Page 1

Installation and user’s guide

M-9904-1122-09-A

RCU10 quadrature compensation unit

Page 2

Document information

Document number: M-9904-1122-09-A

Issue date: 03 2019

© 2004-2019 Renishaw plc. All rights reserved.

Care of equipment

The Renishaw RCU10 compensation system and

associated products are precision instrumentation

products and components and must therefore be

treated with care.

Changes to Renishaw products

Renishaw plc reserves the right to improve,

change or modify its products and documentation

without incurring any obligation to make changes

to Renishaw equipment previously sold or

distributed.

Disclaimer

RENISHAW HAS MADE CONSIDERABLE

EFFORTS TO ENSURE THE CONTENT OF

THIS DOCUMENT IS CORRECT AT THE

DATE OF PUBLICATION BUT MAKES NO

WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW

EXCLUDES LIABILITY, HOWSOEVER

ARISING, FOR ANY INACCURACIES IN THIS

DOCUMENT.

Trademarks

RENISHAW® and the probe emblem used in the

RENISHAW logo are registered trademarks of

Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

All other brand names and product names used

in this document are trade names, service marks,

trademarks, or registered trademarks of their

respective owners.

Safety

This manual gives recommendations for the

safe installation and configuration of the RCU10

compensator system, and associated ancillary

products.

It is the sole responsibility of the OEM/retrofit

company to ensure that, in safety critical

applications, any failure or deviation from

expected operation of this product, howsoever

caused, shall not cause the machine to become

unsafe.

It is the machine supplier’s responsibility to

ensure that the user is made aware of any

hazards that may be involved in the operation

of their machine, including those covered in

Renishaw product documentation, and to ensure

that adequate guards and safety interlocks are

provided.

This manual suggests a number of safety

measures that can be included in machine

design. However, it is the sole responsibilty of the

OEM/system integrator to specify and integrate

measures suitable for the application.

Symbol definition

The following symbol is used in this manual and

in the software to indicate areas requiring special

attention:

WARNING: Information that is vital for

!

Warranty

Renishaw plc warrants its equipment provided

that it is installed and operated exactly as defined

in associated Renishaw documentation.

Claims under warranty must be made from

authorised service centres only, which may be

advised by the supplier or distributor.

FCC

This device complies with part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

This equipment has been tested and found

to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference when

the equipment is operated in a commercial

environment. This equipment generates, uses,

and can radiate radio frequency energy and,

if not installed and used in acordance with

the instruction manual, may cause harmful

interference to radio communications. Operation

of this equipment in a residential area is likely to

cause harmful interference in which case the user

will be required to correct the interference at his

own expense.

The user is cautioned that any changes or

modifications not expressly approved by

Renishaw plc or authorized representative could

void the user’s authority to operate the equipment.

EC compliance

Renishaw plc declares that the RCU10

compensator system and transmitters comply

with the applicable directives, standards and

regulations. A copy of the full EC Declaration of

Conformity is available at the following address:

www.renishaw.com/RLECE

the safe installation and operation of the

RCU10 system.

Page 3

WEEE

The use of this symbol on Renishaw products

and/or accompanying documentation indicates

that the product should not be mixed with

general household waste upon disposal. It is the

responsibility of the end user to dispose of this

product at a designated collection point for waste

electrical and electronic equipment (WEEE) to

enable reuse or recycling. Correct disposal of

this product will help to save valuable resources

and prevent potential negative effects on the

environment. For more information, please

contact your local waste disposal service or

Renishaw distributor.

Battery disposal

REACH

Information required by Article 33(1) of

Regulation (EC) No. 1907/2006 (“REACH”)

relating to products containing substances of very

high concern (SVHCs) is available at:

www.renishaw.com/REACH

RoHS compliance

Compliant with EC directive 2011/65/EU (RoHS).

The use of this symbol on the batteries,

packaging or accompanying documents indicates

that used batteries should not be mixed with

general household waste. Please dispose of

the used batteries at a designated collection

point. This will prevent potential negative effects

on the environment and human health which

could otherwise arise from inappropriate waste

handling. Please contact your local authority or

waste disposal service concerning the separate

collection and disposal of batteries. All lithium and

rechargeable batteries must be fully discharged

or protected from short circuiting prior to disposal.

Packaging

Packaging

components

Outer box Cardboard -

Insert Cardboard -

Material 94/62/EC

code

PA P 20

70% recycled

material

PA P 20

70% recycled

material

94/62/EC

number

Bags Low density

polyethylene

LDPE 4

Page 4

General safety notice i

General safety notice

The Renishaw laser encoder and compensator systems are designed for integration into

the primary position feedback loop of a motion system. It is essential that the system is

installed in accordance with the instructions in the installation guide and it is the

responsibility of the system integrator to ensure that, in the event of a failure of any part of

the Renishaw system, the motion system remains safe.

In the case of motion systems with powers or speeds capable of causing injury, it is

essential that appropriate safety protection measures are included in the machine design.

Further guidance on this can be found in the European Standard EN292 “Safety of

machinery – Basic concepts, general principles for design”. It is the sole responsibility of

the OEM/system integrator to select the safety measures appropriate for their application.

The following is a list of measures that should be considered as part of that process.

1. The Renishaw system includes an Error signal output. The control system must be

designed to stop the axis motion if this error output is asserted. In addition to the

Error signal, the position feedback signals can also be configured to go tristate

(open circuit) under fault conditions. Some controllers can be programmed to detect

this, thereby providing a further level of protection in case of failure of the error

signal output (see item 3 below). If the controller is not capable of detecting open

circuit position feedback signals, this option must not be enabled.

2. The axis must include physical limit switches which, when tripped, will stop axis

motion before damage occurs (soft limits alone are insufficient). Note that in the

case of thermally compensated systems, positional corrections of several hundred

ppm are possible. This should be taken into account when defining the relative

positions of soft and hard axis limits.

3. Cable breakage detection (encoder disconnect). The position feedback and Error

signal lines are all provided as differential line driven pairs. Failure in the cable or

failure of the line drivers can be detected by checking that these differential pairs are

always being driven in opposing states. If the lines are not in opposing states, the

motion must be stopped.

4. Motor torque monitoring. If the motor torque exceeds an expected limit, the axis of

motion must be stopped.

5. The machine must include an emergency stop button.

6. Following error detection, if the difference between the controller demand position

and the axis feedback position exceeds an expected limit, then the axis motion must

be stopped.

7. Guards, viewing windows, covers and interlocks may be used to prevent user

access to hazardous areas, and to contain ejected parts or materials.

8. If the machine includes an independent tacho (velocity) feedback system, this

should be cross-checked with the position feedback. For example, if the tacho

indicates the axis is moving, but the position feedback doesn’t, then the axis motion

must be stopped.

Page 5

ii General safety notice

9. In the case of synchronised parallel motion systems (for example twin rail gantry

drive systems), the relative positions of master and slave axes should be monitored.

If the difference in their positions exceeds an expected limit, then axis motion must

be stopped.

Note: In the case of measures 6 – 9, the limits need to be selected carefully depending on

the application and the type of position compensation selected to avoid false alarms.

For further advice consult the appropriate machinery safety standards.

Page 6

Contents iii

Contents

Section 1 System overview

1.1 Introduction ............................................................................................................ 1-2

1.2 System overview ................................................................................................... 1-2

1.3 Compensation functions ........................................................................................ 1-4

1.3.1 Scale factor ............................................................................................... 1-4

1.3.2 Air refractive index compensation ............................................................. 1-4

1.3.3 Encoder thermal expansion compensation ............................................... 1-5

1.3.4 Workpiece thermal expansion compensation ........................................... 1-5

1.3.5 Structure thermal compensation ............................................................... 1-7

1.4 Operational functions ............................................................................................. 1-8

1.4.1 Selectable parameter tables ..................................................................... 1-8

1.4.2 Compensation buffering ............................................................................ 1-8

1.5 System components .............................................................................................. 1-9

1.6 Installation procedure overview ........................................................................... 1-11

Section 2 System design

2.1 Requirements ........................................................................................................ 2-2

2.2 Sensors and sensor networks ............................................................................... 2-3

2.2.1 Environment sensors................................................................................. 2-3

2.2.2 Sensor network connection ....................................................................... 2-4

2.3 Electrical connections ............................................................................................ 2-5

2.3.1 Connector positions................................................................................... 2-5

2.3.2 Connector functions .................................................................................. 2-6

J1 – 24 V dc power .................................................................................... 2-6

J2 – Controller output ................................................................................ 2-6

J3 – Encoder input .................................................................................... 2-6

J4 – Reference switch port ........................................................................ 2-7

J7 – Auxiliary I/O ....................................................................................... 2-8

J8 – PC port .............................................................................................. 2-9

2.4 Velocity/resolution/bandwidth considerations ........................................................ 2-9

2.4.1 Encoder input frequency ......................................................................... 2-10

2.4.2 Output frequency ..................................................................................... 2-10

2.5 Referencing ......................................................................................................... 2-12

2.5.1 Signal format and re-synchronisation ...................................................... 2-12

2.5.2 Referencing options ................................................................................ 2-14

2.6 RCU10 component mounting .............................................................................. 2-17

2.6.1 RCU10-XX-XX or RCU10-PX-XX ........................................................... 2-17

2.6.2 Air temperature sensor ............................................................................ 2-18

2.6.3 Material temperature sensor ................................................................... 2-19

2.6.4 Sensor distribution box ............................................................................ 2-20

Section 3 Kit configuration and part identification

3.1 Defining kit numbers .............................................................................................. 3-2

3.2 Kit numbers and part identification ........................................................................ 3-3

3.2.1 RCU10 kit numbers (laser encoder based systems) ................................ 3-3

3.2.2 RCU10 kit numbers (non-laser encoder based systems) ......................... 3-4

3.3 Additional components and part identification ....................................................... 3-5

Page 7

iv Contents

Section 4 System installation

4.1 System installation ................................................................................................. 4-2

4.1.1 Hardware installation and initial power-up ................................................ 4-2

4.1.2 RCU10 address set-up .............................................................................. 4-2

4.1.3 Electrical ins ta llation .................................................................................. 4-4

4.1.4 RCU CS settings ....................................................................................... 4-4

4.2 System configuration ............................................................................................. 4-5

4.2.1 System configuration ................................................................................. 4-6

4.2.2 Sensor network configuration .................................................................... 4-7

4.2.3 Compensation settings configuration ........................................................ 4-8

4.2.4 Parameter settings configuration ............................................................. 4-13

4.2.5 Transmitting the configuration ................................................................. 4-15

4.3 Configuration validation ....................................................................................... 4-16

Section 5 Controller integration

5.1 Introduction ............................................................................................................ 5-2

5.2 Safety function testing ........................................................................................... 5-2

5.2.1 Encoder error testing ................................................................................. 5-2

5.2.2 RCU10 error testing................................................................................... 5-3

5.2.3 Testing environment sensors .................................................................... 5-5

5.2.4 Auxiliary I/O connector input functions ...................................................... 5-6

5.2.5 Reference mark connector function .......................................................... 5-8

5.2.6 Encoder considerations ............................................................................. 5-9

5.2.7 Integration procedure .............................................................................. 5-10

5.2.8 Making corrections .................................................................................. 5-10

5.2.9 Closing the control loop ........................................................................... 5-11

5.2.10 Motor drive tuning .................................................................................... 5-11

5.2.11 Referencing the system ........................................................................... 5-12

Section 6 Operation

6.1 Standard operation ................................................................................................ 6-2

6.2 RCU CS status during operation ........................................................................... 6-2

6.2.1 Compensation display ............................................................................... 6-3

6.2.2 Sensor display ........................................................................................... 6-4

6.2.3 Diagnostics display .................................................................................... 6-5

6.3 General maintenance ............................................................................................ 6-6

Appendix A RCU10 system specifications

A.1 RCU10 system performance ................................................................................. A-2

A.2 Component performance ....................................................................................... A-4

A.2.1 Compensation unit..................................................................................... A-4

A.2.2 Air sensor .................................................................................................. A-5

A.2.3 Material sensor .......................................................................................... A-5

A.2.4 Pressure sensor ........................................................................................ A-5

Page 8

Contents v

Appendix B Connector pinout and hardware installation details

B.1 Introduction ........................................................................................................... B-2

B.2 24 V dc power (J1) ................................................................................................ B-2

B.2.1 Connector pinout ....................................................................................... B-2

B.2.2 Wiring requirements .................................................................................. B-3

B.3 Controller output (J2) ............................................................................................. B-4

B.3.1 Digital feedback signals ............................................................................ B-4

B.3.1.1 Connector pinout ....................................................................... B-4

B.3.1.2 Wiring requirements .................................................................. B-5

B.3.2 Analogue feedback signals ....................................................................... B-6

B.3.2.1 Connector pinout ....................................................................... B-6

B.3.2.2 Wiring requirements .................................................................. B-7

B.4 Encoder input (J3) ................................................................................................. B-8

B.4.1 Connector pinout ....................................................................................... B-8

B.4.2 Wiring requirements .................................................................................. B-9

B.5 Reference switch port (J4) ................................................................................... B-10

B.5.1 Connector pinout ..................................................................................... B-10

B.5.2 Wiring requirements ................................................................................ B-10

B.6 Auxiliary I/O (J7) .................................................................................................. B-11

B.6.1 Connector pinout ..................................................................................... B-11

B.6.2 Wiring requirements ................................................................................ B-11

B.7 PC port (J8) ......................................................................................................... B-13

B.7.1 Connector pinout ..................................................................................... B-13

B.7.2 Wiring requirements ................................................................................ B-13

B.8 Fastlink port ......................................................................................................... B-14

B.9 Sensors (J5, J6) .................................................................................................. B-14

B.9.1 Connector pinout ..................................................................................... B-14

B.9.2 Wiring requirements ................................................................................ B-15

Appendix C RCU CS

C.1 RCU CS ................................................................................................................. C-2

C.1.1 Overview ................................................................................................... C-2

C.1.2 Access levels ............................................................................................. C-2

C.1.3 Operating modes ....................................................................................... C-3

C.1.4 Configuration data ..................................................................................... C-4

C.2 RCU CS installation ............................................................................................... C-5

C.2.1 System requirements ................................................................................ C-5

C.2.2 Installation procedure ................................................................................ C-6

C.2.3 Screen layout ............................................................................................ C-7

Appendix D Compensation system status information and diagnostics

D.1 Diagnostics ............................................................................................................ D-2

D.1.1 Process overview ...................................................................................... D-2

D.2 Error descriptions .................................................................................................. D-3

D.3 RCU CS information screens ................................................................................ D-4

D.3.1 Compensation system screen ................................................................... D-4

D.3.2 Compensation axis screen ........................................................................ D-8

D.3.3 Sensor data screen ................................................................................... D-9

D.3.3.1 Individual “View status” screen ............................................... D-10

Page 9

vi Contents

D.3.4 Diagnostics ............................................................................................. D-13

D.3.4.1 System status screen .............................................................. D-13

D.3.4.2 RCU diagnostics screen (top display) ..................................... D-14

D.3.4.3 RCU diagnostics – Configuration tab ...................................... D-15

D.3.4.4 Axis diagnostics – Compensation tab ..................................... D-17

D.3.4.5 Axis diagnostics – Communication tab .................................... D-19

D.3.4.6 Axis diagnostics – Sensors tab ............................................... D-21

Appendix E Commissioning tests

E.1 System performance testing .................................................................................. E-2

E.1.1 Prerequisites .............................................................................................. E-2

E.1.2 Test 1 – Linear compensation (air refractive index or encoder scale

compensation) ........................................................................................... E-3

E.1.3 Test 2 – Workpiece thermal expansion compensation ............................. E-4

E.1.4 Test 3 – Workpiece thermal expansion at higher temperatures ............... E-5

E.1.5 Test 4 – Workpiece temperature change at material reference position .. E-5

E.1.6 Test 5 – Static workpiece temperature change at distance ...................... E-6

Appendix F Extended capability

F.1 Extended RCU10 system capability ...................................................................... F-2

F.1.1 Extended system capability ....................................................................... F-2

F.1.2 Extended system status monitoring .......................................................... F-2

F.1.2.1 Extended status monitoring ....................................................... F-2

F.1.3 Axis referencing with extended error lines ................................................ F-4

F.1.4 Controlling workpiece compensation from motion control system output

lines ........................................................................................................... F-5

F.1.4.1 Introduction ................................................................................ F-5

F.1.4.2 Enabling workpiece compensation ............................................ F-5

F.1.4.3 Disabling workpiece compensation ........................................... F-5

F.1.4.4 Suspending workpiece compensation ....................................... F-6

F.1.4.5 Multiple fixturing with workpiece compensation ........................ F-6

F.1.5 Parameter table selection .......................................................................... F-7

F.1.6 Compensation buffering ............................................................................ F-8

F.1.7 Configuration of advanced features .......................................................... F-8

F.1.7.1 Multiple parameter tables .......................................................... F-8

F.1.7.2 Operating with multiple parameter tables .................................. F-9

F.2 RCU CS – Additional functionality ....................................................................... F-12

F.2.1 Additional RCU CS configuration functionality ........................................ F-12

F.2.1.1 Saving the configuration .......................................................... F-12

F.2.1.2 Loading a configuration ........................................................... F-13

F.2.1.3 Setting the PC communication port ......................................... F-14

F.2.1.4 Configuring passwords ............................................................ F-15

F.2.1.5 Logging in as new user............................................................ F-16

F.2.1.6 Rebooting the RCU ................................................................. F-16

F.2.2 Data logging ............................................................................................ F-18

F.2.3 Error logging ............................................................................................ F-20

F.2.3.1 Error log descriptions ............................................................... F-25

Page 10

Contents vii

Appendix G Reference

G.1 Compensation equation overview ........................................................................ G-2

G.1.1 Encoder compensation............................................................................. G-2

G.1.1.1 Definition of position terms ........................................................ G-2

G.1.1.2 Definition of compensation terms .............................................. G-3

G.1.2 Laser compensation ................................................................................. G-5

G.1.2.1 Definition of position terms ........................................................ G-5

G.1.2.2 Definition of compensation terms .............................................. G-6

G.2 Air refraction compensation .................................................................................. G-9

G.3 Worked example – laser compensation ............................................................. G-11

G.3.1 Direction sense setting ........................................................................... G-11

G.3.2 Laser dead path (LO) ............................................................................. G-12

G.3.3 Workpiece thermal expansion compensation (α

G.3.4 Machine structure thermal expansion compensation (T

, Twc, WO).................. G-12

w

, S) ................ G-12

sc

Appendix H Test records

H.1 Installation and configuration checklist .................................................................. H-2

H.2 Installation details .................................................................................................. H-3

H.3 Sensor record/test sheet ....................................................................................... H-5

H.4 Parameter table record sheets .............................................................................. H-7

Page 11

viii Contents

This page is intentionally left blank.

Page 12

System overview 1-1

Section 1

System overview

Contained in this section

1.1 Introduction ............................................................................................................ 1-2

1.2 System overview .................................................................................................... 1-2

1.3 Compensation functions ........................................................................................ 1-4

1.3.1 Scale factor ............................................................................................... 1-4

1.3.2 Air refractive index compensation ............................................................. 1-4

1.3.3 Encoder thermal expansion compensation ............................................... 1-5

1.3.4 Workpiece thermal expansion compensation ........................................... 1-5

1.3.5 Structure thermal compensation ............................................................... 1-7

1.4 Operational functions ............................................................................................. 1-8

1.4.1 Selectable parameter tables ...................................................................... 1-8

1.4.2 Compensation buffering ............................................................................ 1-8

1.5 System components .............................................................................................. 1-9

1.6 Installation procedure overview ........................................................................... 1-11

Page 13

1-2 System overview

1.1 Introduction

This manual covers the installation, configuration and operation of the Renishaw RCU10

real-time quadrature compensator system.

1.2 System overview

The RCU10 real-time quadrature compensation system overcomes environmental error

sources in linear motion systems to improve process accuracy and repeatability. The

RCU10 monitors a machine’s ambient environment, via a network of sensors, and uses

advanced digital signal processing to perform real-time compensation on the position

feedback signals.

The RCU10 can provide:

Refractive index compensation, for laser encoders, using air pressure and

temperature sensors.

Scale thermal expansion compensation, for incremental linear encoders, using

material temperature sensors.

Thermal expansion compensation of machine structure and workpieces, using

material temperature sensors.

Format conversion – digital (A quad B) to analogue (Sin/Cos)

Scale factor conversion – laser wavelength to engineering units

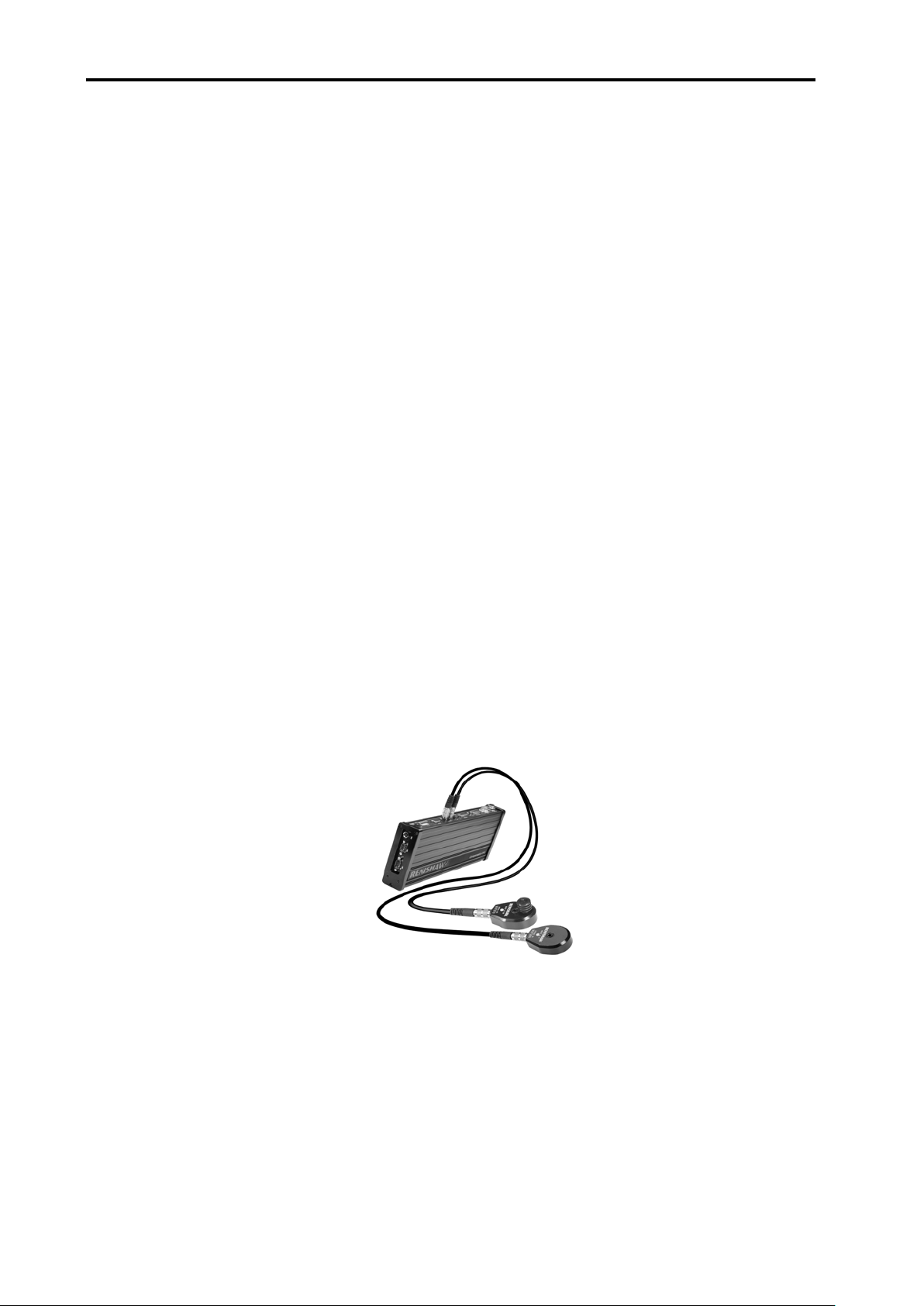

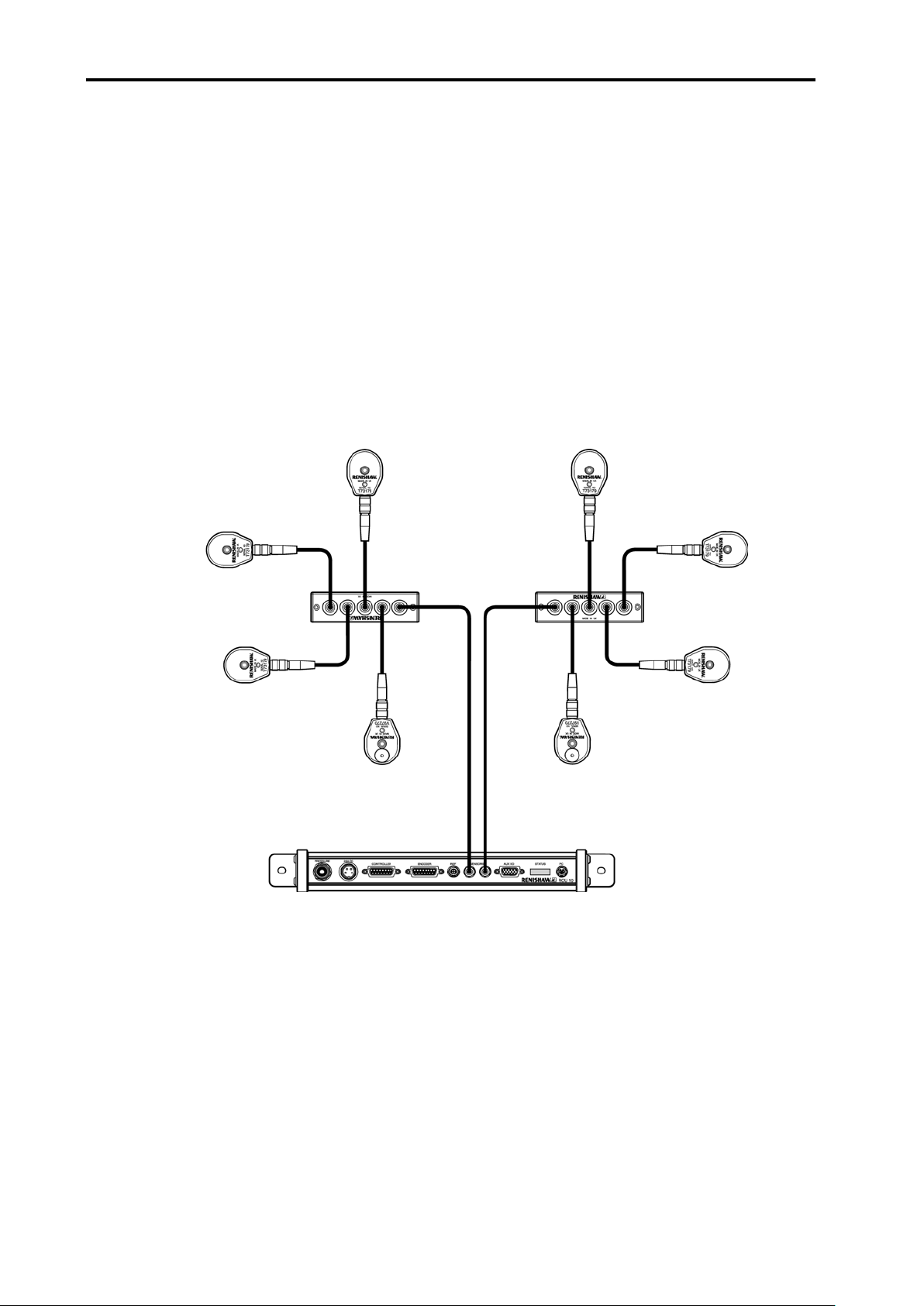

Figure 1.1 – RCU10-P with sensors

Page 14

System overview 1-3

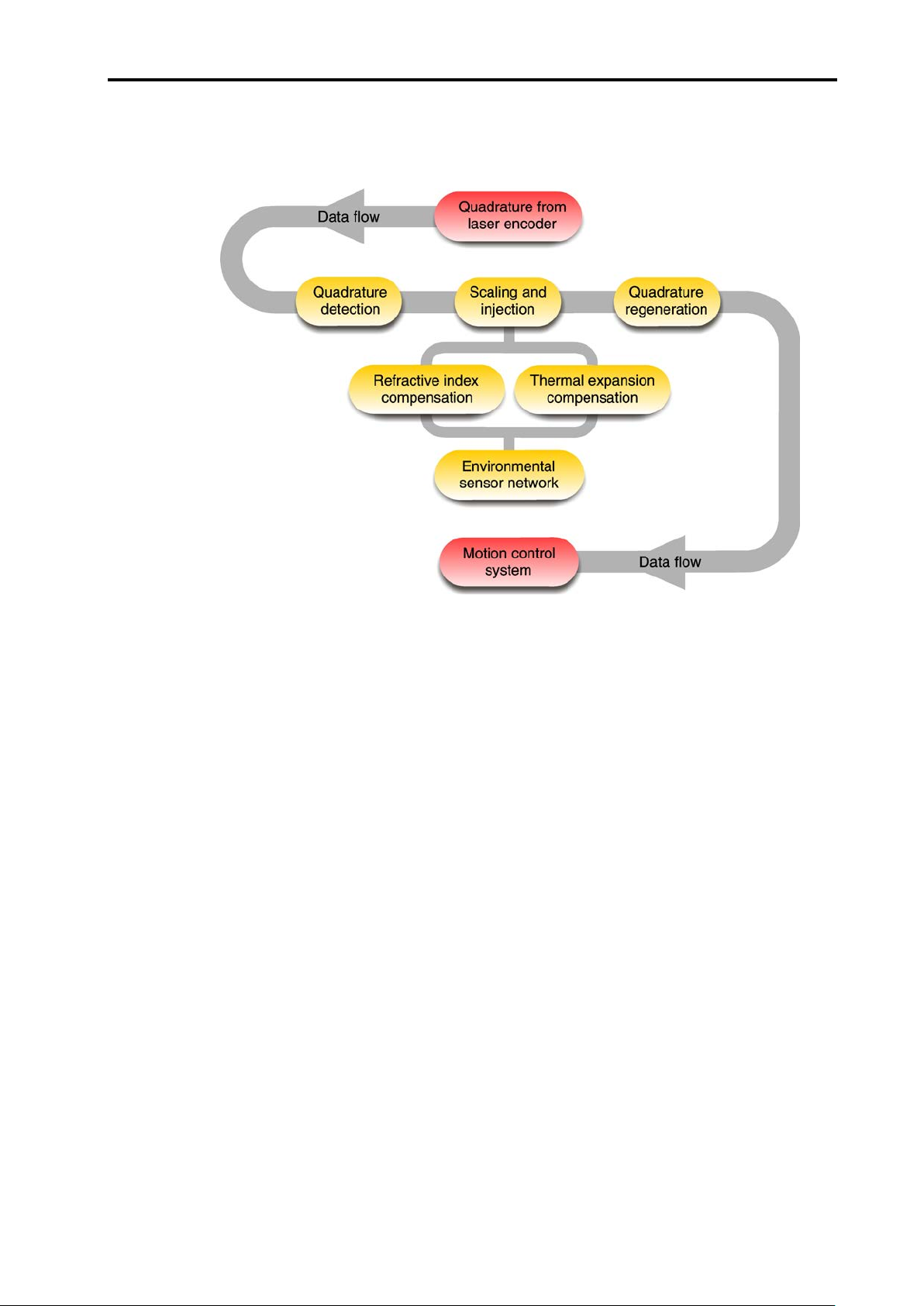

A functional block diagram of the RCU10 is show below:

Figure 1.2 – Internal block diagram of operation when used in conjunction with a

laser encoder

The RCU10 processor accepts digital quadrature, along with the environmental data

collected by factory-calibrated sensors, and calculates the total amount of compensation

necessary to correct the axis position. The required compensation is then applied through

quadrature scaling and injection (addition or removal of quadrature pulses) into the

encoder feedback signal, the total process being completely transparent to the motion

controller. The corrected feedback signals are provided to the motion controller in either

RS422 digital A quad B or analogue Sin/Cos 1 Vpp formats, with a nominal accuracy of

±1 ppm (refractive index only) or ±2 ppm (with 10 ppm/°C material compensation).

The RCU10 compensator is available in two models:

RCU10-P, which contains an internal air pressure sensor

RCU10, which does not contain an air pressure sensor

One compensator is required for each machine axis that is to be compensated.

When laser encoders are being used, one compensator in the system must be an

RCU10-P so that the ambient air pressure can be determined and refractive index

compensation applied. The basic RCU10 may be used for conventional (non-laser)

encoders or for ‘slave’ axes in a laser encoder system.

Page 15

1-4 System overview

When used as a multi-axis system, the RCU10s are linked via a high-speed serial link;

this allows the RCU10s to share sensor information and operating data.

Figure 1.3 – Multi-axis system

1.3 Compensation functions

The RCU10 is capable of performing a number of processing functions on position

feedback signals. These compensation modes can be enabled or disabled, depending on

the application requirements and type of encoder used. The following section provides an

overview of these modes. Full details can be found in Appendix G.

1.3.1 Scale factor

The RCU10 is capable of performing a fixed scale factor correction to convert the intrinsic

encoder resolution into a more useable value (e.g. 633 nm -> 1 µm). The scale factors

available depend on the input resolution and the type of output required.

This is the basic mode of operation when no compensation functions are enabled.

1.3.2 Air refractive index compensation

Air refractive index (wavelength) compensation is applied according to the environmental

values received from the air temperature and pressure sensors. This mode of

compensation is used with laser encoders to provide a consistent and accurate feedback

signal regardless of current environmental conditions.

Page 16

System overview 1-5

Since the wavelength of light is a function of the ambient conditions local to the beam

path, without compensation errors can incur. This error is of the order of 1 ppm for each

of the following changes in environmental conditions:

1 °C (≈1.8 °F) Change in air temperature

1 ppm for every 3.3 mbar (≈0.1 in/Hg) Change in air pressure

30% RH @ 40 °C Change in relative humidity

Air temperature sensors are provided to monitor any local temperature variation within the

boundaries of the machine. An air pressure sensor is built into the compensator unit

(RCU10-P model only). Humidity is assumed to be relatively constant, and a fixed value

may be entered via the configuration software.

To enable the RCU10 system to perform in real time, each of these sensors is read, and

the related computation (Edlen’s equation*).

* See Appendix G

1.3.3 Encoder thermal expansion compensation

When using conventional scale encoders, the positional accuracy of the system will

depend on the thermal expansion of the scale substrate material. The RCU10 is capable

of compensating for this effect by measuring the temperature of the scale and applying

the relevant positional correction. This will significantly improve system accuracy when

subjected to temperature variation.

To utilise this compensation mode, a material temperature sensor must be placed on the

scale substrate material and the RCU10 configured with the scale’s coefficient of thermal

expansion (CTE) and the distance between the machine home and expansion origin

position.

1.3.4 Workpiece thermal expansion compensation

The system can also perform material thermal expansion compensation. The function of

this feature is to track workpiece temperature and perform compensation based on its

CTE, such that the axis position is modified in real time to produce a part with the correct

dimensions for current environmental conditions.

To utilise this compensation mode, a material temperature sensor must be fitted to either

the part being machined, or a part of equivalent thermal characteristics. A reference

location, from which the workpiece is expected to expand, should be identified (by

consideration of part fixturing method etc). Once workpiece compensation is enabled, the

machine position will be modified to account for workpiece expansion relative to this

reference location.

Page 17

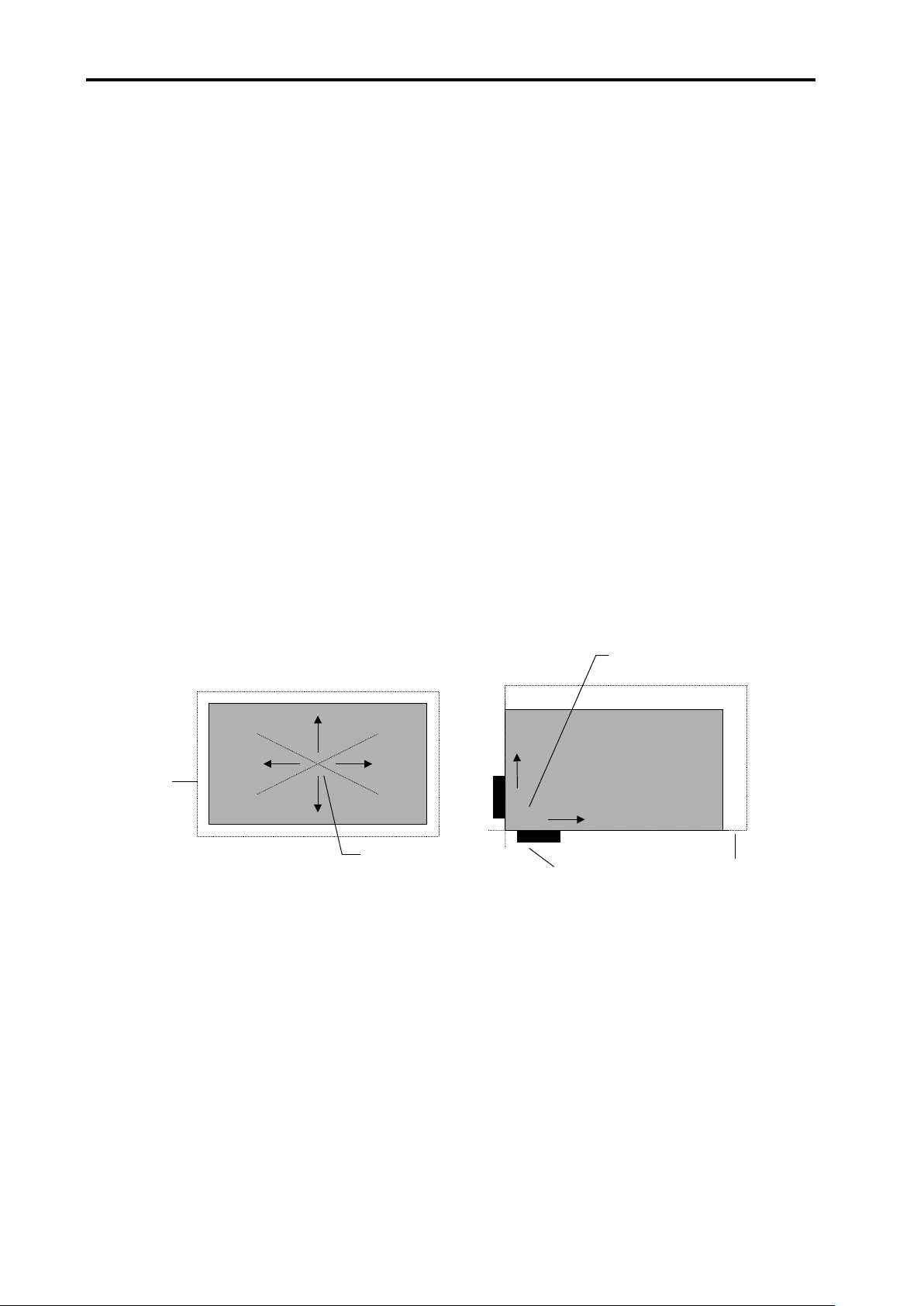

1-6 System overview

New

‘expanded’

size

Reference point,

centre of the

workpiece

Anchor

point

Expanded

size

Expansion is forced in

these directions, away

from the anchor point

Workpiece expansion concept

The size of a workpiece is proportional to its CTE and the ambient temperature. One of

the major sources of error in large parts can be ‘feature misplacement’, which can result

from thermal expansion or contraction of the part.

Consider two matching workpieces – one made at 30 °C (86 °F) and one made at 20 °C

(68 °F). If these parts are machined without workpiece expansion compensation applied,

they will not be the same size when brought together at the same temperature (the part

made at the higher temperature will be smaller than the one made at the lower

temperature).

By constantly monitoring the workpiece temperature, the RCU10 can use its CTE to

calculate the expansion that has occurred relative to a nominal reference temperature of

20 °C (68 °F). This process ensures that parts machined in a poorly controlled

environment will be as accurate and consistent as parts machined in an environment

maintained at 20 °C (68 °F). That is to say, no matter what temperature the part is

machined at, it will be the correct size when measured at 20 °C (68 °F).

Expansion is a greater problem in large workpieces because the amount of expansion is

proportional to the distance from the reference point. For example, at a point 40 m

(≈130 ft) from the reference point on an aluminium workpiece at 30 °C (86 °F), the error

will be 8 mm (5/16 in).

Figure 1.4 – Workpiece expansion

Workpiece compensation reference point

It is up to each user to establish a reference point suitable for their specific workpiece and

application. Some experimentation may need to be carried out in order to determine how

each fixture or workpiece behaves and thus the best way to apply compensation.

The process of defining a reference point can be complex and depends on many factors.

It is up to the user to decide on the best jigging and anchoring options for the workpiece.

Page 18

System overview 1-7

Expansion coefficients

The RCU10 recognises expansion coefficients as parts per million per degree Celsius or

degree Fahrenheit (the unit of temperature used depends on how the user configures the

system). The reference temperature for material expansion is 20 °C (68 °F).

Table 1.1 below shows example expansion coefficients for aluminium and steel:

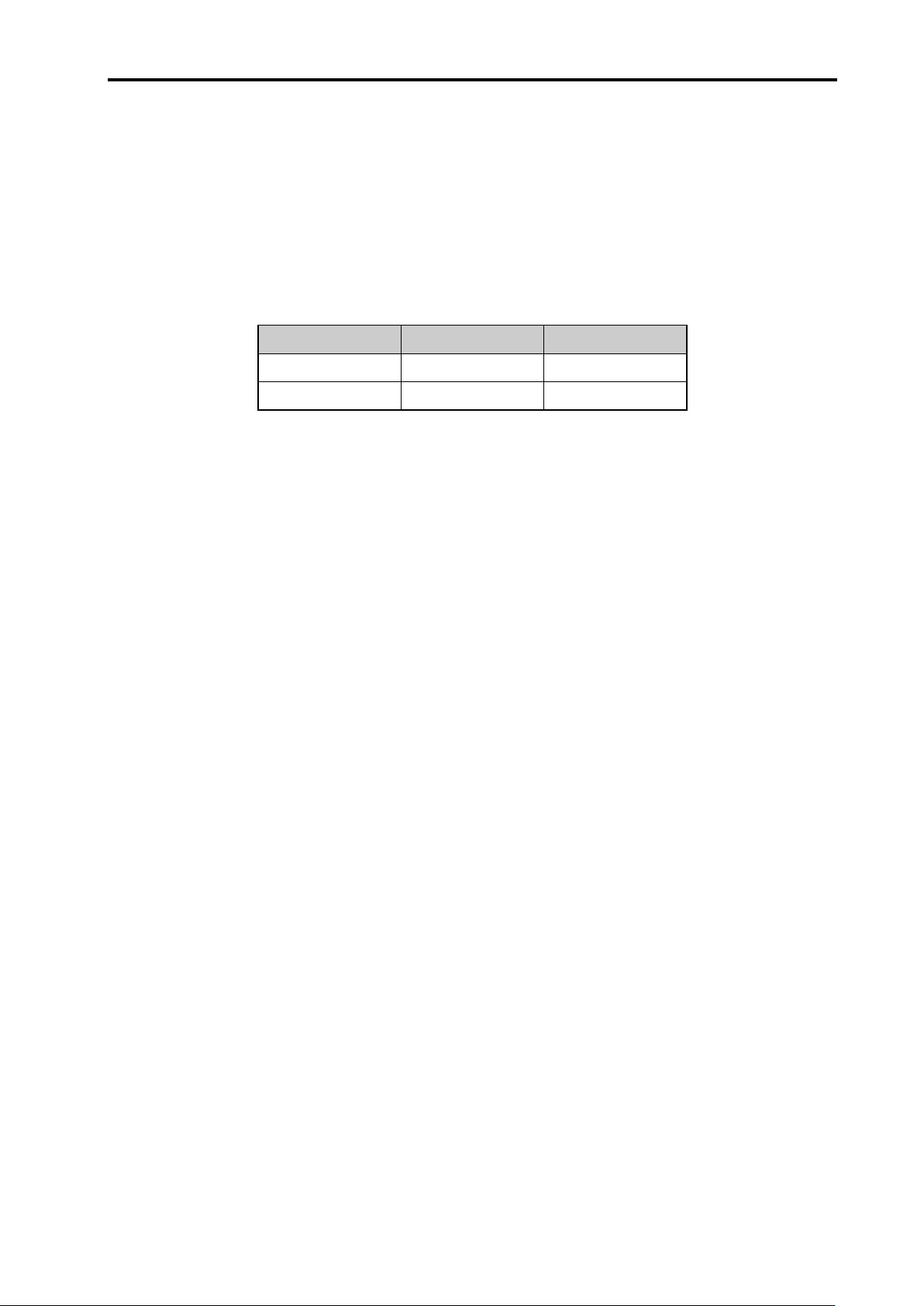

Table 1.1 – Expansion coefficients

Material ppm/°C ppm/°F

Aluminium 20 11.11

Steel 10 5.56

Use the following formula to convert from ppm/°C to ppm/°F:

[ppm/°C] multiplied by 5/9 = [ppm/°F]

e.g. 20 ppm/°C x 5/9 = 11.11 ppm/°F

1.3.5 Structure thermal compensation

An additional source of positioning error may be the thermal distortion of the machine

structure. This could manifest in a number of ways including:

expansion of the spindle

expansion of the machine structure

As long as the thermal effect is linear and not related to axis position, the RCU10 can be

used to reduce the error.

To utilise this compensation mode, a material temperature sensor must be placed on the

applicable part of the machine structure and the RCU10 configured with the number of

micrometres of correction required per degree C.

Page 19

1-8 System overview

1.4 Operational functions

A number of useful operational functions (some optional) are available on the RCU10 to

provide flexibility and ease of use.

1.4.1 Selectable parameter tables

A number of ‘parameter tables’ are available for use during operation, which are

selectable through external I/O. These allow easy ‘switching’ of a number of common

options/operations, including:

Dead path or reference offset from scale expansion origin

Workpiece temperature sensor

Workpiece expansion coefficient

Workpiece origin offset

Workpiece origin type

The use of these switchable parameters allows numerous functions such as:

Multiple machine home positions

Changing to an alternative machining zone

Use of multiple workpiece material sensors (for multiple machine zones or other

reasons)

Changing of the material type (e.g. aluminium/steel)

1.4.2 Compensation buffering

When the RCU10 is in this mode, it will continue to monitor the encoder input and perform

the relevant quadrature scaling. However, any injection required to maintain compensated

position will be stored in a buffer within the RCU10. When the mode is disabled, any

stored (buffered) count is slowly injected into the motion feedback loop and the fully

compensated position re-established. The rate at which this compensation is injected is

user-configurable.

This function is useful where an axis needs to be temporarily disabled, but the original

position recovered at a later time. For example, some machines have an Emergency Stop

button that can be used to temporarily stop machine operation, but continue after it is

released without having to re-home the machine. In this case the injection compensation

is buffered, preventing any movement during the ‘E-stop’ period which would cause a

following error on the machine controller.

Page 20

System overview 1-9

Powered from 24

digital signal processor based compensation electronics and

an

laser encoder and require refractiv

RCU10

applications, only one RCU10

compensation for additional axes is provided by

RCU10

the pressure senso

the network via a high-speed serial link.

Similar to the RCU10

not contain a pressure sensor.

Note that one RCU10 compensation un

axis to be compensated. For example, a three

encoder based system would need:

and a three

need:

3 off RCU10-XX-XX

The air temperature sensor is used in applications that

require refractive index compensation. The sensor contains a

calibrated thermistor to monitor ambient air temperature in

the range of 0 °C to 40 °C. The temperature readin

converted into a digital signal inside the sensor, which

reduces susceptibility to noise when the reading is

transmitted to the RCU10.

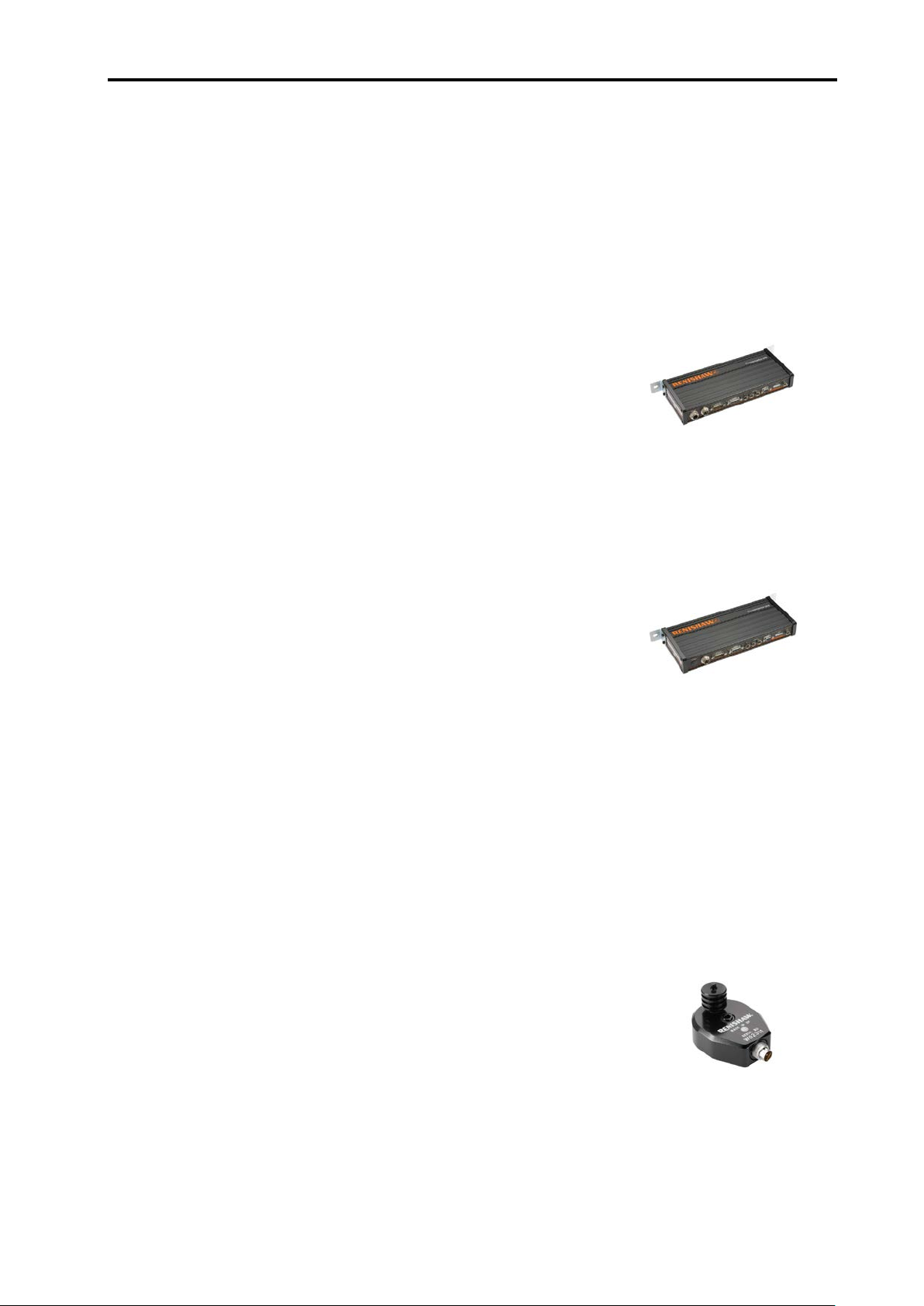

1.5 System components

The following provides a brief overview of the main system components:

Compensation unit with internal air pressure sensor

(part number: RCU10-PX-XX)

V dc, the RCU10-PX-XX contains the

internal air pressure sensor. For applications that use a

e index compensation, the

-PX-XX unit is a requirement. In multi-axis

-PX-XX is necessary because

-XX-XX units (detailed below). In these applications,

r reading is distributed to other RCU10s in

Compensation unit (part number: RCU10-XX-XX)

-PX-XX, however this assembly does

it is required for each

-axis laser

1 off RCU10-PX-XX

2 off RCU10-XX-XX

-axis tape or glass scale encoder system would

Air temperature sensor (part number: RCU10-AT-XX)

g is

Page 21

1-10 System overview

The material temperature sensor is used in applications

scale, workpiece or machine structure compensation. The sensor

contains a calibrated thermistor to monitor material surface

temperature in the range of 0 °C to 55 °C. The temperature reading is

converted into a digital signal inside the senso

susceptibility to noise when the reading is transmitted to the RCU10.

A five

the RCU10 units, or to the remote sensor distribution

number RCU10

of cable is required, sensor cables can be daisy

cable lengths in 5-metre increments to be configured.

Supplied on a CD

compensation system to meet the requirements of the application.

Communication with the RCU10 units is established through an

RS485 serial link; in some instances this may nec

USB to RS232 converter

and the RCU10 units.

The high

linked as a netwo

set up by connecting the computer system to only one of the RCU10

units. Any information required by remote RCU10 compensators in the

network is automatically distributed across the link to the appropriat

RCU10 compensator when the configuration file is transmitted to the

RCU10s.

Once in operation, the high

as the environmental sensor readings to be shared amongst all

compensators in the network.

This is used to connect a computer serial port to the RCU10

compensation unit.

Laser encoder technical documentation

(part number: A

CD containing pdfs of data sheet

laser encoder product

Material temperature sensor (part number: RCU10-MT-XX)

that require

r, which reduces

Sensor cable (part number: RCU10-TC-X5)

-metre cable that connects sensors directly to the sensor ports on

units (part

-DB-XX). In applications where more than five meters

-chained enabling

RCU CS configuration software (part number: RCU10-CS-XX)

-ROM, this software enables the user to configure the

RS232 or

essitate the use of a

(A-8014-0670) between the computer s ystem

High-speed serial link cable (part number: A-9904-1451)

-speed serial link cable allows a number of RCU10 units to be

rk. During configuration a multi-axis system can be

-speed serial link enables parameters such

PC RS232 cable (part number: A-9904-1456)

-9904-2407)

s and installation guides for

s.

e

Page 22

System overview 1-11

System design

Section 2

Define the required RCU10 kit number

Section 3

Check delivered kit contains all expected components

Section 3

System installation

Section 4

Whilst undertaking this process, the feedback loop to the

machine must not be closed and all motion must be disabled.

The system installation process is split into the following

sections:

•

Hardware installation and initial power-up

•

RCU10 unit address set-up

•

Electrical installation

•

System configuration

•

Configuration validation

Controller integration

Section 5

Operation

Section 6

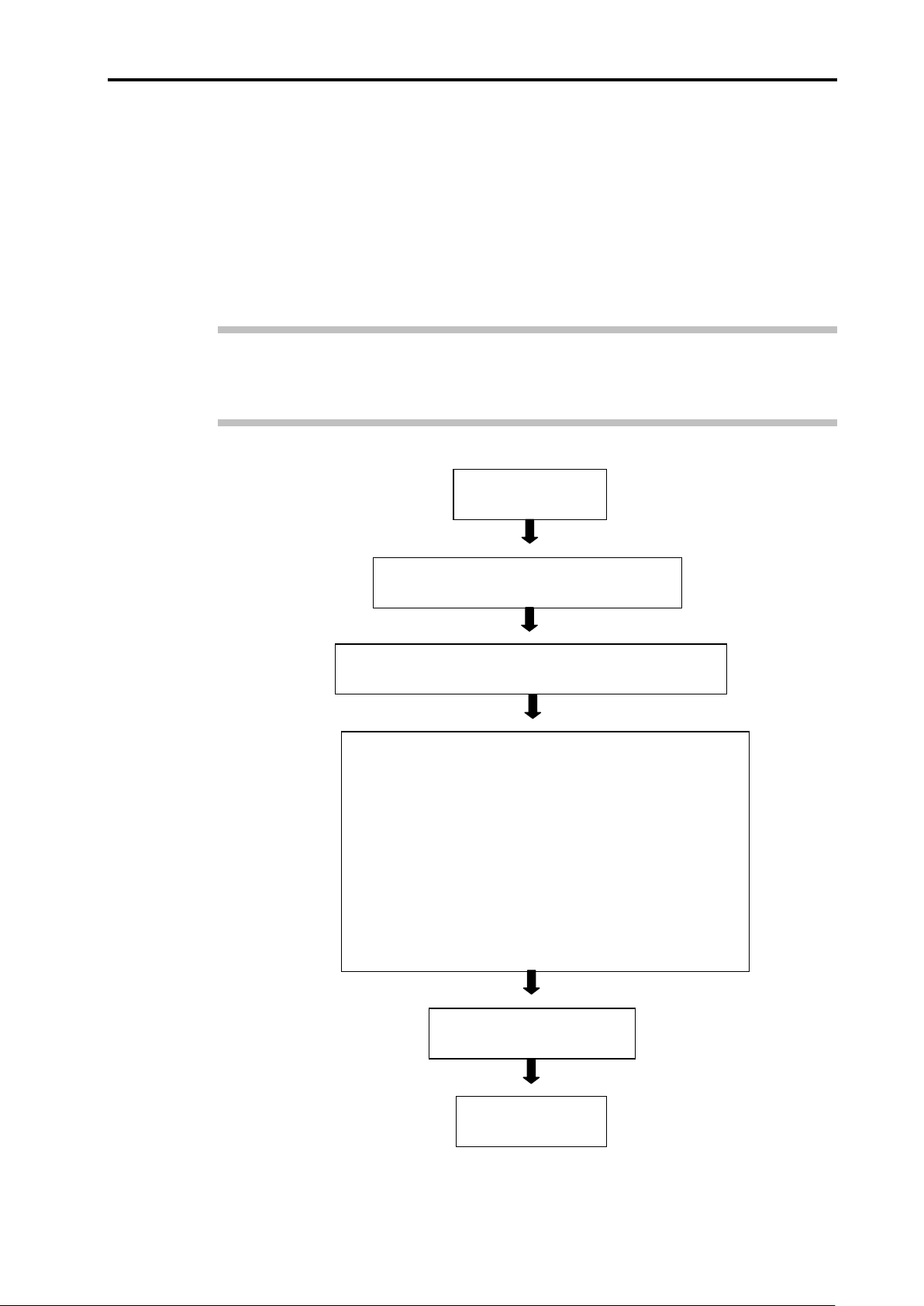

1.6 Installation procedure overview

Since the RCU10 system may be used in a diverse range of applications, from simple

open-loop calibration systems to complex multi-axis closed loop motion systems, it is

difficult to specify an optimum installation procedure for all cases. However, if sections 2

to 6 of this manual are followed sequentially, as outlined in the procedure below, the user

will be taken through a typical installation process.

Note: The user should be aware that to streamline the installation process, detailed

information has been placed within the appendices. Reference to these appendices is

made where appropriate.

Figure 1.5 – Installation flow diagram

Page 23

1-12 System overview

This page is intentionally left blank.

Page 24

System design 2-1

Section 2

System design

Contained in this section

2.1 Requirements ........................................................................................................ 2-2

2.2 Sensors and sensor networks ............................................................................... 2-3

2.2.1 Environment sensors ................................................................................. 2-3

2.2.2 Sensor network connection ....................................................................... 2-4

2.3 Electrical connections ............................................................................................ 2-5

2.3.1 Connector positions ................................................................................... 2-5

2.3.2 Connector functions .................................................................................. 2-6

J1 – 24 V dc power .................................................................................... 2-6

J2 – Controller output ................................................................................ 2-6

J3 – Encoder input..................................................................................... 2-6

J4 – Reference switch port ........................................................................ 2-7

J7 – Auxiliary I/O ....................................................................................... 2-8

J8 – PC port............................................................................................... 2-9

2.4 Velocity/resolution/bandwidth considerations ........................................................ 2-9

2.4.1 Encoder input frequency .......................................................................... 2-10

2.4.2 Output frequency ..................................................................................... 2-10

2.5 Referencing ......................................................................................................... 2-12

2.5.1 Signal format and re-synchronisation ...................................................... 2-12

2.5.2 Referencing options ................................................................................ 2-14

2.6 RCU10 component mounting .............................................................................. 2-17

2.6.1 RCU10-XX-XX or RCU10-PX-XX ........................................................... 2-

2.6.2 Air temperature sensor ............................................................................ 2-18

2.6.3 Material temperature sensor ................................................................... 2-19

2.6.4 Sensor distribution box ............................................................................ 2-20

17

Page 25

2-2 System design

2.1 Requirements

The RCU10 has been designed for maximum flexibility so that it can suit a wide range of

applications whilst maintaining simple configuration and installation. In order to use the

RCU10 system certain requirements should be met:

24 V dc power source ±2 V with each compensator requiring up to 250 mA. The

power source should have short circuit protection.

An encoder that provides digital quadrature in differential RS422 format at one of

the resolutions defined in Section 2.4.2.

Figure 2.1 – RS422 differential line driver outputs

An axis controller which:

accepts either:

• digital quadrature in differential RS422 format, or

• analogue (Sine/Cosine) quadrature in 1 Vpp format.

is capable of recognising an error condition by one of the following methods:

• RS422 differential error line.

• quadrature disconnection (loss of differential drive of digital inputs,

amplitude drop in analogue input applications).

In the simplest configuration it is possible to use the RCU10 without any input

control lines. However, for basic or extended operation the controller should have

input/output lines working at either 24 V or 5 V logic thresholds.

Basic operation:

• one controller output line (reset)

• one controller input line (error)

Extended operation:

• controller output lines – maximum of six per axis (all RCU10 functions used)

• controller input lines – maximum of three per axis (error, suspend and

warning)

Page 26

System design 2-3

2.2 Sensors and sensor networks

2.2.1 Environment sensors

Two types of remote RCU10 sensor are available – one for sensing air temperature and

one for sensing material temperature. Both sensors have built-in electronics to convert the

temperature reading into RS485 data. Consequently, many sensors can be linked

together to form a network. Furthermore, the signal is digital, making it less susceptible to

electrical noise and allowing it to be transmitted without error over a longer distance.

Each sensor in a system needs a unique address for the network to work correctly. The

RCU10 sensors are factory-programmed with an address that is the same as the serial

number of the sensor (engraved on the sensor body).

Each sensor port can supply power to a maximum of four sensors, which means a total of

eight connected to any single RCU10 axis.

The sensors for a particular axis do not have to physically plug into the related axis's

RCU10; sensors may plug into any RCU10. The configuration software allows the user to

assign any sensor data to any RCU10 within the system.

The sensors may be connected using the standard pre-made cables available in 5 m

lengths from Renishaw. Alternatively, custom cables may be made by the user (connector

kits are available). Please see Appendix B for standard and custom cable specifications.

Figure 2.2 – Air temperature and material temperature sensors

Page 27

2-4 System design

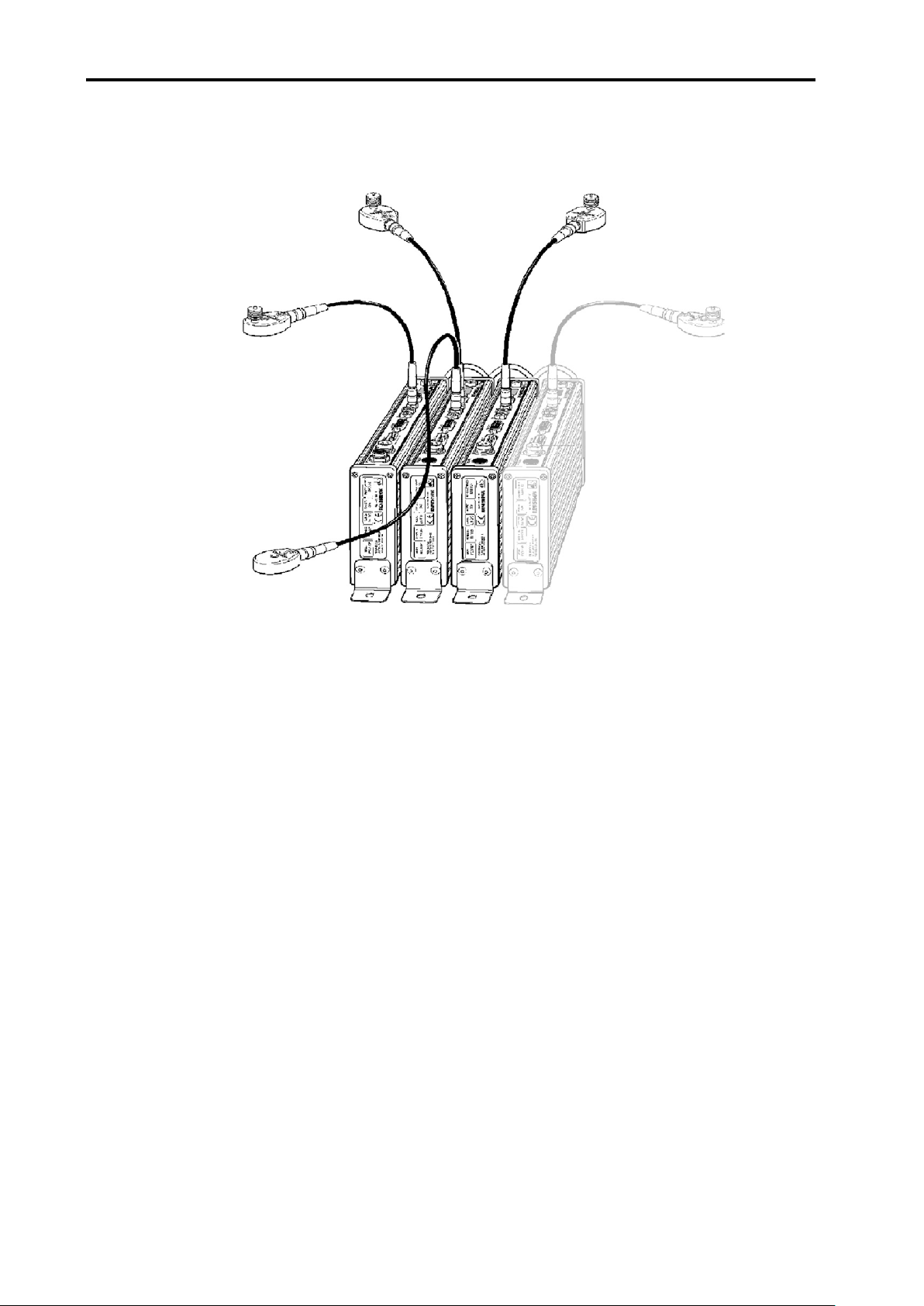

2.2.2 Sensor network connection

Two sensor network ports (J5 and J6 – see Figure 2.4) are provided per RCU10, to which

all the air temperature and material temperature sensors are connected. Up to four

sensors may be connected to each RCU10 sensor port using the sensor distribution box

(as shown in Figure 2.3), making a maximum of eight sensors per RCU10. There is a limit

of 32 sensors per multi axis system.

Additionally, of these 32 sensors, only 24 may be distributed. Distributed sensors are

those configured to be used by RCU10s other than the RCU (or RLU) to which they are

directly connected. This may be necessary when a sensor is to be used by more than one

axis, or where connection to a different RCU10 is more convenient than connection to the

one that will use it.

Figure 2.3 – Sensor distribution

Page 28

System design 2-5

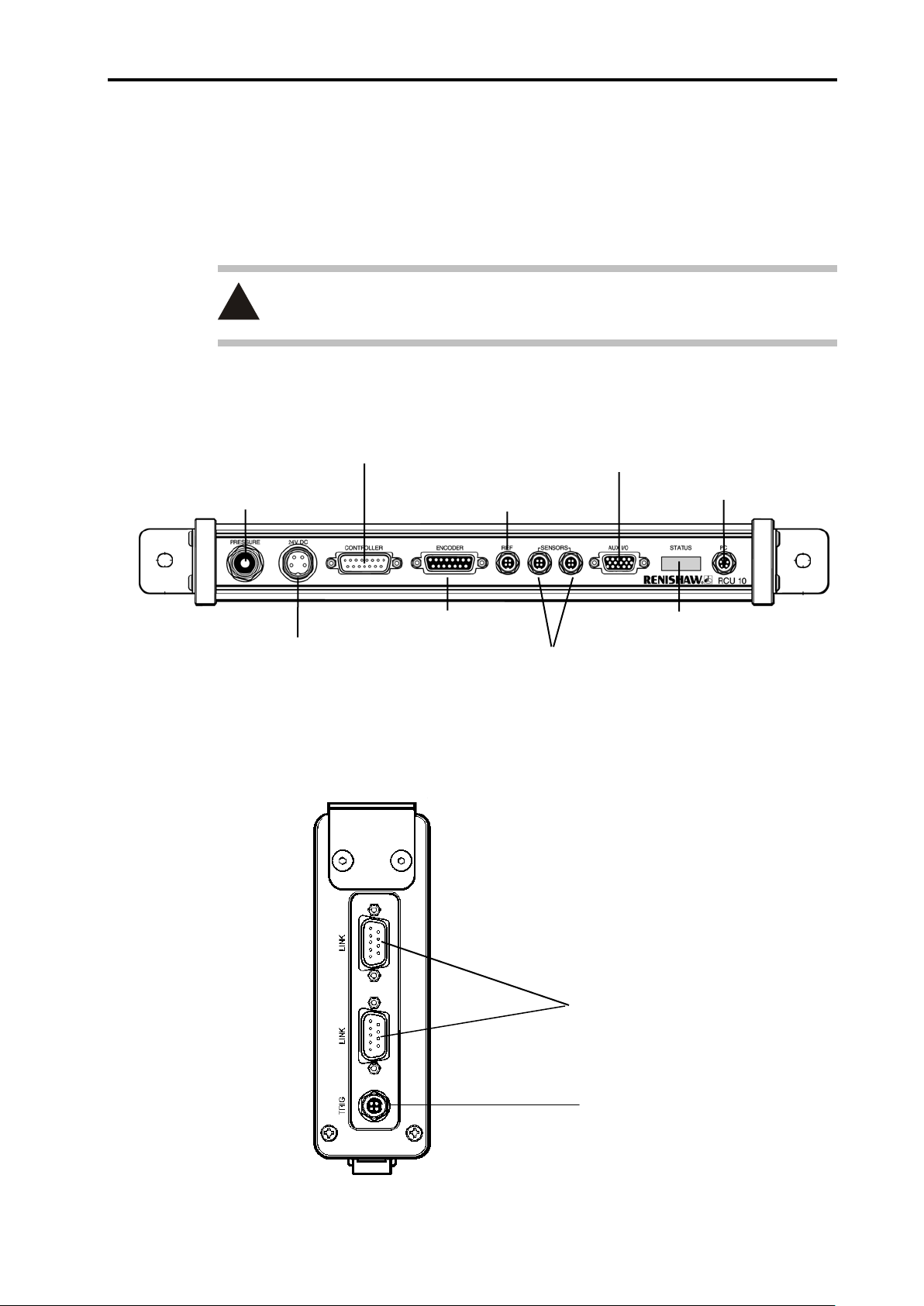

Not currently used

Pressure sensor

(optional)

J1 – 24 V dc power

J2 – Controller output

J3 – Encoder input

J4 – Reference switch port

J5 and J6 – Sensor network ports

J7 – Auxiliary I/O

Status display

J8 – PC port

!

High-speed serial

2.3 Electrical connections

The following pages provide details of the RCU10 input and output ports and the signal

functions and types. For information on the connectors and hardware installation details

refer to Appendix B.

CAUTION: Do not connect anything other than Renishaw environmental sensors

to the sensor ports.

2.3.1 Connector posit ions

Figure 2.4 – Front panel layout

communication link

Figure 2.5 – Top panel layout

Page 29

2-6 System design

!

2.3.2 Connector funct ions

J1 – 24 V dc power

The RCU10 uses 24 V dc as its power supply. Power supply requirements can be found in

Appendix A. If required, a power supply with a remote sense function can be used. For

connector pinout and hardware installation details please refer to Appendix B.

Note: When using a network of RCU10s the 24 V supply should be applied

simultaneously for all units.

CAUTION: The correct power supply voltage is 24 V ± 2 V. Power supplies

outside this range may give unreliable operation.

J2 – Controller output

The controller output connector provides the position feedback signals that pass to the

machine control or counter. These comprise digital A quad B (or analogue sinusoidal)

encoder signals, reference Z pulse and error signals.

The RCU10 can be configured to provide output position data to the machine controller in

either digital incremental A quad B (RS422 differential line driver output) or analogue

incremental sine/cosine format (1 Vpp differential sine and cosine line driver outputs)

using the configuration software. The output resolution of the RCU10 system may be

selected from a number of available options, depending on the encoder input resolution

and output format required.

Renishaw supplies connector kits to assist users in the construction of suitable cables –

please refer to Appendix B for connector pinout and hardware installation details.

J3 – Encoder input

The RCU10 has been designed to accept digital quadrature from three main types of

encoder:

Renishaw RLE10 laser encoder

Renishaw HS10 laser encoder

Generic tape/glass scale

The encoder type is selected through the configuration software, and the encoder input

port must be wired to suit the selected type. Renishaw supplies connector kits to assist

users in the construction of suitable cables – please refer to Appendix B for connector

pinout and hardware installation details.

The tables in section 2.4.2 show the available RCU10 output resolutions for a given

encoder type and input resolution – along with the maximum velocities, as discussed in

section 2.4.

Page 30

System design 2-7

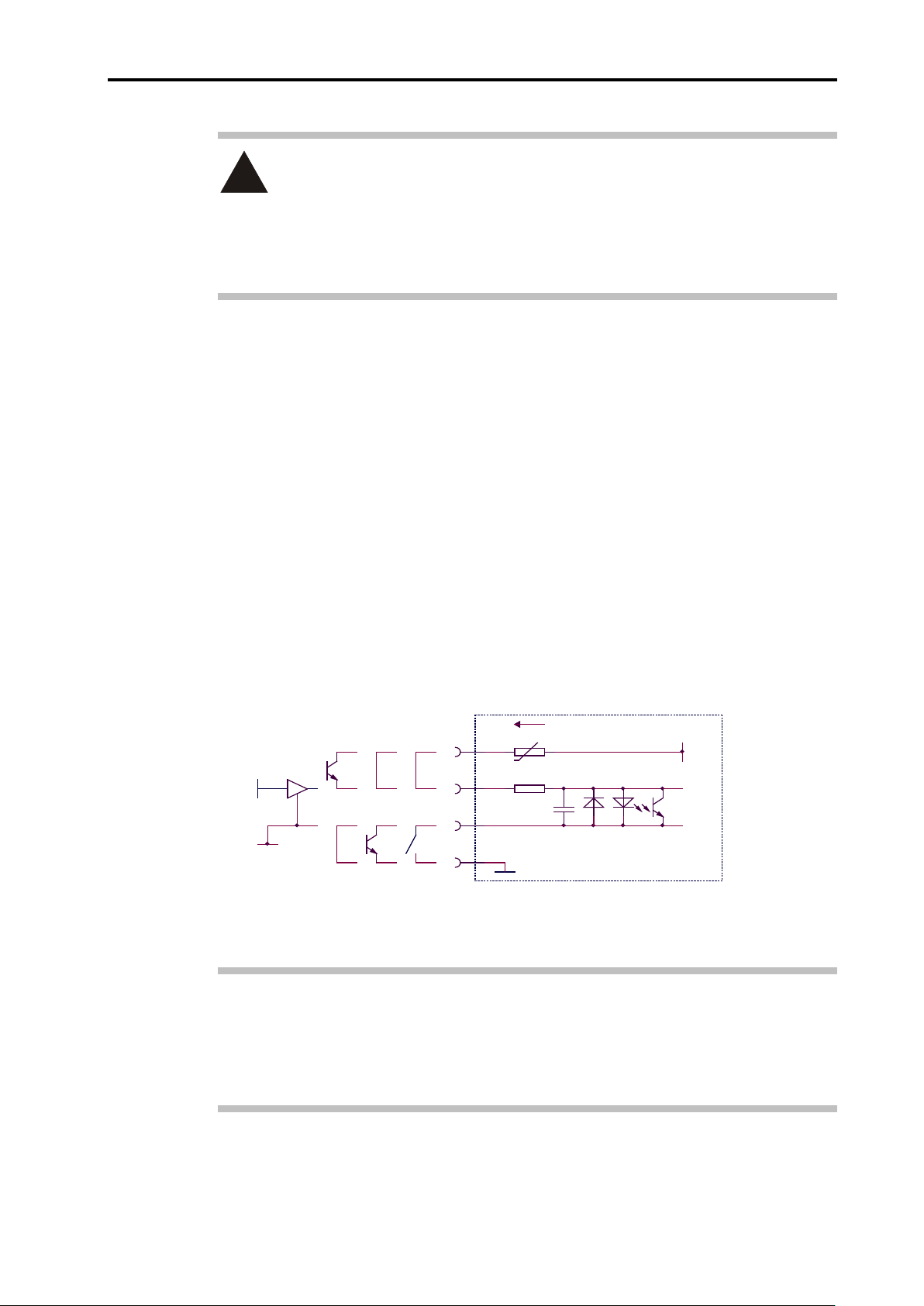

RCU10

100 mA MAX

+

5 V

4

3

5 V

driver

High

side

0 V

Low

side

Switch

5 V

0 V

2

1

!

WARNING: To ensure that the motion control system receives quadrature of the

expected resolution and frequency, it is important to set both the input and output

resolutions of the Renishaw system correctly. If the quadrature resolution is set

incorrectly, the axis may move for distances and at speeds that are not expected. For

example, if the output resolution of the RCU10 system is set to double that of the

controller input, the axis may move twice as far and twice as fast as expected.

J4 – Reference switch port

The reference mark input may be used to receive a reference position marker pulse. Two

options are available when configuring the RCU10: either a reference mark derived from

the encoder (through the encoder where Z and /Z are the reference mark input lines), or

connected to the REF input. The REF input can accept a range of actuator types that

have solid state (high side or low side), 5 V logic signal or mechanical switch output

formats.

The reference process is triggered by the current’s rising edge on switch closure. The

reference signal must last for at least one input encoder pulse transition and, once the

process has been started, another cannot be activated for a period of 1 second. Providing

this is adhered to, no restriction is placed on axis velocity during referencing, except for

the repeatability caused by the time delay introduced by the interface circuit. Please refer

to Appendix B for connector pinout and hardware installation details and section 2.5 for

signal and phasing information.

Figure 2.6 – Reference mark actuator connection

Notes: TTL driver signals are not suitable for use here. The thresholds are 3 V high

and 1 V low.

The reference mark signal will only function in conjunction with quadrature, ie

not stationary.

Page 31

2-8 System design

J7 – Auxiliary I/O

The auxiliary input/output connector provides various functions that can be used to control

and monitor the operation of the RCU10. These functions are described below.

Table 2.1 – J7 pinouts (Auxilia ry I/O)

Pin Auxiliary

I/O function

1, 11

12, 13

3

4

7 PULL -

5 /Seek reference I Enables search for reference mark input. LOW

15 /Reset I

14

5 V and 24 V

outputs

Parameter table

select 1 and 2

/Workpiece

compensation

enable

/Workpiece

compensation

temperature freeze

/Compensation

buffering enable

I/O Active

O

I

I Enables workpiece compensation. LOW

I

I Enables the compensation buffering function. LOW

5 V and 24 V outputs @ 100 mA max.

Link to PULL for voltage selection.

Used to select active parameter table.

(Refer to parameter table operation in Appendix F).

Freezes the value of the workpiece temperature at

the current value when activated.

All I/O is weakly pulled to the voltage set of this

terminal i.e. 5 V or 24 V.

Connect to 5 V (1) or 24 V (11) as required.

Note: This must also be selected to match the

RCU10 configuration.

Resets the RCU10 output error latch and HS10

laser (if used). Reset signal must be held active for

a minimum of 100 ms to ensure correct operation.

-

-

LOW

-

LOW

6 /Error (24 V) O

9 /Suspend O LOW

10 /Warning O LOW

The port can be configured to work with either 5 V or 24 V logic I/O by connecting the

PULL input, within the auxiliary I/O connector, to either 5 V (pin 1) or 24 V (pin 11)

respectively. Also ensure that the relevant threshold is selected in the Controller Logic

parameter in the system configuration (see section 4.2.3 for details). Please refer to

Appendix B for connector pinout and hardware installation details.

Outputs that may be used as an advanced option to

determine the state of the RCU10 (see below).

LOW

Page 32

System design 2-9

J8 – PC port

The PC port is used to connect the RCU10 to the RS232 port of a computer. Once

connected, the PC may be used with the Renishaw RCU CS software to both configure

the RCU10 and monitor the RCU10 during operation.

The PC port may be used with either a standard RS232 interface or an RS485 interface.

The RS485 format is used when long distances are required between the RCU10 and the

PC or, in situations where a high level of electrical noise is expected. Connection should

be made to either the RS232 or

The PC may be connected using the standard pre-made RS232 cable available in a 1 m

length from Renishaw. Alternatively, custom cables may be made by the user (connector

kits are available). Please see Appendix B for connector pinouts and standard cable

specifications.

Notes: New PCs are increasingly being supplied with no RS232 ports (ie USB ports

only). Because of the interface problems this presents, Renishaw supplies a

serial-USB adaptor (see section 3.3 for ordering details).

RS485 as required, but not to both simultaneously.

On multi-axis systems only one PC must be connected.

2.4 Velocity/resolution/bandwidth considerations

One of the key considerations in configuring an encoder feedback system is to ensure

that certain frequency dependent parameters are configured correctly.

These parameters are:

Encoder resolution

Maximum required axis velocity

RCU10 input sample rate

RCU10 output resolution

RCU10 output update rate

Controller sample rate

The logical sequence for determining these parameters is as follows:

Page 33

2-10 System design

2.4.1 Encoder input frequency

Determine the encoder resolution.

Determine the maximum required axis velocity (see Tables 2.2 to 2.5 to determine

the maximum velocity for different resolutions and encoders).

Calculate the maximum encoder (edge-to-edge) frequency as follows:

Encoder frequency (MHz) = Velocity (m/s)

Ensure that the encoder frequency is less than 20 MHz and less than the RCU10

sample rate setting.

Note: The input sample rate of the RCU should be at least 25% greater than the encoder

output quadrature rate.

Encoder resolution (µm)

2.4.2 Output frequenc y

Determine the RCU10 output (controller input) resolution.

Calculate the maximum output frequency as follows:

Output frequency (MHz) = Velocity (m/s)

Output resolution (µm)

Ensure that the RCU10 output update rate is at least 5% greater than the output

frequency.

Ensure that the controller sample rate is greater than the RCU10 update rate

setting.

In the case where analogue (Sine/Cos) output signals are being used from the RCU10,

the frequency of the sinusoids can also be calculated as shown above.

Note: The customer’s controller must have an input bandwidth which is at least 25%

greater than the output quadrature rate of the RCU.

Page 34

System design 2-11

Table 2.2 – Maximum velocity for digital output resol u tions - RLE10 or HS10 laser encoder

Encoder input

resolution

(nm)

633 5.000 m/s

316 5.000 m/s 5.000 m/s

158 3.164 m/s 3.164 m/s

79.1 1.582 m/s 1.582 m/s

39.6 * 0.791 m/s 0.791 m/s

19.8 * 0.396 m/s 0.396 m/s

9.9 * 0.197 m/s 0.197 m/s 0.197 m/s

* only available from RLE10

Table 2.3 – Maximum velocity for analogue output resolutions - RLE10 or HS10 laser encoder

Encoder input

resolution (nm)

316 5.00 m/s

158 3.164 m/s 3.164 m/s 3.164 m/s

0.01 0.02 0.05 0.1 0.5 1 5

20 25 40 50 100

RCU10 output resolution (digital (µm))

RCU10 output resolution (sinusoid period (µm))

79.1 1.582 m/s 1.582 m/s 1.582 m/s 1.582 m/s

39.6 * 0.791 m/s 0.791 m/s

* only available from RLE10

Table 2.4 – Maximum velocity for digital output resol utions - tape/glass scale encoder

Encoder input

resolution (µm)

0.1 2.000 m/s 2.000 m/s 2.000 m/s

0.5 5.000 m/s 5.000 m/s 5.000 m/s

1 5.000 m/s 5.000 m/s

5 5.000 m/s

Table 2.5 – Maximum velocity for analogue output resol utions - tape/glass scale encoder

Encoder input

resolution (µm)

0.1 2.000 m/s 2.000 m/s 2.000 m/s

0.1 0.5 1 5

RCU10 output resolution (digital (µm))

RCU10 output resolution (sinusoid period (µm))

40 50 100

Page 35

2-12 System design

A quad

Bquad

Reference Input

Reference Output

5 Output Counts

FORWARD

2.5 Referencing

2.5.1 Signal format and re-synchronisation

When using a laser encoder, the exact phasing of the reference signal relative to the sine

and cosine signals cannot normally be guaranteed, because the position of the interfering

light waves is not mechanically registered relative to the position of the reference switch.

To overcome this, the RCU10 includes a circuit that re-phases the position signals so that

the reference mark output occurs synchronised and in a repeatable position.

Digital interface re-synchronisation

The output is produced when A is high and B is high. The re-synchronisation process

ensures a reference output will occur at 5 ±1 output quadrature counts later than the

reference input.

Figure 2.7 – Digital interface re-synchronisation

Page 36

System design 2-13

Cosine

Sine

Reference In

REFERENCE Valid

320 Output Counts

Reference Out

FORWARD

256 Output Counts

Analogue interface re-synchronisation

The output is produced between –45° and +135° and is valid when the amplitude of sine

and cosine are equal. The re-synchronisation process ensures a reference output starts

nominally 256 output counts later than the reference input and is valid at 320 ±1.

Figure 2-8 – Analogue interface re-synchronisation

Page 37

2-14 System design

2.5.2 Referenci ng options

Axis referencing with minimum control inputs

In the simplest configuration it is possible to use the RCU10 without any input control lines

by linking ‘Seek Reference’ and ‘Reset’ to 0 V.

When ‘Seek Reference’ is linked permanently to 0 V, the reference mark input will be

permanently active, and every time the machine passes over the reference actuator an

output reference mark will be issued. In this case it is advisable that the reference position

is located outside the normal working zone of the axis.

Linking ‘Reset’ permanently to 0 V will cause the RCU10 to automatically reset the error

output state when the cause of the error has ceased. For momentary error conditions, the

output will be active for at least 100 ms.

Figures 2.9 and 2.10 show the sequence for referencing the axis with laser and non-laser

encoders respectively with both 'Seek Reference’ and ‘Reset’ linked to 0 V.

Figure 2.9 – Simple mode axis referencing sequence with laser encoder input and

Seek reference and Reset inputs to RCU10 tied to 0 V

Page 38

System design 2-15

Figure 2.10 – Simple mode axis referencing sequence with non-laser encoder input

and Seek reference and Reset inputs to RCU10 tied to 0 V

Axis referencing with ‘Seek reference' and ‘Reset’ provided by the motion controller

In applications where it is not possible to locate the reference position outside the working

zone, the ‘Seek Reference’ line can be used to enable a reference cycle. In this mode of

operation, taking the ‘Seek Reference’ line low enables the reference mark input line into

the RCU10. At all other times (i.e with ‘Seek Reference’ high) the reference mark request

is ignored.

Figures 2.11 and 2.12 show the axis referencing sequence for laser and non-laser

encoders respectively with when both ‘Seek Reference’ and ‘Reset’ signals are provided

by the machine controller.

Note that following a power-up of the compensation system, it is recommended that a

‘Reset’ be applied as shown in Figures 2.11 and 2.12.

Page 39

2-16 System design

Page 40

System design 2-17

350 (13.78)

325 (12.8)

293 (11.54)

133.5

42 (1.65)

Mounting holes

Dimensions in

mm (in)

2.6 RCU10 component mounting

2.6.1 RCU10-XX-XX or RCU10-PX-XX

The RCU10 is intended to be mounted in an electrical control cabinet or similar

environment. It is constructed with IP40 protection and therefore needs to be protected

from harsh environmental conditions.

The RCU10 may be mounted in any orientation, although the status display window is

intended to be read with the unit vertical (display window to the top).

If the RCU10-P is to be contained in a sealed enclosure, it will be necessary to port the

pressure sensor aperture to the outside environment such that the correct air pressure is

measured. This can be done by using 4 mm O.D. plastic tubing which will simply push fit

into the aperture. To remove the plastic tube, push the collet towards the connector whilst

pulling the tube.

Figure 2.13 – RCU10 dimensions

7 mm x 9.5 mm

(5.26)

For connector/cable clearance purposes, allow 100 mm (4 in) from the front face of the

RCU10. Additionally, if a multi-axis system is being installed, allow 100 mm (4 in) from the

top face of the unit for the high-speed serial link cables.

Note: Using the fixings supplied with the unit (M4 x 5 cap head screws + 4 mm plain

washers) ensures that earthing is achieved directly through the brackets.

Page 41

2-18 System design

∅ 3.5 (0.13)

16 (0.63)

36 (1.42)

34 (1.34)

25 (0.98)

46 (1.81)

90 (3.5) min

75 (2.95) min

Standard cable

Armoured cable

Dimensions in mm (in)

2.6.2 Air temperature sensor

RCU10-AT-XX

The air temperature sensor may be mounted either by the built-in magnetic base or using

the central mounting hole. It is recommended for permanent installations that the

mounting hole be used for security.

The sensor should be positioned in a dry location in air next to the laser beam. An

armoured cable option is available for applications where there is a danger of the cable

being stressed or cut.

The sensor is show below with both the standard and armoured cable options, with

minimum clearance dimensions indicated.

Figure 2.14 – Air temperature sensor dimensions

Page 42

System design 2-19

16 (0.63)

36 (1.42)

17 (0.67)

∅3.5 (0.13)

25 (0.98)

46 (1.81)

90 (3.5)

75 (2.95) min

Standard cable

Armoured cable

Dimensions in

mm (in)

2.6.3 Material temperature sensor

RCU10-MT-XX

The material temperature sensor may be mounted in a similar way to the air temperature

sensor, by using either the built-in magnetic base or the central mounting hole. It is

recommended for permanent installations that the mounting hole be used for security.

The material sensors have IP67 protection and therefore can be placed in positions that

may have liquid or particle contamination. It is common for material temperature sensors

to be mounted in variable locations on a machine area, being removed and replaced as

required. An armoured cable option is available for applications where there is a danger of

the cable being stressed or cut.

Figure 2.15 – Material temperature sensor dimensions

Note: For maximum accuracy it is important to maintain good thermal contact between

the base of the sensor and the material being measured. Thermally conductive grease/oil

or paste may be beneficial.

Page 43

2-20 System design

110 (4.33)

17 (0.67)

∅ 3.5 (0.14) C’BORE ∅ 6 (0.24) x 3 (0.12)

100 (3.94)

8.5 (0.35)

5 (0.2)

30 (1.18)

2.6.4 Sensor distribution box

RCU10-DB-XX

The sensor distribution box allows up to four sensors to be connected to a single RCU10

sensor port. One cable is attached to the RCU10 and the sensors are plugged into the

distribution box at a remote location.