Page 1

Installation and user’s guide

H-2000-5219-05-A

RMP60 - radio machine probe

Page 2

© 2006 Renishaw. All rights reserved.

Disclaimer

This document may not be copied

or reproduced in whole or in part,

or transferred to any other media or

language, by any means, without the

prior written permission of Renishaw.

The publication of material within this

document does not imply freedom

from the patent rights of Renishaw plc.

Renishaw Part no: H-2000-5219-05-A

Issued: 01.06

Considerable effort has been made to ensure

that the contents of this document are free

from inaccuracies and omissions. However,

Renishaw makes no warranties with respect

to the contents of this document and specifically

disclaims any implied warranties. Renishaw

reserves the right to make changes to this

document and to the product described herein

without obligation to notify any person of such

changes.

Trademarks

RENISHAW® and the probe emblem used in

the RENISHAW logo are registered trademarks

of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw

plc.

RENISHAW® is a registered trademark of

Renishaw plc in the UK and other countries.

All brand names and product names used in this

document are trade names, service marks,

trademarks, or registered trademarks of their

respective owners.

Page 3

Contents

Contents

1

EC declaration of conformity ........................... 2

FCC declaration............................................... 3

Safety ............................................................... 3

Installation and User’s guide ........................... 4

Typical probe system with

radio transmission ........................................... 5

System performance ....................................... 6

Operating envelope ......................................... 8

RMP60 dimensions ......................................... 9

Stylus weak link ............................................. 10

Operating mode ............................................. 11

Probe settings ................................................ 12

Multiple probe mode ...................................... 14

Reviewing current probe settings.................. 16

Changing probe settings ............................... 18

RMP60-RMI partnership................................ 22

RMP60 batteries............................................ 24

Battery life expectancy .................................. 26

RMP60 shank mounting ................................ 28

Stylus on-centre adjustment.......................... 29

Stylus trigger force and adjustment .............. 30

Diaphragm replacement ................................ 31

RMP60M system ........................................... 33

RMP60M dimensions .................................... 34

RMP60M screw torque values ...................... 35

Fault finding ................................................... 36

Parts list ......................................................... 41

Probe settings record table .......................... 44

Page 4

2

EC DECLARA TION OF CONFORMITY

Renishaw plc declares that the product:

Name: RMP60/RMP60M

Description: Radio machine probe

has been manufactured in conformity with the following standard:

BS EN 61326:1998/ Electrical equipment for measurement,

control and laboratory use - EMC requirements.

Immunity to annex A - industrial locations.

Emissions to class A - (non-domestic) limits.

and that it complies with the requirements of directive (as amended):

89/336/EEC Electromagnetic compatibility

The above information is summarised from the full EC declaration

of conformity. A copy is available from Renishaw on request.

Radio approvals

Page 5

3

FCC DECLARA TION (USA)

FCC Section 15.19

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device may accept any interference

received, including interference that may cause

undesired operation.

FCC Section 15.105

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment.

This equipment generates, uses , and can radiate

radio frequency energy and, if not installed and

used in accordance with the instruction manual, may

cause harmful interference to radio communications.

Operation of this equipment in a residential area is

likely to cause harmful interference, in which case

you will be required to correct the interference at

your own expense.

FCC Section 15.21

The user is cautioned that any changes or

modifications not expressly approved by Renishaw

plc, or authorised representative could void the

user’s authority to operate the equipment.

SAFETY

Information for the user

Beware of unexpected movement. The user

should remain outside of the full working

envelope of probe head/extension/probe

combinations.

Handle and dispose of batteries in according to

the manufacturers recommendations. Use only

the recommended batteries. Do not allow the

battery terminals to contact other metallic

objects.

In all applications involving the use of machine

tools or CMMs, eye protection is recommended.

Refer to the machine supplier’s operating

instructions.

Information for the machine supplier

It is the machine supplier’s responsibility to

ensure that the user is made aware of any

hazards involved in operation, including those

mentioned in Renishaw product documentation,

and to ensure that adequate guards and safety

interlocks are provided.

Under certain circumstances the probe signal

may falsely indicate a probe seated condition.

Do not rely on probe signals to stop the

machine’s movement.

Page 6

4

Installation and user’s guide

Installation and user’s guide

Warranty

Equipment requiring attention under warranty

must be returned to your supplier. No claims

will be considered where Renishaw equipment

has been misused, or repairs or adjustments

have been attempted by unauthorised persons.

Changes to equipment

Renishaw reserve the right to change

specifications without obligation to change

equipment previously sold.

CNC machine

CNC machine tools must always be operated

by competent persons in accordance with

manufacturers instructions.

Care of the probe

Keep system components clean and treat

the probe as a precision tool.

Patent notice

Features of products shown in this guide,

and of related products, are the subject of the

following patents and/or patent applications:

EP 0390342

EP 0652413

EP 0695926

EP 1373995

EP 142550

EP 1457786

EP 2,945,709

JP 3,126,797

JP 2004-522,961

JP 2004-279,417

JP 2005-502,035

US 5,040,931

US 5,212,872

US 5,279,042

US 5,669,151

US 6,941,671 B2

US 2003-01799097

WO 2004-057552

WO 2004-090467

Page 7

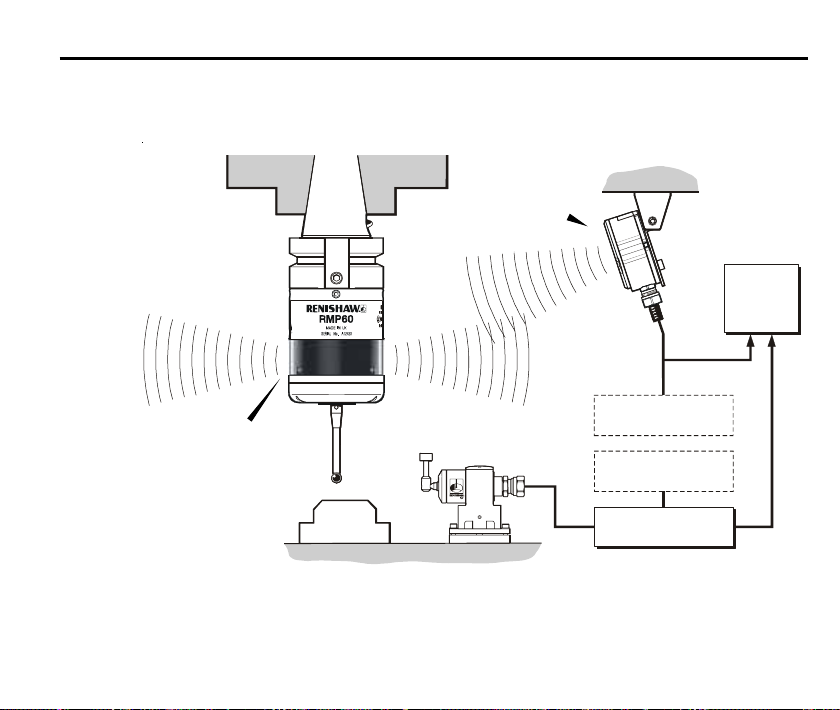

Typical probe system with radio transmission

Typical probe system with radio transmission

CNC machining centre spindle

5

RMP60

inspection probe

Probe status LEDs

Workpiece

A workpiece set-up and inspection probe is

in effect another tool in the system. A probing

cycle may be included at any stage of the

machining process.

Stylus

RMI

interface

Typical tool setting probe

Cable

Probe data is transmitted from the RMP60

(or RMP60M) to the RMI via the radio link.

The RMI converts probe signals into a form

compatible with the machine CNC control.

RMI

mounting bracket

C N C

machine

control

Optional

power supply unit

Optional

power supply unit

Interface unit

Page 8

6

System performance

System performance

RMP60 and RMP60M have identical user options and radio performance

Operating envelope

Radio transmission does not require line-of sight

and will pass through very small gaps and

machine tool windows. This allows easy

installation, either inside or outside the machine

enclosure.

Coolant and swarf residue accumulating on the

RMP60/M and RMI may have a detrimental

effect on transmission performance. Wipe clean

as often as is necessary to maintain unrestricted

transmission.

When operating, do not touch either the RMI

cover or the probe glass window with your hand,

as this will affect the performance.

Operation in extremes of temperature will result

in some reduction in range.

RMI position

The probe system should be positioned so that

the optimum range can be achieved over the full

travel of the machine axes. Always face the front

cover of the RMI in the general direction of the

machining area and the tool magazine, ensuring

both are within the operating envelope.

To assist in finding the optimum position of the

RMI, the signal quality is displayed on an RMI

signal LED.

Note: RMP60/M in radio-on configuration

The RMP60/M has a built-in hibernate mode

(battery saving mode) that saves battery life

when the RMI is unpowered in radio-on

(radio-off or time-off) configurations.

The RMP60/M goes into hibernate 30 seconds

after the RMI is unpowered (or the RMP60 is

out of range).

When in hibernate, the RMP60/M checks for a

powered RMI every 30 seconds. If found, the

RMP60/M goes from hibernate to standby,

ready for radio-on.

Page 9

System performance

7

Probe repeatability

Maximum 2 Sigma (2σ) value.

Repeatability of 1.0 µm (40 µ in) is valid for a

test velocity of 480 mm/min (1.57 ft/min) at the

stylus tip, using a stylus 50 mm (1.97 in) long.

RMP60 IP rating IPX8

RMP60 weight (without shank)

Without batteries 855 g (30.16 oz)

With batteries 901 g (31.79 oz)

RMP60M weight (without shank)

Without batteries 690 g (24.34 oz)

With batteries 736 g (25.95 oz)

Max spin speed

RMP60 1000 rev/min

RMP60M Dependent on configuration

Environment

RMP60

RMP60M

RMI

Storage

Normal

operating

Temperature

-10 °C to 70 °C

(14 °F to 158 °F)

5 °C to 50 °C

(41 F° to 122 °F)

Page 10

8

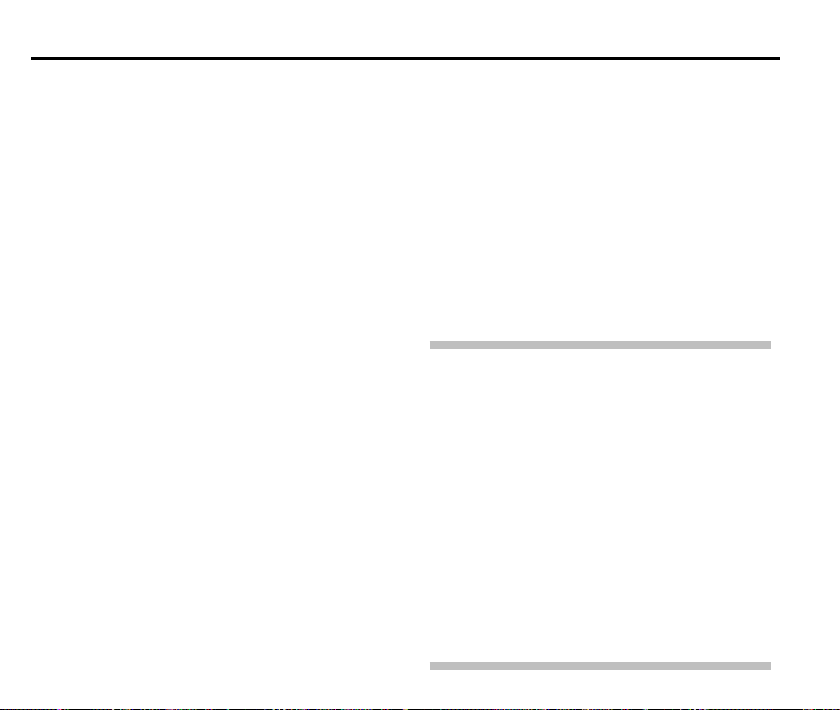

Operating envelope

Operating envelope

RMP60 probe + RMI

RMP60 and RMI must be within each other’s

operating envelope. The operating envelope

shows line-of-sight performance, however radio

transmission does not require line-of-sight as

long as any reflected radio path is less than

the 15 m (49.2 ft) system operating range

75°

60°

45°

30°

15°

0°

75°

60°

Always face the front cover of the RMI in the

general direction of the machining area and

the tool magazine, ensuring both are within

the operating envelope.

Range metres (feet)

OPERATING AND SWITCH ON/OFF

75°

15 (49)

60°

45°

30°

15°

45°

30°

15°

0°

10 (33)

5 (16)

15°

30°

45°

60°

75°

(16)

90°

5

10

(33)

(49)

15°

30°

15

75°

45°

60°

0°

15°

30°

45°

60°

5 (16)

10 (33)

15 (49)

75°

Page 11

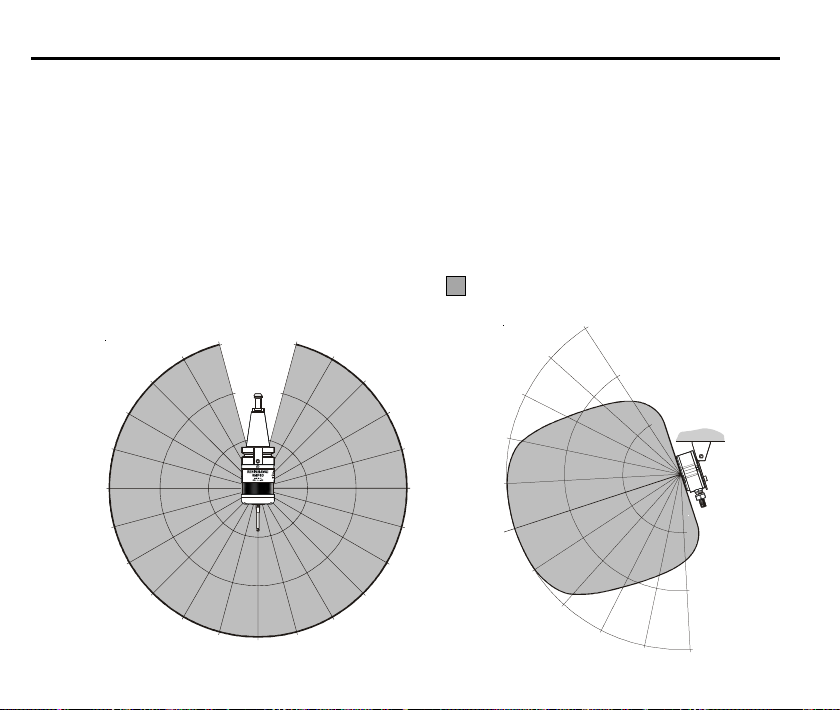

RMP60 dimensions

9

RMP60 dimensions

19 (0.75)50 (1.97)

M4 stylus

18°

18°

Ø63 (Ø2.48)

RMP60 window

STYLUS OVERTRAVEL LIMITS

Stylus length

50 (1.96)

100 (3.93)

Battery cassette

Status LEDs

76 (2.99)

±X / ±Y

21 (0.82)

37 (1.45)

Shank switch

(optional)

Bobbin

alignment dot

Z

11 (0.43)

11 (0.43)

dimensions mm (in)

A range of probe

ready shanks

are available

from Renishaw

Page 12

10

Stylus with weak link

Stylus weak link

Must be used with steel styli.

For optimum metrology performance, do not use

the weak link with ceramic or carbon fibre styli.

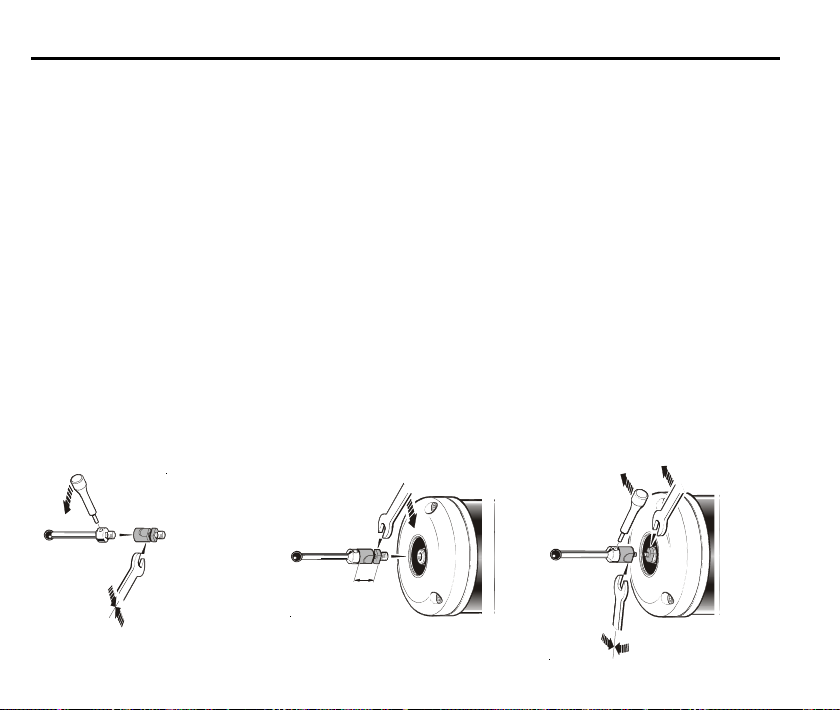

Fitting stylus with weak link onto RMP60

In the event of excessive stylus overtravel,

the weak link is designed to break, thereby

protecting the probe from damage.

Take care to avoid stressing the weak link

during assembly.

Fitting a weak link

2 Nm (1.7 lbf.ft)

Removing a broken weak link

5 mm AF

2 Nm (1.7 lbf.ft)

12 mm

(0.47 in)

Page 13

Operating mode

Operating mode

11

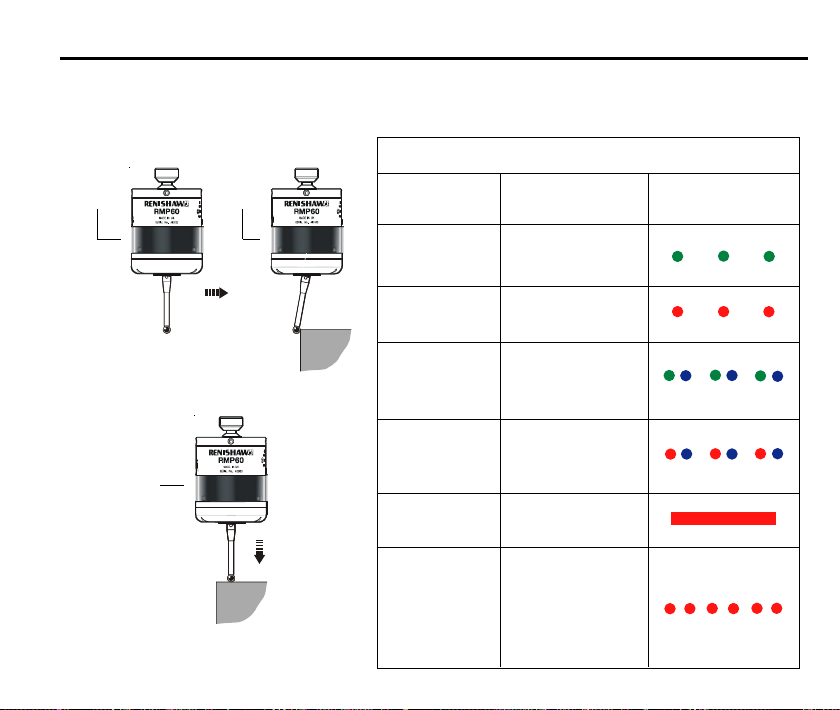

LEDs

flashing

green

LEDs

flashing

red

➤

➤

LEDs

flashing

red

➤

X / Y

PROBE STATUS LEDs

LED colour

Flashing

green

Flashing

red

Flashing

green

and blue

Flashing

red and

blue

Constant

red

Z

Rapid

flashing

red

Probe status

Probe seated in

operating mode

Probe triggered in

operating mode

Probe seated in

operating mode

- low battery

Probe triggered in

operating mode

- low battery

Battery dead

Extremely dead

alkaline batteries

or unsuitable

lithium thionyl

chloride batteries

Graphic hint

Page 14

12

Probe settings

Probe settings

The RMP60 probe can be in one of three modes:

Stand-by mode - The RMP60 is waiting for a

switch on signal.

Operating mode - Activated by one of the

switch on methods described on this page.

In this mode the RMP60 is now ready for use.

Configuration mode - The trigger logic

configuration method allows the following

settings to be configured.

Switch-on / switch-off methods

The following switch on / switch off options

can be configured:

1. Radio on / Radio off

2. Radio on / Timer off

3. Spin on / Spin off

4. Spin on / Timer off

Note:

The RMP60 will be switched on after 1 second

in all modes.

After being switched on, the RMP60 must be

on for 1 second minimum (7 seconds for spin

start) before being switched off.

5. Shank switch on / Shank switch off

Page 15

Switch-on method Switch-off methods available

Probe settings

13

Radio on

Radio switch on when

commanded by an M code.

Spin on

Spin at 650 rev/min for

1 second minimum (6 seconds

maximum).

Shank switch on

Radio off

Radio switch off when commanded by an M code.

A timer automatically switches the probe off after 90 minutes

from the last trigger if not turned off by an M code.

Timer off (time out)

Time out will occur (12, 33 or 134 seconds) after the last probe

trigger or reseat.

Spin off

Spin at 650 rev/min for 1 second minimum (6 seconds

maximum).

A timer automatically switches the probe off after 90 minutes

from the last trigger if not spun.

Timer off (time out)

Time out will occur (12, 33 or 134 seconds) after the last probe

trigger or reseat.

Shank switch off

Page 16

14

Multiple probe mode

Multiple probe mode

RMP60 can be user configured using trigger

logic to allow multiple RMP60s to be used

with a single RMI.

Note:

Radio turn on cannot be used in multiple probe

mode.

To allow multiple probes/single RMI in close

proximity, 16 choices of ‘mode-on’ colours are

available – each representing a different

machine tool installation. The choices are

shown on the next page and in ‘Changing

probe settings’.

All probes on a single RMI machine should be

set to the same ‘mode-on’ colour choice; any

multiple probes on adjacent machines should

all be set to an alternative ‘mode-on’ colour

choice. Multiple probe mode will not appear in

the configuration of the probe if radio turn on

has been selected.

Only one of the multiple probes per machine

will need partnering as, by configuring multiple

probes to a single ‘mode-on’ choice, all probes

have the same identification. The probe to be

partnered, is par tnered after selection of

multiple probe on in ‘Changing probe settings’.

There is no limit to the number of probes that

can be used with a single RMI as long as they

all have the same ‘mode-on’ colour choice.

All RMP60s are factory-set to ‘mode off’.

The addition of further probe(s) into a single

probe installation requires all probes to be

re-configured to the same multiple probe

‘mode-on’ choice and the repartnering of

one of the probes to the installed RMI.

The addition of further probes (or replacements)

into a multi probe installation is achieved simply

by reconfiguration to the same ‘mode-on’

colour choice.

Note:

Any number of RMP60s set to ‘mode-off ’ can

be used alongside RMP60s set to ‘Multiple

probe mode’.

Page 17

Multiple mode settings table

MULTIPLE PROBE MODE

15

MODE OFF

Deflect

stylus

< 4 sec

to cycle

to next

setting

MACHINE 1 MACHINE 2

MACHINE 5 MACHINE 6

MACHINE 9 MACHINE 10

MACHINE 13 MACHINE 14

MODE ON

MACHINE 3

MACHINE 7

MACHINE 11

MACHINE 15

Return to MODE OFF

MACHINE 4

MACHINE 8

MACHINE 12

MACHINE 16

Page 18

16 Reviewing current probe settings

Reviewing current probe settings

1. Insert batteries, or if already inser ted remove

for 5 seconds and replace.

2. DO NOT deflect the stylus when reviewing

settings.

3. The LEDs will show the following sequence.

LED CHECK

SWITCH-ON METHOD

RADIO ON

(omitted if Multiple Probe

Mode was selected)

SHANK ON

SPIN ON

oror

continued on next page

Page 19

Reviewing current probe settings

SWITCH-OFF METHOD

(omitted for shank-on)

17

RADIO OFF

or SPIN OFF

MODE OFF

SHORT TIME OUT

12 sec

MULTIPLE PROBE MODE (omitted for radio-on)

(see ‘Multiple probe mode’ to view all 16 choices)

MACHINE 1 MACHINE 2

or

or

BATTERY STATUS

BA TTER Y GOOD

PROBE IN STAND-BY MODE (after 5 sec)

MEDIUM TIME OUT

33 sec

or

MODE ON

or

LONG TIME OUT

134 sec

oror

MACHINE 16

BA TTER Y LOW

Page 20

18

Changing probe settings

Changing probe settings

Probe settings can be configured using the

trigger logic.

1. Insert the batteries, or if already inser ted,

remove for 5 seconds and replace.

2. Deflect the stylus and hold deflected until

5 red flashes occur at end of the review

sequence.

Note:

If battery power is low then each of the

5 red flashes will be followed by a blue flash.

See ‘Probe settings’ for further details.

3. The probe will now be in the configuration

mode and the current switch on method will

flash. The probe settings can be changed as

shown below.

Note:

Settings are saved as they are changed

4. To exit the trigger logic at any point, leave

the stylus undeflected for over 20 seconds.

5. Settings record table

For quick reference, Renishaw suggest

that you record your settings in the table

at the back of this guide.

These settings will be needed if the probe

is replaced.

Page 21

Changing probe settings

TO CHANGE SWITCH-ON METHOD

19

RADIO ON

(omitted if Multiple Probe

Mode was selected)

RADIO

or

SPIN

Deflect

stylus

< 4 s

Deflect

SHANK ON

Deflect

stylus

< 4 s

Deflect stylus < 4 seconds

Deflect stylus > 4 seconds

TO CHANGE SWITCH-OFF METHOD

(omitted if shank turn on was selected)

SHORT

TIME OUT

12 s

Deflect

stylus

< 4 s

MEDIUM

TIME OUT

33 s

Deflect stylus < 4 seconds

Deflect stylus > 4 seconds

stylus

< 4 s

SPIN ON

Deflect

stylus

< 4 s

LONG

TIME OUT

134 s

Page 22

20

Changing probe settings

ACQUISTION MODE

ACQUISITION MODE

OFF

Cease triggering here, unless the

multiple probe mode is required

in which case

Deflect stylus > 4 seconds

Deflect

stylus

< 4 s

Deflect stylus < 4 seconds

ACQUISITION MODE

ON

Note: After the RMI

has been acquired, the

RMP60 will only show

Acquistion Mode Off.

See RMP60 - RMI

partnership.

Page 23

MODE OFF

Deflect

stylus

< 4 s

Changing probe settings

MULTIPLE PROBE MODE

(see “Multiple probe mode” to view all 16 choices)

MODE ON

MACHINE 1

Deflect

stylus

< 4 s

Deflect stylus < 4 seconds

Deflect stylus > 4 seconds

21

MACHINE 16MACHINE 2

ACQUISTION MODE

ACQUISITION MODE

OFF

Deflect stylus

Deflect stylus < 4 seconds

> 4 seconds

Return to

TO CHANGE SWITCH-ON METHOD

Deflect

stylus

< 4 s

ACQUISITION MODE

ON

Note: After the RMI

has been acquired, the

RMP60 will only show

Acquistion Mode Off.

See RMP60 - RMI

partnership.

Page 24

22

RMP60-RMI partnership

RMP60-RMI partnership

System setup is achieved using trigger logic and

powering on the RMI.

Trigger logic is a method that allows user

configuration of the options available in the

RMP60. Trigger logic uses a sequence of

RMP60 triggering and battery inser tion followed

by further RMP60 triggering.

This leads the user through a series of choices,

allowing selection of the required options.

Reviewing of choices can be made by battery

insertion alone. See Reviewing probe settings.

To par tner an RMP60 and RMI

Partnering is only required during initial system

set-up. Further partnering is only required if

either the RMP60 or RMI is changed.

Partnering will not be lost by reconfiguration

of probe settings or when changing batteries.

Partnering can take place anywhere within the

operating envelope.

1. Use trigger logic to access the RMP60

configuration mode.

2. Configure the turn on method (if not

configured).

3. Configure the turn off method (if not

configured).

4. Enter the acquisition mode by deflecting

the stylus.

5. Remain in ‘Acquisition Mode Off’ by not

releasing the stylus. This allows time to get

the RMI ready for partnering.

6. Power on the RMI.

7. Watch the RMI signal LED; after a couple

of seconds the LED will repeatedly flash on

and off green. This is the start of a 10

second interval in which the RMI is in

acquisition mode.

continued on next page

Page 25

RMP60-RMI partnership

23

8. Release the RMP60 stylus and trigger it a

couple of times. This causes the RMP60 to

go into (and out of) acquisition mode.

9. The RMI signal LED will change to

repeatedly flashing red and yellow (for the

remainder of the 10 second interval),

indicating a successful partnering.

10. Leave the RMP60 for 20 seconds to go

into standby.

11. The system is ready to use.

Note

To check that turn on and off settings have not

accidentally been changed, remove and insert

batteries to review the current probe settings.

Note

When holding the RMP60, do NOT wrap a

hand, or anything else, around the glass

window.

Note

When the RMP60 and RMI become partners

the RMI records the RMP60 identity. It is not

possible for an RMI to be partnered with more

than one RMP60 in ‘Standard Mode’ - see

Multiple Probe Mode.

It is possible for an RMP60 to be partnered

with more than one RMI, but the system will

not function correctly.

Page 26

24

RMP60 batteries

RMP60 batteries

Replacing batteries

Only use specified batteries.

Clean and dry the RMP60 with a cloth or paper

towel before removing the battery cover. Where

the RMP60 has been exposed to coolant, it is

recommended that the area around the battery

cover is cleaned.

To access the RMP60 batteries, remove the

battery cover by rotating the securing screw 30°

anticlockwise and withdraw the battery cassette.

Take care to avoid damaging the cover gasket.

When inserting the batteries, ensure they are

loaded as shown (see next page).

If one or more batteries are incorrectly loaded

the probe will not respond.

Do not mix new and used batteries or battery

types, as this will result in reduced life and

damage to the batteries.

Always ensure that the cover gasket and mating

surfaces are clean and free from damage before

reassembly.

Page 27

RMP60 batteries

25

Battery cassette

DO NOT leave exhausted batteries in probe

DO NOT allow coolant or debris to enter

the battery compartment

DO check for correct battery polarity

+

-

+

Batteries 2 x AA

Please dispose of exhausted batteries

in accordance with local regulations.

!

Do not dispose of batteries in fire.

-

Page 28

26

Battery life expectancy

Battery life expectancy

Typical battery life

Using standard alkaline batteries at 5 % usage,

typically the probe will continue to operate for

approximately 1 week after a low battery

warning is first indicated.

Replace the batteries as soon as is practicable.

BATTERY

Two

AA type

Alkaline

LTC

SHANK/SPIN TURN ON

STAND-BY

LIFE

(days - typical)

650 100 130 65 140

1,300 200 260 130 280

5% USAGE

72 min/day

(days - typical)

LTC (Lithium Thionyl Chloride)

After batteries are inserted into the RMP60,

the LEDs will indicate the current settings.

In order to achieve the stated radio turn-on life

(stand-by or 5% usage), the RMP60 must

be in range of its powered partner RMI.

RADIO TURN ON

STAND-BY

LIFE

(days - typical)

5% USAGE

72 min/day

(days - typical)

CONTINUOUS

USE

(hours - typical)

Page 29

Low battery indicator

Battery life expectancy

27

The low battery warning will be signalled by

the alternate blue flashing of the probe status

LED when the end of the usable battery life

is approaching. Simultaneously, the low battery

LED on the RMI will be lit.

Dead battery indicator

When the battery voltage drops below the

threshold where performance can no longer

be guaranteed, the RMP60 probe status LED

will change to constant red, followed by flashing

red.

Battery specification

The RMP60 requires two identical AA size

batteries, individually rated at a voltage of

between 1.2 V and 3.6 V.

The standard batteries are AA alkaline.

Alternative batteries are lithium thionyl

chloride (3.6 V), Nickel Cadmium (NiCd) or

Nickel Metal Hydride (NiMh).

Rechargeable batteries: either Nickel Metal

Hydride (NiMh) or Nickel Cadmium (NiCd)

can be used. Expect a battery life of

approximately 50% of alkaline figures.

For applications requiring maximum battery

life, a high capacity lithium thionyl chloride

type is essential.

Sources for lithium thionyl chloride

batteries

Please use these specified part numbers only

Supplier Part number

RS 596-602, 201-9438,

Radio Shack 23-037

Manufacturer Part number

Saft LS 14500

Sonnenschein SL 760/S

Tadiran TL-5903/S, TL-2100/S

Xeno XL-060F

Page 30

28

RMP60 shank mounting

RMP60 shank mounting

Stage 1 RMP60 shank mounting

If the RMP60 is not to be used with a shank

switch, proceed from step 3.

1. Remove the plug from the rear of the

RMP60 using pliers.

2. Place the bobbin into the shank.

3. Fully slacken the four screws A.

4. Grease the two screws B, and fit into the

shank.

5. Fit the RMP60 onto the shank, and visually

position it central relative to the shank.

6. Partially tighten screws B to 2 - 3 Nm

(1.5 - 2.2 lbf.ft).

(If the RMP60 is NOT to be on-centre adjusted,

fully tighten screws B to 6-8 Nm (4.4 - 5.9 lbf ft).

The RMP60 assembly is ready for use.

For on-centre adjustment, complete steps 7-10

(see next page).

Probe to shank alignment dot

(used when bobbin is fitted)

Bobbin

Shank switch

Note :

1. During adjustment, care should be taken

NOT to rotate the probe relative to the shank,

as damage to the shank switch bobbin may

occur (if fitted).

2. If a probe on a shank is accidentally

dropped, it should be checked for on-centre

position.

3. Do NOT hit or tap the probe to achieve

on-centre adjustment.

Rear plug

(optional)

A

B

Page 31

Stylus on-centre adjustment

Stylus on-centre adjustment (if required)

Stage 2 On-centre adjustment

7. Each of the four screws A will move the

probe relative to the shank, in the X or Y

direction, as pressure is applied.

Tighten individually, backing off after each

movement.

8. When the stylus tip run-out is less than

20 µm, fully tighten screws B to 6 - 8 Nm

(4.4 - 5.9 lbf.ft).

9. For final centering, use screws A to move

the RMP60, progressively slackening on one

side and tightening the opposite screw, as

the final setting is approached, using two

hexagon keys.

Tip run out of 5 µm (0.0002 in) should be

achievable.

10. It is important that all four screws A are tight

or tightened to 1.5 - 3.5 Nm (1.1 - 2.6 lbf.ft)

once the final setting has been achieved.

2.5 mm AF

A

29

SHANK

4 mm AF

B

PROBE

Page 32

30

Stylus trigger force and adjustment

Stylus trigger force and adjustment

Spring force within the probe causes the stylus to sit in a unique

position, and return to this position following each stylus deflection.

Stylus trigger force is set by Renishaw. The user should only

adjust the trigger force in special circumstances, e.g. excessive

machine vibration or insufficient force to support the stylus weight.

To adjust the trigger force, turn the adjusting screw anticlockwise

to reduce force (more sensitive) or clockwise to increase

force (less sensitive). A stop prevents damage, which

could be caused by over-tightening the adjusting screw.

Stylus trigger force

Z direction

5.30 N / 530 gf (18.69 ozf)

X/Y direction (50 mm stylus)

X/Y trigger forces vary, depending on trigger direction.

There are 3 high force and 3 low force X/Y directions:

Factory setting for low force direction = 0.75 N / 75 gf (2.6 ozf)

Factory setting for high force direction = 1.4 N / 140 gf (4.9 ozf)

Maximum setting for low force direction = 2 N / 200 gf (7.0 ozf)

Maximum setting for high force direction = 3.5 N / 350 gf (12.3 ozf)

Minimum setting for low force direction = 0.5N / 50 gf (1.7 ozf)

Minimum setting for high force direction = 0.9 N / 90 gf (3.2 ozf)

Reduce

force

2 mm AF

Increase

force

Page 33

Diaphragm replacement

Diaphragm replacement

31

RMP60 DIAPHRAGMS

The probe mechanism is protected from coolant

and debris by two diaphragms. These provide

adequate protection under normal working

conditions.

The user should periodically check the outer

diaphragm for signs of damage. If this is evident,

replace the outer diaphragm.

The user must not remove the inner diaphragm.

If damaged, return the probe to your supplier.

OUTER DIAPHRAGM INSPECTION

1. Remove the stylus.

2. Undo the three M3 front cover screws and

remove the front cover.

3. Inspect the outer diaphragm for damage.

4. To remove the outer diaphragm, grip by the

outer edge and pull off.

INNER DIAPHRAGM INSPECTION

5. Inspect the inner diaphragm for damage.

If damaged return the probe to your supplier.

DO NOT REMOVE THE INNER DIAPHRAGM

AS THE WARRANTY WILL BE VOID.

Page 34

32

OUTER DIAPHRAGM REPLACEMENT

6. Fit the new diaphragm over centre.

7. Locate the outer edge of the diaphragm to

8. Refit the front cover and the M3 screws.

9. Refit the stylus and re-calibrate the probe.

Diaphragm replacement

rest on the outer edge of the inner

diaphragm.

M3 screw

2.5 mm AF

1 Nm

(0.74 lbf.ft)

Cover

Outer

diaphragm

Inner

diaphragm

Page 35

RMP60M system

RMP60M is a special modular version

of RMP60. It enables probe inspection

of part features inaccessible to RMP60,

by fitting selected adaptors and

extensions as shown.

RMP60M

module

RMP60M extension

LPE extension bar

RMP60M

LP2 adaptor

MA4 90°

adaptor

M4 stylus

RMP60M probe module

RMP60M system

LP2 probe

see parts list

33

M4

stylus

Page 36

34

RMP60M dimensions

RMP60M dimensions

dimensions mm (in)

66,25

(2.61)

Ø63,00

66,25

(2.61)

Ø63,00

50,00 / 100,00 / 150,00

(1.97) / (3.94) / (5.91)

12,50 (0.49)

(Ø2.48)

100,00 / 150,00 / 200,00

(3.94) / (5.91) / (7.88)

(Ø2.48)

Ø25,00

(Ø0.98)

40,75

(1.60)

50,50

(1.99)

Ø63,00

(Ø2.48)

Page 37

RMP60M screw torque values

RMP60M screw torque values

10 Nm - 12 Nm

2,6 Nm

(1.92 lbf.ft)

2,6 Nm

(1.92 lbf.ft)

(7.37 lbf.ft - 8.84 lbf.ft)

35

2,6 Nm

(1.92 lb. ft)

Page 38

36

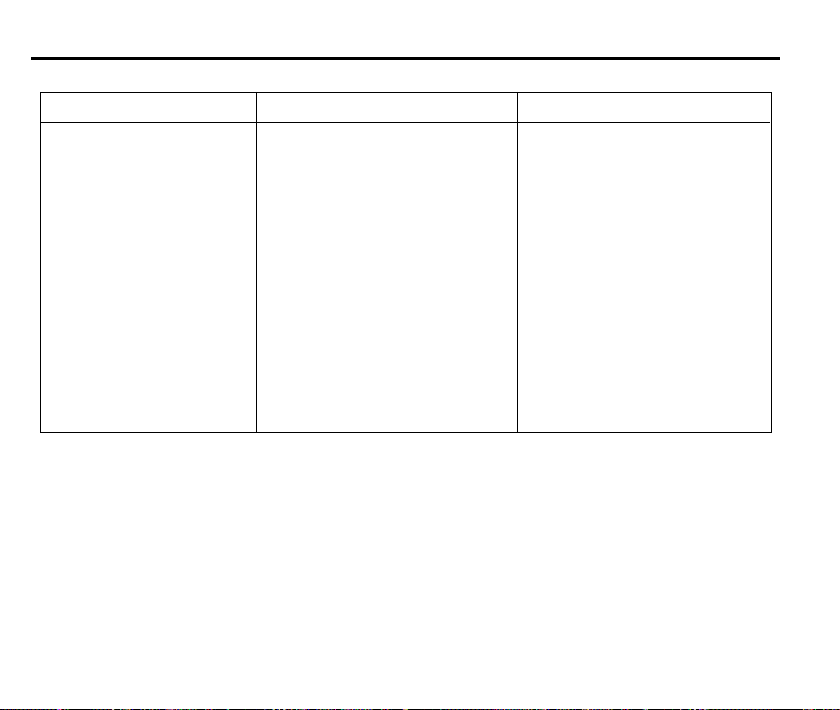

Fault-finding

Fault finding - If in doubt, consult your probe supplier.

Sympton Cause Action

RMP60 fails to switch on.

Dead batteries.

Batteries incorrectly

inserted.

Probe out of range

No RMI ‘start/stop’ signal

(radio-on mode only)

Incorrect spin speed

(spin switch on only).

Malfunctioning shank switch

(shank switch mode only).

Incorrect switch on method

configured.

Incorrect Multiple Probe Mode

setting configured

RMP60 in hibernate mode

(radio-on mode only).

Change batteries.

Check/change batteries.

Check position of RMI,

see Operating envelope.

Check RMI for green start LED.

Check spin speed.

Check switch operation.

Check configuration and alter

as required.

Check configuration and alter

as required.

Ensure probe is in range

and wait up to 30 seconds.

Check position of RMI,

see Operating envelope.

Page 39

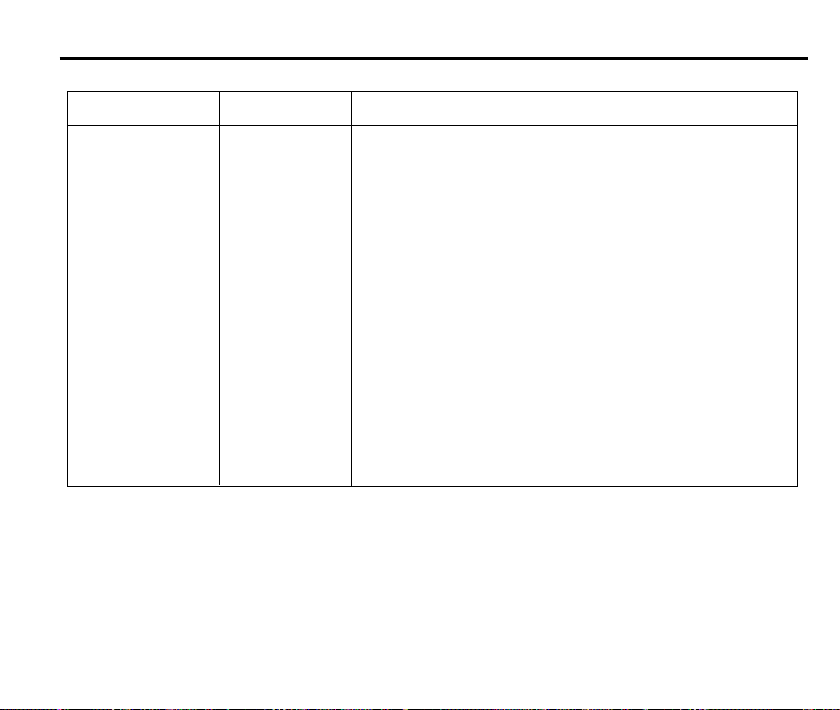

Symptom Cause Action

Fault-finding

37

RMP60 fails to switch off.

RMP60 status LEDs

continuous red.

Poor battery life.

Incorrect switch off method

configured.

No RMI ‘start/stop’ signal

(radio on mode only)

Probe in time out mode and

placed in tool magazine and is

being triggered by movement.

Malfunctioning shank switch

(shank switch mode only).

Incorrect spin speed

(spin switch on only).

Dead batteries.

Radio link failure – RMP out

of RMI range.

RMI power has been removed.

Local radio interference.

Check configuration and alter as

required.

Check RMI for green start LED.

Review use of time out mode.

Increase spring force.

Check switch operation.

Check spin speed.

Change batteries.

Check position of RMI,

see Operating envelope.

Check power to RMI, leave

RMI powered all the time.

Identify source and move it

away from the RMP60 and RMI.

Page 40

38

Symptom Cause Action

Fault-finding

Probe crash.

RMP60 status LEDs do

not correspond to RMI

status LEDs.

RMP60 probe status

LED continually lit red.

Inspection probe using

tool setting probe signals.

Probe length offset

missing/incorrect.

Workpiece obstructing probe

path.

Radio link failure – RMP60

out of RMI range.

RMP60 has been

enclosed/shielded by metal.

RMP60 and RMI are not

partnered.

Dead batteries.

Review program.

Review installation.

Review probe software.

Review program.

Check position of RMI,

see Operating envelope.

Review installation.

Partner RMP60 and RMI.

Change batteries.

Page 41

Symptom Cause Action

RMI error LED lit during

probing cycle.

Probe timed out.

Probe out of range.

Change setting.

Review turn off method.

Check position of RMI,

see Operating envelope.

39Fault-finding

RMI error LED illuminated

during intended probe cycle.

RMI low battery LED lit.

Reduced range.

Poor repeatability.

Probe not switched on.

Probe out of range.

Low batteries.

Local radio interference.

Probing occurs within

machine’s acceleration/

deceleration zones.

Probe feedrate too high.

Temperature variation.

Wear in machine tool.

Check configuration and

alter as required.

Check position of RMI,

see Operating envelope.

Change batteries soon.

Identify and move.

Review probe software.

Check feedrate and correct,

test at different speeds.

Minimise temperature change.

Calibrate more frequently.

Calibrate just before use.

Perform health check on

machine.

Page 42

40

Symptom Cause Action

Fault-finding

Poor measurement

results.

Debris on part or stylus.

Repeatability of probe

into spindle.

Loose probe to shank

mounting or stylus.

Offsets not being updated.

Calibrated feature has moved.

Measurement occurs as

stylus leaves surface.

Calibration and probing

speeds different.

Clean and recalibrate.

Verify by repeated toolchange

and single point move.

Check and tighten as

required, recalibrate.

Review software.

Check.

Review software.

Review software.

Page 43

Parts list

Parts list - Please quote the Part no. when ordering equipment.

Type Part no. Description

RMP60 A-4113-0001 RMP60 probe with batteries, tool kit and user’s guide

(set to radio on/radio off).

Battery P-BT03-0005 AA batteries - Alkaline - supplied as standard with probe

(two required).

Battery P-BT03-0008 AA batteries - Lithium thionyl chloride (two required).

Stylus A-5000-3709 PS3-1C ceramic stylus 50 mm long with Ø6 mm ball.

Weak link kit A-2085-0068 Weak link (Part no. M-2085-0069 (x 2) and

5 mm AF spanner.

TK A-4038-0304 Probe tool kit comprising: Ø1.98 mm stylus tool,

2.0 mm AF hexagon key 2.5 mm AF hexagon key (x 2),

4 mm AF hexagon key, shank grub screws (x 2),

weak link and 5 mm AF spanner.

Diaphragm kit A-4038-0302 RMP60 outer diaphragm.

Battery cassette A-4038-0300 RMP60 battery cassette assembly.

Cassette seal A-4038-0301 Battery cassette housing seal.

41

Page 44

42

Bobbin A-4038-0303 Bobbin for shank switch.

RMI A-4113-0050 RMI, side exit, with 15 m (49.2 ft) cable, tool kit and

Mtg brkt A-2033-0830 Mounting bracket with fixing screws, washers and nuts.

Styli — For complete listing, please see Renishaw Styli guide.

Software — For complete listing of Renishaw software for machine,

tools please see data sheets. Part no. H-2000-2289 and

Shanks — For complete listing, please see Renishaw data sheet

Parts list

Type Part no. Description

User’s guide.

Part no. H-1000-3200.

H-2000-2298.

H-2000-2011.

Page 45

Type Part no. Description

RMP60M module A-4113-1003 RMP60M module with batteries, tool kit and User’s guide.

(set to radio on/radio off).

Extension L100 A-4038-1010 RMP60M extension - 100 mm long.

Extension L150 A-4038-1027 RMP60M extension - 150 mm long.

Extension L200 A-4038-1028 RMP60M extension - 200 mm long.

Probe module A-4038-1002 RMP60M probe module assembly.

RMP60M/LP2 A-4038-0212 RMP60M LP2 adaptor assembly

LPE1 A-2063-7001 LPE1 extension bar - 50 mm long.

LPE2 A-2063-7002 LPE2 extension bar - 100 mm long.

LPE3 A-2063-7003 LPE3 extension bar - 150 mm long.

MA4 A-2063-7600 MA4 90° adaptor assembly.

43Parts list

Page 46

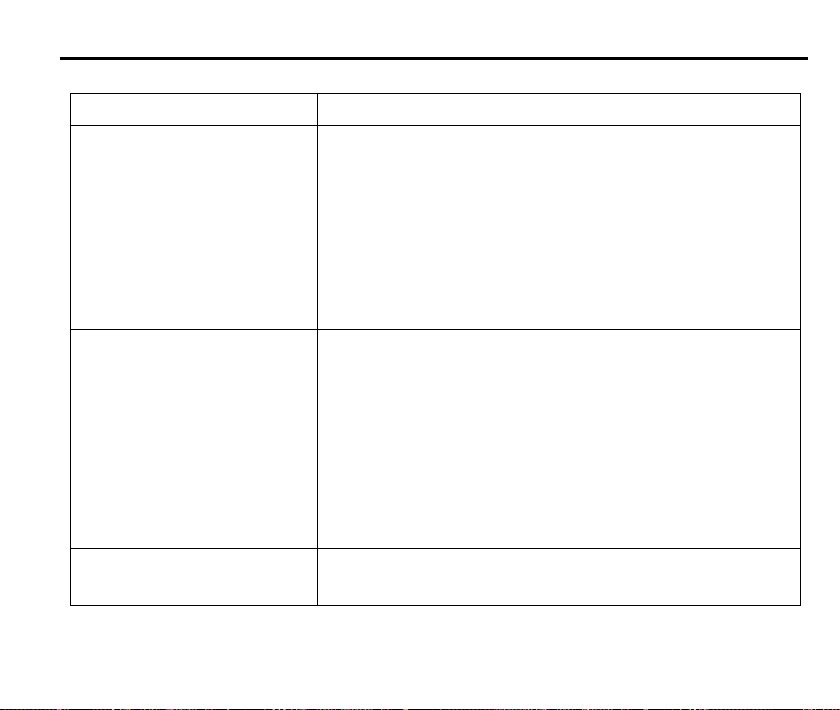

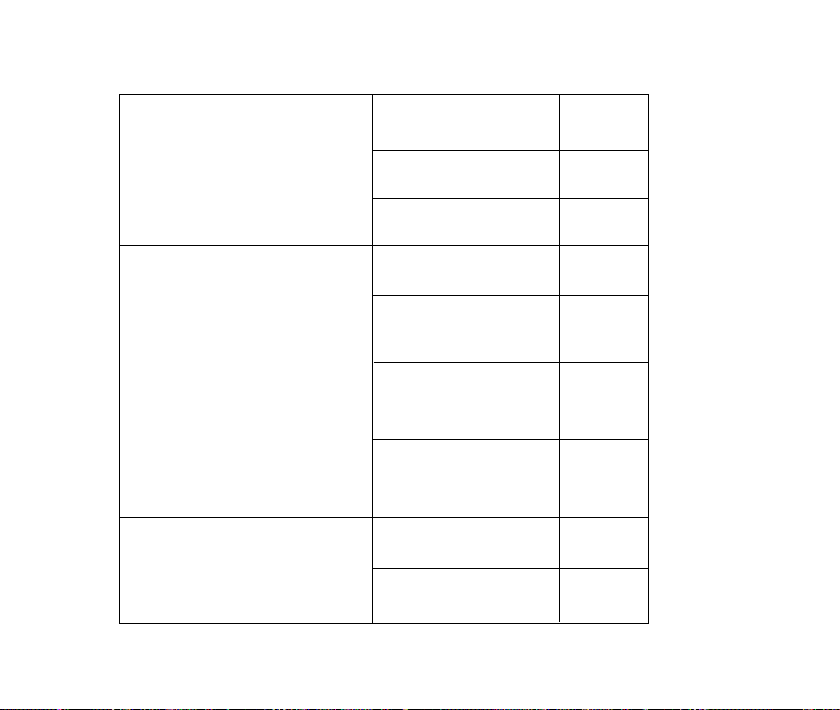

Probe settings record table

44

✔ tick

Switch-on method

Switch-off method

Multiple probe mode

Radio on

Shank on

Spin on

Radio or spin

Short timeout

12 seconds

Medium timeout

33 seconds

Long timeout

134 seconds

Off (factory set)

On (machine number)

RMP60 serial no.

--------------------------------------------------------------------------

Page 47

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main web site at

www.renishaw.com/contact

*H-2000-5219-05*

Loading...

Loading...