Page 1

Installation guide

M-9531-9818-01-B

RGH22 RGS20 linear encoder system

Page 2

Contents

Product compliance 1

Storage and handling 2

RGH22 readhead installation drawing 3

RGS20 scale installation drawing 4

Scale application 5

End clamps 5

Reference mark and limit switch actuator installation 6

Readhead mounting and alignment 6

Reference mark set-up 7

Limit switch 7

Output signals 7

Speed 8

Electrical connections 9

Output specications 10

General specications 12

Scale specications 12

RGH22 RGS20 installation guide

Page 3

1

RGH22 RGS20 installation guide

Product compliance

C

Renishaw plc declares that RGH22 complies with the applicable standards and regulations.

A copy of the EC Declaration of Conformity is available on request.

FCC compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The user is cautioned that any changes or modications not expressly approved by Renishaw plc or

authorised representative could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be

used with the unit to ensure compliance.

RoHS compliance

Compliant with EC directive 2011/65/EU (RoHS)

Further information

Further information relating to the RGH22 encoder range can be found in the RGH22 encoder system

Data sheet (L-9517-9676). This can be downloaded from our website www.renishaw.com/encoder

and is also available from your local representative. This document may not be copied or reproduced

in whole or in part, or transferred to any other media or language, by any means without the written

prior permission of Renishaw. The publication of material within this document does not imply freedom

from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS

DOCUMENT IS CORRECT AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES

OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product

should not be mixed with general household waste upon disposal. It is the responsibility of the end user to

dispose of this product at a designated collection point for waste electrical and electronic equipment (WEEE)

to enable reuse or recycling. Correct disposal of this product will help to save valuable resources and prevent

potential negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

The packaging of our products contains the following materials and can be recycled.

Packaging Component Material ISO 11469 Recycling Guidance

Outer box Cardboard Not applicable Recyclable

Polypropylene PP Recyclable

Inserts Low Density Polyethylene Foam LDPE Recyclable

Cardboard Not applicable Recyclable

Bags High Density Polyethylene Bag HDPE Recyclable

Metalised Polyethylene PE Recyclable

Page 4

2

RGH22 RGS20 installation guide

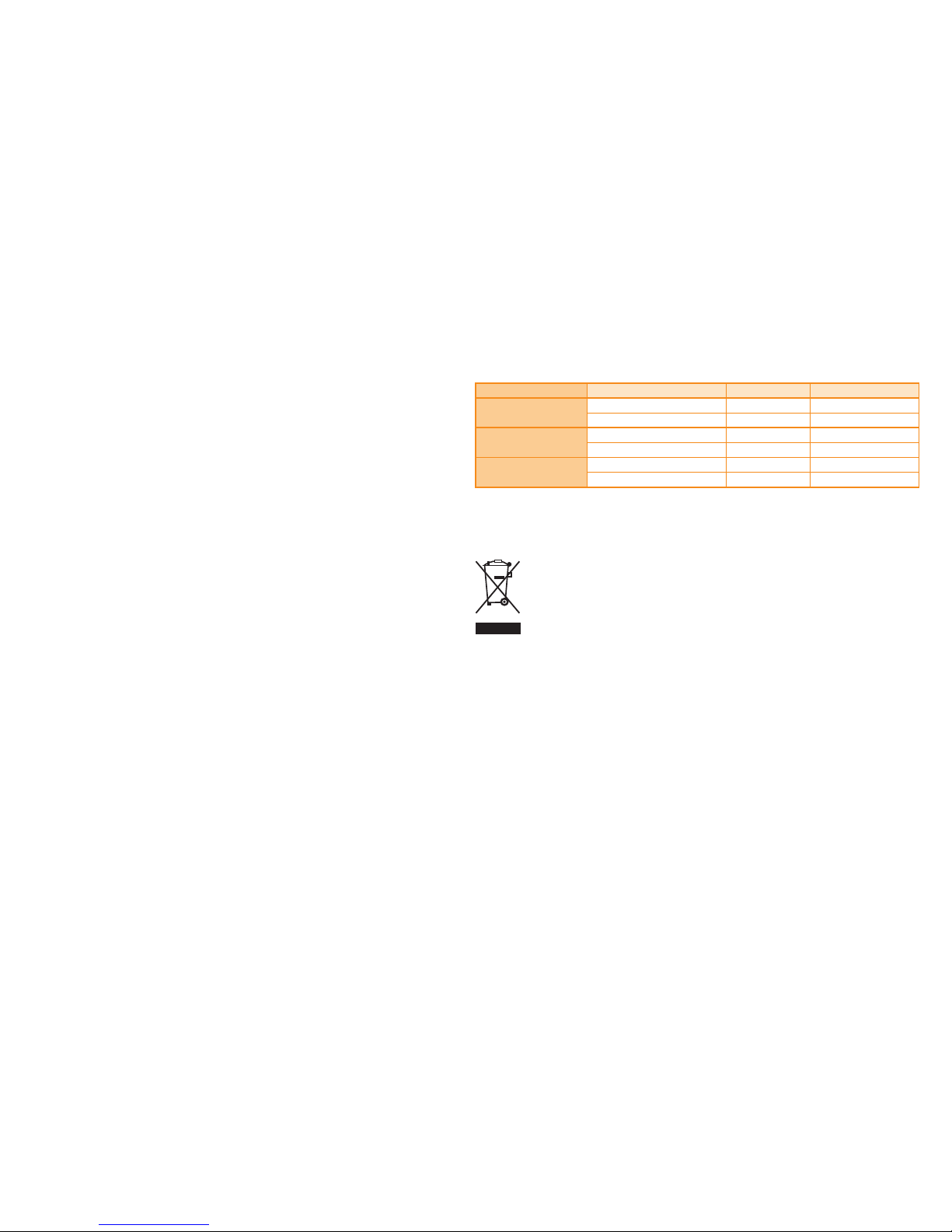

Storage and handling

N-heptane

CH3(CH2)5CH

3

Propan-2-ol

CH

3

CHOHCH

3

Acetone

CH3COCH

3

Methylated

Spirits

Chlorinated

Solvents

RGS20 – 100 mm

NOTE: Ensure self-adhesive

tape is on outside of bend.

Minimum bend radius

Operating

Storage

System

+55 °C

0 °C

System

+70 °C

−20 °C

Humidity

95% relative humidity

(non-condensing)

to EN 60068-2-78

Page 5

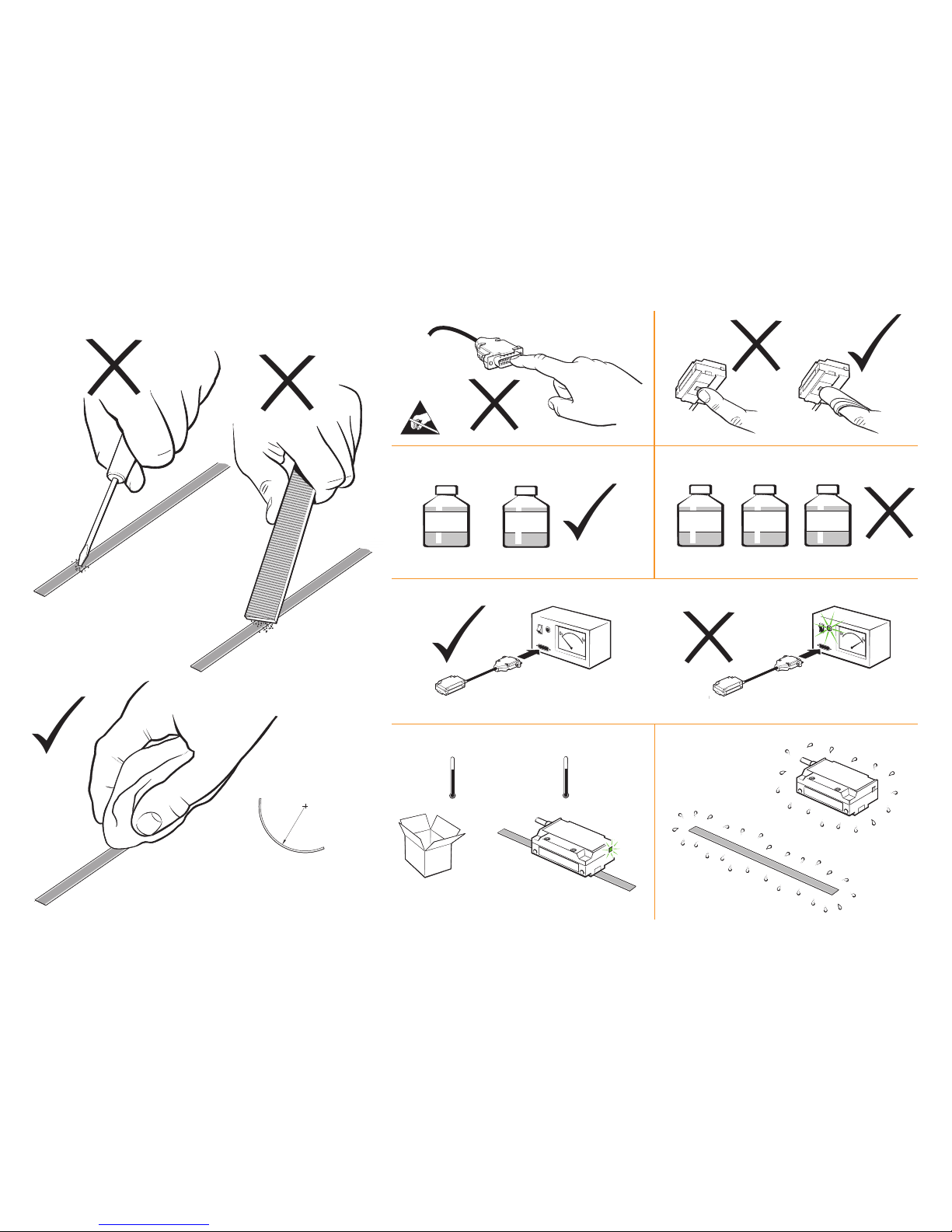

R>50 dynamic bend radius

R>10 static bend radius

>6

4

4

Reference mark sensor position

Optical centre

2 holes M3 x 0.5 x 9.5 deep

‡

(Yaw tol. ± 0.5°)

0.38

15.5

10

Q limit switch sensor position

Q limit switch actuator

(

A-9531-0251)

Mount dimple up

(size as P actuator)

(Roll tol. ± 1°)

0.13

14.6

P limit switch sensor position

2 holes M3 x 0.5 x 7.5 deep

‡

P limit switch actuator

(A-9531-0251)

Dimple to substrate

14.5

7

14

10.6

*

2.2

*

Ø4.7 max

5

*

2

*

(Pitch tol. ± 1°)

0.8

44

38

3

Readhead to

scale clearance

Rideheight 0.8 ± 0.1

A

Detail A

Scale surface

7.6

†

3

*

13

9

27

3.6

11.6

17

*

*

Dimensions measured from substrate. †Alternative mounting faces

‡

The recommended thread engagement is 5 mm. The recommended tightening torque is between 0.5 and 0.7 Nm.

Set-up LED

23.5

Arrow indicates forward direction

of readhead relative to scale

Scale thickness:

0.2 (RGS20-S)

0.3 (RGS20-P)

14.6

3

RGH22 RGS20 installation guide

RGH22 readhead installation drawing

Dimensions and tolerances in mm

3

10.5

6 (RGS20-S)

6.3 (RGS20-P)

Reference mark actuator

Epoxy mounted

(A-9531-0250)

Page 6

4

RGH22 RGS20 installation guide

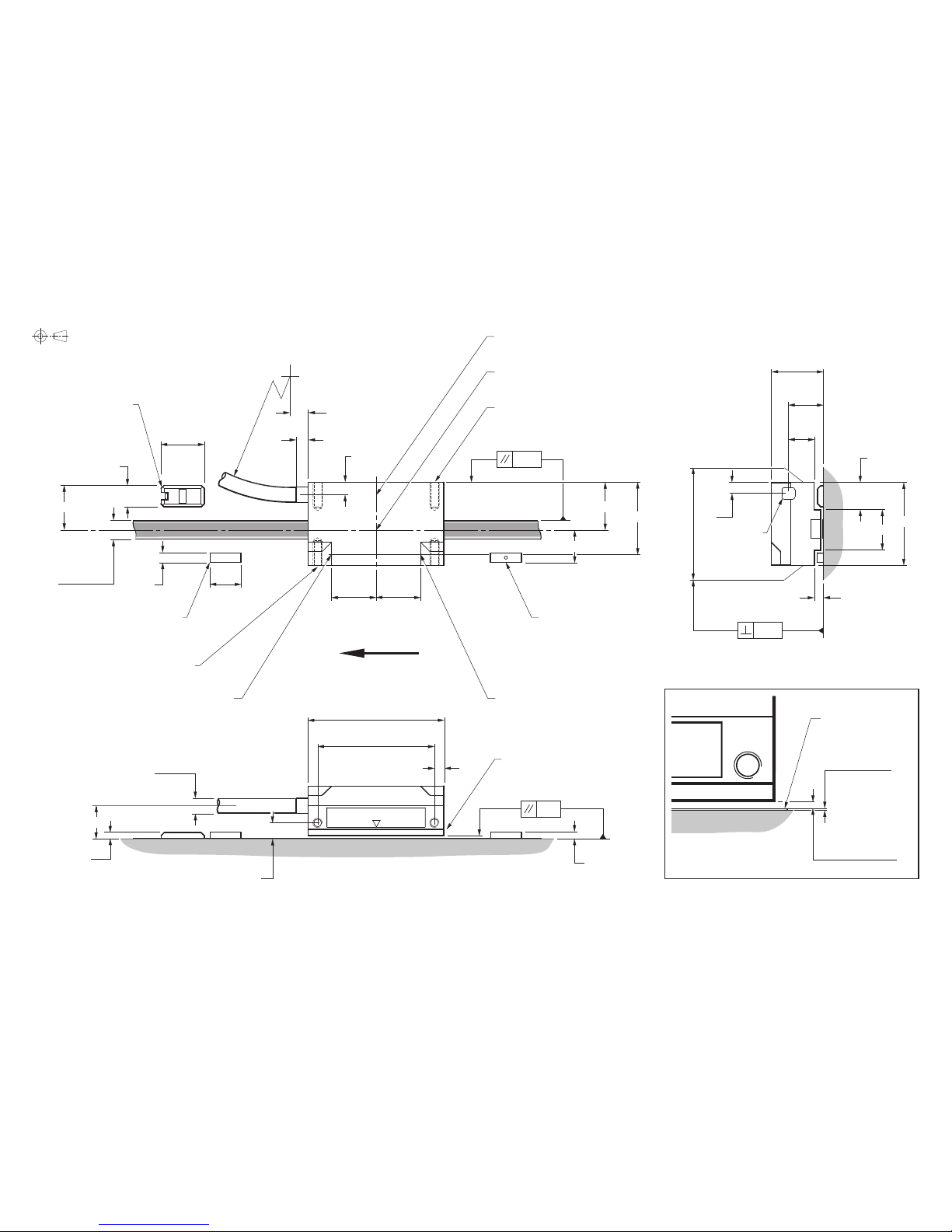

RGS20 scale installation drawing

Dimensions and tolerances in mm

NOTE: The surface roughness of the scale mounting surface must be ≤3.2 Ra.

The parallelism of the scale surface to the axis of motion (readhead rideheight variation) must be within 0.05 mm.

Overall length (ML + 70)

Scale length (ML + 40)

Measuring length (ML)

Readhead optical centreline

Reference mark sensor position (inside readhead)

0.5

0.2/100

F

>5

>5

<10

30

13

6 (RGS20-S)

6.3 (RGS20-P)

F = axis of motion

22

14

8

10

5

Optional bolted reference mark actuator

(A-9531-0287)

<10

Q limit

P limit

Reference mark actuator position range

>3

>3

Page 7

End clamps

A-9523-4015 is an end clamp kit designed to be used with Renishaw RGS scale.

IMPORTANT: End clamps should be used to ensure positional stability of the scale and

reference mark repeatability.

NOTE: End clamps can be mounted before or after readhead installation.

Ensure that excess glue is wiped away from scale as it may affect the readhead signal level.

3

The end clamp features two small regions

of contact adhesive. These will temporarily

hold the end clamp in position while the

glue cures. Remove the backing tape

from either side.

15 mm

1

Remove the lacquer coating from the

last 15 mm of each end of the scale

with a knife and clean with one of

the recommended solvents

(see ‘Storage and handling’).

4

Immediately position end clamp

over the end of the scale.

Allow 24 hours at 20 °C

for full cure.

2

Thoroughly mix up a sachet of glue

(A-9531-0342) and apply a small amount

to the underside of the end clamp.

RGA22G - scale applicator (recommended for shorter axes or where space is limited)

The RGA22G scale applicator (A-9531-0239) is designed specically for installing RGS20-S scale for use with

the RGH22 readhead. When installing RGS20-P scale use scale applicator (A-9531-3528).

1

Allow scale to acclimatize to installation environment prior to installation.

2

Mark out ‘START’ and ‘FINISH’ points for the scale on the axis substrate. Ensure that there is room for the

end clamps (see ‘RGS20 installation drawing’).

3

Thoroughly clean and degrease the substrate using recommended solvents (see 'Storage and handling').

Allow substrate to dry before applying scale.

4

Mount the scale applicator to the readhead mounting bracket using M3 screws. Place the shim supplied

with the readhead between the applicator and substrate to set the nominal height.

NOTE: Scale applicator can be mounted either way round

to enable easiest orientation for scale installation.

5

Move axis close to scale start position, leaving enough room for the scale to be inserted through the

applicator, as shown below.

6

Begin to remove the backing paper from the scale

and insert scale into the applicator up to the

‘START’ point (as shown).

Ensure backing tape is routed

under the splitter screw.

Scale application

RGA22 - scale applicator (recommended for longer axes)

The RGA22 scale applicator kit (A-9531-0265) is designed specically

for installing RGS20-S scale for use with the RGH22 readhead.

When installing RGS20-P scale use applicator kit (A-9531-0280).

For instructions on how to use the RGA22 please refer to the

‘RGA22 scale applicator User’s guide’ (M-9531-0297).

Backing paper

Scale

8

Slowly and smoothly move the applicator through the entire axis of travel, ensuring the backing

paper is pulled manually from the scale and does not catch under the applicator.

9

Remove applicator and, if necessary, adhere the remaining scale manually.

Apply rm nger pressure via a clean lint-free cloth along the length of the scale after application

to ensure complete adhesion

10

Clean scale using Renishaw scale cleaning wipes (A-9523-4040) or a clean, dry, lint-free cloth.

11

Fit end clamps (see ‘End clamps’ section).

12

Allow 24 hours for complete adhesion of scale before tting reference mark and limit magnets.

START

Direction of scale application

Splitter screw

7

Apply nger pressure to the scale at the ‘START’ point, using a clean lint-free cloth, to ensure scale end

adheres well to the substrate.

M3 mounting holes

‘START’ point

5

RGH22 RGS20 installation guide

Page 8

6

RGH22 RGS20 installation guide

Reference mark and limit switch actuator installation

To aid location of reference mark and limit switches,

the orange shim should be used as shown.

Reference mark and limit switch actuators can be

mounted independently from each other,

but within the limits specied by the

relevant installation drawing.

Limit switch actuator

Reference mark actuator

Ensure that excess glue does not enter the reference mark actuator adjustment mechanism.

Single limit switches

For single limit switch detection, limit switch actuator should be mounted with the dimple uppermost.

Dual limit switches

Some versions of the RGH22 are congured to detect dual limit switch actuators.

NOTE: Refer to RGH22 installation drawing for limit switch actuator positioning.

Reference mark actuators

Reference marks provide a repeatable ‘datum position’ for the readhead.

Actuators are available in either bolted or glued formats (see below)

Limit switch actuators

There are several different size limit switch actuators available:

A-9531-2054

50 mm limit switch

actuator

A-9531-2052

24.4 mm limit switch

actuator

A-9531-0251

10 mm limit switch

actuator

A-9531-0250

Epoxy-mounted

reference mark actuator

A-9531-0287

Screw-mounted

reference mark actuator

Readhead mounting and alignment

Mounting brackets

The bracket must have a at mounting surface and should provide adjustment to enable conformance to the

installation tolerances, allow adjustment to the rideheight of the readhead, and be sufciently stiff to prevent

deection or vibration of the readhead during operation.

Readhead set-up

Ensure that the scale, readhead optical window and mounting face are clean and free from obstructions.

To set nominal rideheight, place the blue or orange spacer with the aperture directly under the optical

centre of the readhead to allow normal LED function during set-up procedure. The orange spacer also

helps to position readhead with respect to offset and yaw relative to the scale

NOTE: Ensure readhead xing screws are tightened to 0.5 Nm - 0.7 Nm.

Adjust the readhead to achieve a solid Green LED. When correctly installed the set-up LED remains Green

along the full axis of travel.

An external set-up signal (X or VX) is also available on RGH22 readheads for use where the LED is not

visible. In this case, 5 V indicates optimum set-up,

while a 0 V signal indicates that the

set-up should be adjusted.

Green Orange Red

Ya w

0° ± 0.5°

Pitch

0° ± 1°

Roll

0° ± 1°

0.8 ± 0.1 mm

Rideheight

orange spacer

or

blue spacer

Page 9

Reference mark set-up

To ensure unidirectional repeatability, the reference mark requires phasing with the scale in the direction

of normal datuming operation.

A reference pulse is output in both directions, but repeatability is guaranteed only in the phased direction.

The readhead should be set up correctly ensuring a green LED indication over the full length of travel.

The reference mark actuator should be installed as shown on the installation drawing.

NOTE: It is recommended that a datum procedure is performed as part of any power-up sequence to

ensure the correct datum position is recorded.

NOTE: Reference mark output is synchronised with the incremental channels, giving unit of resolution

pulse width. For further details see RGH22 Data sheet (Part number L-9517-9676).

Phasing procedure

The readhead must be moved over the reference mark in the direction to be used for the datuming

operation. The reference mark is phased correctly when the set-up LED ashes red for 0.25 seconds.

If it ashes orange or goes blank, the reference mark adjuster screw should be turned anti-clockwise

by

1

8

turn and the procedure repeated until a red ash is obtained.

1

8

turn

Red Orange Blank

LED ash during reference mark traverse only

*

NOTE: Dual limit versions (P, Q, R, S and H) utilise the black wire (pin 11) as the P limit output.

The ‘E’ alarm signal on these versions is only available at the orange wire as a single-ended E- output.

Dual limit readheads are only available with F, D, or X terminations.

Alarm

For RGH22D, X, Z, P, Q, R, - alarm asserted when signal amplitude <15%.

For RGH22Y, S, H - alarm asserted when: - Signal amplitude >150% - Readhead exceeds specied maximum speed

Also, outputs are 3-stated at signal amplitude <15%

Output signals

RGH22 D, X, Z, Y, H, P, Q, R, S, RS422A digital

7

RGH22 RGS20 installation guide

12 pin circular plug (termination code R)

52

28

15 pin D type plug (termination code D)

40

16

52

Limit switch

Limit switch detection is entirely independent of other readhead functions - the signal is only output

when the readhead is positioned over the limit switch actuator.

Function Signal Colour

15 way D-type

plug

(D)

12 way circular

(R)

16 way in-line

connector

(X)

Power

5 V

Brown 7 2 A

Brown (link) 8 12 M

0 V

White 2 10 B

White (link) 9 11 N

Incremental signals

A

+ Green 14 5 G

- Yellow 6 6 D

B

+ Blue 13 8 R

- Red 5 1 F

Reference mark

Z

+ Violet 12 3 K

- Grey 4 4 O

Limit switch

*

Q Pink 10 – H

Alarm

E

+ Black 11 9 I

- Orange 3 7 P

External set-up

X Clear 1 – E

Shield

Inner Green / Yellow 15 11 (link) L

Outer – Case Case Case

In-line connector plug (termination code X)

66

17

Page 10

*

NOTE: Dual limit versions (A) utilise the clear wire (pin 7) as the VP limit output. The VX external set-up signal on these

versions is not available. Dual limit readheads are only available with F, L or X terminations.

†

Only connected with option 17 ††Only connected with option 18

Output signals (continued)

RGH22 A, B 1 Vpp analogue

12 pin circular coupling plug (termination code W)

52

28

In-line connector plug (termination code X)

66

17

‡

Reference mark uni-directional operation

The RGH22 reference mark output is not repeatable in both directions. Certain controllers will ag an error

when they see different reference mark positions in the forward and reverse directions.

BID DIR pins allow the readhead to be congured to ignore the reference pulse output in the unphased

direction (see section Reference mark set-up).

8

RGH22 RGS20 installation guide

Analogue readheads

RGH22A and B – 4 m/s (-3dB)

Speed

Digital readheads

Non-clocked output readheads

x 4 safety factor

Encoder velocity (m/s)

Resolution (µm)

Clocked output readheads

The RGH22Y, S, and H readheads are available with a variety of different clocked outputs.

Customers must ensure they comply with the lowest recommended counter input frequency.

BID/DIR connections

Function Signal Colour

15 way

D-type plug

(L)

12 way

circular

(V)

12 way

circular

coupling

(W)

16 way

in-line

connector

(X)

Power

5 V

Brown 4 2 2 A

Brown (link) 5 12 12 M

0 V

White 12 10 10 B

White (link) 13 11 11 N

Incremental signals

V

1

+ Red 9 5 5 F

- Blue 1 6 6 R

V

2

+ Yellow 10 8 8 D

- Green 2 1 1 G

Reference mark

V

0

+ Violet 3 3 3 K

- Grey 11 4 4 O

Limit switch

*

V

q

Pink 8 N/C N/C H

External set-up

V

x

Clear 7 N/C N/C E

Reference mark

uni-directional

operation

‡

BID Black 6

9

†

9

††

I

DIR Orange 14

7

†

7

††

P

Shield

Inner Green/Yellow 15 11 (link) 11 (link) L

Outer – Case Case Case Case

12 pin circular plug (termination code V)

52

28

15 pin D type plug (termination code L)

40

16

52

BID / DIR connection

To:- Reference mark output direction

For bi-directional operation (normal)

BID +5 V or not connected

Forward and reverse

DIR Do not connect

BID / DIR connection

To:- Reference mark output direction

For uni-directional operation

BID 0 V

DIR +5 V or not connected Forward only

DIR 0 V Reverse only

Head type Maximum speed (m/s) Lowest recommended counter input frequency (MHz)

D and P (5 µm) 10

X and Q (1 µm) 5

Z and R (0.5 µm) 3

Options

Maximum speed (m/s)

Lowest recommended counter input

frequency (MHz)

Head type

Y and S

(0.1 µm)

H

(50 nm)

61 1.3 0.6 20

62 0.7 0.3 10

63 0.35 0.15 5

Page 11

9

RGH22 RGS20 installation guide

Electrical connections

Grounding and shielding

*

Maximum extension cable length

RGH22A and B -100 m, RGH22D, X, Z, P, Q and R - 50 m, RGH22Y, S and H -20 m

RGH22

Customer

electronics

Extension cable

*

Inner shield

Outer shield

Output

signals

0 V

5 V

IMPORTANT: The outer shield should be connected to the machine earth (Field Ground). The inner shield should be connected

to 0 V. Care should be taken to ensure that the inner and outer shields are insulated from each other. If the inner and outer shields

are connected together, this will cause a short between 0 V and earth, which could cause electrical noise issues.

Recommended signal termination

Digital outputs - RGH22D, X, Z, Y, H, P, Q, R and S

Analogue output - RGH22 A, B

V0 V1 V2+

V0 V1 V2-

120 Ω

Standard RS422A line receiver circuitry.

Capacitors recommended for improved noise immunity.

†

Only required on alarm channel E for fail safe operation.

Customer

electronics

120 Ω

A B Z E-

Cable Z0 = 120 Ω

Readhead

A B Z E+

0 V

0 V

220 pF

220 pF

Limit output

5 V - 25 V

R

P Q Vp V

q

Select R so that maximum current does not exceed 20 mA.

Alternatively, use a relay or opto-isolator.

1k

†

0 V

1k

†

Page 12

10

RGH22 RGS20 installation guide

Output specications

Digital output signals - type RGH22D, X, Z, Y, H, P, Q, R and S

Form - Square wave differential line driver to EIA RS422A (except limit switches P, Q and external set-up signal X)

Synchronised pulse Z, duration as resolution S.

Repeatability of position (uni-directional) maintained within

±10 °C from installation temperature and for speed <250 mm/s.

For RGH22Y, S, H only Z pulse re-synchronised at power-up

with any one of the quadrature states (00, 01, 11, 10).

Actuation device A-9531-0250 or A-9531-0287

Reference

†

Incremental

†

2 channels A and B in quadrature (90° phase shifted)

Signal period P

Resolution S

A

B

Z

Actuation device A-9531-0251, A-9531-2052 or A-9531-2054.

*Dual limit available with flying lead, 15 pin D connector or in-line X connector only.

†Inverse signals not shown for clarity.

Limit open collector output

Single limit D, X, Z, Y

Dual limit P, Q, R, S, H

*

Length of actuating magnet

Repeatability

<0.1 mm typical

P Q

Length of actuating magnet

Repeatability

<0.1 mm typical

Q

Asynchronous pulse Q

Between 50% and 70% signal level, X is a

duty cycle, 20 µm duration.

Time spent at 5 V increases with signal level.

At >70% signal level X is nominal 5 V.

External set-up

voltage at X

5 (nom)

50% 70%

100%

0

0

signal level

20 ms minimum

E

Alarm

RGH22D, P, X, Q, Z and R

Alarm output asserted when <15% signal

RGH22Y, S and H

Options 61, 62 and 63

Single ended line driven output alarm asserted when >150% signal or overspeed (RGH22S and H only).

Differential line driver output alarm asserted when >150% signal or overspeed (RGH22Y only).

3-state output alarm asserted when <15% signal.

Line driven alarm output

†

E- only on dual limit readheads (RGH22P, Q, R, S and H only)

3-state output

Differentially transmitted signals forced open circuit for >20 ms when alarm conditions valid.

Asynchronous pulse P, Q

Model P (µm) S (µm)

RGH22D and P 20 5

RGH22X and Q 4 1

RGH22Z and R 2 0.5

RGH22Y and S 0.4 0.1

RGH22H 0.2 0.05

Option Alarm type

00A Differential line driven output (RGH22D, X and Z only)

00A Single ended line dr iven output (RGH22P, Q and R only)

20A 3-state output

Page 13

11

RGH22 RGS20 installation guide

Output specications (continued)

Analogue output signals - type RGH22B and A (1Vpp)

Actuation device A-9531-0251, A-9531-2052 or A-9531-2054.

Limit open collector output

Single limit RGH22B

Dual limit RGH22A

Asynchronous pulse Vp V

q

Length of actuating magnet

Repeatability

<0.1 mm typical

V

q

Asynchronous pulse V

q

Between 50% and 70% signal level,

VX is a duty cycle, 20 µm duration.

Time spent at 5 V increases with signal level.

At >70% signal level VX is nominal 5 V.

External set-up

voltage at V

X

5 (nom)

50%

70%

100%

0

0

signal level

20 µm

90°

108°-18°

0°

Incremental 2 channels V

1

and V2 differential sinusoids in quadrature (90° phase shifted)

Differential pulse V0 - 18° to 108°.

Duration 126° (electrical).

Repeatability of position (uni-directional) maintained

within ±10 °C from installation temperature and for

speed <250 mm/s.

Actuation device A-9531-0250 or A-9531-0037

0.6 to 1.2 Vpp with

green LED indication

and 120 Ω termination.

Reference

(V1 +) - (V1-)

(V2 +) - (V2-)

0.8 to 1.2 Vpp

(V0+) - (V0-)

P Q

Length of actuating magnet

Repeatability

<0.1 mm typical

Page 14

12

RGH22 RGS20 installation guide

General specications

Power supply 5 V ± 5% 120 mA (typical), 200 mA RGH22Y, S and H

NOTE: Current consumption figures refer to unterminated readheads.

For digital outputs a further 25 mA per channel pair (e.g. A+, A-) will

be drawn when terminated with 120 Ω.

For analogue outputs a further 20 mA will be drawn when terminated

with 120 Ω.

Power from a 5 V dc supply complying with the requirements for SELV

of standard IEC BS EN 60950-1.

Ripple 200 mVpp@frequency up to 500 kHz maximum.

Temperature Storage −20 °C to +70 °C

Operating 0 °C to +55 °C

Humidity 95% relative humidity (non-condensing) to EN 60068-2-78

Sealing IP50

Acceleration Operating 500 m/s2, 3 axes

Shock Non-operating 1000 m/s2, 6 ms, ½ sine, 3 axes

Vibration Operating 100 m/s2 max @ 55 Hz to 2000 Hz, 3 axes

Mass Readhead 45 g

Cable 38 g/m

Cable 12 core, double shielded, maximum diameter 4.7 mm.

Flex life >20 x 106 cycles at 50 mm bend radius.

Renishaw encoder systems have been designed to the relevant EMC standards, but must be correctly

integrated to achieve EMC compliance. In particular, attention to shielding arrangements is essential.

Scale specications

Scale type RGS20-S Reective gold plated steel tape with protective lacquer coating.

Adhesive backing tape allows direct mounting to the machine substrate.

RGS20-P Reective gold plated steel tape with tough polyester coating for

applications using harsh solvents.

Adhesive backing tape allows direct mounting to the machine substrate.

Scale period 20 µm

Linearity RGS20-S ±3 µm /m

RGS20-P ±5 µm/ m

Scale length Up to 50 m (>50 m by special order)

Form (H x W) RGS20-S 0.2 mm x 6 mm (includes adhesive)

RGS20-P 0.3 mm x 6.3 mm (includes adhesive)

Substrate materials Metals, ceramics and composites with expansion coefcients

between 0 and 22 µm/m/°C

(steel, aluminium, Invar, granite, ceramic etc.)

Coefcient of thermal expansion Matches that of substrate material when scale ends are xed by

epoxy mounted end clamps

End xing Epoxy mounted end clamps (A-9523-4015) using 2 part epoxy

adhesive (A-9531-0342)

Scale end movement <1 µm over temperature range −20 °C to +50 °C

Temperature Operating −10 °C to +120 °C.

Minimum installation 10 °C

Storage −20 °C to +70 °C.

Humidity 95% relative humidity (non-condensing) to EN 60068-2-78

Page 15

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

*M-9531-9818-01*

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

RENISHAW® and the probe symbol used in the RENISHAW logo are registered trade marks

of Renishaw plc in the United Kingdom and other countries.

apply innovation and names and designations of other Renishaw products and technologies

are trade marks of Renishaw plc or its subsidiaries.

© 2001-2018 Renishaw plc All rights reserved Issued 1018

Loading...

Loading...