Page 1

Installation guide

M-9541-0084-04-C

RGH24/25U series readhead

Page 2

EMC compliance

The RG2 encoder system conforms to the relevant harmonised European standards for

electromagnetic compatibility as detailed below.

BS EN 61326

Patents

Features of Renishaw’s encoder systems and similar products are the subjects of the following

patents and patent applications:

EP 0207121 JP 1549396 US 4959542 EP 0274491

US 4,974,962 EP 0274492 US 4926566 EP 0383901

JP 2,963,926 US 5,088,209 EP 0388453 JP 2837483

US 5,063,685 EP 0514081 JP 3,202,316 US 5,241,173

EP 0543513 JP 248,895/1993 US 5,302,820 EP 0748436

US 5,861,953 EP 826138 B JP 506,211/1999 US 6,051,971

EP 1147377 JP 2003-512,611 US 6,588,333 B1

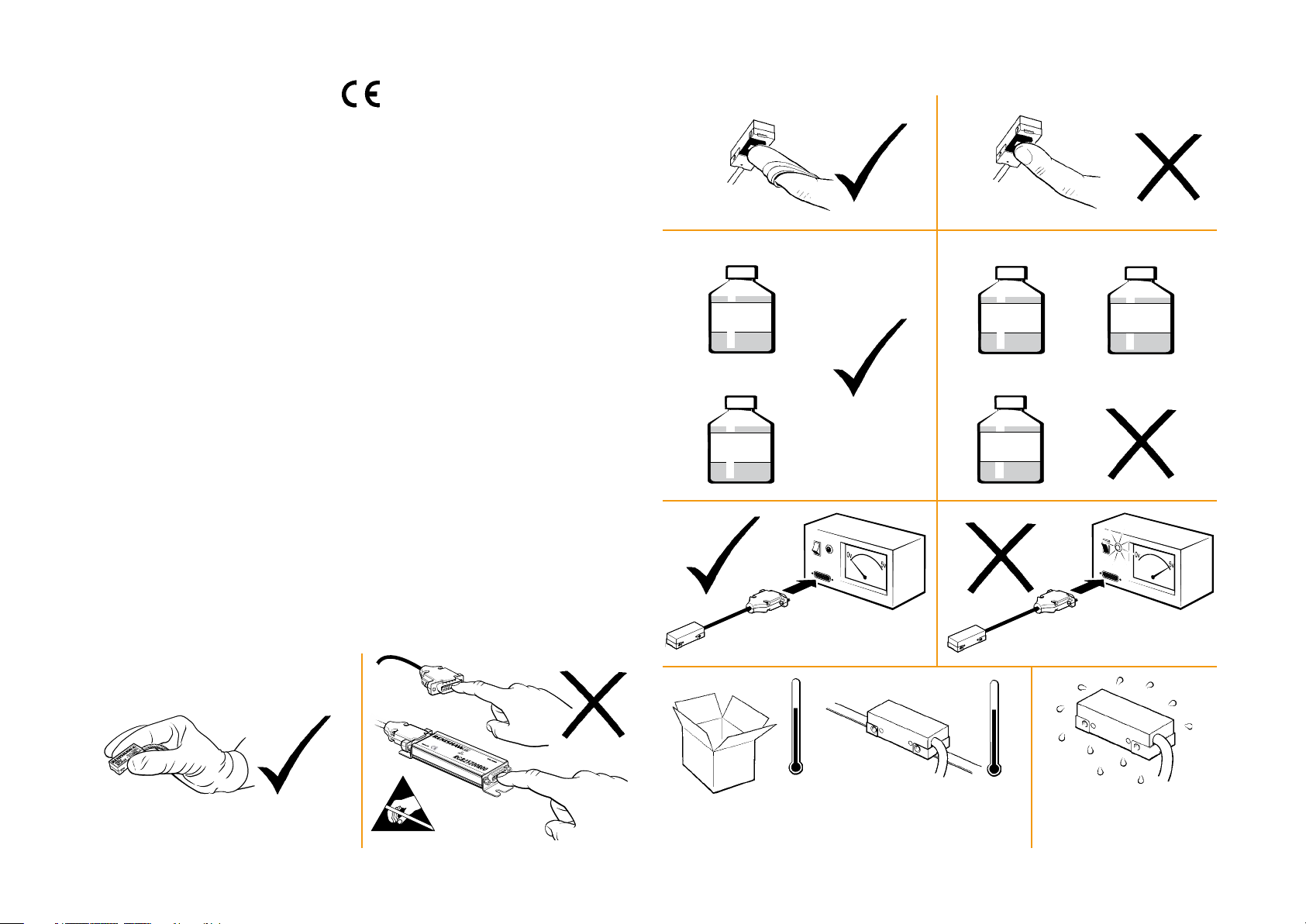

Storage and handling (continued)

N-heptane

CH3(CH2)5CH

3

Acetone

CH3COCH

3

Chlorinated

Solvents

Further information

For further information relating to the installation of RGH24/25 readheads, see also the RGH24

and/or the RGH25 (UHV) Data sheets (Part numbers L-9517-0166, L-9517-0168 and L-9517-9164),

and the Scale installation guide (Part number M-9517-2855). These can be downloaded from our

website www.renishaw.com/encoder and are also available from your local representative.

This document may not be copied or reproduced in whole or in part, or transferred to any other

media or language, by any means without the written prior permission of Renishaw.

The publication of material within this document does not imply freedom from the patent rights of

Renishaw plc.

Disclaimer

Considerable effort has been made to ensure that the contents of this document are free from

inaccuracies and omissions. However, Renishaw makes no warranties with respect to the contents

of this document and specifically disclaims any implied warranties. Renishaw reserves the right to

make changes to this document and to the product described herein without obligation to notify any

person of such changes.

Storage and handling

UHV version only

Propan-2-ol

CH3CHOHCH

3

+70 °C

-20 °C

System

Methylated

Spirits

+55 °C

0 °C

System

Storage <95% RH

Operating <80% RH

Page 3

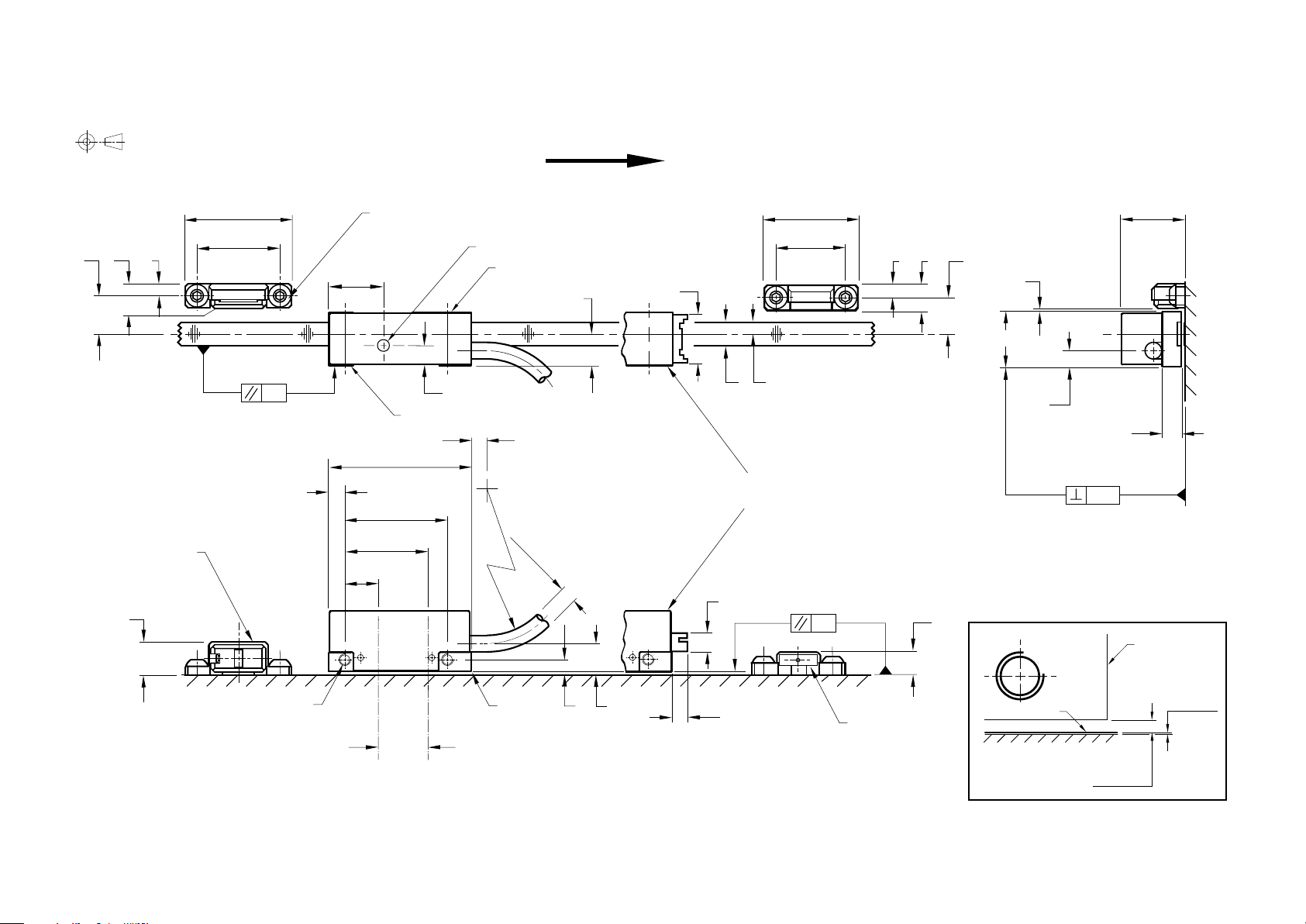

RGH24/ 25 Installation drawing

Dimensions and tolerances in mm.

27

9.5

6.2

A-9541-0037

Reference mark

8.5*

3

actuator

21

0.3

(Yaw Tol. ± 0.5°)

Arrow indicates forward direction of

Fixing screws

M3 x 0.5 x 8

12.8

readhead relative to scale

Set-up LED

Alternative mounting face

8

11.9

23

17

3

6

9.3

0.8

15.8*

13.5

3

5.5

Mounting face

>4

6

3.8

4.8

(Extent of mounting faces)

36

4

26

21.1

>R20 Dynamic bend radius

>R10 Static bend radius

Ø4.4 max

JST connector

version

0.09

(Roll Tol. ± 1°)

8.5

5

(Pitch Tol. ± 1°)

0.6

6.4*

Detail A

Readhead

2 Mounting holes

M3 x 0.5 through

*Dimensions measured from substrate

Optical centreline

A

4*

Reference mark sensor /

limit switch sensor position

Scale

8*

4.3

Scale surface

thickness

0.2

A-9541-0040

Limit switch

actuator

Readhead to

scale clearance

0.8 ± 0.1

Rideheight

Page 4

Readhead mounting/installation

Mounting brackets

The bracket must have a flat mounting surface, enable conformance to the installation tolerances,

allow adjustment to the rideheight of the readhead, and be sufficiently stiff to prevent deflection of the

readhead during operation. For easier installation, adjust the roll and yaw of the bracket with respect

to the axis of readhead travel before the RGH24 or RGH25 is attached. This can be done with a clock

gauge and a precision square.

Readhead set-up

To set nominal rideheight, position readhead spacer with ‘L’ shaped aperture under the optical

centre of the readhead to allow normal LED function during set-up procedure. Ensure that the scale,

readhead optical window and mounting face are clean and free from obstructions.

NOTE: Ensure readhead fixing screws are tightened to 0.5 Nm - 0.7 Nm.

Pitch

0° ± 1°

Yaw

0° ± 0.5°

Roll

0° ± 1°

RGH24

Green Orange Red

RGH25 and RGB25

IMPORTANT: The RGH24 range does not incorporate a separate Alarm ‘E’ signal. Low signal is

indicated by a 3-state output of the line driver channels. For further details, refer to the Data sheet

Part No. L-9517-0166.

Limit switch

A limit switch signal is output when the readhead sensor passes over the magnetic actuator.

For full output specification refer to RGH24 Data sheet (Part number L- 9517- 0166) and

RGH25 Data sheet (Part number L- 9517- 0168).

Reference mark set-up

To ensure unidirectional repeatability, the reference mark requires phasing with the scale in

the direction of normal datuming operation.

A reference pulse is output in both directions, but repeatabilty is guaranteed only in the

phased direction.

Ensure readhead is set up correctly with a green LED indication over the full length of travel and

that the reference mark actuator is fitted correctly.

NOTE: It is recommended that a datum procedure is performed as part of any power-up sequence

to ensure the correct datum position is recorded.

NOTE: Reference mark output is synchronised with the incremental channels, giving unit of

resolution pulse width. For further details see RGH24 and RGH25 Data sheets (L- 9517- 0166 and

L-9517-0168)

Phasing procedure

The readhead must be moved over the reference mark in the direction to be used for the datuming

operation. The reference mark is phased correctly when the set-up LED flashes red for 0.25 seconds.

If it flashes orange or goes blank, the reference mark adjuster screw should

be turned anti-clockwise by

a red flash is obtained.

1

/

8 turn and the procedure repeated until

0.8 ± 0.1 mm

Rideheight

Green Orange Red

For reliable operation, the set-up LED should be GREEN when readhead is moved along the

full axis travel.

An external set-up signal (X or VX) is also available on RGB25 interfaces for use where the LED is

not visible. In this case, 5V indicates optimum set-up, while a 0V signal indicates that the set-up

should be adjusted. The JST version of the RGH24 has an LED repeater signal that can be used in

cases where the LED is not visible.

RGH24

Red Orange Blank

LED flash during reference

mark traverse only

1

/

turn

8

Page 5

RGB25 Installation drawing

Dimensions in mm

torque

19.2

0.35 Nm

Phasing procedure continued

RGH25 + RGB25

Red Orange Blank

Output

15 way D type

plug

1

/

turn

8

LED flash during reference

mark traverse only

Set up LED

Connections

RGB25 input (all models)

127

100

114

142

20

16.2

33.3

12

(A-9539-2018)

Input

socket

15 way D type

Function

Power

Incremental

signals

Reference mark

Not connected

Sin monitor

Cos monitor

Shield

Signal

5 V

0 V

Vmid

A phase

B phase

C phase

HALL

-

-

-

Inner shield (not UHV)

Outer shield

RGH25 core

wire colour

Red

White

Brown

Green

Yellow

Blue

Pink

-

Do not connect

Do not connect

RGB25 interface

D type socket input

8

9

3

6

5

4

1

2, 7, 11, 12, 13

14

10

15

Case

15 pin

41

Max. screw size M4

when installing brackets

NOTE: Remove washers

Optional mounting brackets

RGB25 input

Page 6

RGH24 D, X, Z, W, Y, H, I, O RS422A digital

Function

Power

Incremental

signals

Reference

mark/Limit

switch

Shield

Remote

LED driver

Signal

A

B

Z+/Q -

Z-/Q +

Inner

Outer

Green

Red

5 V

0 V

+

-

+

-

Colour

Brown

White

Green

Yellow

Blue

Red

Pink

Grey

Inner shield

Outer shield

N/A

N/A

9 pin D type

(A)

5

1

2

6

4

8

3

7

9

Case

N/A

N/A

JST

(Z)

9

10

8

7

2

1

5

6

N/A

N/A

4

3

15 pin D type

(D)

7,8

2,9

14

6

13

5

12

4

15

Case

N/A

N/A

3-state Alarm

For RGH24D, X, Z, incremental channels forced open circuit for >20 ms when signal too low for reliable operation.

For RGH24W, Y, H, I, O incremental channels forced open circuit for >10 ms when signal too low or speed too

high for reliable operation.

RGH24 B 1Vpp, RGH24C 12µA analogue

Function

Power

Incremental

signals

Reference

mark

Shield

Signal

5 V

0 V

V1+/I1+

V1-/I1-

V2+/I2+

V2-/I2-

V0+/I0+

V0-/I0-

Inner

Outer

Colour

Brown

White

Green

Yellow

Blue

Red

Pink

Grey

–

–

9 pin D type (A)

(B and C outputs)

5

1

2

6

4

8

3

7

9

Case

15 pin D type (L)

(B outputs only)

4, 5

12, 13

9

1

10

2

3

11

15

Case

9 pin circular (C)

(C outputs only)

6

5

8

7

4

3

2

1

9

Case

RGB25 output (all models)

Function

Power

Alarm

External set-up

Shield

Reserved

Incremental

signals

Reference mark /

Limit switch

Digital

signal

A+

A-

B+

B-

Z+/Q+

Z-/Q-

Signal

5 V

5 V

0 V

0 V

E+

E-

X/V

Inner

Outer

–

‘B’

signal

V1+

V1-

V2+

V2-

V0+/Vq+

V0-/Vq-

Digital

outputs

7

8

2

9

11

3

x

1

N O T C O N N EC TE D

Case

15

‘C’

signal

I1+

I1-

I2+

I2-

I0+/Iq+

I0-/Iq-

Digital

outputs

14

6

13

5

12

4

Analogue

outputs

4

5

12

13

N/A

N/A

7

Case

15

Analogue

outputs

9

1

10

2

3

11

Alarm

For RGB25D, X, Z alarm asserted for signal amplitude <15%.

For RGB25Y, H alarm asserted when: - Signal amplitude >150% - Readhead exceeds specified maximum speed.

Also, outputs are 3-stated at signal amplitude <15%

1652

31

9 pin D type plug (Termination code A)

52 26

9 pin circular plug (Termination code C)

15 pin D type plug (Termination code D, L)

10 pin JST plug

(Termination code Z)

52

16

40

RGB25 output

Page 7

General specifications

Power supply

RGH24 5 V ± 5% 120 mA

RGH25+RGB25 (system) 5 V ± 5% 200 mA

RGH25UHV (readhead only) 5 V ± 5% 50 mA

NOTE: For digital outputs, current consumption figures

refer to unterminated readhead

A further 25 mA per channel pair (eg A+, A-) will be

drawn when terminated with 120 Ω.

Renishaw encoder systems must be powered from a

5 V dc supply complying with the requirements for

SELV of standard EN (IEC) 60950.

Ripple

Bake-out temperature

Sealing (readhead) IP40

Acceleration (readhead) operating 500 m / s

200 mVpp maximum@ frequency up to 500 kHz maximum

120 °C (RGH25UHV only)

2

BS EN 60068-2-7:1993

(IEC 68-2-7:1983)

Shock (readhead) non-operating 1000 m /s2, 6 ms, ½ sine BS EN 60068-2-27:1993

(IEC 68-2-27:1987)

Vibration (readhead) operating 100 m/s2, 55 Hz to 2000 Hz BS EN 60068-2-6:1996

(IEC 68-2-6:1995)

Mass RGH24: 11 g RGH25: 9 g

RGB25 interface: 95 g

Cable: standard 34 g/m UHV 23 g /m

Cable

Standard Double shielded, maximum outside diameter 4.4 mm.

Flex life >20 x 106 cycles at 20 mm bend radius.

UHV Single tinned copper braided shield over PTFE

insulated cores.

NOTE:

standard 15 pin ‘D’ type connector fitted is

not vacuum compatible.

The RGH24/25 series readheads have been designed to the relevant EMC standards, but

must be correctly integrated to achieve EMC compliance. In particular, attention to shielding

arrangements is critical. Renishaw recommends the use of a double screened cable to

connect RGH24 JST as used in the cable variants of the RGH24/ 25.

NOTE: Class 1M LED product. LED radiation. Do not view directly with optical instruments.

s/interfaces.

RGH25 and RGB25 grounding and shielding

RGH25

Inner shield

(except UHV)

RGB25

Extension cable**

0 V power

Outer shield

Pin 15

**Maximum extension cable length:

RGB25B - 100 m, RGB25D, X, Z - 50 m, RGB25C - 30 m, RGB25Y, H - 20 m

Recommended signal termination

Digital outputs - RGH24D, X, Z, W, Y, H, I, O - RGB25D, X, Z, Y, H

#

Only required on alarm channel E (not RGH24)

Readhead/interface

A B Z E Q+

Cable Z0 = 120R

A B Z E Q-

Analogue outputs - RGH24B, RGB25B

V0 V1 V2+

120R

1k

1k

5V

120R

0 V

Customer

#

electronics

#

Customer

electronics

5 V

Output

signals

0 V

Electrical connections

RGH24 grounding and shielding

RGH24

Inner shield

Extension cable*

Outer shield

*Maximum extension cable length:

RGH24B -100 m, RGH24D, X, Z - 50 m, RGH24C -30 m, RGH24W, Y, H, I, O -20 m

Customer

electronics

5 V

0 V

Output

signals

V0 V1 V2-

Remote LED driver outputs

The output of the integral set-up LED

is available from the JST connector

versions only to allow remote

monitoring of readhead installation.

+

–

Green

Red

150R

Green

Red/Green

LED

Red

Page 8

Readhead part numbers

RGH24

30

X

A 00

A

Datum

A - Standard reference sensor

B - Limit switch sensor (RGH24D, H, I, O, W, X, Y and Z only)

Options

00 - Standard (RGH24B, C, D, X and Z only)

01 - JST connector (RGH24D, X and Z only)

30 - 12 MHz customer clock (RGH24H, I, O and Y only)

31 - 8 MHz customer clock (RGH24H, I, O and Y only)

32 - 6 MHz customer clock (RGH24W only)

33 - 4 MHz customer clock (RGH24H, I, O, W and Y only)

35 - 12 MHz customer clock (RGH24H, I, O and Y JST connector version only)

36 - 8 MHz customer clock (RGH24H, I, O and Y JST connector version only)

37 - 6 MHz customer clock (RGH24W JST connector version only)

38 - 4 MHz customer clock (RGH24H, I, O, W and Y JST connector version only)

Termination

A - 9 pin D type plug

C - 9 pin circular plug (RGH24C only)

D - 15 pin D type plug (RGH24D, H, I, O, W, X, Y and Z only)

F - unterminated cable

L - 15 pin D type plug (RGH24B only)

Z - JST connector (RGH24D, H, I, O, W, X, Y, and Z only)

Cable length

00 - no cable (JST connector only)

15 - 1.5 m (all except JST connector)

30 - 3 m (all except JST connector)

50 - 5 m (all except JST connector)

Output

Analogue B - 1 Vpp

C - 12 µA

Digital D - 5 µm

X - 1 µm

Z - 0.5 µm

W - 0.2 µm

Y - 0.1 µm

H - 50 nm

I - 20 nm

O - 10 nm

Readhead series

Readhead part numbers

RGH25U

15

J 00

A

Datum

A - Standard reference sensor

B - Limit switch sensor

Options

00 - Standard head

01 - Vacuum head and cable

Termination

J - 15 pin D type plug for RGB25 interface (non-vacuum only)

M - 15 pin D type plug for RGB25 interface (vacuum only)

Cable length

15 - 1.5 m

30 - 3 m

50 - 5 m

Readhead series

Interface part numbers for use with RGH25U

RGB25

H

00

61

R

Options

00 - Standard.(RGB25B, C, D, X, and Z only)

61 - 20 MHz customer clock (RGB25H and Y only)

62 - 10 MHz customer clock (RGB25H and Y only)

63 - 5 MHz customer clock (RGB25H and Y only)

Type of datum sensor

R - Standard reference sensor

L - Limit switch sensor

Alarm

00 - E+/E- alarm for signal amplitude <15% (RGB25D, X and Z only)

- E+/E- alarm for signal amplitude >150%; overspeed alarm;

3 state alarm for signal amplitude <15% (RGB25H and Y only)

- No alarm (RGB25B and C only)

01 - 3 state alarm for signal amplitude <15% (RGB25D, X and Z only)

Output

Analogue B - 1 Vpp

C - 12 µA

Digital D - 5 µm

X - 1 µm

Z - 0.5 µm

Y - 0.1 µm

H - 50 nm

Interface series

C - Vacuum reference sensor

D - Vacuum Limit switch sensor

NOTE: Not all combinations are valid. Check valid options online at www.renishaw.com/epc

NOTE: Not all combinations are valid. Check valid options online at www.renishaw.com/epc

Page 9

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

RENISHAW® and the probe emblem used in the RENISHAW logo are

registered trademarks of Renishaw plc in the UK and other countries.

apply innovation is a trademark of Renishaw plc.

Renishaw reserves the right to change specifications without notice.

2001-2007 Renishaw plc Issued 0607 Part No. M-9541-0084-04-C

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

*M-9541-0084-04*

Loading...

Loading...