Page 1

RGA22G scale guide

Scale applicator tool for RGH22 readhead installations

The RGA22G scale guide is mounted in place of any Renishaw RGH22 readhead and

uses the motion of the axis to apply RGS-S tape scale parallel to the guideway whilst

simultaneously removing the backing paper - a one man, one hit operation.

● Prepare scale and surface

● Ensure scale is cut to correct length and mounting surface has been prepared (refer to

RGS-S scale installation guide for details)

● Install the scale guide

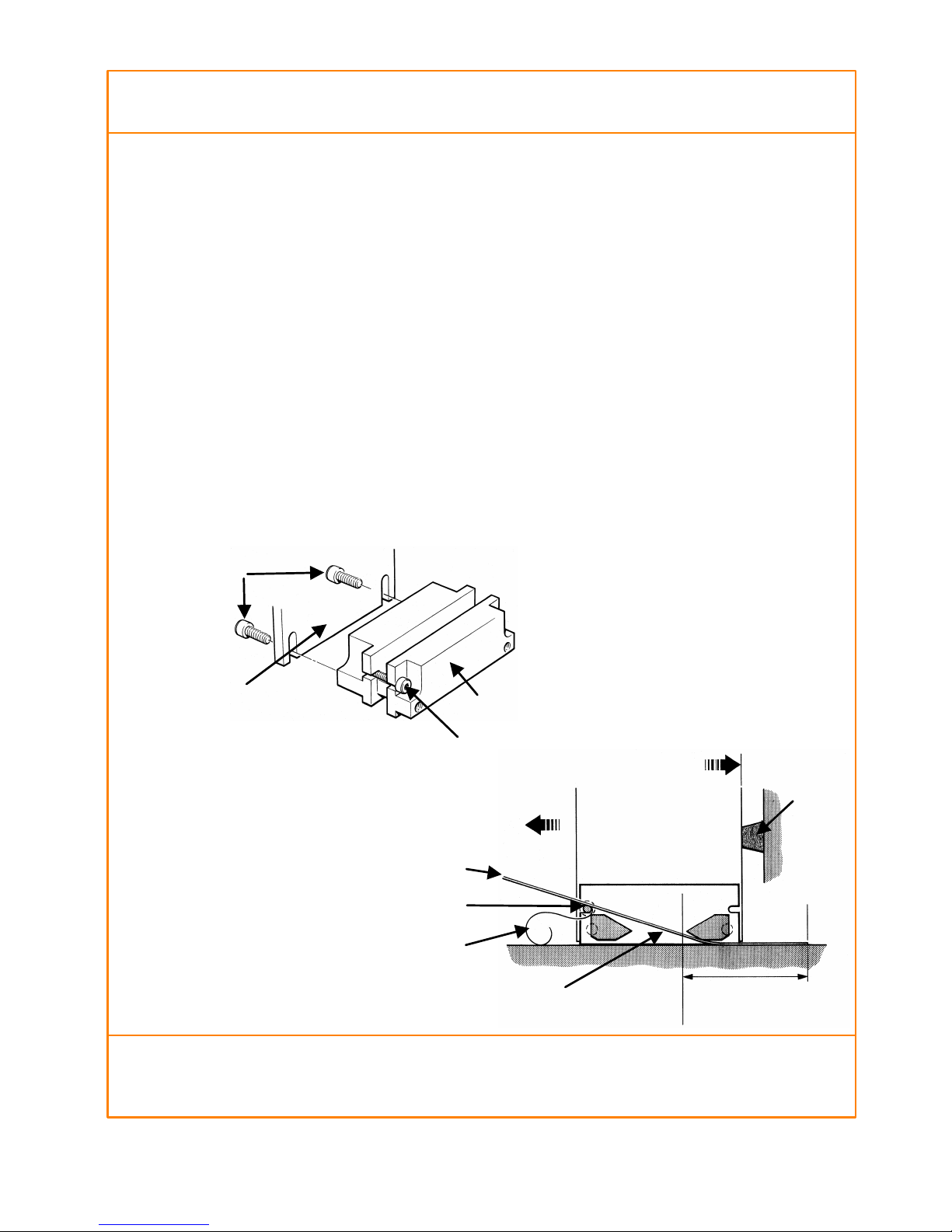

● Mount the scale guide to the readhead bracket as shown in figure 1

● Be careful to check that the readhead and the scale guide have the same orientation, as

the readhead does not lie centrally over the scale

● Move the guide to the start of axis travel. Note the direction of scale application as shown

in figure 2

● The design of the RGA22G allows scale application in either direction

(continued overleaf)

Scale installation

Part No. M-9531-1281

abcdh

I N S T A L L A T I O N I N S T R U C T I O N S H E E T

efg

Limit of travel

20mm

Figure 2

Direction of scale

application

Backing paper

RGA22G scale guide

Limit stop

Start of measuring length

Splitter screw

RGS-S tape scale

Mounting screws

Readhead

mounting

bracket

RGA22G scale guide

Figure 1

Splitter screw

Page 2

● Load the scale into the scale guide

● Remove the splitter screw (see figure 1) from the scale guide body

● Separate the backing paper from the first 40mm of scale and feed it into the scale

guide as shown in figure 2

● Relocate the splitter screw behind the backing paper as shown in figure 2

● Push the scale carefully through to the end of scale mark, ensuring that it does not

stick to the mounting surface until it is in position. NOTE to prevent the scale sticking

to the mounting surface during this operation it may be necessary to re-apply

approximately 20mm of backing paper to the end of the scale before inserting through

scale guide. This can then be removed before to fitting end clamps.

● Attach the end of the scale to the mounting surface with light finger pressure

● Apply the scale

● Traverse the axis through its full travel at a slow, steady speed

● While moving the axis

● Apply a light finger pressure to the scale behind the scale guide to

attach it to the mounting surface

● Gently pull the backing paper away from in front of the scale guide as it

is separated

● Remove the scale guide

● When the axis has reached the limit of its travel, lock the axis in place and unbolt the

scale guide from the readhead mounting bracket

● Withdraw the scale guide along the scale whilst applying the remaining scale using

light finger pressure

● Ensure complete adhesion of the scale to the mounting surface by applying firm finger

pressure along the full length of the scale from the centre outwards to each end

● Fit RGC-F end clamps (refer to RGS-S scale installation guide for details)

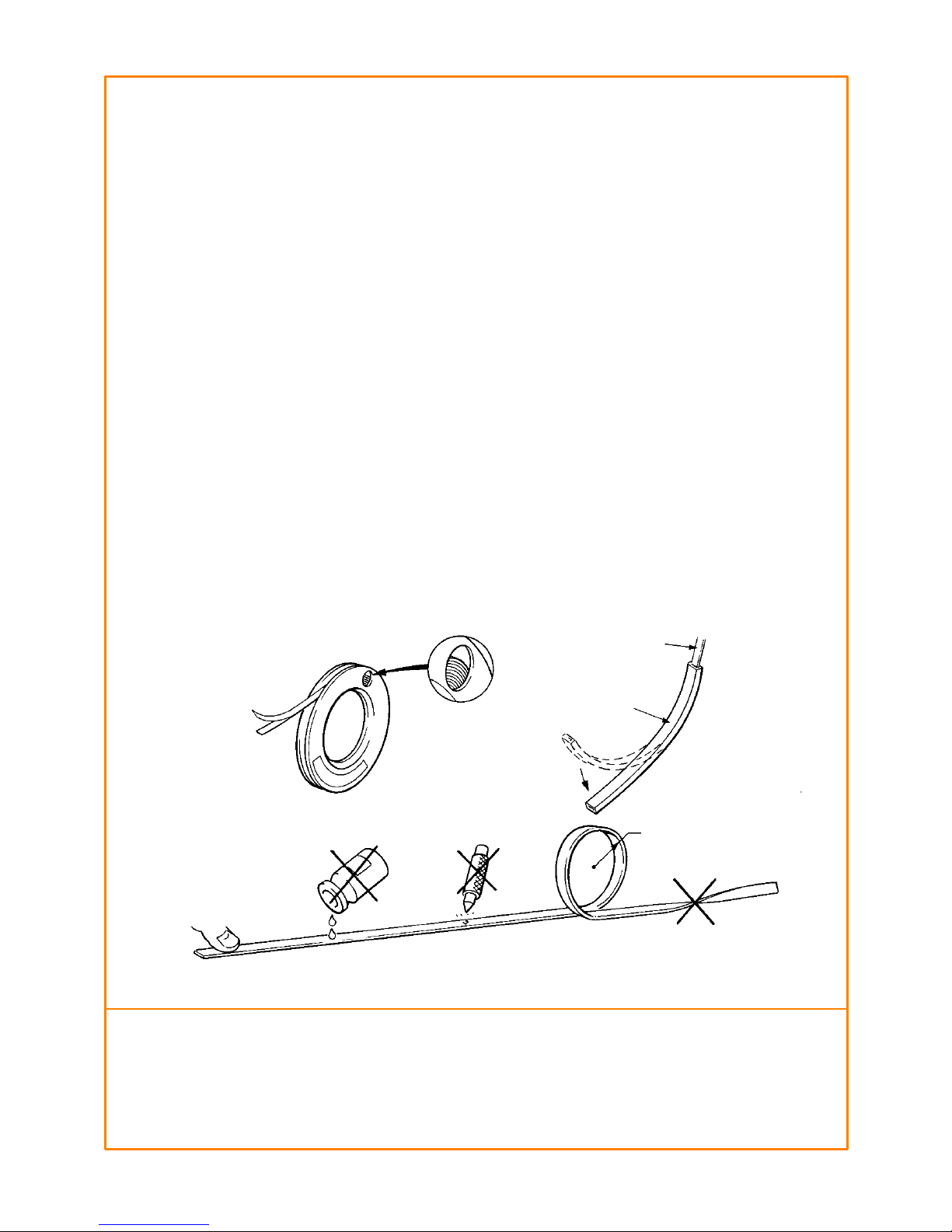

DO NOT remove the scale for refitting or use elsewhere once it has been applied to the mounting surface.

The scale can be applied once only.

Plastic extrusion for

lengths under 6m

Scale

Keep coils tight

during storage

Straighten coils to

withdraw scale

Avoid alcohol and

solvents

Do not twistNo sharp objects

Reel for lengths

over 6m

Scale surface

is immune to

handling

>100mm

Scale handling precautions

abcdh

Renishaw reserves the right to change specifications without notice © 1999 Renishaw plc

Printed in England 499 Part No M-9531-1281-02

Renishaw plc

Encoder Products Division

New Mills, Wotton-under-Edge

Gloucestershire GL12 8JR, UK

Tel: +44 (0)1453 523 634

(07000 RENISHAW)

Fax: +44 (0)1453 523 760

E mail encoder.products@renishaw.com

Internet http://www.renishaw.com

USA, Renishaw Inc

Tel +1 847 843 3666

Fax +1 847 843 1744

Japan, Renishaw KK

Tel +81 3 5350 2201

Fax +81 3 5350 2207

Germany, Renishaw GmbH

Tel +49 712 797 960

Fax +49 712 788 237

France, Renishaw SA

Tel +33 1 64 61 84 84

Fax +33 1 64 61 65 26

Italy, Renishaw SpA

Tel +39 11 9 66 10 52

Fax +39 11 9 66 40 83

Spain, Renishaw Iberica SA

Tel +55 11 7295 2866

Fax +55 11 7295 1641

Switzerland, Renishaw AG

Tel +41 55 410 66 66

Fax +41 55 410 66 69

Hong Kong, Renishaw (Hong Kong) Ltd

Tel +852 2753 0638

Fax +852 2756 8786

Brazil, Renishaw Latino America Ltda

Tel +55 11 7295 2866

Fax +55 11 7295 1641

Renishaw’s Representative Offices

People’s Republic of China, Beijing

Tel +86 10 6461 2689

Fax +86 10 6461 2687

Singapore

Tel +65 438 2778

Fax +65 438 4780

Indonesia, Jakarta

Tel/fax +62 21 424 3934

India, Bangalore (liaison office)

Tel/fax +91 80 224 3223

Loading...

Loading...