Renishaw RGH40, RGS40-G Installation Manual

Installation guide

M-9550-9023-01-A

RGH40 RGS40-G linear encoder system

Contents

Product compliance 1

Storage and handling 2

RGH40 installation drawing 3

RGS40-G glass scale installation drawing (adhesive mounting) 4

Adhesive mounting installation 5

RGS40-G glass scale installation drawing (clip/clamp mounting) 6

Clip/clamp mounting installation 7

Reference mark actuator installation 8

Limit switch installation 8

Readhead mounting and alignment 8

Reference mark set-up 8

Limit switch 8

Output signals 9

Speed 10

Electrical connections 11

Output specications 12

General specications 13

Scale specications 13

RGH40 RGS40-G installation guide

RGH40 RGS40-G installation guide

1

The packaging of our products contains the following materials and can be recycled.

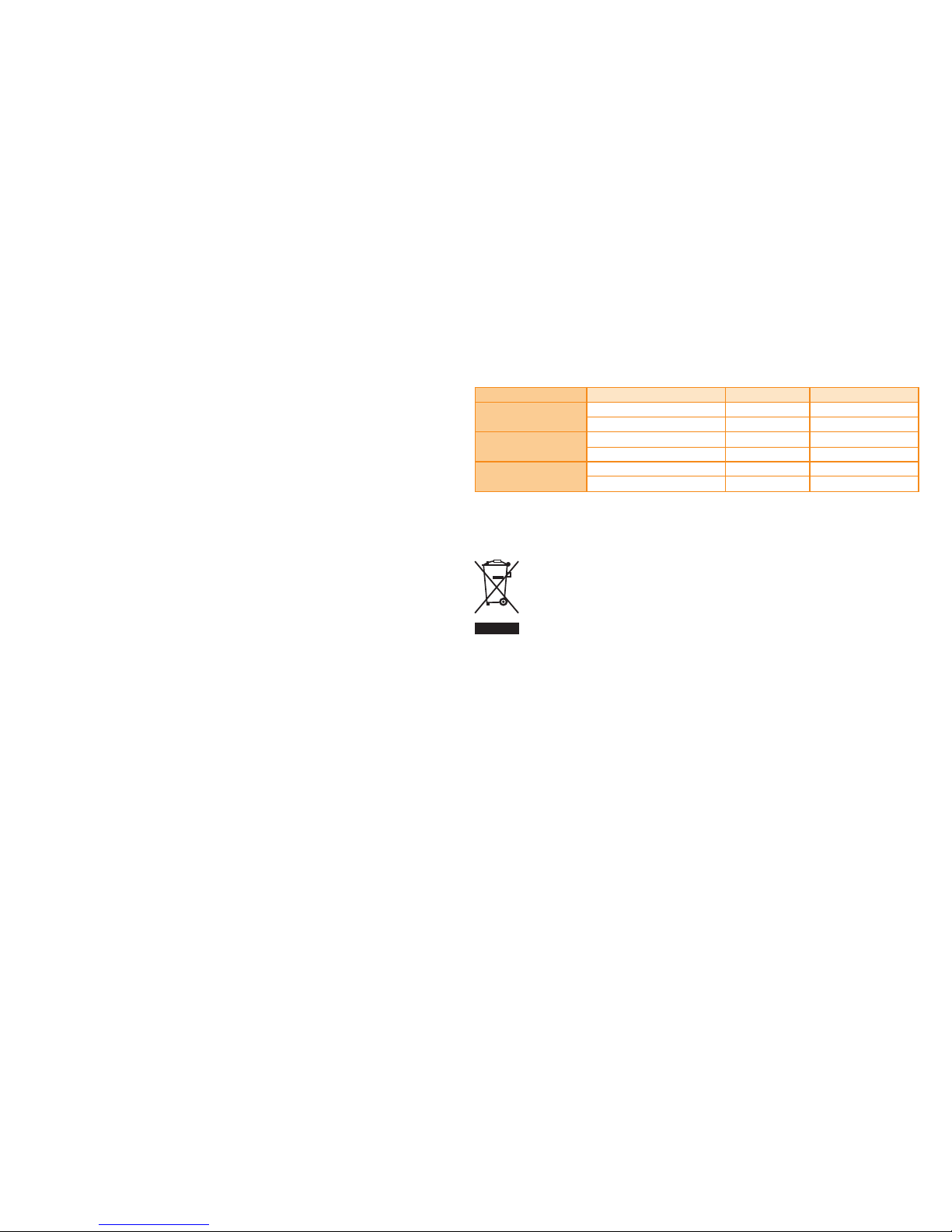

Packaging Component Material ISO 11469 Recycling Guidance

Outer box Cardboard Not applicable Recyclable

Polypropylene PP Recyclable

Inserts Low Density Polyethylene Foam LDPE Recyclable

Cardboard Not applicable Recyclable

Bags High Density Polyethylene Bag HDPE Recyclable

Metalised Polyethylene PE Recyclable

Product compliance

C

Renishaw plc declares that RGH40 complies with the applicable standards and regulations.

A copy of the EC Declaration of Conformity is available on request.

FCC compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The user is cautioned that any changes or modications not expressly approved by Renishaw plc or

authorised representative could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be

used with the unit to ensure compliance.

RoHS compliance

Compliant with EC directive 2011/65/EU (RoHS)

Further information

Further information relating to the RGH40 encoder range can be found in the RGH40 System

Data sheet. (L-9517-9752) This can be downloaded from our website www.renishaw.com/encoder

and is also available from your local representative. This document may not be copied or reproduced

in whole or in part, transferred to any other media or language, by any means without the written

prior permission of Renishaw. The publication of material within this document does not imply freedom

from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS

DOCUMENT IS CORRECT AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES

OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product

should not be mixed with general household waste upon disposal. It is the responsibility of the end user to

dispose of this product at a designated collection point for waste electrical and electronic equipment (WEEE)

to enable reuse or recycling. Correct disposal of this product will help to save valuable resources and prevent

potential negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

Chlorinated

Solvents

Acetone

Methylated

Spirits

CH3COCH

3

N-heptane

CH3(CH2)5CH

3

Propan-2-ol

CH

3

CHOHCH

3

System

+70 °C

-20 °C

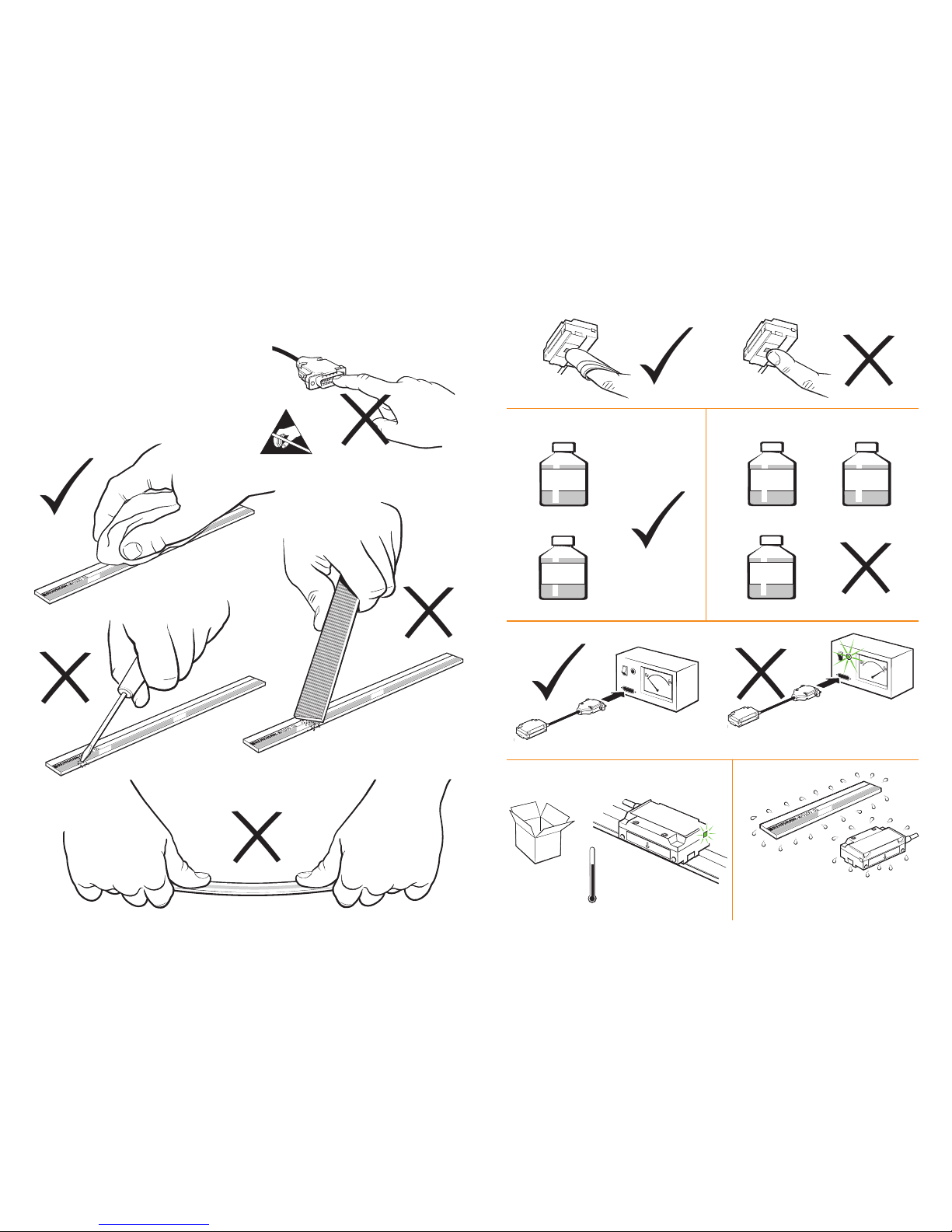

Storage and handling

RGS40-G is a non-contact optical encoder scale that

provides good immunity against contaminants such

as dust, ngerprints and light oils. However, in harsh

environments such as machine tool applications,

protection should be provided to prevent ingress

of coolant or oil.

Humidity

Storage

Operating

RGH40 RGS40-G installation guide

2

95% relative humidity

(non-condensing)

to EN 60068-2-78

System

+55 °C

0 °C

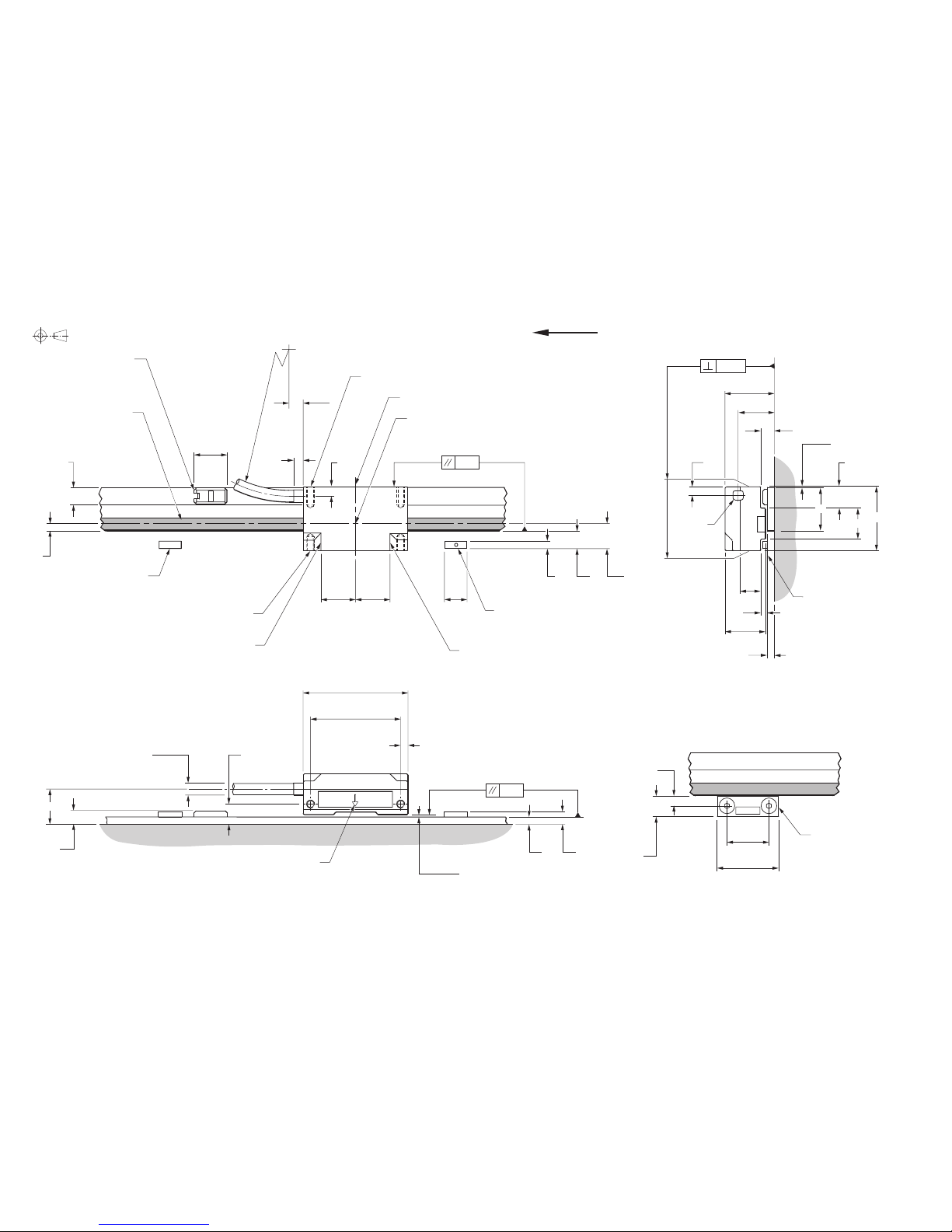

RGH40 installation drawing

Dimensions and tolerances in mm

RGH40 RGS40-G installation guide

3

Arrow indicates forward direction of

readhead relative to scale

R>50 Dynamic bend radius

R>10 Static bend radius

Scale graduations

2 mounting holes M3 x 9.5 deep

†

Reference mark sensor position

Optical centreline

Reference mark actuator

(A-9531-0250)

P limit magnet

(A-9531-0251)

Mount dimple down

(Dimensions same as Q limit)

P limit switch

sensor position

Arrow indicates optical and

reference mark centreline

(Roll tol. ±1°)

Q limit magnet

(A-9531-0251)

Mount dimple up for Q

Optional bolted limit magnet

P (A-9550-0047),

Q (A-9550-0048)

Mounting ledge or

top surface of bracket

for limit switch actuator

(Pitch tol. ±1°)

0.8

0.8

7.5

10.5

Q limit switch

sensor position

10

14.6

17.5

25.5

Optional bolted limit magnet

3

7

14

4

6 min

(Yaw tol. ±1°)

20.7

15.3

3.6

5.7

8.6

*

Set-up

LED

0.13

27

9

18

2.9

4.9

4.05

8.5

7.7

5.1

14.4

Ø4.5 ±0.2

44

38

3

2 mounting holes

M3 x 7.5 deep

†

2.9

17

2.8

3

13

14.6

4

Rideheight

0.8 ±0.15

0.5 ±0.5

*

Extent of mounting faces.

†

The recommended thread engagement is 5 mm. The recommended tightening torque is between 0.5 and 0.7 Nm.

Loading...

Loading...