Page 1

Installation and user’s guide

H-2000-5220-01-A

RMI - radio machine interface

Page 2

© 2003 Renishaw. All rights reserved.

Disclaimer

Renishaw® is a registered trademark of

Renishaw plc.

This document may not be copied or

reproduced in whole or in part, or

transferred to any other media or language,

by any means, without the prior written

permission of Renishaw.

The publication of material within this

document does not imply freedom from

the patent rights of Renishaw plc.

Renishaw part no: H-2000-5220-1-A

Issued: 08.2003

Considerable effort has been made to ensure

that the contents of this document are free from

inaccuracies and omissions. However, Renishaw

makes no warranties with respect to the

contents of this document and specifically

disclaims any implied warranties. Renishaw

reserves the right to make changes to this

document and to the product described herein

without obligation to notify any person of such

changes.

Trademarks

All brand names and product names used in

this document are trade names, service marks,

trademarks, or registered trademarks of their

respective owners.

Page 3

EC DECLARATION OF CONFORMITY

Renishaw plc declare that the product:-

Name: RMI

Description: Radio Machine Interface

has been manufactured in conformity with the following standard: -

BS EN 61326:1998/ Electrical equipment for measurement, control and

laboratory use - EMC requirements.

Immunity to annex A - industrial locations.

Emissions to class A (non-domestic) limits.

and that it complies with the requirements of directive (as amended): -

89/336/EEC Electromagnetic compatibility

The above information is summarised from the full EC declaration of

conformity. A copy is available from Renishaw on request.

1

Page 4

2

Installation and user’s guide

Installation and user’s guide

Warranty

Equipment requiring attention under warranty

must be returned to your supplier. No claims will

be considered where Renishaw equipment has

been misused, or repairs or adjustments have

been attempted by unauthorised persons.

Care of the RMI

Keep system components clean and treat the

RMI with care.

Do not apply metallic labels to the front of the RMI.

Changes to equipment

Renishaw reserve the right to change

specifications without obligation to change

equipment previously sold.

Weight

RMI including 15 metres (49.2 ft) of cable

= 1,700 g (60 oz).

CAUTION: Only qualified persons should

!

adjust switches.

CNC machine

CNC machine tools must always be operated

by competent persons in accordance with

manufacturers instructions.

Environment

Temperature

The RMI is specified for storage over

–10° to 70° C (14° to 158° F) and operation

over 5° to 60° C (41° to 140° F) ambient

temperature range.

Sealing

The unit is fully sealed to IPX8.

Patent notice

Features of products shown in this guide,

and of related products, are the subject of the

following patents and/or patent applications:

EP 0652413

US 4599524

US 5,279,042

JP 3,126,797

WO 02/063235

WO 03/021182

Page 5

Contents

Contents

3

RMI .................................................................. 4

Operating envelope ......................................... 5

RMI visual diagnostics .................................... 6

RMI outputs ..................................................... 8

RMI output waveforms .................................. 10

Wiring diagram .............................................. 12

Switches SW1, SW2 and start input ............. 13

RMI cable ...................................................... 15

RMI cable sealing and fitting

flexible conduit ............................................... 16

RMI-RMP partnership ................................... 17

Installation with inspection and

tool setting probe ........................................... 18

Remote external audible output .................... 19

Mounting bracket .......................................... 20

Removing and refitting the RMI cover .......... 21

Removing and refitting PCB .......................... 23

Side to rear exit conversion .......................... 23

Screw torque values ..................................... 24

Parts list ......................................................... 25

Page 6

4

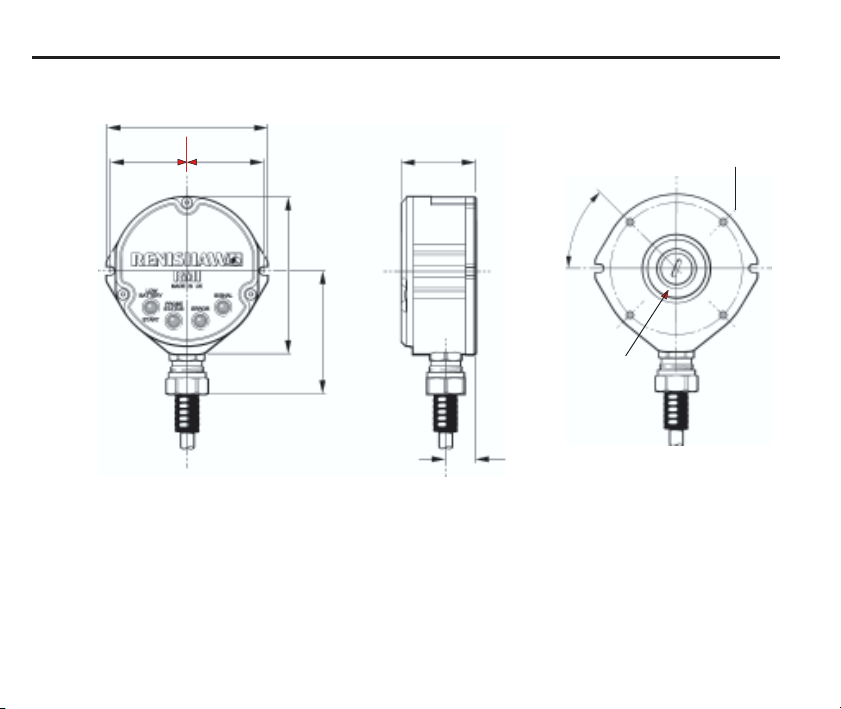

RMI

RMI

RMI

The RMI is a combined radio tranceiver and

machine interface.

The RMI is designed to be mounted within

the machine's working envelope.

Power supply

The RMI can draw its supply from the CNC

machine 12 V to 30 V d.c. supply and presents a

97 (3.82)

46 (1.81)

46 (1.81)

45 (1.77)

50 (1.97)

74 (2.91)

dimensions mm (in)

44 (1.73)

45°

To use a flush rear

exit a 25 (1.0) hole

is required for

connector

17.5 (0.69)

peak load of up to 250 mA during turn on

(typically 100 mA from 24 V).

Alternatively, power may be supplied from

a Renishaw PSU3 power supply unit.

Input voltage ripple

The input voltage ripple shall not cause the

voltage to fall below 12 V, or rise above 30 V.

4 holes M5 x 13

deep on 80 p.c.d.

Page 7

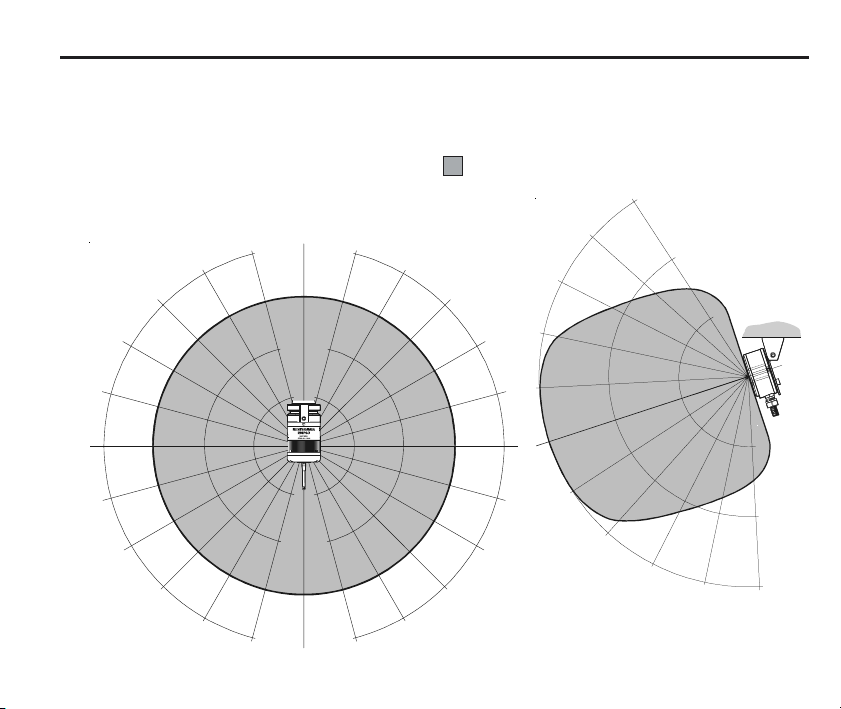

Operating envelope

RMP60 probe + RMI

RMP60 and RMI must be within each others

operating envelope shown.

30°

45°

60°

75°

90°

75°

Range metres (feet)

OPERATING AND SWITCH ON/OFF

60°

45°

30°

Operating envelope

75°

15 (49)

60°

45°

5

10 (33)

5 (16)

15°

0°

15°

30°

45°

60°

75°

5

(1 6)

10 10

(33) (33)

15 15

(49) (49)

90°

60°

75°

45°

30°

15°

15°

0°

15°

30°

45°

60°

5

(16)

10

(33)

15

(49)

75°

Page 8

6

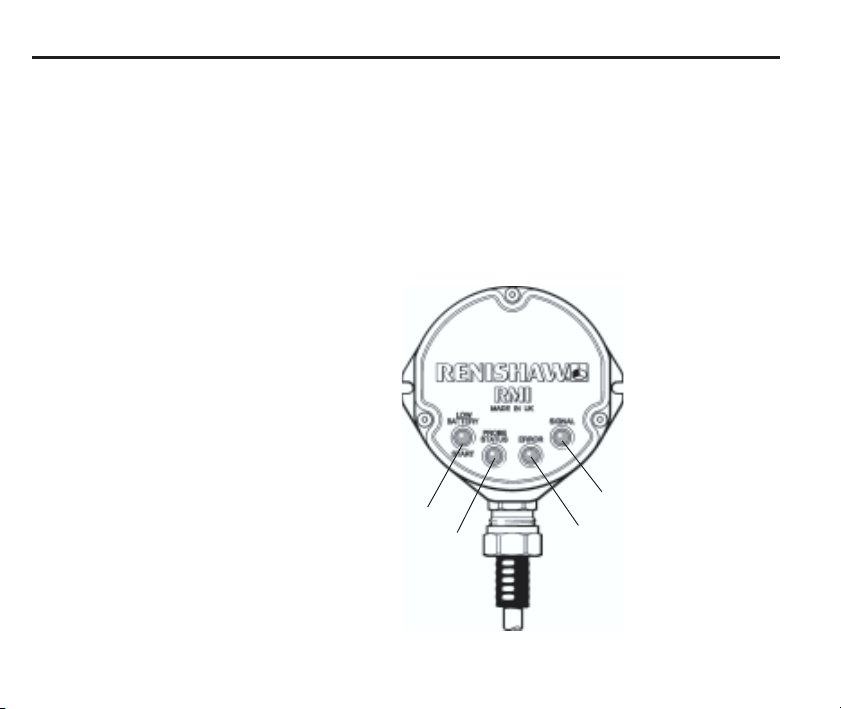

RMI visual diagnostics

RMI visual diagnostics

A visual indication of system status is provided by LED's.

Status is continuously updated and indication is provided for

START, LOW BATTERY, PROBE STATUS, ERROR, SIGNAL STRENGTH

LED LIGHT SIGNALS

1. LOW BATTERY

Red Battery is low.

Green M code start/stop in

progress.

Yellow Battery low & M code

start/stop in progress.

Off Battery is O.K. (and no

M code start/stop in

progress).

2. PROBE STATUS

Red Probe triggered or unknown

status.

Green Probe is seated.

KEEP THE

FRONT COVER

CLEAN

4

1

2

3

Page 9

RMI visual diagnostics

7

3. ERROR

Red Error, other outputs may

be incorrect.

Off No Error.

4. SIGNAL

Green Full signal strength.

Yellow Medium signal strength.

Red Low signal strength, radio

link may fail.

Off No signal detected.

Green/off Flashing: RMI is acquisition

mode, and can acquire a

partner RMP.

Red/yellow Flashing: RMI has (just)

acquired a new partner RMP.

Notes.

1. The probe status LED will always be

illuminated when power is present.

There is no ‘power present’ LED.

2. All the indicators report the status of the

partner RMP. If there is no partner in range,

or the partner is off then the probe status

and error LEDs will be red and the other

LEDs will be off.

3. When the RMI is powered it will enter the

acquire partner mode which will be indicated

by the flashing green signal LED.

After a short time (~12 secs) it will switch to

its normal mode listening for its partner.

4. The conditions shown by the low battery,

probe status and error LEDs are the same

as those present on the electrical signal

outputs.

Page 10

8

RMI outputs

RMI outputs

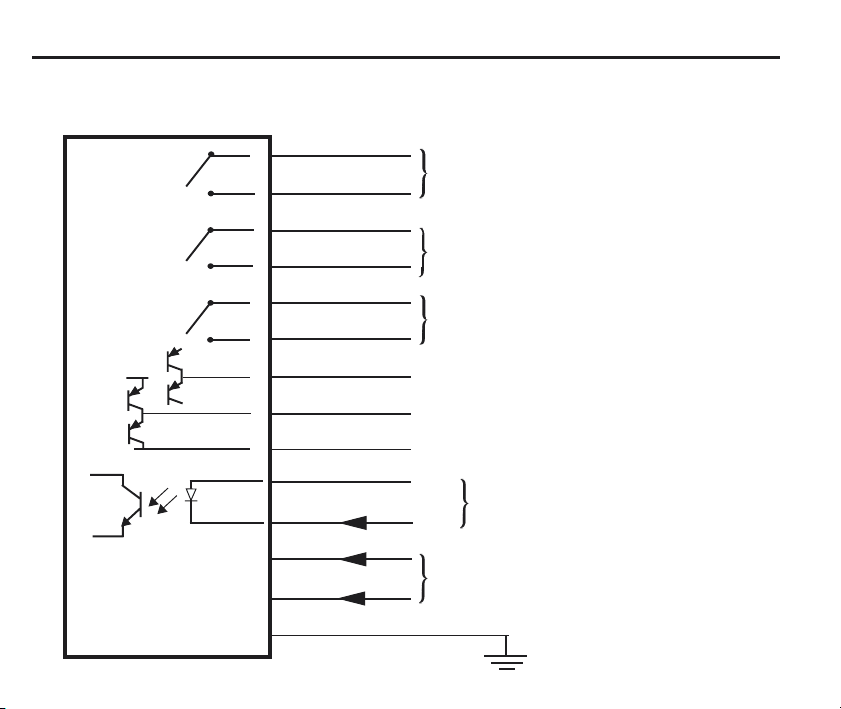

There are four outputs:

Probe status 1 (SSR)

Probe status 2a (driven skip 5 V isolated)

Probe status 2b (driven at power supply

voltage)

Error (SSR)

Low battery (SSR)

All outputs can be individually inverted by using

switches SW1 and SW2 - see pages 16 and 17.

Switching time = Less than 10 µs (low to high)

Switching time = Less than 10 µs (high to low)

If overload occurs, remove source or problem,

turn off power supply and the unit will reset itself.

.

SSR outputs:

DC ‘ON’ resistance 60 ohms max.

Up to 50 mA protected.

Switching time = Less than 10 µs (low to high)

Switching time = Less than 10 µs (high to low)

Power supply reversal will not damage the

SSR outputs, but may trip the electronic

over current circuits.

Driven outputs:

Sourcing - Up to 50 mA protected.

Sinking - Up to 50 mA unprotected, but

overload will still be indicated by

LEDs.

Page 11

RMI outputs

CAUTION:

Power supply voltage

!

Do not exceed 30 V between the black wire and the screen wire (grey/black), or the red

wire and screen wire (grey/black), or the red and black wires (power supply), as this could

result in permanent damage to the RMI and/or the customer power supply.

The use of in-line fuses at the machine cabinet end is recommended to provide protection

for the RMI and cable

Screen connection

A good connection should be made to machine ground (star point).

!

Output stage circuit

!

Output stage supplies (+ve, –ve) should not be switched on and off to enable/disable them

as this can cause the over current protection to switch off the output completely.

Ensure that outputs from the RMI do not exceed specified current ratings.

RMI outputs

9

Page 12

10

RMI output waveforms

RMI

OUTPUTS

SSR / driven

output

(switch

position)

PROBE STATUS 1

(LEVEL)

Normally closed

PROBE STATUS 1

(PULSED)

Normally closed

PROBE STATUS 2

(LEVEL)

Normally low

PROBE STATUS 2

(PULSED)

Power

off

SSR

open

SSR

closed

SSR

open

SSR

closed

Output

high

Output

low

Output

high

Probe

switch

on

Seated

Probe

trigger

PROBE

Triggered

Probe

reseat

Seated

Error

e.g.

low signal

Error

clear

Low

battery

Probe

switch

off

Normally low

Output

low

Page 13

RMI output waveforms

RMI output waveforms (outputs can be inverted by switches)

PROBE

RMI

OUTPUTS

Power

off

Probe

switch

on

Seated

Triggered

Probe

trigger

Probe

reseat

Seated

Error

e.g.

low signal

Error

clear

Low

battery

11

Probe

switch

off

ERROR

Normally

SSR

open

SSR

closed

closed

LOW

BATTERY

Normally

SSR

open

SSR

closed

closed

SIGNAL DELAYS

1. Transmission delay Probe trigger to output change of state = 10 ms ±10 µs.

2. Start delay Time from initiation of start signal to valid signal transmission = 1 second.

Note : Pulsed outputs are 40 ms ±1 ms duration.

Page 14

12

Wiring diagram

Wiring diagram (with the output groupings shown)

Turquoise

RMI

5 V

+24 V

0 V

Screen

Turquoise / black

Violet

Violet / black

Green

Green / black

Orange

Yellow

Grey

White

Brown

Red

Black

Grey/Black

Probe status pair (SSR)

Low battery pair (SSR)

Error pair (SSR)

Skip drive at power supply voltage

High speed skip drive (5 V)

High speed skip return (0 V)

+ve

–ve

Start input

Power supply (12 to 30 V)

Machine ground (star point)

Page 15

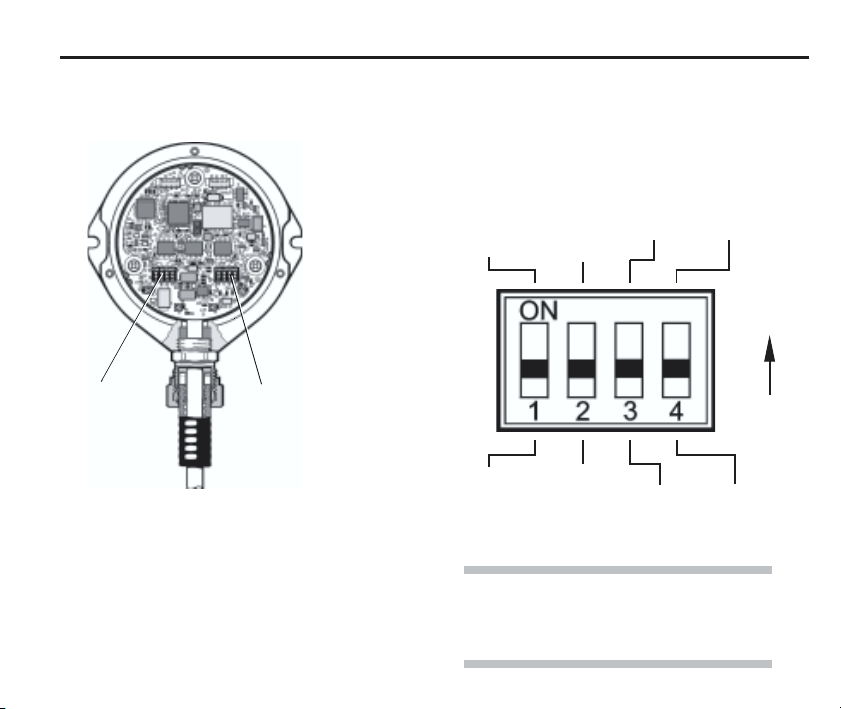

Switches SW1, SW2, and start input

Switches SW1, SW2 and start input

SWITCH SW1 output configuration

13

Factory settings shown

To gain access to

SW1

the switches, remove

SW2

the RMI cover - see

page 20

Start input

To initiate a MACHINE START signal, an

input of between 8 V and 30 V is required

between the START wires (WHITE +ve and

BROWN –ve). (Typical load up to 15 mA).

This is an isolated input. The minimum

pulse width is 1 ms.

PROBE

STATUS 1

Pulsed

PROBE

STATUS 1

Level

PROBE

STATUS 1

N.O.

PROBE

STATUS 1

N.C.

LOW BAT

N.O.

LOW BAT

N.C.

ERROR

N.O.

ERROR

NOTE:

Exercise caution when using error SSR in

N.O. mode.

ON

N.C.

Page 16

14

Switches SW1, SW2, and start input

Switch SW2 output configuration

PROBE

STATUS 2

Pulsed

PROBE

STATUS 2

Trigger low

HEIDENHAIN

COMPATIBLE

On

NOT USED

ON

PROBE

STATUS 2

Level

PROBE

STATUS 1

Trigger high

NOTE:

When in Heidenhain compatible on mode M code turn off cannot be used

HEIDENHAIN

COMPATIBLE

Off

NOT USED

Page 17

RMI cable

RMI cable

15

Cable termination

A ferrule should be crimped onto each cable

core for more positive connection at the terminal

box. To fit a ferrule, insert the prepared core into

ferrule, until the end is flush with the end of the

ferrule as shown below. Then crimp with pliers.

Core end flush

Core

Ferrule

with ferrule

Crimp

Standard cable

The RMI standard cable is 15 m (49.2 ft) long,

longer cables are avaible (see page 25).

Cable specification:

Ø7.5 mm (0.29 in), 13 core screened cable,

each core 18 x 0.1 mm.

NOTE:

Maximum total cable length is 50 m (164 ft) at 24V

Page 18

16 RMI cable sealing and fitting flexible conduit

RMI cable sealing

Coolant and dirt are prevented from entering the

RMI by the cable sealing gland. The RMI cable

is protected against physical damage by fitting

flexible conduit if required.

Fitting flexible conduit

Recommended flexible conduit is Anamet

sealtite HFX (5/16 in) polyeurethane).

1. Slide nut B and plastic olive onto conduit.

2. Screw conduit termination piece into end of

conduit.

3. Fit conduit to adaptor A and tighten nut B.

CAUTION: Failure to adequately protect the cable can result in system failure due to either

cable damage or coolant ingress through cores into the RMI.

!

Failure due to inadequate cable protection will invalidate the warranty.

When tightening or loosening nut B onto conduit ensure that torque is only applied between

A and B.

Cable

Flexible

conduit

Adaptor A

Conduit termination

piece

Plastic olive

Nut B

Page 19

RMP-RMI partnership

System setup/establishing RMP-RMI partnership.

17

Set up is done by using the RMP trigger logic

and powering on the RMI at a particular time

during the process.

1. Use trigger logic to set RMP turn on/ off

modes as desired.

2. Use trigger logic to access RMP acquisition

mode (turquoise/light blue flashes 2 short

and 1 long).

WARNING:

!

When holding the RMP do NOT wrap a

hand, or anything else, around the glass

window.

3. Power on the RMI.

4. Wait until RMI signal led flashes green.

5. Trigger the probe (min 0.1 sec, max 2 sec).

6. When the partnership is established the

RMI signal LED will flash red and yellow.

7. Allow ~10 seconds for both RMP and RMI

to timeout, all RMP LEDs off, RMI signal

LED off. The system is then ready for use.

8. Note: If the RMP flashes 2 turquoise short

followed by 1 red long it is still trying to

partner an RMI.

Note:

When the RMP and RMI become partners the

RMI records the RMP serial number. It is not

possible for an RMI to be partners with more than

one RMP.

It is possible for an RMP to be partners with more

than one RMI, but the system will not

work correctly if more than one partner RMI is

powered on at any one time.

Page 20

18

Installation with inspection and tool setting probe

Installation with inspection and tooletting probe

On machines where the RMI is to be integrated with a tool setting probe input,

and only one probe input is provided on the control, an M code can be utilised

to drive an external relay and effectively select which probe is to be monitored :

CONTROL

PROBE INPUT

M CODE

RELAY

Probe status

from RMI

Probe status

from tool setter

Page 21

Remote external audible autoput

Remote external audible output

19

The pulsed output can be utilized to operate

an external remote audible indicator.

Wiring configurations are shown below.

Option 1. Using 5 V output

RMI

0 V

Yellow

Grey

Pulsed (skip)

OR

Option 2. Using machine voltage output

RMI

0 V

Orange

Black

Skip drive (power supply)

The audible indicator must comply with the

output transistor specification

i.e. 50 mA peak

30 V peak

Pulse duration is 40 ms ±1 ms.

Note: This is not possible if both skip

drives are being monitored by

the control

+ve

–ve

+ve

–ve

Page 22

20

Mounting bracket

Mounting bracket (optional)

dimensions mm (in)

NOTE:

Install RMI with cable exiting from

lower side for good coolant run off.

Mounting bracket cannot be used

with an RMI in rear exit configuration.

Do not apply any metallic label to

the front cover, as this will shield

the antenna.

2.0

(0.08)

25

25

(0.98)

(0.98)

3 holes Ø6.4 (0.25)

30

(1.18)

25

(0.98)

45

(1.77)

Paired holes permit RMI mounting

in alternative orienation.

100,5 (3.95)

45 (1.77)

90 (3.54)

45°

19 (0.75)

38 (1.50)

3 grip protrusions

2.0

(0.08)

6 holes

Ø5.3 (0.20)

Page 23

Removing and refitting the RMI cover

21

RMI cover

It is not necessary to remove the RMI from

the machine, when adjusting the switches or

installing new parts. For torque settings please

see page 24.

Removing the RMI cover

1. Clean RMI to ensure no debris enters unit.

2. Unscrew the three captive cover screws

evenly (2 mm key).

3. When removing cover DO NOT twist or

rotate by hand.

Fitting the RMI cover

1. Before fitting the cover, check for any

damage to screws or scratch marks which

could prevent sealing.

2. Ensure that the 'O' ring seating on the RMI

body is clean, and there are no scratch

marks which could prevent complete

sealing.

3 Ensure that the cover, antenna contacts

and 'O' ring are clean.

4. Place cover complete with 'O' ring

onto the RMI body.

Note :

The 'O' ring should be lubricated with

silicone grease to prevent nicking.

Do not get any grease on the antenna

contacts.

5. Tighten each captive screw a few turns at

a time, to pull the cover down evenly.

Screw torque is 1.4 Nm (1.03 lbf.ft).

Page 24

22

Removing and refitting the RMI cover

RMI body

Cable clamp

PCB

RMI cover

Conduit adaptor

Conduit

Cable

CAUTION:

!

KEEP RMI CLEAN No liquids or solid particles must be allowed to enter the RMI body.

DO NOT allow the antenna contacts to be contaminated.

Page 25

Removing and refitting PCB / Side to rear exit conversion

23

Removing and

refitting PCB

To remove PCB

1. Remove the RMI cover (page 20).

2. Remove 3 crosshead screws retaining

PCB. Carefully remove PCB and

disconnect cable connection to PCB.

To fit PCB

1. Connect PCB to cable connector. Insert

PCB and retain with 3 cross head screws.

2. Replace RMI cover (page 20).

CAUTION

!

TAKE CARE HANDLING THE PCB

Hold edge of PCB only, do not

touch surface components

Side exit cable to rear exit

cable conversion

1. Remove RMI cover (page 20)

2. Remove PCB.

3. Unscrew cable clamp (2 x crosshead

screws).

4. Unscrew conduit gland from RMI body.

5. Unscrew rear exit plug and rubber gromit

from RMI body.

6. Carefully remove cable assembly and refit

through rear exit hole. Tighten conduit gland.

7. Fit rubber gromit and rear exit plug to side

exit hole and tighten.

8. Fit cable assembly using cable clamp at

3 o’clock position.

9. Replace PCB.

10. Replace RMI cover (page 20).

Page 26

24

Screw torque values

Screw torque values Nm (lbf.ft).

3 mm AF

2 Nm

(1.47 lbf.ft)

4 mm AF

5.1 Nm

(3.76 lbf.ft)

19 mm AF

HOLD

Conduit adaptor to RMI body

10 Nm (7.38 lbf.ft)

Rear exit plug (not shown)

10 Nm (7.38 lbf.ft)

2 mm

1.4 Nm

(1.03 lbf.ft)

22.2 mm AF (7/8 AF)

Page 27

Parts list

Parts list - Please quote the Part no. when ordering equipment.

Type Part No. Description

RMI A-4113-0050 RMI with 15 m (49.2 ft) of Cable.

Mtg Brkt A-2033-0830 Mounting bracket.

Cover A-4113-0105 Cover/anntenna asembly: including cover screws and O ring.

Cable assy A-4113-0101 Cable assembly 15 m (49.2 ft) long.

Cable assy A-4113-0106 Cable assembly 30 m (98.4 ft) long.

Cable assy A-4113-0107 Cable assembly 50 m (164 ft) long.

PCB A-4113-0520 RMI circuit board

Tool kit A-4113-0104 2mm hex key, 4 mm hex key, 14 x ferrules, 4 x M5 screw,

2 x M5 nut, 4 x M5 washer, O ring (34.5 x 3 mm)

The serial number of each RMI is found at the top of the housing.

25

Page 28

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire, GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

*H-2000-5220-01-A*

Loading...

Loading...