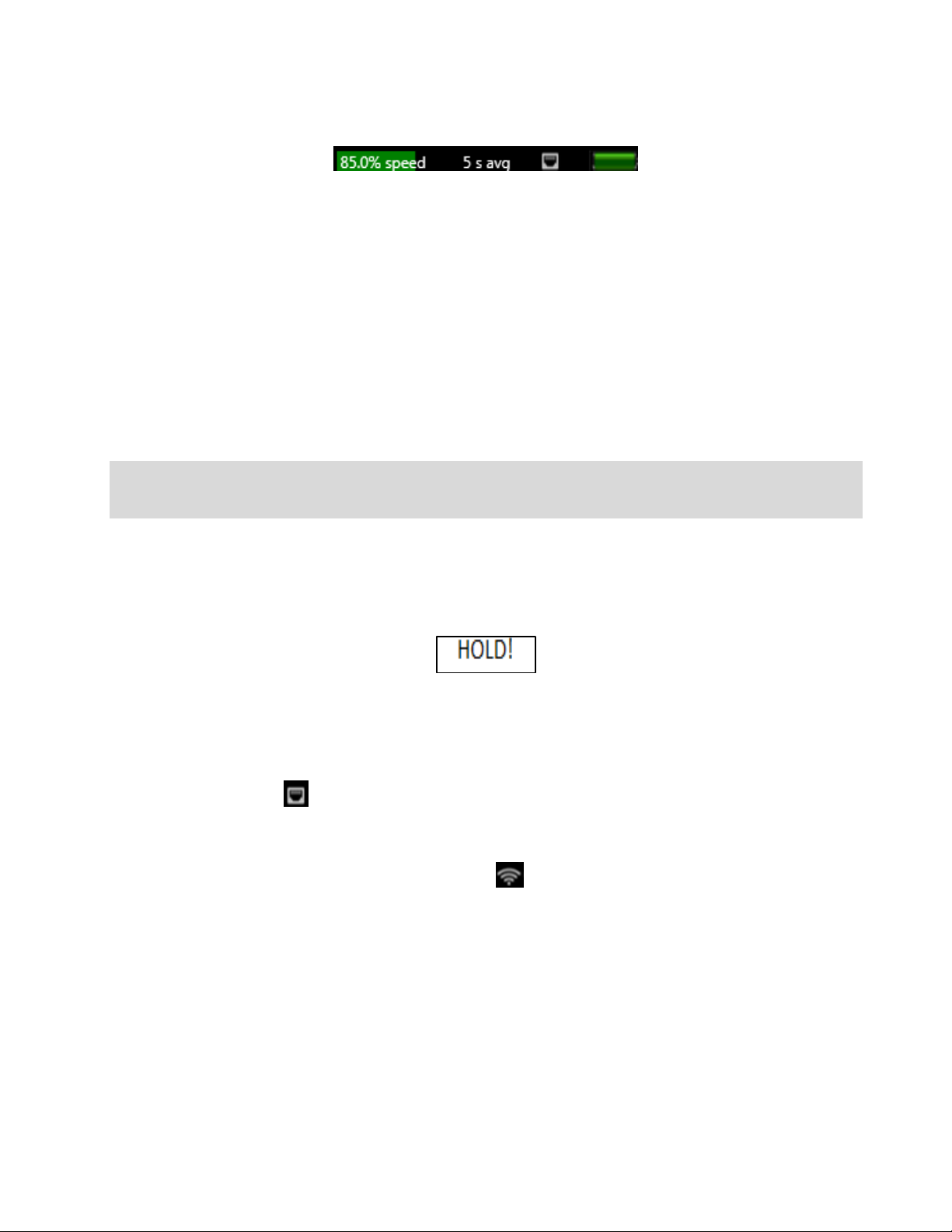

Figure 9: Top Bar

2.5.1. What speed is being sent to the fan on the “Fan Speed” output?

The % Speed indicates the percentage of the fan’s total speed capacity that the gauge is directing the fan to

achieve (85% Fan Speed shown in the example above).

2.5.2. Over what time period is the Result being averaged?

When Time Averaging is active, the gauge will display the time that the [Channel A] and [Channel B]

Readings are averaged over. 5 second Time Averaging is shown in Figure 9. Regardless of the time

averaging setting, the display will update every second.

Time Averaging periods of 1s, 5s, 10s, 30s can be selected directly, or another time to spend averaging can

be entered manually.

Tip: When changing the fan speed, set pressure, or taking a reading after making any other changes, wait for twice

the Time Averaging period to elapse before taking a reading. Taking a reading too quickly can lead to recording

incorrect results.

2.5.3. Result display can be frozen to write down values

When the [Channel A] Reading is tapped, “HOLD!” will instead be displayed (and flashes) in place of the

Time Averaging value to indicate [Channel A] and [Channel B] display values are frozen to the values that

were present when the display was tapped.

Figure 10: Tapping [Channel A] display area will "HOLD" the Result

2.5.4. Is the gauge connected to a Network?

The wired network icon appears when the network Status is set to “Wired”. ([Settings] [Network]

[Status]) Set ”Wired” when an Ethernet cable is connected to the “Network” cable port on the bottom

of the gauge.

For a DM32 with WiFi capability enabled, the WiFi icon appears when the network Status is set to one

of the WiFi choices and the gauge successfully connects to the associated wireless network. Set ”WiFi-

Create” to have the gauge generate a WiFi hotspot to which a phone or computer can connect, or set

”WiFi-Join” to have the gauge connect to an existing WiFi network. See section 5.4 for full instructions on

connecting your DM32 to a “WiFi” network.

Gauges with serial numbers starting with 4 have WiFi capability which can be enabled if the WiFi module is

purchased.

2.5.5. How much battery life is left in the gauge?

Page 15 of 94

©Retrotec Inc. 2014

The battery life indicator shows how much life is left in the rechargeable battery inside the gauge. A fully

charged battery will last approximately 8 hours before needing recharging. Gauges will discharge faster if

WiFi is being used. To extend battery life, choose a “Network” setting of “Disabled”

The gauge battery is charged via the USB cable port on the gauge. The fastest way to charge the gauge is to

plug the USB cable into the provided USB-to-mains AC power adapter, as the mains adapter will provide

maximum current. Plugging the USB cable into a USB port on your computer will also charge the gauge,

but at a much slower rate, and will only extend the length of time before needing to use the AC adapter

(the draw can be higher than what most computers normally provide on the USB output).

Figure 11: AC Adapter provided to charge battery via USB connector

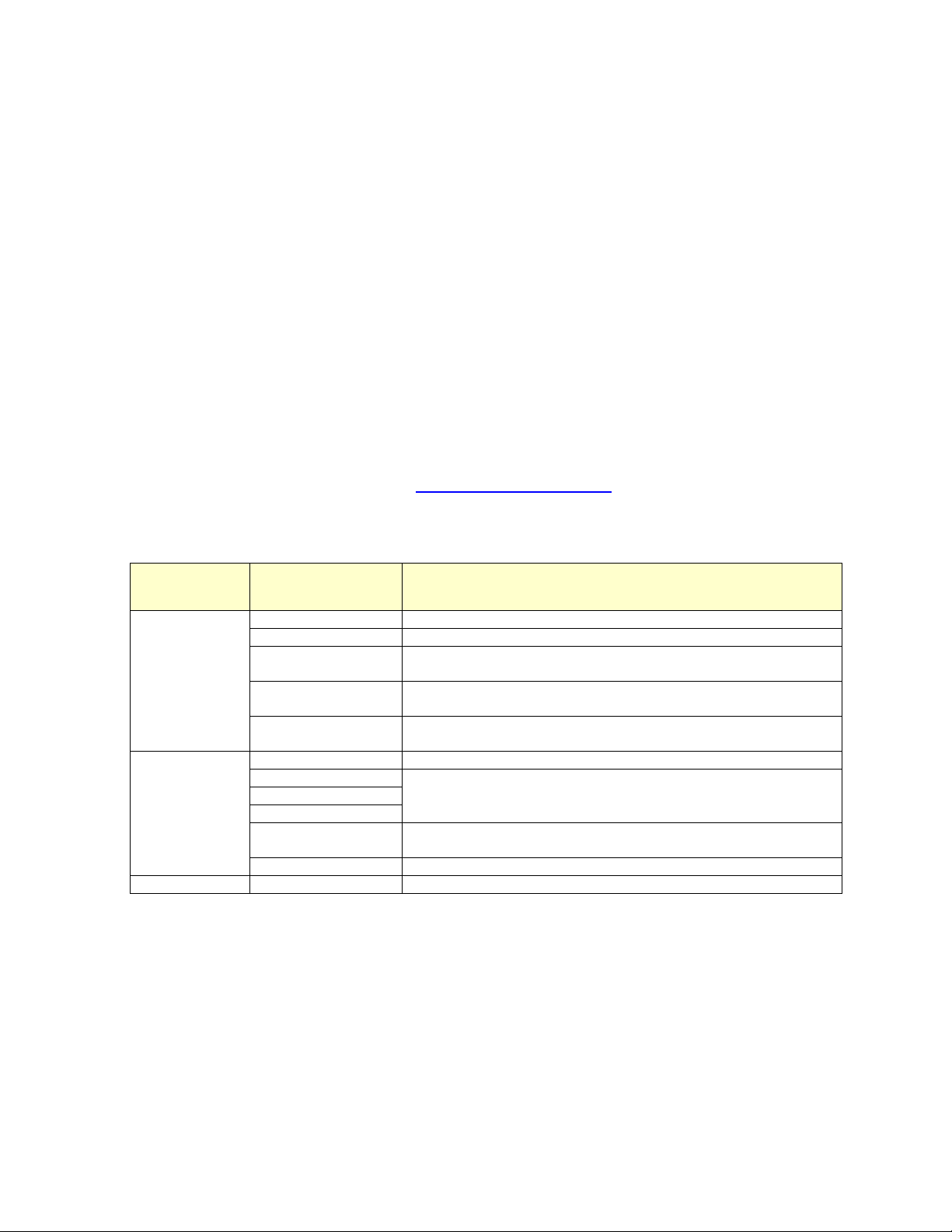

Table 3: Gauge battery life indications

Battery life

indicator icon

Battery life

remaining

Electrical

Potential

100 %

≥4.2 V

90 %

4.12 V

80 %

4.04 V

70 %

3.96 V

60 %

3.88 V

50 %

3.80 V

40 %

3.72 V

30 %

3.64 V

20 %

3.56 V

10 %

3.48 V

DM32 is Charging (USB from

DM32 is connected to power)

When the battery is charging, a red light on the front of the gauge (bottom right corner) will be on solidly

(not flashing). Once the light goes off, the gauge is fully charged. Additionally, the battery life indicator on

the Top Bar will be blue when the battery is being charged and the gauge is powered on.

With the gauge plugged into the wall outlet, the battery charges at 1A, and will take approximately 4.2

hours to fully charge a depleted battery. With the gauge plugged into the USB port of a computer, it

charges at around 500mA, not enough to maintain the gauge so will not charge the battery.

Page 16 of 94

©Retrotec Inc. 2014

When the gauge is plugged into mains power on a completely depleted battery, it may take a few minutes

to gain sufficient charge to have enough power to show the splash screen. If you press the power button

and the screen flashes without showing the splash screen, this indicates the gauge is still in the process of

gaining enough charge and will start shortly. (the gauge may also repeatedly run the Re-calibrate

touchscreen procedure when battery is too low). Plugging the gauge into the computer when the battery is

depleted will not provide enough power to restore the gauge, it must be plugged into mains power.

The Lithium-Polymer rechargeable battery provided with the gauge can last up to 3 years. Once the battery

becomes unable to hold a charge, it must be changed. Changing the battery will require return to the

factory, conveniently at about the same time that the gauge will need a factory re-calibration.

2.6 Use keys on the Home screen to control gauge operation

2.6.1. [Channel A] Pressure Reading

The [Channel A] display always shows the pressure difference between the blue pressure port “input A”

and the red pressure port “ref A”. If the pressure tubes are connected as illustrated in Retrotec’s Door Fan

Operation manual, [Channel A] shows the building pressure.

The pressure units can be displayed in units of Pa, psf or in WC. To change the units for the [Channel A]

Reading, from the Home screen, tap [Settings] [Result to be displayed] [Pressure:] until the desired

units are displayed.

The [Channel A] Reading will be negative if there is a higher pressure on the “-“ (red) pressure port

The [Channel A] Reading will be positive if there is a higher pressure on the “+“ (blue) pressure

port

The [Channel A] Reading is also a key; when it is tapped the [Channel A] and [Channel B] displays are

frozen. This feature is convenient for jotting down test data. “HOLD!” will be displayed in the Top Bar to

indicate the readings have been frozen.

2.6.2. [Channel B] Pressure Reading or Result

The [Channel B] display can show the pressure difference between the yellow pressure port “ref B” and the

green pressure port “input B”. If the pressure tubes are connected as illustrated in Retrotec’s Door Fan

Operation manual, [Channel B] shows the Fan Pressure.

The [Channel B] pressure will be negative if there is a higher pressure on the “-“ (yellow) pressure

port

The [Channel B] pressure will be positive if there is a higher pressure on the “+“ (green) pressure

port

The gauge can also use the pressure on Channel B to calculate and display different results for the [Channel

B] Result, such as:

Pressure: Pa, psf or in WC

Flow: CFM, L/s, cu m/s, cu m/h

Flow/Area (Permeability): CFM/sq ft, CFM/100 sq ft, CFM/1000sq ft, (cu m/h)/sq m, (L/s)/sq m

Air changes per hour: /h

Equivalent leakage area extrapolated to 10 Pa, “EqLA10”: sq ft, sq in, sq cm

Equivalent leakage area, “EqLA”: sq ft, sq in, sq cm

Effective leakage area, “EfLA”: sq ft, sq in, sq cm

Effective leakage area extrapolated to 4 Pa, “EfLA4”: sq ft, sq in, sq cm

Page 17 of 94

©Retrotec Inc. 2014

Equivalent leakage area per enclosure area at 10 Pa, “EqLA10/area”: sq in/sq ft, sq cm/sq m)

Effective leakage area per enclosure area at 4 Pa, “EfLA4/area”: (sq in/sq ft, sq in/100sq ft, sq ft/sq

ft, sq cm/sq m)

The [Channel B] display is also a key: when tapped, the “Result to display” on [Channel B] will change. In

the list that shows up, tapping a [Result] to highlight it (in brighter red), will select it as the displayed

[Channel B] Result of choice. Once highlighted, the [Result] can be tapped repeatedly to cycle through all

the different units available for display of that Result.

Refer to Retrotec’s Residential & Commercial Airtightness Requirements document for Results required

according to various standards, codes, and regions.

2.6.3. Set the [Range/Device] connected to the gauge

“Device” refers to the calibrated fan or other device being used to conduct the current test in conjunction

with the gauge. It is important to make sure that the correct Device is selected because the calculation for

each of the Results is based on equations that are different for each Device.

“Range” or “Range Configurations” are the rings or plates installed on a calibrated fan to limit the air flow

through it, so that the fan can achieve a measurable Fan Pressure, even when moving only a small amount

of air (for more information, see Retrotec’s Manual-Door Fan Operation). Select the Range that matches

the Range Ring or Plate that is installed on the fan to ensure that the gauge performs accurate calculations

and displays correct results.

Table 4: List of devices compatible with the DM32

Device

Manufacturer

Device displayed

Description

Retrotec

200

Model 200 fan, DucTester

1000

Model 1000 systems with 0.75 hp yellow wheel rim style fans

2000

Model Q46 and Q56 systems with 0.75 hp yellow foam core fan. Same

curves as 1000.

3000

Older Model Q4E, Q5E and QMG systems with 2 hp yellow foam core

Door Fan. Same curves as 1000.

3000SR

Model Q4E, Q5E and QMG systems with 2 hp yellow foam core Door Fan –

all fans are self-referencing (have green tube)

TEC

MN DB

Duct testing fan

MN 3 (110V)

0.75 hp black wheel rim style fan

MN 3 (230V)

MN 4 (230V)

Exhaust

Exhaust Fan Flow Meter – measures air flow through residential exhaust

fans between 10 and 124 CFM.

TrueFlow®

True Flow Grid – measures flow through a residential air handler

Generic

Hole Flow

Plate with a hole of a known size

Retrotec calibrated fans connected to the gauge with a Speed Control Cable can have their speed of

operation controlled by the gauge through the “Fan Speed” control output.

Fans manufactured by TEC (such as the DuctBlaster or Minneapolis Model 3 or 4) can be controlled by the

gauge “Fan Speed” control output if an optional Retrotec-TEC Fan speed control Adapter is connected

between the gauge and the TEC fan, in line with the Speed Control cable as shown in Figure 12. The

Minneapolis fan speed control must have the cruise input.

Connecting the pressure tubing to your TEC fan as described in Retrotec literature allows the gauge to

correctly calculate results.

Page 18 of 94

©Retrotec Inc. 2014

Figure 12: Control a TEC fan using the gauge and Fan Speed Control Adapter (part FN275, produced by Retrotec)

Table 5: Images of devices compatible with the gauge

“200”

“1000”- yellow tube only

“2000”- yellow tube only

“3000”- yellow tube only

“3000SR”-yellow and green tube

“MN DB”

“MN 3/4”

“Exhaust” (Fan Flow Meter)

Page 19 of 94

©Retrotec Inc. 2014

“TrueFlow”

2.6.4. Estimate Results with [@ Pressure]

The [@] pressure key enables the gauge to calculate and display the estimated [Channel B] Result that

would be achieved, as if the target pressure was reached (also known as “extrapolation”). The [@

Pressure] key only appears on the Home screen if [Set Speed] or [Set Pressure] functions are used and the

gauge is measuring pressures on Channel A and B.

This function is useful in situations when the fan has reached 100% speed and the enclosure

pressure still has not reached the target pressure.

Additionally, this function is useful since the measured [Channel A] pressure will usually be slightly

over or under the desired/set pressure, making it difficult to report results that exactly at the

specified pressure.

Tapping [@ Pressure] will toggle the extrapolation function on or off. The label under [Channel B] display

will change to indicate whether [@ Pressure] “is On” (e.g., CFM@25.0Pa) or “is Off” (e.g., CFM).

Details of how the gauge calculates the flow at exactly the target pressure, when [Channel A] has not

reached exactly the set target pressure, can be found in Appendix D.

If the [Set Speed] function is used, [@ Pressure] extrapolates the [Channel B] Result to the [Default

@ Pressure] set in the “Settings” screen, using the “n value” chosen in [Settings].

If the [Set Pressure] function is used, [@ Pressure] extrapolates the [Channel B] Result to the

pressure entered for [Set Pressure], using the “n value” chosen in [Settings].

The @ Pressure function provides unique advantages over non-extrapolated results:

There is no need to achieve an exact [Channel A] pressure (e.g. to a precision of 0.1 Pa)

[Channel B] Results can be obtained even if the test pressure cannot be reached**

**Although the gauge can extrapolate results to any pressure, it is more accurate when the actual

enclosure pressure read on [Channel A] is close to the target pressure. As a rule of thumb, extrapolation

can be used if the actual enclosure pressure reaches at least 80% of the target pressure. If 80% cannot be

reached, more fans are needed to complete the test (See Retrotec’s Manual-Lge-Multi-Fan Testing).

Example #1 - Inaccuracy

A 50 Pa building pressure is desired, but only 20 Pa can be reached (due to severe leakiness). In this

instance, the extrapolated results for flow “@ 50 Pa” do not represent the reality of the testing conditions

and might be highly inaccurate.

In the same situation, a 45 Pa building pressure is achieved. The extrapolated “@ 50 Pa” pressure is now

much more accurate, and provides an acceptable result.

Page 20 of 94

©Retrotec Inc. 2014

2.6.5. Setting “n value” for @Pressure extrapolation

The “n value” is a number set between 0.5 and 1.0 that is used in the calculation when extrapolating

[Channel B] results to a pressure that is not the pressure read on [Channel A]. It can be changed by tapping

[Settings][…] [Ducts=0.6, House=0.65]. Set it to 0.65 for houses, and 0.60 for ductwork. Set to 0.5 for

tests using the Retrotec House or duct simulator, air handler flow and any large hole that is not composed

of long thin cracks.

Technical details about the “n value” are shown in Appendix D.

2.6.6. Capture and apply a Baseline using [Settings]

Some buildings have an initial pressure imbalance between the indoors and outdoors, prior to any testing.

This pressure imbalance is called the Baseline pressure, bias pressure, or static pressure. The Baseline

function allows the user to capture the Baseline pressure under the existing test conditions. See Section

4.1 for illustrations of how to capture a Baseline. Once captured, the gauge will automatically subtract the

Baseline pressure from all subsequently measured pressure readings, and will display only the adjusted

pressures on the screen. The gauge averages Baseline pressure for a user-defined duration.

Tip: A 30 second Baseline acquisition is typically enough to establish an accurate baseline measurement. If the

building conditions change during the test, the baseline should be cleared and a new measurement should be taken.

2.7 Gauge compensates for sensor drift with Auto Zero

Over time, the pressure readings on [Channel A] and [Channel B] can start to drift away slowly from the

true pressure value. The longer the gauge remains on, the larger this error could become. The “Auto Zero”

is a feature on the gauge that will automatically correct these errors at regular intervals. By default, Auto

Zero occurs every 30 seconds. When using set speed or set pressure, the AutoZero interval is three

minutes. This interval (seconds) can be changed using the “DM32 Configurator” software on a PC. See

Retrotec’s Manual-Software-DM32 Configurator for details.

Page 21 of 94

©Retrotec Inc. 2014

3. Get Results directly from the gauge

3.1 Connect Speed Control Cable between the

gauge and fan

Refer to section 2.1 which describes the connection ports from the gauge to a

device such as a Retrotec calibrated fan. The connections for pressure tubing

between a DM32 and a device are the same as the connections between a DM-2

gauge and that device.

Refer to Retrotec’s Manual-Door Fan Operation for detailed illustrations on these connections, depending

on what kind of test is to be performed.

3.2 Connect pressure tubes to gauge

3.3 Control the test and read Results on the Home screen

Tap [Range/Device] to select the Range Configuration in use

If the Range Configurations associated with the Device in use do not appear, tap [Change

Device] to change the Device first

Tap [Settings] to display gauge settings that can be changed

If the [Area] or [Volume] key appears, tap to enter a value for conditioned area or volume, which

will be used to compute the result displayed on [Channel B]

Tap [Set Speed] to run the fan at a particular speed

Tap [Set Pressure] to achieve a particular enclosure pressure

Tap [Channel A] to Hold results being displayed

Tap [Channel B] to change the “Result to be displayed”

Tap [@Pressure] to estimate a [Channel B] Result at the set pressure

To jump to screen illustrations showing how to use each function, click on the hyperlink in the above list.

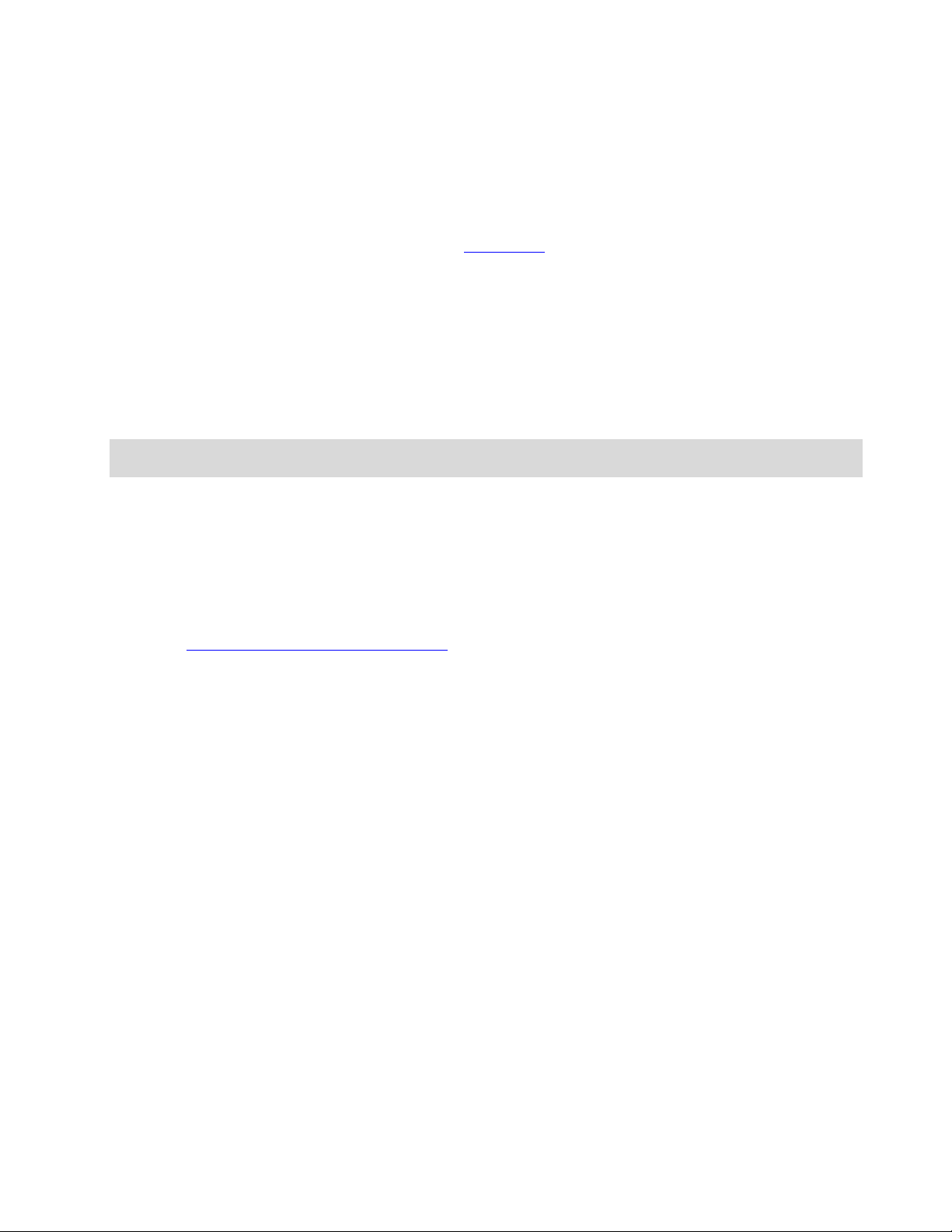

3.3.1. Tap [Range/Device] to match Range on Device in use

Figure 13: Change Range for selected Device

3.3.2. Tap [Range/Device] [Change Device] to change Device in use

Page 22 of 94

©Retrotec Inc. 2014

Figure 14: Change Device in use

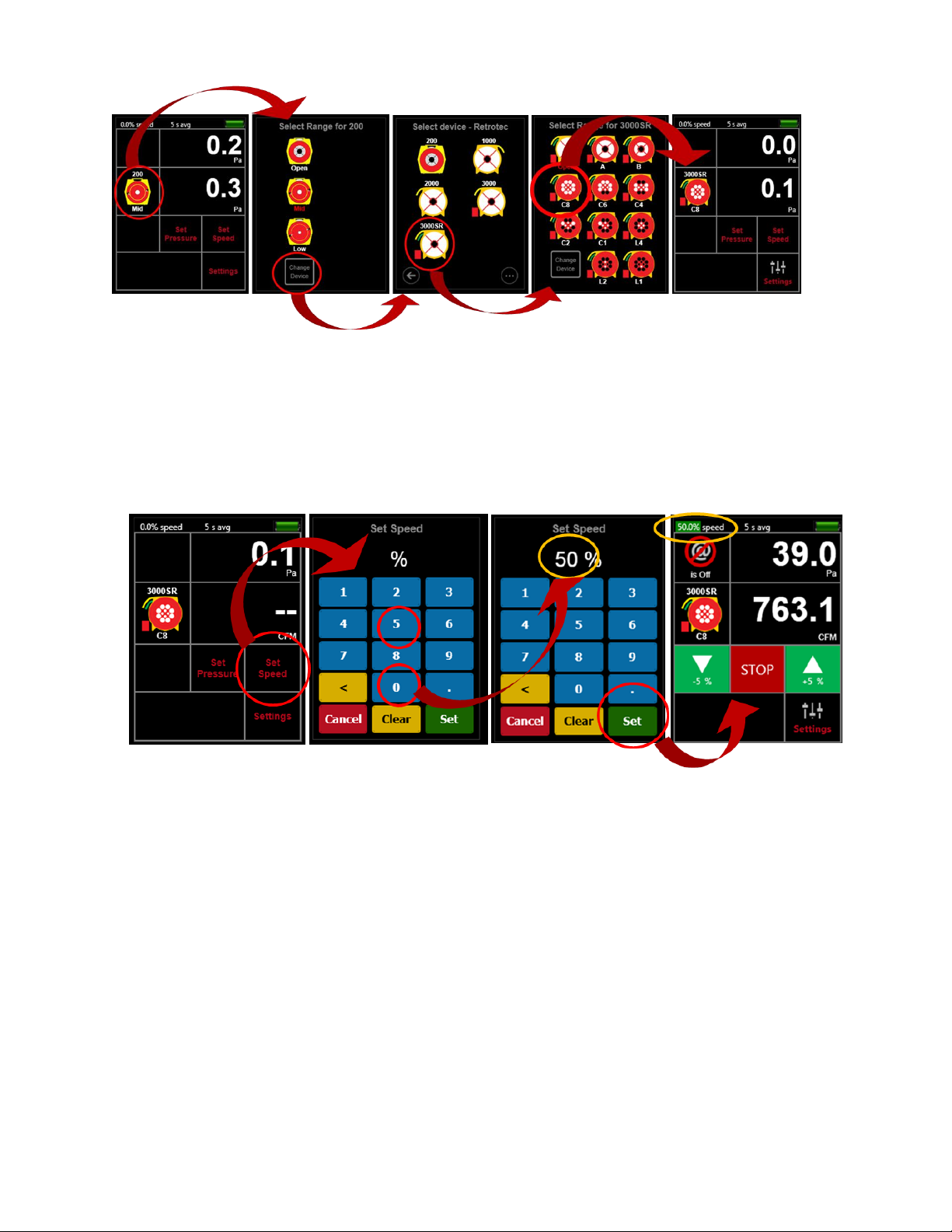

3.3.3. Tap [Set Speed] to run the fan at a particular speed

The gauge can automatically control the fan speed on Retrotec systems to achieve a specific fan speed,

entered by the user.

Figure 15: Set gauge speed control output

Fans manufactured by TEC (such as the DuctBlaster or Minneapolis Model 3 or 4) can also be controlled if

an optional Retrotec-TEC speed control Adapter is connected between the gauge and the TEC fan in the

Speed Control cable as shown in Figure 12. Pressure tubing needs to be attached to the gauge using the

Retrotec conventions described in the Retrotec literature.

3.3.4. Tap [Jog] keys to adjust speed up or down 5%

Page 23 of 94

©Retrotec Inc. 2014

Figure 16: Adjust speed up or down 5% using [Jog] keys

3.3.5. Tap [Set Pressure] to achieve a particular enclosure pressure

The gauge can achieve a target enclosure pressure entered by the user. The gauge controls pressure by

automatically adjusting the speed control output based on the pressure reading on Channel A. Retrotec

fans can be controlled directly from the gauge.

Figure 17: Set gauge to achieve target pressure

Fans manufactured by TEC can also be controlled if the optional Retrotec-TEC speed control Adapter is

connected between the gauge and the TEC fan as shown in Figure 12. Pressure tubing needs to be

attached to the gauge using the Retrotec conventions described in the Retrotec literature.

Page 24 of 94

©Retrotec Inc. 2014

3.3.6. Tap [Jog] keys to adjust pressure up or down 5 Pa

Figure 18: Adjust pressure up or down 5 Pa using [Jog] keys

3.3.7. Tap [Area] or [Volume] to enter dimension for particular Results

The [Area] key only appears on the Home screen if one of the permeability results requiring an input of

area for the calculation is selected as the “Result to be displayed” on [Channel B].

Figure 19: Enter an [Area] if the Result to be displayed is calculated with an Area

The [Area] key from the Home screen opens the same screen as the [Settings][Area] key combination.

The [Volume] key only appears on the Home screen if “ACH” (Air Changes per hour) is selected as the

“Result to be displayed” on [Channel B].

Page 25 of 94

©Retrotec Inc. 2014

Figure 20: Enter a [Volume] if Result to be displayed is "ACH"

The [Volume] key from the Home screen opens the same screen as the [Settings][Volume] key

combination.

3.3.8. Tap [Channel A] to “Hold” readings and results

[Channel A] also acts as a key, so by tapping here, the results can be frozen at the value in place when the

key is tapped, called “Hold”. When active, you will see “Hold” displayed and flashing in the Top Bar. “Hold”

allows the user to copy results down without them changing and flashing. Changing the Result is even

available when display is frozen using “HOLD!”.

Figure 21: “HOLD!” Result on display by tapping [Channel A]

To remove “HOLD!” and release the display, tap again on [Channel A], or hit a Jog key.

Page 26 of 94

©Retrotec Inc. 2014

Figure 22: Remove "HOLD!" by tapping [Channel A] or a [Jog] key

3.3.9. Tap [Channel B] or [Settings] to change Result or units to be displayed

[Channel B] acts as a key, so by tapping it you can change the Result to be displayed at [Channel B]. The

Result to be displayed can also be changed by tapping on [Settings].

Figure 23: Change “Result to be displayed” during operation

Page 27 of 94

©Retrotec Inc. 2014

Changing the Result to be displayed can occur even while the fan is running during [Set Pressure] or [Set

Speed] so user can see multiple results for one fan speed setting. Changing the Result is even available

when display is frozen using “HOLD!”.

Figure 24: Tap [Channel B] to change “Result being displayed”

Each of the available results can be displayed with the user’s choice of units.

Figure 25: Change Flow result units from “CFM” to “cu m/h”

3.3.10. Tap [@ Pressure] to estimate Result at a different pressure

Page 28 of 94

©Retrotec Inc. 2014

When the gauge is controlling to a speed or pressure so that fan speed is not at 0%, the gauge can

extrapolate the Result and show a value for the Result that would have been achieved if the pressure on

Channel A had reached a different value. The “different value” mentioned is called the extrapolation

pressure or “@ Pressure”. If setting speed, the extrapolation pressure will be the “Default @ Pressure” the

user can enter in the second “Settings” screen. If setting pressure, the extrapolation pressure will be

exactly the target pressure.

If setting target pressure to zero, then the gauge does not allow @ pressure extrapolation to be used.

For mathematical details on @Pressure extrapolation, see Appendix D. For practical information on

extrapolation, see 2.6.4.

Figure 26: Turn [@ Pressure] on

Figure 27: [@ Pressure] is not available when Pressure is the Result on Channel B

Figure 28: [@ Pressure] is not available when the gauge is not actively controlling a fan

If [Set Pressure] function is used:

Page 29 of 94

©Retrotec Inc. 2014

Tapping [@ Pressure] so that it “is On” extrapolates the [Channel B] Result to the [Set Pressure]

target entered, using the “n” value specified in the second “Settings” screen.

Tapping a [Jog] key so that target pressure changes causes the “@ Pressure” label to change as

well.

Figure 29: [@ Pressure] extrapolates to the target pressure when a pressure is set

Figure 30: Jogging pressure while using [@ Pressure] changes target and @ pressure label

If [Set Speed] function is used:

Tapping [@ Pressure] so that it “is On” extrapolates the [Channel B] Result to the [Default @

Pressure] using the “n” value, both set in the second “Settings” screen.

Loading...

Loading...