Page 1

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

SP80 ultra-high accuracy scanning

probe

Class leading performance with

flexible use of styli

The SP80 is a quill-mounted scanning probe that uses

digital scale and readhead technology, plus Renishaw’s

innovative isolated optical metrology principles, to provide

exceptional scanning performance, even with long styli.

The digital scale and readheads with 0.02 µm resolution

enable exceptional scanning performance with up to

1000 mm long and 500 g mass styli, including star

configurations.

The SP80 has a kinematic mount that offers a repeatable

connection to the mating plate mounted on the quill (KM80),

allowing the probe to be removed easily. Unbalanced star

configurations do not require counterbalancing and the

kinematic stylus changing allows for repeatable relocation

of the stylus, optimising stylus arrangements for each

feature, and overcoming the need for requalification.

Using an isolated optical metrology system that measures

the deflection of the whole mechanism, the SP80 provides

accurate position sensing without stacked axis errors.

Additionally, kinematic stylus holders provide crash

protection in the XY plane, and a bump stop prevents

damage to the probe in the Z-axis.

Key benefits

Long stylus carrying capability - with high accuracy

The combination of long stylus reach with maintained high accuracy

performance makes SP80 the first choice scanning probe for many

applications.

Rapid stylus interchange

Interchange of the stylus holders (SH80) can be automated for

optimised productivity by using a rack system and stylus change ports

(SCP80) mounted to Renishaw’s modular rack system.

Low cost of ownership

SP80’s system modularity enables expansion as required. Robust

design promotes long working life but should anything go wrong,

Renishaw’s rapid service / exchange program minimises downtime.

Horizontal mounting option - SP80H

A horizontal mounting option is also available.

Innovations

Isolated optical metrology

SP80 directly measures the deflection of

the whole mechanism, which provides

outstandingly accurate position sensing.

The isolated optical metrology system

can detect sources of variable error

such as thermal and dynamic effects.

By contrast, probes with displacement

sensors mounted to stacked axes suffer

from increased dynamic latency.

Page 2

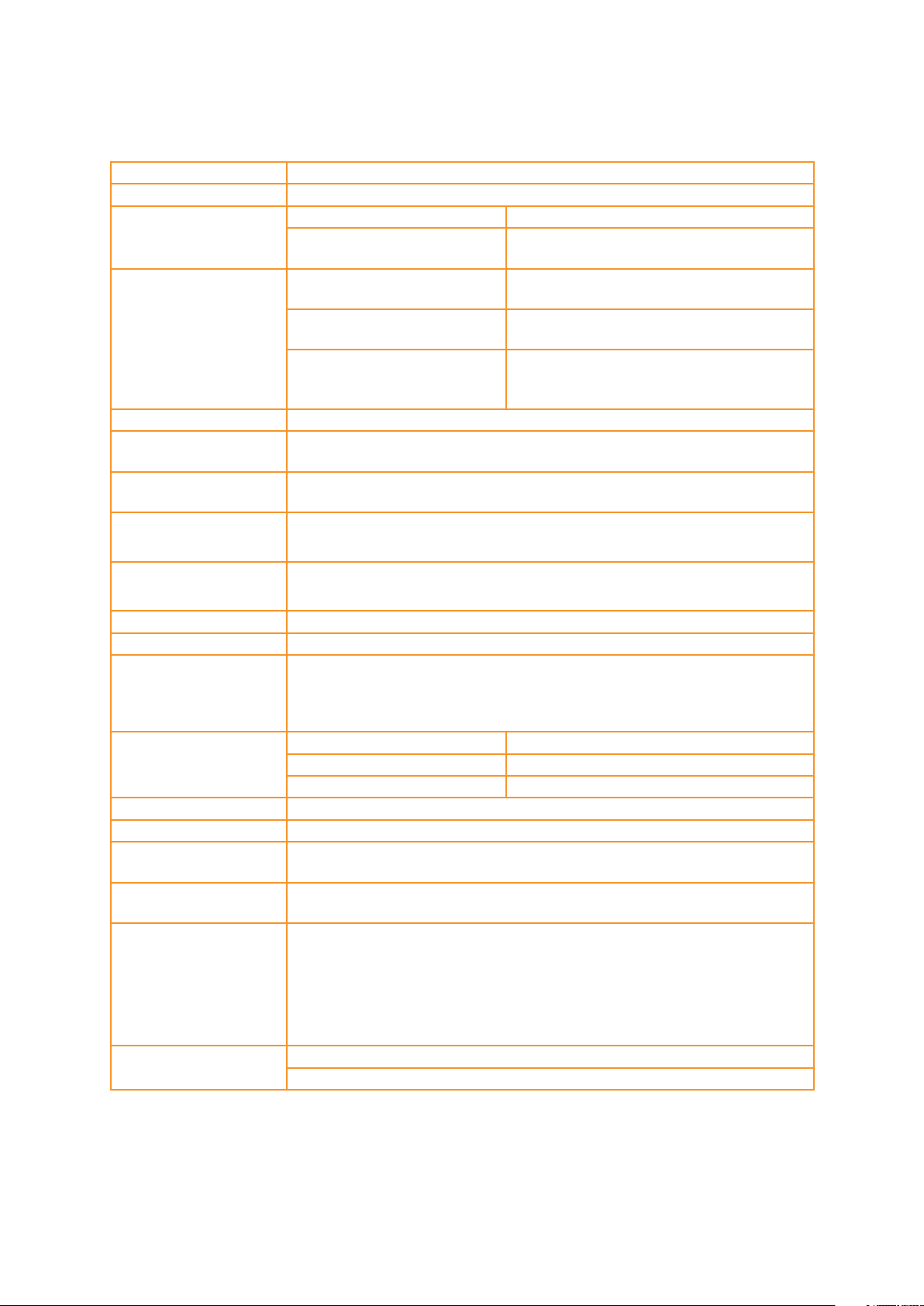

Specifications

Probe attributes

Orientation

Size

Quill mounting

Measurement range

Overtravel range

Resolution of digital

scales

Measurement capability

test to ISO10360-2 **

Scanning capability test

to ISO10360-4 **

Return to zero

Spring rate

Stylus carrying

capability

Ultra-high accuracy scanning probe with 3-axis measurement (±PX, ±PY, ±PZ) *

Vertical with SP80, horizontal with SP80H

Body 80 mm (3.15 in) square

Length (including SH80 stylus

holder)

KM80 80 mm (3.15 in) square quill to kinematic SP80

KM6080 60 mm (2.36 in) square quill to 80 mm (3.15 in)

SM80 Shank mount and other custom made adaptor

3-axis measurement: ±25 mm (±0.12 in) (PX, PY, PZ) *

PX* and PY* protected by breakout of the kinematic joint to the SH80 PZ* has a

mechanical ‘bump-stop’

0.02 µm

Better than 1.0 µm with a 50 mm stylus

Better than 2.0 µm with a 1000 mm stylus

Better than 0.5 µm with a 50 mm stylus

Better than 6.0 µm with a 1000 mm stylus

Approximately 1% of working deflection

Approximately 1.8 N/mm (X, Y, Z)

Renishaw M5 stylus range

Maximum 500 g mass (unbalanced)

150 mm (5.91 in)

quill mount (standard)

square kinematic SP80 probe mount (option)

plates available - contact your Renishaw supplier

for details

Maximum 1000 mm projection ***

Mass

Pull off force of SH80

Probe power supply

System power supply

(including IU80)

SP80 probe outputs (PX,

PY, PZ) *

Interfacing

options

Change rack system

* Where P specifies that it is the probe’s axis rather than the machine’s

** Tested on a CMM with specification of 0.48 µm +L/1000

*** SH80 EXT stylus holder must be used with 1000 mm stylus extensions

SP80 probe body only 860 g

SH80 stylus holder 185 g

KM80 quill mount 110 g

<20 N when using SCP80 - otherwise approximately 80 N

+9 V to +18 V at 300 mA maximum dc

+5 V ±0.25 V at 1 A maximum dc

1.5 V ±0.25 V p-p. analogue quadrature signal (nominal 2.5 V zero crossing

reference)

• Using a UCC2-2 SP80 daughtercard for direct integration

• Using a Renishaw PCI counter card (CC6) and the Renishaw interpolator unit

(IU80)

• Other interface cards designed by the OEM and using in conjunction with an IU80

• Using a counter card and interpolator units designed by the OEM

SCP80 units mounted to MRS or MRS2

SCP80V units mounted to MRS or MRS2 for rear facing styli

Page 3

SP80 performance

The plot below illustrates SP80’s remarkable high accuracy scanning performance with increasing stylus lengths.

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

ISO 10360-4 filtered data (µm)

1.0

0.5

0.00

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050

Stylus length (mm)

CMM specification: U = 0.48 µm ±L/1000

60 UPR harmonic filtering

Scan deflection = 0.5 mm

Scan speed = 5 mm/s (except on 1000 mm stylus

where scan speed = 2 mm/s)

Isolated optical metrology

Isolated optical metrology can be explained as a feature of the transducer system. The readheads for each axis are

fixed to the body of the probe, and measure the deflection in each direction. Any inter-axis movement caused by the

arc motion of each pair of parallel-acting springs is directly measured by the sensor system. The squareness and

straightness of the SP80’s axes are, therefore, not derived from the mechanism, but optically from the scale cube

itself. Direct measurement of the stylus motion relative to the static probe body removes the need for moving wire

connections which may impede motion

Electrical connection

Readheads

attached to

probe body

for readheads

‘Moving cube’

with scales

Light is reflected

from the moving

cube onto the

readhead

Shaded areas

indicate the moving

parts

Stylus mount

Page 4

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

In summary

SP80 and SP80H are the scanning probes of choice for automotive and power train sectors where high accuracy

form measurement with deep reach into components is required. The system’s flexibility and affordability is

acknowledged as being significant in terms of user benefits such as:

• Ultra-high accuracy measurement, provided by digital scale and readheads

• Long styli carrying capability for access to deep features

• Isolated optical metrology for direct accurate measurement of stylus deflection

• Kinematic stylus holder changing for system flexibility

• Low inertia mechanism for excellent dynamic response

• Bump stop crash protection in the Z-axis, together with a detachable stylus holder for XY crash protection

• No motors, resulting in excellent thermal stability and reliability

Additional information

Selected part numbers

NOTE: Please see www.renishaw.com/SP80 for further options.

A-2238-0700 SP80 probe kit

(includes probe body, SH80, KM80, PL157 probe cable and 60 mm × D8 stylus)

A-2238-0703 KM80 - standard quill mounting plate

A-2238-0705 SH80 - stylus holder

A-2238-0489 SH80 EXT - stylus holder

A-2238-0706 SCP80 - stylus change port

A-2238-0720 IU80 - interpolator unit

A-4068-0400 CC6 - PCI counter card

A-1333-0021 UCC1 / SP80 daughtercard

A-1016-7133 PL158 - IU80 to CC6 cable

A-1016-7129 PL156 - IU80 unterminated cable

© 2003 - 2014 Renishaw plc Renishaw reserves the right to change specifications without notice Printed in England 0914

US hybrid part no. H-1000-2125-01-B

Printed in England 0914 Part no. H-1000-2124-01-B

Loading...

Loading...