Page 1

Installation and user’s guide

H-1000-5131-01-A

TP20 probe for FARO arm

Page 2

© 2007 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or

transferred to any other media or language, by any means, without the

prior written permission of Renishaw.

The publication of material within this document does not imply freedom

from the patent rights of Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of this

document are free from inaccuracies and omissions. However, Renishaw

makes no warranties with respect to the contents of this document and

specifically disclaims any implied warranties. Renishaw reserves the right

to make changes to this document and to the product described herein

without obligation to notify any person of such changes.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All other brand names and product names used in this document are

trade names, service marks, trademarks, or registered trademarks of their

respective owners.

Renishaw part no: H-1000-5131-01-A

Issued: 12 2007

Page 3

TP20 probe for FARO arm

installation and user’s guide

1

Page 4

2

Care of equipment

Renishaw probes and associated systems are precision tools used for

obtaining precise measurements and must therefore be treated with

care.

Changes to equipment

Renishaw reserves the right to improve, change or modify its hardware

or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

Warranty

Renishaw plc warrants its equipment provided that it is installed

exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw

equipment (e.g. interfaces and/or cabling) is to be used or substituted

for Renishaw equipment. Failure to comply with this will invalidate the

Renishaw warranty.

Claims under warranty must be made from authorised service

centres only, which may be advised by the supplier or distributor.

Patents

Aspects of the TP20 probing system and aspects of similar systems

are the subject of the following patents and patent applications.

Care of equipment

EP 548328

EP 750171

EP 501710

EP 826136

EP 566719

JP 3294269

JP JP 3279317

JP 2,510,804

JP 505,622/1999

US 5,323,540

US 5,505,005

US 5,327,657

US 5,404,649

US 5,339,535

US 5,918,378

US 6012230

Page 5

Contents

Contents

1 Introduction ...................................................................................4

2 Product description .......................................................................5

2.1 The FARO TP20 touch-trigger probe kit ............................... 5

2.1.1 The probe body .......................................................5

2.1.2 The probe modules.................................................. 7

3 Product installation ........................................................................ 9

3.1 Fitting the TP20 probe onto a FARO arm ............................. 9

3.2 Fitting a stylus onto the probe module .................................9

3.3 Fitting the probe module and stylus onto the probe body ..11

4 Technical data - TP20 probe module changing touch-trigger probe .. 12

4.1 Measuring performance .....................................................12

4.1.1 Probing forces and overtravel limits ....................... 13

4.1.2 Probe module changing repeatability .................... 13

4.1.3 Technical specification ........................................... 14

5 Applications guide ....................................................................... 15

5.1 Probe module selection ......................................................15

5.1.1 The low force probe module .................................. 16

5.1.2 The standard force probe modules ........................16

5.1.3 The medium force probe module ...........................16

5.1.4 The extended force probe module .........................16

5.1.5 The 6-way probe module ....................................... 16

5.2 Stylus selection ..................................................................17

5.2.1 Recommended stylus limits ................................... 19

6 Product maintenance .................................................................. 24

3

Page 6

4

Introduction

1 Introduction

The Renishaw TP20 probe module changing touch-trigger probe is

a 5-way or 6-way kinematic probe with the facility to change stylus

configurations without the need for re-qualification.

The TP20 comprises a two-piece design – a probe body and

detachable probe module(s).

TP20 probe body

TP20 probe module

changing touchtrigger probe

Figure 1 - The TP20 probe

Page 7

Product description

2 Product description

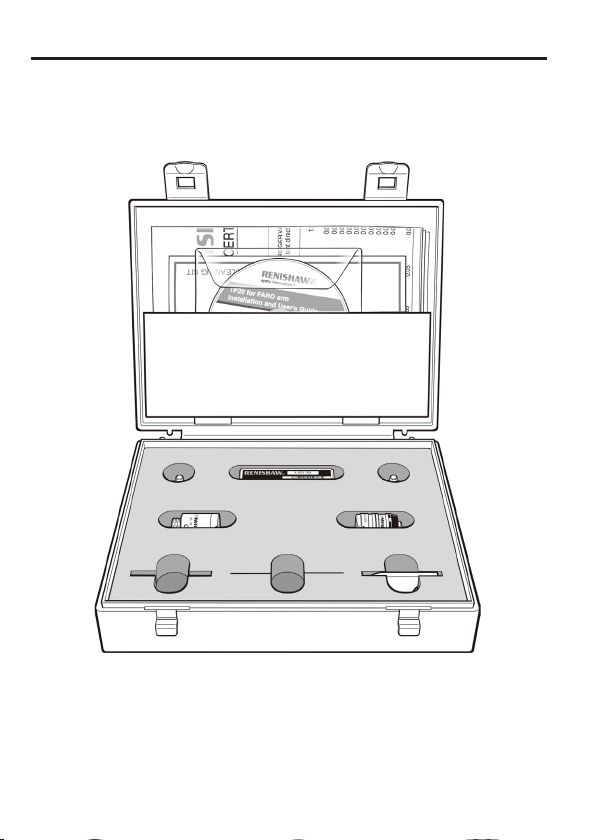

2.1 The FARO TP20 touch-trigger probe kit

The standard Renishaw TP20 touch-trigger probe kit (see figure 2)

comprises the following primary components:

• One TP20 probe body

• One medium force TP20 probe module (see page 8 for available

combinations)

• Ø 6 mm (0.24 in) x 10 mm (0.39 in) stylus

• Ø 2 mm (0.08 in) x 10 mm (0.39 in) stylus

• Probe and stylus tools

2.1.1 The probe body

The probe body incorporates a standard Renishaw M8 × 1.25 screw

connector mount and is designed to house the mating half of the

probe module’s kinematic coupling.

5

Page 8

6

Product description

Figure 2 - The TP20 probe for FARO arm kit

Page 9

Product description

2.1.2 The probe modules

Each probe module, which houses the kinematic switching touch

sensor mechanism, carries the stylus assembly and provides

overtravel in the X, Y and +Z axes (–Z is offered when using the TP20

6-way probe module). Incorporating an M2 stylus mounting, each

probe module is compatible with Renishaw’s comprehensive range of

M2 styli.

Designed to minimise the possibility of probe module misalignment

generating a probe ‘seated’ signal, the probe module is held in position

by a magnetically retained, highly repeatable kinematic coupling.

Electrical contact pins conduct the probe sense voltage through the

coupling.

Trigger force options

The standard force probe module is suitable for most applications

(when used with the recommended stylus range), but sometimes the

effects of stylus length and mass, combined with acceleration and

vibration, can cause the probe to false trigger (these are referred to as

‘spurious triggers’).

To allow the TP20 to be used where acceleration forces would

otherwise result in spurious touches, a choice of higher force probe

modules is available. A low force probe module is also available for

measurement of delicate materials. Refer to the applications guide

later in this document for information on how to select the correct

probe module for your application.

7

Page 10

8

The type of probe modules supplied with your probe will be clearly

marked on each probe module’s front ring. The probe modules also

carry a colour-coded front cap as follows:

• Low force (LF) probe module (green cap)

• Standard force (SF) probe module (black cap)

• Medium force (MF) probe module (grey cap) (supplied)

• Extended force (EF) probe module (brown cap)

• 6-way (6W) probe module (blue cap)

• Extension module 1 standard force (EM1 STD) (black cap)

• Extension module 2 standard force (EM2 STD) (black cap)

The following TP20 probe module kits are available from your supplier:

Product description

TP20 probe module kit

(probe module only)

Low force probe module A-1371-0392

Standard force probe module A-1371-0270

Medium force probe module A-1371-0271

Extended force probe module A-1371-0272

6-way probe module A-1371-0419

EM1 STD probe module A-1371-0430

EM2 STD probe module A-1371-0431

EM1 STD and EM2 STD probe modules A-1371-0432

Part number

Page 11

Product installation

3 Product installation

3.1 Fitting the TP20 probe onto a FARO arm

To fit the TP20 probe carry out the following procedure (see figure 3):

1. By hand, screw the threaded end of the probe body into the TP20

adaptor and finger tighten to secure.

2. Fit the S1 ‘C’ wrench (supplied) onto the probe body as shown in

Figure 3.

3. Using the S1 ‘C’ wrench, fully finger tighten the probe body into

the M8 bush (0.3 Nm – 0.5 Nm).

3.2 Fitting a stylus onto the probe module

To fit a stylus onto the probe module, carry out the following procedure

(see figure 3):

1. Screw the threaded end of your chosen stylus into the M2 stylus

mount of the probe module and finger tighten to secure.

2. Using the type S7 stylus tools provided, or type S20 wrench if

fitting a stylus from the Renishaw GF range, fully finger tighten

the stylus into the stylus mount to achieve the recommended

tightening torque of between 0.05 Nm and 0.15 Nm (maximum

permissible torque is 0.3 Nm).

9

NOTE: For advice on both stylus and probe module selection, refer to

the applications guide later in this publication.

Page 12

10

Product installation

Probe body

Probe module

TP20 adaptor

S1 ‘C’ wrench

S7 stylus tool

M2 stylus

Figure 3 - Fitting the TP20 probe onto the FARO adaptor

Page 13

Product installation

11

3.3 Fitting the probe module and stylus onto the probe

body

To fit the probe module and stylus onto the probe body, carry out the

following procedure (see figure 4):

1. Visually examine the mating faces of both the probe module

and the probe head for cleanliness; where necessary, clean the

mating surfaces using the CK200 cleaning kit (supplied).

2. Offer up the probe module to the probe body and, ensuring the

three alignment marks on both the probe module and probe

body are correctly aligned, allow the probe module to engage the

probe body under magnetic force.

Alignment marks

Alignment marks

Figure 4 - Fitting the probe module and stylus onto the probe body

Page 14

12

Technical data

4 Technical data - TP20 probe module

changing touch-trigger probe

4.1 Measuring performance

NOTE: The following data is derived from high accuracy test rig

measurements and may not represent the performance achievable

on an arm. Please consult your supplier for overall system accuracy

information.

Performance at 10 mm stylus length

Parameter Probe module type

LF SF MF EF 6-way EM1

Unidirectional

repeatability*

(2s)

2D (XY) form

measurement

deviation*

* Measured at a trigger speed of 8 mm/s

Test stylus ball diameter 4 mm

0.35 µm0.35 µm0.50 µm0.65 µm0.8 µm0.35 µm0.35

±0.6 µm±0.8 µm±1.0 µm±2.0 µm±1.5 µm±0.8 µm±0.8

STD

EM2

STD

µm

µm

Page 15

4.1.1 Probing forces and overtravel limits

Technical data

13

Probe

module

type and

stylus

length

LF

10 mm

SF

10 mm

MF

25 mm

EF

50 mm

6-way

10 mm

EM1 STD

10 mm

EM2 STD

10 mm

Trigger force

(nominal at

stylus tip)

XY Z XY +Z -Z XY +Z -Z

0.055 N

(5.5 gf)

0.08 N

(8 gf)

0.1 N

(10 gf)

0.1 N

(10 gf)

0.14 N

(14 gf)

0.08 N

(8 gf)

0.08 N

(8 gf)

0.65 N

(65 gf)

0.75 N

(75 gf)

1.9 N

(190 gf)

3.2 N

(320 gf)

1.6 N

(160 gf)

0.75 N

(75 gf)

0.75 N

(75 gf)

Parameter

Overtravel force*

(max. at stylus tip)

0.09 N

0.2-0.3 N

(20-30 gf)

0.2-0.4 N

20-40 gf)

0.2-0.5 N

(20-50 gf)

0.25 N

(25 gf)

0.2-0.3 N

(20-30 gf)

0.2-0.3 N

(20-30 gf)

(9 gf)

1.15 N

(115 gf)

3.5 N

(350 gf)

7.0 N

(700 gf)

10 N

(1kgf)

2.5 N

(250 gf)

3.5 N

(350 gf)

3.5 N

(350 gf)

- ±14°

- ±14°

- ±14°

- ±14°

9.0 N

(900 gf)

- ±14°

- ±14°

Overtravel

displacement*

3.1

mm

4.0

mm

3.7

mm

2.4

mm

4.5 mm1.5

±14°

4.0

mm

4.0

mm

* NOTE: The probe module may detach if this value is exceeded.

4.1.2 Probe module changing repeatability

Probe module changing Repeatability

Manual changing 2.0 µm

-

-

-

-

mm

-

-

Page 16

14

4.1.3 Technical specification

Technical data

Dimensions

Diameter

Probe mount

Stylus mount

Sense directions

Probe module pull-

off force

Sealing

Probe module life

Length

13.2 mm (0.52 in)

LF/SF/MF/EF 38 mm (1.5 in)

EM1 STD 88 mm (3.46 in)

EM2 STD 113 mm (4.45 in)

6-way 42 mm (1.65 in)

Thread M8 x 1.25 x 5 mm

Thread M2 x 0.4

LF/SF/MF/EF/

EM1 STD/EM2

STD

6-way 6-way (±X, ±Y, ±Z)

10 N (1 kgf) maximum

IP30

25,000 changes

5-way (±X, ±Y, +Z)

Page 17

Applications guide

5 Applications guide

5.1 Probe module selection

To obtain the best possible performance from your TP20 probe,

it is important to select the correct probe module for your specific

application. When choosing the probe module to be used, the

following considerations should be addressed:

• The mass of the stylus assembly and its centre of gravity. It is

always best to use the shortest stylus possible.

• The orientation of the probe body.

• The levels of acceleration and vibration to which the TP20 probe

will be subjected. These will vary with movement and velocity.

The following probe modules are available for use with the TP20

probe; each probe module is clearly marked on its front ring and also

carries a colour-coded front cap as follows:

• Low force probe module (green cap)

• Standard force probe module (black cap)

• Medium force probe module (grey cap) (supplied)

15

• Extended force probe module (brown cap)

• 6-way probe module (blue cap)

• EM1 STD probe module (black cap)

• EM2 STD probe module (black cap)

Page 18

16

5.1.1 The low force probe module

The low force probe module, identified by a green cap, is suited to

applications that require a low trigger force, for example rubber seals.

5.1.2 The standard force probe modules

The standard force probe modules (SF, EM1 STD and EM2 STD) are

identified by black caps and are suited to the majority of applications.

5.1.3 The medium force probe module

The medium force probe module, identified by a grey cap, is provided

for use where a higher trigger force than standard is required.

5.1.4 The extended force probe module

The extended force probe module is identified by a brown cap.

Typically, this probe module will only be required with large stylus

assemblies, and where spurious triggers caused by acceleration

preclude the use of either the standard or medium force probe

modules.

5.1.5 The 6-way probe module

The 6-way probe module is identified by a blue cap. This probe

module is designed for 6-way operation where there is a requirement

to measure in the –Z direction, for example when measuring

undercuts.

Applications guide

Page 19

Applications guide

17

5.2 Stylus selection

NOTE: Choosing the best stylus for a given application is an

important factor in achieving optimum probe performance. For

further information on the full range of Renishaw styli, please refer to

Renishaw’s styli and accessories brochure (H 1000-3200) which can

be ordered from your supplier or downloaded from Renishaw’s web

site, www.renishaw.com.

When selecting a stylus, it is important that the stylus length is kept to

the minimum required to access all features to be measured, and that

the stylus type offers the maximum possible stiffness. Factors that

affect stiffness are:

• Joints in the styli: that tend to reduce rigidity and should therefore

be kept to the absolute minimum.

• Stem diameters: that are governed by the ball tip diameter of the

stylus.

• Stem material: that can be stainless steel, ceramic or graphite

fibre (GF).

It is also important to ensure that the stylus ball diameter chosen is as

large as is practical. This not only ensures that the stylus will be as

stiff as possible, but also reduces the stylus’s susceptibility to surface

form and surface finish.

Page 20

18

Owing to the modular construction of the TP20, when selecting and

using styli the following criteria should be applied:

• Work only within the recommended stylus limits for each probe

• Always use the shortest possible stylus.

• If using larger styli than those recommended for use with each

• Minimise the mass of styli by using either ceramic or graphite

Applications guide

module (refer to Recommended stylus limits).

probe module, always conduct trials to establish the effect on

measuring performance.

fibre (GF) stems.

Page 21

Applications guide

5.2.1 Recommended stylus limits

Owing to the modular construction of the TP20 probe, it is

recommended that the limits shown in figures 5 to 9 are applied when

selecting styli to be used.

The medium force and extended force probe modules

The medium force and extended force probe modules have the

following recommended stylus limits:

• Any stylus type up to 60 mm (2.36 in) long.

• Star and cranked styli up to 20 mm (0.79) offset.

30 mm

(1.18 in)

60 mm

(2.36 in)

19

Min: 10 mm (0.39 in) Max: 40 mm (1.57 in)

Figure 5 - Recommended stylus limits for medium and extended force

probe modules

Page 22

20

The low force probe module

The low force probe module has the following recommended stylus

limits:

• Steel and carbide styli up to 30 mm (1.18 in) long

• No star or cranked styli

Applications guide

Max: 30 mm

(1.18 in)

Figure 6 - Recommended stylus limits for low force probe module

Page 23

Applications guide

The standard force probe modules

The standard force probe modules (SF, EM1 STD and EM2 STD) can

be used with the following range of styli:

• Steel and carbide styli up to 40 mm (1.57 in) long.

• Renishaw graphite fibre (GF) type styli up to 50 mm (1.97 in) long.

• Star and cranked styli up to 20 mm (0.79 in) offset.

20 mm

(0.79 in)

Steel: 40 mm

(1.57 in)

GF: 50 mm

(1.97 in)

21

Min: 10 mm (0.39 in) Max: 40 mm (1.57 in)

Figure 7 - Recommended stylus limits for standard force probe

modules

Page 24

22

The 6-way probe module

The recommended stylus limits for the 6-way probe module are:

• Any stylus type up to 30 mm (1.18 in) long

• Star and cranked styli up to 10 mm offset

Applications guide

Max: 20 mm

(0.79 in)

Max: 30 mm

Max: 20 mm (0.79 in)

Figure 8 - Recommended stylus limits for 6-way probe module

Page 25

Applications guide

Comparative stylus lengths

A comparison of the minimum and maximum stylus lengths for use

with each probe module is shown in figure 9.

LF

SF

MF

EF

6W

EM1 STD

EM2 STD

23

10 mm

(0.39 in)

Figure 9 - Comparative stylus lengths

50 mm

(1.97 in)

100 mm

(3.94 in)

Page 26

24

Product maintenance

6 Product maintenance

NOTE: Maintenance of the TP20 probe is restricted to the periodic

cleaning of the kinematic couplings of both the probe body and the

probe module(s). To aid cleaning of these couplings, each TP20 probe

is supplied with a Renishaw CK200 cleaning kit.

Each Renishaw CK200 cleaning kit contains a specialised material

to effectively remove contamination from the precision ball/V groove

seatings, electrical contacts and permanent magnets of the kinematic

couplings.

NOTE: When operating the TP20 probe in environments subjected

to airborne contamination, the user should determine the frequency

of cleaning required to ensure the kinematic couplings remains

uncontaminated.

Whilst the kinematic coupling mechanism is highly tolerant of nonmetallic dust, regular inspection and cleaning with the material

provided is recommended to ensure continued high performance.

Instructions for use are included with the cleaning kit. If required,

replacement kits can be ordered from your supplier (part number

A-1085-0016).

Probe modules that are not attached to the probe body should be

stored in their transport boxes, to prevent contamination.

Page 27

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

For worldwide contact details, please

www.renishaw.com/contact

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

visit our main website at

*H-1000-5131-01*

Loading...

Loading...