Page 1

Installation guide

Draft 5 16/04/18

H-6570-8501-01-A

RMP400 high accuracy radio machine

probe

Page 2

© 2018 Renishaw plc. All rights reserved.

Draft 5 16/04/18

This document may not be copied or reproduced

in whole or in part, or transferred to any other

media or language, by any means, without the

prior written permission of Renishaw plc.

The publication of material within this document

does not imply freedom from the patent rights of

Renishaw plc.

Renishaw part no: H-6570-8501-01-A

Issued: ??.????

Page 3

Contents

Draft 5 16/04/18

Before you begin .............................................................1.1

i

Before you begin

Disclaimer

Trade marks

Warranty

Changes to equipment

CNC machines

Care of the probe

Patents

EU declaration of conformity

FCC Information to user (USA only)

WEEE directive

Radio approval

Safety

....................................................................1.5

............................................................1.1

..............................................................1.1

.............................................................1.1

................................................................1.1

.....................................................1.1

...........................................................1.1

.........................................................1.1

.................................................................1.2

...................................................1.3

.............................................1.3

.............................................................1.3

.............................................................1.4

RMP400 basics ...............................................................2.1

Introduction

Getting started

System interface

Trigger Logic™

Probe modes

Configurable settings

Switch-on/switch-off methods

Enhanced trigger filter

Auto-reset function

Multiple probe mode

Acquisition mode

RMP400 dimensions

RMP400 specification

Recommended styli

................................................................2.1

...........................................................2.1

..........................................................2.2

...........................................................2.2

...............................................................2.2

.........................................................2.2

................................................2.2

.....................................................2.4

........................................................2.4

.......................................................2.4

.........................................................2.5

.........................................................2.6

........................................................2.7

..........................................................2.9

Page 4

RMP400 installation guide

Draft 5 16/04/18

System installation ...........................................................3.1

Installing the RMP400 with an RMI or RMI-Q ......................................3.1

Operating envelope .......................................................3.1

Positioning the RMP400 and RMI or RMI-Q ....................................3.2

Contents

ii

Performance envelope .....................................................3.2

Preparing the RMP400 for use .................................................3.3

Fitting the stylus ..........................................................3.3

Installing the batteries .....................................................3.4

Mounting the probe on a shank ..............................................3.5

Stylus on-centre adjustment .................................................3.6

Calibrating the RMP400 ......................................................3.7

Why calibrate a probe? ....................................................3.7

Calibrating in a bored hole or on a turned diameter ...............................3.7

Calibrating in a ring gauge or on a datum sphere ................................3.7

Calibrating the probe length .................................................3.7

Trigger Logic™ ...............................................................4.1

Reviewing the probe settings ..................................................4.1

Multiple probe mode settings ..................................................4.2

Probe settings record ........................................................4.3

Changing the probe settings ...................................................4.4

RMP400 – RMI partnership .................................................... 4.6

RMP400 – RMI-Q partnership .................................................. 4.7

Operating mode .............................................................4.8

Maintenance .................................................................5.1

Maintenance ...............................................................5.1

Cleaning the probe ..........................................................5.1

Changing the batteries .......................................................5.2

Fault-finding .................................................................6.1

Parts list .....................................................................7.1

Page 5

see Section 1, “Before you begin”

Draft 5 16/04/18

Before you begin

1.1

Before you begin

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF THIS

DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES

OR REPRESENTATIONS REGARDING

THE CONTENT. RENISHAW EXCLUDES

LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trade marks

RENISHAW and the probe symbol used in the

RENISHAW logo are registered trade marks of

Renishaw plc in the United Kingdom and other

countries. apply innovation and names and

designations of other Renishaw products and

technologies are trade marks of Renishaw plc or

its subsidiaries.

Warranty

Equipment requiring attention under warranty

must be returned to your equipment supplier.

Unless otherwise specifically agreed in writing

between you and Renishaw, if you purchased

the equipment from a Renishaw company, the

warranty provisions contained in Renishaw’s

CONDITIONS OF SALE apply. You should consult

these conditions in order to find out the details

of your warranty but, in summary, the main

exclusions from the warranty are if the equipment

has been:

• neglected, mishandled or inappropriately used;

or

• modified or altered in any way except with the

prior written agreement of Renishaw.

If you purchased the equipment from any other

supplier, you should contact them to find out what

repairs are covered by their warranty.

Google Play and the Google Play logo are

trademarks of Google LLC.

Apple and the Apple logo are trademarks of

Apple Inc., registered in the U.S. and other

countries. App Store is a service mark of Apple

Inc.,registered in the U.S. and other countries.

All other brand names and product names used

in this document are trade names, trade marks, or

registered trade marks of their respective owners.

Changes to equipment

Renishaw reserves the right to change equipment

specifications without notice.

CNC machines

CNC machine tools must always be operated by

fully trained personnel in accordance with the

manufacturer’s instructions.

Care of the probe

Keep system components clean and treat the

probe as a precision tool.

Page 6

Before you begin

Draft 5 16/04/18

Patents

Features of the RMP400, and other similar

Renishaw products, are the subject of one or

more of the following patents and/or patent

applications:

1.2

Patents will be listed

here when we have

them.. Possibly all

RMP40 patents and

strain gauge patents

(Steve to confirm)

Page 7

EU declaration of conformity

Draft 5 16/04/18

FCC Information to user (USA only)

C

Renishaw plc declares that the RMP400 complies

with the applicable standards and regulations.

Contact Renishaw plc or visit

www.renishaw.com/mtpdoc for the full EU

declaration of conformity.

WEEE directive

47 CFR Section 15.19

This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful

interference, and

2. This device must accept any interference

received, including interference that may

cause undesired operation.

47 CFR Section 15.21

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc or authorised representative could

void the user’s authority to operate the equipment.

Before you begin

1.3

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of

this product will help to save valuable resources

and prevent potential negative effects on the

environment. For more information, please contact

your local waste disposal service or Renishaw

distributor.

Page 8

Before you begin

Draft 5 16/04/18

1.4

Radio approval

Will be listed here, when there are some (testing

to take place first).

Page 9

Safety

Draft 5 16/04/18

Information to the user

• Do not get batteries wet.

• If a battery is damaged, exercise caution when

handling it.

The RMP400 is supplied with two nonrechargeable ½AA lithium-thionyl chloride

batteries (approved to BS EN 62133:2013

[IEC 62133:2012]). Once the charge in these

batteries is depleted, do not attempt to recharge

them.

The use of this symbol on the batteries,

packaging or accompanying documents indicates

that used batteries should not be mixed with

general household waste. Please dispose of

the used batteries at a designated collection

point. This will prevent potential negative effects

on the environment and human health which

could otherwise arise from inappropriate waste

handling. Please contact your local authority or

waste disposal service concerning the separate

collection and disposal of batteries. All lithium and

rechargeable batteries must be fully discharged or

protected from short circuiting prior to disposal.

Please ensure replacement batteries are of the

correct type and are fitted in accordance with

the instructions in this manual (see page 5.2,

“Changing the batteries”), and as indicated on the

product. For specific battery operating, safety and

disposal guidelines, please refer to the battery

manufacturer’s literature.

• Ensure that all batteries are inserted with the

correct polarity.

• Do not store batteries in direct sunlight or rain.

• Do not heat or dispose of batteries in a fire.

• Avoid forced discharge of the batteries.

Please ensure that you comply with international

and national battery transport regulations when

transporting batteries or the products.

Lithium batteries are classified as dangerous

goods and strict controls apply to their shipment

by air. To reduce the risk of shipment delays, if you

need to return the products to Renishaw for any

reason, do not return any batteries.

In all applications involving the use of machine

tools or CMMs, eye protection is recommended.

The RMP400 has a glass window. Handle with

care if broken to avoid injury.

Information to the machine supplier/

installer

It is the machine supplier’s responsibility to ensure

that the user is made aware of any hazards

involved in operation, including those mentioned

in Renishaw product literature, and to ensure

that adequate guards and safety interlocks are

provided.

Under certain circumstances, the probe signal

may falsely indicate a probe seated condition. Do

not rely on probe signals to halt the movement of

the machine.

Information to the equipment installer

All Renishaw equipment is designed to comply

with the relevant EC and FCC regulatory

requirements. It is the responsibility of the

equipment installer to ensure that the following

guidelines are adhered to, in order for the product

to function in accordance with these regulations:

• any interface MUST be installed in a position

away from any potential sources of electrical

noise, i.e. power transformers, servo drives etc;

Before you begin

1.5

• Do not short-circuit the batteries.

• Do not disassemble, pierce, deform or apply

excessive pressure to the batteries.

• Do not swallow the batteries.

• Keep the batteries out of the reach of children.

• all 0 V/ground connections should be

connected to the machine “star point” (the “star

point” is a single point return for all equipment

ground and screen cables). This is very

important and failure to adhere to this can

cause a potential difference between grounds;

Page 10

• all screens must be connected as outlined in

Draft 5 16/04/18

the user instructions;

• cables must not be routed alongside high

current sources, i.e. motor power supply cables

etc, or be near high-speed data lines;

Before you begin

1.6

• cable lengths should always be kept to a

minimum.

Equipment operation

If this equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

Page 11

see Section 2, “RMP400 basics”

Draft 5 16/04/18

RMP400 basics

2.1

Introduction

The RMP400 offers an unrivalled combination

of size, accuracy, reliability and robustness

and, allows high-accuracy probing on small to

medium machining centres or other machines

where line-of-sight problems affect optical signal

transmission.

Successfully combining patented RENGAGE™

strain gauge technology with the patented

frequency hopping radio transmission system of

the RMP40, the RMP400 provides existing probe

users with a simple upgrade to solid-state strain

gauge technology and all the associated benefits

this brings:

• excellent 3D performance to allow probing of

contoured surfaces;

• improved repeatability in all probing directions;

• a low triggering force combined with low pre-

travel variation to provide high accuracy, even

when used with long styli;

Performing this calibration for every 3D

direction can be time-consuming.

The RMP400 has almost no pre-travel

variation, so a single calibration value may be

used for any probing angle in 2D or 3D. This

results in a vastly reduced calibration time. An

additional benefit is a corresponding reduction

in errors introduced by environmental changes

within the machine during a long calibration

cycle.

• The ability to be used in applications

where axial and radial reorientations are

used, enabled by the use of solid state

accelerometers:

The auto-reset function is required and

recommendations should be followed for

optimum metrology performance.

Getting started

Three multicolour probe LEDs provide visual

indication of selected probe settings.

• a proven ten-fold improvement in life (10 million

triggers); ????

• the elimination of reseat failures;

• high resistance to machine tool vibration;

• resistance to shock and false triggering

through the use of solid state accelerometers.

In addition to providing high-accuracy

measurement on your machine tool, the RMP400

also offers:

• Faster calibration:

On complex 3D parts, it is common to

measure in several different directions. Each

direction of a standard mechanical probe must

be calibrated, to ensure that the pre-travel

variation is compensated in the measurement.

For example:

• Switch-on and switch-off methods

• Probe status – triggered or seated

• Battery condition

Batteries are inserted or removed as shown (see

page 3.5, “Installing the batteries”) for further

information).

On insertion of batteries, the LEDs will begin

to flash (see page 4.1, “Reviewing the probe

settings”).

Page 12

System interface

Draft 5 16/04/18

Configurable settings

The RMI and RMI-Q are integrated interfaces/

receivers used to communicate between the

RMP400 probe and the machine control.

RMP400 basics

2.2

Trigger Logic™

Trigger Logic (see Section 4, “Trigger Logic™”) is

a method that allows the user to view and select

all available mode settings in order to customise

a probe to suit a specific application. Trigger

Logic is activated by battery insertion and uses

a sequence of stylus deflections (triggering) to

systematically lead the user through the available

choices to allow selection of the required mode

options.

A Trigger Logic app is available that simplifies this

process with clear, interactive instructions and

informative videos and is available for download

on the following app stores.

Switch-on/switch-off methods

The following switch-on/switch-off options are

user-configurable.

• Radio on/Radio off

• Radio on/Timer off

• Spin on/Spin off

• Spin on/Timer off

or

Current probe settings can be reviewed by

simply removing the batteries for a minimum of

seconds, and then replacing them to activate

five

the Trigger Logic review sequence.

Pr

obe modes

The RMP400 probe can be in one of three modes:

Standb

signal.

NOTE: The RMP400 will enter hibernation mode

should the system interface be powered off or

out of range for a period of 30 seconds (only

applicable to “radio on” mode).

y mode – Probe is waiting for a switch-on

Operational mode – When activated by one of

the switch-on methods, the probe is switched on

and ready for use.

Configuration mode – Ready to change the

probe settings using Trigger Logic.

Page 13

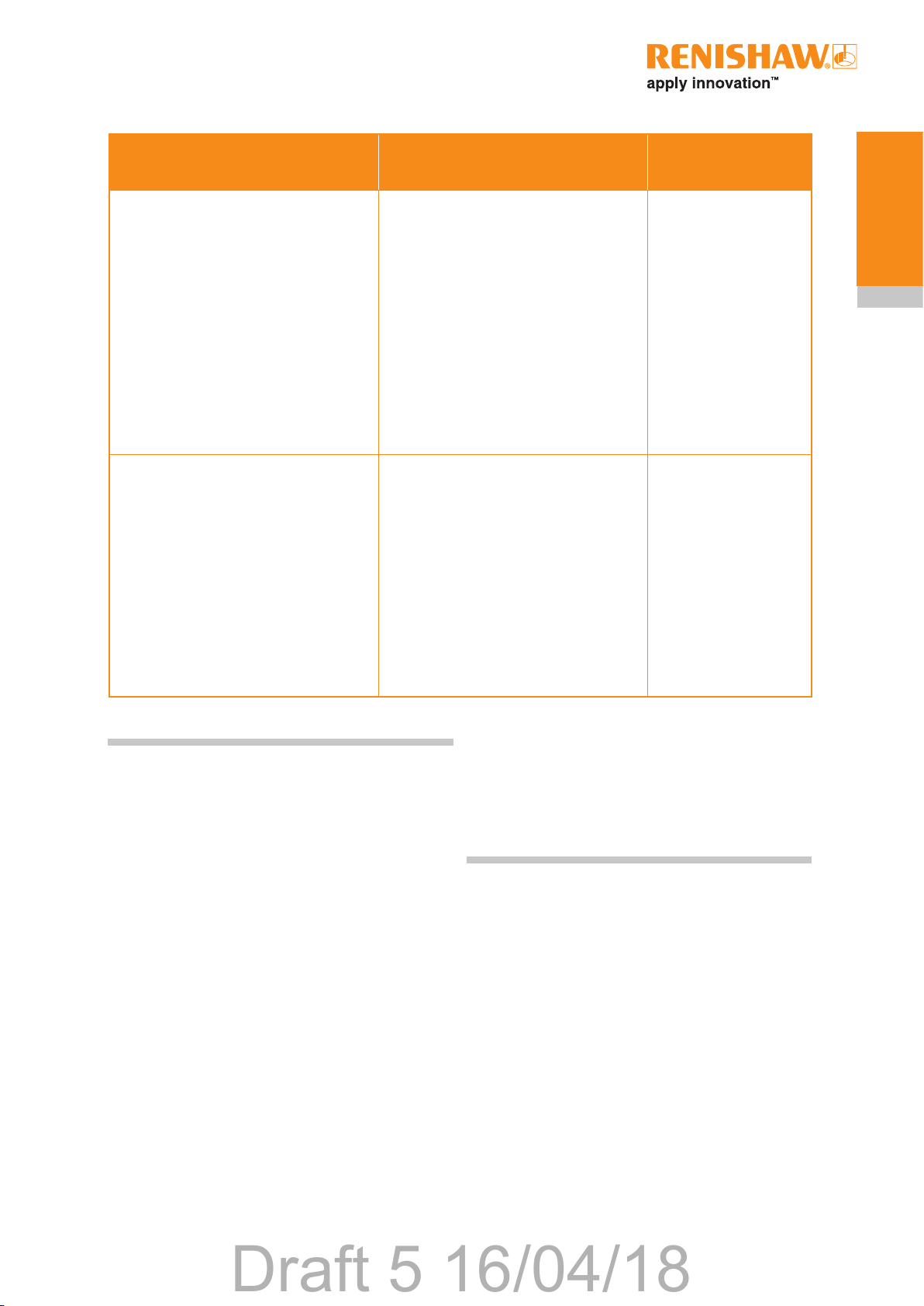

RMP400 switch-on method

Draft 5 16/04/18

Switch-on options are configurable

RMP400 switch-off method

Switch-off options are configurable

Probe ready time

Radio on

Radio switch on is commanded by

machine input.

Spin on

Spin at 500 rev/min for one second

minimum.

Radio off

Radio switch off is commanded by

machine input. A timer automatically

switches the probe off 90 minutes

after the last trigger if it is not turned

off by machine input.

Timer off (timeout)

Timeout will occur 12, 33 or 134

seconds (user configurable) after the

last probe trigger or reseat.

Spin off

Spin at 500 rev/min for one second

minimum. A timer automatically

switches the probe off 90 minutes

after the last trigger if it is not spun.

Timer off (timeout)

Timeout will occur 12, 33 or 134

seconds (user configurable) after the

last probe trigger or reseat.

1.7 seconds

maximum.

RMP400 basics

2.3

2.5 seconds. (The

probe must be

stationary for 2.5

seconds minimum

after it has stopped

spinning.)

NOTES:

In “radio on” mode, the switch-on time is user

selectable “fast” or “standard” when using

RMI-Q (selection is made in RMI-Q). Otherwise

1.7 seconds.

For more information on the user selectable

switch-on time when operating with RMI-Q, please

refer to the installation guide RMI-Q radio machine

interface (Renishaw part no. H-5687-8504).

In “radio on” mode, the switch-on time assumes

a good radio communication link. In a poor RF

environment this may rise to a maximum of

3.0 seconds.

In “spin on” mode, the one second starts from

the moment the spindle reaches 500 rev/min.

The RMP400 must be on for a minimum of

one second before being switched off.

Page 14

RMP400 installation guide

Draft 5 16/04/18

Enhanced trigger filter

Probes subjected to high levels of vibration or

shock loads may output signals without having

contacted any surface. The enhanced trigger filter

improves the probe’s resistance to these effects.

RMP400 basics

2.4

When the filter is enabled, a constant 8 ms or

16 ms delay is introduced to the probe’s output.

The factory setting is 8 ms. If false triggering is

noticed, then consider increasing the filter delay to

16 ms.

Auto-reset function

In previous strain gauge products, the probe was

required to be turned off during reorientation

moves. The auto-reset function in the RMP400

can compensate for stylus forces, resulting from

changes in probe orientation, that can cause the

probe to trigger.

This feature is controlled by solid state

accelerometers and is suitable for applications

where axial and radial reorientation of the probe is

applied.

To achieve optimum metrology performance

when the auto-reset function is turned on, a dwell

is recommended before making a programmed

move that follows any reorientation of the probe.

When using a stylus of up to 150 mm long,

a 0.2 second dwell is necessary. In most

applications the machine response time will

adequately provide this.

Up to four RMP400s can be used with a single

RMI-Q in “radio on/radio off” mode. For further

details of this functionality, please refer to the

installation guide RMI-Q radio machine interface

(Renishaw part no. H-5687-8504).

NOTES:

Multiple probe mode is a function of the RMP400,

as such, the option will not appear when the

“radio on” option has been selected.

RMP400 probes which are set to “multiple probe

mode on” can coexist alongside any number of

RMP400 probes set to “multiple probe mode off”.

To allow multiple radio probes to work in close

proximity, and with a single RMI or RMI-Q,

16 choices of “mode on” colours are available,

each representing a different machine tool

installation. (see page 4.2, “Multiple probe

settings”).

All probes operating with a single RMI or RMI-Q

must be set to the same “mode on” colour choice;

any multiple probes located on adjacent machines

must all be set to an alternative “mode on” colour

choice.

NOTE: Each probe per “mode on” colour choice

needs to be partnered with the RMI or RMI-Q.

By configuring multiple probes to a single “mode

on” colour choice, all probes using this “mode on”

colour choice will have the same identity.

When using a heavy stylus configuration, or a

stylus longer than 150 mm, it is recommended

that the RMP400 should be turned off during

reorientation moves.

Multiple probe mode

The RMP400 can be configured, using Trigger

Logic, to allow multiple radio probes in “spin on/

spin off” or “shank on/shank off” to be used with a

single RMI or RMI-Q.

The probe to be partnered is partnered after

selecting the multiple probe mode setting and

choosing the “mode on” option. (see page 4.4,

“Changing the probe settings”).

There is no limit to the number of probes that can

be used with a single RMI or RMI-Q so long as

they all have the same “mode on” colour choice.

All RMP400 probes are factory set to “mode off”.

The addition of any further probe(s) into a single

probe installation will require that all probes are

reconfigured to the same “mode on” colour choice

and that one of the probes is then repartnered

with the RMI or RMI-Q.

Page 15

The addition of any further probe(s), or

Draft 5 16/04/18

replacements, into a multi-probe installation can

be achieved simply through the reconfiguration of

the probe to the same “mode on” colour choice.

Acquisition mode

System set-up is achieved using Trigger Logic and

powering-on the RMI or RMI-Q.

Partnering is only required during initial system

set-up. Further partnering is only required if either

the RMP400 or RMI/RMI-Q is changed.

NOTES:

Systems using the RMI-Q can be partnered with

up to four RMP400s manually. Alternatively this

can be achieved by using ReniKey; a Renishaw

machine macro cycle which does not require the

RMI-Q to be power cycled.

RMP400 basics

2.5

For more information or to download ReniKey free

of charge visit:

www.renishaw.com/mtpsupport/renikey

Partnering by ReniKey is not available for RMI.

Partnering will not be lost by reconfiguration of

probe settings or when changing batteries, except

where multiple probe mode is selected.

Partnering can take place anywhere within the

operating envelope.

Page 16

RMP400 dimensions

Draft 5 16/04/18

RMP400 basics

2.6

50 (1.97)

M4 stylus

11°

Ø40 (Ø1.57)

Dimensions given in mm (in)

Stylus length ±X/±Y Z

50 (1.97) 12 (0.47) 6 (0.24)

100 (3.94) 22 (0.87) 6 (0.24)

11°

RMP400 window

Stylus overtravel limits

19 (0.75)

50.5 (1.99)

Battery cassette

A range of probe-ready shanks is

available from Renishaw

Probe status LED

Page 17

RMP400 specification

Draft 5 16/04/18

Principal application

Dimensions

Weight (without shank)

Transmission type

Radio frequency

Switch-on methods

Switch-off methods

Probe feedrate (minimum)

Spindle speed (maximum)

Operating range

Receiver/interface

Sense directions

Unidirectional repeatability

Workpiece inspection and job set-up on multi-tasking machines,

machining centres and gantry machining centres.

Length

Diameter

With batteries

Without batteries

Frequency hopping spread spectrum (FHSS) radio

2400 MHz to 2483.5 MHz

Radio M-code or spin on

Radio M-code, timer or spin off

3 mm/min (0.12 in/min) (see note 6)

1000 rev/min

Up to 15 m (49.2 ft)

RMI or RMI-Q combined interface and receiver unit

±X, ±Y, +Z

0.25 µm (10 µin) 2s – 50 mm stylus length (see note 1)

0.35 µm (14 µin) 2s – 100 mm stylus length

50.5 mm (1.99 in)

40 mm (1.57 in)

262 g (9.24 oz)

242 g (8.54 oz)

RMP400 basics

2.7

X, Y (2D) form measurement

deviation

X, Y, Z (3D) form

measurement deviation

Stylus trigger force

(see notes 2 and 5)

XY plane (typical minimum)

+Z direction (typical minimum)

Stylus overtravel force

XY plane (typical minimum)

+Z direction (typical minimum)

Stylus overtravel

Note 1 Performance specification is tested at a standard test velocity of 240 mm/min (9.45 in/min) with a 50 mm (1.97 in)

carbon fibre stylus. Significantly higher velocity is possible depending on application requirements.

Note 2 Trigger force, which is critical in some applications, is the force exerted on the component by the stylus when the

probe triggers. The maximum force applied will occur after the trigger point (overtravel). The force value depends on

related variables including measuring speed and machine deceleration. RENGAGE™ equipped probes offer ultralow trigger forces.

Note 3

Note 4

Note 5 These are the factory settings, manual adjustment is not possible.

Note 6 Speeds below 3 mm/min commonly occur when manually moving the probe using the handwheel with a very fine

Stylus overtravel force in the XY plane typically occurs 70 µm (2755.91 µin) after the trigger point and rises by

0.1 N mm 10 gf/mm (9.1 oz/in) until the machine tool stops (in the high force direction and using a 50 mm (1.97 in)

carbon fibre stylus).

Stylus overtravel force in the +Z direction occurs 10 µm (393.70 µin) to 11 µm (433.07 µin) after the trigger point and

rises by 1.2 N/mm, 122 gf/mm (109.60 oz/in) until the machine tool stops.

feedrate.

±0.25 µm (10 µin) – 50 mm stylus length (see note 1)

±0.25 µm (10 µin) – 100 mm stylus length

±1.00 µm (40 µin) – 50 mm stylus length (see note 1)

±1.75 µm (70 µin) – 100 mm stylus length

0.06 N, 6 gf (0.22 ozf)

2.55 N, 260 gf (9.17 ozf)

1.04 N, 106 gf (3.74 ozf) (see note 3)

5.50 N, 561 gf (19.78 ozf) (see note 4)

XY plane

+Z plane

TBC by end of March

±11°

6 mm (0.23 in)

TBC

Page 18

RMP400 installation guide

Draft 5 16/04/18

RMP400 basics

2.8

Typical battery life

Environment

Battery types

Battery reserve life

Typical battery life

Battery type

Standby life 5% usage

IP rating IPX8, BS EN 60529:1992+A2:2013

(IEC 60529:1989+A1:1999+A2:2013)

IK rating IK01 (BS EN IEC 62262: 2002) [for glass

window]

Storage temperature

Operating temperature +5 °C to +50 °C (+41 °F to +122 °F)

2 × ½AA 3.6 V lithium-thionyl chloride (LTC)

Approximately one week after a low battery warning is first given (based

on 5% usage).

See the table below.

Spin switch on Radio switch on

(72 minutes/day)

–10 °C to +70 °C (+14 °F to +158 °F)

Standby life 5% usage

(72 minutes/day)

Continuous use

Lithium-thionyl

chloride

NOTE: Using RMP400 with “fast radio on” mode will result in a 20% reduction in standby battery life

and a 10% reduction in 5% usage battery life.

230 days 90 days 230 days 90 days 165 hours

Page 19

Recommended styli

Draft 5 16/04/18

High modulus carbon fibre styli are designed to

minimise pre-travel and improve accuracy, as

the stem material is extremely stiff. This inherent

stiffness makes the following styli most suitable for

strain gauge applications.

B

RMP400 basics

2.9

D

A

C

Part number A-5003-7306

Carbon fibre

A

Ball diameter mm (inch) 6 (0.24) 6 (0.24) 6 (0.24) 6 (0.24)

B

Length mm (inch) 50 (1.97) 100 (3.94) 150 (5.91) 200 (7.88)

C

Stem diameter mm (inch) 4.5 (0.18) 4.5 (0.18) 4.5 (0.18) 4.5 (0.18)

D

EWL mm (inch) 38.5 (1.52) 88.5 (3.48) 138.5 (5.45) 188.5 (7.42)

Mass in g (oz) 4.1 (0.14) 6.2 (0.22) 7.5 (0.26) 8.7 (0.31)

The featured range of solid carbon fibre styli

ensure the best possible performance of the

RMP400.

It is possible that the featured range of solid

carbon fibre styli may not be suitable for every

RMP400 application and that it may be necessary

to select specialised styli configurations to meet

specific application requirements.

In applications where specialised styli are to be

used, it may be beneficial to reduce the speed of

probing moves. It has been seen in some cases

that specialist styli configurations do not exhibit

the probing characteristics and performance

that would have otherwise been expected and

achieved when using standard styli. Reducing the

speed of the probing move may, in some cases,

improve the performance of the probe.

A-5003-6510

Carbon fibre

When selecting components for an application

specific stylus, it is recommended that

a configuration with the least number of

components is chosen. The stylus diameter

should always be as large as possible and the

overall stylus length kept to a minimum. If a stem

with a reduced diameter is required, then it is

recommended that an M4 stem with a short length

and reduced diameter is selected.

A-5003-6511

Carbon fibre

A-5003-6512

Carbon fibre

Page 20

RMP400 basics

Draft 5 16/04/18

2.10

This page is intentionally left blank.

Page 21

see Section 3, “System installation”

Draft 5 16/04/18

System installation

Installing the RMP400 with an RMI or RMI-Q

3.1

CNC machining

centre spindle

RMP400

inspection probe

Stylus

Workpiece

Typical tool

setting probe

Operating envelope

Radio transmission does not require line-of-sight

between the probe and interface as it works

via reflected paths, and will pass through gaps

and machine tool windows. This allows easy

installation, either inside or outside the machine

enclosure, as long as the probe and RMI or

RMI-Q are kept within the performance envelope

shown overleaf.

RMI or RMI-Q

interface

When operating, do not cover the probe glass

window, RMI or RMI-Q with your hands, as this

will affect the performance.

Mounting

bracket

CNC

machine

control

Cable

Interface unit

Coolant and swarf residue accumulating on

the RMP400 and RMI or RMI-Q may have a

detrimental effect on transmission performance.

Wipe clean as often as is necessary to maintain

unrestricted transmission.

Page 22

Positioning the RMP400 and RMI or

Draft 5 16/04/18

RMI-Q

NOTE: Installing the RMP400 and RMI or RMI-Q

with the RMP400 in radio-on configuration

System

installation

3.2

The probe system should be positioned so that

the optimum range can be achieved over the full

travel of the machine’s axes. Always face the front

cover of the RMI or RMI-Q in the general direction

of the machining area and the tool magazine,

ensuring both are within the performance

envelope shown below. To assist in finding the

optimum position of the RMI or RMI-Q, the signal

quality is displayed on an RMI or RMI-Q signal

LED.

The RMP400 has a built-in hibernation mode

(battery-saving mode) that saves battery life

when the RMI or RMI-Q is unpowered in radio-on

(radio-off or timer-off) configurations. The RMP400

goes into hibernation mode 30 seconds after

the RMI or RMI-Q is unpowered (or the RMP400

is out of range). When in hibernation mode, the

RMP400 checks for a powered RMI or RMI-Q

every 30 seconds. If found, the RMP400 goes

from hibernation mode to standby mode, ready for

radio-on.

Performance envelope

The RMP400 and RMI or RMI-Q must be within

each other’s performance envelope, as shown

below. The performance envelope shows line-ofsight performance, however, this is not necessary

for the RMP400 radio transmission as it will

operate with any reflected radio path provided

that the reflected path length does not exceed the

15 m (49.2 ft) operating range.

Performance envelope when using the RMP400 with the RMI or RMI-Q

75°

60°

45°

75°

15 (49)

60°

45°

30°

15°

0°

15°

30°

45°

60°

Typical plot at +20 °C (+68 °F)

Transmission range in m (ft)

75°

10 (33)

5 (16)

90°

75°

75°

60°

45°

30°

15°

0°

15°

30°

45°

60°

Operating and switch-on / switch-off

30°

15°

0°

15°

30°

45°

60°

5 (16)

10 (33)

15 (49)

75°

Page 23

Preparing the RMP400 for use

Draft 5 16/04/18

Fitting the stylus

1

System

3.3

installation

2

M-5000-3707

1.8 Nm – 2.2 Nm

(1.3 lbf.ft – 1.6 lbf.ft)

Page 24

System

Draft 5 16/04/18

installation

3.4

Installing the batteries

NOTES:

See (Section 5,“Maintenance”)for a list of suitable

battery types.

If dead batteries are inadvertently inserted, the

LEDs will remain a constant red.

Do not allow coolant or debris to enter the battery

compartment. When inserting batteries, check that

the battery polarity is correct.

After the batteries have been inserted, the LEDs

will display the current probe settings, for details,

(see Section 4, “Trigger Logic™”).

1

3

2

Please remove the

battery isolation device

from the battery

compartment before use.

4

Page 25

Mounting the probe on a shank

Draft 5 16/04/18

1

2 mm A/F

× 4

× 2

2 mm A/F

× 2

× 4

System

3.5

installation

2

2 mm A/F

× 2

0.5 Nm – 1.5 Nm

(0.4 lbf.ft – 1.1 lbf.ft)

Page 26

Stylus on-centre adjustment

Draft 5 16/04/18

System

installation

3.6

NOTES:

If a probe and shank assembly is dropped, it must

be rechecked for correct on-centre adjustment.

Do not hit or tap the probe to achieve on-centre

adjustment.

1

× 4

360°

±10 µm

2

1.5 Nm – 2.2 Nm

(1.1 lbf.ft – 1.6 lbf.ft)

360°

±10 µm

× 2

3

× 4

1.5 Nm – 2.2 Nm

(1.1 lbf.ft – 1.6 lbf.ft)

360°

±2.5 µm

Page 27

Calibrating the RMP400

Draft 5 16/04/18

Why calibrate a probe?

A spindle probe is just one component of the

measurement system which communicates with

the machine tool. Each part of the system can

introduce a constant difference between the

position that the stylus touches and the position

that is reported to the machine. If the probe is

not calibrated, this difference will appear as an

inaccuracy in the measurement. Calibration of the

probe allows the probing software to compensate

for this difference.

Calibrating in a bored hole or on a turned diameter

Calibrating a probe, either in a bored hole or on

a turned diameter of known size, automatically

stores values for the offset of the stylus ball to

the spindle centre line. The stored values are

then used automatically in the measuring cycles.

Measured values are compensated by these

values so that they are relative to the true spindle

centre line.

Calibrating in a ring gauge or on a datum sphere

System

3.7

installation

During normal use, the difference between the

touch position and the reported position does

not change, but it is important that the probe is

calibrated in the following circumstances:

• when a probe system is to be used for the first

time;

• when the enhanced trigger filter delay is

changed;

• when a new stylus is fitted to the probe;

• when it is suspected that the stylus has

become distorted or that the probe has been

crashed;

• at regular intervals to compensate for

mechanical changes of your machine tool;

• if repeatability of relocation of the probe shank

is poor. In this case, the probe may need to be

recalibrated each time it is selected.

It is good practice to set the tip of the stylus oncentre, because this reduces the effect of any

variation in spindle and tool orientation (see page

3.6, “Stylus on-centre adjustment”). A small

amount of run-out is acceptable, and can be

compensated for as part of the normal calibration

process.

Calibrating a probe either in a ring gauge or

on a datum sphere with a known diameter

automatically stores one or more value for the

radius of the stylus ball. The stored values are

then used automatically by the measuring cycles

to give the true size of the feature. The values are

also used to give true positions of single surface

features.

NOTE: The stored radius values are based on the

true electronic trigger points. These values are

different from the physical sizes.

Calibrating the probe length

Calibrating a probe on a known reference surface

determines the length of the probe, based on

the electronic trigger point. The stored value for

length is different from the physical length of the

probe assembly. Additionally, the operation can

automatically compensate for machine and fixture

height errors by adjusting the probe length value

that is stored.

Three different operations are to be used when

calibrating a probe. They are:

• calibrating either in a bored hole or on a turned

diameter of known position;

• calibrating either in a ring gauge or on a datum

sphere;

• calibrating the probe length.

Page 28

System

Draft 5 16/04/18

installation

3.8

This page is intentionally left blank.

Page 29

see Section 4, “Trigger Logic™”

Draft 5 16/04/18

Trigger Logic™

Reviewing the probe settings

4.1

1

Key to the symbols

LED short flash

LED long flash

2

> 5 s

3

Switch-on method

Radio on

(omitted if “multiple probe mode” is selected)

Switch-off method

Radio off or

Spin off

Auto-reset off

Trigger filter

on 8 ms

Auto-reset off

Trigger filter

or

Short timeout

or

Enhanced trigger filter and auto-reset facility

on 16 ms

12 s

or

Auto-reset on

Trigger filter

Medium timeout

or

on 8 ms

33 s

Auto-reset on

Trigger filter

or

Spin on

or

or

on 16 ms

Long timeout

134 s

Auto-reset off

Trigger filter

or

LED check

off

Hibernation mode (only for “radio on”)

On

30 s

Multiple probe mode (omitted for “radio on”)

see “Multiple probe mode settings” to view all 16 choices

Mode off Mode on

Machine 1

or

Battery good

or

Machine 2

or

Battery status

or

Probe in standby mode (after 5 seconds)

On

5 s

or

or

Battery low

Off

or

Machine 16

Page 30

Trigger Logic

Draft 5 16/04/18

4.2

RMP400 installation guide

Multiple probe mode settings

Deflect the stylus for less than 4 seconds to cycle

to the next setting.

Multiple probe mode

Mode off Mode on

Machine 1

or

or

Machine 2

or

Machine 3

or

Machine 4

Machine 5

Machine 9

Machine 13

Machine 6

or

Machine 10

or

Machine 14

or

Machine 7

or

Machine 11

or

Machine 15

or

or

Machine 12

or

Machine 16

or

Return to

“Mode off”

Machine 8

Page 31

Probe settings record

Draft 5 16/04/18

This page is provided to note your probe’s

settings.

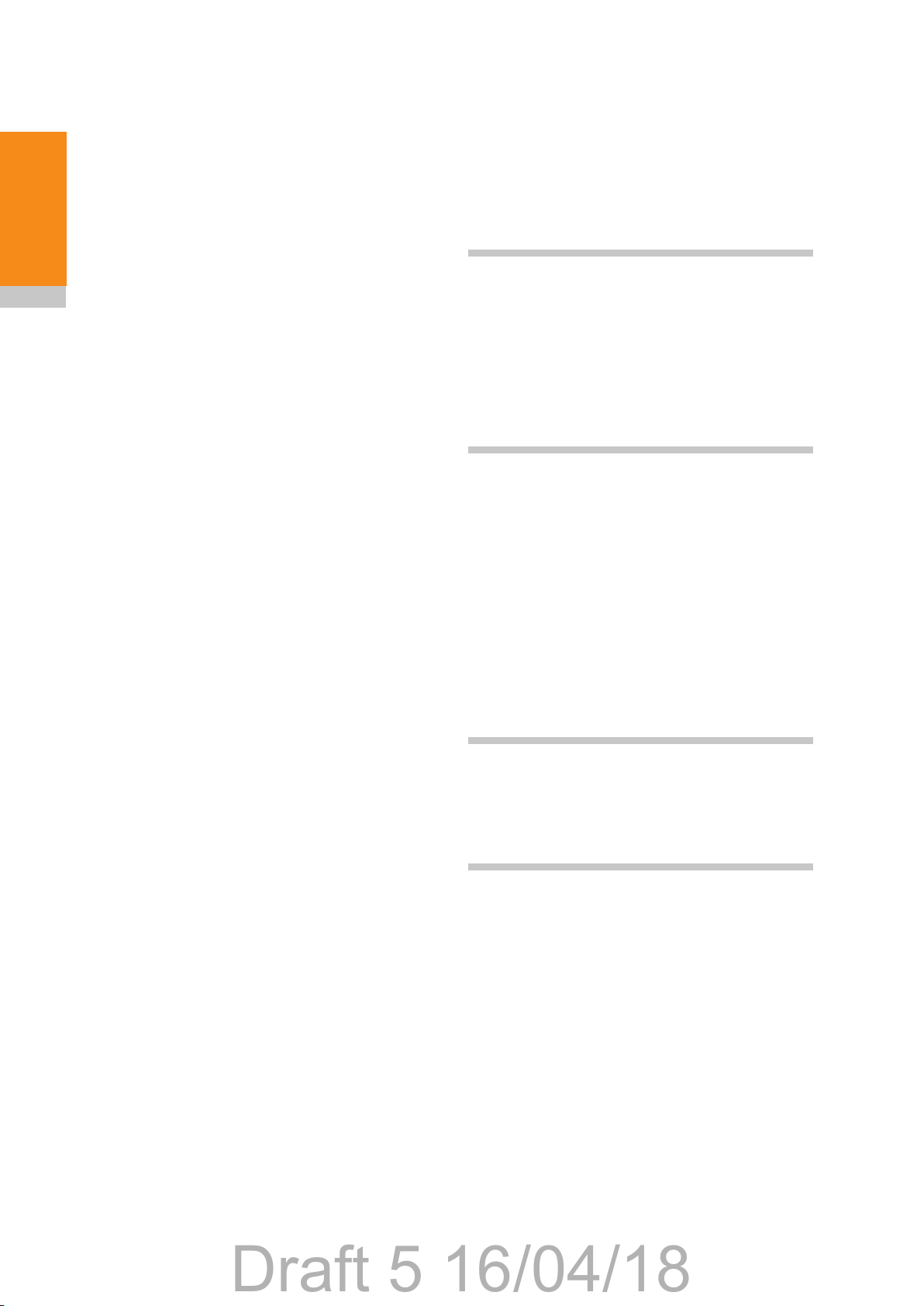

Switch-on method

Radio on

Spin on

tick

Factory

settings

tick

New

settings

Trigger Logic

4.3

Switch-off method

Auto-reset and

enhanced trigger filter

Radio or spin

Short timeout (12 s)

Medium timeout (33 s)

Long timeout (134 s)

Auto reset off /

Trigger filter on (8 ms)

Auto reset off /

Trigger filter on (16 ms)

Auto reset on /

Trigger filter on (8 ms)

Auto reset on /

Trigger filter on (16 ms)

Auto reset off / Trigger filter off

Hibernation mode

Multiple probe mode

Factory settings are for kit (A-6570-0001) only.

On (30 s)

On (5 s)

Off

Off (factory set)

On (machine number) See “Multiple

probe settings”

RMP400 serial no ........................................

Page 32

RMP400 installation guide

Draft 5 16/04/18

Trigger Logic

4.4

Probe partnering function

The probe partnering function enables the

RMP400 to be partnered with the RMI or RMI-Q

independently of the configuration process for

other probe settings. To partner RMP400 with

RMI or RMI-Q, insert the batteries or, if they

have already been installed, remove them for five

seconds and then refit them.

Following an LED check, the RMP400 will

proceed to show the probe settings, this will end

with “Probe status” being displayed. If the battery

power is good, probe status will be eight green

flashes. If battery power is low, each green flash

will be followed by a blue flash.

Key to the symbols

LED short flash

LED long flash

Deflect the stylus for less than 4 seconds

to move to the next menu option.

To exit, leave the stylus untouched for

more than 120 seconds.

Acquisition successful. Probe is now in

standby.

Whilst the “Probe status” is being displayed,

deflect and immediately release the stylus to

enter “Acquisition mode”.

“Acquisition mode off” will be displayed as a

sequence of light blue flashes, at this point the

RMI or RMI-Q must be turned on.

On the RMP400 select “Acquisition mode on”

by deflecting the stylus for less than 4 seconds.

After a successful acquisition, the RMP400 will

timeout after 8 seconds and then go into standby.

If “Acquisition mode on” is not selected, the

RMP400 will timeout after 120 seconds and then

go into standby (see page 4.10, “RMP400 – RMI

partnership”) or (see page 4.11, “RMP400 –

RMI-Q partnership”).

1

2

> 5 s

3

LED check

All probe settings will be shown, ending

with “Probe status” being displayed.

Probe status (seated)

Battery good

or

Whilst the “Probe status” is being displayed,

deflect and release the stylus to enter

“Acquisition mode off”. Probe status will flash

red to acknowledge this.

Battery good

Battery low

Probe status

or

Battery low

At this point turn on either the RMI or RMI-Q.

Page 33

After 8

Draft 5 16/04/18

seconds

Acquisition mode

Acquisition mode off

120 seconds

probe in standby

If acquisition is unsuccessful “Acquisition mode off” will be

displayed again after 8 seconds.

Deflect the stylus for less than 4 seconds to select “Acquisition

mode on” again.

Acquisition mode on

8 seconds

probe in standby

Acquisition

successful

Trigger Logic

4.5

Page 34

RMP400 installation guide

Draft 5 16/04/18

Changing the probe settings

Insert the batteries or, if they have already been

installed, remove them for five seconds and then

refit them.

1

2

> 5 s

3

Trigger Logic

4.6

Following the LED check, immediately deflect the

stylus and hold it deflected until eight red flashes

have been observed (if the battery power is low,

each red flash will be followed by a blue flash).

Keep the stylus deflected until the “Switch-on

method” setting is displayed, then release it.

CAUTION: Do not remove the batteries whilst

in configuration mode. To exit, leave the stylus

untouched for more than 20 seconds.

Key to the symbols

LED short flash

LED long flash

Deflect the stylus for less than 4 seconds

to move to the next menu option.

Deflect the stylus for more than

4 seconds to move to the next menu.

To exit, leave the stylus untouched for

more than 120 seconds.

To exit, leave the stylus untouched for

more than 20 seconds.

LED check

Probe status (triggered)

Battery good

or

Battery low

Switch-on method

(omitted if “multiple probe mode” was selected)

Radio on

Switch-off method

Radio off or

Spin off

Enhanced trigger filter setting and auto-reset facility

Auto reset off

Trigger filter

on 8 ms

Auto reset off

Trigger filter

on 16 ms

Short

timeout

12 s

Auto reset on

Trigger filter

Medium

timeout

on 8 ms

33 s

Spin on

Long

timeout

134 s

Auto reset on

Trigger filter

on 16 ms

Auto reset off

Trigger filter

off

Page 35

Acquisition mode

Draft 5 16/04/18

Acquisition mode off

Acquisition mode on

120 seconds

probe in standby

Trigger Logic

Hibernation mode (only for “radio on”)

On

30 s

Stop triggering here, unless “Multiple probe

mode” is required, in which case deflect the

stylus for more than 4 seconds.

Multiple probe mode (omitted for “radio on”)

(see “Multiple probe mode settings” to view all 16 choices)

Mode off Mode on

Machine 1 Machine 2

If no changes are made in “Multiple probe mode”, then deflecting the

stylus for more than 4 seconds will return the probe settings to beginning

of the Trigger Logic menu. If “Multiple probe mode” is selected, proceed to

“Acquisition mode” to repartner one probe with the RMI-Q.

On

5 s

Off

Machine 16

4.7

Acquisition mode

Acquisition mode off

Return to the beginning of the Trigger Logic menu

NOTE: If using “Multiple probe mode”, refer

to the installation guide RMI radio machine

interface (Renishaw part no. H-4113-8554) or the

installation guide RMI-Q radio machine interface

(Renishaw part no. H-5687-8504).

NOTE: To partner an RMP400 with an RMI

please see “RMP400 – RMI partnership”. Once

acquisition has been successful, the RMP400 will

revert to “Acquisition mode off”.

Acquisition mode on

120 seconds

probe in standby

New settings

complete,

probe in

standby

NOTE: Further probes used require the same

“Multiple probe mode” setting, but do not need

to be partnered with the RMI or RMI-Q.

NOTE: To partner an RMP400 with an RMI-Q

please see “RMP400 – RMI-Q partnership”. Once

acquisition has been successful, the RMP400 will

revert to “Acquisition mode off”.

Page 36

RMP400 installation guide

Draft 5 16/04/18

Trigger Logic

4.8

Master reset function

RMP400 features a master reset function to assist

user’s who have mistakenly changed the probe

settings into an unintended state.

The application of the master reset function will

clear all current probe settings and return the

probe to default settings.

The default settings are as follows:

• Radio switch-on

• Radio switch-off

• Auto-reset on, Enhanced trigger filter on 8 ms

• Hibernation mode on 30 s

• Multiple probe mode off

The default settings may not be representative of

the required probe settings. Further configuration

of RMP400 may subsequently be necessary to

achieve the required probe settings.

To reset the probe

1. First enter into the Trigger Logic™ menu and

ensure that the stylus is no longer deflected.

2. From within the Trigger Logic menu, hold the

stylus deflected for 20 seconds. After this

the status LEDs will proceed to flash yellow

eight times. A confirmation for master reset

is required, if nothing is done the probe will

timeout.

To confirm that a master reset is required,

release the stylus and then hold the stylus

deflected again until the eight yellow flash

sequence has ended. This action will clear

all probe settings and return the probe to

default settings. Following an LED check the

RMP400 will then go back into Trigger Logic

and will display “Switch-on method”.

3. Further configuration using Trigger Logic may

be necessary to achieve the required probe

settings.

1. Probe is in the Trigger Logic menu.

Ensure that the stylus is no longer deflected.

2.

Whilst the status LEDs are flashing yellow to confirm that

a master reset is required, release the stylus and then

hold the stylus deflected again until the eight yellow flash

sequence has ended.

System status LED

Deflect the stylus for 20 seconds until the

status LEDs start to flash yellow eight times.

Previous settings have been cleared.

The probe now has default settings.

Page 37

LED check

Draft 5 16/04/18

Switch-on method

3.

NOTE: RMP400 will continue to be partnered with either the RMI or RMI-Q following the

activation of the master reset function, unless “Multiple probe mode” has been used.

Configure probe settings as required

using Trigger Logic

Probe is now back in the Trigger

Logic menu and will display

“Switch-on method”.

Trigger Logic

4.9

Page 38

Trigger Logic

Draft 5 16/04/18

4.10

RMP400 – RMI partnership

System set-up is achieved using Trigger Logic

and powering the RMI. Partnering is only required

during initial system set-up. Further partnering

will be required if either the RMP400 or RMI

is changed, or if a system is reconfigured for

multiple probes (multiple probe mode).

Acquisition mode

Acquisition mode off

Switch the RMI on

SIGNAL LED

Partnering will not be lost by reconfiguring the

probe settings or when changing batteries, except

where multiple probe mode is selected. Partnering

can take place anywhere within the operating

envelope.

In configuration mode, configure the probe

settings as required until you reach the

“Acquisition mode” menu, which defaults to

“Acquisition mode off”.

NOTE: Please refer to the

installation guide RMI radio

machine interface (Renishaw part

no. H-4113-8554) when partnering

the RMP400.

RMI in acquisition mode

Deflect the stylus to select “Acquisition

mode on”. Ensure this is done within

8 seconds of the RMI signal LED

flashing green.

> 20 s

SIGNAL LED

New partner RMP acquired

The probe is now in standby

and the system is ready for use.

Page 39

RMP400 – RMI-Q partnership

Draft 5 16/04/18

System set-up is achieved by using Trigger Logic

and powering on the RMI-Q or applying ReniKey.

Partnering is required during initial system set-up.

Further partnering will be required if either the

RMP400 or RMI-Q is changed.

Partnering will not be lost by reconfiguring

the probe settings or changing the batteries.

Partnering can take place anywhere within the

operating envelope.

Acquisition mode

Acquisition mode off

Switch the RMI-Q on

An RMP400 that is partnered with the RMI-Q

but then used with another system will need to

be repartnered before being used again with the

RMI-Q.

In configuration mode, configure the probe

settings as required until you reach the

“Acquisition mode” menu, which defaults to

“Acquisition mode off”.

Trigger Logic

4.11

SYSTEM STATUS LED

RMI-Q in acquisition mode

with empty probe location

NOTE: Please refer to the

installation guide RMI-Q radio

machine interface (Renishaw part

no. H-5687-8504) when partnering

up to four RMPs.

or

Deflect the stylus to select “Acquisition

mode on”. Ensure this is done within 60

seconds of the RMI-Q system status

LED flashing green.

SYSTEM STATUS LED

New partner RMP acquired

Displayed for 5 seconds

SYSTEM STATUS LED

RMI-Q in acquisition mode

with full probe location

SYSTEM STATUS LED

Acquisition pending

SYSTEM STATUS LED

or

RMP cleared from location

> 20 s

The probe is now in standby

and the system is ready for use.

Page 40

Operating mode

Draft 5 16/04/18

Trigger Logic

4.12

LEDs

flashing

green

X/Y

Probe status LEDs

LED colour Probe status Graphic hint

Flashing green Probe seated in operating mode

Flashing red Probe triggered in operating mode

Flashing green and blue Probe seated in operating mode – low battery

Flashing red and blue Probe triggered in operating mode – low battery

LEDs

flashing

red

LEDs

flashing

red

Z

Constant red Battery dead

Flashing red

or

Flashing red and green

or

Sequence when batteries are inserted

Constant blue Probe damaged beyond use

NOTE: Due to the nature of lithium-thionyl

chloride batteries, if a “low battery” LED warning is

ignored, it is possible for the following sequence of

events to occur:

1. When the probe is active, the batteries

discharge until battery power becomes too

low for the probe to operate correctly.

2. The probe stops functioning, but then

reactivates as the batteries recover

sufficiently to provide the probe with power.

Unsuitable battery

4. Again, the batteries discharge and the probe

ceases to function.

5. Again, the batteries recover sufficiently

to provide the probe with power, and the

sequence repeats itself.

3. The probe begins to run through the LED

review sequence (see page 4.1, “Reviewing

the probe settings”).

Page 41

see Section 5,“Maintenance”

Draft 5 16/04/18

Maintenance

5.1

Maintenance

You may undertake the maintenance routines

described in these instructions.

Further dismantling and repair of Renishaw

equipment is a highly specialised operation, which

must be carried out at an authorised Renishaw

Service Centre.

Equipment requiring repair, overhaul or attention

under warranty should be returned to your

supplier.

Cleaning the probe

Wipe the window of the probe with a clean cloth

to remove machining residue. This should be

done on a regular basis to maintain optimum

transmission.

CAUTION: The RMP400 has a glass window.

Handle with care if broken to avoid injury.

Page 42

Changing the batteries

Draft 5 16/04/18

Maintenance

5.2

1

CAUTIONS:

Do not leave dead batteries in the probe.

When changing batteries, do not allow coolant or

debris to enter the battery compartment.

When changing batteries, check that the battery

polarity is correct.

Take care to avoid damaging the battery cassette

gasket.

Only use specified batteries.

2

CAUTION: Please dispose of dead batteries in

accordance with local regulations. Never dispose

of batteries in a fire.

Page 43

3

Draft 5 16/04/18

Ecocel

Saft:

Tadiran:

Xeno:

NOTES:

After removing the old batteries, wait more than

5 seconds before inserting the new batteries.

Do not mix new and used batteries or battery

types, as this will result in reduced life and

damage to the batteries.

Always ensure that the cassette gasket and

mating surfaces are clean and free from dirt

before reassembly.

If dead batteries are inadvertently inserted, the

LEDs will remain a constant red.

Battery type

½ AA lithium-thionyl chloride (3.6 V) × 2

EB1426

LS 14250C

LS 14250

SL-750

XL-050F

Dubilier:

Maxell:

Sanyo

Tadiran:

Varta:

Maintenance

5.3

SB-AA02

ER3S

CR 14250SE

SL-350, SL-550,

TL-4902, TL-5902,

TL-2150, TL-5101

CR ½AA

4

5

Page 44

Maintenance

Draft 5 16/04/18

5.4

This page is intentionally left blank.

Page 45

see Section 6,“Fault-finding”

Draft 5 16/04/18

Fault-finding

Symptom Cause Action

6.1

Probe fails to

power up (no LEDs

illuminated or fails

to indicate current

probe settings).

Probe fails to

switch on.

Dead batteries. Change batteries.

Unsuitable batteries. Fit suitable batteries.

Batteries inserted incorrectly. Check battery insertion/polarity.

Batteries removed for too short a time

and probe has not reset.

Poor connection between battery

cassette mating surfaces and

contacts.

Dead batteries. Change batteries.

Batteries inserted incorrectly. Check battery insertion/polarity.

Probe out of range. Check position of RMI or RMI-Q,

No RMI or RMI-Q “start/stop” signal

(“radio on” method only).

Remove batteries for a minimum

of 5 seconds.

Remove any dirt and clean the

contacts before reassembly.

(see operating envelope).

Check RMI or RMI-Q for green

start LED.

Incorrect spin speed (“spin on”

method only).

Incorrect switch on method

configured.

Incorrect multiple probe mode setting

configured.

RMP400 in hibernation mode (radio

on method only).

Spin on is within 1 second of spin off. Check for 1 second dwell following

Check spin speed and duration.

Check configuration and alter as

required.

Check configuration and alter as

required.

Ensure probe is in range and wait

up to 30 seconds, then resend

switch-on signal.

Check position of RMI or RMI-Q,

see operating envelope.

spin off.

Page 46

Symptom Cause Action

Draft 5 16/04/18

Fault-finding

6.2

Machine stops

unexpectedly during a

probing cycle.

Radio link failure/RMP400 out of

range.

RMI or RMI-Q receiver/machine

fault.

Dead batteries. Change batteries.

Excessive machine vibration

causing false probe trigger.

Probe unable to find target

surface.

Adjacent probe. Reconfigure adjacent probe to low

Stylus not given sufficient time to

settle from a rapid deceleration.

Check interface/receiver and

remove obstruction.

Refer to receiver/machine user’s

guide.

Enable enhanced trigger filter.

Check that part is correctly

positioned and that stylus has not

broken.

power mode and reduce range of

receiver.

Add a short dwell before the

probing move (length of dwell will

depend on stylus length and rate

of deceleration). Maximum dwell is

one second.

Probe crashes.

Probe permanently

triggered.

Workpiece obstructing probe path. Review probing software.

Probe length offset missing Review probing software.

In cases where there is more than

one probe on a machine, incorrect

probe activated.

Probe orientation has changed –

i.e. from horizontal to vertical.

New stylus has been fitted. Turn probe off and on again.

Probe was switched on when

stylus was deflected.

Probe has not settled before a

trigger move occurs following a

rotation or rapid move (“Autoreset” mode only).

Probe has collided with an object

during a rotation or rapid move

(“Auto-reset” mode only).

Review interface wiring or part

program.

Select probe “Auto-reset” function.

Turn probe off and on again.

Ensure stylus is seated during

switch on.

Turn probe off and on again, and

increase the dwell from 0.2 to

0.5 second dwell before probing

move.

Turn probe off and on again.

Page 47

Symptom Cause Action

Draft 5 16/04/18

Poor probe repeatability

and/or accuracy.

Debris on part or stylus. Clean part and stylus.

Poor tool change repeatability. Redatum probe after each tool

change.

Loose probe mounting on shank

or loose stylus.

Excessive machine vibration. Enable enhanced trigger filter.

Calibration out of date and/or

incorrect offsets.

Calibration and probing speeds

not the same.

Calibration feature has moved. Correct the position.

Measurement occurs as stylus

leaves surface.

Check and tighten as appropriate.

Eliminate vibrations.

Review probing software.

Review probing software.

Review probing software.

Fault-finding

6.3

RMP400 status LEDs do

not correspond to RMI

or RMI-Q status LEDs.

Measurement occurs within

the machine’s acceleration and

deceleration zone.

Probing speed too high or too

slow.

Temperature variation causes

machine and workpiece

movement.

Machine tool faulty. Perform health checks on

Radio link failure – RMP400 out

of RMI or RMI-Q range.

RMP400 has been enclosed/

shielded by metal.

RMP400 and RMI or RMI-Q are

not partnered.

Review probing software and

probe filter settings.

Perform simple repeatability trials

at various speeds.

Minimise temperature changes.

machine tool.

Check position of RMI or RMI-Q,

see operating envelope.

Remove from obstruction.

Partner RMP400 and RMI or

RMI-Q.

Page 48

Symptom Cause Action

Draft 5 16/04/18

Fault-finding

6.4

RMI or RMI-Q error LED

lit during probing cycle.

RMI or RMI-Q low

battery LED lit.

Reduced range.

Probe not switched on or probe

timed out.

Probe out of range. Check position of RMI or RMI-Q,

Dead batteries. Change batteries.

RMP400 and RMI or RMI-Q are

not partnered.

Probe selection error. Verify that one RMP is working

“Fast” turn-on error. Ensure that all RMPs are ‘Q’

Low batteries. Change batteries soon.

Local radio interference. Identify and remove.

Change setting. Review switch-off

method.

see operating envelope.

Partner RMP400 with RMI or

RMI-Q.

and is correctly selected.

marked probes, or change the

RMI-Q turn-on time to “standard”.

Probe fails to switch off.

Probe goes into Trigger

Logic™ configuration

mode and cannot be

reset.

Probe status LED shows

a constant blue

Incorrect “switch-off” method

configured.

No RMI or RMI-Q “start/stop”

signal (“radio on” method only).

Probe in timeout mode and

placed in tool magazine and

being triggered by movement.

Incorrect spin speed (spin switch

on only).

Spin off is within 1 second of a

spin on

Probe was triggered when

batteries were inserted.

Probe damaged beyond use. Return the probe to your nearest

Check configuration and alter as

required.

Check RMI or RMI-Q for green

start LED.

Use shorter timeout setting or use

different switch-off method.

Check spin speed.

Check for a 1 second dwell

following a spin on.

Do not touch the stylus or stylus

mounting face during battery

insertion.

Renishaw supplier for repair/

replacement.

Page 49

see Section 7,“Parts list”

Draft 5 16/04/18

Parts list

Item Part number Description

RMP400 A-6570-0001 RMP400 probe with batteries, tool kit and quick-start guide

Battery P-BT03-0007 ½AA battery – lithium-thionyl chloride (pack of two).

7.1

(factory-set to radio on/radio off).

Stylus A-5003-7306

Stylus A-5003-6510 100.0 mm (3.94 in) long carbon fibre stylus with Ø6.0 mm

Stylus A-5003-6511 150.0 mm (5.91 in) long carbon fibre stylus with Ø6.0 mm

Stylus A-5003-6512 200.0 mm (7.88 in) long carbon fibre stylus with Ø6.0 mm

Tool kit A-4071-0060 Probe tool kit comprising Ø1.98 mm stylus tool,

Battery cassette A-4071-0031 Battery cassette assembly.

Battery gasket A-4038-0301 Battery cap gasket kit.

RMI A-4113-0050

RMI-Q A-5687-0050 RMI-Q (side exit) with 15 m (49.2 ft) cable, tool kit and

Mounting bracket A-2033-0830 Mounting bracket with fixing screws, washers and nuts.

Styli tool M-5000-3707 Tool for tightening/releasing styli.

50.0 mm (1.97 in) long carbon fibre stylus with Ø6.0 mm

(0.24 in) ball.

(0.24 in) ball.

(0.24 in) ball.

(0.24 in) ball.

2.00 mm AF hexagon key and shank grub screw (× 6).

RMI (side exit) with 15 m (49.2 ft) cable, tool kit and user’s

guide.

quick-start guide.

Publications. These can be downloaded from our web site at www.renishaw.com.

RMP400 H-6570-8500 Quick-start guide: for rapid set-up of the RMP400 probe.

RMI QSG A-4113-8550 Quick-start guide: for rapid set-up of the RMI.

RMI IG H-4113-8554 Installation guide: for set-up of the RMI.

RMI-Q QSG H-5687-8500 Quick-start guide: for rapid set-up of the RMI-Q.

RMI-Q IG H-5687-8504 Installation guide: for set-up of the RMI-Q.

Styli H-1000-3200 Technical specifications guide: Styli and accessories – or visit

our Web shop at www.renishaw.com/shop.

Probe software H-2000-2298 Data sheet: Probe software for machine tools – programs and

features.

Taper shanks H-2000-2011 Data sheet: taper shanks for machine tool probes.

Page 50

Renishaw plc

Draft 5 16/04/18

New Mills, Wotton-under-Edge

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details, visit

www.renishaw.com/contact

© 2018 Renishaw plc

Issued: ??.????

*H-6570-8501-01*

Part no. H-6570-8501-01-A

Loading...

Loading...