Page 1

REVO-2 user's guide

Documentation part number H-1000-7590-04-D

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

1

Page 2

General information

© 2017 ‐ 2019 Renishaw plc. All rights reserved.

This document may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any means, without

the prior written permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of Renishaw plc.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT IS CORRECT AT THE DATE OF

PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY,

HOWSOEVER ARISING, FOR ANY INACCURACIES IN THIS DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the RENISHAW logo are registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All brand names and product names used in this document are trade names, service marks, trademarks, or registered trademarks of their

respective owners.

All trademarks and trade names are acknowledged.

WEEE

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product should not be mixed with the

general household waste upon disposal. It is the responsibility of the end user to dispose of this product at a designated collection point for

waste electrical and electronic equipment (WEEE) to enable reuse or recycling. Correct disposal of this product will help save valuable

resources and prevent potential negative effects on the environment. For more information, please contact your local waste disposal service

or Renishaw distributor.

Warranty

Renishaw plc warrants its equipment for a limited period (as set out in our Standard Terms and Conditions of Sale) provided that it is installed

exactly as defined in associated Renishaw documentation.

Prior consent must be obtained from Renishaw if non-Renishaw equipment (e.g. interfaces and/or cabling) is to be used or substituted. Failure

to comply with this will invalidate the Renishaw warranty.

Claims under warranty must be made from authorised service centres only, which may be advised by the supplier or distributor.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

2

Page 3

Care of equipment

Renishaw probes and associated systems are precision tools used for obtaining precise measurements and must therefore be treated with

care.

Changes to Renishaw products

Renishaw reserves the right to improve, change or modify its hardware or software without incurring any obligations to make changes to

Renishaw equipment previously sold.

Packaging

To aid end user recycling and disposal the materials used in the different components of the packaging are stated here:

Packaging component Material 94/62/EC code 94/62/EC number

Outer box Cardboard PAP 20

Outer foam inserts Polyurethane foam PET 01

Accessory packaging High density polyethylene bag

(HDPE)

HDPE 02

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

3

Page 4

Patents

Features of the REVO-2 system and associated products, equipment and techniques are the subjects of one or more of the following patents

and patent applications:

CA2015/049341 CN100453970 EP1086354 IN259801 JP2016-533484 US2016-0238373

CN101166951 EP1687589 IN279118 JP2018-514773 US2018-0058884

CN101166953 EP1877727 IN292511 JP4695762 US6633051

CN101405563 EP1877732 IN294476 JP5196356 US7533574

CN101405564 EP1989504 IN295786 JP5350216 US7809523

CN101490430 EP2002206 IN296310 JP5425476 US7861430

CN101772690 EP2002207 WO2006/114603 JP5653581 US7885777

CN102305613 EP2035719 WO2007/107776 JP5658863 US7971365

CN102906533 EP2140318 WO2011/135282 JP5706158 US8006398

CN103842766 EP2167911 WO2014/191729 JP5851969 US8186882

CN105408723 EP2431707 WO2015/049341 JP6013533 US8302321

CN105793695 EP2564151 WO 2018/091867 JP6199870 US8425119

CN107532930 EP2764324 JP6348577 US8474148

EP3004797 US8511898

EP3052926 US8601701

EP3289314 US8756973

US8978261

US9038282

US9366519

US9903713

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

4

Page 5

Product compliance

EU declaration of conformity

Contact Renishaw plc or visit www.renishaw.com/EU for the full EU declaration.

FCC (USA only)

Information to user (47 CFR 15.105)

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case you will be required to correct the interference at your own expense.

Information to user (47 CFR 15.21)

The user is cautioned that any changes or modifications not expressly approved by Renishaw plc or authorised representative could void the

user's authority to operate the equipment.

Equipment label (47 CFR 15.19)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

FDA

Statement of compliance (Laser Notice 50 and Laser Notice 53)

The RSP2, RSP2 V2 and SFP1 probes comply with 21 CFR 1040.10 and 1040.11 except for deviations pursuant to Laser Notice No. 50, dated

June 24, 2007 and Laser Notice No. 53, dated March 23, 2007.

REACH regulation

Information required by Article 33﴾1﴿ of Regulation ﴾EC﴿ No. 1907/2006 ﴾“REACH”﴿ relating to products containing substances of very high

concern (SVHCs) is available at:

www.renishaw.com/REACH

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

5

Page 6

China RoHS

Contact Renishaw plc or visit www.renishaw.com/ChinaRoHS for the full China RoHS tabulation.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

6

Page 7

Safety

CAUTION: Before unpacking and installing the REVO-2 system, the user should carefully read the safety instructions below and

ensure that they are followed at all times by all operators.

The RSP2, RSP2 V2, SFP1 and RSP3-x are only to be used with the Renishaw REVO and REVO-2 head.

Operators must be trained in the use and application of the REVO and REVO-2 system and accompanying products, in the context

of the machine it is fitted to, before being allowed to operate that machine.

Permanent magnets are used in some components of the REVO-2 system and associated products. It is important to keep them

away from items which may be affected by magnetic fields, e.g. data storage systems, pacemakers and watches etc.

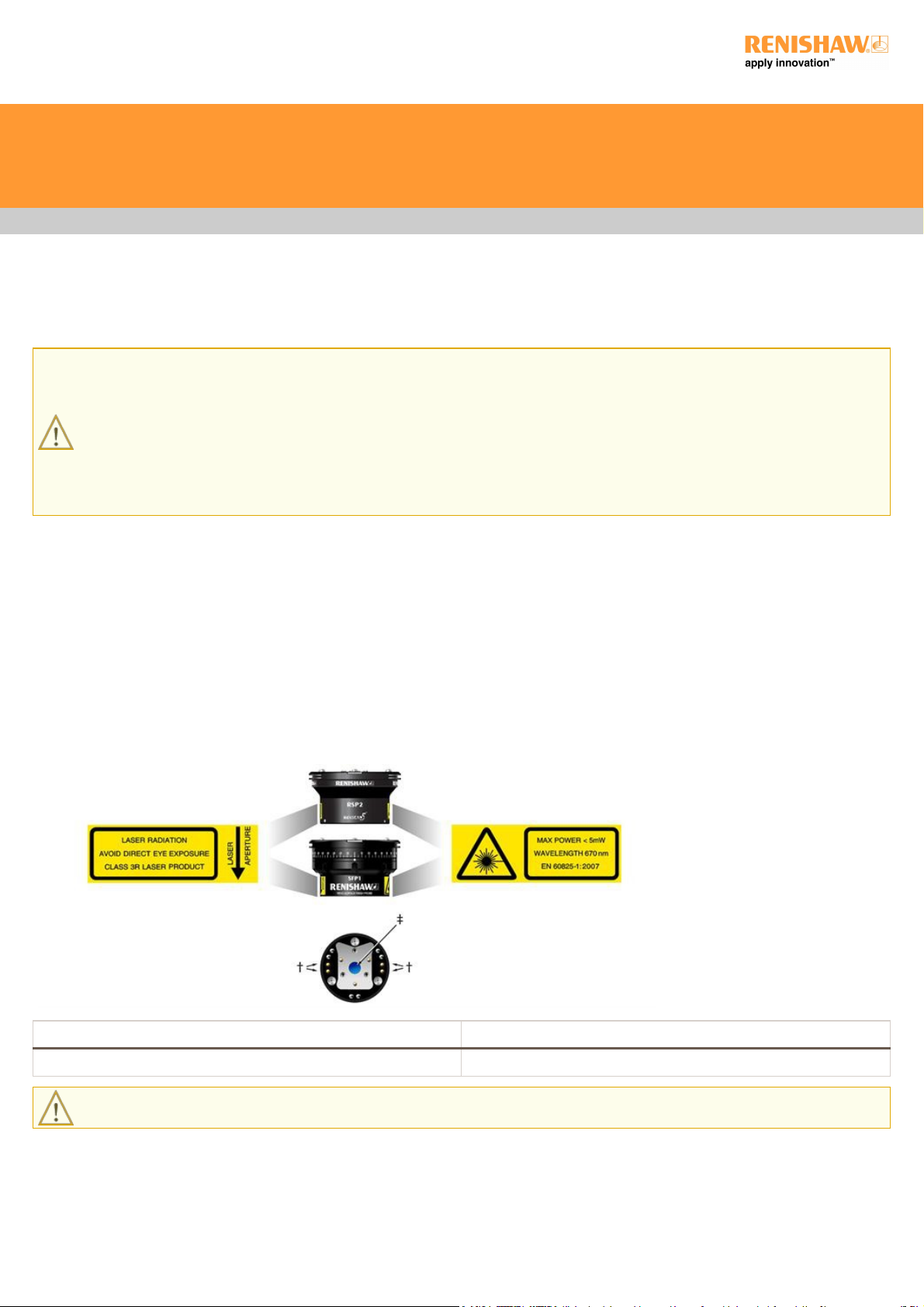

Class 3R RSP2 and SFP1 laser emissions

References are made to features indicated as † and ‡ in the illustrations below. Please ensure that you understand all safety instructions.

Familiarisation with the REVO-2 system components is recommended.

Safety illustration of Class 3R RSP2 and SFP1

These versions of RSP2 and SFP1 have been classified as Class 3R laser products according to EN 60825-1:2007. This classification is based

on the laser power that would be emitted in the unlikely event of breakage of the stylus holder, as required by the ‘single fault' criteria in EN

60825-1. In the absence of such a fault, the emitted laser power is negligible.

Key

† Interlock switch contacts ‡ Laser aperture and optical window

CAUTION: Do not remove the safety warning labels located on both the RSP2 and SFP1 probe body.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

7

Page 8

Laser output

Maximum output: < 5 mW

Pulse duration: continuous wave

Wavelength: 670 nm

Beam divergence: 2 mrad

The RSP2 and SFP1 bodies contain embedded Class 3B laser sources, and should not be used in the event of serious damage to, or rupture of,

any part of the product. In such cases, IMMEDIATELY disconnect the power source, remove and do not attempt to re-use the parts. Contact

your supplier for advice.

Under normal operation, the laser beam is totally enclosed within the probe body and stylus holder body and is inaccessible to the user.

Removing the stylus holder breaks two sets of interlock switch contacts, indicated as †, to automatically switch off the laser power and prevent

exposure to the beam.

At suitable intervals, the interlock contacts should be inspected and checked to ensure that they are clean and free from airborne

contamination, such as dust, debris or swarf. In unlikely circumstances, such contamination could cause a short circuit of the pins and thus

increase the risk of sending power to the laser, without a stylus holder being attached. Never connect conducting objects to, or between, the

contacts. Follow the cleaning instructions in the maintenance section.

Before inspecting, always remove the RSP2 or SFP1 from the head. Never look directly into the laser aperture, indicated as ‡, whilst the RSP2

or SFP1 body is still connected to the probe head.

In the unlikely event of the stylus holder stem breaking without dislodging the interlocked connection between probe and stylus holder, there

is a small risk of exposure to class 3R laser light from the aperture of the broken stylus stem. Direct viewing may cause permanent damage to

eyesight and should be avoided. Should breakage occur, avoid looking directly at any emitted or reflected laser light and press the emergency

stop button on the hand control unit to avoid unexpected movement. Then manually remove the probe and stylus holder from the REVO-2

head. Once this is done, the machine should be moved manually clear of the part and the damage assessed. Under no circumstances should

any attempt be made to repair or re-use the damaged stylus holder. Contact your supplier for advice.

Class 1 RSP2 V2 laser emissions

References are made to features indicated as ‡ in the illustrations below. Please ensure that you understand all safety instructions.

Familiarisation with the REVO system components is recommended.

Safety illustration of Class 1 RSP2 V2

This version of RSP2 has been classified as a Class 1 laser product according to EN 60825-1:2014.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

8

Page 9

Key

‡ Optical window

The RSP2 V2 body contains embedded Class 3B laser sources, and should not be used in the event of serious damage to, or rupture of, any

part of the product. In such cases, IMMEDIATELY disconnect the power source, remove and do not attempt to re-use the parts. Contact your

supplier for advice.

Before inspecting, always remove the RSP2 V2 from the head.

If the stylus holder is removed manually, or by excessive overtravel, the beam is accessible via the optical window indicated as ‡ in the

illustration. Under normal circumstances, to prevent possible distraction hazards, the laser will be automatically turned off when the stylus

holder is removed.

CAUTION: The stylus holder should be replaced as soon as practicably possible.

RSP3-x LED emissions

The RSP3-x scanning probe incorporates embedded high power LED sources and should not be used in the event of serious damage to, or

rupture of, any part of the RSP3-x. In such cases IMMEDIATELY disconnect the power source, remove and do not attempt to re-use the parts.

Contact your supplier for advice.

RCP TC-2 and RCP TC-3

The method of interrupting power is to disconnect the power cable or turn off the supply.

Air filters

Air supply pressure at the input to the air filters should be a maximum of 8.5 bar. Please observe normal compressed air precautions.

General operation and maintenance

The product is only to be used with the Renishaw UCC S5 controller.

It is recommended that the power is removed before performing any maintenance operations.

Maintenance is restricted to procedures described in the maintenance section.

Care should be taken to ensure that the laser aperture windows, indicated as ‡, located on the RSP2, RSP2 V2, SFP1 and the mating stylus

holders, do not become damaged as they are made of glass and could cause injury if broken.

CAUTION: Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

9

Page 10

Warnings

Beware of unexpected movement. The user should remain outside of the full working envelope of probe head and stylus. The machine

supplier should ensure the user is aware of the full working envelope of the system.

In all applications involving the use of machine tools or CMMs, eye protection is recommended.

It is the machine supplier's responsibility to ensure that the user is made aware of any hazards involved in operation, including those

mentioned in Renishaw product documentation, and to ensure that adequate guards and safety interlocks are provided.

Refer to the machine supplier's operating instructions.

The system components contain no user serviceable parts, with the exception of RCP TC-2, RCP TC-3, RCP2 and FCR25. No attempt should be

made to disassemble any part of the product. In the event of a problem please contact your supplier for assistance.

Under certain circumstances the probe signal may falsely indicate a probe-seated condition. Do not rely on probe signals to stop machine

movement.

Probe trigger override will prevent machine backing off in the event of a probe collision.

The probe joints are designed to release the probe and / or the stylus holder in the event of a crash.

This equipment is not suitable for use in a potentially explosive atmosphere.

Pinch hazards exist between parts. Do not hold the probe or probe head during movements.

It is essential for continued safety that all fuses are replaced by the correct type and rating.

REVO-2 must be transported in Renishaw supplied packaging.

The cables must meet Renishaw specifications. Incorrect cabling could cause damage to the equipment.

WARNING: Avoid touching the probes (including counter balance arms), stylus holders and other modules when the REVO-2 head

is engaged (servo LED green) and the system is ready for measurement.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

10

Page 11

International safety instructions

BG ‐ ПРЕДУПРЕЖДЕНИЕ

Моля, обърнете на приложение 1 и прочетете инструкциите за безопасност на вашия собствен език, преди за разопаковате и

монтирате този продукт.

CZ ‐ VÝSTRAHA

Před rozbalením a instalací tohoto výrobku si přečtěte bezpečnostní pokyny ve vlastním jazyce uvedené v příloze 1.

DA - ADVARSEL

Læs sikkerhedsinstrukserne i Appendix 1 FØR udpakning og installation af dette produkt.

DE - WARNHINWEIS

Bevor Sie dieses Produkt auspacken und installieren, konsultieren Sie bitte Anhang 1 und lesen Sie die Sicherheitshinweise in Ihrer Sprache.

EL ‐ ΠΡΟΕΙΔΟΠΟΙΗΣΗ

Γυρίστε στο Κεφάλαιο 1 και διαβάστε τις οδηγίες ασφαλείας στη δική σας γλώσσα προτού ανοίξετε αυτό το προϊόν για να το

εγκαταστήσετε.

EN - WARNING

Before unpacking and installing this product, please consult Appendix 1 and read the safety instructions in your language.

ES - ADVERTENCIA

Consulte el apéndice 1 y lea las instrucciones de seguridad en su idioma antes de desempaquetar e instalar este producto.

ET - HOIATUS

Palun vaadake 1. lisa ning lugege enne selle toote lahtipakkimist ja paigaldamist ohutusjuhend läbi.

FI - VAROITUKSIA

Lue liitteessä 1 olevat omalla kielelläsi kirjoitetut turvaohjeet ennen tämän tuotteen pakkauksen avaamista ja asentamista.

FR - AVERTISSEMENT

Consulter l'annexe 1 et les instructions de sécurité dans votre propre langue avant de déballer et d'installer ce produit.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

11

Page 12

GA - RABHADH

Téigh chuig aguisín 1 agus déan na treoracha sábháilteachta a léamh i do theanga féin le do thoil sula ndéantar an táirge seo a dhíphacáil

agus a shuiteáil.

HR - NAPOMENA

Prije nego što proizvod izvadite iz ambalaže i ugradite ga, otvorite Prilog 1 i pročitajte sigurnosne upute na svom jeziku.

HU – FIGYELMEZTETÉS

A termék kicsomagolása és telepítése előtt olvassa el az 1. számú függelékben található, az Ön anyanyelvén hozzáférhető biztonsági

utasításokat.

IT - AVVISO

Prima di aprire ed installare questo prodotto, leggere le istruzioni di sicurezza nella vostra lingua riportate nell'Appendice 1.

JA ‐ 警告

この製品を箱から取り出し設置する前に、付録 1 に記載された安全性に関する注意書きをお読みください。

LT – ĮSPĖJIMAS

Prieš išpakuodami ir įdiegdami produktą, turite grįžti prie 1 priedo ir perskaityti nurodymus dėl saugos savo kalba.

LV – BRĪDINĀJUMS

Pirms šī izstrādājuma izsaiņošanas un uzstādīšanas izskatiet 1. pielikumā sniegtās drošības instrukcijas savā valodā.

MT - TWISSIJA

Jekk jogħġbok mur f'appendiċi 1 u aqra l‐istruzzjonijiet tas‐sigurtà fil‐lingwa tiegħek qabel ma toħroġ dan il‐prodott mill‐ippakkjar u

tinstallah.

NL - WAARSCHUWING

Ga naar appendix 1 en lees de veiligheidsinstructies in uw eigen taal, voordat u dit product uitpakt en installeert.

PL ‐ OSTRZEŻENIE

Przed rozpakowaniem i zainstalowaniem tego produktu prosimy o zapoznanie się z Dodatkiem 1 i przeczytanie zaleceń dotyczących

bezpieczeństwa w danym języku.

PT ‐ ADVERTÊNCIA

Você deve retornar ao Anexo 1 e ler as instruções de segurança em seu idioma antes de desembalar e instalar este produto.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

12

Page 13

RO - AVERTISMENT

Înainte de a desface ambalajul şi a instala acest produs, vă rugăm să căutaţi Anexa 1 şi să citiţi cu atenţie instrucţiunile de siguranță, în limba

română.

SK ‐ VÝSTRAHA

Pred rozbalením a inštaláciou tohto produktu si pozrite prílohu 1 a prečítajte si bezpečnostné pokyny vo vašom jazyku.

SL - OPOZORILO

Preden izdelek vzamete iz embalaže in ga vgradite, odprite Prilogo 1 in preberite varnostna navodila v svojem jeziku.

SV - VARNING

Gå till bilaga 1 och läs säkerhetsinstruktionerna på ditt eget språk innan du packar upp och installerar denna produkt.

TW ‐ 警告

在拆開和安裝本產品之前,請翻頁至附錄 1 閱讀母語的安全指示。

中文 — 警告

在拆包和安装本产品之前,请翻到附录1,阅读中文版安全说明。

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

13

Page 14

References and associated documents

The following Renishaw documents are referred to in this document or may be a source of further relevant information. They can be acquired

from the Renishaw website www.renishaw.com.

Title Document number

Installation and user's guide: RSP3 H-1000-5124

Installation and user's guide: SFP1 surface finish probe H-1000-5273

Installation guide: SFP2 surface finish probe H-1000-5365

User's guide: RVP H-1000-3322

Installation and user's guide: MRS modular rack system H-1000-5088

Installation guide: MRS2 modular rack system H-1000-5255

Technical specifications guide: Styli and accessories H-1000-3200

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

14

Page 15

System description

REVO-2 is a dynamic measuring head and probe system from Renishaw. It is a revolutionary product designed to maximise measurement

throughput whilst maintaining high system accuracy.

Unlike conventional scanning methods which rely on speeding up the motion of the CMM axes to allow them to measure faster, REVO-2 uses

the head motion for most of the motion needed during fast measurement, leaving the CMM for slow linear motion, hence minimising

dynamic errors.

UCCserver is software that accompanies the Renishaw UCC family of controllers. It is used for tasks such as sensor calibration and

organization as stipulated by the I++ DME protocol.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

15

Page 16

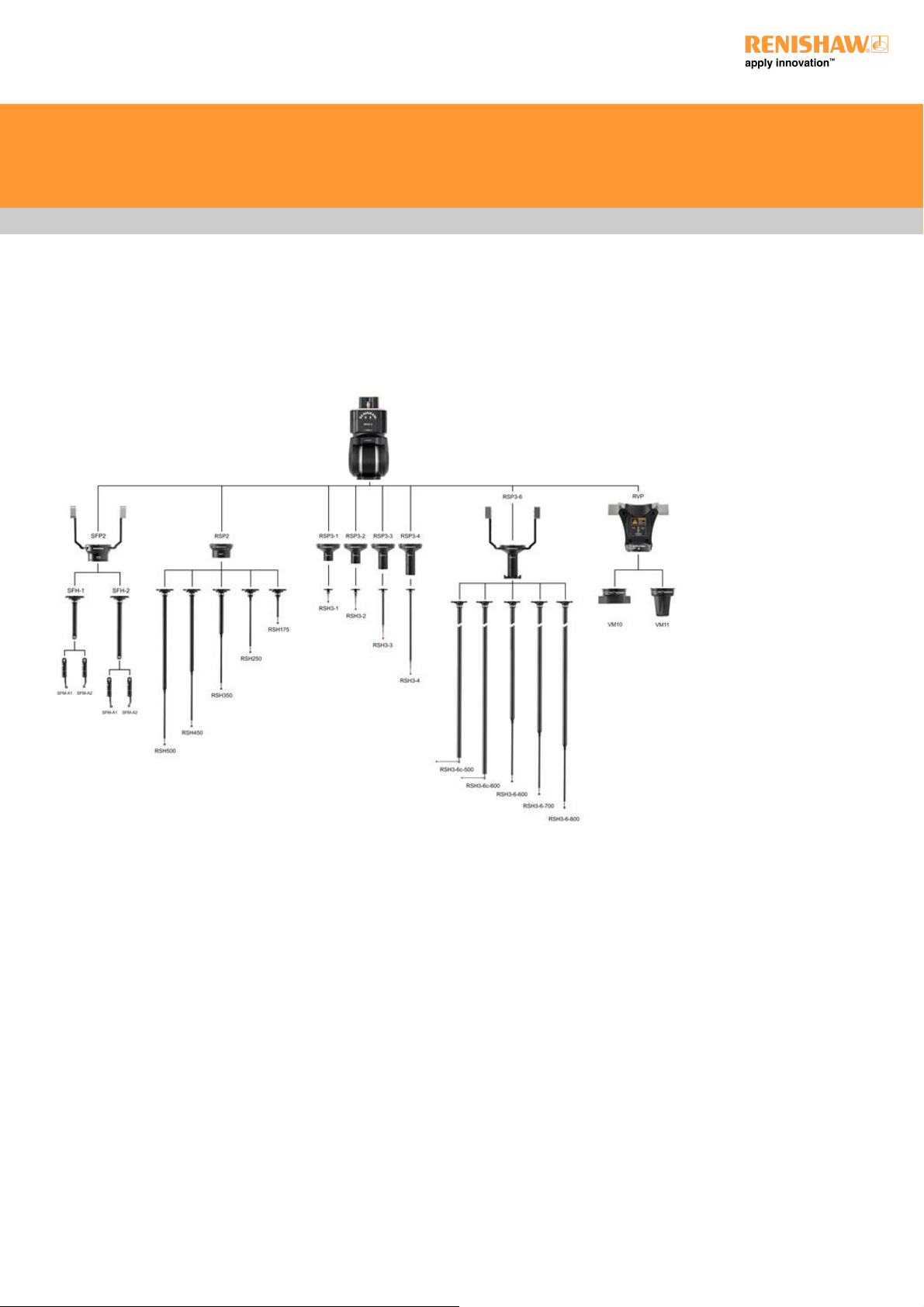

System components

REVO-2 head

RSP2 scanning probe

RSH175 stylus holder

RSH250 stylus holder

RSH350 stylus holder

RSH450 stylus holder

RSH500 stylus holder

RSP3-1 3D scanning probe

RSH3-1 stylus holder

RSP3-2 3D scanning probe

RSH3-2 stylus holder

RSP3-3 3D scanning probe

RSH3-3 stylus holder

RSP3-4 3D scanning probe

RSH3-4 stylus holder

RSP3-6

RSH3-6c-500

RSH3-6c-600

RSH3-6-600

RSH3-6-700

RSH3-6-800

SFP2 surface finish probe

SFM-# surface finish module

SFH-1 and SFH-2 surface finish holders

SFA1, SFA2, SFA3 surface finish artefact

TFP tip find probe

SFA holding accessories

MST module setting tool

RVP REVO vision probe

VM10 vision module

VM11 vision module

REVO rack kit

MRS2 modular rack system

RCP REVO change port (original)

RCP2 REVO change port (latest version)

RCP TC-2, RCP TC-3 REVO change ports with thermal control

FCR25 flexible change rack

VPCP vision probe change port

VMCP vision module change port

TDA Tip datuming artefact

VA10 and VA11 vision artefacts

UCC S5 controller

SPA3 servo power amplifier

MCU5-2, MCU W-2 joysticks

Datum ball

Air filter

NOTE: The system components are organised in application-dependent kits.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

16

Page 17

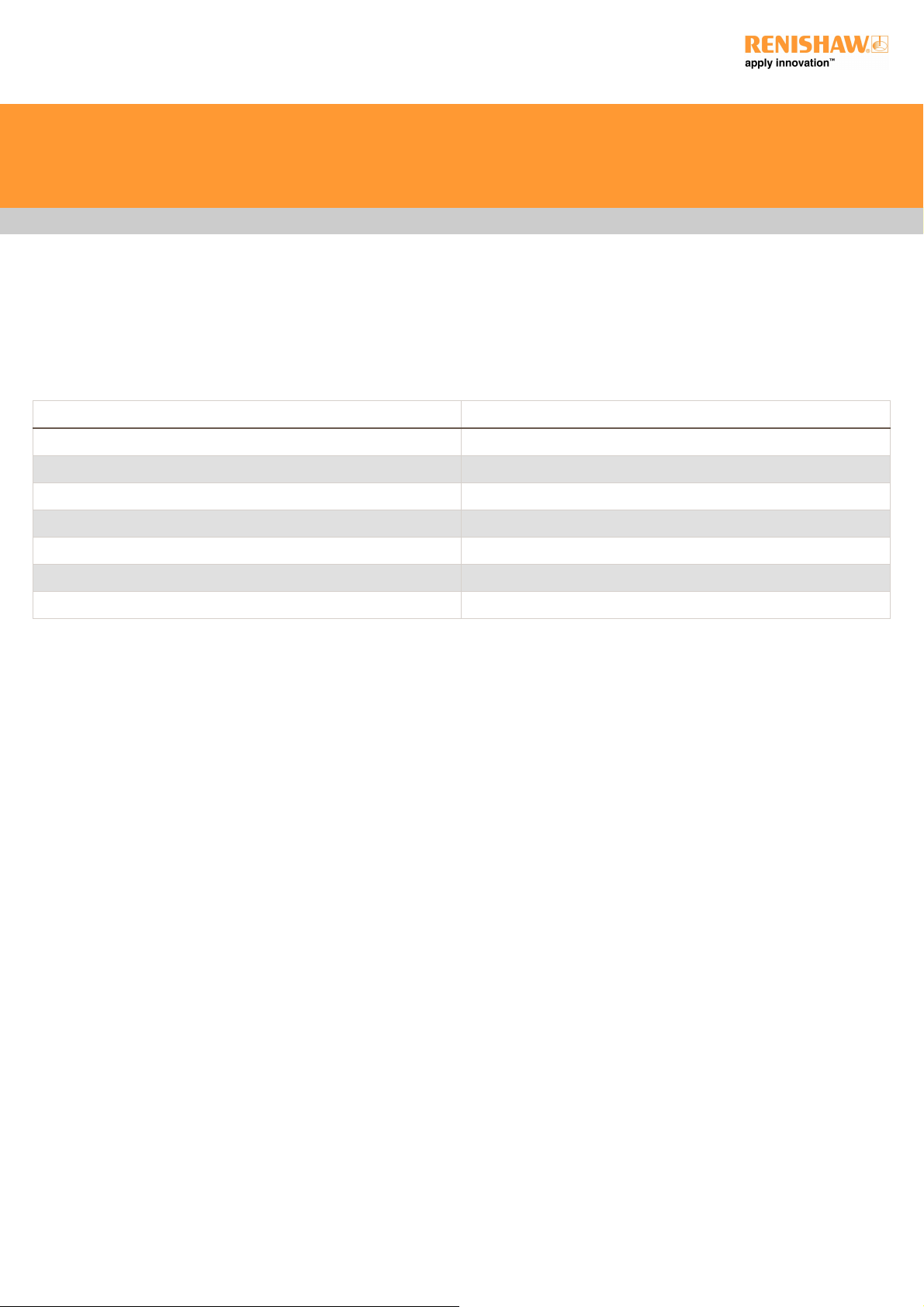

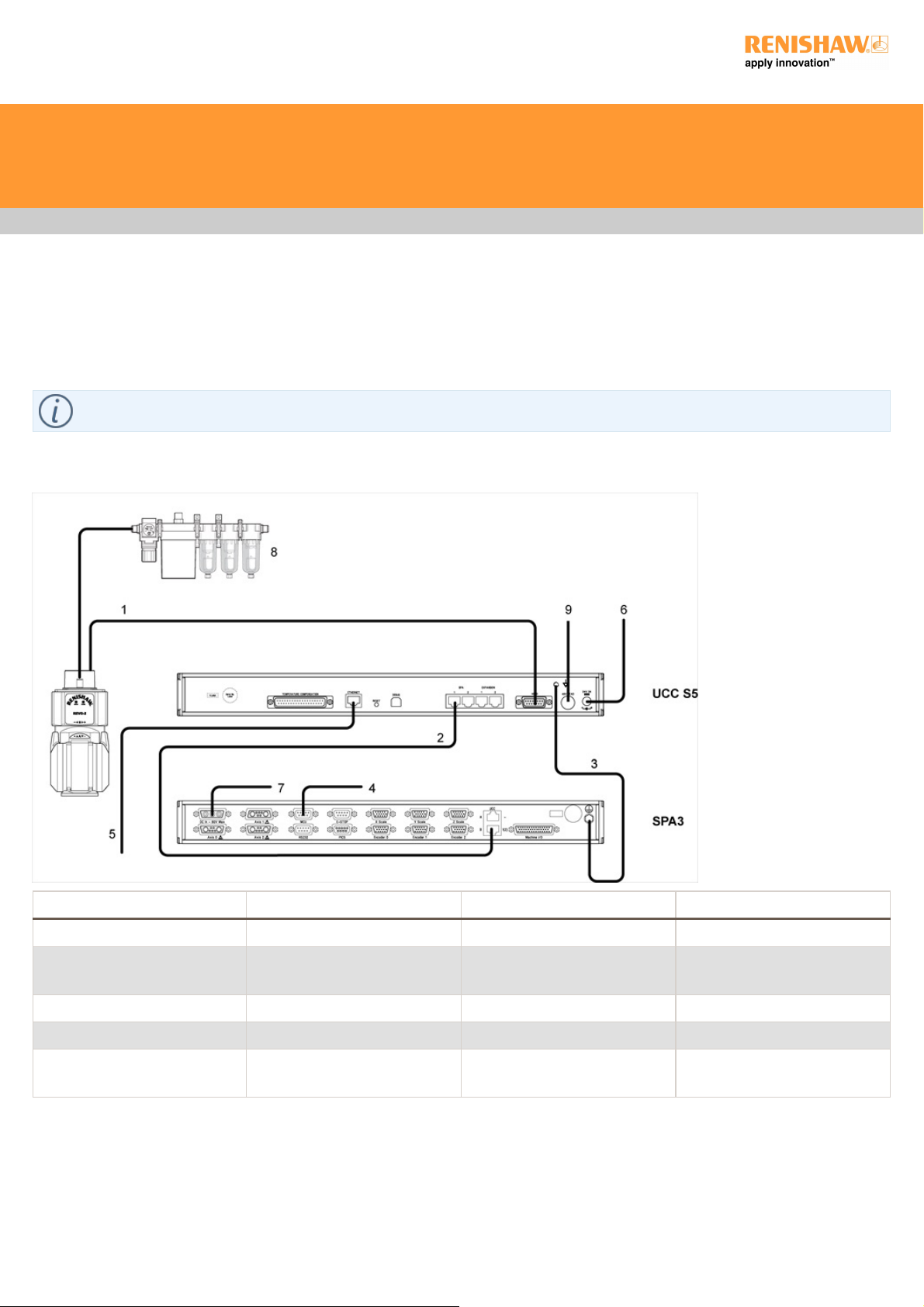

System connections

The REVO-2 system components are connected as shown below.

NOTE: REVO-2 requires just a single cable for power and communications.

Installation for up to 3 axes with head cable less than 25 m

Key Description Key Description

1 Orange head cable 6 24 V power supply (supplied)

2 Cat 5 300 mm cable (supplied) 7 25 V - 80 V power supply (not

supplied)

3 16 / 0.2 mm earth connection 8 Air filter

4 MCU connection 9 48 V power supply (supplied)

5 Cat 5 ethernet cable (5 m cross-

over cable supplied) to host PC

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

17

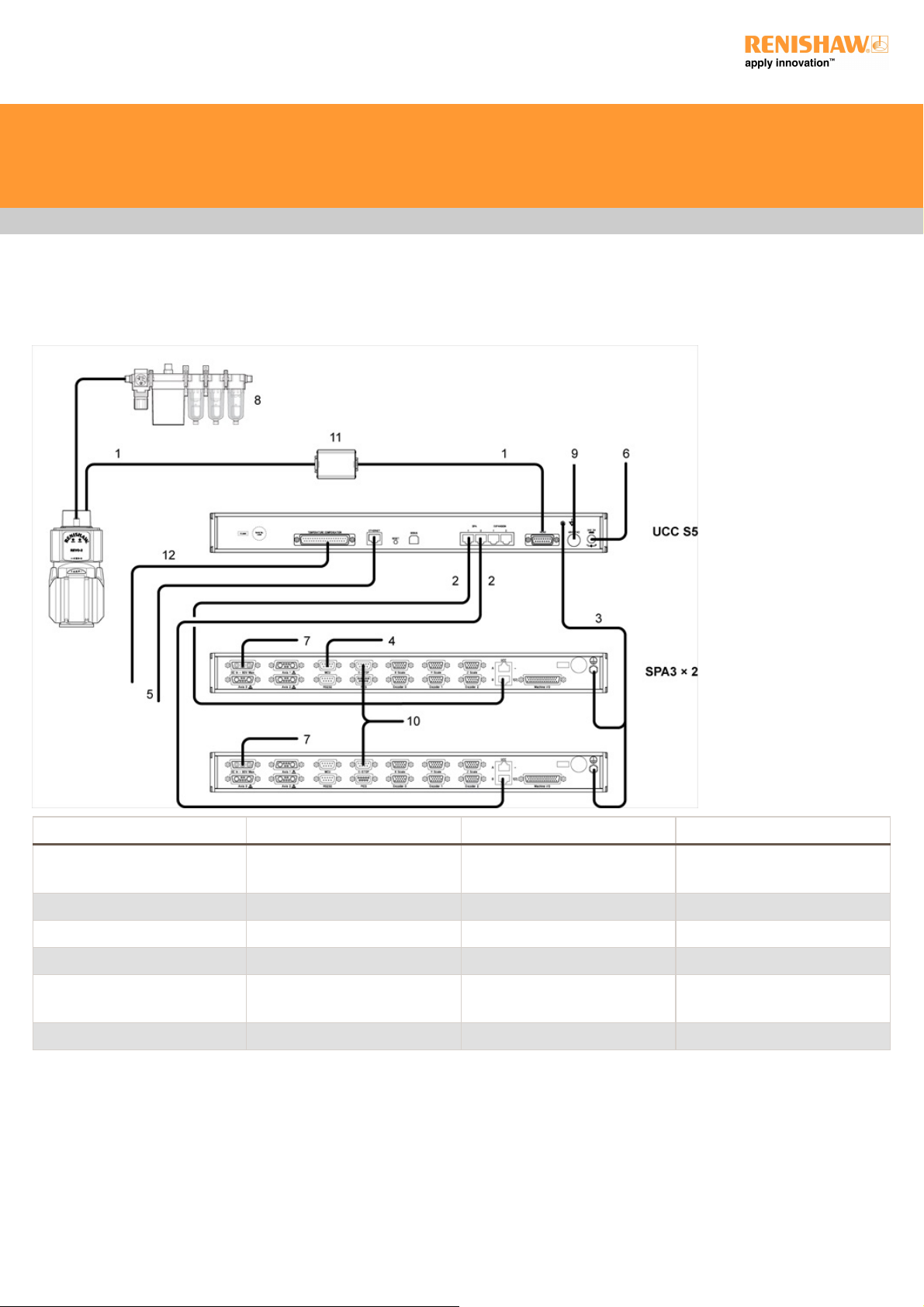

Page 18

Installation for 4 - 6 axes with head cable exceeding 25 m and thermal effect compensation (TEC)

Key Description Key Description

1 Orange head cable 7 25 V - 80 V power supply (not

supplied)

2 Cat 5 300 mm cable (supplied) 8 Air filter

3 16 / 0.2 mm earth connection 9 48 V power supply (supplied)

4 MCU connection 10 E-STOP link cable (supplied)

5 Cat 5 ethernet cable (5 m cross-

over cable supplied) to host PC

11 Head comms signal booster

6 24 V power supply (supplied) 12 TEC input

The REVO-2 head and CMM system are operated through UCCserver which uses I++DME command protocol to communicate between the

system application software and the UCC S5.

Full 5-axis scanning capability is achieved through interaction between the UCC S5, the REVO-2 and the SPA3, to co-ordinate all the motion

and metrology aspects across the three CMM axes and the two head axes.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

18

Page 19

Environmental and electrical specifications

Environmental specification

Operating temperature range 10 °C to 40 °C ﴾50 °F to 104 °F﴿

Storage temperature range ‐25 °C to +70 °C ﴾‐13 °F to 158 °F﴿

Operating humidity 0% to 80% (non-condensing)

Storage humidity 0% to 80% (non-condensing)

Electrical specification

The REVO-2 head and probe electronics are powered from the UCC S5.

The RCP TC-2 and RCP TC-3 are powered by a separate power supply that is supplied by Renishaw.

No other additional power supplies are required.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

19

Page 20

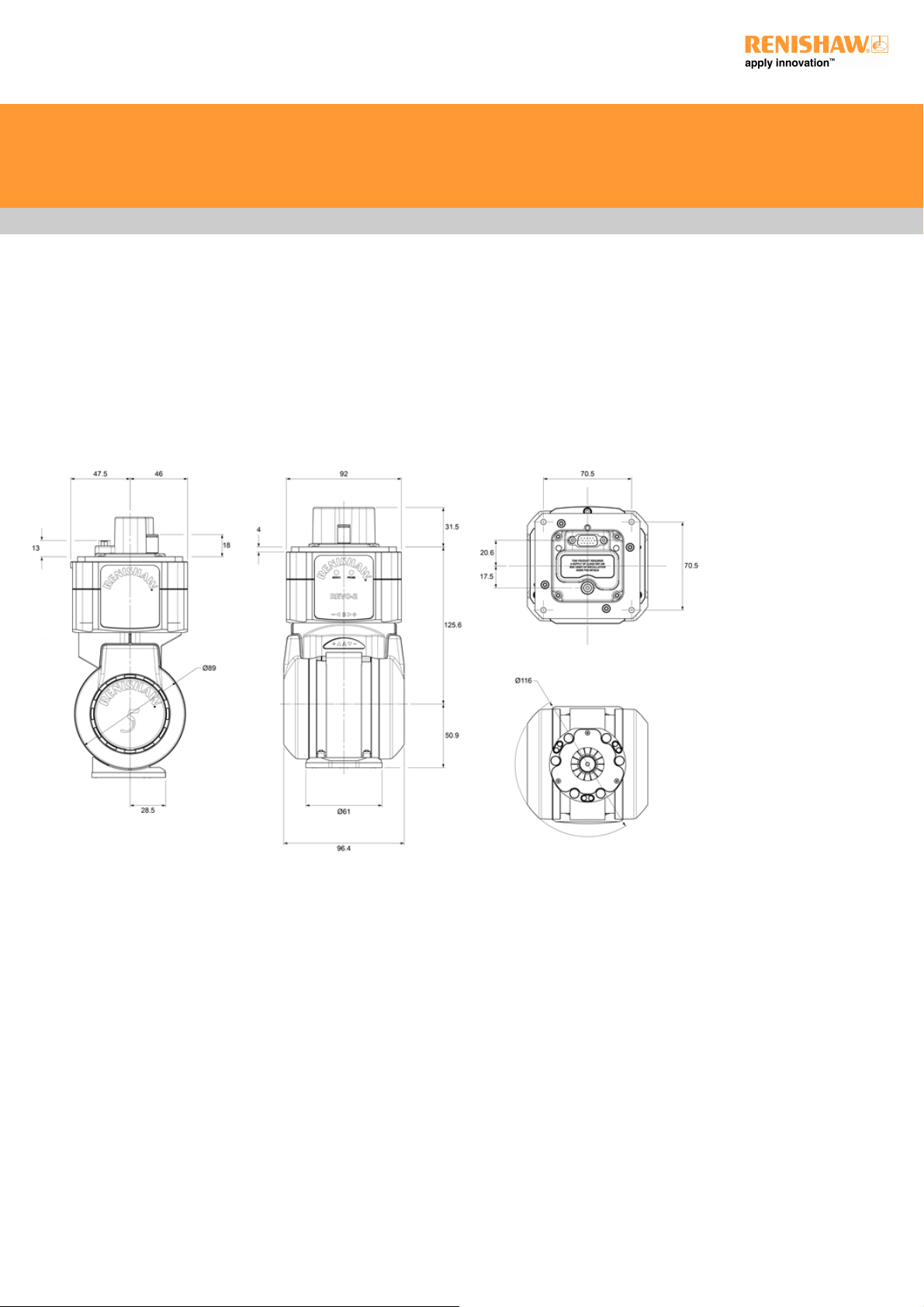

Physical specification

Weight

2.1 kg (without cables or probe or quill adaptor where applicable)

Dimensions

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

20

Page 21

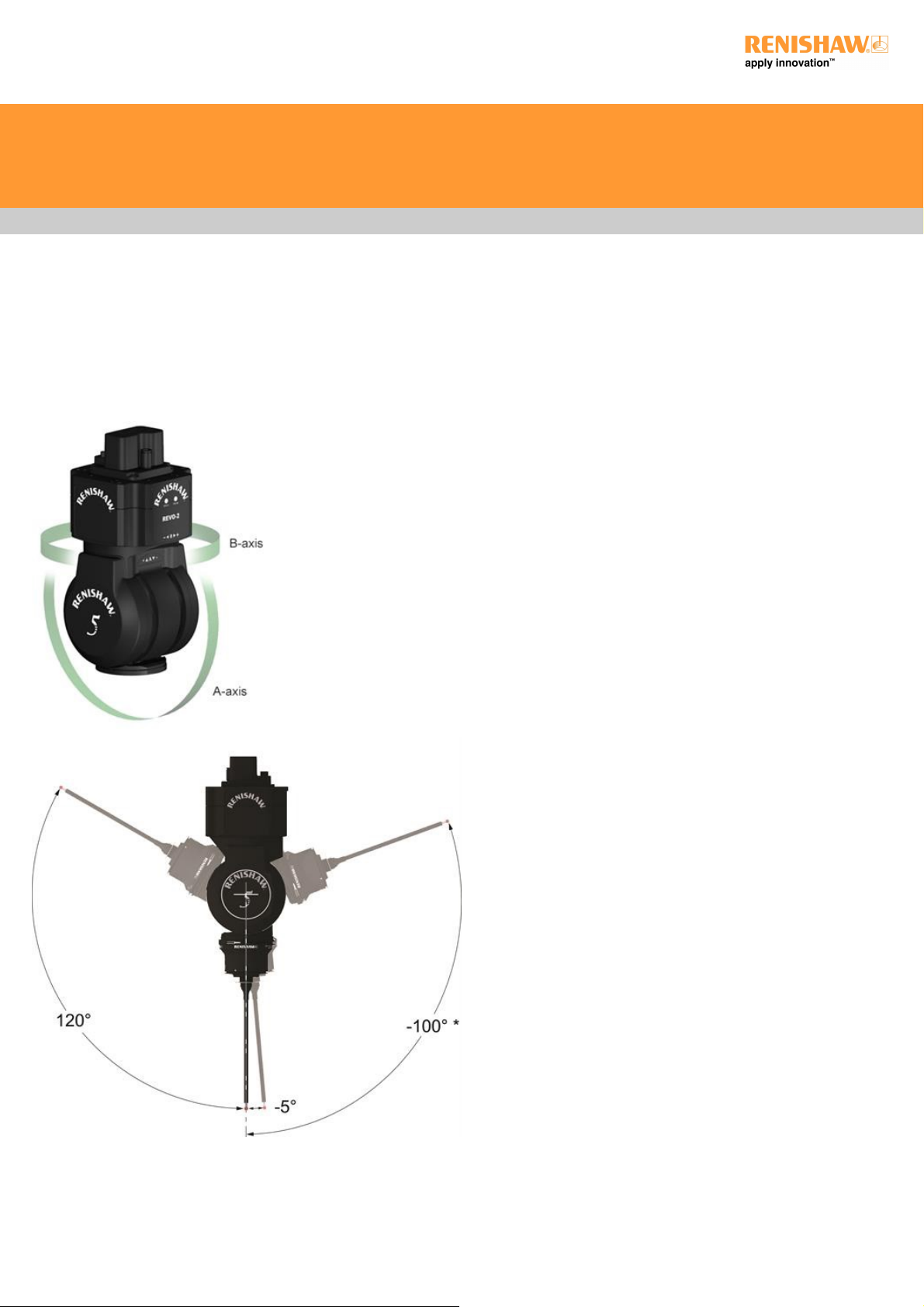

Head axis range

The REVO-2 head has two rotary axes (A and B) and is normally mounted on the CMM quill to create a 5-axis measuring system. The REVO-2

head's B-axis is mounted on the CMM quill and can rotate continuously in both directions. The A-axis, which is orthogonal to the B-axis, has

220° of travel. The head can only be mounted in the vertical orientation shown below:

* This movement is for calibration and use of RSP3 probes only.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

21

Page 22

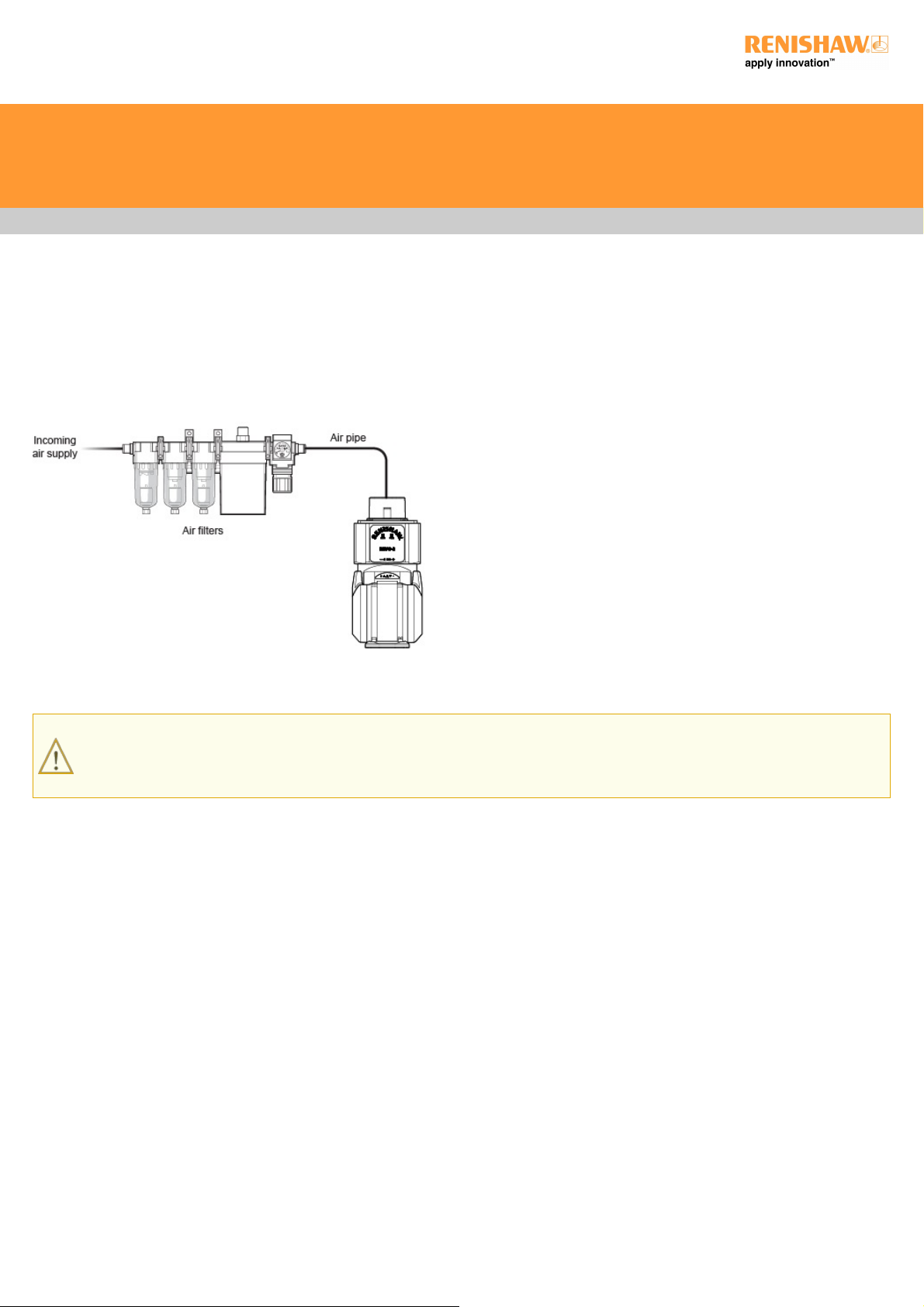

Air supply

It is important that the air supply to the head is maintained while the head is powered as the air supplies the bearings and provides air for

thermal management.

Air filter maintenance

WARNING: It is vital that the supplied air filters are used for REVO-2 and that the filter unit is maintained to the filter

manufacturer's specification. Failure to comply with the specification will invalidate the warranty and is likely to result in permanent

damage to the REVO-2 head requiring replacement at full cost.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

22

Page 23

To maintain the air quality:

1. Ensure the air provided to the filtration system meets the specification given.

Incoming air supply specification:

Air pressure 5 bar - 8.5 bar*

Air consumption Up to 50 litres per minute

BS ISO 8537-1:2010 [4:4:4]

Particle size 15 μm

Dirt concentration

8 mg/m

3

Dew point +3 °C

Oil

5 mg/m

3

* NOTE: The exact values are dependent on the inherent characteristics of the air pipe between the air filters and the REVO-2 head.

Please ask the installer for the specification.

If the air pressure falls outside the range given, the head metrology results will be affected.

2. Regularly monitor the dew point indicator (see image below) and follow the instructions given in the table.

For more information please visit the air filtration manufacturer's website http://www.smcpneumatics.com and search for IDG5 filters. (Please

refer to the section 'REVO air filter service kits' for details on air filter service kit part numbers).

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

23

Page 24

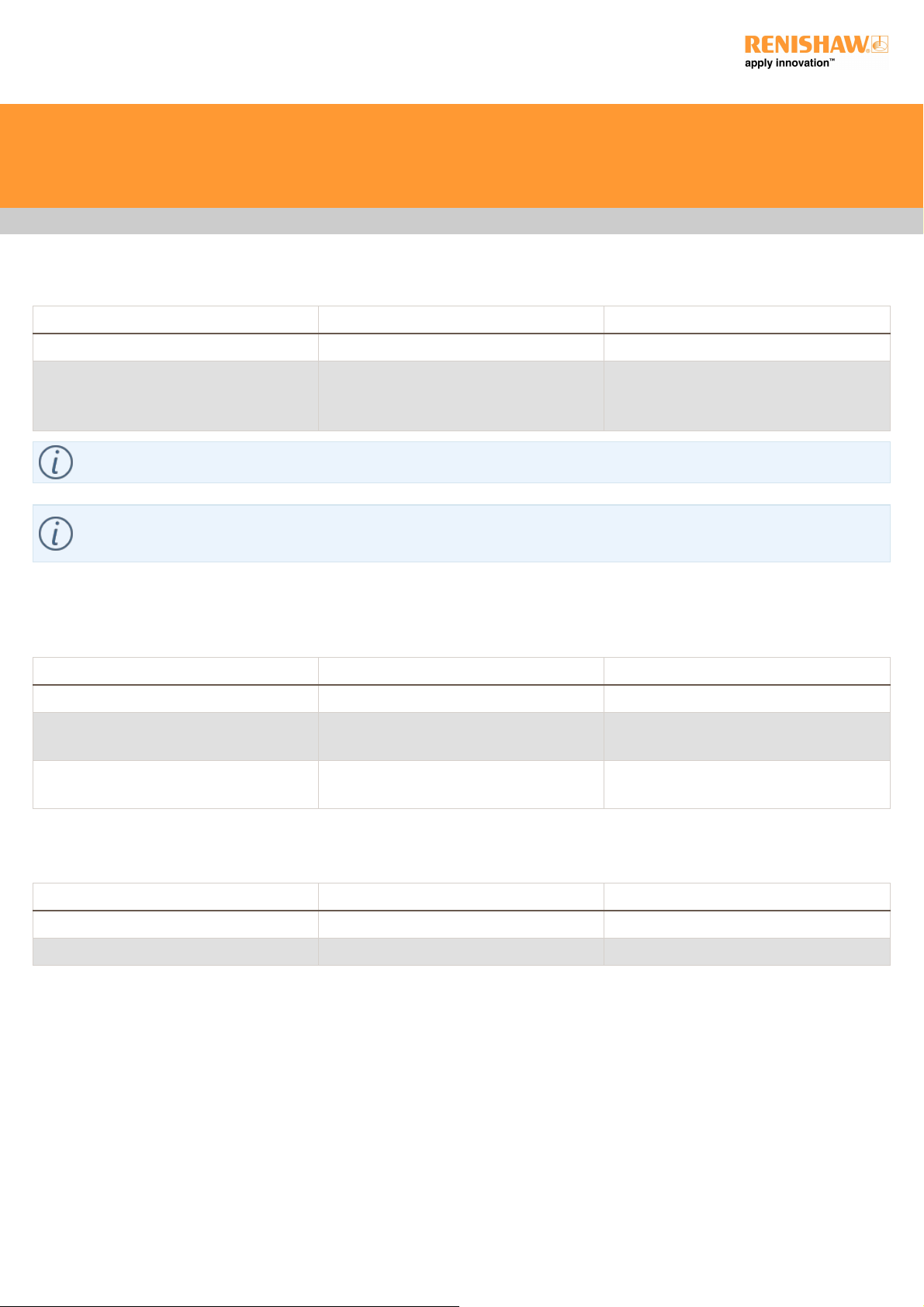

Dew point indications and maintenance instructions

Grain colour Causes Solutions

Blue / green Normal operation. No action required.

Pink / yellow Water and oil flow into membrane air dryer. 1) Check and replace filters if necessary.

2) Check condition of inlet air for excess oil

or water.

NOTE: The grains may be pink / yellow on delivery and can take up to 1½ hours to turn blue / green when air is connected.

NOTE: When dew point indicator absorbs vapourised oil content or other gaseous components in the compressed air, it may turn a

colour other than blue / green or pink / yellow.

Air filter service kits

The Renishaw filter service kit (M-3060-0933) contains:

SMC part number Description Quantity

AF20P-060S 5 μm filter element for use with AF20 unit 1

AFM20P-060AS 0.3 μm filter element for use with AFM20

unit

1

AFD20P-060AS 0.01 μm filter element for use with AFD20

unit

1

We recommend that the above filter kit is replaced every two years.

The Renishaw membrane dryer service kit (M-3060-0943) contains:

SMC part number Description Quantity

IDG-EL5 Membrane module kit for use with IDG5 unit 1

IDG-DP01 Dew point indicator kit for use with IDG5 unit 1

We recommend that the above filter kit is replaced every four years.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

24

Page 25

Probes and stylus holders

The REVO-2 head uses a purpose-designed set of Renishaw probes. The type of probe used is dependent upon the application.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

25

Page 26

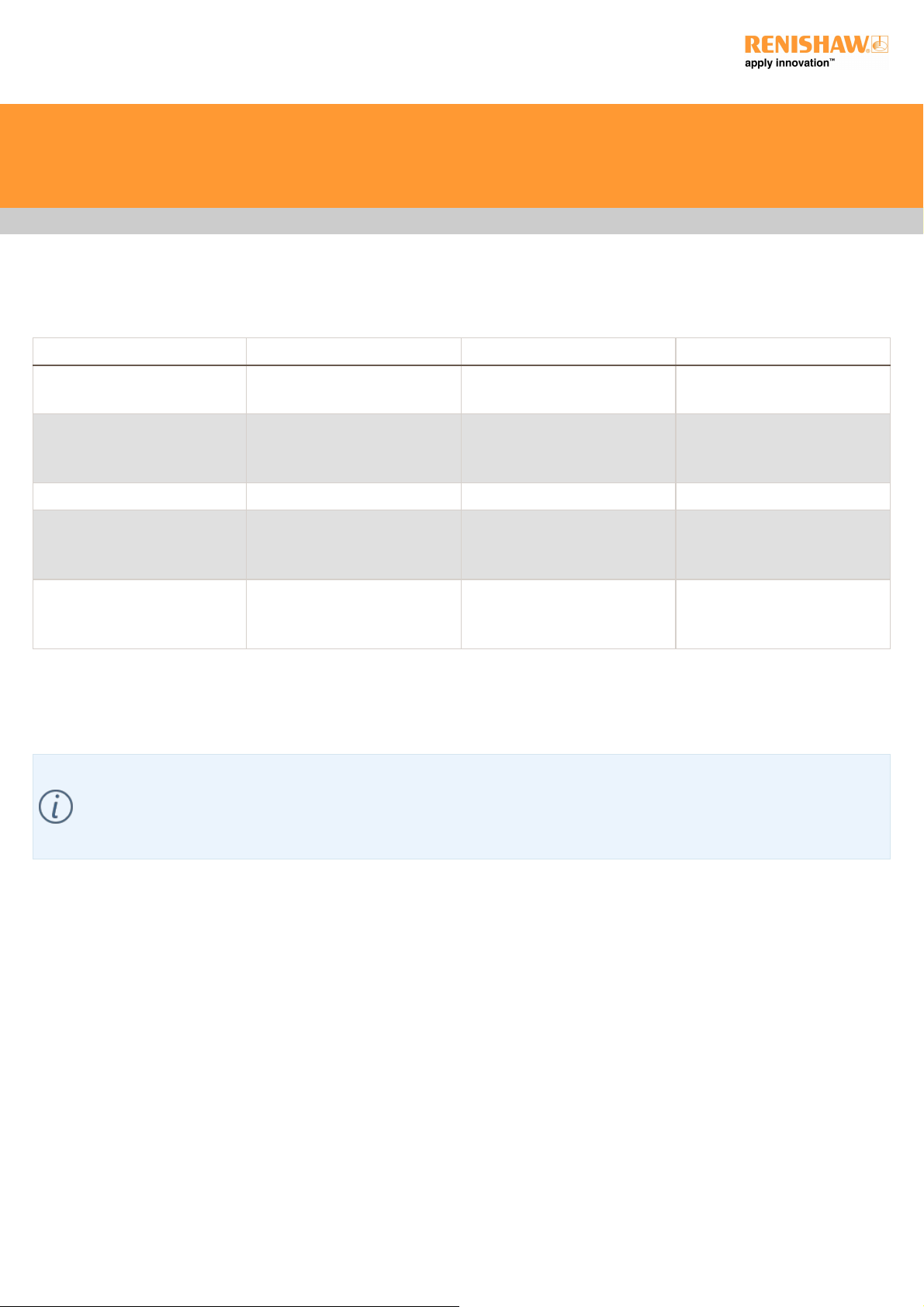

REVO-2 probe specification

RSP2 and RSP2 V2 RSP3-x SFP2

Used for High-speed 5-axis 2D scanning *

and single point taking

3-axis traditional CMM scanning

and single point taking

Surface finish measurement

Stylus range M2 but range has been selected

to opimise high speed scanning

performance **

M3 SFS-#

SFM-#

Cranked styli No Yes Yes

Crash protection XY and –Z via break off of either

module or stylus holder, +Z via

integral bump-stop design

XY and –Z via break off of either

module or stylus holder, +Z via

integral bump-stop design

XY and –Z via break off of holder

Calibration Uses Ø30 mm sphere supplied

with REVO‐2 or optional Ø45

mm sphere

Uses Ø30 mm sphere supplied

with REVO‐2 or optional Ø45

mm sphere

Uses SFA# and TFP

* All scans should be configured to allow an angle no greater than 45° between the measured surface and the axis of the RSP2 or RSP2 V2

probe.

** For more detail refer to UCCserver 5.0 (or newer) or PBC-01909.

NOTES: For optimum metrology, it is essential that all probe and stylus holder changes are carried out automatically through the

appropriate change ports.

Avoid touching the joint faces, as they will become contaminated. It is vital that the joint surfaces are protected and stay clean.

Replace covers when not in use.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

26

Page 27

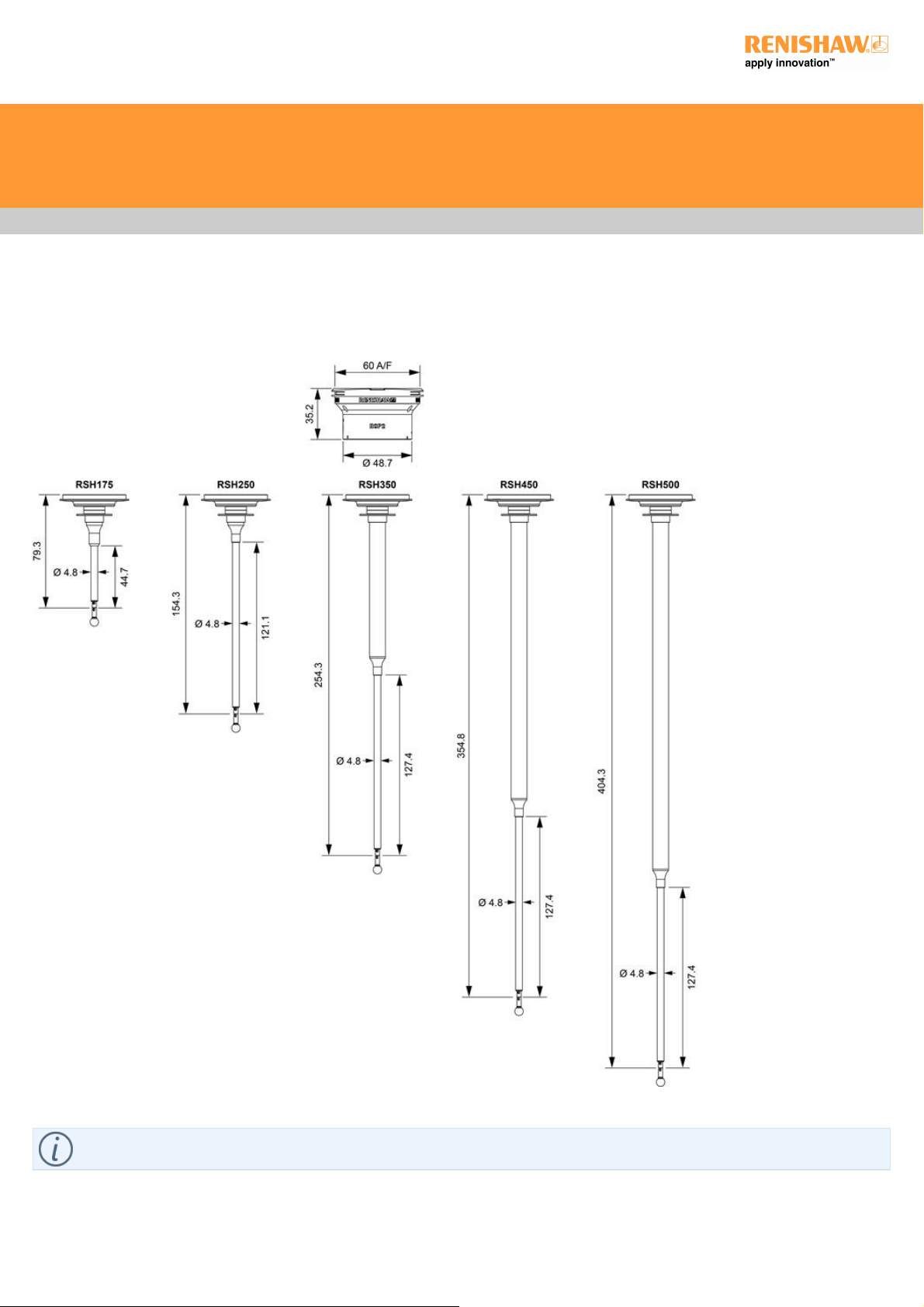

RSP2 V2 and RSH dimensions

NOTE: Boxed dimensions are to the kinematic planes and in mm.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

27

Page 28

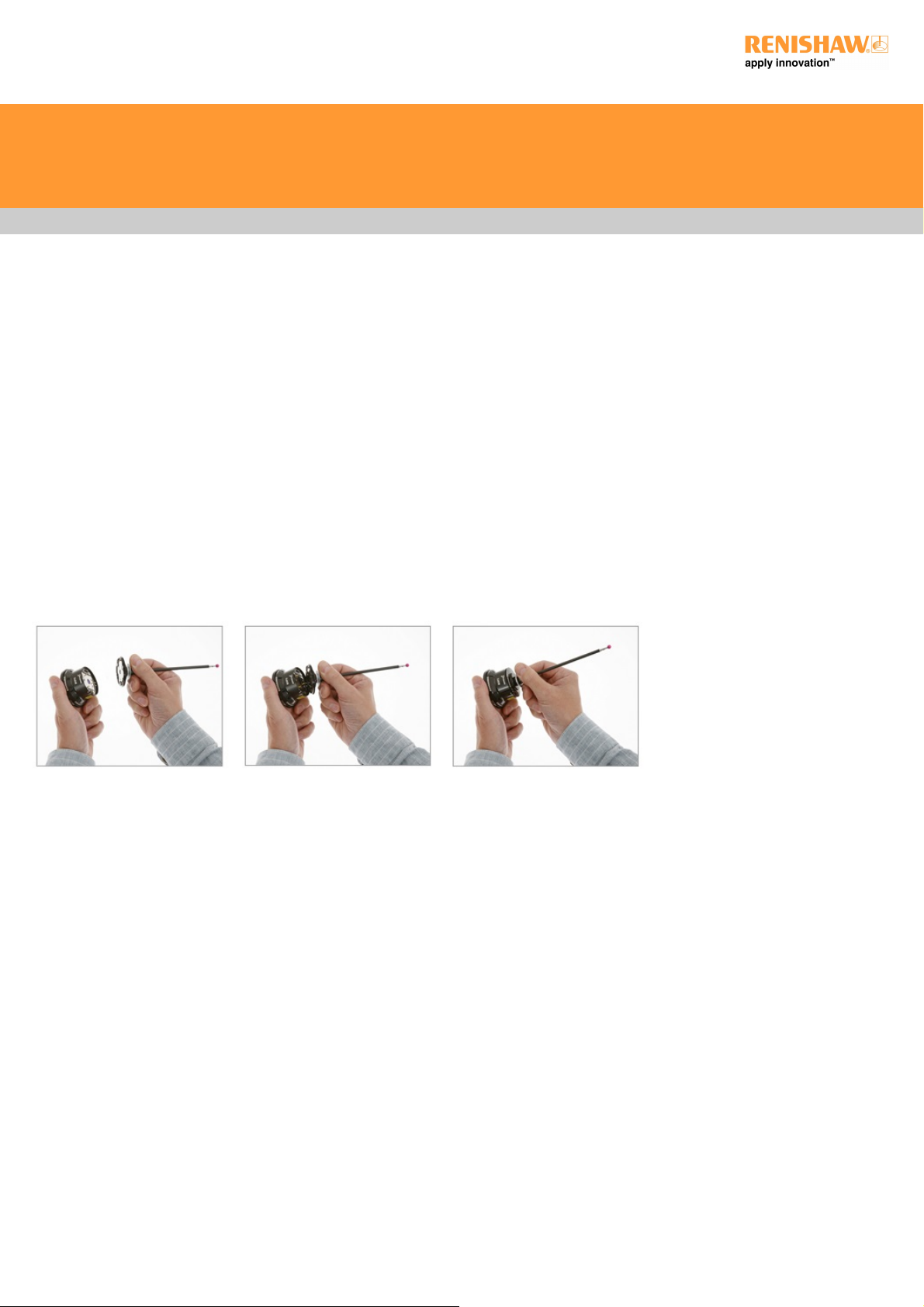

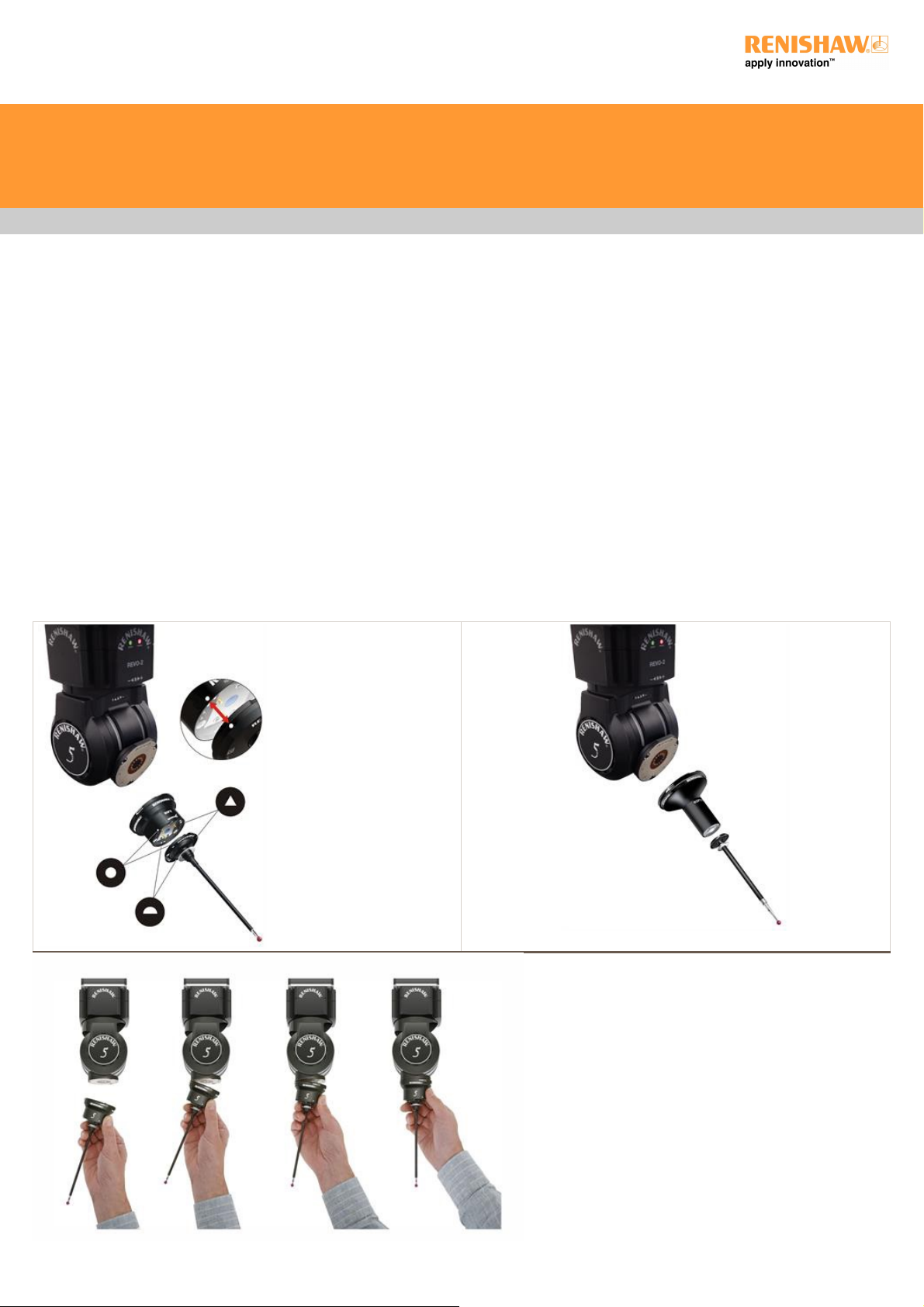

Manually mounting / removing the stylus holders from REVO-2 probes

To manually mount the stylus holder to the REVO-2 probe:

1. Align the front sides of the probe and stylus with each other (look at the "Renishaw" engraving on the side of probe or alignment marks as

applicable).

2. Carefully offer up the stylus holder to the probe, allowing the magnetic attraction to gently make the kinematic joint.

3. Gently attempt to rotate the stylus holder to ensure correct location.

To manually remove the stylus holder from the REVO-2 probe:

1. Securely hold the stylus holder.

2. Gently tilt the stylus holder to break the kinematic joint and separate.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

28

Page 29

Manually mounting / removing the probes from REVO-2

To manually mount the probe to the REVO-2 head:

1. Align the front sides of the head and probe with each other (look at the "Renishaw" engraving on the side of probe or alignment marks, as

applicable).

2. Carefully offer up the probe to the REVO-2 head, allowing the magnetic attraction to gently make the kinematic joint; also gently attempt to

rotate the probe to ensure correct location.

To manually remove the probe from the REVO-2 head:

1. Securely hold the probe.

2. Gently tilt to break the kinematic joint and separate.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

29

Page 30

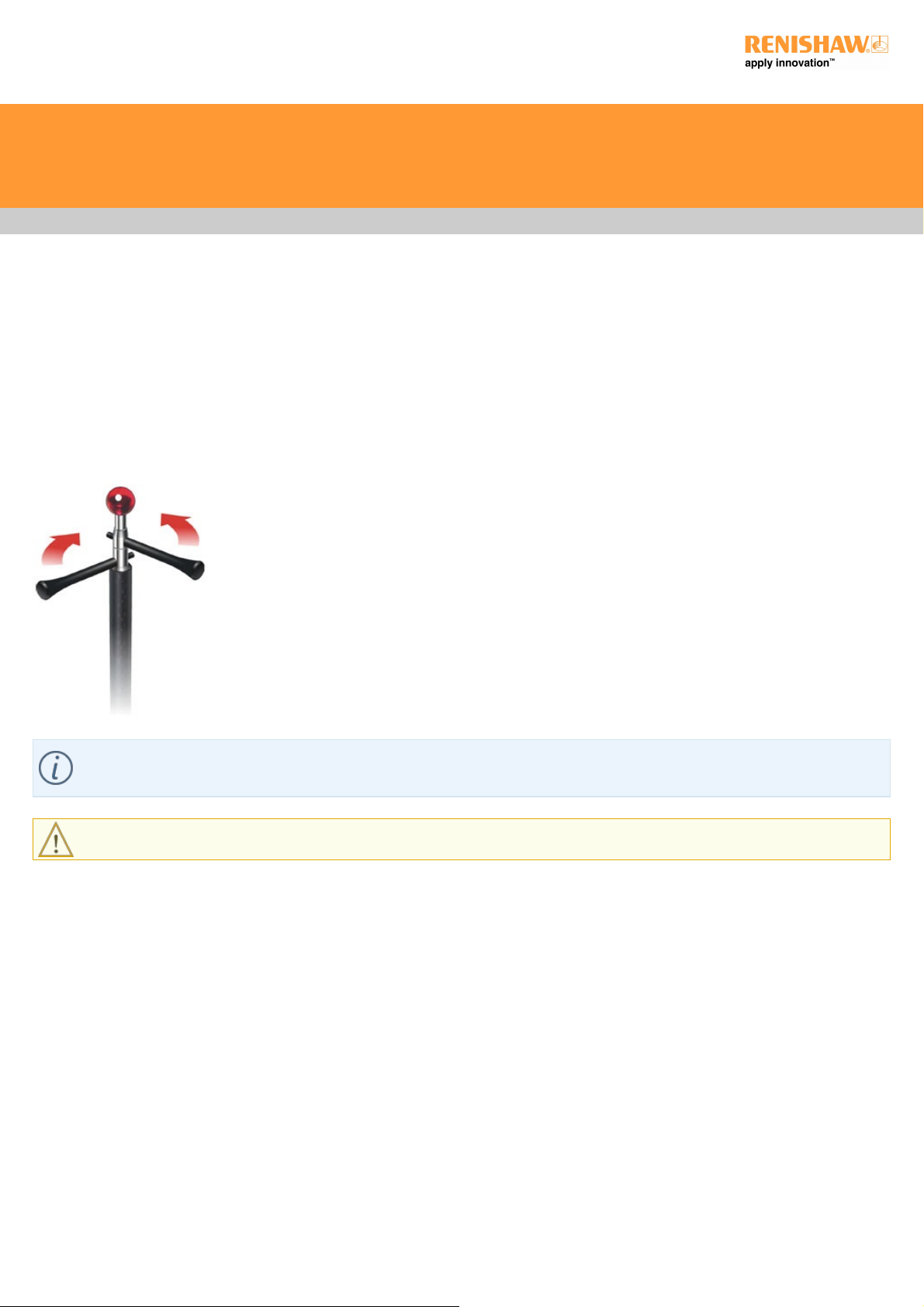

Manually mounting / removing the stylus from stylus holders

1. The stylus holder must be removed from the probe before mounting / removing a stylus.

2. Always use the correct stylus tools to tighten and undo the threaded joints between the stylus and the stylus holder, thus avoiding excess

torque (see diagram below).

NOTE: If a spare stylus removal tool is needed order Renishaw part A-5000-7835 (the set comprises two S7 stylus tools in a plastic

box).

CAUTION: Failure to use two tools as shown is likely to break the stylus holder.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

30

Page 31

System status indicators

The head incorporates two LEDs for status indication in various modes:

LED status Servo LED Probe LED

Off No power (probe LED also off) Probe trigger

Green Servos on Probe calibrated

Red Servos off Stylus removed (or probe error)

Red flash Comms to head failed (probe LED also off) Probe removed from head

Amber 'Soft engage' mode Probe turned off

Amber flash Auto-tune in progress Probe not calibrated

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

31

Page 32

Calibration

System calibration

The REVO-2 datum sphere is used to calibrate the REVO-2 head as well as RSP2 and RSP3-x probe configurations.

The SFP1 is calibrated using the SFA that is fixed to the MRS rail.

For the minimum required CMM volume please refer to the table and diagram below:

Probe type A ﴾in mm﴿ ‐ Ø30 sphere A ﴾in mm﴿ ‐ Ø45 sphere

RSP2 with RSH175 420* 435*

RSP2 with RSH250 570* 585*

RSP2 with RSH350 770* 785*

RSP2 with RSH450 970* 985*

RSP2 with RSH500 1070* 1085*

* For a Ø6 mm × 10 mm stylus.

Dimensions in mm

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

32

Page 33

Fitting the REVO datum sphere

Kit contents

NOTE: The calibration diameter of the sphere is engraved on the stem. Please ensure the exact value is used when commissioning

the system.

The REVO datum sphere kits consist of the following:

Part description Technical specification

Datum ball Ø30 mm or optional Ø45 mm

Fixing studs (adaptor studs) M6 × 1

Fixing studs (adaptor studs) M8 × 1.25

Fixing studs (adaptor studs) M10 × 1.5

Fixing studs (adaptor studs) 5/16 in UNC (double groove)*

Fixing studs (adaptor studs) 3/8 in UNC (single groove)*

Base Ø60 mm

C spanner n/a

Tommy bar ﴾×2﴿ n/a

* NOTE: Grooves on the fixing stud are to differentiate between metric and imperial measures. They are not a functional feature.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

33

Page 34

Fitting the REVO datum sphere

Please observe the correct order of assembly for the REVO datum sphere by following steps 1, 2 and 3 as shown below.

DO NOT tighten or untighten by holding the sphere.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

34

Page 35

Maintenance

CAUTION: Always refer to the 'Safety' and 'Warnings' sections of this guide. Failure to do so could lead to personal injury.

Following the simple procedures given below will prolong the operational life and maintain the high performance of the system.

The user should determine the frequency of inspection and maintenance actions according to the conditions of use.

The head labels are best cleaned with a slightly damp cloth. All other system components should be cleaned using a soft, lint free cloth and

must be kept dry.

The kinematic coupling mechanisms incorporated throughout the system have precision ball seating and permanent magnets. It is

recommended that all these features be cleaned before first use, and thereafter at regular intervals. The frequency of cleaning depends on the

local environment conditions, but should be at least every 500 changes.

A cleaning kit for the precision ball seating and permanent magnet is available from your Renishaw supplier (part number A-1085-0016). It

comprises strips of ‘yellow tack' material. Use the yellow tack to clean the areas indicated with arrows on the image below.

With clean hands, tear off a small piece, shape into a small ball and press into/onto each of the features in turn, rotating to a fresh piece of

material as you work around.

CAUTION: Ensure no yellow tack debris is left on the surface. The yellow tack should not be used for the optical windows.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

35

Page 36

The electrical contacts indicated with arrows in the image below should be carefully cleaned using an alcohol based cleaner.

Optical windows should be cleaned by first blowing or brushing away any debris followed by wiping with a lint-free cloth and a suitable

alcohol based cleaner such as isopropyl alcohol (IPA).

Styli maintenance

Stylus balls, threads and mating faces should be cleaned using a proprietary cleaning cloth or solvent. Stylus balls should be regularly

inspected for damage or ‘pick‐up' of component material.

Renishaw offers a range of ball materials suited to scanning of different component materials. See the Styli and accessories - technical

specifications guide (Renishaw part number H-1000-3200).

SFA maintenance

Periodically visually inspect the SFA for scratches.

Rack port maintenance

CAUTION: Always refer to the 'Safety' and 'Warnings' sections of this guide. Failure to do so could lead to personal injury.

Periodic cleaning of the ports, lids and outer surfaces, using a soft, lint free cloth, is recommended to prevent contamination of stored probes

and modules.

A port replacement kit for FCR25 is available to allow the user to service ports should they become worn or damaged (Renishaw part number

A-5036-0049).

A lid replacement kit for RCP2 is also available (Renishaw part number A-3061-1962).

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

36

Page 37

The maintenance of the optical windows in the REVO-2 system

CAUTION: Always refer to the 'Safety' and 'Warnings' sections of this guide. Failure to do so could lead to personal injury.

The REVO-2 probe and stylus holder optical windows should be cleaned using a proprietary lens cleaning kit to blow or brush debris away

from the window, then carefully wiped with lint free cloth and isopropyl alcohol (IPA). Extreme care must be taken to avoid damaging the

optical coating or scratching the glass.

NOTE: Cleanliness of the optical windows is important to maintain the highest level of performance of the probe and stylus holder.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

37

Page 38

Appendix 1 - International safety statements

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

38

Page 39

BG ‐ Безопасност

ВНИМАНИЕ: Преди разопаковане и монтиране на системата REVO‐2, потребителят трябва внимателно да прочете

инструкциите по безопасност по‐долу и да гарантира, че те ще се спазват през цялото време от всички оператори.

RSP2, RSP2 V2, SFP1 и RSP3‐x трябва да се използват само с главата REVO / REVO‐2 на Renishaw.

Операторите трябва да са обучени в употребата и прилагането на системата REVO / REVO‐2 и придружаващите я продукти,

към които се монтира машината преди да могат да работят с тази машина.

В някои компоненти на системата REVO‐2 и свързаните с нея продукти са използвани постоянни магнити. Важно е те да се

пазят от елементи, които биха могли да бъдат засегнати от магнитни полета, напр. – системи за запаметяване на данни,

водачи, часовници и др.

Лазерни емисии от клас 3R RSP2 и SFP1

Препратките са направени към характеристики, обозначени като † и ‡ в следващите илюстрации. Моля, уверете се че разбирате всички

съвети за безопасност. Препоръчва се запознаване с компонентите на системата REVO‐2.

Илюстрация за безопасност от клас 3R RSP2 и SFP1

Тези версии RSP2 и SFP1 се класифицират като лазерни продукти от клас 3R в съответствие с EN 60825‐1:2007. Тази класификация се

основава на мощността на лазера, която би се излъчвала в случай на счупване на държача на острието, както се изисква от критерия

за „единична повреда” в EN 60825‐1. При отсъствие на такава повреда, излъчваната от лазера мощност е пренебрежимо малка.

Клавиш

† Контакти на превключвателя на блокировката ‡ Бленда на лазера и оптично прозорче

ВНИМАНИЕ: Да не се свалят етикетите с предупреждения по безопасност, разположени на корпуса на пробниците RSP2 и

SFP1.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

39

Page 40

Мощност на лазера

Максимална изходна мощност: < 5 mW

Продължителност на импулса: непрекъсната вълна

Дължина на вълната: 670 нм

Отклонение на лъча: 2 милирадиана

Корпусите на RSP2 и SFP1 съдържат вградени лазерни източници клас 3B и не трябва да се използват в случай на сериозна повреда

или скъсване на някоя част на изделието. В такива случаи ВЕДНАГА изключвайте източника на захранване и отстранявайте, но не

опитвайте да използвате частите повторно. Обърнете се към доставчика си за съвет.

При нормална работа лазерният лъч е напълно затворен в корпуса на пробника и корпуса на държача на острието и е недостъпен за

потребителя. Свалянето на държача на острието прекъсва двата комплекта контакти, означени с †, на превключвателя на

блокировката за автоматично изключване на захранването на лазера и предотвратяване на излагане на въздействието на лъча.

Контактите на превключвателя трябва да се проверяват през редовни интервали, за да се гарантира, че са чисти и без замърсители на

въздуха като прах, отломки или стружки. При малко вероятни обстоятелства такова замърсяване би могло да причини късо

съединение на пиновете и да увеличи риска от подаване на захранване към лазера без да е докоснат държача на острието. Да не се

свързват проводими предмети към или между контактите. Да се спазват инструкциите за почистване в раздел за поддръжка.

Преди проверка, винаги сваляйте RSP2 или SFP1 от главата. Никога да не се гледа директно в блендата на лазера, обозначена като ‡,

докато корпусът на RSP2 или SFP1 е все още свързан към главата на пробника.

В малко вероятния случай на счупване на стеблото на държача на острието без отместване на блокираното свързване между

пробника и държача на острието има малък риск от излагане на лазерна светлина от клас 3R от малката бленда на счупеното стебло

на острието. Директното гледане може да доведе до перманентна повреда на зрението и трябва да се избягва. Ако настъпи счупване,

избягвайте директно гледане към излъчена или отразена лазерна светлина и натиснете бутона за аварийно спиране на ръчния пулт за

управление, за да се избегне неочаквано движение. След това ръчно свалете пробника и държача на острието от главата REVO‐2. След

като се направи това, машината трябва да се премести ръчно, за да се открие детайлът и се получи достъп до повредата. При никакви

обстоятелства не трябва да се правят опити за ремонт или повторна употреба на повреден държач на острието. Обърнете се към

доставчика си за съвет.

Лазерни емисии от клас 1 RSP2 V2

Препратките са направени към характеристики, обозначени като ‡ в следващите илюстрации. Моля, уверете се че разбирате всички

съвети за безопасност. Препоръчва се запознаване с компонентите на системата REVO‐2.

Илюстрация за безопасност от клас 1 RSP2 V2

Тази версия на RSP2 се класифицира като лазерен продукт от клас 1 в съответствие с EN 60825‐1:2014.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

40

Page 41

Клавиш

‡ Оптично прозорче

Корпусът на RSP2 V2 съдържа вграден лазерни източници от клас 3B и не трябва да се използва в случай на сериозна повреда или

скъсване на някоя част на изделието. В такива случаи ВЕДНАГА изключвайте източника на захранване и отстранявайте, но не

опитвайте да използвате частите повторно. Обърнете се към доставчика си за съвет.

Преди проверка винаги сваляйте RSP2 V2 от главата.

Ако държачът на острието бъде свален ръчно, или чрез излизане извън работния ход, лъчът е достъпен през оптичното прозорче,

показано като ‡ на илюстрацията. При нормални обстоятелства, за да предотвратите опасностите от разсейване, лазерът ще бъде

изключен автоматично, когато държачът на острието бъде отстранен.

ВНИМАНИЕ: Държачът на острието трябва да бъде сменен веднага, когато е практически възможно.

Емисии от светодиодите на RSP3‐x

Сондата за сканиране на RSP3‐x съдържа вградени светодиодни източници с висока мощност и не трябва да се използва в случай на

сериозна повреда или скъсване на някоя част на RSP3‐x. В такива случаи ВЕДНАГА изключвайте източника на захранване и

отстранявайте, но не опитвайте да използвате частите повторно. Обърнете се към доставчика си за съвет.

RCP TC‐2 и RCP TC‐3

Методът за прекъсване на захранването е откачване на захранващия кабел или изключване на захранването.

Въздушни филтри

Налягането на подавания въздух на входа на въздушните филтри трябва да е максимум 8,5 бара. Моля, спазвайте обичайните

предпазни мерки при работа със сгъстен въздух.

Обща експлоатация и поддръжка

Продуктът трябва да се използва само с контролер UCC S5 на Renishaw.

Преди извършване на всякакви работи по поддръжката се препоръчва да се изключва захранването.

Поддръжката се ограничава до описаните в раздела по поддържа процедури.

Трябва да се внимава, за да се гарантира, че прозорчетата на блендата на лазера, означени с ‡, разположени на RSP2, RSP2 V2, SFP1 и

на държача на острието, няма да се повредят, тъй като са изработени от стъкло и биха могли да причинят нараняване, ако се счупят.

ВНИМАНИЕ: Използването на органи за управление или настройка или изпълнението на процедури, различни от

описаните в настоящото, може да доведе до опасно излагане на излъчване.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

41

Page 42

Предупреждения

Пазете се от неочаквано движение. Потребителят трябва да остава извън пълния работен обсег на главата на пробника и острието.

Доставчикът на машината трябва да се увери, че потребителят е наясно с пълния работен обсег на системата.

Препоръчва се защита на очите във всички приложения, включващи използване на машини или CMM.

Отговорност на доставчика на машината е да гарантира, че на потребителя са обяснени всякакви рискове по време на работа,

включително онези, упоменати в документацията на продуктите Renishaw и да гарантира осигуряване на съответни предпазители и

обезопасителни блокировки.

Вж. инструкциите за работа на доставчика на машината.

Компонентите на системата не съдържат детайли, които да се обслужват от потребителя с изключение на RCP TC‐2, RCP TC‐3, RCP2 и

FCR25. Не трябва да се правят опити за разглобяване на който и да било детайл на изделието. В случай на проблем се обръщайте към

доставчика си за съдействие.

При определени обстоятелства сигналът от пробника може да посочва фалшиво състояние на опрян пробник. Да не се разчита на

сигналите от пробника за спиране движението на машината.

Байпасът на спусъка на пробника ще предотврати обратния ход на машината в случай на сблъскване на пробника.

Съединенията на пробника са конструирани да освобождават пробника и/или държача на острието в случай на авария.

Това оборудване не е подходящо за работа в потенциално експлозивна атмосфера.

Съществуват рискове от притискане между частите. Да не се държи пробникът или главата на пробника по време на работните

движения.

За непрекъснатата безопасност е от значение всички предпазители да се сменят с такива с точния тип и номинал.

Главата да се транспортира само в доставената от Renishaw опаковка.

Кабелите трябва да отговарят на спецификациите на Renishaw. Неправилното окабеляване би могло да причини повреда на

оборудването.

ПРЕДУПРЕЖДЕНИЕ: Избягвайте да докосвате сондите ﴾включително контрабаласиращите рамена﴿, стилус държачи и

други модули, когато главата REVO‐2 е активирана ﴾серво LED свети зелено﴿ и системата е готова за измерване.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

42

Page 43

CZ ‐ Bezpečnost

UPOZORNĚNÍ: Před vybalením a instalací systému REVO‐2 by si měl uživatel pozorně přečíst níže uvedené bezpečnostní pokyny a

zajistit, aby je všechny osoby používající systém neustále dodržovaly.

Sondy RSP2, RSP2 V2, SFP1 a RSP3‐x používejte pouze s hlavicí REVO / REVO‐2 společnosti Renishaw.

Než bude moci personál obsluhy začít pracovat se strojem, ke kterému je připojen systém REVO / REVO‐2, je nutné, aby byl

vyškolen v oblasti používání tohoto systému a doplňujících produktů v souvislosti s daným strojem.

V některých součástech snímacího systému REVO‐2 a přidružených produktech jsou použity permanentní magnety. Je nutné je

uchovávat mimo dosah předmětů, na které by mohlo nepříznivě působit magnetické pole, jako jsou například systémy pro

ukládání dat, kardiostimulátory, hodinky atd.

Sondy RSP2 a SFP1 – laserové záření třídy 3R

Prvky označené v textu symboly † a ‡ najdete na následujících obrázcích. Ujistěte se, že všem bezpečnostním pokynům zcela rozumíte. Je třeba

se důkladně obeznámit se součástmi systému REVO‐2.

Obrázky týkající se bezpečnosti sond RSP2 a SFP1 třídy 3R

Tyto verze sond RSP2 a SFP1 jsou klasifikovány jako laserové výrobky třídy 3R podle normy EN 60825‐1:2007. Klasifikace je založena na

laserovém výkonu, který by byl v nepravděpodobném případě zlomení držáku doteku vyzářen, jak požadují kritéria „jednoduché poruchy“ v

normě EN 60825‐1. Pokud k takové poruše nedojde, je vyzařovaný laserový výkon zanedbatelný.

Význam značek

† Ochranné kontakty vypínače ‡ Apertura laseru a optické okénko

UPOZORNĚNÍ: Neodstraňujte bezpečnostní výstražné štítky umístěné na tělese obou sond RSP2 a SFP1.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

43

Page 44

Výstupní energie laseru

Maximální výstupní energie: < 5 mW

Trvání impulzu: netlumená vlna

Vlnová délka: 670 nm

Divergence paprsku: 2 mrad

Tělesa sond RSP2 a SFP1 obsahují integrované laserové zdroje třídy 3B a nesmějí být použity v případě vážného poškození nebo prasknutí

kterékoliv části výrobku. V takových případech OKAMŽITĚ odpojte napájecí zdroj, poškozený díl demontujte a zajistěte, že nebude dále

používán. Kontaktujte svého dodavatele.

Při normálním provozu je laserový paprsek dokonale uzavřen v tělese sondy a tělese držáku doteku a je pro uživatele nepřístupný. Demontáž

držáku doteku přeruší dvě sady ochranných kontaktů vypínače s označením †, které automaticky vypínají napájení laseru a zabraňují expozici

paprsku.

Pravidelnou prohlídkou a kontrolou ochranných kontaktů by mělo být zjištěno, zda jsou čisté a zda neobsahují vzduchem přenášené nečistoty,

jako je například prach nebo třísky odletující při obrábění. Za určitých, málo pravděpodobných okolností by takové znečištění mohlo mezi

kolíky způsobit zkrat, a tím by došlo ke zvýšení rizika, že bude laser napájen, i když nebude připojen držák doteku. Ke kontaktům nikdy

nepřipojujte vodivé předměty. Postupujte podle návodu na čištění v kapitole o údržbě.

Před kontrolou vždy demontujte sondu RSP2 nebo SFP1 z hlavice. Nikdy se nedívejte přímo do apertury laseru s označením ‡, dokud je těleso

sondy RSP2 nebo SFP1 stále připojené ke snímací hlavici.

V nepravděpodobném případě zlomení stopky držáku doteku, aniž by se přerušilo chráněné spojení mezi sondou a držákem doteku, existuje

malé riziko vystavení se laserovému záření třídy 3R z malého otvoru ve zlomené stopce držáku doteku. Přímý pohled může způsobit trvalé

poškození zraku a je nutné se mu vyhnout. Správný postup pro případ zlomení je vyhnout se přímému pohledu na jakýkoliv vyzářený nebo

odražený laserový paprsek a stisknout tlačítko nouzového zastavení na ruční řídicí jednotce, aby se zabránilo nečekanému pohybu stroje.

Následně ručně demontujte sondu a držák doteku z hlavice REVO‐2. Potom je třeba ručně odsunout stroj od součásti a vyhodnotit poškození.

Za žádných okolností se nepokoušejte poškozený držák doteku opravit nebo znovu použít. Kontaktujte svého dodavatele.

Sonda RSP2 V2 – laserové záření třídy 1

Prvky označené v textu symbolem ‡ najdete na následujících obrázcích. Ujistěte se, že všem bezpečnostním pokynům zcela rozumíte. Je třeba

se důkladně obeznámit se součástmi systému REVO‐2.

Bezpečnostní vyobrazení k sondě RSP2 V2 třídy 1

Tato verze sondy RSP2 je klasifikována jako laserový výrobek třídy 1 podle normy EN 60825‐1:2014.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

44

Page 45

Význam značek

‡ Optické okénko

Těleso sondy RSP2 V2 obsahuje integrované laserové zdroje třídy 3B, proto se nesmí používat v případě vážného poškození nebo prasknutí

kterékoliv části výrobku. V takových případech OKAMŽITĚ odpojte napájecí zdroj, poškozený díl demontujte a zajistěte, že nebude dále

používán. Kontaktujte svého dodavatele.

Před kontrolou vždy demontujte sondu RSP2 V2 z hlavice.

Je‐li držák doteku demontován ručně nebo v důsledku nadměrného přejetí, je paprsek přístupný přes optické okénko označené na obrázku

symbolem ‡. Za běžných okolností bude laser při demontáži držáku doteku automaticky vypnut na ochranu před rizikem případného

rozptýlení.

UPOZORNĚNÍ: Držák doteku je třeba vyměnit co nejdříve.

Vyzařování LED diod u sondy RSP3‐x

Skenovací sonda RSP3 obsahuje integrované velmi výkonné diodové zdroje, které nesmějí být použity v případě vážného poškození nebo

prasknutí kterékoliv části sondy RSP3‐x. V takových případech OKAMŽITĚ odpojte napájecí zdroj, poškozený díl demontujte a zajistěte, že

nebude dále používán. Kontaktujte svého dodavatele.

RCP TC-2 a RCP TC-3

Dodávku výkonu lze přerušit odpojením napájecího kabelu nebo vypnutím napájení.

Vzduchové filtry

Tlak přívodního vzduchu na vstupu ke vzduchovým filtrům by měl být maximálně 8,5 baru. Dodržujte prosím normální bezpečnostní opatření

pro stlačený vzduch.

Provoz a údržba obecně

Výrobek používejte pouze s řídicím systémem UCC S5 společnosti Renishaw.

Doporučuje se odpojit elektrické napájení před prováděním jakýchkoliv operací údržby.

Údržba se omezuje na postupy popsané v kapitole o údržbě.

Pozornost by měla být věnována také tomu, aby nebyla poškozena okénka apertury laseru označená symbolem ‡ umístěná na sondách RSP2,

RSP2 V2 a SFP1 a na dosedacích držácích doteku. Tato okénka jsou vyrobena ze skla a mohla by být příčinou zranění.

UPOZORNĚNÍ: Při použití jiných ovládacích prvků či jiných nastavení nebo při provádění jiných postupů než těch, které jsou zde

uvedeny, můžete být vystaveni nebezpečnému záření.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

45

Page 46

Výstrahy

Dejte pozor na nečekaný pohyb stroje. Uživatel se musí zdržovat mimo pracovní rozsah stroje, zejména mimo místa pohybu snímací hlavice a

doteku. Dodavatel stroje by měl zajistit, aby byl uživatel obeznámen s celým pracovním rozsahem systému.

Při jakékoli práci s obráběcími stroji nebo souřadnicovými měřicími stroji ﴾CMM﴿ je doporučeno používat ochranné brýle.

Povinností dodavatele stroje je informovat uživatele o nebezpečích spojených s provozem i o nebezpečích zmiňovaných v dokumentaci k

produktům společnosti Renishaw a zajistit dostatečné ochranné a bezpečnostní systémy.

Přečtěte si provozní pokyny dodavatele příslušného stroje.

Komponenty systému neobsahují žádné části, jejichž servis by mohl provádět uživatel, s výjimkou RCP TC‐2, RCP TC‐3, RCP2 a FCR25.

Nepokoušejte se demontovat jakoukoliv část výrobku. Setkáte‐li se s problémem, kontaktujte prosím svého dodavatele.

Za určitých okolností může signál sondy nesprávně označovat klidový stav sondy. Nevyužívejte signály sondy jako hlavní impuls pro

zastavování stroje.

Vyřazení sepnutí sondy zabrání zpětnému pohybu stroje v případě kolize sondy.

Spoje sondy jsou navrženy tak, aby uvolnily sondu a/nebo držák doteku v případě kolize.

Toto zařízení není vhodné pro užití v potenciálně výbušném prostředí.

Existuje riziko přiskřípnutí mezi součástmi. Sondu ani snímací hlavici při pohybu nepřidržujte.

V zájmu zachování trvalé bezpečnosti je nezbytné, aby byly všechny pojistky nahrazovány správným typem se správnou hodnotou.

Hlavice se musí přepravovat v obalu dodaném společností Renishaw.

Kabely musí splňovat specifikace společnosti Renishaw. Nesprávná kabeláž může způsobit poškození zařízení.

VÝSTRAHA: Při zapojení hlavy REVO‐2 a při přípravě systému k měření se vyvarujte dotyku sond ﴾včetně protizávaží﴿, držáku

stylusu a ostatních modulů ﴾zelená kontrolka LED﴿.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

46

Page 47

DA - Sikkerhed

FORSIGTIG! Før udpakning og installation af REVO‐2‐systemet skal brugeren omhyggeligt læse nedenstående

sikkerhedsinstruktioner og sørge for, at de altid bliver fulgt af alle, der betjener probesystemet.

RSP2, SFP1 og RSP3 er kun til brug sammen med Renishaw REVO / REVO-2-hovedet.

Operatørerne skal være uddannet i brugen og anvendelsen af REVO / REVO‐2‐systemet og de medfølgende produkter i

forbindelsen med den maskine, det er monteret på, før de får tilladelse til at betjene maskinen.

Der anvendes permanente magneter i visse komponenter i REVO‐2‐systemet og de tilhørende produkter. Det er vigtigt at holde

dem på afstand af komponenter, der kan påvirkes af magnetiske felter, f.eks. datalagringssystemer, pacemakere, ure osv.

Klasse 3R RSP2 og SFP1 laser emissioner

Der er henvisninger til de funktioner, der er indikeret som † og ‡ på illustrationerne nedenfor. Sørg for, at du forstår alle

sikkerhedsinstruktionerne. Det anbefales at gøre sig bekendt med REVO‐2‐systememkomponenterne.

Sikkerhedsillustration til Klasse 3R RSP2 og SFP1

Disse versioner til RSP2 og SFP1 er blevet klassificeret som Klasse 3R laserprodukter i overensstemmelse med EN 60825-1:2007. Denne

klassifikation er baseret på den lasereffekt, der udstråles i det usandsynlige tilfælde, at der sker brud på stylusholderen, som krævet af kriteriet

'single fault' i EN 60825‐1. Medmindre der opstår en sådan fejl, er den udstrålede lasereffekt ubetydelig.

Tast

† Låsekontakter ‡ Laserapparat og optisk vindue

FORSIGTIG! Fjern ikke sikkerhedsmærkaten, som er anbragt på RSP2 og SFP1 probeenheden.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

47

Page 48

Laserudgangssignal:

Maksimal udgangseffekt: < 5 mW

Impulsvarighed: kontinuert bølge

Bølgelængde: 670 nm

Divergens for strålebundt: 2 mrad

RSP2‐ og SFP1‐enhederne indeholder indbyggede Klasse 3B laserkilder og må ikke anvendes i tilfælde af alvorlig beskadigelse af eller brud

på nogen del af produktet. I sådanne tilfælde skal strømkilden OMGÅENDE frakobles, og delene skal fjernes og ikke forsøges genbrugt.

Kontakt leverandøren for at få rådgivning.

Under normal betjening er laserstrålen totalt indesluttet i selve proben og stylusholderen, og der er ikke adgang for brugeren. Fjernelse af

stylusholderen afbryder to sæt låsekontakter angivet som †, så laserstrømmen automatisk afbrydes og forhindrer, at man udsættes for

strålen.

Låsekontakterne skal med passende mellemrum undersøges og kontrolleres, så de er rene og fri for luftbåren kontaminering, f.eks. støv,

snavs eller metalspåner. Under usædvanlige omstændigheder kan en sådan kontaminering forårsage kortslutning af stifterne og derved øge

risikoen for at sende strøm til laseren, uden at der er en stylus monteret. Forbind aldrig ledende genstande til eller mellem kontakterne. Følg

rengøringsanvisningerne i vedligeholdelsesafsnittet.

Før undersøgelse skal RSP2 eller SFP1 altid fjernes fra hovedet. Se aldrig direkte ind i laserblænde, angivet som ‡, mens RSP2‐ eller SFP1‐

enheden fortsat er forbundet til probehovedet.

Hvis det usandsynlige skulle ske, at stylusholderskaftet knækker, uden at låseforbindelsen mellem proben og stylusholderen forskydes, er der

en lille risiko for at blive udsat for klasse 3R laserlys fra åbningen i det knækkede stylusskaft. Synet kan tage skade ved at kigge direkte ind i

den, og det bør undgås. Hvis der skulle ske brud, så undgå at se direkte ind i enhver form for udsendt eller reflekteret laserlys og trykke på

nødstopknappen på håndbetjeningen for at undgå uventet bevægelse. Fjern derefter manuelt proben og stylusholderen fra REVO‐2‐hovedet.

Når dette er gjort, skal maskinen manuelt flyttes fri af delen, og skaden vurderes. Der må under ingen omstændigheder gøres noget forsøg på

at reparere eller genbruge den beskadigede stylusholder. Kontakt leverandøren for at få rådgivning.

Klasse 1 RSP2 V2 laser emissioner

Der er henvisninger til de funktioner, der er indikeret som ‡ på illustrationerne nedenfor. Sørg for, at du forstår alle sikkerhedsinstruktionerne.

Det anbefales at gøre sig bekendt med REVO‐2‐systememkomponenterne.

Sikkerhedsillustration til Klasse 1 RSP2 V2

Denne version af RSP2 er blevet klassificeret som et Klasse 1 laserprodukt i overensstemmelse med EN 60825-1:2014.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

48

Page 49

Tast

‡ Optisk vindue

RSP2 V2‐enheden indeholder indbyggede Klasse 3B laserkilder og ikke må anvendes i tilfælde af alvorlig beskadigelse af eller brud på nogen

del af produktet. I sådanne tilfælde skal strømkilden OMGÅENDE frakobles, og delene skal fjernes og ikke forsøges genbrugt. Kontakt

leverandøren for at få rådgivning.

Før undersøgelse skal RSP2 V2 altid fjernes fra hovedet.

Hvis stylusholderen fjernes manuelt, eller bevæger sig for langt, er der adgang til strålen via det optiske vindue, der er angivet som ‡ på

illustrationen. Under normale omstændigheder slukkes laseren automatisk, når stylusholderen fjernes, for at undgå forvirring.

FORSIGTIG! Stylusholderen skal udskiftes, så snart det er praktisk muligt.

RSP3‐x LED‐stråling

RSP3‐x‐scanningsproben indeholder kraftige LED‐kilder og må ikke anvendes i tilfælde af alvorlig beskadigelse af eller brud på nogen del af

RSP3‐x. I sådanne tilfælde skal du ØJEBLIKKELIG afbryde for strømforsyningen, fjerne og ikke forsøge at genbruge delene. Kontakt

leverandøren for at få rådgivning.

RCP TC-2 og RCP TC-3

Metoden til afbrydelse af strømmen er at frakoble strømkablet eller slukke for strømforsyningen.

Luftfiltre

Lufttrykket ved indgangen til luftfiltrene må maksimalt være 8,5 bar. Overhold de normale sikkerhedsforskrifter for trykluft.

Almindelig betjening og vedligeholdelse

Produktet anvendes kun sammen med Renishaw UCC S5 styringen.

Det anbefales, at afbryde strømmen før udførelse af enhver form for vedligeholdelse.

Vedligeholdelse er begrænset til de procedurer, som er beskrevet i vedligeholdelsesafsnittet.

Pas på, at laserblænde vinduer, angivet med ‡, der findes på RSP2, RSP2 V2, SFP1 og de tilsvarende stylusholdere, ikke bliver beskadigede, da

de er fremstillet af glas og kan forårsage kvæstelser.

FORSIGTIG! Brug af kontrolenheder, justeringsenheder eller ydelsesprocedurer ud over dem, som er angivet heri, kan bevirke, at

man udsættes for farlig stråling.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

49

Page 50

Advarsler

Pas på uventede bevægelser. Brugeren bør holde sig uden for hele probehovedets og stylus arbejdsområde. Maskinleverandøren

bør sikre, at brugeren er bekendt med systemets fulde arbejdsområde.

Pas på uventede bevægelser. Brugeren bør holde sig uden for hele probehovedets og stylus arbejdsområde. Maskinleverandøren bør sikre, at

brugeren er bekendt med systemets fulde arbejdsområde.

I alle tilfælde, hvor der anvendes værktøjs‐ og koordinatmålemaskiner, anbefales det at bære beskyttelsesbriller.

Det er maskinleverandørens ansvar at sikre, at brugeren er bekendt med eventuelle risici i forbindelse med driften, herunder de risici, som er

nævnt i Renishaws produktdokumentation, og at sikre, at der er tilstrækkelig afskærmning af sikkerhedsblokeringer.

Se maskinleverandørens brugervejledning.

Systemkomponenterne indeholder ingen dele, der kan serviceres af brugeren, med undtagelse af RCP TC-2, RCP TC-3, RCP2 og FCR25.

Adskillelse af nogen del af produktet bør ikke forsøges. Kontakt leverandøren for at få assistance, hvis der opstår et problem.

Under visse omstændigheder kan sondesignalet ved en fejl angive, at sonden står stille. Stol ikke på, at probesignaler vil stoppe maskinens

bevægelse.

Tilsidesættelse af probetriggeren forhindrer maskinen i at køre tilbage i tilfælde af probekollision.

Probesamlingerne er designet til at frigøre proben og/eller stylusholderen i tilfælde af sammenstød.

Dette udstyr er uegnet til brug i en atmosfære med eksplosionsfare.

Der er risiko for at komme i klemme mellem delene. Hold ikke proben eller probehovedet under bevægelse.

Det er vigtigt for den forsatte sikkerhed, at alle sikringer skiftes ud med en af samme type og samme nominelle effekt.

Hovedet skal transporteres i Renishaws medfølgende emballage.

Kablerne skal opfylde Renishaw's specifikationer. Forkert kabelføring kan forårsage skade på udstyret.

ADVARSEL: Undgå at berøre sensorerne ﴾inkl. balanceringsarme﴿, penneholder og andre moduler, når REVO‐2‐hovedet er sluttet

til ﴾servo‐LED lyser grøn﴿, og systemet er klar til måling.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

50

Page 51

DE - Sicherheitshinweise

ACHTUNG: Lesen sie bitte sorgfältig vor dem Auspacken und Installieren des REVO‐2‐Systems die folgenden Sicherheitshinweise

und sorgen Sie dafür, dass diese auch von allen Anwendern beachtet werden.

RSP2, RSP2 V2, SFP1 und RSP3‐x Tastermodule dürfen nur mit dem REVO / REVO‐2 Messkopf von Renishaw verwendet werden.

Vor der Bedienung der Maschine müssen alle Maschinenbediener über Gebrauch und Anwendung des Messsystems REVO /

REVO‐2 und der zugehörigen Produkte in Verbindung mit der damit ausgerüsteten Maschine geschult werden.

In einigen Bauteilen des REVO‐2‐Systems und einigen zugehörigen Produkten sind Permanentmagneten eingebaut. Wichtig!

Halten Sie diese von Geräten fern, die durch Magnetfelder beeinträchtigt werden können, wie z. B. Datenspeicher,

Herzschrittmacher, Uhren usw.

RSP2 und SFP1 Laserstrahlungen der Klasse 3R

In den nachfolgenden Abbildungen wird auf bestimmte Eigenschaften ﴾gekennzeichnet durch † und ‡﴿ verwiesen. Achten Sie darauf, dass Sie

sämtliche Sicherheitshinweise verstehen. Es wird empfohlen, dass Sie sich mit den Systemkomponenten des REVO‐2‐Systems vertraut

machen.

Sicherheitsmerkmale RSP2 und SFP1 - Laserprodukte der Klasse 3R

Diese Versionen des RSP2 und SFP1 entsprechen gemäß DIN EN 60825‐1:2007 der Laserklasse 3R. Die Einstufung basiert auf der

Strahlungsleistung, die im unwahrscheinlichen Fall eines Bruchs des Tastereinsatzhalters abgegeben würde, gemäß den „Einzelfehler“‐

Kriterien in EN 60825-1. Diese abgegebene Strahlungsleistung ist bei Nichteintreten eines solchen Fehlers unwesentlich.

Taste

† Verriegelungskontakte ‡ Laseröffnung und optisches Fenster

ACHTUNG: Niemals die Sicherheits‐Warnaufkleber am Gehäuse des RSP2 bzw. SFP1 entfernen.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

51

Page 52

Ausgangsleistung des Lasers

Maximale Ausgangsleistung: < 5 mW

Pulsdauer: kontinuierliche Welle

Wellenlänge: 670 nm

Strahldivergenz: 2 mrad

Die RSP2 und SFP1 Gehäuse enthalten eingebettete Laserquellen der Klasse 3B und sollten im Falle einer größeren Beschädigung bzw. Bruch

eines Teils des Produkts nicht mehr verwendet werden. Unterbrechen Sie in einem solchen Fall SOFORT die Stromzufuhr und entfernen Sie

die Teile; sie dürfen nicht wiederverwendet werden. Wenden Sie sich an Ihren Lieferanten, um Hilfe zu erhalten.

Unter normalen Betriebsbedingungen ist der Laserstrahl vollständig in der Tasteraufnahme und im Tastereinsatzhalter eingeschlossen und für

den Anwender nicht zugänglich. Beim Entfernen des Tastereinsatzhalters werden zwei Verriegelungskontakte [gekennzeichnet durch †]

unterbrochen, wodurch die Spannungsversorgung des Lasers automatisch abgeschaltet und ein Austreten der Laserstrahlung verhindert wird.

In geeigneten Zeitabständen sollten die Verriegelungskontakte überprüft werden. Stellen Sie sicher, dass diese sauber und frei von Staub,

Spänen und sonstigen Verunreinigungen sind. In seltenen Fällen kann eine solche Verschmutzung zu einem Kurzschluss an den Stiften

führen. Dies erhöht das Risiko, dass Strom zum Laser fließt, obwohl kein Tastereinsatzhalter befestigt ist. Bringen Sie niemals leitende

Gegenstände an oder zwischen die Kontakte. Beachten Sie die Anweisungen für die Reinigung im Abschnitt "Instandhaltung".

Entfernen Sie, vor einer Inspektion, immer den RSP2 bzw. SFP1 vom REVO‐2 Messkopf. Sehen Sie niemals direkt in die Laseröffnung

﴾Laseröffnung durch ‡, gekennzeichnet﴿, solange der RSP2 bzw. SFP1 noch mit dem Messkopf verbunden ist.

In dem unwahrscheinlichen Fall, dass der Schaft des Tastereinsatzhalters brechen sollte, ohne dass die Verriegelung zwischen dem Messtaster

und dem Tastereinsatzhalter gelöst wird, besteht eine geringe Gefahr einer Bestrahlung mit Laserlicht der Klasse 3R aus der Auslassöffnung

des gebrochenen Tastereinsatzschafts. Ein direkter Augenkontakt mit dem Strahl kann zu einer dauerhaften Schädigung des Sehvermögens

führen und sollte vermieden werden. Sollte es zu einem Bruch kommen, vermeiden Sie es, direkt in das ausgestrahlte oder reflektierte

Laserlicht zu sehen und drücken Sie die Not‐Aus‐Taste an der MCU5 Handsteuerung, um eine unerwartete Bewegung zu verhindern.

Entfernen Sie dann von Hand den Messtaster und Tastereinsatzhalter vom REVO‐2 Messkopf. Anschließend sollte die Maschine ebenfalls

manuell vom Werkstück verfahren und der Schaden untersucht werden. Unter keinen Umständen sollten Versuche unternommen werden,

den beschädigten Tastereinsatzhalter zu reparieren oder wiederzuverwenden. Wenden Sie sich an Ihren Lieferanten, um Hilfe zu erhalten.

Klasse 1 RSP2 V2 Laserstrahlungen

In den nachfolgenden Abbildungen wird auf bestimmte Eigenschaften ﴾gekennzeichnet durch ‡﴿ verwiesen. Achten Sie darauf, dass Sie

sämtliche Sicherheitshinweise verstehen. Es wird empfohlen, dass Sie sich mit den Systemkomponenten des REVO‐2‐Systems vertraut

machen.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

52

Page 53

Sicherheitsmerkmale – Klasse 1 RSP2 V2

Diese Version des RSP2 wurde als Laserprodukt der Klasse 1, gemäß der Norm EN 60825‐1:2014, eingestuft.

Taste

‡ Optische Fenster

Das RSP2 V2 Gehäuse enthält eingebettete Laserquellen der Klasse 3B und sollte im Falle einer größeren Beschädigung bzw. Bruch eines Teils

des Produkts nicht mehr verwendet werden. Unterbrechen Sie in einem solchen Fall SOFORT die Stromzufuhr und entfernen Sie die Teile; sie

dürfen nicht wiederverwendet werden. Wenden Sie sich an Ihren Lieferanten, um Hilfe zu erhalten.

Entfernen Sie, vor einer Inspektion, immer den RSP2 V2 vom REVO Messkopf.

Beim manuellen Entfernen des Tastereinsatzhalters wird der Strahl über das optische Fenster zugänglich, wie in der Abbildung

﴾gekennzeichnet durch ‡﴿ dargestellt. Unter normalen Umständen wird der Laser beim Entfernen des Tastereinsatzhalters automatisch

abgeschaltet, um das Risiko von Laserstreustrahlung zu vermeiden.

ACHTUNG: Der Tastereinsatzhalter sollte so schnell wie praktisch durchführbar ausgewechselt werden.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

53

Page 54

RSP3-x LED-Emissionen

Der RSP3‐x Scantaster enthält eingebettete Hochleistungs‐LEDs und sollte im Falle einer größeren Beschädigung bzw. Bruch eines Bauteils

des RSP3-x nicht mehr verwendet werden. Unterbrechen Sie in einem solchen Fall SOFORT die Stromzufuhr und entfernen Sie die Teile; sie

dürfen nicht wiederverwendet werden. Wenden Sie sich an Ihren Lieferanten, um Hilfe zu erhalten.

RCP TC-2 und RCP TC-3

Zur Unterbrechung der Spannungsversorgung sollte das Netzkabel entfernt oder der Strom abgeschaltet werden.

Luftfilter

Der Druck der Luftzufuhr am Luftfiltereingang darf maximal 8,5 bar betragen. Bitte beachten Sie die üblichen Sicherheitsvorkehrungen für

Druckluft.

Allgemeiner Betrieb und Wartung

Das Produkt darf nur mit der UCC S5 Steuerung von Renishaw verwendet werden.

Es wird empfohlen, die Stromversorgung vor der Durchführung jeglicher Wartungsarbeiten, zu unterbrechen.

Die Wartungsarbeiten beschränken sich auf die im Abschnitt "Wartung" beschriebenen Maßnahmen.

Achten Sie darauf, dass die Fenster der Laseröffnung ﴾gekennzeichnet durch ‡﴿ am RSP2, RSP2 V2, SFP1 und den passenden

Tastereinsatzhaltern nicht beschädigt werden. Sie sind aus Glas und können zu Verletzungen führen.

ACHTUNG: Eine anderweitige Benutzung der Steuerungen oder Einstellungen oder das Anwenden anderer Verfahren als die hier

beschriebenen kann zum Austritt gefährlicher Strahlung führen.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

54

Page 55

Warnhinweise

Vorsicht vor unerwarteten Bewegungen. Der Anwender darf sich nur außerhalb des Messtaster‐Arbeitsbereiches aufhalten. Der

Maschinenlieferant muss sicherstellen, dass sich der Anwender über den vollen Arbeitsbereich des Systems bewusst ist.

Bei Arbeiten an Koordinatenmessgeräten und Werkzeugmaschinen wird ein Augenschutz empfohlen.

Es obliegt dem Maschinenlieferanten, den Anwender über alle Gefahren, die sich aus dem Betrieb der Ausrüstung, einschließlich der, die in der

Renishaw Produktdokumentation erwähnt sind, zu unterrichten und sicherzustellen, dass ausreichende Schutzvorrichtungen und

Sicherheitsverriegelungen eingebaut sind.

Beachten Sie auch die Bedienungsanleitung des Maschinenlieferanten.

Die Systemkomponenten, mit Ausnahme von RCP TC-2, RCP TC-3, RCP2 und FCR25, enthalten keine Teile, die durch den Anwender gewartet

werden können. Versuchen Sie nicht, einzelne Bauteile des Produkts zu demontieren. Im Falle eines Problems fordern Sie bitte Hilfe bei Ihrem

Lieferanten an.

Es kann passieren, dass der Messtaster fälschlicherweise eine Ruhestellung signalisiert. Verlassen Sie sich nicht alleine auf das

Messtastersignal, um Maschinenbewegungen zu stoppen.

Die Übersteuerung der Messtasterauslenkung verhindert ein Rücksetzen der Maschine im Falle einer Kollision des Messtasters.

Die Messtasteranschlüsse sind so konzipiert, dass der Messtaster und/oder der Tastereinsatzhalter im Falle eines Zusammenstoßes abgelöst

werden.

Dieses System darf nicht in potenziell explosiver Atmosphäre verwendet werden.

Zwischen Bauteilen besteht Einklemmgefahr. Der Messtaster und der Messkopf dürfen während des Betriebs nicht berührt oder festgehalten

werden.

Aus Sicherheitsgründen dürfen nur die empfohlenen Sicherungen ﴾Typ und Leistung﴿ verwendet werden.

Der Messkopf darf nur in der von Renishaw gelieferten Verpackung transportiert werden.

Die Kabel müssen den Spezifikationen von Renishaw entsprechen. Eine falsche Verkabelung kann zu Schäden am System führen.

WARNUNG: Berühren Sie die Messtaster ﴾einschließlich Ausgleichsarmen﴿, Tastereinsatzhalter und anderen Module nicht, wenn

der REVO‐2 Kopf eingeschaltet ﴾grüne Servo‐LED﴿ und das System messbereit ist.

REVO-2 user's guide

www.renishaw.com

Issued 07 2019

55

Page 56

EL ‐ Ασφάλεια

ΠΡΟΣΟΧΗ: Πριν από την αποσυσκευασία κι εγκατάσταση του συστήματος REVO‐2, ο χρήστης πρέπει να διαβάσει προσεκτικά

τις οδηγίες ασφαλείας που ακολουθούν και να διασφαλίσει ότι θα εφαρμόζονται πάντοτε από όλους τους χειριστές του

συστήματος.

Τα RSP2, RSP2 V2, SFP1 και RSP3‐x πρέπει να χρησιμοποιούνται μόνο με την κεφαλή REVO / REVO‐2 της Renishaw.

Οι χειριστές πρέπει να είναι εκπαιδευμένοι στη χρήση και εφαρμογή του συστήματος αισθητήρα REVO / REVO‐2 και των

συνοδευτικών προϊόντων, σε σχέση με το μηχάνημα στο οποίο τοποθετείται, για να τους επιτραπεί να χρησιμοποιήσουν το

συγκεκριμένο μηχάνημα.

Σε ορισμένα εξαρτήματα του συστήματος REVO‐2 και των σχετικών προϊόντων χρησιμοποιούνται μόνιμοι μαγνήτες. Είναι

σημαντικό να κρατάτε τους μαγνήτες μακριά από στοιχεία που μπορεί να επηρεαστούν από μαγνητικά πεδία, π.χ. συστήματα

αποθήκευσης δεδομένων, βηματοδότες, ρολόγια, κ.λπ.

Εκπομπές λέιζερ των 3R RSP2 και SFP1