Installation guide

H-5480-8504-01-A

RMP40 - radio machine probe

© 2010 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media

or language, by any means, without the prior written permission of Renishaw plc.

The publication of material within this document does not imply freedom from the patent rights of

Renishaw plc.

Renishaw part no: H-5480-8504-01-A

First issued: 01.10

Contents

Contents

Before you begin

Before you begin ............................................................1.1

i

Disclaimer

Trademarks

Warranty

Changes to equipment

CNC machines

Care of the probe

Patents

EC Declaration of Conformity

WEEE DIRECTIVE

FCC DECLARATION (USA)

Radio approval

Safety

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5

..............................................................1.1

.............................................................1.1

................................................................1.1

.....................................................1.1

...........................................................1.1

.........................................................1.1

.................................................................1.2

..................................................1.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.3

.............................................................1.4

RMP40 basics

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

Getting started

System interface

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1

..........................................................2.1

Trigger Logic™

Modes of operation

Configurable settings

Switch on/switch off methods

Enhanced trigger filter

Multiple probe mode

Acquisition mode

RMP40 dimensions

RMP40 specification

...........................................................2.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2

.........................................................2.2

.......................................................2.4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.4

..........................................................2.5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.6

................................................2.2

.....................................................2.2

RMP40 installation guide

System installation

Installing the RMP40 with an RMI ...............................................3.1

Contents

ii

Operating envelope

Performance envelope when using the RMP40 with the RMI

RMP40 / RMI positioning

Performance envelope

Preparing the RMP40 for use

Fitting the stylus

Installing the batteries

Mounting the probe on a shank

Stylus on-centre adjustment

Calibrating the RMP40

Why calibrate a probe?

Calibrating in a bored hole or on a turned diameter

Calibrating in a ring gauge or on a datum sphere

Calibrating the probe length

.......................................................3.1

.......................3.2

...................................................3.2

.....................................................3.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.3

..........................................................3.3

.....................................................3.4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.5

.................................................3.6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.7

....................................................3.7

...............................3.7

................................3.7

.................................................3.7

Trigger Logic™

Reviewing the current probe settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.1

Multiple probe settings

Probe settings record

Changing the probe settings

RMP40 – RMI partnership

Operating mode

.............................................................4.7

.......................................................4.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3

...................................................4.4

.....................................................4.6

Maintenance

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

Cleaning the probe

Changing the batteries

Battery type

................................................................5.3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.2

RMP40M system

RMP40M system ............................................................6.1

RMP40M dimensions

RMP40M screw torque values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.2

Fault finding

Parts list

Before you begin

1.1

Before you begin

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF THIS

DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES

OR REPRESENTATIONS REGARDING

THE CONTENT. RENISHAW EXCLUDES

LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the

RENISHAW logo are registered trademarks of

Renishaw plc in the UK and other countries.

apply innovation™ and Trigger Logic™ are

trademarks of Renishaw plc.

Changes to equipment

Renishaw reserves the right to change equipment

specifications without notice.

CNC machines

CNC machine tools must always be operated by

fully trained personnel in accordance with the

manufacturer's instructions.

Care of the probe

Keep system components clean and treat the

probe as a precision tool.

All other brand names and product names used

in this document are trade names, service marks,

trademarks, or registered trademarks of their

respective owners.

Warranty

Equipment requiring attention under warranty

must be returned to your equipment supplier.

No claims will be considered where Renishaw

equipment has been misused, or where

repairs or adjustments have been attempted by

unauthorised persons. Prior consent must be

obtained in instances where Renishaw equipment

is to be substituted or omitted. Failure to comply

with this requirement will invalidate the warranty.

RMP40 installation guide

1.2

Before you begin

Patents

Features of the RMP40 probe, and other similar

Renishaw probes, are subject of one or more of

the following patents and/or patent applications:

CN 100466003

CN 101287958

CN 101482402

EP 0652413

EP 0695926

EP 1185838

EP 1373995

EP 1425550

EP 1457786

EP 1477767

EP 1477768

EP 1576560

EP 1701234

EP 1734426

EP 1804020

EP 1931936

EP 1988439

IN 2004-057552

IN 2004-057552

IN 2007-028964

IN 215787

JP 2004-279417

JP 2008-203270

JP 3126797

JP 3967592

JP 2004-522961

JP 2006-313567

JP 2006-511860

JP 2009-507240

JP 4237051

TW 200720626

US. 5150529

US. 5279042

US. 5669151

US. 7285935

US. 6776344

US. 2006-0215614

US. 2009-0049704

US. 2009-0130987

US. 6776344

US. 6941671

US. 7145468

US. 7441707

US. 7486195

1.3

Before you begin

C

Renishaw PLC hereby declares that the RMP40 is

in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

Contact Renishaw PLC at

www.renishaw.com/rmp40/cert

for the full EC Declaration of Conformity.

WEEE DIRECTIVE

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of

this product will help to save valuable resources

and prevent potential negative effects on the

environment. For more information, please contact

your local waste disposal service or Renishaw

distributor.

FCC DECLARATION (USA)

FCC Section 15.19

This device complies with Part 15 of the FCC

rules.

Operation is subject to the following two

conditions:

1. This device may not cause harmful

interference.

2. This device may accept any interference

received, including interference that may

cause undesired operation.

FCC Section 15.105

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment

in a residential area is likely to cause harmful

interference, in which case you will be required to

correct the interference at your own expense.

FCC Section 15.21

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc, or authorised representative could

void the user’s authority to operate the equipment.

RMP40 installation guide

1.4

Before you begin

Radio approval

PENDING RADIO APPROVAL

1.5

Before you begin

Safety

!

Information to the user

The RMP40 and RMP40M are supplied with two

non-rechargeable ½ AA lithium metal batteries.

Once the charge in these batteries is depleted,

please dispose of them in accordance with your

local environmental and safety laws. Do not

attempt to re-charge these batteries.

Please ensure replacement batteries are of the

correct type and are fitted with the correct polarity

in accordance with the instructions in this manual

and as indicated on the product. For specific

battery operating, safety and disposal guidelines,

please refer to the battery manufacturers'

literature.

• Ensurethatallbatteriesareinsertedwith

the correct polarity.

• Donotstoreindirectsunlightorrain.

Information to the machine supplier/ installer

It is the machine supplier's responsibility to ensure

that the user is made aware of any hazards

involved in operation, including those mentioned

in Renishaw product literature, and to ensure

that adequate guards and safety interlocks are

provided.

Under certain circumstances, the probe signal

may falsely indicate a probe seated condition. Do

not rely on probe signals to halt the movement of

the machine.

Information to the equipment installer

All Renishaw equipment is designed to comply

with the relevant EEC and FCC regulatory

requirements. It is the responsibility of the

equipment installer to ensure that the following

guidelines are adhered to, in order for the product

to function in accordance with these regulations:

• Donotheatordisposeofthebatteryinfire.

• Avoidforceddischargeofthebattery.

• Donotshortcircuit.

• Donotdisassemble,applyexcessive

pressure, pierce or deform.

• Donotswallowandkeepoutofreachof

children.

• Donotgetbatterywet.

If battery is damaged, exercise caution when

handling.

Please ensure that you comply with international

and national battery transport regulations when

transporting batteries or the products. Lithium

batteries are classified as dangerous goods and

strict controls apply on their shipment by air. To

reduce the risk of shipment delays, should you

need to return the products to Renishaw for any

reason, do not return any batteries.

The RMP40 has a glass window. Handle with care

if broken to avoid injury.

any interface MUST be installed in a position

•

away from any potential sources of electrical

noise, i.e. power transformers, servo drives

etc;

all ground connections should be connected

•

to the machine 'star point' (the 'star point'

is a single point return for all equipment

ground and screen cables). This is very

important and failure to adhere to this

can cause a potential difference between

grounds;

all screens must be connected as outlined in

•

the user instructions;

cables must not be routed alongside high

•

current sources, i.e. motor power supply

cables etc, or be near high speed data lines;

cable lengths should always be kept to a

•

minimum.

Equipment operation

If this equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

Before you begin

1.6

RMP40 installation guide

This page left intentionally blank

RMP40 basics

2.12.1

Introduction

RMP40 forms part of Renishaw's family of new

generation radio transmission probes. It is ideally

suited to large machine centres or where line-ofsight between probe and receiver is difficult to

achieve or where Z travel is limited.

RMP40 features an integrated probe module

delivering exceptional robustness and generous

overtravel.

RMP40 complies with FCC regulations and

operates in the 2.4 GHz band. It delivers

interference-free transmission through the use of

FHSS (Frequency Hopping Spread Spectrum).

This allows many systems to operate in the same

machine shop without risk of cross-interference.

All RMP40 settings are configured using ‘Trigger

Logic’. This technique enables the user to review

and subsequently change probe settings by

deflecting the stylus whilst observing the LED

display.

Configurable settings are:

Getting started

Three multicolour LEDs provide visual indication

of selected probe settings.

For example:

Switch-on and switch-off methods

•

• Probe status - triggered or seated

• Battery condition

Batteries are inserted or removed as shown (see

‘RMP40 batteries’ for further information).

On insertion of batteries, the LEDs will begin to

flash (see ‘Reviewing current probe settings’ for

further information).

System interface

The RMI integrated interface/receiver is used to

communicate between the RMP40 probe and the

machine controller.

• Radio on / Radio off

• Radio on / Timer off

• Spin on / Spin off

• Spin on / Timer off

• Filter on / Filter off

• Multiple probe mode on / multiple probe

mode off.

RMP40 installation guide

2.2

RMP40 basics

Trigger Logic™

Trigger Logic™ (see Section 4, "Trigger Logic™")

is a method that allows the user to view and select

all available mode settings in order to customise a

probe to suit a specific application. Trigger Logic™

is activated by battery insertion and subsequent

stylus deflection. A sequence of stylus deflection

(triggering) is then used to systematically lead

the user through the available choices to allow

selection of the required mode options.

Current probe settings can be reviewed by

simply removing the batteries for a minimum of

5 seconds, and then replacing them to activate

the Trigger Logic™ review sequence.

Modes of operation

The RMP40 probe can be in one of three modes:

Configurable settings

Switch on/switch off methods

The following switch on/switch off options are

user-configurable.

1. Radio on / Radio off

2. Radio on / Timer off

3. Spin on / Spin off

4. Spin on / Timer off

Enhanced trigger filter

Probes subjected to high levels of vibration or

shock loads may output signals without having

contacted any surface. The enhanced trigger filter

improves the probes resistance to these effects.

Standby mode: where the probe is awaiting a

switch on signal.

Operational mode: activated by one of the switch

on methods described on this page. In this mode

the RMP40 is ready for use.

Configuration mode: where Trigger Logic™ may

be used to configure the following probe settings.

When the filter is enabled, a constant 10 ms delay

is introduced to the probe output.

The RMP40 is factory set to trigger filter off.

NOTE:

approach speed to allow for the increased stylus

overtravel during the extended time delay.

It may be necessary to reduce the probe

2.3

RMP40 basics

RMP40 switch on method

Switch on options are configurable

RMP40 switch off method

Switch off options are configurable

Switch on time

Radio on

Radio switch on is commanded by

machine input.

Spin on

Spin at 500 rev/min for 1 second

minimum (6 seconds maximum).

Radio off

Radio switch off is commanded by

machine input. A timer automatically

switches the probe off 90 minutes

after the last trigger if it is not turned

off by machine input.

Timer off (timeout)

Timeout will occur 12, 33 or 134

seconds (user configurable) after the

last probe trigger or reseat.

Spin off

Spin at 500 rev/min for 1 second

minimum (6 seconds maximum).

A timer automatically switches the

probe off 90 minutes after the last

trigger if it is not spun.

1 second maximum

Note: This assumes

a good radio

communication link.

In a poor RF

environment this may

rise to a maximum of

3 seconds.

2 seconds maximum.

Note: The 2 seconds

starts from the

moment the spindle

reaches 500 rev/min.

Timer off (timeout)

Timeout will occur 12, 33 or 134

seconds (user configurable) after the

last probe trigger or reseat.

NOTE: After being switched on, the RMP40 must be on for 1 second minimum (the RMP40 must be

spun down before it can be spun off again) before being switched off.

RMP40 installation guide

2.4

RMP40 basics

Multiple probe mode

The RMP40 can be configured, using Trigger

Logic™, to allow multiple radio probes to be used

with a single RMI.

NOTES:

The 'radio on' switch on method cannot be used

in multiple probe mode. Multiple probe mode will

not appear as an option if the 'radio on' option has

been selected.

RMP40 probes which are set to 'multiple probe

mode on' can coexist alongside any number of

RMP40 probes set to 'mode off'.

To allow multiple radio probes to work in close

proximity, and with a single RMI, 16 choices of

'mode on' colours are available, each representing

a different machine tool installation. The colour

choices available are as shown on page 4.2.

All probes operating with a single RMI must be set

to the same 'mode on' colour choice; any multiple

probes located on adjacent machines must all be

set to an alternative 'mode on' colour choice.

Only one probe per 'mode on' colour choice needs

to be partnered with the RMI as, by configuring

multiple probes to a single 'mode on' colour

choice, all probes using this 'mode on' colour

choice will have the same identity. The probe to be

partnered is partnered after selecting the 'multiple

probe mode' setting and choosing the 'mode

on' option. See 'Changing the probe settings' in

Section 4, "Trigger Logic™".

The addition of any further probe(s) into a single

probe installation will require that all probes are

reconfigured to the same 'mode on' colour choice

and that one of the probes is then repartnered

with the RMI.

The addition of any further probe(s), or

replacements, into a multi-probe installation can

be achieved simply through the reconfiguration of

the probe to the same 'mode on' colour choice.

Acquisition mode

System set-up is achieved using Trigger Logic™

and powering on the RMI.

Partnering is only required during initial system

set-up. Further partnering is only required if either

the RMP40 or RMI is changed.

Partnering will not be lost by reconfiguration of

probe settings or when changing batteries, except

where multiple probe mode is selected .

Partnering can take place anywhere within the

operating envelope.

There is no limit to the number of probes that can

be used with a single RMI so long as they all have

the same 'mode on' colour choice.

All RMP40 probes are factory set to 'mode off'.

2.5

RMP40 basics

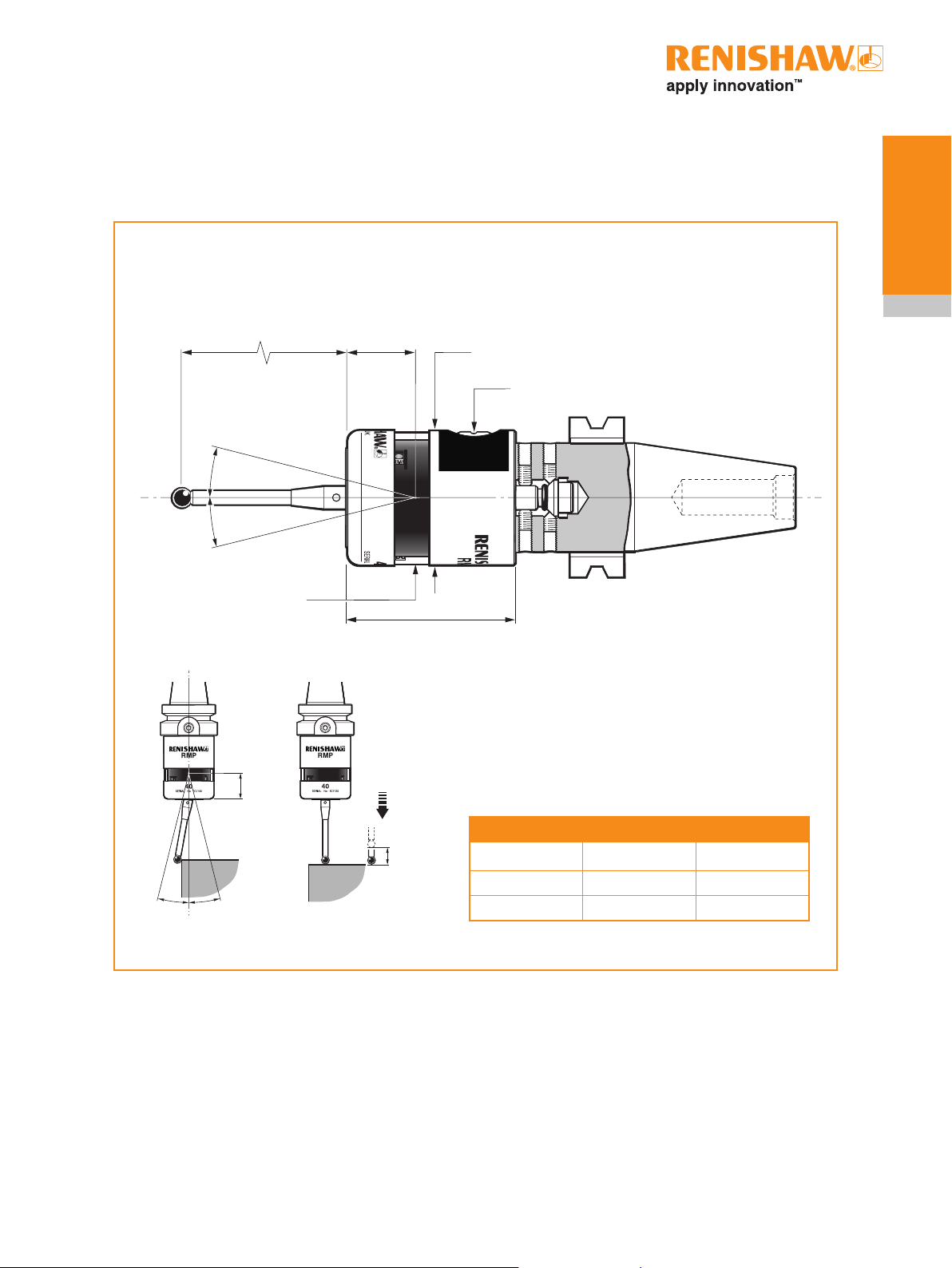

RMP40 dimensions

50 (1.97)

M4 stylus

12.5°

12.5°

Dimensions given in mm (in)

19 (0.75)

Ø40 (Ø1.57)

Battery cassette

RMP40 window

±X ±Y

50 (1.97)

+Z

A range of probe-ready

shanks is available from

Renishaw

Stylus overtravel limits

Stylus length ±X/±Y +Z

50 (1.97) 12 (0.47) 6 (0.24)

100 (3.94) 22 (0.87) 6 (0.24)

Loading...

Loading...