Operating Instructions

RF100 XL 3D printer, fully-assembled

Item No. 1592461 RF100 XL Plus

Item No. 1592620 RF100 XL Page 2 - 61

Table of contents

Page

1. Introduction .......................................................................................................................................................... 4

2. Explanation of symbols ........................................................................................................................................ 4

3. Intended use ........................................................................................................................................................ 5

4. Package contents ................................................................................................................................................ 5

5. SD card contents ................................................................................................................................................. 6

a) 3D models .....................................................................................................................................................6

b) Cong ............................................................................................................................................................ 6

c) Operating instructions .................................................................................................................................... 7

d) Software ........................................................................................................................................................7

6. Features and functions ........................................................................................................................................ 7

7. Working principles of the 3D printer .....................................................................................................................8

8. Safety instructions ...............................................................................................................................................9

a) General information ....................................................................................................................................... 9

b) Setup ........................................................................................................................................................... 10

c) Mains cable/connection ............................................................................................................................... 10

d) Operation ..................................................................................................................................................... 11

9. Control elements and components .................................................................................................................... 12

a) 3D printer ..................................................................................................................................................... 12

b) Accessories ................................................................................................................................................. 13

10. Before installation .............................................................................................................................................. 14

11. Assembly ...........................................................................................................................................................14

a) Setting up the 3D printer .............................................................................................................................. 14

b) Installation and connection .......................................................................................................................... 14

12. Control panel .....................................................................................................................................................16

a) General functions ...................................................................................................................................... 16

b) Menu options and functions .........................................................................................................................17

c) Display layout during the printing process ................................................................................................... 24

d) Menu overview ............................................................................................................................................25

13. Tips for 3D printing ............................................................................................................................................27

a) Nozzle temperature ..................................................................................................................................... 27

b) Preventing nozzle blockages ....................................................................................................................... 27

c) Layer thickness ............................................................................................................................................ 28

d) Hot plate temperature (for item no. 1592461) .............................................................................................28

14. Preparation ........................................................................................................................................................ 29

a) Calibrating the print bed ..............................................................................................................................29

2

b) Attaching the lament .................................................................................................................................. 30

c) Loading the lament .................................................................................................................................... 30

d) Removing the lament ................................................................................................................................. 32

e) Changing/replacing the lament .................................................................................................................. 33

f) Installing the "Cura" software (optional) ...................................................................................................... 33

15. Printing from the SD card/USB stick .................................................................................................................. 34

a) Printing from the SD card ............................................................................................................................ 34

b) Printing from a USB stick ............................................................................................................................. 35

c) Starting the printing process ....................................................................................................................... 36

d) Pausing the printing process ....................................................................................................................... 37

e) Conguring parameters during the printing process .................................................................................... 38

f) Restarting the 3D printer ............................................................................................................................. 38

16. Printing with the "Cura" software ....................................................................................................................... 39

a) Installation ...................................................................................................................................................39

b) Setting up the software (Windows

®

) ............................................................................................................ 40

c) Setting up the software (Mac OS) ............................................................................................................... 44

d) Software settings (Windows

e) Loading conguration les (Windows

®

) .....................................................................................................................48

®

) ....................................................................................................... 52

f) Loading conguration les (Mac OS) .......................................................................................................... 52

g) Loading model les (Windows

®

and Mac OS) ............................................................................................. 53

h) Disabling the control icons on the 3D printer ............................................................................................... 54

i) Starting the printing process ........................................................................................................................ 54

j) Stopping the printing process ...................................................................................................................... 55

17. Updating the 3D printer rmware ....................................................................................................................... 55

a) Displaying the rmware version ................................................................................................................... 55

b) Performing a rmware update ................................................................................................................... 55

18. Cleaning and maintenance ................................................................................................................................ 56

a) Cleaning the printer ..................................................................................................................................... 56

b) Cleaning the nozzle ..................................................................................................................................... 56

c) Cleaning the inside of the extruder .............................................................................................................. 57

d) Cleaning the print bed .................................................................................................................................57

e) Removing the lament ................................................................................................................................. 57

f) Storing the 3D printer .................................................................................................................................. 57

19. Troubleshooting .................................................................................................................................................58

20. Disposal ............................................................................................................................................................. 60

21. Technical data .................................................................................................................................................... 60

a) General information ..................................................................................................................................... 60

b) RF100 XL Plus (item no. 1592461) .............................................................................................................61

c) RF100 XL (item no. 1592620) ..................................................................................................................... 61

3

1. Introduction

Dear customer,

Thank you for purchasing this product.

This product complies with statutory national and European regulations.

To ensure that the product remains in this state and to guarantee safe operation, always follow the instructions in this

manual.

These operating instructions are part of this product. They contain important information on setting up and

using the product. Please consider this if you give the product to a third party, and keep the instructions for

future reference.

If there are any technical questions, please contact:

International: www.conrad.com/contact

United Kingdom: www.conrad-electronic.co.uk/contact

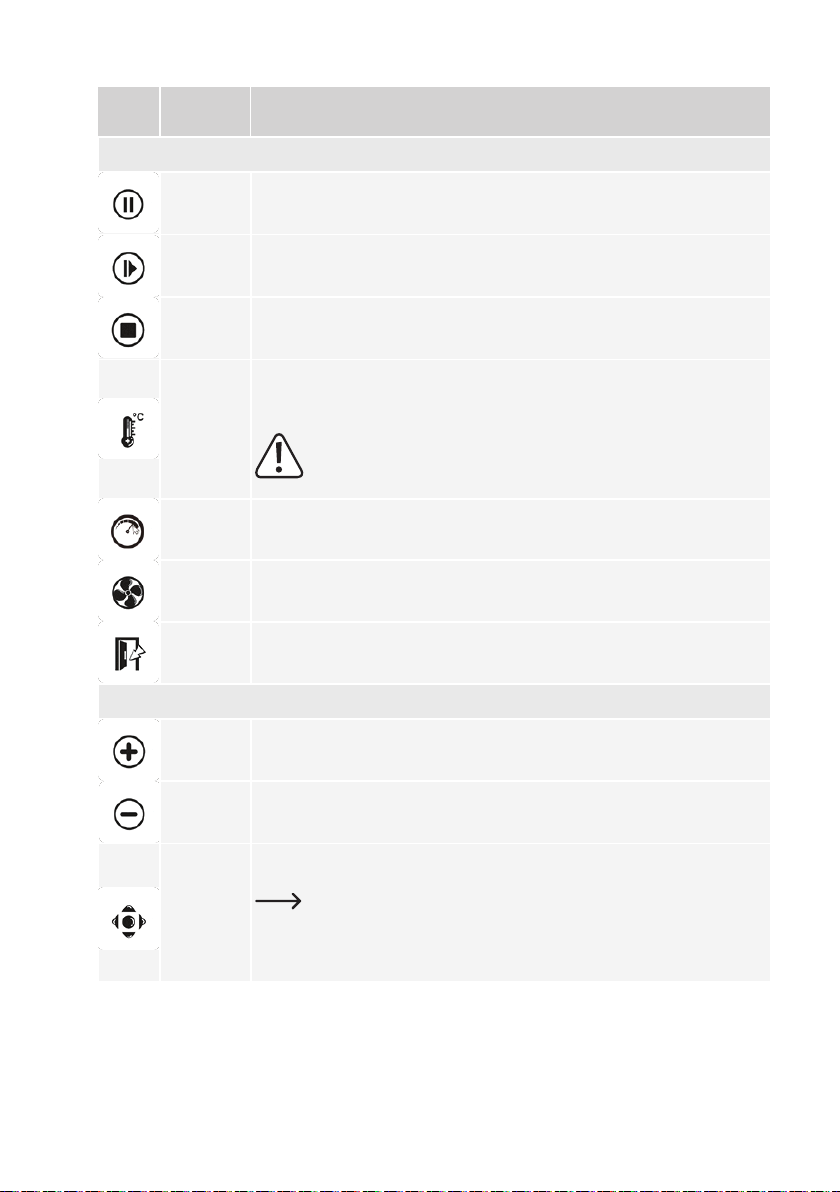

2. Explanation of symbols

The symbol with the lightning in a triangle indicates that there is a risk to your health, e.g. due to an electric

shock.

The symbol with an exclamation mark in a triangle is used to highlight important information in these

operating instructions. Always read this information carefully.

This symbol warns you against hot surfaces that may cause injuries.

This symbol warns you against hand injuries that may occur if you insert your hands into the device.

This symbol warns you against hand injuries that may be caused by the belt.

For indoor use only.

Read the operating instructions carefully.

The arrow symbol indicates special information and advice on how to use the product.

4

3. Intended use

The 3D printer is shipped pre-assembled and ready to use. It can be controlled with the computer software provided

or the built-in touchscreen colour display. It features a powder-coated metal housing to ensure a long lifespan. The

printer can print objects up to a size of 200 x 200 x 200 mm and comes with bright built-in LEDs that enable you to

monitor the printing progress. The SD card comes with 100 preset 3D models that can be printed in a few mouse

clicks.

The 3D printer must be connected to a standard mains socket (100–240 V/AC, 50/60 Hz). It is intended for private

use only.

The printer is intended for indoor use only. Contact with moisture (e.g. in bathrooms) must be avoided under all

circumstances.

For safety and approval purposes, you must not rebuild and/or modify this product. Using the product for purposes

other than those described above may damage the product. Improper use may lead to short circuits, re, electric

shocks or other hazards. Read the instructions carefully and store them in a safe place. Always provide these

instructions when giving the product to a third party.

All company and product names are trademarks of their respective owners. All rights reserved.

Up-to-date operating instructions, 3D model les and conguration les

To download the latest operating instructions, 3D model les and conguration les, visit www.conrad.com/downloads

or scan the QR code on this page. Follow the instructions on the website.

4. Package contents

• Fully-assembled 3D printer

• 250 g original Renkforce PLA lament (1.75 mm,

white)

• 8 GB SD card with “Cura" software, 100+ ready-to-

print 3D model les

• Power adapter

• Mains cable

• Quick start guide (in German and English)

• Filament spool holder

• Filament tube

• USB cable

• Scraper

• Tweezers

• Side cutters

• 2.0 mm hex key

• 2.5 mm hex key

• 2x screws to secure the lament spool holder

• Glass print bed with pre-installed print bed lm (with

item no. 1592620)

- Includes hot plate and blue tape (with item no.

1592461)

• 5 x original Renkforce lament samples (copper, wood,

glow-in-the-dark, colour-change and elastic, 1.75 mm

/ 50 g)

• 50 g ABS lament (1.75 mm, black) (with item no.

1592461)

5

5. SD card contents

• The SD card contains the following folders:

- "3D models"

- "Cong"

- "Manual" (user manual)

- "Software"

To view the contents of the SD card, connect the 3D printer (with the SD card inserted) to your computer.

The control panel on the printer only gives you limited access to the SD card.

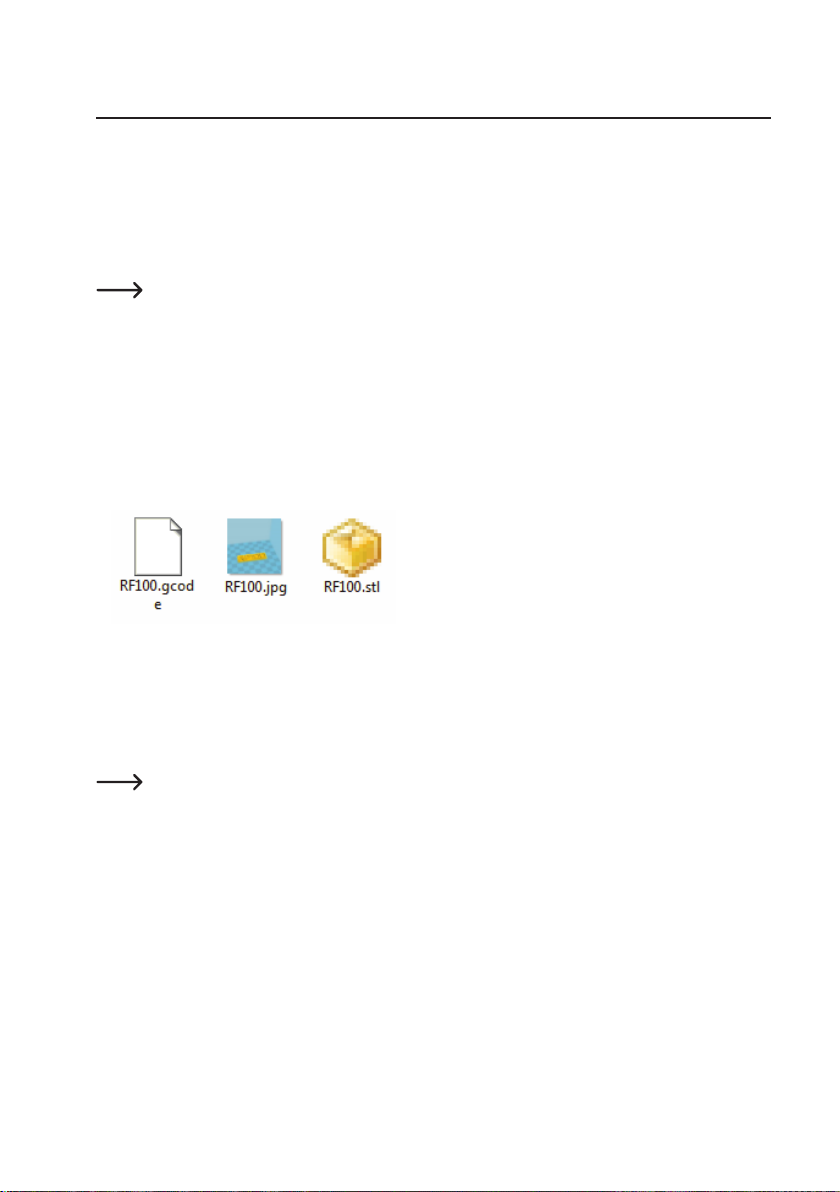

a) 3D models

• The "3D models" folder contains several subfolders, including "Basic shape", "Capital letters (A-Z), "Constellation",

"Mathematical symbols", "Numbers (0-9)" and "VariousObjects".

• These subfolders contain over 100 3D models.

• Each model is available in .gcode (.Digicode), .jpg and .stl format. Example: "RF100 ":

• The JPG le allows you to preview the model.

The STL le allows you to create your own GCODE le using the "Cura" software.

Use the GCODE le for printing.

• To start printing, insert the SD card into the slot on the 3D printer, or load the .stl le on your computer using the

"Cura" software.

The printer's control panel only lists the les in .gcode format.

b) Cong

• The "Cong" folder contains conguration les for different lament materials:

- "Copper" (copper)

- "Elastic" (Elastic material)

- "PLA"

- "Wood" (wood)

- "ABS"

6

• Load the conguration le in "Cura" to print an object using the corresponding material (see “e) Loading conguration

les (Windows

®

)” on page 52 for details).

The contents of this folder are not displayed on the control panel. These cong les are recommended for

use with the supplied laments. You can also use "Cura" to create your own conguration les.

c) Operating instructions

• The quick start guide is saved to the "Manual" folder.

The contents of this folder are not displayed on the control panel.

d) Software

• The "Software" folder contains the Windows® and Mac OS installation les for the "Cura" software and the

necessary USB drivers.

The contents of this folder are not displayed on the control panel.

6. Features and functions

• Fully assembled and ready-to-use 3D printer

• Max. size of the printed object: 200 x 200 x 200 mm

• High-precision extruder with 0.4 mm nozzle

• Colour touchscreen control panel

• Works with a computer (via USB) or an SD card/USB stick

• Supports printing from an SD card, PC and USB stick

• Manually-congurable printer parameters

• Extremely stable metal design

• Suitable for 1.75 mm PLA, wood, copper, elastic, glow-in-the-dark and thermocolour laments (for item no.

1592620, 1592461) and ABS laments (for item no. 1592461)

• Over 100 ready-to-use 3D models

• Includes "Cura" software

7

7. Working principles of the 3D printer

• The 3D printer requires a le containing the three-dimensional data of the object that you wish to print (.stl is a

standard format).

• You can create these les using suitable software or a 3D scanner. You can also download ready-to-use print les

from the Internet to print objects quickly.

• The printer software converts the three-dimensional data into a .gcode le that contains information about the

printed layers and temperatures for the nozzle and other components.

• The .gcode le can be sent to the printer from a computer via the USB port, or you can insert an SD card containing

the le into the printer and use the built-in control panel.

• The 3D printer creates the object layer by layer (by fusing the lament material). The lament material is transported

from the lament spool to the nozzle.

• The lament material is melted in the extruder and applied layer by layer to the print bed via a ne nozzle.

• The print bed moves along the Z axis (up/down), and the extruder moves along the X (left/right) and Y (forwards/

backwards) axes. This allows the printer to create a three-dimensional object by applying the layers horizontally.

A 3D printer is a very complex machine that requires you to congure numerous parameters

according to the 3D printer model, printed object and lament material.

The printing temperature, lament material, print bed calibration settings, size/shape of the printed

object and the surface of the print bed also affect how the printed object adheres to the print bed.

Draughts, grease on the print bed and other factors can also affect the quality and durability of the

printed object.

It is therefore not possible to ensure high-quality prints without testing the parameters in advance.

Change the parameters in small steps to ensure optimal results for your desired application. The

pre-installed print templates on the SD card can be used for reference, but need to be ne-tuned

based on the aforementioned parameters to ensure optimal results.

8

8. Safety instructions

Read the operating instructions and safety information carefully. If you do not follow the safety

instructions and information on proper handling in this manual, we will assume no liability for any

resulting personal injury or damage to property. Such cases will invalidate the warranty/guarantee.

a) General information

• For safety reasons, unauthorised conversions and/or modications to the product are not permitted

(other than those indicated in these instructions), as this may damage the components and affect the

functionality/safety of the device.

• All people who use, install, mount or repair this product must be suitably qualied and follow the

instructions.

• The 3D printer is not suitable for people with physical, sensory or mental disabilities or people who are

not suitably qualied.

• This product is not a toy and must be kept out of the reach of children! Children do not understand the

hazards associated with the incorrect use of electrical devices.

• The mechanical components are high-precision parts. Do not use any force, as this may damage the

components and render the 3D printer unusable.

• Never cover the product during use. Only move, transport or store the product when it is switched off.

• Do not leave packaging material lying around carelessly, as it may become dangerous playing material

for children.

• Protect the product against extreme temperatures, direct sunlight, strong jolts, vibrations, ammable

gases, vapours, dust, solvents, high humidity, moisture (e.g. rainwater and steam) and strong mechanical

loads.

• If it is no longer possible to operate the product safely, stop using it and prevent unauthorized use. Safe

operation can no longer be guaranteed if the product:

- is visibly damaged,

- is no longer working properly,

- has been stored for extended periods in adverse ambient conditions or

- has been subjected to any serious transport-related stress.

• Always handle the product carefully. Jolts, impacts or a fall even from a low height may damage the

product.

• Do not cover the ventilation slots on the bottom of the printer. Do not insert sharp objects into the printer,

as this may cause an electric shock.

• Never attempt to disassemble the 3D printer or service any of the interior components.

• Warning, LED light: Do not look directly at the LED light! Do not look into the beam directly or with optical

instruments!

• Observe all additional safety information in the individual sections of these instructions.

• Consult a technician if you are not sure how to use or connect the product.

• Maintenance, modications and repairs must be done by a technician or a specialist repair centre.

9

• If you have questions which remain unanswered by these operating instructions, contact our technical

support service or other technical personnel.

b) Setup

• Place the 3D printer on a level, horizontal surface of a sufcient size.

• Install the 3D printer in a location that is out of the reach of children.

• Ensure that the power switch on the printer is easily accessible so that you can switch it off quickly in

the event of a fault.

• Do not expose the printer to extreme temperatures, strong vibrations, high humidity (e.g. rainwater or

steam) or strong mechanical loads.

• Never place containers (e.g. glasses or vases) lled with liquid on or directly next to the printer or pour

liquids over the appliance. Liquids may come into contact with the interior components and impair the

electrical safety of the product or cause a re or fatal electric shock.

If the printer comes into contact with liquids, isolate the mains socket (e.g. switch off the circuit breaker

and RCD), and then unplug the mains plug from the mains socket. Disconnect all cables from the printer.

Discontinue use and take the printer to a specialist repair centre.

• Do not place open ames (e.g. burning candles) on or next to the printer.

c) Mains cable/connection

• The mains socket that the printer is plugged into must be easily accessible.

• Only power the product using the mains adapter provided.

• Only insert the mains adapter into a standard mains socket that is connected to the public grid. Before

plugging in the power adapter, check whether the voltage stated on the power adapter complies with the

voltage of your electricity supplier.

• Fully unwind the mains cable before use, otherwise the cable may overheat and cause a re!

• Never connect or disconnect the power adapter if your hands are wet.

• Never unplug the power adapter from the mains socket by pulling on the cable. Always use the grips

on the plug.

• Make sure that the mains cable is not squeezed, bent, damaged by sharp edges or subjected to

mechanical stress. Avoid excessive thermal stress on the mains cable from extreme heat or cold. Do not

attempt to modify the mains cable, as this may cause permanent damage. Damaged mains cables can

cause a fatal electric shock.

• Do not allow the mains cable to hang over the edge of the table or other surface supporting the 3D

printer.

• Always lay the cables so that nobody can trip over or become entangled in them, as this may cause an

injury.

• For safety reasons, disconnect the power adapter from the mains socket during storms.

• Unplug the power adapter if you do not plan to use the 3D printer for an extended period.

• Always disconnect the power adapter before leaving the printer unattended.

10

• Before conducting any repair or modication work, disconnect the printer from the mains and computer

and allow it to cool down.

• Do not touch the mains cable if there are any signs of damage. If the mains cable is damaged, isolate

the mains socket (e.g. switch off the circuit breaker and RCD), and then unplug the mains plug from the

mains socket. Do not use the printer with a damaged mains cable.

d) Operation

• Do not use the 3D printer outdoors.

• Do not use the printer near bath tubs, showers, swimming pools or washbasins. It must not be exposed

to moisture.

•

• The nozzle (for item no. 1592620 and 1592461) and hot plate (for item no. 1592461) become very hot

during use. Never touch these parts during or shortly after use. Allow them to cool down sufciently

(approx. 60 mins).

• Do not place any objects on the printer, as this may cause it to overheat. Never cover the printer during

use.

•

• Before conducting any repair or maintenance work, disconnect the printer from the power supply (unplug

the power adapter) and allow it to cool down.

• The printer makes a noise during use and may produce an odour depending on the type of lament

material used. Bear these points in mind when selecting a setup location and choosing the lament

material. Ensure that there is sufcient ventilation, or install an extraction system. Avoid inhaling the

vapours produced by the printer. Other lament materials that are not recommended may produce

poisonous vapours or gases.

• Do not operate the device when it is unattended.

• Only use the product in temperate climates. It is not suitable for use in tropical climates.

• Never use the product immediately after it has been brought from a cold room into a warm one. The

condensation generated may destroy the product. Allow the product to reach room temperature before

connecting it and putting it to use. This may take several hours.

Some parts of the printer can become very hot and may cause burns. Exercise caution in the

presence of children and vulnerable people.

Never place your hands inside the 3D printer during use. The printer contains

moving mechanical parts that may cause an injury.

11

9. Control elements and components

8

7

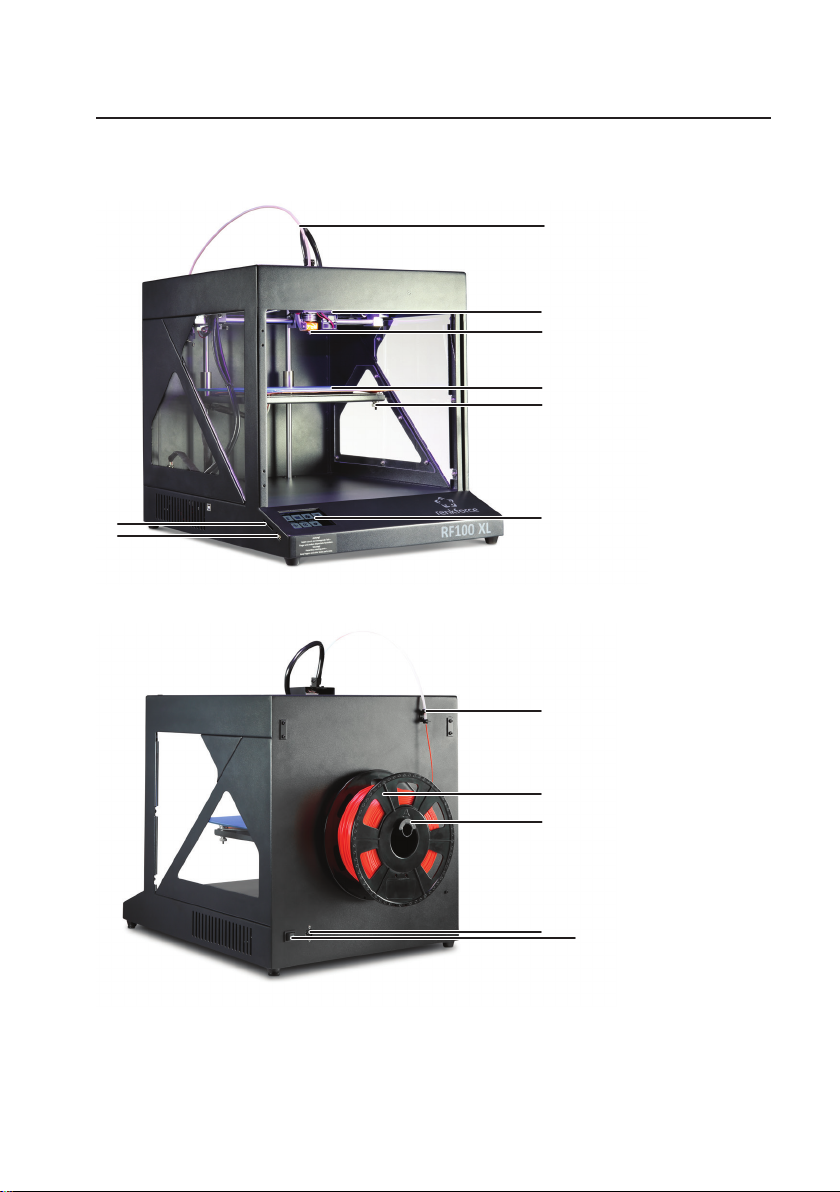

a) 3D printer

Front

Back

1

1 Filament tube

2 Extruder

3 Nozzle

2

3

4 Printer bed (item no.

1592620)

4

5

6

Printer bed with hot plate

(item no. 1592461)

5 Levelling screw (x3)

6 Colour touchscreen

display

7 USB port

8 Card reader

9

9 Filament tube holder

10 Filament with spool

10

11 Filament spool holder

11

12 Power-in socket

13 On/off switch

12

13

12

b) Accessories

A

O

N

M

L

I

K H G

A ABS lament (for item no. 1592461)

B Small power adapter (for item no. 1592620)

C Large power adapter (for item no. 1592461)

D Mains cable

E USB cable

F Scraper

G SD card

H Tweezers

I 2 / 2.5 mm hex key

J 2x screws

K Wire cutter

L Filament tube

M Filament spool holder

N 5x Original Renkforce lament samples

O Original Renkforce PLA lament with spool

J

B

C

D

E

F

13

10. Before installation

• Carefully remove all parts from the packaging.

• Remove the protective lm from the colour touch display.

• Cut the cable ties on both sides using a wire cutter.

• Ensure that no parts are missing or damaged. Do not use the printer if parts are missing or damaged.

11. Assembly

a) Setting up the 3D printer

When choosing a location for the 3D printer, ensure that the power switch is easily accessible so that you

can switch it off quickly in the event of a fault.

Ensure that there is sufcient ventilation around the printer. Do not place the printer on soft surfaces (e.g.

rug or bed). The air must be able to circulate freely and must not be obstructed by other objects. This would

prevent heat from dissipating from the printer and lead to overheating (re hazard).

Place the printer on a stable surface and ensure that it is securely in place. It may cause an injury if it falls

off the surface.

Ensure that the USB and mains cable are not pinched or damaged by sharp edges.

Lay the cables in a place where people will not trip over them or become entangled. This may cause an

injury.

• Place the 3D printer on a dry, level surface that is not sensitive to vibrations.

Anti-slip feet are attached to the bottom of the printer. If necessary, place a protective cover underneath the printer

to prevent the surface from getting scratched.

b) Installation and connection

The mains socket must be close to the printer and easily accessible so that you can quickly

disconnect the printer from the mains in the event of a fault.

Exercise caution when handling the mains cable and connecting it to the mains. Mains voltages

can cause fatal electric shocks.

Before connecting the printer to the mains, check that the voltage stated on the printer matches

the voltage of the mains socket. If not, do not connect the printer to the mains. An incorrect mains

voltage can cause irreparable damage to the printer and endanger the user.

14

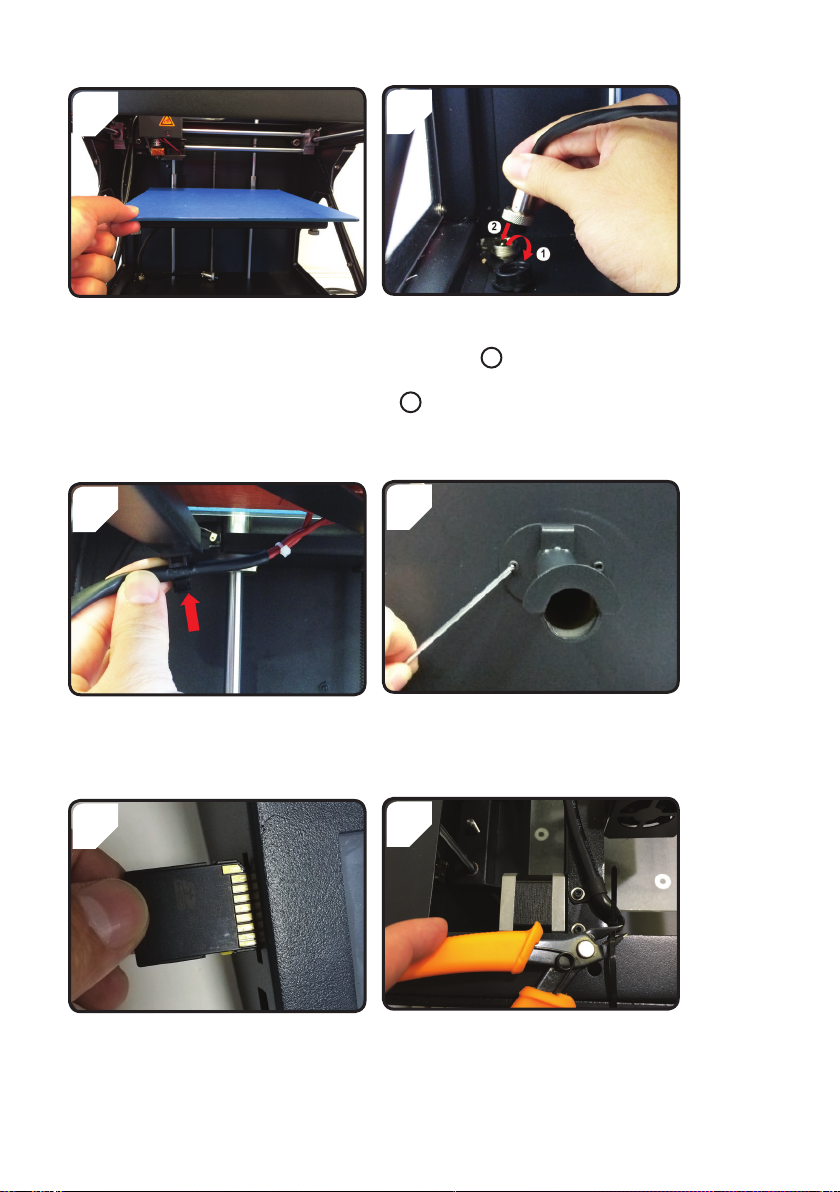

1

2

1

2

• Insert the print bed.

3

Only for item no. 1592461

• Insert the hot plate cable into the cable holder

(on the bottom of the print bed).

5

Only for item no. 1592461

• Remove the protective cover on the hot plate

power socket (

• Plug the hot plate power cable into the socket

).

(

• Secure the connection: Turn the lock nut onto

the hot plate connection.

).

4

• Use two screws and the 2.5 mm hex key to attach the

lament spool holder to the back of the 3D printer.

The "nose" on the end of the holder should face upwards.

6

• Insert the SD card with the label facing

downwards.

• Cut through the cable tie on both sides using the

wide cutter.

15

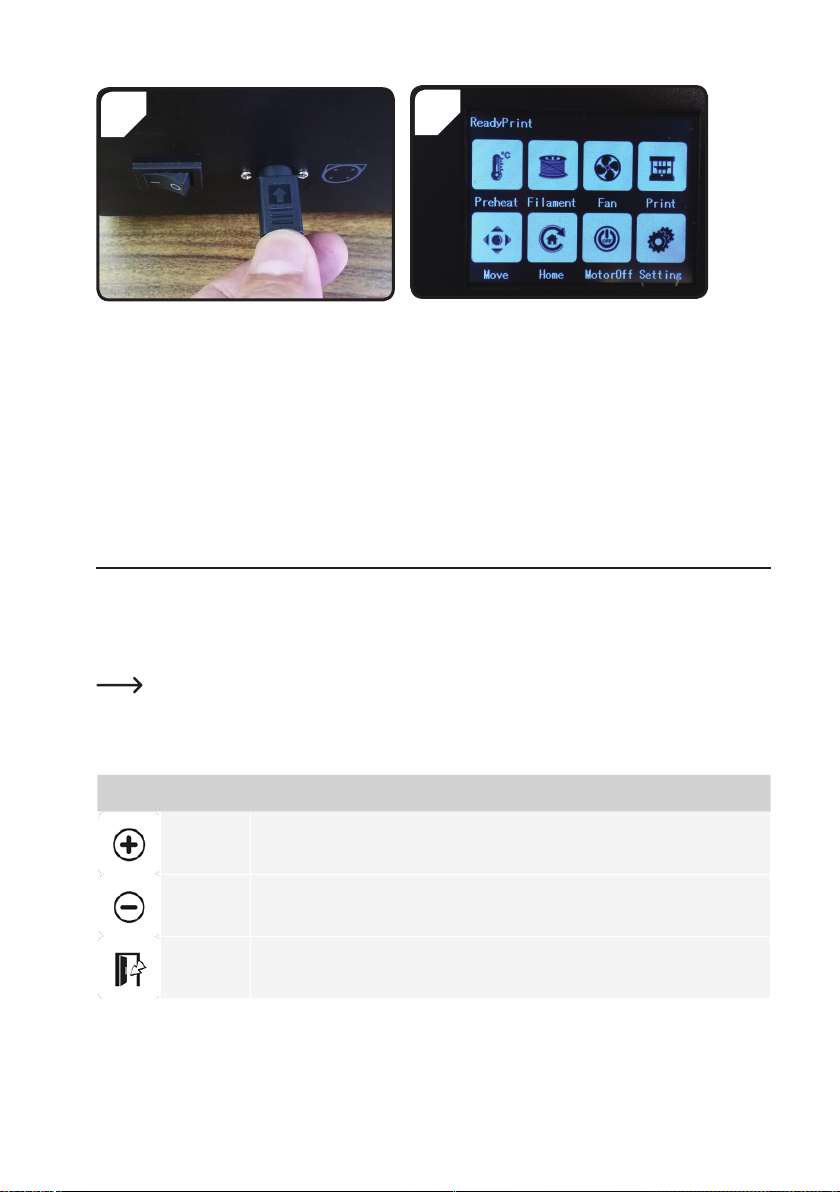

7

8

• Connect the mains cable to the power adapter,

and then connect the power cable to the 3D

printer.

• Plug the mains plug on the power cable into a

mains socket.

• Move the on/off switch to the I position to switch

the 3D printer on.

• The printer light will turn on.

• < ReadyPrint > will appear on the touchscreen

display.

The 3D printer is now ready for use.

12. Control panel

• The following explanations apply to printer rmware V2.1. Newer versions may have different functions.

• The 3D printer can be controlled using the control panel on the colour touchscreen display.

• Some options are highlighted in yellow after conrmation.

The hot plate settings only apply to the RF100 XL Plus (item no. 1592461).

a) General functions

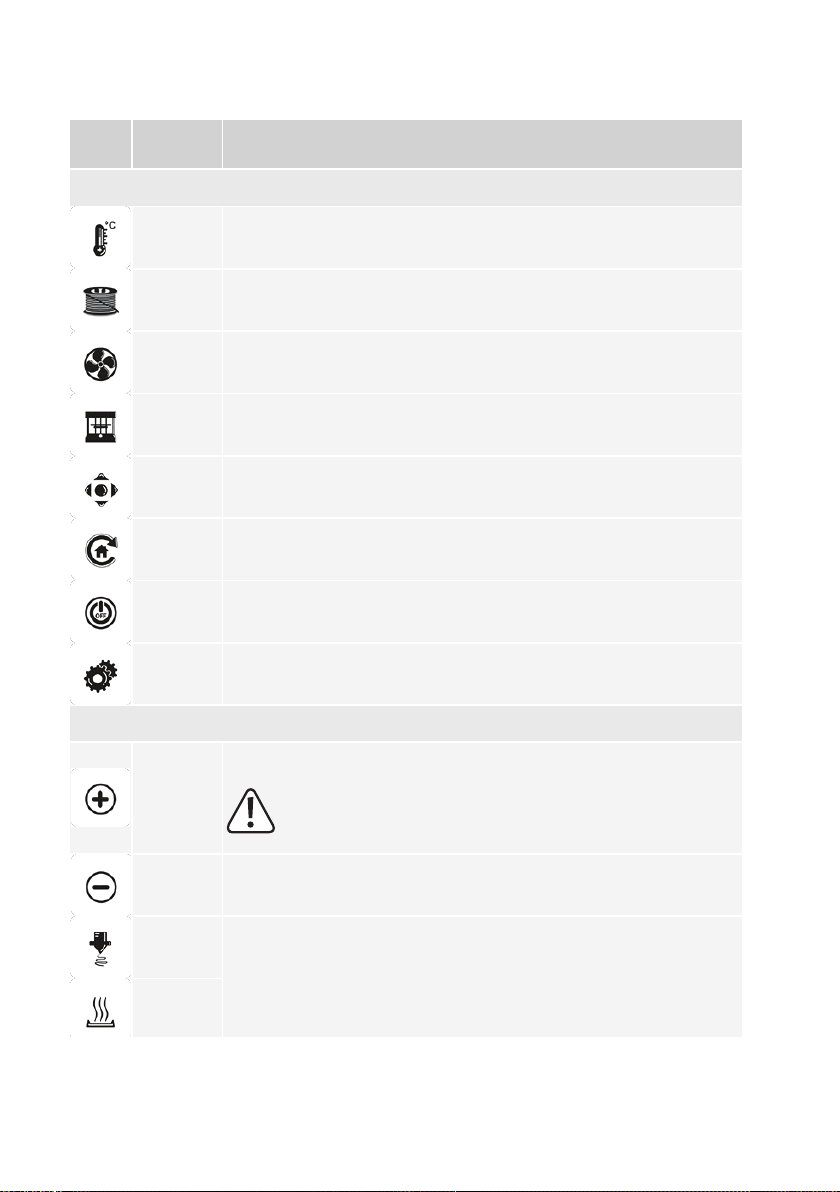

Icon Menu option Function

< Add > Increase the corresponding value.

16

< Dec > Decrease the corresponding value.

< Back > Return to the previous menu.

b) Menu options and functions

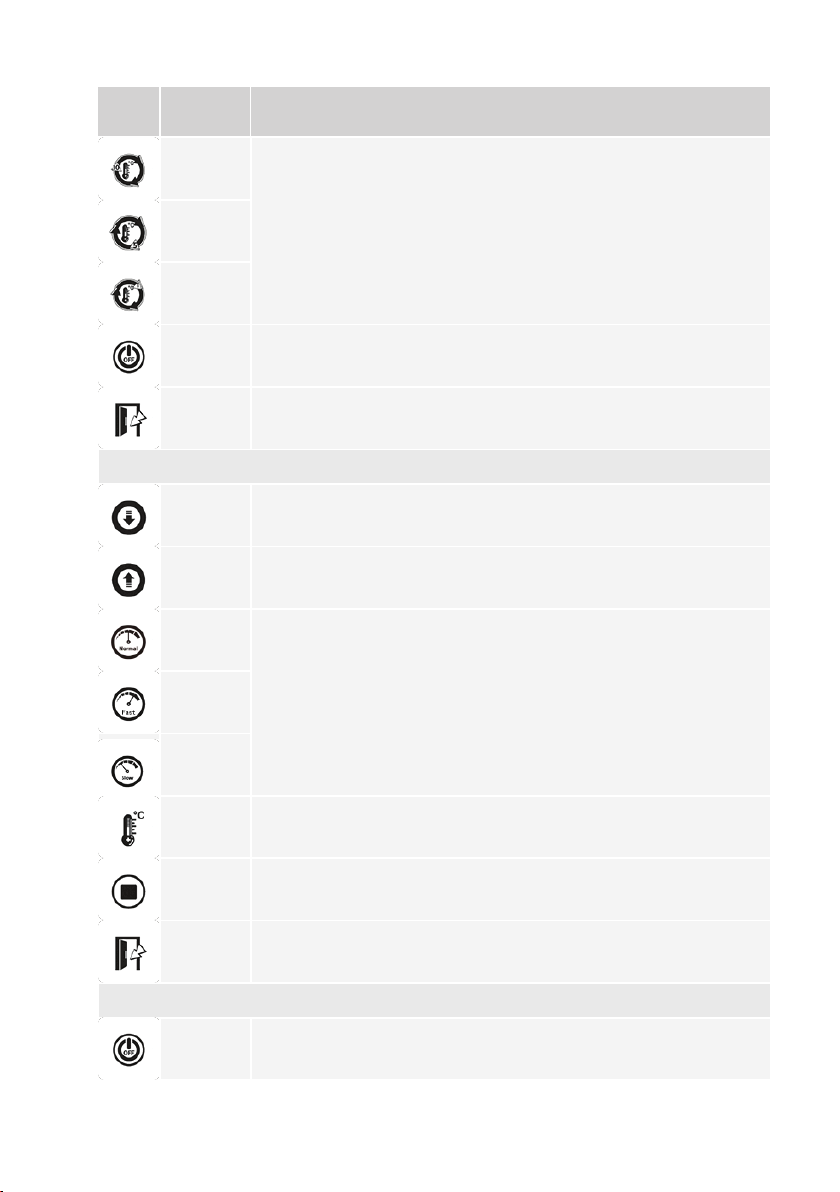

Icon Menu option Function

Main menu < ReadyPrint > (3D printer is ready for use)

< Preheat > Go to the < Preheat > menu to adjust the temperature of the nozzle or hot plate.

< Filament > Go to the < Filament Change > menu to insert or remove a lament.

< Fan > Go to the < Fan > menu to set the fan speed.

< Print > Go to the < ChooseFile > menu to select a preset printing model.

< Move > Go to the < Move > menu to set the position of the X, Y and Z axes.

< Home > Go to the < Home > menu to set the X, Y and Z axes to the default position.

< MotorOFF >

< Setting > Go to the < Set > menu to congure additional settings.

< Preheat > menu

< Add >

< Dec > Decrease the temperature of the extruder or hot plate.

< Extruder >

< Heatbed >

Switch off the motor. The extruder and print bed can be moved by hand on the X, Y and

Z axes.

Increase the temperature of the extruder or hot plate.

Do not use the nozzle continuously at 260 °C. Continuously operating the

printer at temperatures above 260 °C signicantly reduces the life span of the

extruder. Allow the printer to cool down before using it again.

Heated object - < Extruder > (Extruder/nozzle) / < Heatbed > (hot plate) - select by

touching the corresponding icon.

17

Icon Menu option Function

< 10°C >

< 5°C >

< 1°C >

< Turn Off >

< Back > Return to the previous menu (< ReadyPrint >).

< Filament Change > menu

< Load >

< Unload >

< Normal >

< Fast >

< Slow >

The temperature can be set in 10/5/1 % increments. Touch an icon to select one of these

options.

Switches off the nozzle (for item no. 1592461, 1592620) or the hot plate (for item

no. 1592461).

Load lament into the extruder.

The nozzle temperature must be higher than 170 °C.

Remove lament from the extruder.

The nozzle temperature must be higher than 170 °C.

Touch the icon to set the loading/conveying speed for the lament. There are 3 speed

settings:

- < Normal > (default setting)

- < Fast >

- < Slow >

The loading speed depends on the print speed.

The nozzle may become blocked if the loading speed is too high.

< Preheat > Go to the < Preheat > menu to adjust the temperature.

< Stop > Stops the extruder (for item no. 1592461, 1592620) or the hot plate (for item no. 1592461).

< Back > Return to the previous menu (< ReadyPrint >).

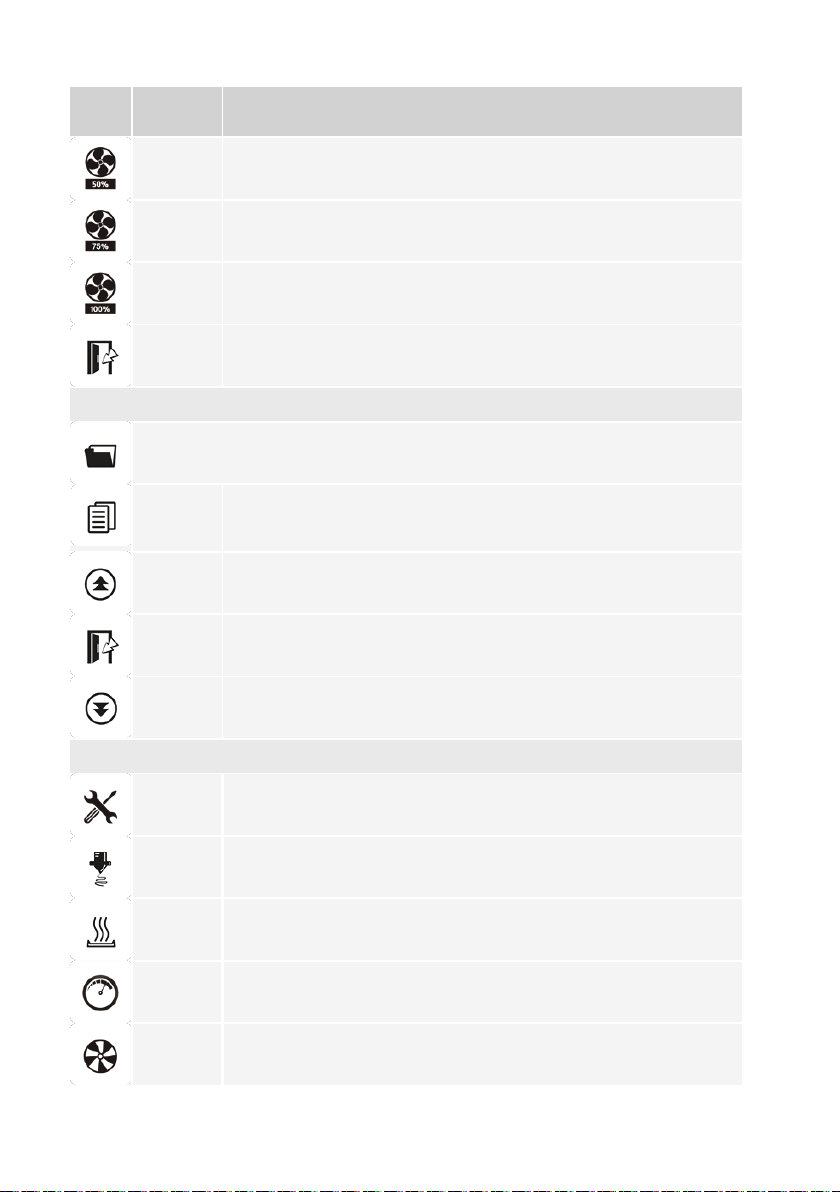

< Fan > menu (fan for cooling the printed object)

< Turn off > Switches the fan off.

18

Icon Menu option Function

< 50% > Reduces the fan speed by half.

< 75% > Reduces the fan speed by 25%.

< 100% > Sets the fan speed to maximum (default setting).

< Back > Return to the main menu (< ReadyPrint >).

< Print > menu

See “5. SD card contents” on page 6 for details.

< gcode >

< PageUP > Return to the previous page.

< Back > Return to the main menu (< ReadyPrint >).

< Page

Down >

< Option > menu, displayed during the printing process

< Option >

Before printing: Select a print template in .gcode format.

During printing: Display the printing status and view/congure the parameters.

Go to the next page and view more print templates.

List with parameters for setting the print speed, nozzle temperature, hot plate temperature,

fan speed and lament loading speed.

Display the nozzle temperature.

Display the hot plate temperature.

Display the printing speed.

Display the fan speed.

19

Icon Menu option Function

< Printing > menu, displayed during the printing process

< Pause > Pause the printing process.

< Resume > Resume the printing process.

< Stop >

< Temp. >

< Speed > Access the < Speed > menu to adjust the printing/lament loading speed.

< Fan > Access the < Fan > menu to set the fan speed.

< Back > Return to the previous menu (< Option >).

< Speed > menu, displayed during the printing process

< Add > Increase the printing/lament loading speed.

< Dec > Decrease the printing/lament loading speed.

< Move>

Stop the printing process. The nozzle and print bed will return to their initial position. The

extruder will start the cooling process. It may take several seconds for the extruder to

stop moving.

Set the temperature of the nozzle or hot plate.

You can choose a nozzle temperature between 0 and 260 °C.

Do not use the nozzle continuously at 260 °C. Continuously operating the

printer at temperatures above 260 °C signicantly reduces the life span of the

extruder. Allow the printer to cool down before using it again.

The printing speed can be set from 10 to 300 %. The standard setting is 100 %.

The printing speed is set by the "Cura" software when the GCODE le is

generated. The speed option allows you to adjust the speed as a percentage

of the preset speed (e.g. 150 %). For best results, use the "Cura" software to

set the desired speed.

20

Icon Menu option Function

The lament loading speed can be set from 10 to 300 %. The standard setting is 100%.

< Flow>

< 10% >

The loading speed depends on the print speed.

The nozzle may become blocked if the loading speed is too high.

< 5% >

< 1% >

< Back > Return to the previous menu (< Speed >).

< Move > menu (moves the axes)

< X+ >

< Y+ >

< Z+ >

< 10 mm >

< 1 mm >

< 0.1 mm >

The speed can be set in 10/5/1% increments. Touch an icon to select one of these

options.

Select the amount of movement for the X-axis:

The extruder will move x steps to the right along the X-axis.

Select the amount of movement for the Y-axis:

The extruder will move backwards along the Y-axis towards the control panel.

Select the amount of movement for the Z-axis:

The extruder will move x steps downwards along the Z-axis.

The X/Y/Z-axis movements can be adjusted in 10/1/0.1 mm increments. Touch an icon

to select one of these options.

The default increment is 10 mm.

< X- >

< Y- >

Select the amount of movement for the X-axis:

The extruder will move x steps to the left along the X-axis.

Select the amount of movement for the Y-axis:

The extruder will move forwards along the Y-axis.

21

Icon Menu option Function

< Z- >

< Back > Return to the main menu (< ReadyPrint >).

< Home > menu

< Home All > The print bed and extruder will return to their initial position.

< Home X > The extruder will return to the zero position along the X-axis.

< Home Y > The extruder will return to the zero position along the Y-axis.

< Home Z > The extruder will return to the zero position along the Z-axis.

< Back > Return to the main menu (< ReadyPrint >).

< Set > menu

< USB

Settings >

< Select

Source >

Select the amount of movement for the Z-axis:

The extruder will move upwards along the Z-axis.

Access the < FileSys > menu to select the printing source.

Access the < Connect > menu to select the connection source.

22

< Leveling > Access the < Leveling > menu to calibrate the print bed.

< About > Display the rmware version and model number of the 3D printer.

< Back > Return to the main menu (< ReadyPrint >).

Icon Menu option Function

< FileSys > menu

Select "Print from the SD card" (default setting).

< SD Card >

Touch to conrm your selection. The icon will be highlighted in yellow.

The 3D printer must be disconnected from your computer. If necessary, unplug

the USB cable from your computer.

< USB drive >

< Back > Return to the previous menu (< Set >).

< Connect > menu

< 9600 > No function.

< 57600 > No function.

< 115200 >

< 25000 >

< Back > Return to the previous menu (< Set >).

Select "Print from a USB stick".

Touch to conrm your selection. The icon will be highlighted in yellow.

Select "Control the 3D printer via the control panel".

Touch to conrm your selection. The icon will be highlighted in yellow.

The 3D printer must be disconnected from your computer. If necessary, unplug

the USB cable from your computer.

Select "Control the 3D printer with a computer".

Touch to conrm your selection. The icon will be highlighted in yellow.

You will not be able to set the parameters via the control panel after connecting

the 3D printer to a computer.

< Leveling > menu

< First >

< Second >

Set the rst calibration point for the print bed. The extruder will move to the rst calibration

point.

Set the second calibration point for the print bed. The extruder will move to the second

calibration point.

23

Icon Menu option Function

5 4

67

< Third >

< Fourth >

< Back > Return to the previous menu (< Set >).

Set the third calibration point for the print bed. The extruder will move to the third

calibration point.

Set the fourth calibration point for the print bed. The extruder will move to the fourth

calibration point.

c) Display layout during the printing process

1 Name of the print model that is currently printing

2 < Option > menu for setting the print/fan/lament

1

loading speed and nozzle/hot plate temperature.

2

9

8

3 Current position of the Z-axis

4 Fan speed

3

5 Print speed

6 Hot plate: Current temperature / target temperature

7 Nozzle temperature (current temperature / target

temperature)

8 Elapsed time

9 Printing progress in %

24

d) Menu overview

The menu structure may vary depending on the rmware version.

Preheat

Filament

Filament

Change

Fan

Ready

Print

Print

Add

Dec

Extruder Heatbed

10°C 1°C 5°C

TurnOff

Back

Load

Unload

Normal Fast Slow

Preheat

Stop

Back

Turnoff

50% 75% 100%

Back

gcode Option Printing

PageUP

Page

Down

Back

Resume

Pause

Stop

Temp. --> Preheat

Add

Dec

Adjust

Speed

Fan --> Fan

Back

Move

Flow

10% 1% 5%

Back

25

Ready

Print

Move

Home

Motor

OFF

Setting

Set

X+

Y+

Z+

10 mm 0,1 mm 1 mm

X-

Y-

Z-

Back

Home All

Home X

Home Y

Home Z

Back

USB

Settings

FileSys

Select

Source

Connect

Leveling

About

Back

SD Card

USB

drive

Back

115200

25000

Back

First

Second

Third

Fourth

Back

26

13. Tips for 3D printing

Never disconnect the power supply, USB cable or SD card during the printing process.

• The print quality depends on numerous factors. These include:

- Print speed

- Layer thickness

- Printer bed calibration

- Nozzle temperature

- Hot plate temperature (for item. 1592461)

- Filament loading speed

- 3D model structure

• These factors mean that it is not always possible to achieve a satisfactory result after the rst print attempt. Fine-

tune the parameters to improve the print quality.

• Each material requires different print settings.

• Avoid an overhang of more than 45°. If necessary, use the structural platform option in "Cura" and remove the

platform after printing.

a) Nozzle temperature

• The optimum nozzle temperature depends on the lament material and the layer thickness. The printing temperature

for the lament varies depending on the material and manufacturer. Always check the specications of the lament

before printing. For best results, use Renkforce Original laments.

• Use the standard temperature for the rst test print.

• To optimize the print quality, print the same object with the same layer thickness and a different nozzle temperature.

Adjust the temperature in 5 °C increments, and then compare the test prints.

This enables you to determine the optimal nozzle temperature for different laments and layer thicknesses.

• If the nozzle temperature is too high, the material may fail to cool down quickly, causing it to melt into the layer

underneath.

• If the nozzle temperature is too low, the lament will be too thick and it will not ow evenly. In addition, the lament

layers may not adhere properly.

b) Preventing nozzle blockages

• Do not leave the nozzle at a high temperature for an extended period without printing.

• When loading the lament, hold the nozzle at a distance of least 20 mm from the print bed.

• Remove the lament after use.

• Ensure that there is sufcient ventilation. Do not cover the ventilation slots on the extruder.

27

c) Layer thickness

• The layer thickness determines the height of the individual layers and therefore the resolution and quality of the

printed object.

• Thinner layers produce higher quality prints, but result in longer printing times.

• Thicker layers result in lower quality prints and shorter printing times.

Experiment with the aforementioned parameters until the printer produces a satisfactory result for your

chosen material.

Use the PLA lament for the rst few test prints, as this material is easy to handle and does not stick

together when it cools down. It also adheres very well to the print bed.

d) Hot plate temperature (for item no. 1592461)

• The optimal hot plate temperature depends on the lament material. Using an optimal temperature ensures that the

printed object adheres well to the hot plate.

• When the blue tape runs out, replace it with an identical tape to improve the surface adhesion.

• If the temperature of the hot plate is too high, the printed object may become distorted, or the lower layers may

cool down too slowly.

• If the temperature of the hot plate is too low, the printed object may not adhere properly, or the edges may become

loose during printing.

PLA can be printed without the hot plate. The optimal temperature in this scenario is 60 °C.

When printing with PLA (especially with small objects with a small surface area), the hot bed should be

covered with plastering tape or a slightly textured masking tape to improve the surface adhesion.

28

14. Preparation

a) Calibrating the print bed

1

• Tighten the 3 levelling screws under the print

bed as far as they will go.

3

• Go to the < ReadyPrint > menu. Select < Set >,

and then select < Levelling >.

• Touch < First >. The nozzle will move to the

rst point.

• Turn the rst levelling screw to control the

distance between the nozzle and print bed.

• The distance should be approximately 0.3 m

(use an A4 sheet of paper as a measurement

aid). The paper should be gently clamped so

that you feel slight resistance when moving the

paper. The nozzle must not touch the print bed!

2

• Place an A4 sheet of paper between the nozzle

and the print bed to use as a measurement

guide.

4

• Repeat step 3 for the second, third, and fourth

point (calibration sequence and motion direction of

the nozzle are shown above).

When adjusting the print bed, always ensure that the distance between the nozzle and the print bed is the

same, otherwise the print bed will be uneven and the printed objects will not adhere properly.

If the distance between the nozzle and print bed is too small/large, repeat steps 3 and 4.

29

b) Attaching the lament

1

3

• Insert the lament into the tube until

approximately 5 cm is visible at the end of the

extruder.

2

• Insert the lament tube into the tube holder.• Mount the lament on the spool holder.

c) Loading the lament

1

• In the < ReadyPrint > menu, select < Move > and

then press < Z+ > twice to increase the distance

between the nozzle and the print bed.

30

2

• Go to the < ReadyPrint > menu. Select

< Filament >, and then select < Preheat >.

• Touch < Add > several times until the target

temperature of 220 °C is displayed.

3

4

• Go to the < Filament Change > menu and wait

until the current temperature (in this case 221 °C)

has reached the target temperature (220 °C).

• Touch < Load >.

5

• Gently slide the lament forwards until it is

slowly pulled into the extruder.

• Release the lament.

When adjusting the print bed, always ensure that the distance between the nozzle and the print bed is the

same, otherwise the print bed will be uneven and the printed objects will not adhere properly.

• <Filament changing > will appear on the

touchscreen display. The 3D printer is now ready

to load the lament.

6

• If lament comes out of the nozzle, touch < Stop >.

• Use the tweezers to remove excess lament.

31

d) Removing the lament

• Ensure that the nozzle temperature is not higher than 170 °C.

Do not touch the nozzle – burn hazard!

1

• Go to the < Home > menu and select < Home

All >. The print bed and extruder will return to

the initial position.

3

• Go back to the < ReadyPrint > menu. Select <

Filament >, and then select < Preheat >.

2

• In the < ReadyPrint > menu, select < Move > and

then press < Z+ > twice to increase the distance

between the nozzle and the print bed.

4

• Press < Add > several times until the target

temperature of 220 °C is reached.

5

• Wait until the actual temperature (in this case

220 °C) has reached the target temperature.

32

6

• Go back to the < Filament Change > menu, and

then select < Unload >.

7

8

• If the lament can be pulled out of the top of the

extruder, select < Stop >.

• Carefully remove the lament and lament tube

from the top of the extruder.

• Go back to the < Preheat > menu and select

< Turn off >.

• The extruder will stop heating. < OFF > will be

displayed in place of the target temperature.

• Use the tweezers to remove lament residue from

the nozzle.

e) Changing/replacing the lament

Change the lament when you want to use another colour or material.

Replace the lament when it is empty.

Before changing or replacing the lament, the extruder must be heated to ensure that the old lament can be removed

from the extruder without any residue.

Do not touch the nozzle – burn hazard!

• Remove the lament.

• Remove the lament spool from the spool holder and place the new lament on the spool holder.

• Align the lament.

• Load the lament.

• Extrude the new lament until the residue from the old lament has been completely removed from the extruder.

This can be determined by the change in colour.

• Remove the residue with the tweezers

f) Installing the "Cura" software (optional)

Refer to “16. Printing with the “Cura” software” on page 39 for detailed instructions.

33

15. Printing from the SD card/USB stick

The printer may produce smoke or steam during the heating process. This is normal. Ensure that there is

sufcient ventilation.

Never expose the print bed to mechanical stress, as this may cause it to break.

Printing directly from an SD card/USB stick (USB stick not included) is only possible via the control panel. The

software does not need to be installed. If the 3D printer is connected to a computer, it must be disconnected before

printing. Unplug the USB cable, otherwise the 3D printer will not recognize the SD card/USB stick.

a) Printing from the SD card

1

< Setting >.

3

• Select < SD card > as the print source.

2

• Select < USB Settings >.• Go to the < ReadyPrint > menu and select

4

• Go back to the < Set > menu and select < Select

Source >.

34

5

• Select < 115200 > to control the 3D printer via

the control panel.

b) Printing from a USB stick

By default, the printing source is set to the SD card. If you want to print from a USB stick, follow the steps below.

1

< Setting >.

3

• Select < USB Drive > as the print source.

2

• Select < USB Settings >.• Go to the < ReadyPrint > menu and select

4

• Go back to the < Set > menu and select < Select

Source >.

35

5

• Select < 115200 > to control the 3D printer via

the control panel.

• The icon will be highlighted in yellow for

conrmation.

c) Starting the printing process

1

• Go to the < ReadyPrint > menu and select

< Print >. Keep touching < PageDown > until the

< 3D Models > folder is displayed.

• Open the < 3D Models > folder.

2

• Select a ready-to-print model (e.g. < RF100.

gcode >) from the < 3D Models > folder.

36

3

4

• Touch < OK > to conrm.

5

• Let the object cool down for a few minutes

when it has nished printing.

• Remove the print bed (if necessary) and

carefully remove the printed object with the

scraper.

• < Printing > will appear on the touchscreen

display.

• The print bed will move towards zero along

the Z-axis. The nozzle will move to the starting

position and start to heat up.

• Printing will start when the target temperature

(e.g. 210 °C) has been reached.

• The printing progress is displayed in percent.

d) Pausing the printing process

The nozzle continues to heat when printing is paused. Only pause printing for short periods, otherwise the

nozzle may overheat and become blocked.

• Go to the < Printing > menu and select <Pause >.

• To continue printing, select < Resume >.

37

e) Conguring parameters during the printing process

Only recommended for experienced users.

• Go to the < Option > menu and select < Printing > to set the print speed, nozzle/hot plate temperature and fan/

lament loading speed.

Print speed: Observe the printing process and adjust the print speed accordingly. The print speed affects

the print quality for certain objects and laments. For example, if the print speed is too high, the printed

object may not adhere properly to the print bed.

Nozzle temperature: Do not use the nozzle continuously at 260 °C. Continuously operating the printer

at temperatures above 260 °C signicantly reduces the life span of the extruder. Allow the printer to cool

down before using it again.

Hot plate temperature (order no. 1592461): Adjust the hot plate temperature when printing objects with

ABS.

Flow (load speed of the lament in the extruder): Observe the printing process and adjust the speed

Fan speed for cooling the printed object: Let the object cool down for a few minutes when it has nished

accordingly. If the speed is too high, the nozzle may become blocked.

printing. If the object is not easy to remove, carefully detach it using the scraper.

The fan speed for cooling the motor cannot be set manually. The fan turns off automatically when the

nozzle temperature reaches 40 °C.

Stopping the printing process

• To stop printing, go to the < Printing > menu and select < Stop >. It may take several seconds for the 3D printer to

come to a complete standstill.

• The nozzle will return to its initial position and the print bed will move downwards. The nozzle will start to cool down.

f) Restarting the 3D printer

• Restart the 3D printer in the following scenarios:

- If incorrect/no information is displayed on the colour touchscreen display.

- If the 3D printer does not work properly.

• If a USB cable is connected, unplug it from the printer.

• Switch the 3D printer off. Wait for a moment and turn it back on. You can now use the printer as normal.

38

16. Printing with the "Cura" software

General information

• The 3D printer is compatible with the "Cura" software, which is available for Windows® and Mac OS.

Visit https://ultimaker.com/ for more information on operating system and hardware requirements. Ensure that your

computer meets the minimum requirements.

• Due to space limitations, it is not possible to provide instructions for all functions of the software in this manual.

Visit https://ultimaker.com/ for detailed instructions.

• The following section provides instructions on the basic functions and tells you how to produce your rst prints. To

simplify this process, the SD card comes with material-specic conguration les for the "Cura" software.

• "Cura" is a powerful software suite for 3D printers. It is easy to use and suitable for beginners.

The SD card comes with a precongured version of the software for Windows® and Mac OS. We

recommend that you install this version of the software to avoid the need to manually congure the software

settings. The required drivers (for Windows

• You can use the "Cura" software to perform the following tasks:

- Place, rotate and scale the 3D object

- Divide the printed object into thin layers (the 3D printer prints the object layer by layer). This creates a GCODE

le.

- Check GCODE les for errors and printability

- Generate structural platforms and rafts for improving the print quality

- Transfer GCODE les to the printer or save the les to an SD card to print without a computer

- Congure and save printer/lament-specic les

- Manage printer and lament proles

®

) are included on the SD card.

a) Installation

• Open the installation le "Cura_15.04.6.exe" (Windows®) or "Cura-15.04.6 -MacOS.dmg" (Mac OS) from the

"Software" directory on the SD card.

• Follow the onscreen instructions during installation. Visit https://ultimaker.com/ for detailed instructions.

39

b) Setting up the software (Windows®)

Connecting the 3D printer

• Connect the 3D printer to a USB port on your computer using the USB cable provided. Switch the 3D printer on.

Keep the 3D printer switched on when it is connected to the computer.

• When you connect the 3D printer to your computer for the rst time, the operating system will automatically detect

the new hardware and search for a suitable driver.

If no suitable driver is found, follow the steps below to manually install the USB drivers:

1 Open the device manager on your computer.

A new device will be displayed under "Other devices".

2 Right click on "USB Serial Port" and select "Update Driver

Software...".

3 Click on "Browse my computer for driver software".

The required driver is saved to the SD card in the "software/

ft232 usb UART driver" folder.

4 Follow the onscreen instructions to complete the update.

Starting the software

The conguration wizard will launch when the installation is complete. This provides step-by-step instructions for

conguring the 3D printer.

Enter the information specic to your 3D printer model (RF100 XL or RF100 XL Plus).

40

1 Select the desired language (e.g. English).

2 Click "Next".

1

2

41

3 Select "Other".

4 Click "Next".

5 Select "Custom...".

6 Click "Next".

3

4

42

5

6

7

7 Enter the parameters as shown. For the

RF100 XL Plus, select "Heat bed" (hot plate).

8 Click "Finish" to close the conguration

wizard.

8

7

8

43

c) Setting up the software (Mac OS)

• Ensure that you set up the printer prole in the software before connecting the printer to your computer.

1 When the installation is complete,

right click on the "Cura" symbol in

the "Applications" folder. Select

"Show Package Contents".

2 Search for "Resources/

machine_proles".

3 Select the prole le ("RF100

XL.ini" or "RF100 XL plus.ini")

on the SD card and copy it to the

"machine_proles" folder.

44

4 Launch the "Cura" software.

5 Go to the "Machine" menu and

select "Add new machine",

6 Click "Next >".

6

45

7 Select "Other".

8 Click "Next >".

7

8

46

9 Select the 3D printer model.

10 Click "Next >".

9

10

9

10

47

11 Click "Finish". This completes the

installation process.

d) Software settings (Windows®)

You can also congure additional settings. These settings are intended for experienced users. Refer to the

online software help for more information on these functions.

Conguring the incorrect settings can damage the 3D printer or result in defective prints. Beginners should

use the basic settings.

1 Start the software.

2 Select "Machine".

3 Select "Machine settings".

11

48

4 Select the serial port to which

the 3D printer is connected. The

port number is independent of

the system (see “Connecting

the 3D printer” on page 40

for details). Set the "Baud rate"

to "115200" (for both 3D printer

models). Set the "Serial port"

to "COM3" (for the RF100 XL)

or "AUTO" (for the RF100 XL

Plus).

5 Click "OK". "Machine settings"

will close.

6 Congure the parameters under

"Basic Settings" as shown.

These are the parameter

options for a PLA lament.

A small info window will

be displayed when you

move the mouse over

the parameter.

4

5

4

5

6

49

7 Congure the parameters under

"Advanced" as shown. These

are the possible parameters for

a PLA lament.

8 Select "Open expert settings"

under "Expert".

7

8

50

9

9 Congure the parameters under

"Support" as shown.

10 Click "OK".

10

Filament diameter

The lament diameter is specied by the lament manufacturer. If the lament diameter is not specied (e.g. there is

no label on the lament spool) you can calculate the diameter as follows:

• Measure 1 m of lament material.

• Take diameter measurements at 10 different points at equal intervals (measure at least 1 m of material). Use a

caliper to take the measurements.

• Calculate the average of all the measurements to obtain the lament diameter.

The optimal temperatures vary considerably depending on the lament manufacturer, therefore you should do several

test prints to determine the best temperature for your chosen lament material. Adjust the temperature in 5 °C

increments and compare the results during or after printing. The rst layer should always be printed more slowly at a

slightly higher temperature to ensure that it adheres to the print bed.

51

e) Loading conguration les (Windows®)

• You can load a preset conguration le for your lament from the SD card to simplify the printing process. These

conguration les are also available to download from www.conrad.com.

1

1 Click "File".

2 Select "Open Prole ...".

2

3 Select the desired lament conguration le from the pop-up window and conrm your selection.

The conguration les are saved to the SD card in the "Cong" folder. Alternatively, you can skip this step

and congure the settings from the previous section (see “d) Software settings (Windows®)” on page 48

for details).

f) Loading conguration les (Mac OS)

• Conguration les for Mac OS are not included on the SD card.

• These conguration les are available for download from www.conrad.com/downloads.

• Copy the les to your computer.

• Load the conguration les by repeating the steps in “c) Setting up the software (Mac OS)” on page 44.

Ensure that the downloaded conguration les start with "RF100 XL-xxx" or "RF100 XL Plus-xxx". Only

these les are compatible with Mac OS. Files that start with "Cong-xxx" are only compatible with

Windows®.

52

g) Loading model les (Windows® and Mac OS)

• The "3D models" folder on the SD card contains a few examples for your rst prints. You can also download a wide

range of 3D models from the Internet. Alternatively, you can use a 3D program to design your own model. Ensure

that the 3D model is in .stl format.

• Load the model le by running the mouse over the virtual print bed in the main window, or by clicking on

le will be automatically converted into .gcode format.

If the SD card is not inserted into your computer, click on the symbol to save the GCODE le to your computer.

• To print without using your computer, save the GCODE le to the SD card. Insert the SD card into the 3D printer

and initiate printing via the control panel.

• If the SD card is inserted into your computer, the

to the SD card.

symbol will be displayed, which enables you to save the le

. The

53

h) Disabling the control icons on the 3D printer

• By default, the printer is controlled via the control panel.

• If you wish to control the printer using the software, the connection source must be changed.

1

• Go to the <ReadyPrint> menu and select <

Setting >.

2

• Select <Select Source >, and then select

< 250000 > to control the printer using the

software.

i) Starting the printing process

• The symbol will appear when the printer is connected to a computer via the USB cable.

1

1 Right-click on the symbol.

Select "Print from COM3" to start

printing. (Alternatively, you can

save the .gcode le to the SD

card).

2

2 Click "Print".

The nozzle will start to heat up.

You can start printing when the

"Printing temperature" has been

reached.

54

3

j) Stopping the printing process

Select "Cancel print" in the "Cura software" to stop printing.

Data is buffered by the software, therefore it may take up to 1 minute for the 3D printer to stop printing.

Do not select "Cancel print" when the nozzle is heating, otherwise you may have to remove the USB cable

and restart the 3D printer.

The nozzle temperature will be kept constant after the print task is cancelled. To cool the nozzle, set the

temperature to 0 °C and select < Move axis > from the 3D printer menu to move the print bed downwards.

Remove the USB cable and restart the 3D printer.

17. Updating the 3D printer rmware

This version of the instructions is valid for rmware version 2.1 or higher. Check for rmware updates on a regular

basis.

a) Displaying the rmware version

• Go to the < ReadyPrint > main menu and select < Setting > to open the < Set > menu.

• Select < About > from the < Set > menu.

• The rmware version number will be displayed.

b) Performing a rmware update

• To download the latest rmware version, visit www.conrad.com/downloads or scan the QR code

on this page.

• Unzip the rmware folder, which contains the following three les:

- mks_pic

- mks_cong.txt

- mkstft28.bin

• Copy these three les to the SD card.

• Switch the 3D printer off. Insert the SD card into the card reader on the 3D printer.

• Switch the printer back on. The 3D printer will automatically start the update when the SD card is detected. The

update progress is shown on the display.

Do not remove the SD card from the card reader during the update, as this may cause irreparable

damage.

• The < ReadyPrint> menu will be displayed when the rmware update is complete.

• Check the current rmware version (see “a) Displaying the rmware version” on page 55 for details).

55

• By default, the printer is controlled via your computer when the rmware update is complete. If you wish to control

the printer via the control panel and print from the SD card, enable "Control the 3D printer via the control panel"

and set the print source:

- Go to the < ReadyPrint > main menu and select < Setting > to open the < Set > menu.

- Select < SelectSource > from the < Set > menu, and then select < 115200 >.

• Go back to the < ReadyPrint > menu.

• Restart the 3D printer.

• Two les and a folder are saved to the SD card during the update process. Delete these les (e.g. on your computer).

These les cannot be deleted via the control panel (only via your computer).

Delete these les immediately after the update, otherwise the next update may not install properly.

18. Cleaning and maintenance

Do not use aggressive detergents, rubbing alcohol or other chemical solutions, as these could damage the

casing or even impair the functioning of the product.

Never immerse the printer in water.

Burn hazard! Never touch the hot nozzle with bare ngers.

a) Cleaning the printer

• Use a dry, soft cloth or a brush to clean the exterior of the 3D printer.

b) Cleaning the nozzle

Cleaning the outside of the nozzle

• Use a dry, soft cloth or other similar material to wipe the nozzle after each print.

The nozzle must still be hot. If this is not the case, heat the nozzle before cleaning it.

56

Cleaning the inside of the nozzle

• Heat the nozzle. Load/remove the lament until the lament ows normally.

If the nozzle does not eject enough lament, let the nozzle cool down to the melting temperature stated by

the lament manufacturer (the lament must be viscous) and carefully extract the lament until it has been

removed from the extruder (including impurities). Cut off the contaminated part from the lament and reload

it after the nozzle has heated up again.

c) Cleaning the inside of the extruder

• For details, download the "Cleaning and maintenance" booklet from www.conrad.com/downloads, or scan the QR

code on page 5. Follow the instructions on the website.

d) Cleaning the print bed

• Carefully remove residues from the print bed using the scraper.

e) Removing the lament

• Ensure that the nozzle temperature is not higher than 170 °C.

If the lament is metal or wood, cut through it, replace it with a PLA lament, and then remove the PLA

lament. The PLA lament will eliminate any residues from the wood or metal lament.

f) Storing the 3D printer

• Remove the lament.

• Move the on/off switch to the O position and disconnect the 3D printer from the power supply. Allow it to cool down

to room temperature.

• Clean the 3D printer if you do not plan to use it for an extended period.

• Store the 3D printer in a dry, dust-free location out of the reach of the children.

57

19. Troubleshooting

Problem Possible solution

The 3D printer does not switch on. The

touchscreen display and printer light do

not turn on.

You cannot establish a USB connection

with the 3D printer.

The printed object is defective.

The ow of lament stops, or there is not

enough lament material.

Check that the mains cable is connected properly.

Check the mains socket. Is it supplied with electricity?

Check that the USB cable is connected.

Have you selected the correct USB port in the software?

Are the required drivers installed?

Disconnect and then reinsert the USB cable.

Switch the 3D printer off, and then switch it back on.

Restart your computer.

Use a different USB port on your computer.

Connect the 3D printer directly to a USB port on your computer. Do

not use a USB hub.

Check the nozzle temperature settings. These must be suitable for

the lament material and printed object. Experiment with several

temperature settings.

Do not start printing until the nozzle has reached the required

temperature.

Decrease the distance between the print bed and nozzle (see “a)

Calibrating the print bed” on page 29).

When printing via your computer, avoid using other programs that

require a lot of computing power. Virus scanners and downloads can

affect the transfer of data to the 3D printer. Try printing the same model

via the SD card to check that the USB connection is not the cause of

the problem.

Remove excess lament from the nozzle before each print.

Check the lament spool. It must be able to rotate easily.

Check whether the lament material has become trapped or wrapped

around the spool/spool holder.

Check that the lament was inserted correctly over the lament spool.

Check whether the nozzle temperature is too low for the lament

material.

Check whether the nozzle is blocked. If necessary, clean the nozzle

(see “b) Cleaning the nozzle” on page 56 for details).

58

Problem Possible solution

When printing from the SD card, the 3D printer must be disconnected

from your computer.

Printing stops unexpectedly.

The printed object does not adhere to

the print bed.

The printed object cannot be removed

from the print bed.

Incorrect information is displayed on the

touchscreen display, or the touchscreen

display is empty.

The nozzle cools down unexpectedly.

The transport route to the nozzle is

blocked.

The nozzle is blocked.

The extruder moves in the wrong

direction.

The lament is jammed and cannot be

removed.

The extruder does not heat up or carries

on heating up.

The heating temperature displayed on

the control panel is 0 °C or similar to the

room temperature.

Check the settings on your computer. It must not enter standby mode

(check the power settings) or shut down (after installing software or

software updates) during printing.

The nozzle temperature is too low. Increase the nozzle temperature.

There is residue on the print bed that is preventing the object from

sticking. Clean the print bed (see “d) Cleaning the print bed” on page

57 for details).

The print speed is too high. Select a lower print speed.

Recalibrate the print bed.

Use a raft as an aid for the printed object.

Wait until the printed object has cooled down.

Remove the printed object with the scraper.

Restart the 3D printer (see “f) Restarting the 3D printer” on page 38 ).

Go to the < Preheat > menu and select < Extruder >. Perform an

action within 5 minutes (e.g. add/remove lament or start printing).

Always remove excess lament from the nozzle before each print.

Clean the inside of the nozzle (see “b) Cleaning the nozzle” on page 56).

Remove the extruder and clean the interior (see “c) Cleaning the

inside of the extruder” on page 57).

Check whether the extruder fan is defective. If so, replace the extruder.

Check that the lament spool rotates freely on the holder.

Load and then extract some lament.

Restart the 3D printer.

Go to the < Preheat > menu. Select < Extruder > and wait for

approximately 2 minutes.