Page 1

Installation guide

H-5687-8504-01-A (BETA SITE ONLY)

RMI-Q radio machine interface

Page 2

© 2012 Renishaw plc. All rights reserved.

This document may not be copied or reproduced

in whole or in part, or transferred to any other

media or language, by any means, without the

prior written permission of Renishaw plc.

The publication of material within this document

does not imply freedom from the patent rights of

Renishaw plc.

Renishaw part no: H-5687-8504-01-A

First issued: BETA SITE ONLY

Page 3

Contents

Contents

Before you begin ....................................................................................................1.1

Before you begin ............................................................1.1

i

Disclaimer

Trademarks

Warranty

Changes to equipment

CNC machines

Care of the RMI-Q

RMP probe family

Patents

EC declaration of conformity

WEEE directive

FCC information to the user (USA only)

Radio approval

Radio equipment - Canadian warning statements

Radio approvals

Safety

....................................................................1.5

..............................................................1.1

.............................................................1.1

................................................................1.1

.....................................................1.1

...........................................................1.1

........................................................1.1

.........................................................1.2

.................................................................1.2

...................................................1.3

.............................................................1.3

..........................................1.3

.............................................................1.4

................................1.4

..........................................................1.4

RMI-Q basics ........................................................................................................... 2.1

Introduction ................................................................2.1

Power supply

Input voltage ripple

RMI-Q visual diagnostics

P1, P2, P3, P4 SYSTEM STATUS LEDs

LOW BATTERY / START LED

PROBE STATUS LED

ERROR LED

SIGNAL LED

...............................................................2.1

........................................................2.1

......................................................2.2

.......................................2.3

...............................................2.3

.....................................................2.3

............................................................2.3

............................................................2.3

Page 4

RMI-Q installation guide

RMI-Q inputs ...............................................................2.4

Contents

ii

RMI-Q output waveforms

RMI-Q seated start option

Switches SW1 and SW2

Switch SW1 output configuration

Switch SW2 output configuration

Remote external audible output

RMI-Q dimensions

RMI-Q specification

......................................................2.6

.....................................................2.7

......................................................2.8

.............................................2.8

.............................................2.9

...............................................2.11

..........................................................2.12

.........................................................2.13

System installation ................................................................................................. 3.1

Mounting bracket (optional) ....................................................3.1

Wiring diagram (with output groupings shown)

RMP - RMI-Q partnership

To partner the RMP with the RMI-Q

To partner up to four RMPs with the RMI-Q without ReniKey

Partnering RMPs using ReniKey (Recommended)

.....................................................3.3

...........................................3.3

.....................................3.2

.......................3.4

...............................3.5

Removing the RMP from the RMI-Q

Changing RMP position

RMI-Q cable

Cable sealing

Fitting flexible conduit

Screw torque values

...............................................................3.6

............................................................3.6

.........................................................3.7

...................................................3.5

......................................................3.6

..........................................3.5

Maintenance ............................................................................................................ 4.1

RMI-Q cover ...............................................................4.1

Removing the RMI-Q cover

Replacing the RMI-Q cover

Side exit to rear exit cable conversion

.................................................4.1

.................................................4.2

............................................4.2

Fault finding ............................................................................................................ 6.1

Parts list

.................................................................................................................. 7.1

Page 5

Before you begin

1.1

Before you begin

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF THIS

DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES

OR REPRESENTATIONS REGARDING

THE CONTENT. RENISHAW EXCLUDES

LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW and the probe symbol used in the

RENISHAW logo are registered trade marks of

Renishaw plc in the United Kingdom and other

countries.

apply innovation and names and designations

of other Renishaw products and technologies are

trade marks of Renishaw plc or its subsidiaries.

All other brand names and product names used

in this document are trade names, service marks,

trademarks, or registered trademarks of their

respective owners.

Warranty

Equipment requiring attention under warranty must

be returned to your equipment supplier.

Unless otherwise specifically agreed in writing

between you and Renishaw, if you purchased the

equipment from a Renishaw company, the warranty

provisions contained in Renishaw’s CONDITIONS

OF SALE apply. You should consult these

conditions in order to find out the details of your

warranty, but in summary the main exclusions from

the warranty are if the equipment has been:

• neglected,mishandledorinappropriately

used; or

• modifiedoralteredinanywayexceptwiththe

prior written agreement of Renishaw.

If you purchased the equipment from any other

supplier, you should contact them to find out what

repairs are covered by their warranty.

Changes to equipment

Renishaw reserves the right to change equipment

specifications without notice.

CNC machines

CNC machine tools must always be operated by

fully trained personnel in accordance with the

manufacturer's instructions.

Care of the RMI-Q

Keep system components clean.

Page 6

RMI-Q installation guide

Before you begin

1.2

RMP probe family

The RMP family of probes currently consists of the

RMP40, RMP40M, RLP40, RMP60, RMP60M and

RMP600. The RTS radio tool setter also forms part

of Renishaw's family of radio transmission probes.

The term RMP used throughout this installation

guide refers to both the probes and the tool setter.

Patents

Features of the RMI-Q (and features of similar

products) are the subject of one or more of the

following patents and/or patent applications:

CN 100466003

CN 101287958

CN 101482402A

EP 0652413

EP 1576560

EP 1931936

EP 2216761

IN 2004/057552

IN 2007/028964

IN 215787

JP 2009-507240

JP 3126797

JP 4575781

KR 1001244

TW 1333052

US 2011-00002361-A1

US 5279042

US 7665219

US 7821420

Page 7

EC declaration of conformity

FCC information to the user

(USA only)

C

Renishaw PLC hereby declares that the RMI-Q is

in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

Contact Renishaw at www.renishaw.com/rmi-q for

the full EC Declaration of Conformity.

WEEE directive

47 CFR Section 15.19

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc, or authorised representative could

void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC

rules.

Operation is subject to the following two

conditions:

1. This device may not cause harmful

interference.

2. This device may accept any interference

received, including interference that may

cause undesired operation.

47 CFR Section 15.21

Before you begin

1.3

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of

this product will help to save valuable resources

and prevent potential negative effects on the

environment. For more information, please contact

your local waste disposal service or Renishaw

distributor.

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc, or authorised representative could

void the user’s authority to operate the equipment.

47 CFR Section 15.105

This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits

are designed to provide reasonable protection

against harmful interference when the equipment

is operated in a commercial environment. This

equipment generates, uses, and can radiate

radio frequency energy and, if not installed

and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment

in a residential area is likely to cause harmful

interference, in which case you will be required to

correct the interference at your own expense.

Page 8

RMI-Q installation guide

Before you begin

1.4

Radio approval

Radio equipment - Canadian warning

statements

English

Under Industry Canada regulations, this radio

transmitter may only operate using an antenna of

a type and maximum (or lesser) gain approved for

the transmitter by Industry Canada.

To reduce potential radio interference to other

users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated

power (e.i.r.p.) is not more than that necessary for

successful communication.

This device complies with Industry Canada

licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this

device may not cause interference, and (2) this

device must accept any interference, including

interference that may cause undesired operation

of the device.

Radio approvals

Europe: TBA

USA: TBA

Canada: TBA

Japan: TBA

China: TBA

French

Conformément à la réglementation d'Industrie

Canada, le présent émetteur radio peut

fonctionner avec une antenne d'un type et d'un

gain maximal (ou inférieur) approuvé pour

l'émetteur par Industrie Canada.

Dans le but de réduire les risques de brouillage

radioélectrique à l'intention des autres utilisateurs,

il faut choisir le type d'antenne et son gain

de sorte que la puissance isotrope rayonnée

équivalente (p.i.r.e.) ne dépasse pas l'intensité

nécessaire à l'établissement d'une communication

satisfaisante.

Le présent appareil est conforme aux CNR

d'Industrie Canada applicables aux appareils

radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes : (1)

l'appareil ne doit pas produire de brouillage,

et (2) l'utilisateur de l'appareil doit accepter

tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le

fonctionnement.

Page 9

Safety

Information to the user

In all applications involving the use of machine

tools or CMMs, eye protection is recommended.

Information to the machine supplier/

installer

It is the machine supplier's responsibility to ensure

that the user is made aware of any hazards

involved in operation, including those mentioned

in Renishaw product literature, and to ensure

that adequate guards and safety interlocks are

provided.

Under certain circumstances, the probe signal

may falsely indicate a probe seated condition. Do

not rely on probe signals to halt the movement of

the machine.

Information to the equipment installer

All Renishaw equipment is designed to comply

with the relevant EU and FCC regulatory

requirements. It is the responsibility of the

equipment installer to ensure that the following

guidelines are adhered to, in order for the product

to function in accordance with these regulations:

any interface MUST be installed in a position

•

away from any potential sources of electrical

noise, i.e. power transformers, servo drives

etc;

all ground connections should be connected

•

to the machine 'star point' (the 'star point'

is a single point return for all equipment

ground and screen cables). This is very

important and failure to adhere to this

can cause a potential difference between

grounds;

all screens must be connected as outlined in

•

the user instructions;

Before you begin

1.5

cables must not be routed alongside high

•

current sources, i.e. motor power supply

cables etc, or be near high speed data lines;

cable lengths should always be kept to a

•

minimum.

Equipment operation

If this equipment is used in a manner not specified

by the manufacturer, the protection provided by

the equipment may be impaired.

Page 10

Before you begin

1.6

RMI-Q installation guide

This page left intentionally blank

Page 11

RMI-Q basics

2.12.1

Introduction

CNC machine tools which are using Renishaw

spindle probes with radio signal transmission

for workpiece inspection, or tool setters with

radio signal transmission, require a Renishaw

radio machine interface (such as the RMI-Q)

for signal transmission. The RMI-Q, which acts

as a combined radio transceiver and machine

interface, converts signals from the RMP into

voltage-free solid state relay (SSR) and driven

outputs for transmission to the CNC machine

controller.

The RMI-Q is designed to be mounted within

the machine’s working envelope.

Application of the RMI-Q enables individual

radio turn on and subsequent operation of up to

four separate 2nd generation RMPs, permitting

numerous combinations of radio inspection

probes and/or radio tool setters to be used on the

same machine tool.

Optimum communication performance between

the RMI-Q and the RMP is achieved when the

RMI-Q is aligned towards the RMP in operation.

Other alignments are permissible with negligible

reduction in communication performance.

However, alignment of the RMI-Q away from the

RMP should be avoided as this may result in

reduced communication performance.

CAUTION RMI-Q operation of up to four

!

separate RMPs is different to 'multiple probe

mode' which is a function of the RMP that enables

individual application of multiple probes but does

not use radio turn on.

Power supply

The RMI-Q can draw its supply from the CNC

machine tool's 12 Vdc to 30 Vdc supply and

present a peak load of up to 250 mA during turn

on (typically 100 mA from 24 V).

RTS, and other 2nd generation RMPs, are easily

identified by a 'Q' marking. 1st generation RMPs,

which do not have the 'Q' marking, may also

be used with the RMI-Q. However, in machine

tool applications where more than one RMP

is required, it is recommended that only 2nd

generation RMPs are used. Should there be a

requirement to use a 1st generation RMP with the

RMI-Q, it is necessary that any additional probes

are 'Q' marked 2nd generation RMPs

Input voltage ripple

The input voltage ripple must not cause the

voltage to fall below 12 V or rise above 30 V.

Page 12

RMI-Q installation guide

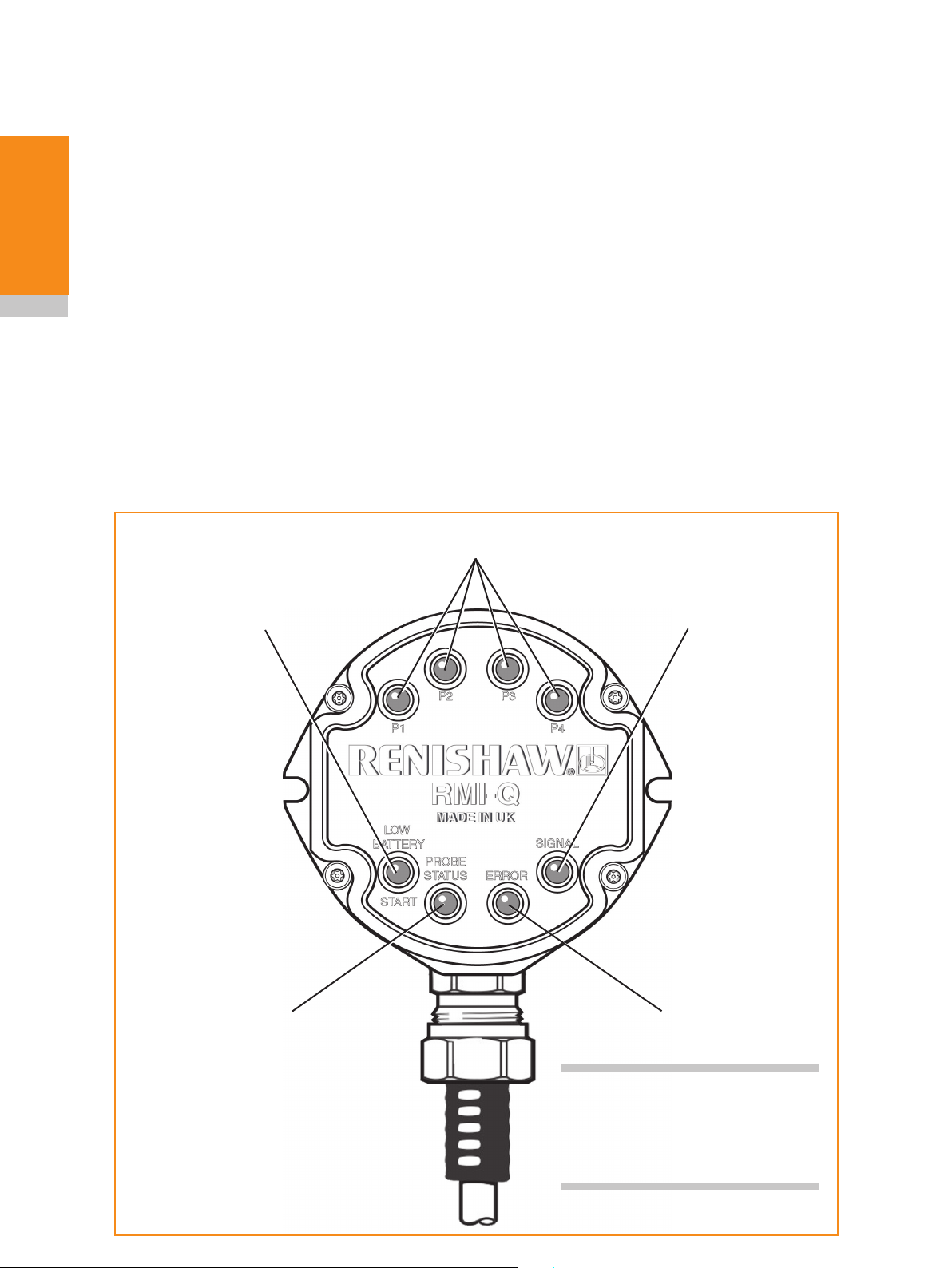

RMI-Q visual diagnostics

A visual indication of system status is provided

by LEDs. Status is continuously updated and

indication is provided for:

P1, P2, P3, P4 SYSTEM STATUS;

RMI-Q basics

•

2.2

LOW BATTERY/START;

•

PROBE STATUS;

•

SIGNAL CONDITION;

•

ERROR;

•

LOW BATTERY / START LED

P1, P2, P3, P4 SYSTEM STATUS LEDs

SIGNAL LED

PROBE STATUS LED

ERROR LED

NOTES:

KEEP THE FRONT COVER CLEAN.

All four lower LEDs flashing

indicates a wiring fault or output

over-current.

Page 13

P1, P2, P3, P4 SYSTEM STATUS LEDs

ERROR LED

Off - Probe number empty.

Yellow - Probe number full, in standby.

Green - Probe number full, operating.

Red - Probe number full, 0.5 s

compatibility error.

Yellow/off - Flashing: Selection error.

Green/yellow - Flashing: Acquisition/clearing

pending, full.

Green/off - Flashing: Acquisition pending,

empty.

Red/yellow - Flashing: Acquisition complete,

probe full.

Red/off - Flashing: Clearing complete,

probe empty.

Off - No error.

Red - Error, other outputs may be

incorrect.

Red/off - Flashing: RMI-Q has an

overcurrent condition.

SIGNAL LED

Off - No probes operating.

Green - Good communications.

Green - yellow - Good communications.

Red - Poor communications, radio link

may fail.

Red/off - Flashing: RMI-Q has an

overcurrent condition.

RMI-Q basics

2.3

LOW BATTERY / START LED

Off - Battery is OK and no M code

start/stop in progress.

Red - Battery is low.

Green - M code start/stop in progress.

Yellow - Battery low and M code

start/stop in progress.

Red/off - Flashing: RMI-Q has an

overcurrent condition.

PROBE STATUS LED

Red - Probe triggered.

Green - Probe seated.

NOTES:

The 'PROBE STATUS' LED is always illuminated

when power is present at the RMI-Q (as the

RMI-Q does not incorporate a separate ‘power

present’ indicator).

All LEDs report the status of the partner RMP. If

there is no partner in range, or the partner is off,

then the 'PROBE STATUS' and 'ERROR' LEDs

will illuminate red. The 'LOW BATTERY/START'

and 'SIGNAL' LEDs will be off.

When the RMI-Q is powered on it will enter

the acquire partner mode. This is indicated by

a flashing green 'SIGNAL' LED (no change in

outputs). After ~60 seconds it will switch to its

normal mode listening for its partner.

The conditions shown by the 'LOW BATTERY/

START', 'PROBE STATUS' and 'ERROR' LEDs

are the same as those present on the electrical

signal outputs.

Red/off - Flashing: RMI-Q has an

overcurrent condition.

Page 14

RMI-Q installation guide

RMI-Q basics

2.4

RMI-Q inputs

Machine start inputs (P1, P2, P3, P4):

'Machine start' inputs are configurable as a level

or pulsed signal.

Level

Pulsed

P1 machine start wires (white +ve and brown -ve).

P2 machine start wires (pink +ve and brown -ve).

P3 machine start wires

(white/red +ve and brown -ve).

P4 machine start wires

(white/blue +ve and brown -ve).

10 to 30 V (2.4 mA at 24 V)

When input is active, probe is

switched on.

12 to 30 V (10 mA at 24 V)

Probe toggles from being switched on/

off. The minimum pulse width is 10 ms.

Output voltages

Sourcing = 4.2 V min at 10 mA.

•

= 2.2 V min at 50 mA.

Sinking = 0.4 V max at 10 mA.

•

= 1.3 V max at 50 mA.

Probe status 2b (driven at power supply

voltage):

Load current = 50 mA max.

•

Output voltages

Sourcing voltage drop

•

= 2.6 V max at 10 mA.

= 3.5 V max at 50 mA.

Sinking voltage drop

•

= 2.0 V max at 10 mA.

= 2.9 V max at 50 mA.

RMI-Q outputs

There are five outputs:

Probe status 1 (SSR).

•

Probe status 2a

•

(5 V isolated driven skip).

Probe status 2b

•

(driven at power supply voltage).

Error (SSR).

•

Low battery (SSR).

•

All outputs can be inverted by using switches SW1

and SW2 - see page 2.8 'Switches SW1 and

SW2'.

Probe status 1, Error, Low battery (SSR):

‘On’ resistance = 50 ohm max.

•

Load voltage = 40 V max.

•

The 'LOW BATTERY/START', 'PROBE STATUS',

'ERROR' and 'SIGNAL' LEDs will start flashing

red when an output overload has occurred. All

outputs will be switched off. If this occurs, turn off

the power supply and remove the source of the

problem. Turning on the power supply will reset

the RMI-Q.

Load current = 100 mA max.

•

Probe status 2a (5 V isolated driven skip):

Load current = 50 mA max.

•

Page 15

!

CAUTIONS:

Power supply voltage

Do not exceed 30 V between the black wire and

the screen wire (green/yellow), or the red wire

and screen wire (green/yellow), or the red and

black wires (power supply), as this could result

in permanent damage to the RMI-Q and/or the

customer power supply.

The use of in-line fuses at the machine cabinet

end is recommended to provide protection for the

RMI and cable.

Screen connection

A good connection must be made to machine

ground (star point).

Output stage circuit

Output stage supplies (+ve, –ve) should not be

switched on and off to enable/disable them as this

can cause the over current protection to switch off

the output completely.

Ensure that outputs from the RMI-Q do not

exceed specified current ratings.

RMI-Q basics

2.5

Page 16

RMI-Q basics

2.6

RMI-Q installation guide

RMI-Q output waveforms

RMI-Q

SSR/driven

output

Probe status 1

(level)

Power

off

Probe

switch

on

SSR open

Seated

Triggered Seated

Probe

trigger

PROBE

Probe

reseat

Error

e.g.

low signal

Error

clear

Low

battery

Probe

switch

off

Normally open

Probe status 1

(pulsed)

Normally open

Error

Normally

closed

RMI-Q

SSR /driven

outputs

Low battery

SSR closed

SSR open

SSR closed

SSR open

SSR closed

Power

off

Probe

switch

on

SSR open

Seated

Triggered Seated

Probe

trigger

PROBE

Probe

reseat

Error

e.g.

low signal

Error

clear

Low

battery

Probe

switch

off

Normally open

Probe status

2a/2b

(level)

Normally low

Probe status

2a/2b

(pulsed)

Normally low

SSR closed

Output high

Output low

Output high

Output low

SIGNAL DELAYS

1. Transmission delay Probe trigger to output change of state ≈ 10 ms variation ±10 µs.

(Standard turn on mode exluding filter delay)

2. Start delay Time from initiation of start signal to valid signal transmission = 1 sec max.

NOTE : Pulsed outputs are 40 ms ±1 ms duration.

Page 17

RMI-Q seated start option

PROBE

RMI-Q

SSR/driven

output

Probe status 1

(level)

Normally open

Probe status 1

(pulsed)

Normally open

Error

Normally

closed

Power

off

Probe

trigger

SSR open

SSR closed

SSR open

SSR closed

SSR open

SSR closed

Triggered

Probe

switch

on

Seated

Probe

reseat

Error

e.g.

low signal

Error

clear

Low

battery

Probe

switch

off

RMI-Q basics

2.7

Page 18

RMI-Q basics

2.8

RMI-Q installation guide

Switches SW1 and SW2

SW1

Switch SW1 output configuration

PROBE STATUS 1

Pulsed

N/O

Low

battery

N/O

Error

N/O

SW2

NOTE: To gain access to

the switches, remove the

front cover (see Section 4,

'Maintenance').

Abbreviations are as follows:

N/O = Normally Open

•

N/C = Normally Closed

•

Factory settings are shown.

ON

Level

CAUTION: Exercise caution when using error or probe SSR in N/O mode as a wiring

!

fault could cause loss of error condition and therefore could result in a non-failsafe condition.

N/C

N/CN/C

Page 19

Switch SW2 output configuration

RMI-Q basics

PROBE STATUS 2a/2b

MACHINE START

Level

Pulsed

Normally

high

ON

Level

Normally

Pulsed

low

Dedicated start (level mode)

In dedicated start, a machine start input is

required per probe that is configured for radio turn

on.

Machine start inputs

P1 P2 P3 P4

Probe selected

None

Q

Q

Q

Q

Probe 1 on

Probe 2 on

Probe 3 on

Probe 4 on

Dedicated

start

Seated

start on

0.5 s

turn on

Factory settings are shown.

Common

start

Seated

start off

Standard

turn on

NOTES :

Level start mode is not compatible with RMPs

configured for radio M code on/time out off.

For RMI compatibility mode, ensure poles 4 and 6

are in the down position and set other poles to the

required configuration.

2.9

Q

Machine start input active. Any attempt to turn on more

than one probe simultaneously will result in an error

condition

Page 20

RMI-Q installation guide

RMI-Q basics

2.10

Common start (level mode)

In common start (level mode), machine start

inputs P2 and P3 are used to select the probe

and machine start input P1 is used to start the

selected probe. All inputs are level.

Machine start inputs

P1, P2 and P3

Probe

start

P1

Probe selection

inputs

P2 P3

Q

Q Q

Q Q

Q Q Q

Q

Machine start input active.

When P1 is off, all probes are off.

When P1 is active, the selected probe will be on.

Probe

selected

Probe 1

Probe 2

Probe 3

Probe 4

NOTES:

Machine start input P4 is not used in common

start.

Any change to the probe selection inputs P2 and

P3 whilst the probe is operating will result in an

error condition.

Level start mode is not compatible with RMPs

configured for radio M code on/time out off.

Common start (pulsed mode)

In common start (pulsed mode), machine start

inputs P2 and P3 are level inputs used to select

the probe. Machine start input P1 is a pulsed input

used to start the selected probe.

Machine start inputs

P1, P2 and P3

Probe

start

P1

Probe selection

inputs

P2 P3

Probe

selected

Probe 1

Q

Q

Q Q

Machine start input pulsed, so selected probe will

change state.

Probe 2

Probe 3

Probe 4

Q Probe selection inputs are level signals.

NOTES:

Machine start input P4 is not used in common

start.

Only the probe start signal P1 will be pulsed and

will change the probe status between on and off.

The probe selection inputs P2 and P3 will be level.

Seated start on

When seated start on is selected, the RMI-Q will

not drop the error line until the RMP has become

seated. This provides compatibility with controllers

that regard the RMP to be in error if it is started in

a triggered condition.

0.5 second turn on

0.5 second turn on provides compatibility with

controllers that have quicker response times, to

give a reduced probing cycle time. Standard turn

on time is 1 second. These turn on times apply to

radio M code on only.

Page 21

Remote external audible output

Any output (set to pulsed) can be utilised to

operate an external remote audible indicator.

The audible indicator must comply with the output

transistor specification.

i.e. up to 50 mA.

up to 30 V.

Wiring configurations are shown below.

RMI-Q basics

2.11

Option 1.

SSR output

Option 2.

Using 5 V output

Option 3.

Using machine

voltage output

RMI-Q

RMI-Q

5 V isolated

driven probe

status

RMI-Q

Driven probe

status output at

supply voltage

Red

Turquoise

Turquoise / Black

0 V Black

Yellow

0 V Grey

Orange

0 V Black

+ve

–ve

+ve

–ve

+ve

–ve

Page 22

RMI-Q basics

2.12

RMI-Q installation guide

RMI-Q dimensions

97 (3.82)

46 (1.81)

44 (1.73)

46 (1.81)

45.5 (1.79)

45°

Slot to suit M5 x 16

bolts supplied

(two places)

47.5 (1.87)

71.5 (2.81)

17.5 (0.69)

4 holes

M5 x 13 deep

on 80 P.C.D..

NOTE: When using rear exit cable,

provide a Ø25 mm (Ø1.0 in) hole in the

mounting for the cable to exit.

Dimensions given in mm (in)

Page 23

RMI-Q specification

Principal application

Dimensions

Weight

Transmission type

Transmission range

Power supply

Cable

Mounting

Any machining centre, 5-axis machine, twin spindle machine and

vertical turret lathe.

Height

Width

Depth

In box

RMI-Q including 15 m

(49.2 ft) of cable

Frequency hopping spread spectrum (FHSS) radio.

2.400 - 2.4835 GHz

2400 - 2483.5 MHz

Up to 15 m (49.2 ft)

12 Vdc to 30 Vdc

8 m (26.2 ft) and 15 m (49.2 ft) standard lengths

Optional 30 m (98.42 ft) and 50 m (164.04 ft) cable assemblies are

also available.

16 core screened cable, each core 18 x 0.1 mm

Mounting bracket allowing directional setting

119 mm (4.68 in)

97 mm (3.82 in)

44 mm (1.73 in)

2,065 g (72.84 oz)

1,625 g (57.32 oz)

RMI-Q basics

2.13

Compatible probes

Environment

Component setting/inspection: RMP40, RMP40M, RMP60, RMP60M

and RMP600

Lathe inspection: RLP40

Tool setting: RTS

IP rating IPX8 (EN/IEC605290)

Storage temperature

Operating temperature +5 °C to +55 °C (+41 °F to +131 °F)

-25 °C to +70 °C (-13 °F to +158 °F)

Page 24

RMI-Q basics

2.14

RMI-Q installation guide

This page left intentionally blank

Page 25

System installation

Mounting bracket (optional)

3.1

Dimensions given in mm (in)

NOTES:

Install RMI-Q with cable exiting from lower side for

good coolant run off.

Mounting bracket cannot be used with an RMI-Q

in rear exit configuration.

25

(0.98)

3 holes Ø6.4 (0.25)

100.5 (3.95)

25

(0.98)

19 (0.75)

3 grip protrusions

38 (1.50)

2.0

(0.08)

30

25

45

(1.18)

(0.98)

(1.77)

45 (1.77)

90 (3.54)

45°

2.0 (0.08)

3 pairs of holes

Ø5.5 (0.20)

permit RMI-Q

mounting in

alternative

orientation

Page 26

RMI-Q installation guide

Wiring diagram (with output groupings shown)

RMI-Q

System

installation

3.2

5 V

12 V to 30 V

Driver

Driver

0 V

Screen

Turquoise

Turquoise/black

Violet

Violet/black

Green

Green/black

White

Pink

White/red

White/blue

Brown

Yellow

Grey

Orange

Red

Black

Green

Signal

Return

See NOTE

Probe status 1 (SSR)

}

Low battery (SSR)

}

Error (SSR)

}

Machine start input [P1]

Machine start input [P2]

Machine start input [P3]

Machine start input [P4]

Machine start common

Probe status 2a

}

(5 V isolated driven skip)

Probe status 2b

Power supply (12 V to 30 V)

}

Machine ground (star point)

NOTE: A switch can be added on installation to aid with powering up the RMI-Q when partnering.

CAUTION: The power supply 0 V should be terminated at the machine ground (star point).

!

A negative supply can be used when wired appropriately.

Page 27

RMP - RMI-Q partnership

The RMP and RMI-Q must be placed into

acquisition mode.

On the RMP, acquisition mode achieved using

Trigger Logic™.

Partnering can take place anywhere within the

operating envelope.

1. Use Trigger Logic™ to access RMP

configuration mode.

2. Configure switch-on method (if applicable).

System

installation

On the RMI-Q, acquisition mode is achieved

either by manually power cycling the RMI-Q, or

via application of ReniKey which is a Renishaw

machine macro cycle.

Trigger Logic™ is a method that allows the user

to view and select all available mode settings

in order to customise a probe to suit a specific

application. Trigger Logic™ is activated by battery

insertion and uses a sequence of stylus deflection

(triggering) to systematically lead the user through

the available choices to allow selection of the

required mode options.

Current probe settings can be reviewed by simply

removing the batteries for a minimum of

5 seconds, and then replacing them to activate

the Trigger Logic™ review sequence.

To partner the RMP with the RMI-Q

Partnering is required during initial system set-up.

Further partnering will be required if either the

RMP or RMI-Q are changed.

3. Configure switch-off method (if applicable).

4. Configure enhanced trigger filter and auto

reset function (if applicable).

5. Enter acquisition mode menu.

6. Power on the RMI-Q or apply one of the

ReniKey commands. Please refer to the

ReniKey programming manual.

7. Watch the RMI-Q P1 system status LED;

after a couple of seconds the LED will

repeatedly flash on and off green. This is

the start of a 60 second interval in which the

RMI-Q is in acquisition mode.

8. Deflect the stylus < 4 seconds to initiate the

acquisition process.

9. After successful acquisition, the RMI-Q P1

system status LED will change to repeatedly

flashing red and yellow (for 5 seconds)

indicating that acquisition is complete and

Probe 1 is full.

3.3

Any RMP that is partnered with the RMI-Q, but

then used with another system, will need to

be cleared first from the RMI-Q before being

partnered with the new system. The RMP will also

need to be partnered again should it be brought

back to the RMI-Q.

Partnering will not be lost by reconfiguration of

probe settings or when changing batteries.

NOTE: Partnering will be lost when multiple

probe mode is selected. Multiple probe mode

is a function of the RMP. See the relevant RMP

installation guide (see Section 6, 'Parts list').

10. Leave RMP for 20 seconds to go into

standby.

11. System is ready to use.

NOTES:

To check that turn on and off settings have not

been accidentally changed, insert batteries to

review current probe settings.

When holding the RMP do NOT wrap a hand, or

anything else, around the glass window.

The system will not function correctly if more than

one partnered RMI-Q is within the transmission

range of the RMP.

Page 28

RMI-Q installation guide

System

installation

3.4

To partner up to four RMPs with the

RMI-Q without ReniKey

The RMI-Q has four machine start inputs

(P1 - P4) that enable partnering of four radio

probes (see wiring diagram on page 3.2).

The partnering procedure is dependant on the

start method that has been selected. See page

2.9 for start methods.

Partnering with dedicated start (Level mode)

If the RMI-Q is powered with all start inputs

held low, the RMI-Q will complete its start up

procedure and partner the RMP as Probe 1.

When the RMI-Q is powered with a single

machine start input held high, the RMI-Q will

complete its start up procedure and partner the

RMP to the probe number represented by the

selected machine start input.

Level mode

Probe to be partnered Machine start input

P1 P2 P3 P4

Probe 1

Probe 2

Probe 3

Probe 4

The system status LED for the selected probe

number will repeatedly flash on and off green

whilst in acquisition mode.

Q

Q

Partnering with common start

When the RMI-Q is powered, specific machine

start inputs need to be held high when partnering

the RMP to a specific probe number.

Pulsed mode

Probe to be partnered Machine start input

P1 P2 P3

Probe 1

Probe 2

Probe 3

Probe 4

Level mode

Probe to be partnered Machine start input

P1 P2 P3

Probe 1

Probe 2

Probe 3

Probe 4

NOTES:

Activation of machine start input (P4) is not

required when common start is selected.

To aid partnering, an on/off switch can be fitted

Q

between the machine power supply and the

RMI-Q (red wire). This enables the RMI-Q to

be momentarily powered off and then back on,

for each of the probes being partnered, without

having to power off the machine.

Q Q

Q Q

Q Q Q

Q

Q

Q Q

Page 29

Partnering RMPs using ReniKey

(Recommended)

ReniKey is a Renishaw machine macro cycle. It

enables up to four RMPs to be partnered with

the RMI-Q without the need to power the RMI-Q

off and then back on for each of the probes

being partnered. Please refer to the ReniKey

programming manual for instructions on how

to use ReniKey with your machine's controller.

Alternatively, refer to www.renishaw.com.

Removing the RMP from the RMI-Q

An RMP must be cleared from the RMI-Q when

it is removed from the system. The probe number

is cleared from the RMI-Q by repeating the

partnering procedure whilst the corresponding

machine start input is held high. The RMI-Q

will then display that the probe number was

cleared. Alternatively, the RMP can be cleared via

application of the ReniKey machine macro cycle.

Please refer to the ReniKey programming manual

on how to use ReniKey with your machine's

controller. Alternatively, refer to www.renishaw.

com. ReniKey can also be used to clear all probe

numbers at the same time. If the cleared RMP

is to be used again with the RMI-Q, it must be

re-partnered.

System

installation

3.5

Changing RMP position

If, during partnering with all procedures, the

RMI-Q acquires an RMP that is already stored

under a different probe number, the RMP will be

cleared from its current location and stored under

the new probe number selected for acquisition.

Page 30

RMI-Q installation guide

System

installation

3.6

RMI-Q cable

Cable termination

A ferrule should be crimped onto each cable wire

for a more positive connection at the terminal box.

Standard cable variants

The RMI-Q standard cables are 8 m (24.6 ft) and

15 m (49.2 ft) long.

Longer cables are available, please see

Section 6, 'Parts list'.

Cable specification

Ø7.6 mm (0.3 in), 16 core screened cable,

each core 18 x 0.1 mm.

NOTE:

Maximum cable length:

30 m (98 ft) at 12 V

50 m (164 ft) at 24 V

Fitting flexible conduit

Cable

Adaptor A

Conduit

termination

piece

Plastic olive

Cable sealing

Coolant and dirt are prevented from entering the

RMI-Q by the cable sealing gland. The RMI-Q

cable can be protected against physical damage

by fitting flexible conduit if required.

Recommended flexible conduit is Anamet™

Sealtite HFX (5/16 in) polyurethane.

A conduit kit is available - see Section 6, 'Parts

list'.

!

CAUTIONS:

Failure to adequately protect the cable can result

in system failure due to either cable damage or

coolant ingress through cores into the RMI-Q.

Failure due to inadequate cable protection will

invalidate the warranty.

When tightening or loosening nut B on the

conduit, ensure that torque is only applied

between A and B.

Flexible

conduit

NOTE: Conduit bulkhead fittings require

a clearance hole for an M16 thread.

1. Slide nut B and plastic olive onto the

conduit.

2. Screw conduit termination piece into end of

the conduit.

3. Fit conduit to adaptor A and tighten nut B.

Nut B

Page 31

Screw torque values

3 mm AF

2 Nm

(1.47 lbf. ft)

4 mm AF

5.1 Nm

(3.76 lbf. ft)

HOLD

19 mm AF

T10 tamperproof

1.0 Nm (0.74 lbf.ft)

System

installation

3.7

22.0 mm AF (7/8 AF)

Conduit adaptor to RMI-Q body 7 Nm (5.16 lbf.ft)

Rear exit plug (not shown) 5 Nm (3.69 lbf.ft)

Page 32

System

installation

3.8

RMI-Q installation guide

This page left intentionally blank

Page 33

Maintenance

4.1

RMI-Q body

PCB

RMI-Q cover

Conduit adaptor

Conduit

Cable

SAFETY

The main power supply to the machine must be switched off before working on the RMI-Q.

!

WARNING

!

Only qualified persons should dismantle this equipment. Faulty workmanship will invalidate the warranty.

KEEP CLEAN

!

Liquids and solid particles must NOT be allowed to enter the RMI-Q body.

Antenna contacts

RMI-Q cover

It is not necessary to remove the RMI-Q from the

machine when adjusting the switches or installing

replacement parts. For torque settings see page

3-5 'Screw torque values'.

The front cover may be removed and replaced,

as detailed in this section, if there is a need to

change configuration.

Removing the RMI-Q cover

1. Clean the RMI-Q thoroughly before

servicing to ensure no debris or coolant

enters the unit.

2. Using the T10 tamper proof key (provided),

unscrew (but do not remove) each captive

screw and washer evenly from the cover.

3. When removing the cover, do not twist or

rotate by hand.

Page 34

RMI-Q installation guide

Maintenance

4.2

Replacing the RMI-Q cover

1. Remove the O-ring from the cover. Ensure

that the O-ring, the O-ring groove and the

cover sealing face are clean. Lubricate the

O-ring with silicone grease and refit to cover.

2. Ensure that the O-ring seating on the

RMI-Q body is clean, and that there are no

scratch marks which could prevent complete

sealing.

3. Ensure that the antenna contacts are clean.

4. Place cover, complete with O-ring, onto the

RMI-Q body.

NOTE :

silicone grease to prevent damage. Do not allow

grease to contaminate the antenna contacts.

IMPORTANT: Do not overtighten the cover as

distortion could occur.

5. Tighten each captive screw and washer a few

The O-ring should be lubricated with

turns at a time, to pull the cover down evenly.

Screw torque is 1.0 Nm (0.74 lbf.ft.).

Side exit to rear exit cable

conversion

1. Remove RMI-Q cover (see page 4.1

'Removing the RMI-Q cover').

2. Remove the three crosshead screws

retaining the PCB. Carefully remove the

PCB and disconnect the cable connection to

the PCB.

3. Unscrew the conduit gland from the RMI-Q

body.

4. Unscrew the rear exit plug and rubber

grommet from the RMI-Q body.

5. Carefully remove the cable assembly and

refit through rear exit hole. Tighten the

conduit gland. For torque settings see page

3.5 'Screw torque values'.

6. Fit the rubber grommet and rear exit plug to

the side exit hole and tighten.

7. Connect the PCB to the cable connector.

Insert the PCB and retain with the three

cross head screws. For torque settings see

page 3.7 'Screw torque values'.

8. Fit the RMI-Q cover (see page 4.2

'Replacing the RMI-Q cover').

CAUTION

!

to rear exit cable must only be undertaken by

qualified personnel. Failure to do so will invalidate

the warranty.

Conversion from side exit cable

Page 35

Fault finding

Symptom Cause Action

5.1

No LEDs lit on RMI-Q.

RMI-Q status LEDs do

not correspond to RMP

status LEDs.

RMI-Q error LED

illuminated (refer to

page 2.3).

Overvoltage, undervoltage or no

power.

Damaged cable Check wiring

Radio link failure - RMP out of

RMI-Q range.

RMP has been enclosed /

shielded by metal.

RMP and RMI-Q are not

partnered.

RMP and RMI-Q are not

partnered.

Dead RMP batteries. Change RMP batteries.

Probe not switched on. Check configuration and alter as

Check voltage supply.

Check position of RMI-Q, refer

to the operating envelope in the

relevant RMP installation guide

(see Section 6, 'Parts list').

Review installation.

Partner RMP and RMI-Q.

Partner RMP and RMI-Q.

required.

All RMI-Q LEDs flashing.

Probe out of range. Check position of RMI-Q, refer

to the operating envelope in the

relevant RMP installation guide

(see Section 6, 'Parts list').

Probe selection error. Verify that one RMP is working

and is correctly selected.

RMP is not compatible with 0.5

second turn on.

Wiring fault. Check wiring.

Output overcurrent. Check wiring, turn power to RMI-Q

Change turn on time to 1 second.

off and on again to reset.

Page 36

RMI-Q installation guide

Symptom Cause Action

Fault-finding

5.2

RMI-Q low battery LED

lit.

Reduced range.

RMI-Q System Status

LED is continually lit

red.

Probe will not turn off.

Low RMP batteries. Change RMP batteries soon.

Local radio interference. Identify and remove.

RMP has been enclosed /

shielded by metal.

RMP is not compatible for 0.5

second turn on.

Time out off used with level start

option.

Review installation.

Change RMI-Q configuration to

standard turn on.

Use an RMP with a 'Q' marking.

Review system setup.

Page 37

Parts list

Type Part number Description

RMI-Q kit A-5687-0049 RMI-Q with 8 m (26.2 ft) cable, tool kit, quick-start guide and radio

approval label.

RMI-Q kit A-5687-0050 RMI-Q with 15 m (49.2 ft) cable, tool kit, quick-start guide and radio

approval label.

Mounting bracket A-2033-0830 Mounting bracket.

Conduit kit A-4113-0306 Conduit kit with 1 m (3.28 ft) of polyurethane conduit and bulkhead

connector (M16 thread).

Cover assembly A-5687-0305 Cover/antenna assembly: including cover screws, torx key and O-ring.

Cable assembly A-5687-0306 Cable assembly 8 m (26.2 ft) long.

Cable assembly A-5687-0302 Cable assembly 15 m (49.2 ft) long.

Cable assembly A-5687-0303 Cable assembly 30 m (98.4 ft) long.

Cable assembly A-5687-0304 Cable assembly 50 m (164 ft) long.

Tool kit A-4113-0300 Comprising: 1 x T10 tamperproof key, 1 x 4 mm hex key,14 x ferrules,

4 x M5 screw, 2 x M5 nut, 4 x M5 washer, 1 x O-ring (Ø34.5 x 3 mm).

RMI-Q support

software

Publications. These can be downloaded from our web site at www.renishaw.com

RMI-Q A-5687-8500 Quick-start guide: for rapid set-up of the RMI-Q radio machine

RMP60 A-4113-8501 Quick-start guide: for rapid set-up of the RMP60 probe, includes CD

RMP600 A-5312-8500 Quick-start guide: for rapid set-up of the RMP600 probe, includes CD

RMP40 A-5480-8500 Quick-start guide: for rapid set-up of the RMP40 probe, includes CD

RLP40 A-5627-8500 Quick-start guide: for rapid set-up of the RLP40 probe, includes CD

RTS A-5646-8500 Quick-start guide: for rapid set-up of the RTS probe, includes CD with

Styli H-1000-3200 Technical specification: Styli and accessories.

Software features H-2000-2289 Data sheet: Probe software for machine tools – illustrated features.

Software list H-2000-2298 Data sheet: Probe software for machine tools – list of programs.

A-5687-???? CD comprising: ReniKey machine macro cycles with programming

manual and macro software for multiple RTS.

interface, includes CD with installation guides.

with installation guides.

with installation guides.

with installation guides.

with installation guides.

installation guides.

6.1

NOTE: The serial number of each RMI-Q is found on the top of the housing.

Page 38

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

+44 (0)1453 524524

T

+44 (0)1453 524901

F

uk@renishaw.com

E

www.renishaw.com

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

*H-5687-8504-01*

© 2012 Renishaw plc Issued (BETA SITE ONLY) Part no. H-5687-8504-01-A

Loading...

Loading...