Page 1

1

Contents

Installation and operation manual

H-9942-9001-01-A

SLM 250 scanning laser module

For end users, installers,

integrators and engineers

Page 2

© 2016 Renishaw plc. All rights reserved.

This document may not be copied or reproduced

in whole or in part, or transferred to any other

media or language, by any means, without the

prior written permission of Renishaw plc.

The publication of material within this document

does not imply freedom from the patent rights of

Renishaw plc.

Renishaw part no: H-9942-9001-01-A

Issued:

10.2016

Trade marks

RENISHAW and the probe symbol used in the

RENISHAW logo are registered trade marks of

Renishaw plc in the United Kingdom and other

countries. apply innovation and names and

designations of other Renishaw products and

technologies are trade marks of Renishaw plc or

its subsidiaries.

All other brand names and product names used

in this document are trade names, trade marks,

or registered trade marks of their respective

owners.

Care of equipment

Renishaw’s SLM 250 and associated accessory

products are precision products and must

therefore be treated with care.

Changes to Renishaw products

Renishaw plc reserves the right to

improve, change or modify its products and

documentation without incurring any obligation

to make changes to equipment previously sold

or distributed.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF

THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO

WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER

ARISING, FOR ANY INACCURACIES IN THIS

DOCUMENT.

Safety

The SLM 250 is a high-performance distance

meter. It is essential that the unit and all

accessories are operated in accordance with the

instructions in this operation manual and it is the

responsibility of the user to ensure that, in the

event of a failure on any part of the Renishaw

system, the laser system remains safe.

In the case of laser systems with powers or

speeds capable of causing injury, it is essential

that appropriate safety protection measures

are included in the machine usage. Further

guidance can be found in the European

BS EN ISO 12100 : 2010 Safety of machinery –

General principles for design – Risk assessment

and risk reduction.

Information to the equipment

supplier/installer

It is the equipment supplier’s responsibility

to ensure that the user is made aware of any

hazards involved in any operations involving

the SLM 250, including those mentioned in

Renishaw product literature.

Page 3

Warranty

Renishaw plc warrants its equipment provided

that it is operated exactly as defined in

associated Renishaw documentation.

Laser safety

DO NOT STARE DIRECTLY

INTO THE BEAM

In accordance with BS EN 60825-1: 2007 and

US standards 21CFR 1040.10 and 1040.11,

except for deviations pursuant to Laser Notice

no. 50, dated June 24, 2007, the SLM 250 is

classified as a Class 1 invisible laser product.

Safety eyewear is not required for the SLM 250.

Do not stare into the beam or shine it into

the eyes of others. It is safe to view a diffusereflected beam. Do not dismantle the unit in any

way; doing so may expose laser radiation in

excess of Class 1 limits.

CAUTION – LASER LIGHT IS BRIGHT AND

BLINDING – DO NOT SHINE AT AIRCRAFT

OR VEHICLES AT ANY DISTANCE

Safety information

The following symbol is used in this manual

wherever important safety information is

present.

Before proceeding with any

electrical connection or

operation of the laser system,

refer to the general safety

information listed throughout

this manual.

DECLARATION OF CONFORMITY

The SLM 250 meets or exceeds the

requirements of the following British and

European Standards:

BS EN ISO 12100 : 2010 –

Safety of machinery – General principles for

design

BS EN 61326-1 : 2013 –

Electrical equipment for measurement, control

and laboratory use – EMC requirements

Part 1 – General requirements

The tests were carried out in compliance with:

Immunity to Table 2 – Industrial locations

Emissions to Class A – Industrial locations

BS EN 60825-1 : 2007 –

Safety of laser products – Part 1: Equipment

classification and requirements

The SLM 250 therefore complies with the

following European Directives:

2006/42/EC – Machinery

2004/108/EC – Electromagnetic compatibility

(EMC) of electrical equipment

2006/95/EC – Low voltage directive (LVD)

relating to electrical equipment designed for use

within certain voltage limits (codified version)

It is declared that the equipment named has

been designed to comply with the relevant

sections of the referenced specifications and

is in accordance with the requirements of the

Directives.

Page 4

FCC (USA only)

Information to the user (47CFR section

15.19)

This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful

interference, and

2. This device must accept any interference

received, including interference that may

cause undesired operation.

Information to user (47CFR section 15.21)

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc or authorised representative

could void the user’s authority to operate the

equipment.

Information to the user (47CFR section

15.105)

This equipment has been tested and found

to comply with the limits of a Class A digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference when

the equipment is operated in a commercial

environment. The equipment generates, uses

and can radiate radio frequency energy and,

if not installed and used in accordance with

the SLM 250 manual, may cause harmful

interference to radio communications.

c

EC declaration of conformity

Renishaw plc declares that the SLM 250

complies with the applicable standards and

regulations.

Renishaw plc hereby declares that the SLM 250

is in compliance with the essential requirements

and other relevant provisions of Directive

1999/5/EC.

Contact Renishaw plc or visit

www.renishaw.com for the full EC declaration of

conformity.

WEEE directive

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is

the responsibility of the end user to dispose

of this product at a designated collection point

for waste electrical and electronic equipment

(WEEE) to enable reuse or recycling. Correct

disposal of this product will help to save

valuable resources and prevent potential

negative effects on the environment. For more

information, please contact your local waste

disposal service or Renishaw distributor.

Page 5

i

Contents

Contents

1 General safety ..........................................................1-1

1.1 Operation and maintenance .........................................1-1

1.2 Warnings........................................................1-1

2 Customer information ....................................................2-1

2.1 Dear Customer ...................................................2-1

2.2 Manual .........................................................2-1

2.3 Product warranty..................................................2-2

3 Introduction ............................................................3-1

3.1 Applications......................................................3-2

4 Equipment description....................................................4-1

4.1 Precautions .....................................................4-2

4.2 Cables .........................................................4-2

4.2.1 Umbilical cable.............................................4-2

4.2.2 Low-voltage power connectors ................................4-3

4.2.3 Ethernet ..................................................4-3

4.3 Electrical .......................................................4-3

5 Laser safety............................................................5-1

5.1 SLM 250 ........................................................5-1

6 Operational guidelines....................................................6-1

6.1 System limitations ................................................6-1

Page 6

ii

Contents

SLM 250 installation and operation manual

7 Maintenance and care of the SLM 250 .......................................7-1

7.1 General ........................................................7-1

7.2 Preventative maintenance ..........................................7-1

7.2.1 In use ....................................................7-1

7.2.2 In storage ................................................7-2

7.2.3 In transportation ...........................................7-2

7.2.4 General ..................................................7-2

8 Network set-up..........................................................8-1

9 SLM 250 software .......................................................9-1

9.1 Installing the SLM 250 software ......................................9-1

10 Command list..........................................................10-1

11 Rotation speed and resolution.............................................11-1

12 Output formats.........................................................12-1

12.1 ASCII data format ................................................12-1

12.2 Binary data format................................................12-3

13 Beam and tilt angles ....................................................13-1

14 Specifications..........................................................14-1

15 Appendix A – Mechanical drawings.........................................15-1

16 Appendix B – Electrical connections ........................................16-1

Page 7

1-1

General safety

1 General safety

CAUTION: Before unpacking and installing the SLM 250, read the safety instructions below

carefully and ensure that they are followed at all times by all operators. Failure to do so could

adversely affect the performance of the SLM 250 and/or lead to personal injury. Operators must

be trained in the use and application of the SLM 250 and accompanying accessories before being

allowed to operate the equipment.

1.1 Operation and maintenance

Following the simple maintenance procedures below will prolong the operational life and continued

high performance of the system. The user should determine the frequency of inspection and

maintenance actions according to the conditions of use.

• The product should only be connected to using the approved connector type and wiring as

prescribed in section 4.2, “Cables”.

• Changing the SLM 250 port and IP addresses must be carried out using only the SLM 250

software application by appropriately trained personnel.

• Disconnect power before performing any maintenance operations.

• Maintenance is restricted to procedures described in section 7, “Maintenance and care of the

SLM 250”.

1.2 Warnings

• Beware of unexpected movement. The user(s) must remain outside the full working envelope of

the SLM 250 whilst in operation.

• It is the machine supplier’s responsibility to ensure that the user is made aware of any hazards

involved in operation, including those mentioned in Renishaw product documentation.

• The SLM 250 must be transported in Renishaw supplied packaging.

• This equipment is not suitable for use in a potentially explosive atmosphere.

Page 8

SLM 250 installation and operation manual

1-2

General safety

This page is intentionally left blank.

Page 9

2-1

Customer

information

2 Customer information

2.1 Dear Customer

We congratulate you on the purchase of an SLM 250. You are now the owner of a high quality laser

measurement device. However, we would ask you to take the time to work carefully through these

operating instructions before using the instrument and to keep the manual with the instrument at all

times.

If your system requires servicing or calibration, or if there are questions arising beyond the scope of

this manual, contact Renishaw’s Service and Support Centre. Contact details are on the back page

of this manual.

Alternatively, for information on your local Renishaw approved service centre, visit our website at

www.renishaw.com

For best service, please make a note of the serial number, which can be found on the instrument.

2.2 Manual

It is important that you read this manual carefully before using the instrument.

This manual gives a full description of the hardware components of the SLM

250.

Further information can be found in the Quick-start Guide which is part of the SLM 250 software

application (see section 9.1, “Installing the SLM 250 software”).

This manual has been compiled with care. However, should you discover any errors we would

be grateful if you could contact Renishaw directly. Reproduction in whole or in part, including

utilisation in machines capable of reproduction or retrieval, without the express written permission

of Renishaw plc, is prohibited. Reverse engineering is also prohibited. The information in this

document is subject to change without notice.

Page 10

SLM 250 installation and operation manual

2-2

Customer

information

2.3 Product warranty

Unless otherwise specified, Renishaw plc warrants the equipment for a period of twelve months

from the date of delivery. This warranty is given subject to the following conditions:

• Renishaw plc shall be under no liability in respect of any defects in the equipment arising from

any drawing, design or specification supplied or modification requested by the customer.

• Renishaw plc shall be under no liability in respect of defects arising from, wilful damage,

negligence, abnormal working conditions, failure to follow Renishaw’s instructions (whether oral

or in writing), misuse or alteration or repair of the equipment without Renishaw’s approval.

• Software is not covered by this warranty.

• Claims in respect of defective equipment must be intimated by notice in writing to Renishaw

plc and the equipment must be retained by the customer pending written instructions from

Renishaw.

• Following authorised return of the equipment, which must be made by the customer on freight

prepaid basis, Renishaw will examine the equipment and, if the claim is justified in Renishaw’s

opinion, will repair the defective equipment or will make replacement without charge. Renishaw

will have no further liability to the customer.

Page 11

3-1

Introduction

3 Introduction

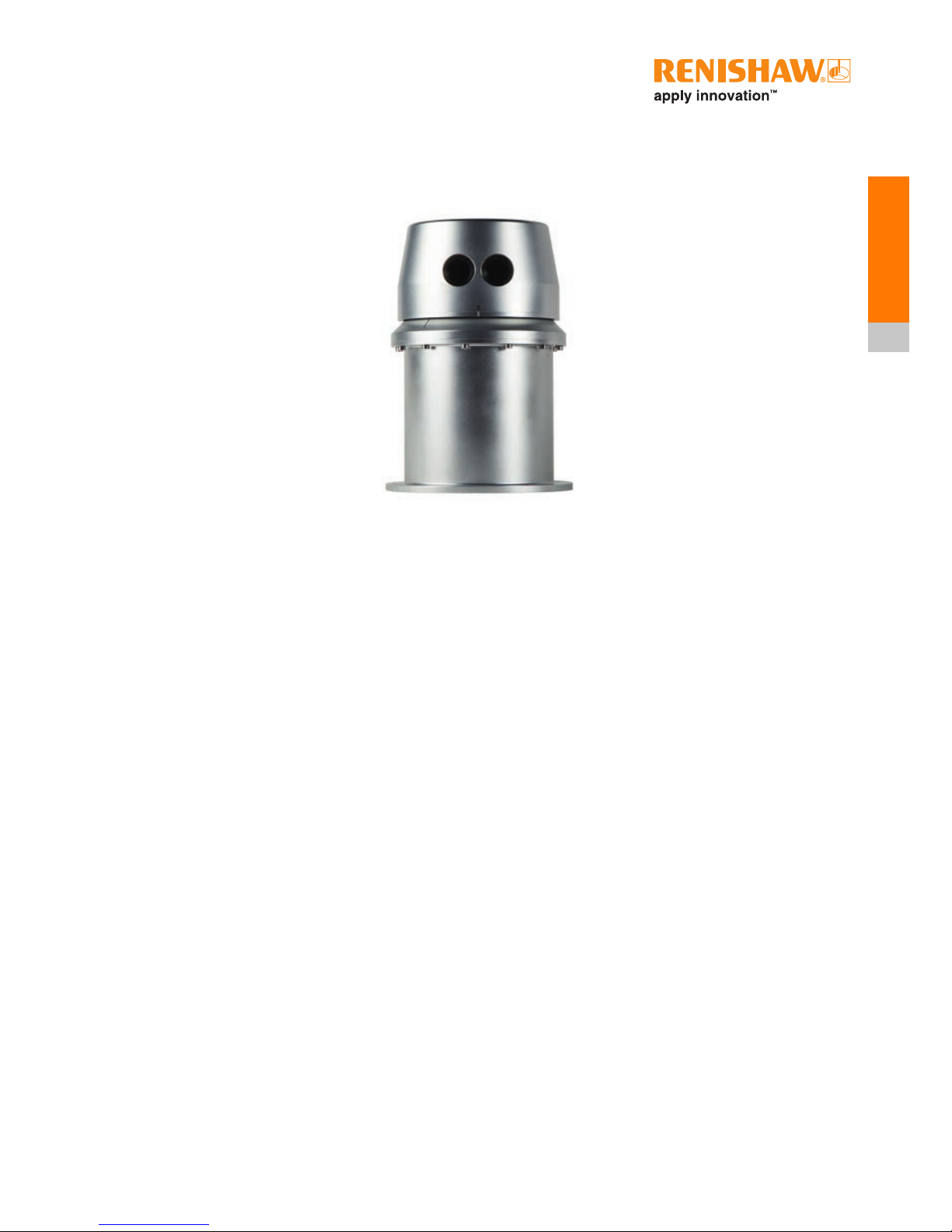

The SLM 250 is a ruggedised field instrument designed to produce fast, efficient 2D laser scans of

the surrounding vicinity.

It is designed to be used as a multi-purpose scanning distance meter that is integrated into other

equipment for a variety of applications.

The module employs the “time of flight” measurement technique to calculate the distance to the

target. Up to 36,000 such measurements can be made every second up to a range of 250 metres

(standard Renishaw test conditions).

The SLM 250 is just one of many laser systems that have been designed by Renishaw. Other

products – such as the Quarryman, Boretrak, C-ALS (Cavity Auto-scanning Laser System), Void

Scanner and Dynascan – have all been proved over many years of demanding use around the

world. These products complement the SLM portfolio and provide a wide range of advanced

measurement solutions to industries including mapping, mining and quarrying, traffic, offshore and

manufacturing.

Figure 1: SLM 250

Page 12

SLM 250 installation and operation manual

3-2

Introduction

3.1 Applications

This unique instrument is suitable for a large number of surveying and measuring functions, such

as:

• security

• quarrying and mining

• coastal mapping

• topographical surveys

• highway infrastructure surveys

• vehicle/vessel positioning.

Page 13

Figure 2: SLM 250 component parts

Laser module with

transmitting and

receiving optics

Aluminium housing

Rotation point

Power and data

interface

4-1

Equipment

description

4 Equipment description

The SLM 250 incorporates an embedded infrared laser module, a motor to spin the laser, encoders

to measure the rotation angle, the connector to provide power and data communications with the

unit, and the electronic circuitry that allows measurements to be taken at ranges up to 250 metres

from the instrument.

The two windows on the laser module protect the transmitting and receiving optics. It is through

these windows that the infrared measuring laser is fired and then received back into the instrument.

It can fire at up to 36,000 times per second.

The laser can range up to 250 metres. The actual range in any given project will depend on a

number of factors, such as atmospheric and environmental conditions, and the reflectivity of the

surface being targeted.

The laser is housed in an aluminium casing. This ensures that the SLM 250 is highly ruggedised

and may be used in demanding environments.

The flange at the bottom of the SLM 250 allows it to be mounted onto a stable surface (see section

15, “Appendix A – Mechanical drawings”). Its construction means it can be mounted vertically or

horizontally, with no loss of performance.

Page 14

SLM 250 installation and operation manual

4-2

Equipment

description

4.1 Precautions

• Avoid directing the laser apertures towards the sun or other high-powered, infrared light

sources.

• Avoid mechanical shock.

The laser is driven by a motor. When the unit is stationary the laser can be rotated by hand without

causing damage to the motor. If the laser is prevented from rotating by an obstruction, the motor

power will initially be increased to try to maintain the rotation speed but will then detect a stall

condition and the drive will be removed, preventing damage to the motor.

Caution: If the obstruction is removed before a stall is detected the rotation speed may

momentarily be in excess of what it should be.

It is advised to minimise any manual movement of the laser and to keep the instrument away from

potential obstructions so the motor may turn freely.

WARNING: Users should not manually or otherwise obstruct the operation of the

motor or allow clothing to come into contact with the device, to avoid entrapment

in the unit.

4.2 Cables

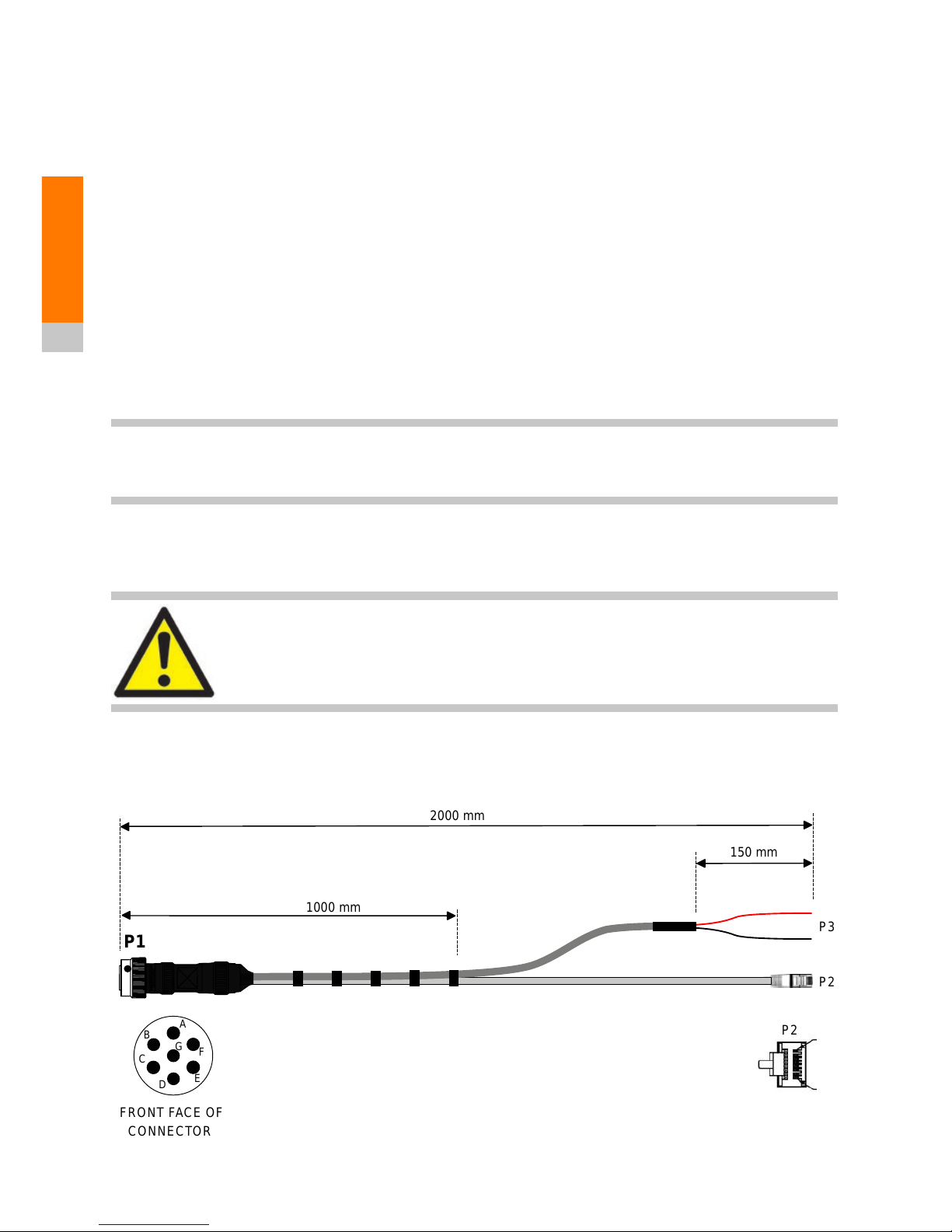

4.2.1 Umbilical cable

Figure 3: Umbilical cable

2000 mm

8

P2

P1

P2

P3

1000 mm

150 mm

8

8

1

2000 mm

P2

P1

P2

P3

1000 mm

150 mm

Wire Schedule

A

BCD

EFG

FRONT FACE OF

CONNECTOR

8

P2

8

8

1

Page 15

4-3

Equipment

description

The umbilical cable is 2 m in length and provides connection for power and Ethernet. Connection

to the SLM is by means of a Mil-Spec MIL-DTL-26482 Series 1 Plug (Renishaw recommends the

use of Weald LMH06T10.07SN.101). For further details of this cable see section 16, “Appendix B –

Electrical connections”.

4.2.2 Low-voltage power connectors

The 4 mm connector plugs are for connection to a low-voltage dc power supply of voltage range

11 Vdc to 16 Vdc.

For cable pin-outs, see section 16, “Appendix B – Electrical connections”.

4.2.3 Ethernet

The Ethernet connector (standard RJ45) allows for connection to a PC/laptop so that

communication to the SLM 250 can be established.

4.3 Electrical

WARNINGS:

• The SLM 250 has no user-serviceable parts. In the event of a problem, please

contact Renishaw’s Service and Support Centre.

• Do not attempt to open the instrument.

• Always isolate the low-voltage dc source before the instrument is removed

(uninstalled) and/or replaced (installed).

• Appropriate visual inspection and electrical safety testing is to be performed

after instrument installation or replacement.

It is recommended that the SLM 250 is powered from an external 14 Vdc source with a minimum

power capability of 100 W.

Note: The SLM motor start-up peak current will be higher than its steady running current,

especially when at the low end of its operating temperature range.

Page 16

SLM 250 installation and operation manual

4-4

Equipment

description

This page is intentionally left blank.

Page 17

5-1

Laser safety

5 Laser safety

The SLM 250 is supplied with one embedded laser module. See below for eye safety classification

and recommendations.

Laser safety

DO NOT STARE DIRECTLY INTO THE BEAM

In accordance with BS EN 60825-1 : 2007 and US standards 21CFR 1040.10 and 1040.11, except

for deviations pursuant to Laser Notice no. 50, dated June 24, 2007, the SLM 250 is classified as a

Class 1 invisible laser product. Safety eyewear is not required for the SLM 250. Do not stare into the

beam or shine it into the eyes of others. It is safe to view a diffuse-reflected beam. Do not dismantle

the unit in any way; doing so may expose laser radiation in excess of Class 1 limits.

5.1 SLM 250

The SLM 250 is classified as a Class 1 laser product with reference to the international standard

BS EN 60825-1 : 2007 Safety of Laser Products. As a Class 1 product, such devices require no

engineering controls beyond requiring the use of tools to open the housing. No laser labelling is

required to be located upon the external structure of these devices. However, the following label is

located upon the external body of the product. It is clearly visible and readable to the user whether

the device is in operation or not.

WARNINGS:

• Invisible laser radiation. Do not stare into the radiated emitted beam.

• Use of controls or adjustments or performance of procedures other than those specified herein

may result in hazardous radiation exposures.

Page 18

SLM 250 installation and operation manual

5-2

Laser safety

WARNING: Opening the protective housing may result in exposure to Class 3B radiation.

This caution label is positioned inside the outer housing on the cover of the laser module emitter

mount. It is therefore only visible by qualified maintenance engineers prior to, and after, access to

the laser emitter.

Only qualified and trained persons should be assigned to operate the SLM 250.

When not in use, the device should be stored in a location where unauthorised personnel cannot

gain access.

CAUTION – LASER LIGHT IS BRIGHT AND BLINDING – DO NOT SHINE AT AIRCRAFT OR

VEHICLES AT ANY DISTANCE

Aligning the SLM 250 with the lenses of CCD-cameras or infrared night vision devices may result in

damage to such devices and is therefore not permitted.

The SLM 250 is intended for use in a locale where the emitted radiation is unlikely to be viewed

with optical instruments.

The SLM 250 is both naked eye safe and eye safe with the use of optical instruments such as

telescopes or binoculars. Nevertheless, Renishaw plc recommends that the SLM 250 is not directly

pointed at persons’ eyes, nor viewed with optical instruments.

CAUTION – DO NOT UNNECESSARILY LOOK INTO THE WINDOWS OF THE SLM 250

Page 19

6-1

Operational

guidelines

6 Operational guidelines

Only qualified and trained persons should be assigned to operate the SLM 250.

The SLM 250 is for range measurements to passive targets. The use of highly reflective targets,

such as survey prisms or cube-corners, must be avoided.

The range information is transmitted via Ethernet using UDP messages.

6.1 System limitations

The SLM 250 is designed to meet IP66 and should not be used in situations that require a higher

level of ingress protection.

The SLM 250 is capable of measuring ranges up to 250 metres to 90% reflective material (e.g.,

Kodak white card). However, the maximum achievable range will depend on a number of factors. In

some circumstances these may prevent any readings from being taken:

• dark, light-absorbent surfaces such as coal

• atmospheric conditions such as dust, fog, heavy rain and snow

• wet, slick, shiny or very smooth surfaces

• an acute angle between the laser and the surface.

The minimum, calibrated range of the laser is 10

m. At shorter distances, readings may still be

recorded, but their accuracy may be diminished.

Where possible, avoid pointing the laser directly into the sun. This could lead to spurious points

being collected.

Page 20

SLM 250 installation and operation manual

6-2

Operational

guidelines

This page is intentionally left blank.

Page 21

7-1

Maintenance

and care

7 Maintenance and care of the SLM 250

7.1 General

Any attempt to dismantle or repair the SLM 250 by unauthorised personnel can be hazardous and

costly. Maintenance carried out by the operator should be restricted to the cleaning and inspection

of external surfaces, lenses and operating controls.

7.2 Preventative maintenance

Preventative maintenance should include the following.

7.2.1 In use

• Avoid directing the laser towards the sun or other high-powered, infrared light sources.

• Avoid mechanical shock.

• Clean and dry the equipment before and after use. Use dedicated lens-cleaning wipes to clean

the windows on the SLM 250.

• Do not use paint solvents to clean the outer structure of the instrument. Use a mild detergent

to clean the outer structure. Use HPLC-grade isopropyl alcohol (propan-2-ol) solution, applied

with a lint-free cloth, to clean the laser module windows.

CAUTION: Repeated exposure to HPLC-grade isopropyl alcohol (propan-2-ol) or mild

detergent may cause skin dryness or cracking. It is recommended that personal protective

equipment (PPE) is used when dispensing and using these cleaning fluids, such as eyewear

and/or face shields, and protective gloves.

• Carry out regular functional testing of the SLM 250.

WARNING: The unit is driven by a motor. If the motor is rotated by hand or

prevented from moving by an obstruction, the motor will not be damaged.

It

is advised to minimise any manual movement of the laser and to keep the

instrument away from potential obstructions so the motor may turn freely.

Nevertheless, the possibility of finger or clothing entrapment exists! Users

should not obstruct the operation of the motor or allow clothing to come into

contact with the device.

Page 22

SLM 250 installation and operation manual

7-2

Maintenance

and care

7.2.2 In storage

• Dry the SLM 250 thoroughly before storing.

• If the module remains unused for several weeks, it is advisable to disconnect any power

sources.

• Store within the environmental temperature limits of −25°C to +70°C.

• When not in use, the module should be stored in a location where unauthorised personnel

cannot gain access.

7.2.3 In transportation

The SLM 250 is supplied in dedicated packaging for delivery to the customer, and consideration

should be given as to how to ship the unit once incorporated into a system. Do not allow the

module to slide around inside transport vehicles or containers.

7.2.4 General

Carry out regular functional testing of the system. Detect and report damage, malfunctions and

poor performance to a Renishaw-approved service centre.

It is advised to arrange an annual service and calibration. Contact a Renishaw approved service

centre for details.

CAUTIONS:

• Unauthorised attempts to carry out maintenance work on the equipment will void all warranty

cover.

• Any faults, malfunctions or poor performance that are detected in the system should be

reported to a Renishaw approved service centre.

Page 23

8-1

Network set-up

8 Network set-up

The method used to communicate with the SLM 250 is through an Ethernet connection with a

PC/laptop. The correct Ethernet parameters need to be established, namely IP (“Internet Protocol”)

address and subnet mask.

Notes:

• These instructions assume a Microsoft Windows 7 operating system. The SLM 250 software

application is also compatible with Windows 8 and 10.

• Further information can be found in the Quick-start Guide which is part of the supplied software

(see section 9, “SLM 250 software”).

Each SLM 250 is delivered with a pre-set IP address, typically 128.2.0.201, which can be found on

a label on the base of the instrument.

For first-time installation, communication needs to be correctly established between the PC/laptop

and SLM 250. This requires the PC/laptop to have an IP address on the same subnet as the

SLM 250.

To enter the IP address and subnet values, follow these steps.

1. To open Network Connections click Start, and then click Control Panel. In the search box,

type “adapter”. Under Network and Sharing Centre, click View network connections.

2. Right-click the network connection to be used with SLM 250, then click Properties. If

prompted for an administrator password or confirmation, enter these.

Page 24

8-2

SLM 250 installation and operation manual

8-2

Network set-up

3. Click the Networking tab. In the section This connection uses the following items, click

Internet Protocol Version 4 (TCP/IPv4) and then click Properties (see Figure 4).

Figure 4: Local area connection properties

Page 25

8-3

Network set-up

4. To specify an IP address, click Use the following IP address, and then enter the IP address

and Subnet mask settings (see Figure 5).

Connection to a PC/laptop requires the computer to have a similar fixed IP address.

Enter the IP address of the PC/laptop in the section Use the following IP address. The IP

address entered should be the same as that of the SLM 250 – except for the last three digits,

which need to be a different number between 1 and 254. This must exclude the IP addresses

currently in use for the SLM 250 unit and other equipment on that subnet.

Click OK.

Note: It is important that both the IP address and subnet mask are entered correctly. Any

deviation from this will result in the PC/laptop and SLM 250 not communicating with each

other.

Figure 5: IP address settings

Page 26

SLM 250 installation and operation manual

8-4

Network set-up

This page is intentionally left blank.

Page 27

9-1

Network set-up

9-1

Software set-up

9 SLM 250 software

9.1 Installing the SLM 250 software

The SLM 250 software allows the user to set up and configure the module. It is loaded on the USB

stick supplied with the instrument. This simple application enables the user to:

• quickly and easily prove the operation of the SLM 250

• check the settings of the module and, if required, alter these to suit the application.

As the SLM 250 is an OEM product that will be integrated into other equipment the user will control

the SLM 250 from within their own software package. The SLM 250 software is intended to help the

integration process.

To launch the software double-click the set-up icon

.

Read through the licence agreement, and if in agreement click I Agree.

Figure 6: Licence agreement

Page 28

SLM 250 installation and operation manual

9-2

Network set-up

9-2

Software set-up

Choose a destination folder for the installation and click Install. The software will now be installed.

To run the program, double-click the SLM250 icon.

For further information on how to use the software click Quick Start.

Figure 7: Choose the install location

Figure 8: SLM250 icon

Figure 9: Quick Start button

Page 29

10-1

Command list

10 Command list

The list of commands in this section will assist in the development of customer software to control

the SLM 250.

A simple, ASCII character-based command/response structure is implemented over Ethernet using

UDP packets.

Commands are either a single command terminated with an ASCII line feed <lf> character (0x0A)

or a single command with associated data, which is again terminated with an ASCII line feed

character.

A UDP-enabled terminal program, such as the Hercules SETUP utility developed by the HW Group,

can be used to communicate directly with the SLM 250 to help software development.

Page 30

SLM 250 installation and operation manual

10-2

Command list

Command

description

Command SLM response

(binary data

mode)

SLM response

(ASCII data

mode)

Response

received if

‘REPLOFF’

Volatile?* Notes

Toggle on or

off the output

of replies to the

commands

H<lf>

∗

REPLON<lf>

REPLIES ON<lf> NO YES

Return device ID

string

?<lf>

∗

MDA072<lf>

MDA072C<lf> YES N/A

Return angle

offset summary

]<lf> See section 13, “Beam and tilt angles” YES N/A

Any characters

typed after “]” may

affect calibration

data

Activate laser A<lf>

∗

Laseron<lf>

Laser on<lf> NO YES

Will only operate

when the laser is

rotating

Disable laser, the

default power-up

mode

B<lf>

∗

lasoff<lf>

Laser off<lf> NO YES

Return current

laser angle

C<lf>

∗

Axxxxx<lf>

Angle - xxxxx<lf> YES N/A

Set maximum

angular

resolution

FH<lf>

∗

Hundr<lf>

1/100th

selected<lf>

NO YES

FT<lf>

∗

Tenth<lf>

1/10th

selected<lf>

Continued

Page 31

10-3

Command list

Command

description

Command SLM response

(binary data

mode)

SLM response

(ASCII data

mode)

Response

received if

‘REPLOFF’

Volatile?* Notes

Get current

range and signal

strength

G<lf>

∗

Rxxxxx<lf>

∗

Sxxxxx<lf>

Range=

xxxxx<lf>

Sigstren=

xxxxx<lf>

YES N/A

Set laser head

rotation speed

(where xx is a

value of 1 Hz to

20 Hz)

Ixx<lf>

∗

D000xx<lf>

Speed set to

xx<lf>

NO YES

Output firmware

revision number

and date

J<lf> Vx.xx -MMM DD YYYY HH:mm:SS YES N/A

Month (MMM); day

(DD); year (YYYY);

hour (HH); minute

(mm); second (SS)

Display origin O<lf>

∗

Oxxxxx

Origin = xxxxx

YES

N/A

xxxxx = 0-35999

Set current angle

as origin

OW<lf>

∗

Oxxxxx

Origin = xxxxx NO

Set origin in

deg/100

O,xxxxx

∗

Oxxxxx

Origin = xxxxx NO

Start

laser

rotation

S<lf>

∗

STARTD<lf>

Scan started<lf> NO YES

Stop

laser

rotation

T<lf>

∗

STOPED<lf>

Scan

stopped<lf>

NO YES

Continued

Page 32

SLM 250 installation and operation manual

10-4

Command list

Command

description

Command SLM response

(binary data

mode)

SLM response

(ASCII data

mode)

Response

received if

‘REPLOFF’

Volatile?* Notes

Get network

settings

V<lf> Returns all the network settings YES N/A

Set IP address

VADDR,xxx.xxx.xxx.xxx<lf>

IP address entered xxx.xxx.xxx.xxx YES NO

Set subnet mask

VMASK,xxx.xxx.xxx.xxx<lf>

Mask entered xxx.xxx.xxx.xxx YES NO

Set FIFO buffer

size

VFIFO,xxxxxx<lf>

Accepted – xxxxxx YES NO

Set default

gateway

VGATEWAY,xxx.xxx.xxx.

xxx<lf>

Default gateway entered

xxx.xxx.xxx.xxx

IP port set to xxxxx

YES NO

Set IP port

VPORT,xxxxx<lf>

YES NO

Transmit ASCII

data

W<lf> N/A

ASCII OUTPUT

ENABLED

NO YES

Transmit binary

data

X<lf>

∗

BINARY

N/A NO YES

Continued

Page 33

10-5

Command list

Command

description

Command SLM response

(binary data

mode)

SLM response

(ASCII data

mode)

Response

received if

‘REPLOFF’

Volatile?* Notes

Get system

status

Y<lf>

∗

FLGSxxxxxxx ∗ Axxxxx ∗ WRDxxx ∗ Binary

FIFO empty

Enable high

Zero found

Red dot off

1/10th. On

Not at eyesafe

speed

Motor not at

correct speed

Angle – XXXXX

Words left = XXX

ASCII mode

YES N/A

ASCII SLM

Response shown as

an example of the

output.

* Volatile – does not retain data when electrical power is turned off or fails.

Table 1: Command list

Page 34

SLM 250 installation and operation manual

10-6

Command list

This page is intentionally left blank.

Page 35

11-1

Rotation speed

and resolution

11 Rotation speed and resolution

The SLM 250 rotation speed can be varied from 1 Hz to 20 Hz, but the maximum firing frequency of

the laser is 36 kHz and as such the resolution is altered by different rotation speeds.

Table 2 shows how the laser firing frequency and data rates differ for different laser rotation speeds.

Setting the resolution mode to 1/100 gives the maximum possible resolution of 0.01° while the

SLM

250 rotates at 1 Hz. As the speed is increased the angular resolution will reduce to maintain

the maximum laser firing rate of 36 kHz.

Setting the resolution mode to 1/10 limits the maximum resolution to 0.1° for SLM 250 rotational

speeds up to 10 Hz. Above 10 Hz, the angular resolution will reduce to 0.2° to maintain the

maximum laser firing rate of 36 kHz.

1/100 mode 1/10 mode

Speed (Hz) Laser firing rate

(Hz)

Angular

resolution (°)

Laser firing rate

(Hz)

Angular

resolution (°)

1 36000 0.01 3600 0.10

2 36000 0.02 7200 0.10

5 36000 0.05 18000 0.10

10 36000 0.10 36000 0.10

15 36000 0.15 36000 0.15

20 36000 0.20 36000 0.20

Table 2: Laser firing frequency and data rates

Page 36

SLM 250 installation and operation manual

11-2

Rotation speed

and resolution

This page is intentionally left blank.

Page 37

12-1

Output formats

12 Output formats

Binary data format is recommended for normal operation of the SLM 250 as it is more efficient in

passing large amounts of data. ASCII would most likely be used only for initial testing of the system

as it can be easily displayed on terminal programs.

Care should be taken when sending multiple H commands to ensure replies are toggled to the

required state.

12.1 ASCII data format

The following command sequence outlines the start-up procedure after system power-up for

configuring the SLM 250 to transmit data in ASCII format.

Table 3: Commands for transmitting ASCII data

Command Description SLM response

H Toggle on or off the output of replies to the

commands

∗

REPLON

W Set data format to ASCII ASCII OUTPUT ENABLED

I10

Set laser rotation speed (in this case 10 Hz) Speed set to 10

A Enable laser Laser on

FH Set resolution mode to 1/100° 1/100th selected

FT Set resolution mode to 1/10° 1/10th selected

S Start scanner Scan started

Page 38

SLM 250 installation and operation manual

12-2

Output formats

ASCII UDP stream format:

$RRRRR,SSSS,GGGGG<cr><lf>$RRRRR,SSSS,GGGGG<cr><lf>…

Where:

Scanning can be stopped with the command:

The factory default number of frames (range, signal strength and angle data) contained in each

UDP packet for this mode is 77, calculated as:

Table 5: ASCII command to stop scanning

Command Description SLM response (ASCII mode)

T Stop scan Scan stopped

1450 (packet size)

= 77 (rounded up)

19 (frame size)

Table 4: ASCII symbols

Symbol Description Number of bits

$

Data header character (0x24) 8

RRRRR

Represents range 40

SSSS

Represents signal strength 32

GGGGG

Represents the angle in one-hundredths of a

degree

40

<lf>

Line feed character (0x0A) 8

<cr>

Carriage return character (0x0D) 8

Page 39

12-3

Output formats

12.2 Binary data format

The following command sequence outlines the start-up procedure after system power-up for

configuring the SLM 250 to transmit binary format.

Care should be taken when sending multiple H commands to ensure replies are toggled to the

required state.

The binary UDP data stream format:

$RRSSGG<lf>$RRSSGG<lf>…

Where:

Table 6: Commands for transmitting binary data

Table 7: Binary symbols

Symbol Description Number of bits

$

Data header character (0x24) 8

RR

Represents range 16

SS

Represents signal strength 16

GG

Represents the angle in one-hundredths of a

degree

16

<lf>

Line feed character (0x0A) 8

Command Description SLM response

H Toggle on or off the output of replies to the

commands

REPLIES ON

X Set data format to binary

∗

BINARY

I10 Set laser rotation speed (in this case 10 Hz)

∗

D00010

A Enable laser

∗

Laseron

FH Set resolution mode to 1/100°

∗

Hundr

FT Set resolution mode to 1/10°

∗

Tenth

S Start scanner

∗

STARTD

Page 40

SLM 250 installation and operation manual

12-4

Output formats

Scanning can be stopped with the command:

The factory default number of frames (range, signal strength and angle data) contained in each

UDP packet for this mode is 19, calculated as:

Table 8: Binary command to stop scanning

Command Description SLM response (binary mode)

T Stop scan

∗

STOPED

148 (packet size)

= 19 (rounded up)

8 (frame size)

Page 41

13-1

Beam and

tilt angles

13 Beam and tilt angles

In theory, the laser beam is designed to project perpendicular to the centre line of the laser housing

in both the X and Y directions; range is measured in the Z direction.

In practice, there are potential misalignments in both X and Y directions which are referred to as the

“beam angle” and “tilt angle” respectively. These angles are measured and stored in the SLM 250

as part of the factory calibration process. They can be accessed using the commands in Table 9.

+X

+X

+Z

−X

−Y

−Y

+Y

+Y

Figure 10: X, Y and Z projections of the laser beam

Command Description SLM response (ASCII mode)

] Display beam and tilt angles System offset summary:

0: Laser 1 beam X offset = +000.123°

1: Laser 1 beam Y offset = −000.456°

2: Laser 2 beam X offset = +000.000

3: Laser 2 beam Y offset = +000.000

4: System pitch offset = +000.000

5: System roll offset = +000.000

6: System yaw offset = +000.000

Table 9: Commands to access the beam and tilt angles

(Note: Only values “0” and “1” contain relevant calibrated data

Page 42

SLM 250 installation and operation manual

13-2

Beam and

tilt angles

This page is intentionally left blank.

Page 43

14-1

Rotation speed

and resolution

14-1

Specifications

14 Specifications

Information contained here is believed to be accurate. However, no responsibility is assumed by

Renishaw for its use. Technical information is subject to change without notice.

SLM 250

Type InGaAs laser diode

Wavelength (typical)

905 nm (peak)

Minimum measurement range 0.5 m

Maximum measurement range

1

>250 m

Accuracy

1, 2, 3

±30 mm (between 10 m and 75 m)

±40 mm (between 75 m and 150 m)

±60 mm (between 150 m and 250 m)

Precision

1, 3, 4

10 mm (between 10 m and 75 m)

15 mm (between 75 m and 150 m)

30 mm (between 150 m and 250 m)

Laser resolution 1 cm

Laser pulse repetition rate Maximum 36 kHz

Laser beam divergence 2.25 × 1.5 mrads

Laser beam footprint (FWHM) 28 × 17.4 mm @ exit aperture

Scanner field of view 360°

Scanner angular resolution Up to 0.01°

Scan rate

Up to 20 Hz

1

Where target is larger than the laser footprint of the laser beam, with perpendicular angle

of incidence and measured under Renishaw calibration conditions to Kodak white card (90%

reflectivity).

2

Accuracy is defined as the degree of conformity of the measured sample mean range to its

actual (real) value, measured with reference to a total station under Renishaw test conditions.

3

Predicted accuracy and precision figures extrapolated from 10 m to 150 m.

4

Precision is defined as the repeatability, or reproducibility, to which the reported value recurs

upon subsequent measurement, 1 σ throughout measurement range.

Page 44

SLM 250 installation and operation manual

14-2

Rotation speed

and resolution

14-2

Specifications

Physical data

Power 11 Vdc to 16 Vdc 80 W (running)

Peak power up to 100 W

Weight 4.8 kg

Dimensions (L × W × H) 170 mm × 170 mm × 241.2 mm

Environmental

Operating temperature −10° C to +50° C

Storage temperature −25° C to +70° C

IP degree of protection

5

Designed to meet IP66

Tests and approvals

CE conformity DoC available

Safety of laser products (Class 1) BS EN 60825-1: 2007 and US

standards (21 CFR 1040.10 and

1040.11 except for deviations

pursuant to Laser No. 50, dated 24

June 2007)

FCC compliance CFR47 Part 15.19, 15.21, 15.105

Safety of machinery BS EN ISO 12100: 2010

5

Environmental compatibility requirements of EN 60529 : 1992+A1 : 2002.

Page 45

15-1

Appendix A –

Drawings

15 Appendix A – Mechanical drawings

ISOMETRIC VIEW

Designer D stockill

Date 26/01/2015

Drawn By T Carter

Date 19/02/2015

Sheet 1 of 1

Title: SLM S

250 Standalone TTO

Part No:

Mod Level:02

Document N

o: N-5917-8020

N

-5917-8020

Project: 591

7

All Dimensions are in mm.

SCALE: NTS

Issue Level:A

241.2

38.5

130.0

153.5

136.0

194.9

17.0

29.02x

155.0 PCD

6off located every 60°

on PCD

30.00°

5/8-11 UNC HeliCoil - 3B 20.00

6.0

68.00

10.0°

6.2

170.0

Page 46

SLM 250 installation and operation manual

15-2

Appendix A –

Drawings

This page is intentionally left blank.

Page 47

16-1

Appendix B –

Electrical

16 Appendix B – Electrical connections

Figure 11: Umbilical cable connections

Figure 12: Umbilical cable wire schedule

2000 mm

8

P2

P1

P2

P3

1000 mm

150 mm

8

8

1

2000 mm

P2

P1

P2

P3

1000 mm

150 mm

Wire Schedule

A

B

C

D

EFG

FRONT FACE OF

CONNECTOR

8

P2

8

8

1

P1 Description Type P2 P3

A Ground Single (16 AWG) -- Black

B Positive Single (16 AWG) -- Red

C Tx+

Pair (CAT5E 26 AWG)

3 -D Tx− 6 -E Rx+

Pair (CAT5E 26 AWG)

1 -F Rx− 2 -G NOT CONNECTED -- --

Page 48

SLM 250 installation and operation manual

16-2

Appendix B –

Electrical

This page is intentionally left blank.

Page 49

Page 50

Renishaw plc

Redwood House, Northminster

Business Park, York, North

Yorkshire, YO26 6QR, UK

T

+44 (0)1904 736736

F

+44 (0)1904 736701

E

spatialmeasurement@renishaw.com

www.renishaw.com

For worldwide contact details, visit

www.renishaw.com/contact

*H-9942-9001-01*

Loading...

Loading...