Ez One Shot

UNIVERSAL

USER’S

MANUAL

Version: 2014.2

CONTENTS

PREFACE

Table of Contents.......................................................

LED & Beeper Indication..............................................

Cloning Mode............................................................

How to fix the scanner to the terminal.......................

How to change a cable.................................................

How to set up the parameter........................................

GENERAL SETTINGS (GROUP 1 - 12)

1

Default, Abort, Check Version, Setup Code Read....

Reading Mode .........................................................

2

Beep tone, Terminator..............................................

3

Send Data Length, Preamble, Postamble................

4

Accuracy Adjustment................................................

5

Code ID, Inverse Barcode........................................

6

Symbologies Code Identifier.....................................

7

Set Code ID....................................................

8~9

Inter-block and Inter-character Delay.....................

10

Keyboard Layout....................................................

11

Caplock Mode, Numeric Key..................................

12

TETHERED SCANNER SETTINGS (GROUP 13 - 19)

Interface, Computer Type.......................................

13

14

Bi-color Setting ......................................................

15

Advanced Autosensing Setting ..............................

16

Advanced Autosensing and Idle Mode Setting.......

17

RS232 - Baud rate, Data bits, Parity.......................

18

RS232 - Stop bit, Handshaking, ACK/NAK,

Flow Control, BCC..................................................

19

Wand Emulation ....................................................

WIRELESS SCANNER SETTINGS (GROUP 20 - 33)

20

Interface.................................................................

21

Bluetooth Profile.....................................................

22

Pincode Setup........................................................

23

Getting Connected - iOS & Android ......................

24

Power Off Timeout.................................................

25

Set Bluetooth Device ID.........................................

26

Set SPP Pincode....................................................

27

SPP Master Mode..................................................

28

SPP Remote Control, Shut Down, Disconnection..

29

Batch Mode, Binary Check Character....................

30

Memory Mode - Memory Mode, Delete Record.....

31

Memory Mode - Data Format, Date & Time Setup.

32

Memory Mode - Date Format, Time Format...........

Memory Mode - Quantity........................................

33

17-18

2-3

5-6

7-8

10

13

14

15

16

19

20

21

11

12

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

4

8

9

CONTENTS

SYMBOLOGIES (GROUP 34 - 51)

34~36 Enable/Disable Barcode Symbology..........43-45

China postcode(Toshiba code)...............................36

37

MSI code, UK Plessey code...................................

Code 93, Telepen, IATA..........................................38

Interleaved 2 of 5, Code 11....................................

39

Industrial 2 of 5, Matrix 2 of 5.................................

40

Codabar..................................................................

41

ABC Codabar, CX Codabar....................................

42

Codabar Coupling...................................................

43

Code 39 (Full ASCII/Standard), Code 32...............

44

UPC-E....................................................................

45

UPC-E(0)&(1), UPC-E EXPAND............................

46

UPC-A....................................................................

47

EAN-8.....................................................................

48

49

EAN-13, ISSN, ISBN, ISMN...................................

EAN/UCC 128, Code 128, PDF417........................

50

51

DataBar(RSS) Stacked, Limited, Expanded...........

FULL ASCII(CODE39)TABLE, FUNCTION

KEY TABLE(GROUP 52 - 66)

52~60

Full ASCII table(Code 39)...........................

Function Key table(Code 39) for PC-AT......

61~63

Trouble Shooting.........................................

64~66

APPENDIX

Appendix 1 Default table........................................

Appendix 2 Cable Pin Assignment.........................

Appendix 3 Barcode test chart...............................

68-76

77-79

80-82

83-86

87-88

89-90

45

47

49

51

53

55

57

58

59

61

62

63

64

65

66

67

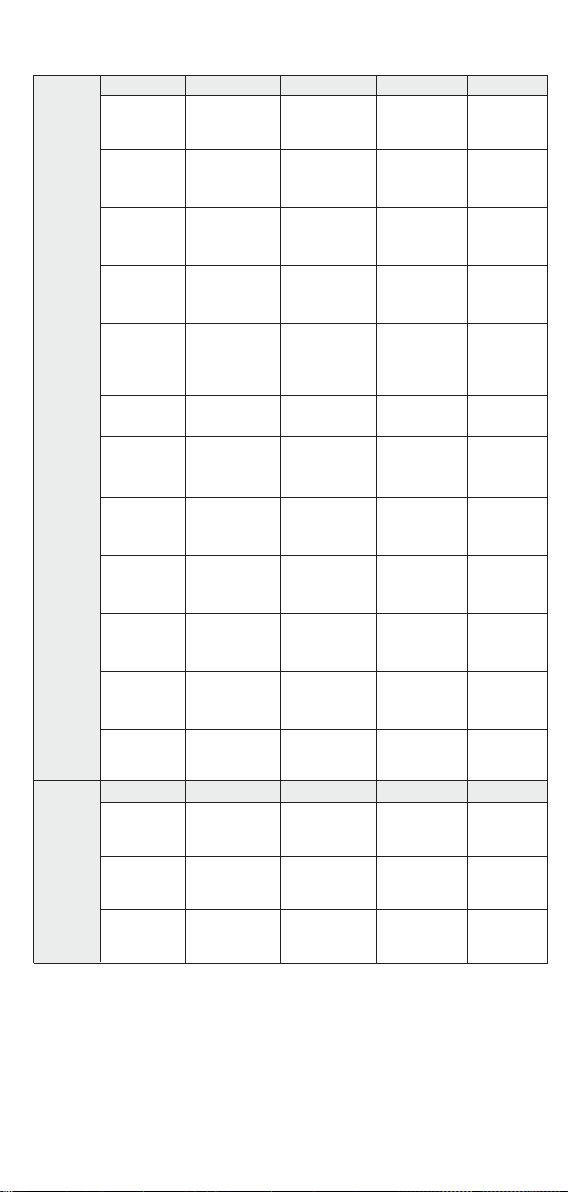

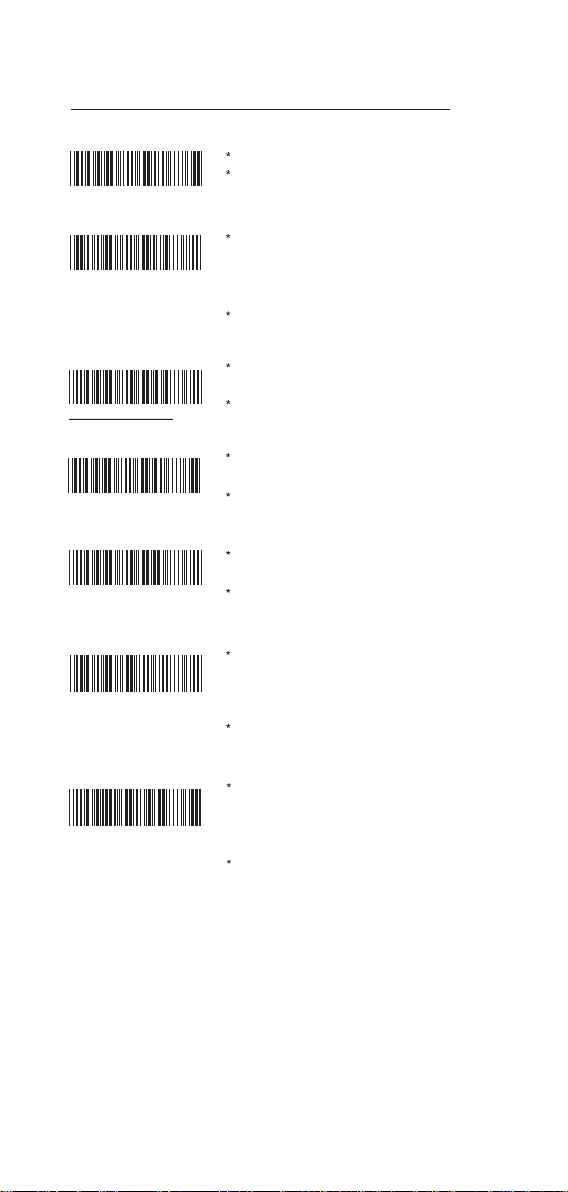

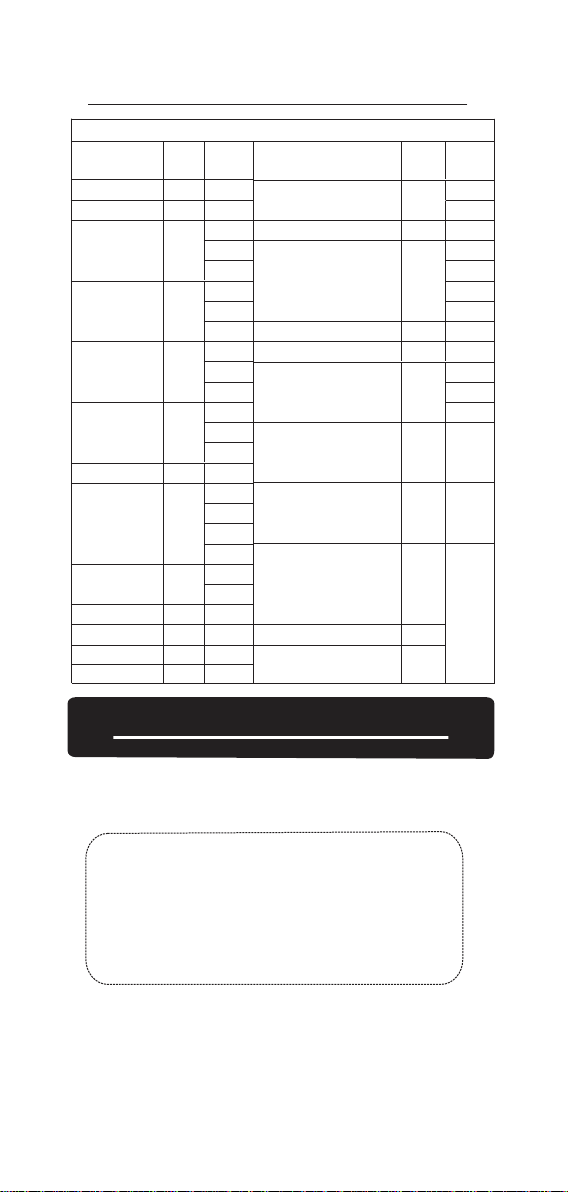

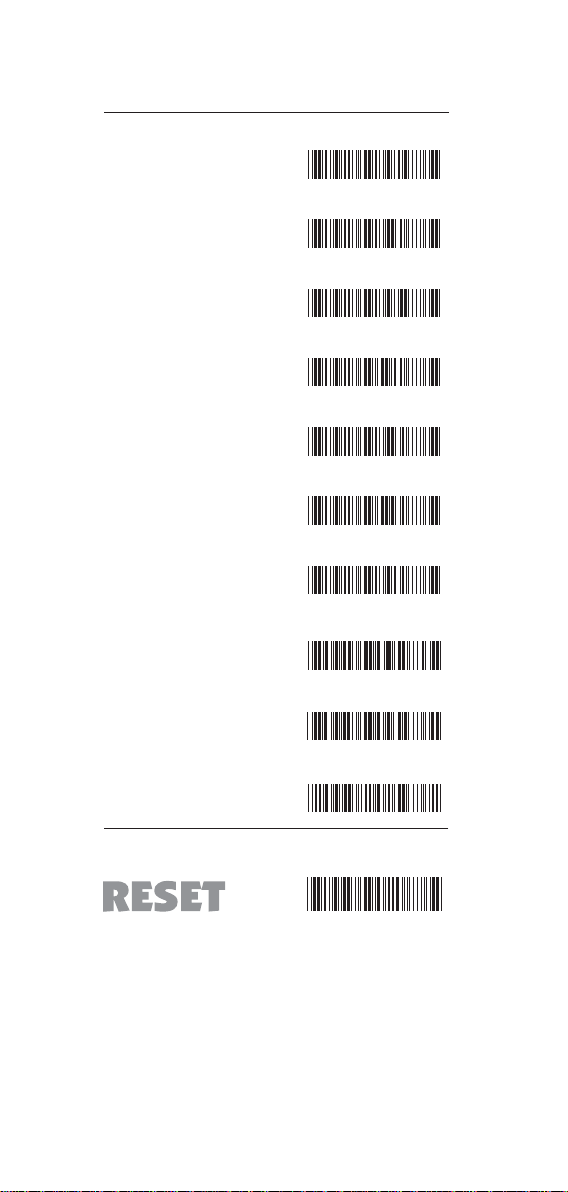

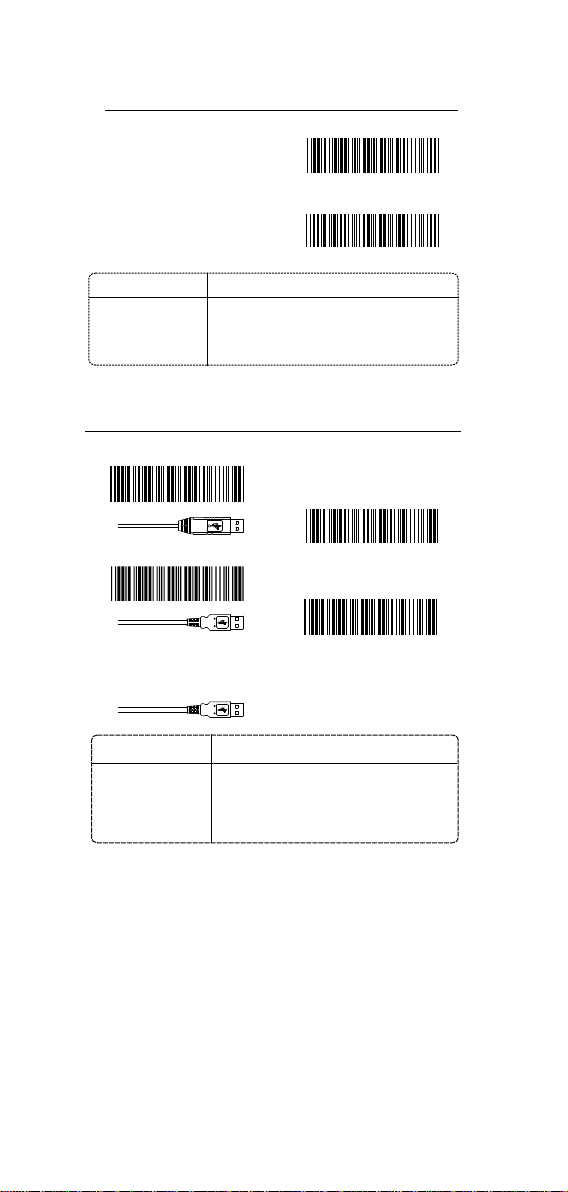

LED & BEEPER INDICATION

Scanner

Status

Initializing/

Power-up

Successful

Barcode

Scan

Successful

Connection

Reads

Configuration

Barcode

Data

Temporarily/

Permanently

Stored

Wireless

Disconnection

Unexpected

Barcode

Scan during

Configuration

Unsuccessful

Pincode

Setup

Barcode

Scann w/o

Connection

Low Power

Blue/Green LED

1 Flash

2 Flashes

1 Flash

Solid for 2 sec

Flashing

Flashing

Red LED

Solid for 2 sec

Flashing

Beeper

1 long beep

1 beep

2 beeps

2 beeps

2 short beeps

3 beeps

3 short beeps

3 short beeps

3 short beeps

5 beeps

Remark

See Batch Mode

or Memory Mode

Scan RESET/

and retry

ABORT

Scan Pincode

Stop and retry

Cradle

Barcode

Scan w/o

Connection

Power Off

or Standby

Status

Successful

Connection

Charging

Full Charge

Flashing

Blue LED

Solid

Several short

beeps

Red LED Green LED

Solid

Flashing

Flashing

See Power Off

Timeout

Remark

Power adaptor

needed

4 hours to

fully charge

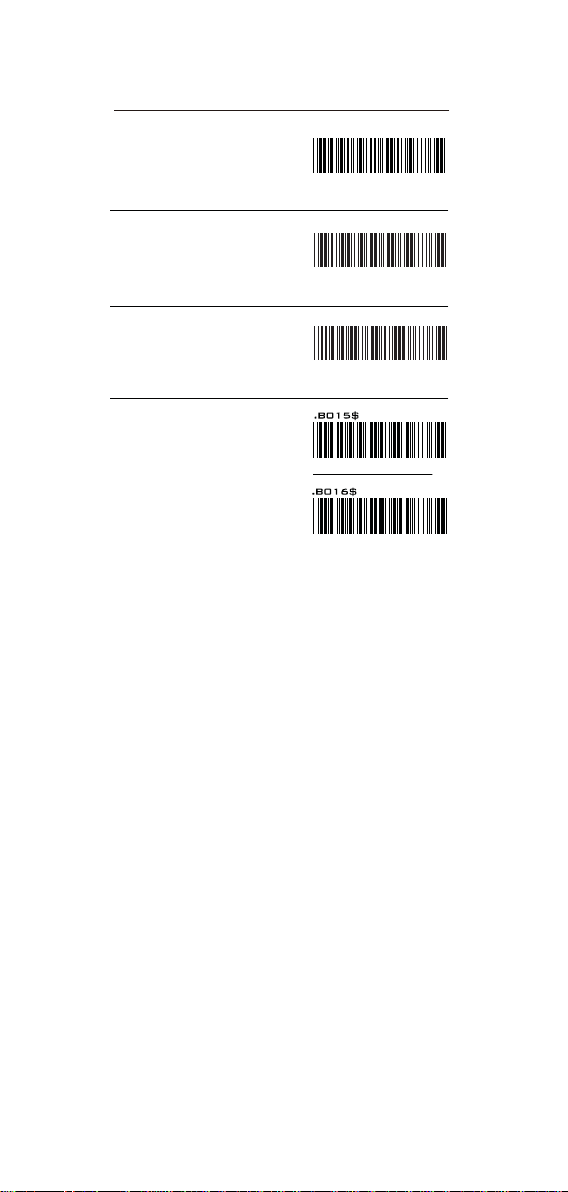

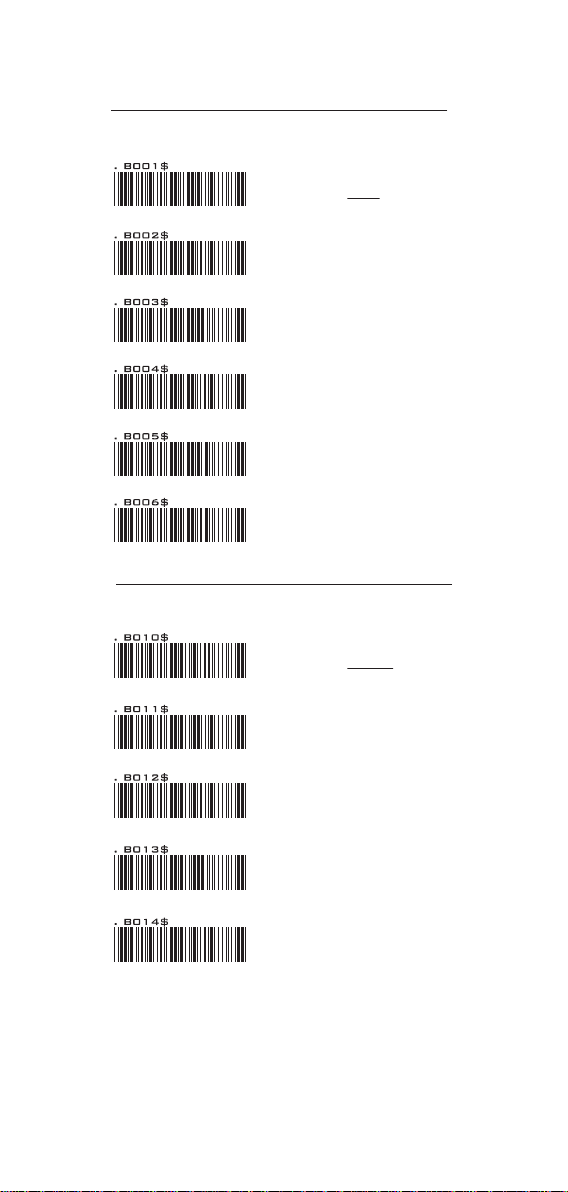

CLONING MODE

WHAT IS CLONING MODE?

CLONING duplicates a scanners settings in other scanners. It can

save time when a number of scanners must be programmed to the

same settings.

HOW SHOULD CLONING WORK?

1. Using this guide, make all the necessary settings for one wand.

2. Scan the CLONING MODE bar code shown below.

3. When CLONING MODE is scanned, all setup parameters will be

converted to alphanumeric characters and shown on the monitor.

4. Using a bar code printer, print out all the setup parameters as

Code 39 bar code labels.

5. Scan the printed labels sequentially with each wand to be

programmed.

. A016$

Figure 1

CLONING MODE

. A018$

CLONING MODE ON- PC/ AT

.A018$(Cloning Mode on PC/AT) - you can clone the settings to a PC/AT

regardless of the kind of device chosen on the scanner.

NOTES:

1. All cloning strings are upper case.

2. All cloning strings printed on labels should be the same as those on

the monitor sequentially from first to last.

3. Cloning mode works in Word Note Pad only.

4. Never edit the data on the first row (.A017$). It is an entry command

for cloning.

5. The cloning string’s length can be adjusted by combining multiple

strings into one, or by breaking one string into multiple strings starting

from the second row after “....”. Length must be in sequences of four,

such as 4, 8, 12, 16, 20 (MAX).

6. Be sure to print the dots exactly where they are shown on the monitor.

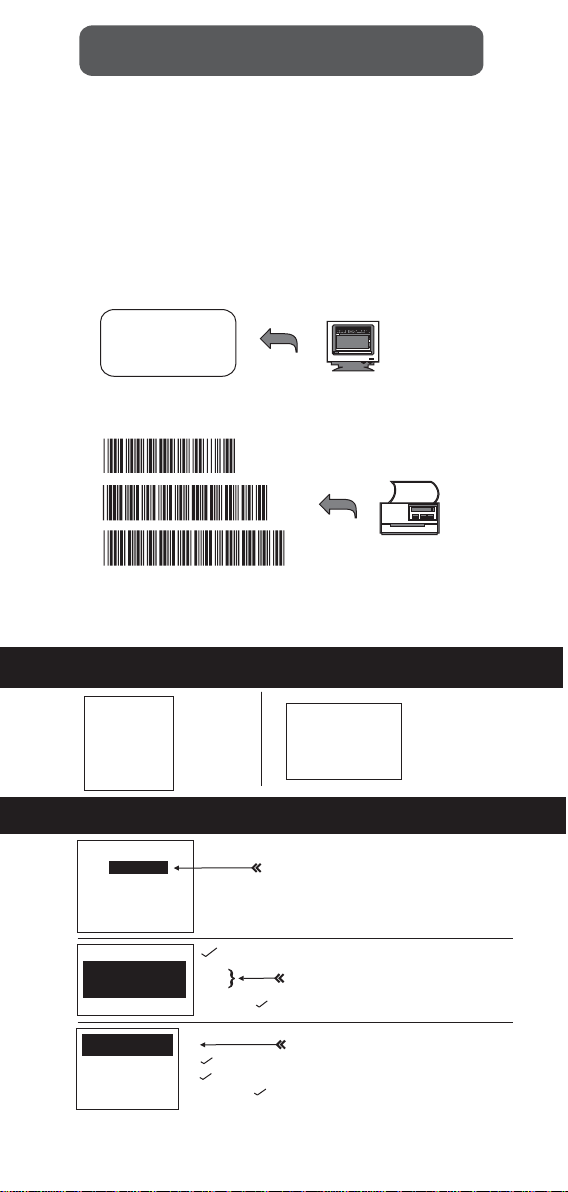

FORMAT OF CLONING

* Format of Cloning:

1st row >>> “.A017$” ( never edit any data of the first row )

2nd row >>> “....XXXX” you can adjust the String’s Length starting

from the dots “....” forward. The length of the string should

be in 4, 8, 12, 16 or 20 ( MAX )digits.

3rd row ~ so on >>> XXXX

End row - A dot “.” Is the ending of cloning.

XXXX Stands for any string

CLONING MODE

EXAMPLE :

1. PROJECT ASSIGNMENTS:

1.1. Beep tone: BEEP LOW -- HIGH.

1.2. Capslock Mode: CAPSLOCK ON.

1.3. Reading Mode: CONTINUOUS AUTO OFF.

2. SETTING PROCEDURE:

2.1. Scan BEEP LOW -- HIGH (GROUP 3).

2.2. Scan CAPSLOCK ON (GROUP 12).

2.3. Scan CONTINUOUS AUTO OFF (GROUP2).

3. All parameters will be converted to alphanumeric characters

and shown on the monitor.

.A017$

....0604

5A025F04

.

4. Print the results shown on the monitor as bar codes with a bar

code printer. The bar codes should be in the Code 39 symbology.

. A017$

. . . . 0604

5A025F04.

5. Scan these labels with any of the wands that must be

programmed with the same settings as the first wand. Be sure

to scan from the first row to the second and so on sequentially,

top to bottom.

.A017$

....

0604

5A02

5F04

.

.A017$

..

..0604

5A02

5F04

.

.A017$

....06045

A025F04

.

.A017$....

0604

5A02

5F04.

CORRECT SETTING

4

4

4

4

. (Dot)

WRONG SETTING

9 x

7 x

. (Dot)

X

4

4

4+.(Dot)

.A017$

....06045A02

5F04.

Wrong Setting: The string “....”

consists of 4 Dots, located at the

beginning of second row; do not

break the “....” into multiple strings.

Wrong Setting: The string lengths of the

second and third row do not match the

length requirements, because rows should

be in length of four digits.

Wrong Setting because you add

“....” after .A017$:

The .A017$ is a FIXED parameter to

enter setup procedure. It is an unchangeable

parameter. Never add, delete or rearrange

data from the FIRST row.

12

4+.(Dot)

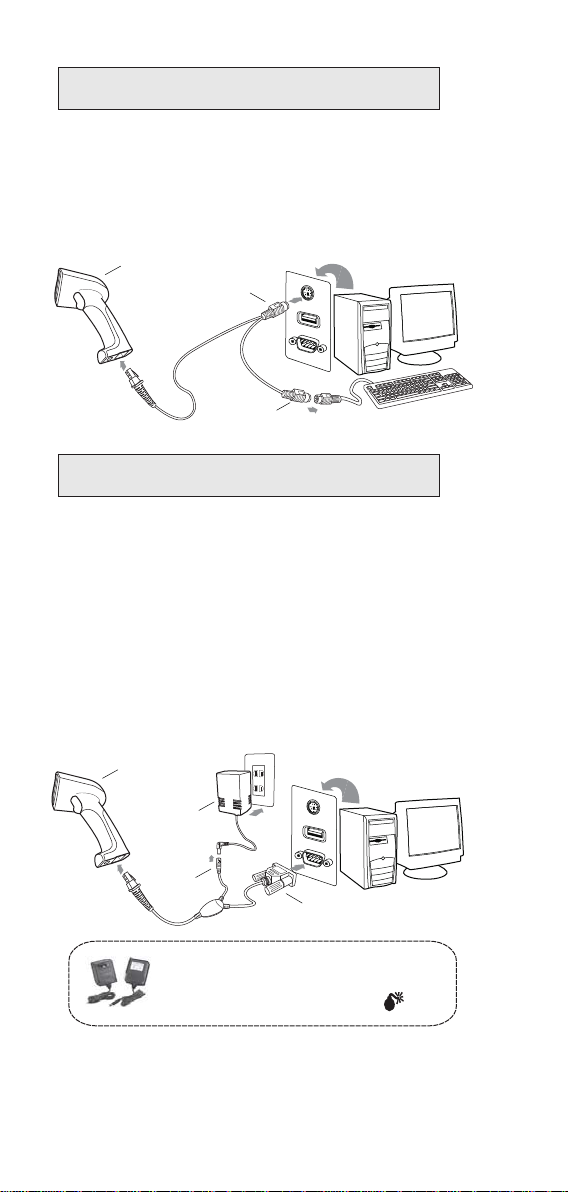

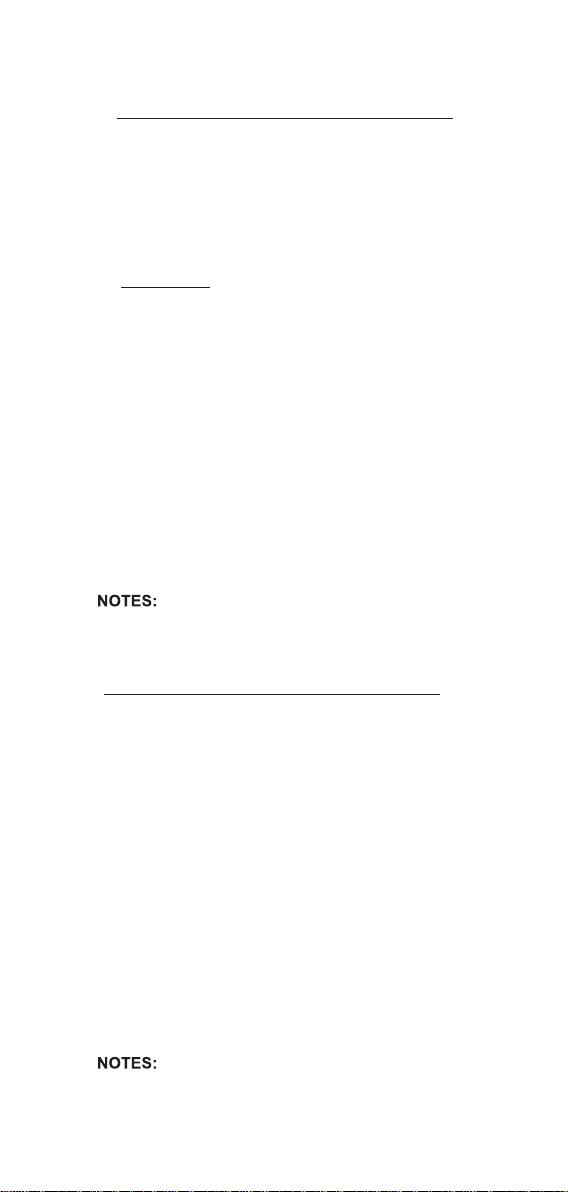

HOW TO CONNECT THE SCANNER TO THE

HOST TERMINAL: Handheld Barcode Scanner

KEYBOARD WEDGE INTERFACE

1. Power down the host computer.

2. Disconnect the keyboard cable from the computer.

3. Connect the “Y ” cable between the keyboard and the scanner and computer.

4. Restart the computer.

5. The scanner will beep.

6. Set the scanner to KEYBOARD interface by referring to GROUP 13

(Interfaces)

7. Scanner will beep to confirm the setting.

8. Scan a bar code to confirm that data shows on the monitor.

Scanner

PS/2

Connector

PS/2

Connector

RS-232 INTERFACE

1. Power down the host computer.

2. Disconnect the cable between the scanner and computer.

3. Connect the power adaptor to the cable.

4. Restart the computer,

5. Plug the power adaptor into a power outlet.

6. The scanner will beep.

7. Set the scanner to RS-232 interface by referring to GROUP 13

(Interfaces).

8. Set RS-232 protocol: Baud Rate, Stop Bits, Handshaking, Data Bits

and Parity.

9. Scan a bar code to confirm that data shows on the monitor.

NOTES:

1. Before plugging the power adaptor into the scanner, be sure the voltage, power

consumption, and inner and outer DC characteristics are correct to avoid serious

damage to the scanner and/or the computer.

2. Make sure the protocol communication settings of the scanner (such as baud rate,

data bits, etc.) match those of the host computer. Otherwise, no data will be

transmitted.

Scanner

Power

Adaptor

Power

Jack

Check the power adaptor to ensure:

1. Input of AC current 110V/ 220V matches the power

supply standard of the country in which the scanner

is being used.

2. Adaptor output is +5V DC

3. The jack input is +5V DC

RS-232

Connector

USB INTERFACE

The USB Interface supported is compatible with Apple MAC series,

, Windows 98, 2000, XP, Vista, 7, 8 and so on.

1. Connect the USB cable between the scanner and the computer.

2. The scanner will beep.

3. The scanner will detect the USB driver automatically. (The first time

the scanner is connected via the USB port, follow the appropriate

instructions for the host computer.)

4. Set the scanner to KEYBOARD/USB interface by referring to

GROUP-13 (Interfaces)

5. Scanner will beep to confirm the setting.

6. Scan a bar code to confirm that data shows on the monitor.

Scanner

USB

Connector

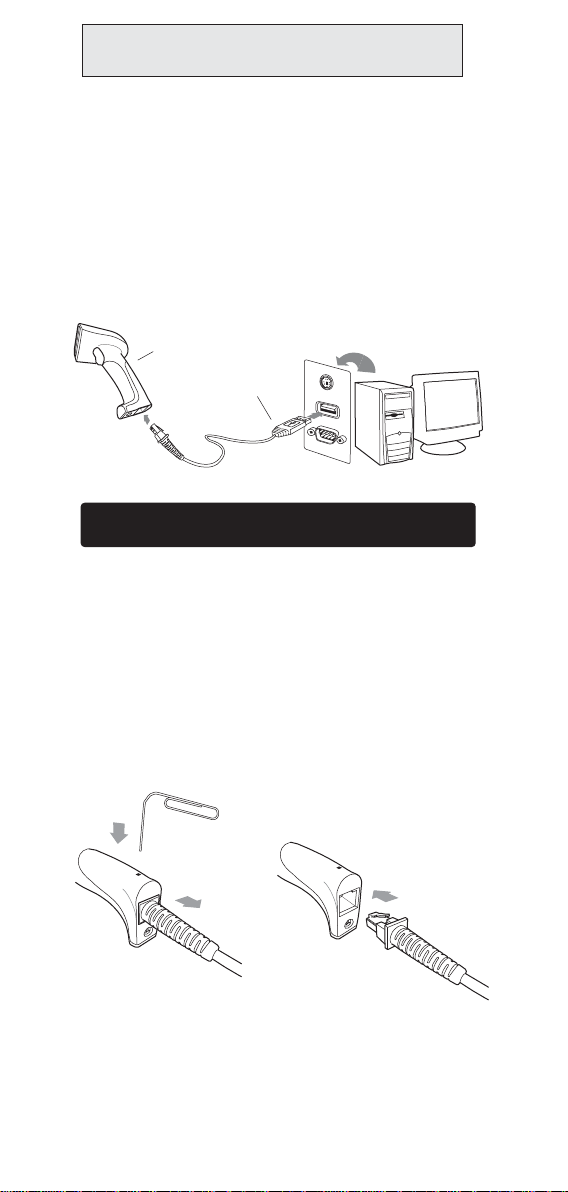

HOW TO CHANGE A CABLE

The scanners are designed to switch easily between interface options.

To switch from one interface to another, the appropriate cable must be

installed. To change a cabl, simply follow these steps:

1. To release the cable, insert a pin or straightened paper clip into the

hole at the base of the scanner where the cable is connected.

2. Remove the cable from the scanner.

3. Plug in the new cable.

After changing to a new cable, be sure to reset the interface setting as

appropriate (including parameter settings for the RS-232 interface).

Step 1

Step 2

Step 3

elbaC weNelbaC tneserP

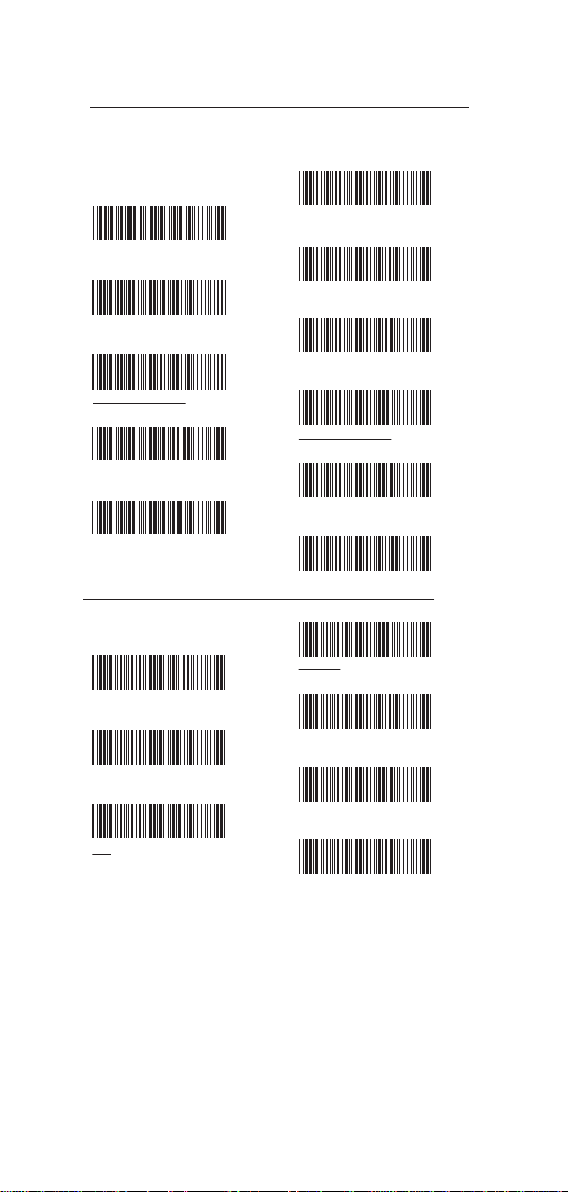

HOW TO SET PARAMETERS

How do you program a scanner with this user’s guide?

1. Use the scanner to scan at the bar code representing the function/

parameter you want to set.

2. When you hear two beeps, the new settings have been defined or

updated into the memory processor.

Default parameters are indicated in bold type and underlined

characters. The character font is ARIAL BLACK. CD = Check Digit.

CDV = Check Digit Verification.

Most settings require only a single bar code, but a few need several

different bar codes to be scanned in order to completely define a

setting. They are:

Preamble / Postamble (maximum 16 digits)

Step 1: Scan CLR PRE/POSTAMBLE.

Step 2: Scan PREAMBLE or POSTAMBLE.

Step 3: Scan any alphanumeric from Full ASCII Table in Group 52-63

Step 4: Scan PREAMBLE or POSTAMBLE.

Min Length / Max Length

Step 1: Scan MIN LENGTH or MAX LENGTH.

Step 2: Scan two digits from Group 60 or Full ASCII numeric table in Appendix

Step 3: Scan MIN LENGTH or MAX LENGTH.

Accuracy Adjustment

Step 1: Scan ACCURACY ADJUSTMENT.

Step 2: Scan one digit from GROUP 5

Step 3: Scan ACCURACY ADJUSTMENT.

Set Code ID (Example: Code 39)

Step 1: Scan CODE 39 SET ID from Group 8

Step 2: Scan either one or two alphanumerics (maximum 2 digits)

from Full ASCII table in Group 54-60

Step 3: Scan CODE 39 SET ID from Group 8

Set A Data - (CX-Codabar, ABC Codabar, Codabar Coupling).

Step 1: Scan SET INSERT DATA.

Step 2: Scan one alphanumeric character from Full ASCII Table in Group 54-60

Step 3: Scan SET INSERT DATA.

NOTES:

1. The scanner will beep three times as a reminder that a setting is

not yet complete.

2. If you make a mistake, forget a step, etc., scan RESET to start again.

. P023$

*.P023$*

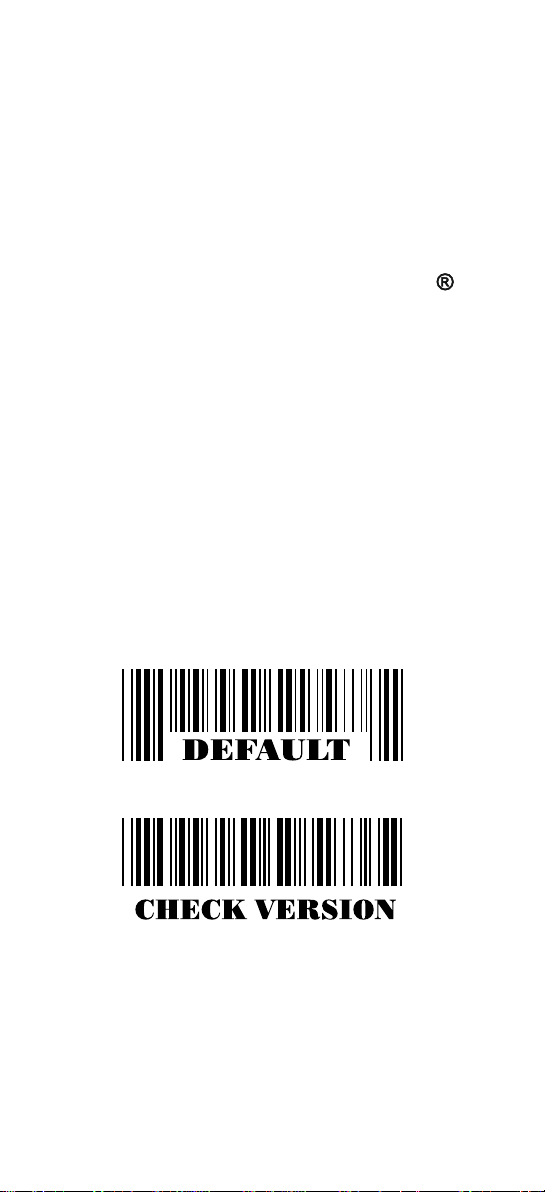

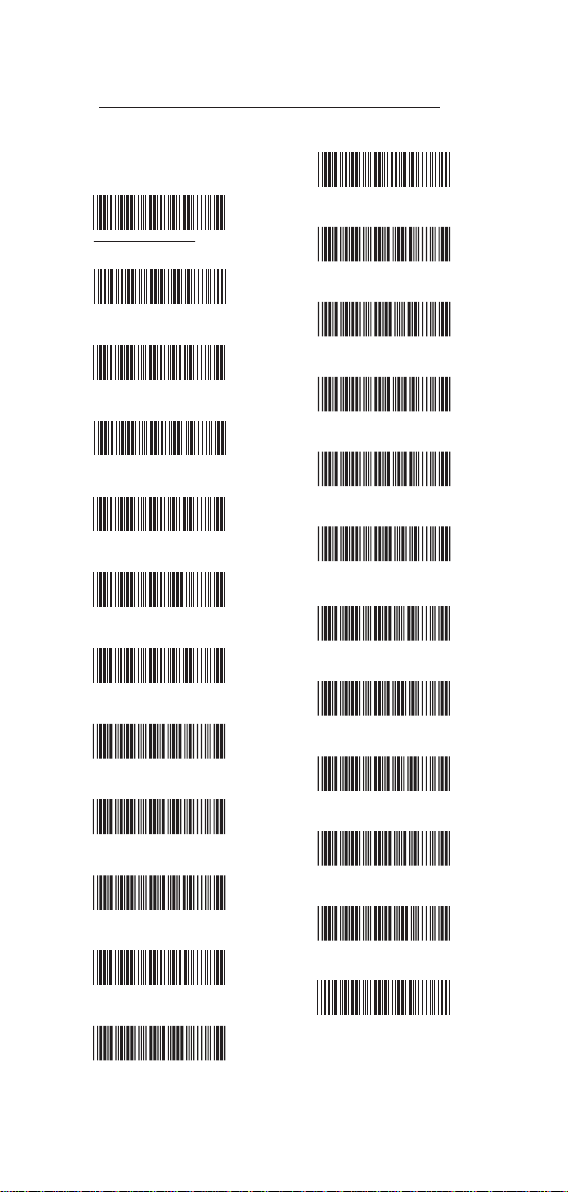

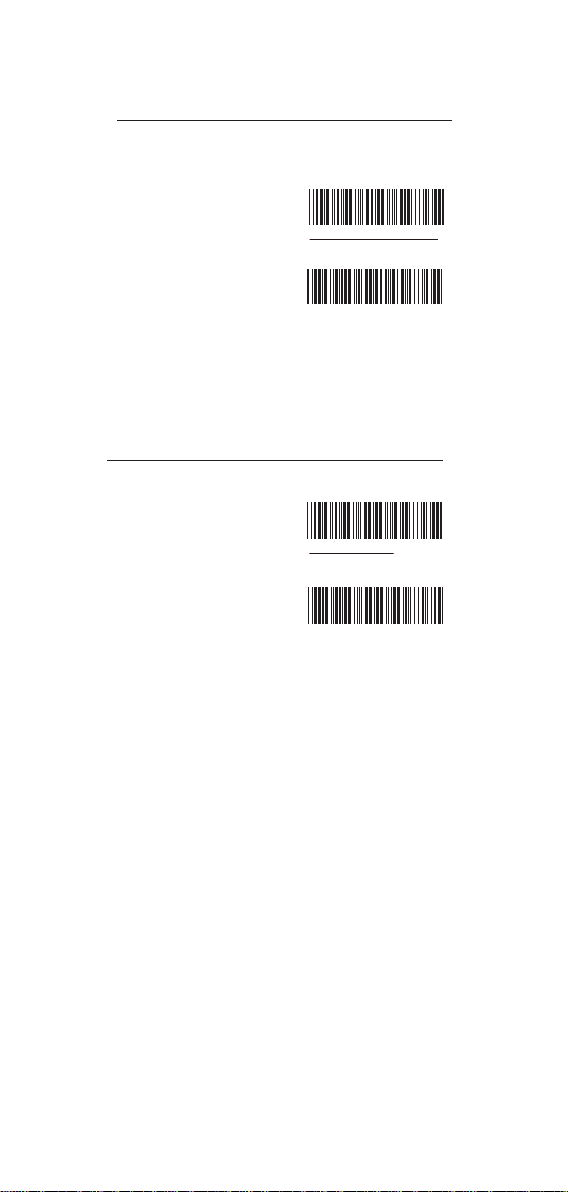

GROUP-1

GENERAL SETTINGS

DEFAULT

*Reset to factory default

CHECK VERSION

*Check firmware version

RESET/ ABORT

*Abort multi-step configuration

. A001$

. A007$

. P023$

SETUP CODE READ

SETUP CODE ON

SETUP CODE OFF

*Caution: Scanning SETUP CODE OFF will turn the

scanner into unprogrammable state and the scanner

will not react to any configuration barcode!

GROUP-2

GENERAL SETTINGS - READING MODE

. F005$

LED is always on.

The trigger does not function in

CONTINUOUS MODE

. F001$

Continuous Mode.

The LED is on steady if a bar code is

close to the scanner, but starts flashing

FLASH MODE

if no bar code is detected after 60

seconds.

The trigger does not function in Flash

Mode.

. F002$

The LED will light when the trigger is

pressed.

TRIGGER MODE

. F006$

The LED will go off when the trigger is

released.

The LED is always on when the trigger

is pressed.

CONTINUOUS AUTO OFF

. F003$

The LED will go off if no bar code has

been detected after 60 seconds.

The LED is always on when the trigger

is pressed.

TOGGLE MODE

The LED will go off if one bar code is

read.

. F007$

If Auto-Sensing Mode(CCD) is on, the

LED will go off if no bar code is detected

*AUTO SENSING MODE (CCD)

after Deactivation Time elapses.

(The default is 3 sec.)

The LED lights automatically when a BAR

CODE is detected.

. F010$

If Auto-Sensing Mode(Laser) is on, the LED

will go off if no barcode is detected after

*AUTO SENSING MODE (Laser)

Deactivation Time elapses.

(The default is 3 sec.)

The laser emits automatically when an

OBJECT is detected.

NOTES:

1. To extend the scanner's life, keep the scanner set to Trigger Mode or

Continuous Auto Off Mode.

2. The LED indicator will glow for GOOD READ.

3. For advanced settings of Auto-Sensing Mode(such as Deactivation Time,

Magnetic Switch and Blue LED) please refer to the next pages.

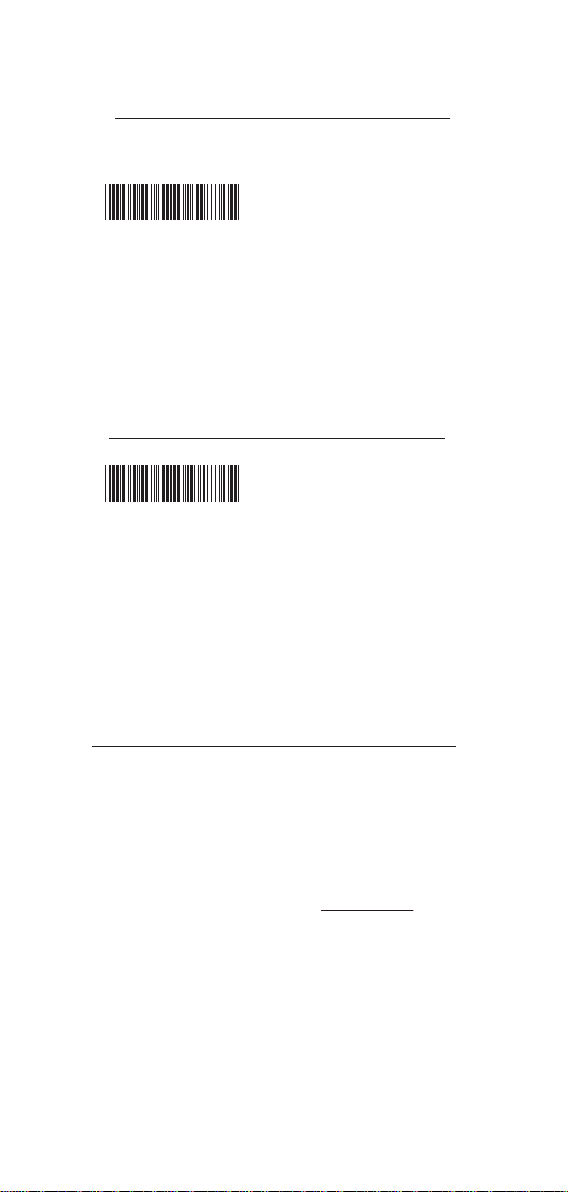

BEEP TONE

2.7KHz Buzzer

(Wireless Scanner)

.F019$

BEEP HIGH

.F021$

BEEP HIGH--LOW

.F018$

BEEP MEDIUM

.F020$

BEEP LOW--HIGH

.F022$

BEEP LOW

GROUP-3

GENERAL SETTINGS

2.1KHz Buzzer

(Tethered Scanner)

. F012$

BEEP OFF

. F014$

BEEP HIGH

. F016$

BEEP HIGH--LOW

. F013$

BEEP MEDIUM

. F015$

BEEP LOW--HIGH

. F017$

BEEP LOW

TERMINATOR

. D010$

NONE

. D011$

. D013$

CR+LF

. D014$

TAB

LF

. D012$

. D015$

SPACE

. D016$

CR

ESC

NOTES:

Below is the position of Terminator among output data string:

[Preamble] [Symbology ID] [Barcode Length] [Barcode Data] [Postamble] [Terminator]

By default, with Preamble, Postamble, Barcode Length and Symbology ID

disabled, the scanner data output will be:

[Barcode Data] [Terminator]

1. For the Keyboard Wedge interface the default terminator is CR.

2. For the USB interface the default terminator is CR.

3. For the RS232 interface the default terminator is CR+LF.

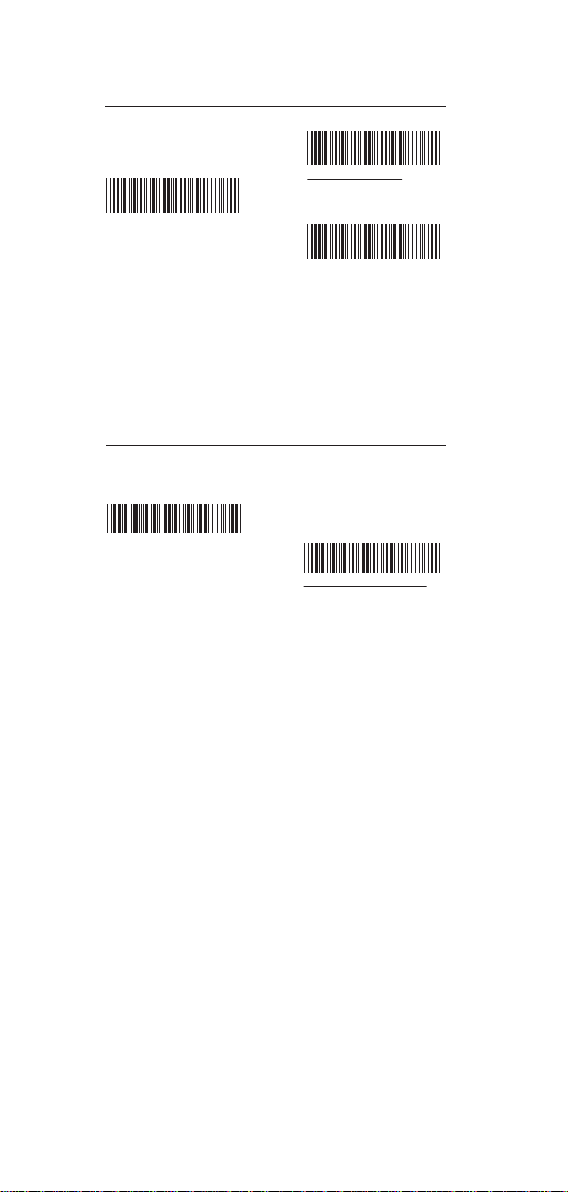

GROUP-4

SEND DATA LENGTH, PREAMBLE & POSTAMBLE.

SEND DATA LENGTH

.D019$

SEND DATA LENGTH ON

.D020$

SEND DATA LENGTH OFF

PREAMBLE & POSTAMBLE ( PREFIX AND SUFFIX )

. A011$

CLEAR PRE/ POSTAMBLE

. A012$

PREAMBLE (16)

. A013$

POSTAMBLE (16)

EXAMPLE:

Set PREAMBLE String as “ ## ”

POSTAMBLE String as “ $$ ”

SETTING PROCEDURE:

STEP 1 : Scan : CLEAR PRE/ POSTAMBLE.

STEP 2 : Scan : PREAMBLE.

STEP 3 : Scan : “ # ” twice from FULL ASCII Table.

STEP 4 : Scan : PREAMBLE.

STEP 5 : Scan : POSTAMBLE.

STEP 6 : Scan : “ $ ” twice from FULL ASCII Table.

STEP 7 : Scan : POSTAMBLE.

DATA FORMAT:

[Preamble] [Symbology ID] [Barcode Length] [Barcode Data] [Postamble] [Terminator]

NOTES:

1. A PREAMBLE is a string of up to 16 characters added

to the beginning of a scanned barcode.

2. A POSTAMBLE is a string of up to 16 characters added

to the end of a scanned barcode.

3. Default value for both: None.

GROUP-5

GENERAL SETTINGS - ACCURACY ADJUSTMENT

0

5

1

6

2

7

3

8

4

9

ACCURACY

. A010$

ADJUSTMENT

Accuracy Adjustment assures a more reliable decoded output.

Enabling the feature and setting a number from 1 to 9 subjects

the decoded output a higher standard of accuracy. The higher

the number, the greater the accuracy.

SETTING PROCEDURE:

1. Scan ACCURACY ADJUSTMENT.

2. Scan one digit (1~9) from barcode menu above.

3. Scan ACCURACY ADJUSTMENT.

. P023$

NOTES:

1. The scanner will beep three times as reminder that a setting

is not yet complete.

2. If you make a mistake, forget a step, etc., scan RESET to start

again.

GROUP-6

GENERAL SETTINGS

ENABLE INVERSE BARCODE

.D021$

DISABLE INVERSE BARCODE

[READS POSITIVE BARCODE ONLY]

.D022$

ENABLE INVERSE BARCODE

[READS POSITIVE & NEGATIVE BARCODES]

ENABLE CODE ID

.A008$

FACTORY ID ON

.A014$

AIM ID ON

.A015$

SET ID ON

DISABLE CODE ID

.A009$

NOTES:

1. Only ONE code ID will be sent.

2. The code ID is located at the position before the bar code data

and after the preamble.

EXAMPLE :

1.Preamble 145287,

2.Code ID: enable AIM ID,

3.Bar code symbologies : EAN 13+5

563987 123453

145287

Preamble

145287

OUTPUT

4

]E0

CODE ID

AIM ID : ]E0

: 145287]E0456398712345312411

BARCODE / DATA

EAN 13 +5

12411

GROUP-7

GENERAL SETTINGS

SYMBOLOGIES CODE ID IDENTIFIER

Symbologies

EAN 128

Code 128

EAN8(+2/+5 OFF)

EAN8(+2 ON)

EAN8(+5 ON)

UPC-E(+2/+5 OFF)

UPC-E(+2 ON)

UPC-E(+5 ON)

UPC-A(+2/+5 OFF)

UPC-A(+2 ON)

UPC-A(+5 ON)

EAN-13(+2/+5 OFF)

EAN-13(+2 ON)

EAN-13(+5 ON)

Code 93

Code 11(disable CDV)

Code 11(send one CD)

Code 11(send two CD)

Code 11(not send CD)

Telepen(ASCII)

Telepen(Numeric)

IATA 2 of 5

China Post Code

PDF417

Factory

ID

T

K

S

E

A

F

L

J

U

R

V

H

Z

AIM ID

(new)

]C1

]C0

]E4

]E4

]E4

]E0

]E3

]E3

]E0

]E3

]E3

]E0

]E3

]E3

]G0

]H0

]H0

]H1

]H3

]B0

]B1

]S0

]X0

]E0

Symbologies

MSI

MSI(MOD 10 / CDV & not send CD)

Code 32

Codabar

Codabar(ABC Codabar)

Codabar(CDV & Send CD)

Codabar(CDV & not send CD)

UK Plessey

Matrix 2 of 5

Full ASCII Code 39(disable CDV)

Full ASCII Code 39(CDV & send CD)

Full ASCII Code 39(CDV & not send CD)

Standard Code 39(disable CDV)

Standard Code 39(CDV & send CD)

Standard Code 39(CDV & not send CD)

Interleaved 2 of 5(CDV & send CD)

Interleaved 2 of 5(CDV & not send CD)

Interleaved 2 of 5(disable CDV)

Databar

Databar Stacked

Databar Stacked Omnidirectional

Databar Truncated

detimiL rabataD5 fo 2 lairtsudnI

Databar Expanded

Databar Expanded Stacked

Factory

ID

O

B

N

P

Y

D

M

I

G

C

Q

AIM ID

(new)

]M0

]M1

]X0

]F0

]F1

]F2

]F4

]P0

]X0

]A4

]A5

]A7

]A0

]A1

]A3

]I1

]I3

]I0

0e]0R]

SET ID - SETTING PROCEDURES

Steps:

1. Scan the SET ID bar code for a particular symbology.

2. Scan one or two alphanumeric characters from the Full ASCII Table.

3. Scan the SET ID bar code again.

Example: Define the MSI Code ID = A, Code 93 = G9

MSI :

Step1: Scan MSI Set ID (Group 9).

Step2: “A” from Group 56.

Step3: Scan MSI Set ID (Group 9).

Code 93:

Step1: Scan Code 93 Set ID (Group8).

Step2: “G” from Group 56, Scan “9” from Group 60.

Step3: Scan Code 93 Set ID (Group8).

NOTES:

1. The length of a Code ID is either one or two characters. If one

character is set, the Code ID output will be one character. If two

characters are set, the Code ID output will be two characters.

2. Only one type of Code ID will be sent.

GROUP-8

GENERAL SETTINGS - SET CODE ID

. P001$

EAN 13 Set ID

. P002$

EAN 8 Set ID

. P003$

UPC E Set ID

. P004$

UPC A Set ID

. P005$

Code 39 Set ID

. P013$

Code 93 Set ID

. P007$

Codabar Set ID

. P021$

IATA Set ID

. P010$

. P016$

. P022$

. P009$

. P011$

. P012$

Code 128 Set ID

EAN 128 Set ID

Telepen Set ID

Code 11 Set ID

Code 32 Set ID

China Post Code

[TOSHIBA Code] Set ID

GROUP-9

GENERAL SETTINGS - SET CODE ID

. P014$

MSI Code Set ID

. P015$

UK Plessey Set ID

. P017$

Matrix 2 of 5 Set ID

Interleaved 2 of 5

Set ID

Industrial 2 of 5 Set ID

Full ASCII Code39

Set ID

GS1 Databar (RSS)

Limited Set ID

GS1 Databar (RSS)

Expanded Set ID

GS1 Databar (RSS)

Set ID

LABEL Code Set ID

[ Reserved ]

. P006$

. P018$

. P008$

. P019$

. P020$

. P024$

. P020$

. P023$

1. The scanner will beep three times as a reminder that a setting is

not yet complete.

2. If you make a mistake, forget a step, etc., scan RESET to start

again.

GROUP-10

GENERAL SETTINGS

INTERBLOCK DELAY

INTERCHARACTER DELAY

0mS

10mS

50mS

100mS

200mS

500mS

140uS

500uS

1mS

4mS

16mS

GROUP-11

GENERAL SETTINGS

KEYBOARD LAYOUT

. C010$

ENGLISH (USA)

. C018$

ENGLISH (UK)

. C012$

FRENCH

. C011$

GERMAN

. C014$

ITALIAN

. C013$

SPANISH

. C017$

CZECH (QWERTY)

. C022$

CZECH (QWERTZ)

. C021$

HUNGARIAN (QWERTZ)

. C024$

HUNGARIAN (101 KEY)

. C016$

SWISS (GERMAN)

. C023$

. C009$

JAPAN (106 key)

. C025$

CANADIAN (FRENCH)

. C034$

CANADIAN

. C029$

(TRADITIONAL)

NORWEGIAN

. C026$

SWEDISH

. C031$

PORTUGUESE

. C030$

BELGIAN (AZERTY)

. C028$

DUTCH

. C027$

DANISH

. C032$

SLOVAK

. C033$

BRAZILIAN (PORTUGUESE)

. C015$

ALT CODE

SWISS (FRENCH)

GROUP-12

GENERAL SETTINGS

CAPITAL LOCK MODE

. A004$

. A005$

CAPLOCK OFF

CAPLOCK ON

. A006$

CAPLOCK FREE

NOTE:

1. When barcode scanner is set to Caplock Free mode,

no matter keyboard Capslock LED indicator is ON or

OFF, output will be always the same as the Original

barcode. In other words, what you see is what output

is.(CODABAR is the exception)

2. If ABCD/ ABCD, abcd/ abcd, ABCD/T*E, abcd/tn*e are

on, they work independently according to their rules.

NUMERIC KEY

. D017$

NUMERIC KEY

. D018$

ALPHANUMERIC KEY

GROUP-13

TETHERED SCANNER SETTINGS

. C004$

COMPUTER TYPE

SYMPTOMS SOLUTION

Scanner seems to be

performing as usual,

but no data is being

output.

CauƟon: Please ensure the correct computer type is set when the

scanner is aƩached to a new host computer. If set to Notebook, the

scanner will operate with no external keyboard.

. C005$

USB HID

. C008$

USB HID

. C006$

*.C006$*

USB VCP

SYMPTOMS

The wand does not

scan/ The scanner

does not scan when

the trigger is

depressed.

CauƟon:

1. This scanner is designed to switch easily between interface

opƟons. To switch from one interface to another, the appropriate

cable must be installed. AŌer changing to a new cable, be sure

to reset the interface seƫng as appropriate.

2. Before switching to USB VCP, please make sure you have

installed proper driver on PC. The driver is available either on

enclosed CD or from your local distributor.

1. Unplug the cable from the host computer.

2. Plug the cable back into the host computer.

3. Set the scanner to the exact computer type

immediately.

SOLUTION

1. Unplug the cable from the host computer.

2. Plug the cable back into the host computer.

3. Set the wand to the correct interface. The

cable needs to match the interface.

PC-AT

. C007$

NOTEBOOK*

INTERFACES SELECTION

. C001$

PS2 KB

. C002$

RS232

GROUP-14

TETHERED SCANNER SETTINGS

(The following are only supported by Bi-Color models)

BI-COLOR: CYCLE MODE

. D027$

*.D027$*

GREEN > RED

. D028$

*.D028$*

RED > GREEN

. D029$

*.D029$*

GREEN > BI-COLOR

. D030$

*.D030$*

RED > BI-COLOR

1. Illumination color will switch back and forth from one to another

when good read does not occur.

2. Illumination color will remain as the one used at the last good read.

BI-COLOR: SINGLE MODE

. D031$

*.D031$*

BI-COLOR

. D032$

*.D032$*

GREEN

. D033$

*.D033$*

RED

1. Illumination color will remain single.

GROUP-15

ADVANCED AUTO-SENSING SETTINGS

(The following is only supported by autosensing models)

MAGNETIC SWITCH

(CCD & LASER SCANNERS)

. F034$

MAGNETIC SWITCH ON

. F035$

MAGNETIC SWITCH OFF

NOTES:

1. The Magnetic Switch is automatically activated when Auto Sensing Mode is on.

2. To enable Magnetic Switch, the scanner should be paired with

an Autosense Stand to perform Auto-Sensing function.

3. When Magnetic Switch is disabled, the scanner will perform

Auto-Sensing function without Autosense Stand.

GREEN LED/ SUPPLEMENT LIGHT

(CCD SCANNER ONLY)

. F032$

GREEN LED ON

. F033$

GREEN LED OFF

NOTES:

1. The green LED is automatically activated when Auto-Sensing

Mode is on.

2. Green LED serves as Supplement Light for a CCD scanner in

order to enhance the sensitivity of scanner in Auto-Sensing

Mode.

GROUP-16

ADVANCED AUTO-SENSING SETTINGS

(The following is only supported by autosensing models)

. F030$

DEACTIVATION TIME

(CCD & LASER SCANNERS)

DEACTIVATION TIME

NOTES:

1. The default of Deactivation Time is 3 Sec.

2. Deactivation Time is the time interval between the last scan and

the automatic deactivation of LED or Laser light in Auto-Sensing

Mode.

3. You can set the Deactivation Time value by the following three

steps:

Step 1: scan Deactivation Time

Step 2: scan two digits(Limit Range: 01 ~ 30sec.) from the Full ASCII

numeric table.

Step 3: scan Deactivation Time

. F031$

SAME CODE INTERVAL

(LASER SCANNER ONLY)

SAME CODE INTERVAL

NOTES:

1. The default of Same Code Interval is 30 Sec.

2. Same Code Interval is the time interval between two consecutive

scans on the SAME bar code in Auto-Sensing Mode.

3. You can set the value of Same Code Interval by the following three

steps:

Step 1: scan Same Code Interval

Step 2: scan two digits(Limit Range: 03 ~ 60sec.)from the Full ASCII

numeric table.

Step 3: scan Same Code Interval

IDLE MODE SETTING

IDLE MODE

.B028$

.B026$

*.B026$*

Idle Mode On

*.B028$*

Pre-Idle Time

NOTES:

1. Idle Mode is only supported by certain models.

2. When Idle Mode is on, the scanner will enter idle state to save

power after a period of inactivity, or Pre-Idle Time(the default

is 1 min).

3. You can set the value of Pre-Idle Time by the following four steps:

Step 1: scan Idle Mode On

Step 2: scan Pre-Idle Time

Step 3: scan one digits(Limit Range: 1~9 Min.)from the Full ASCII

numeric table.

Step 4: scan Pre-Idle Time

.B027$

*.B027$*

Idle Mode Off

GROUP-17

TETHERED SCANNER - RS232 SETTINGS

BAUD RATE

. E001$

300

. E002$

600

. E003$

1200

. E004$

2400

DATA BITS & PARITY

. E008$

8 Bits None

. E009$

8 Bits EVEN

. E010$

8 Bits ODD

. E011$

8 Bits MARK

. E005$

4800

. E006$

9600

. E007$

19200

. E022$

38400

. E012$

8 Bits SPACE

. E013$

7 Bits EVEN

. E014$

7 Bits ODD

. E015$

7 Bits MARK

. E021$

7 Bits SPACE

GROUP-18

TETHERED SCANNER - RS232 SETTINGS

STOP BITS

HANDSHAKING

. E016$

1 STOP BIT

. E017$

2 STOP BITS

. E018$

NONE

. E019$

RTS enable at Power on

. E020$

RTS enable with Communication

ACK / NAK

FLOW CONTROL:

TIME OUT

BCC

. E023$

ON

. E024$

OFF

. E025$

1 Sec

. E026$

3 Sec

. E027$

10 Sec

. E028$

Unlimited

. E029$

RS232 BCC Char On

. E030$

RS232 BCC Char Off

Loading...

Loading...