Renishaw QUANTiC RTLC40-S, QUANTiC RTLC40/FASTRACK, QUANTiC RTLC40, QUANTiC FASTRACK Installation Manual

Page 1

RSLM high accuracy linear encoder

Installation guide

M-9417-9089-03-A

QUANTiC™ linear encoder system

Page 2

Contents

Product compliance 1

Storage and handling 2

RTLC40- S:

Installation drawing (adhesive datum clamp) 3

Scale application 4

End covers 4

Reference mark selector and limit magnet installation 5

Datum clamp 5

RTLC40/FASTRACK:

Installation drawing (adhesive datum clamp) 6

FASTRACK and scale application 7

Scale datum 8

Reference mark selector and limit magnet installation 9

QUANTiC quick-start guide 10

Readhead mounting and alignment 11

System calibration 12

Troubleshooting 13

QUANTiC:

Readhead dimensions 15

Output signals 16

Speed 16

Electrical connections 17

Output specications 17

General specications 18

RTLC40-S and RTLC scale technical specications 18

FASTRACK technical specications 18

QUANTiC linear installation guide

Page 3

Disclaimer

RENISHAW HAS MADE CONSIDERABLE EFFORTS TO ENSURE THE CONTENT OF THIS DOCUMENT

IS CORRECT AT THE DATE OF PUBLICATION BUT MAKES NO WARRANTIES OR REPRESENTATIONS

REGARDING THE CONTENT. RENISHAW EXCLUDES LIABILITY, HOWSOEVER ARISING, FOR ANY

INACCURACIES IN THIS DOCUMENT.

Product compliance

C

Renishaw plc declares that QUANTiC complies with the applicable standards and regulations.

A copy of the EC Declaration of Conformity is available from our website www.renishaw.com

FCC compliance

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

The user is cautioned that any changes or modications not expressly approved by Renishaw plc or

authorised representative could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

NOTE: This unit was tested with shielded cables on the peripheral devices. Shielded cables must be

used with the unit to ensure compliance.

RoHS compliance

Compliant with EC directive 2011/65/EU (RoHS)

Patents

Features of Renishaw’s encoder systems and similar products are the subjects of the following

patents and patent applications:

EP1173731 US6775008 JP4750998 CN100543424 EP1766334

JP4932706 US7659992 CN100507454 EP1766335 IN281839

JP5386081 US7550710 CN101300463 EP1946048 JP5017275

US7624513 CN101310165 EP1957943 US7839296 CN108351229

EP3347681 JP2017042570 KR20180052676 US20180216972 WO2017203210

CN1314511 EP1469969 EP2390045 JP5002559 US8987633

US8466943 CN102057256 EP2294363 JP5475759 JP5755299

KR1550483 US8141265

Further information

Further information relating to the QUANTiC encoder range can be found in the QUANTiC system

Data sheet (L-9517-9778), Advanced Diagnostic Tool ADTi-100 Data sheet (L-9517-9699), Advanced

Diagnostic Tool ADTi-100 and ADT View software user guide (M-6195-9413) and Advanced Diagnostic Tool

ADTi-100 and ADT View software quick-start guide (M-6195-9321). These can be downloaded from our

website www.renishaw.com/encoder and are also available from your local representative. This document

may not be copied or reproduced in whole or in part, or transferred to any other media or language, by any

means without the written prior permission of Renishaw. The publication of material within this document

does not imply freedom from the patent rights of Renishaw plc.

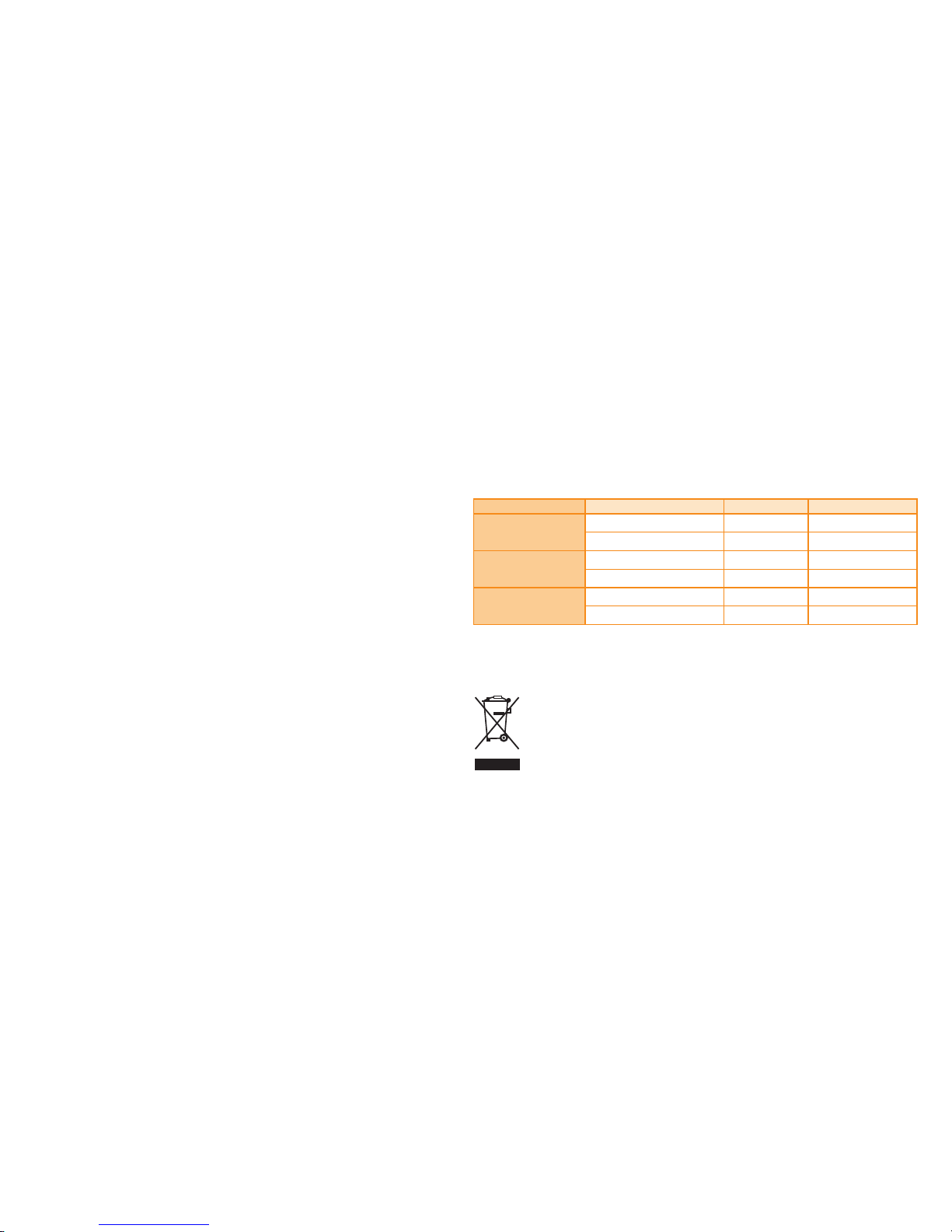

The use of this symbol on Renishaw products and/or accompanying documentation indicates that the product

should not be mixed with general household waste upon disposal. It is the responsibility of the end user to

dispose of this product at a designated collection point for waste electrical and electronic equipment (WEEE)

to enable reuse or recycling. Correct disposal of this product will help to save valuable resources and prevent

potential negative effects on the environment. For more information, please contact your local waste disposal

service or Renishaw distributor.

1

QUANTiC linear installation guide

The packaging of our products contains the following materials and can be recycled.

Packaging Component Material ISO 11469 Recycling Guidance

Outer box

Cardboard Not applicable Recyclable

Polypropylene PP Recyclable

Inserts

Low Density Polyethylene Foam LDPE Recyclable

Cardboard Not applicable Recyclable

Bags

High Density Polyethylene Bag HDPE Recyclable

Metalised Polyethylene PE Recyclable

Page 4

2

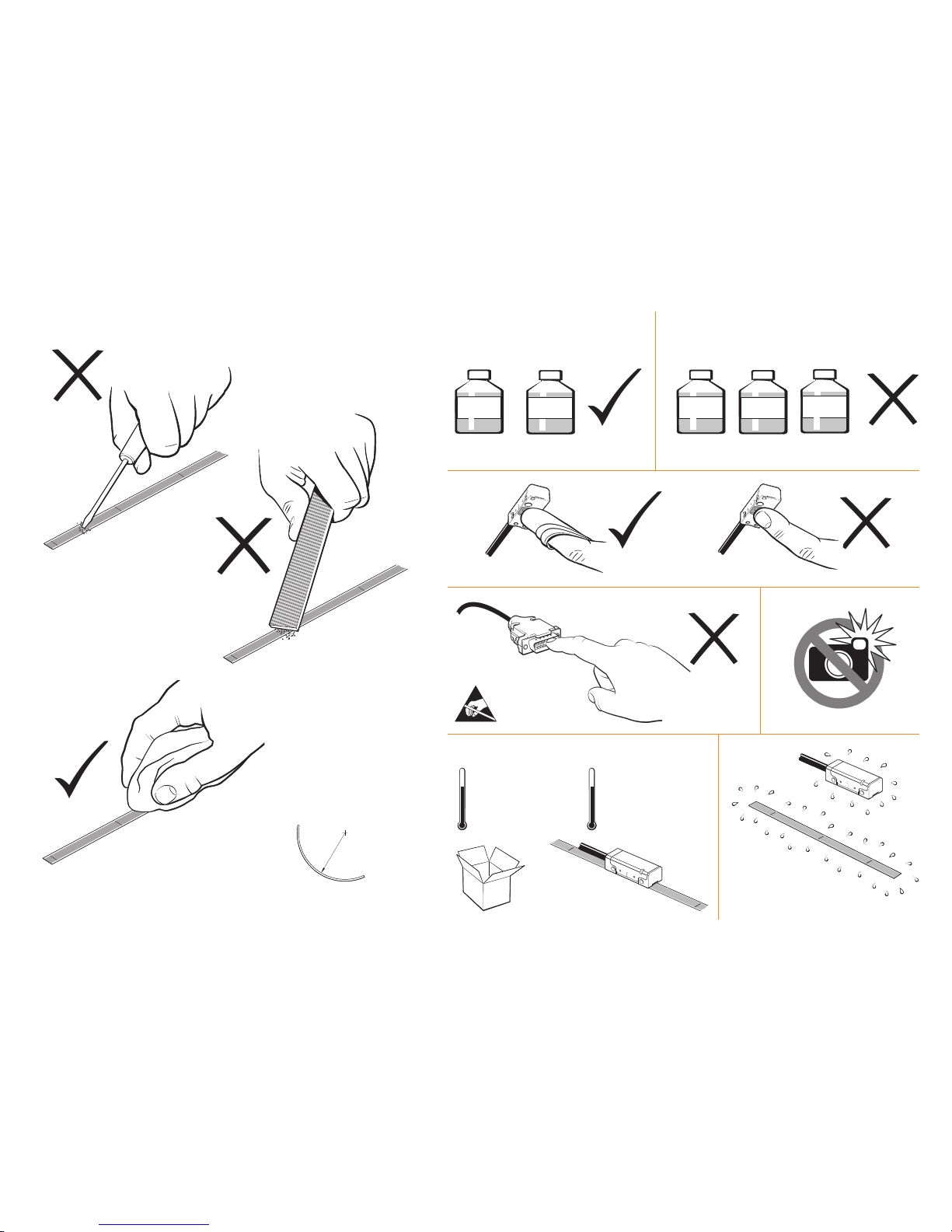

+70 °C

−20 °C

Minimum bend radius

RTLC40-S – 150 mm

RTLC40 – 50 mm

FASTRACK – 200 mm

NOTE: Ensure self-adhesive tape

is on the outside of bend radius.

95% relative humidity

(non-condensing)

to EN 60068-2-78

Humidity

Storage

+70 °C

0 °C

Operating

Storage and handling

N-heptane

CH

3

(CH2)5CH

3

Propan-2-ol

CH3CHOHCH

3

Scale and readhead

Readhead only

Acetone

CH3COCH

3

Methylated

Spirits

Chlorinated

Solvents

QUANTiC linear installation guide

Page 5

3

QUANTiC linear installation guide

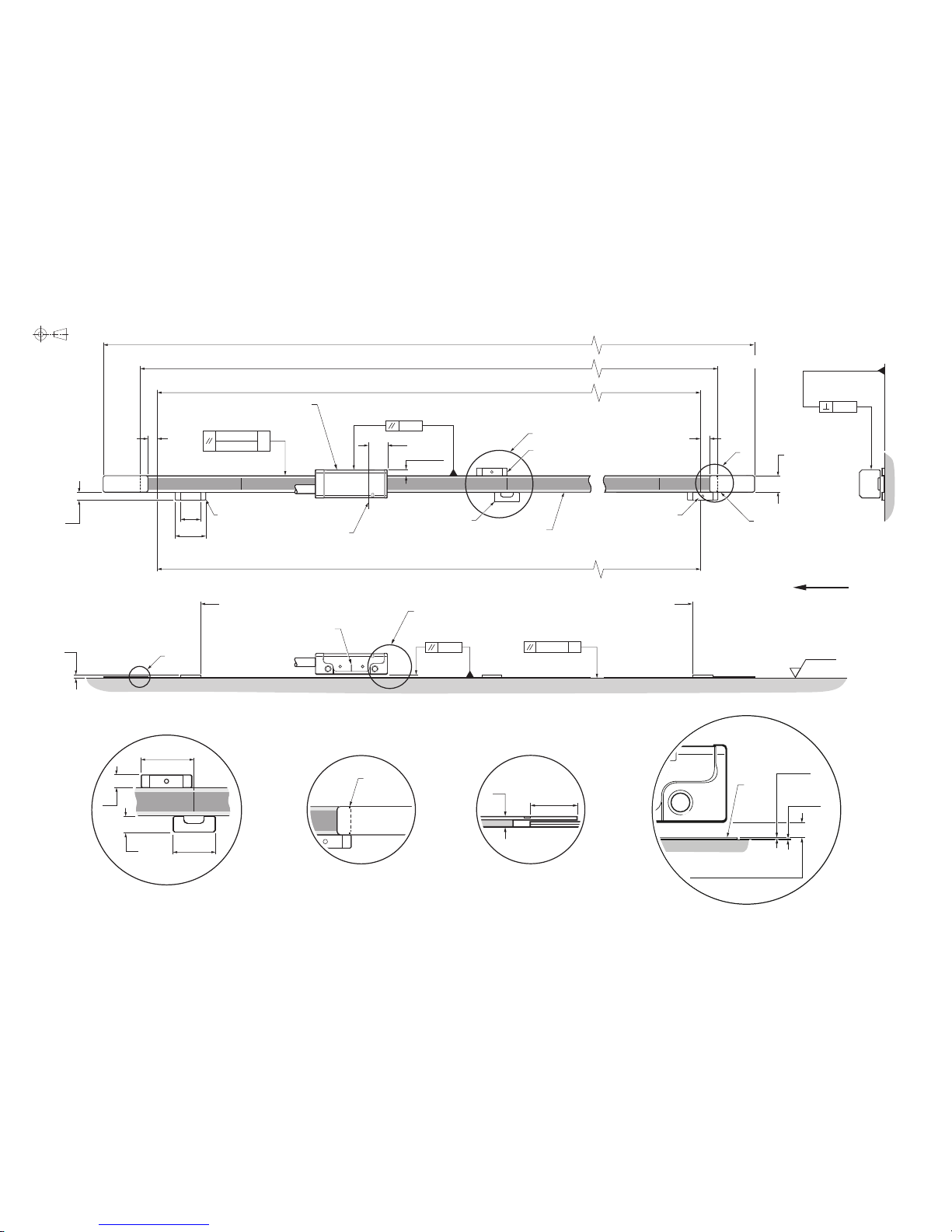

RTLC40-S: Installation drawing (adhesive datum clamp)

Dimensions and tolerances in mm

Scale length (L)

Overall length (L+37)

Measuring length ML = (L−17) (ML = (L−32 ) with dual limits)

Readhead optical detector position at extent of travel

Nominal P limit trigger point

Q limit magnet†

(A-9653-0139)

(Dimensions as P limit)

Reference mark selector magnet†

(A-9653-0143)

B

Optical centreline

(Incremental and reference mark)

5

Optional end cover

(Pair A-9585-0035)

5

8

START (see page 4)

A

C

End cover

alignment

indicator

0.5

F

0.2/100

0.05

F

F = axis of motion

Nominal Q limit trigger point

Ra 3.2

0.8

3.5

Detail A

12

3.7

4.5

Datum clamp

(A-9585-0028)

Detail CDetail B

15 ±1

10

15

3.7

0.12

(Roll tol. ±0.8°)

1.5

*

D

Detail D

0.6

(Pitch tol. ±1°)

0.55

(Yaw tol. ±0.9°)

2.75 ±0.5

Scale

reading

surface

Scale

thickness

0.2

Adhesive

thickness

0.2

Calibration rideheight: 2.1 ±0.2

Operating rideheight: 2.1 ±0.28

*

Dimension from substrate surface. †Bolted reference mark selector magnet and limit magnets available. See page 5 for details.

NOTE: The reference mark selector and limit actuator locations are correct for the readhead orientation shown.

F = axis of motion

P limit magnet†

(A-9653-0138)

QUANTiC

readhead

RTLC40-S

scale

FINISH (see page 4)

Forward direction of readhead

relative to scale

P and Q limit

switch sensor position

9.2

Page 6

4

QUANTiC linear installation guide

9

Remove applicator and, if necessary,

adhere the remaining scale manually.

Apply rm nger pressure via a clean

lint-free cloth along the length of the

scale after application to ensure

complete adhesion.

10

Clean scale using Renishaw scale

cleaning wipes (A-9523-4040) or

a clean, dry, lint-free cloth.

5

Move axis to scale START position, leaving enough room for the scale

to be inserted through the applicator, as shown below.

6

Begin to remove the backing paper from the scale and insert scale into

the applicator up to the ‘START’ point (as shown). Ensure backing paper

is routed under the splitter screw.

7

Apply nger pressure to the scale at the ‘START’ point, using a clean

lint-free cloth, to ensure scale end adheres well to the substrate.

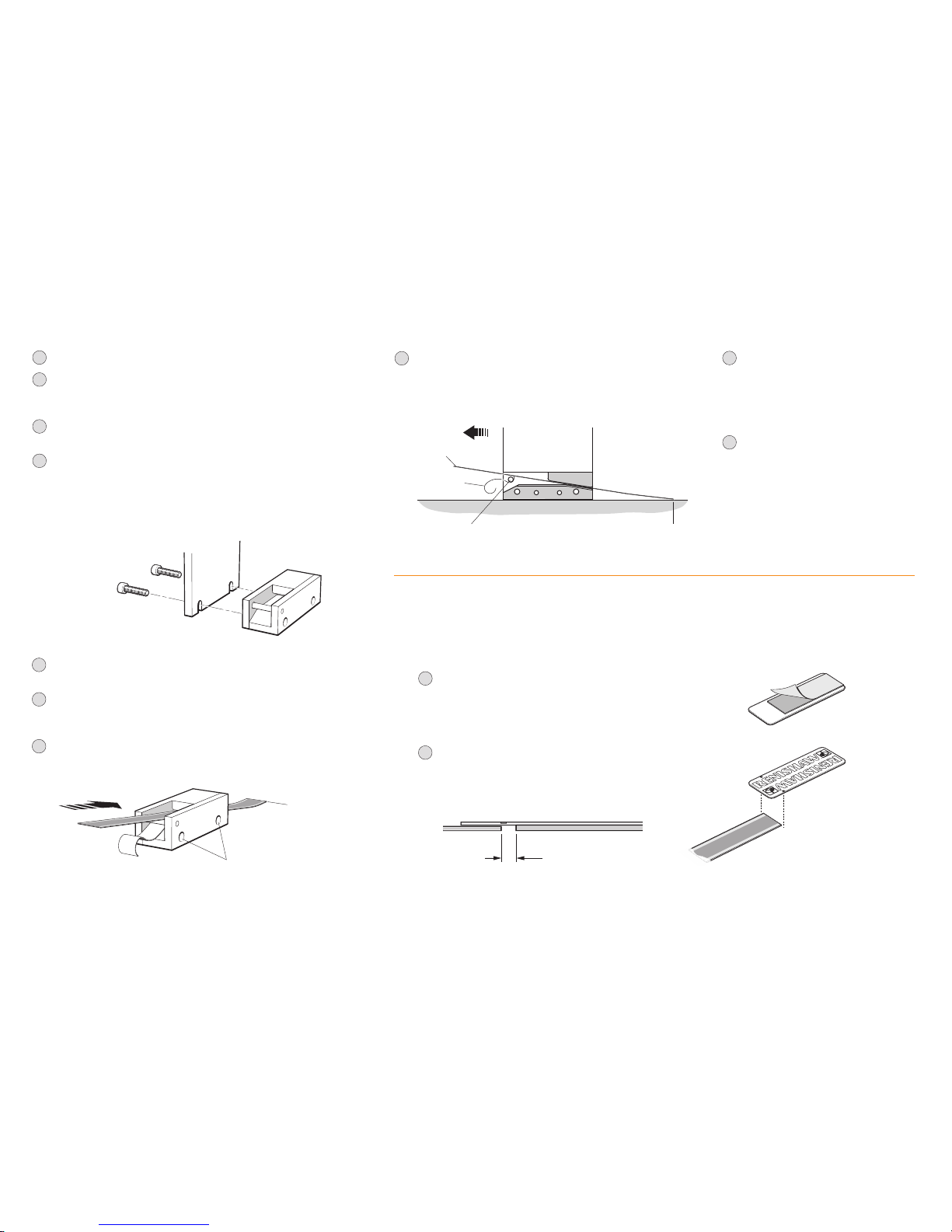

RTLC40-S: Scale application

Scale applicator (A-9589-0115) is designed for use with RTLC40-S scale.

1

Allow scale to acclimatise to installation environment prior to installation.

2

Mark out the ‘START’ and ‘FINISH’ points for the scale on the axis substrate

– ensure that there is room for the optional end covers if required

(see ‘RTLC40-S: Installation drawing’).

3

Thoroughly clean and degrease the substrate using recommended solvents

(see 'Storage and handling'). Allow substrate to dry before applying scale.

4

Mount the scale applicator to the readhead mounting bracket using

M2.5 screws. Place the shim supplied with the readhead between the

applicator and substrate to set the nominal height.

NOTE: Scale applicator can be mounted either way round to enable

easiest orientation for scale installation.

Side mounting scale applicator

(A-9589-0115)

8

Slowly and smoothly move the applicator through the entire axis

of travel, ensuring the backing paper is pulled manually from the

scale and does not catch under the applicator.

START

RTLC40-S

Backing tape

Splitter screw

Direction of scale application

M2.5 mounting holes

START

RTLC40-S: End covers

The end cover kit (A-9585-0035) is designed to be used with RTLC40-S scale.

NOTE: End covers are optional and can be tted before or after readhead installation.

1

Remove the backing tape from the adhesive tape on the back of

the end cover.

2

Align marker on the edges of the end cover with the end of the scale

and place end cover over the scale.

NOTE: There will be a gap* between the end of the scale and

the adhesive tape on the end cover.

*

gap

Page 7

5

RTLC40-S: Reference mark selector and limit magnet installation

IMPORTANT: Allow 24 hours after scale application before tting magnets.

For accuracy and ease of positioning of reference mark selector and limit magnets,

the applicator tool (A-9653-0201) should be used. The magnet should be attached

to the applicator tool as shown. Limit magnets can be positioned at any user

dened location along the scale, but the reference mark selector magnet should

be positioned adjacent to the chosen IN-TRAC reference mark as shown.

As the QUANTiC readhead passes the reference mark selector magnet or limit

switch magnet, a force of up to 0.2 N is generated between the magnet and the

concentrators on the readhead. The design of the bracket should be sufciently

stiff so that it is able to tolerate such force without distorting.

Following the clamping instructions on the scale installation will prevent this

magnetic force from disturbing the scale.

NOTE: Reference and limit magnets may creep when inuenced by magnetic

materials in close proximity. In such cases, they should be held in place using

an additional llet of epoxy glue or similar along the outer edge of the

magnet assembly. Optional bolted reference and limit magnets are available.

Limit trigger point

The limit output is nominally asserted when the readhead limit switch sensor passes

the limit magnet leading edge, but can trigger up to 3 mm before that edge.

(See ‘RTLC40-S: Installation drawing’).

NOTE: External magnetic elds greater than 6mT, in the vicinity of the readhead,

may cause false activation of the limit and reference sensors.

Optional bolted reference mark selector and limit magnets

QUANTiC linear installation guide

2

Place a small amount of adhesive (Loctite® 435™)

in the cut-out on the datum clamp,

ensuring none of the adhesive

wicks onto the scale surface.

Dispensing tips P-TL50-0209

are available.

Ensure the adhesive

wicks along the entire

length of cut-out.

Remove

self-adhesive

backing paper

Reference mark

selector magnet

IN-TRAC

reference mark

Q limit magnet

Applicator tool

(A-9653-0201)

P limit magnet

1

Place the datum clamp with cut-out against the scale at

the chosen location.

A-9585-0028

22

18

10

3.7

Ø2.2

*

1.85

18.5 ±1

The datum clamp (A-9585-0028) xes the RTLC40-S scale rigidly

to the substrate at the location chosen. The metrology of the

system may be compromised if the datum clamp is not used.

The datum clamp does not need to be tted adjacent to a

reference mark. It can be positioned anywhere along the axis

depending upon the customers’ requirements.

*

Supplied with 2 x M2 x 4 screws.

RTLC40-S: Datum clamp

IMPORTANT: Allow 24 hours after scale application before tting datum clamp.

NOTE: The reference mark selector

and limit actuator locations are correct

for the readhead orientation shown.

Bolted magnet type Part number

P limit A-9653-0292

Q limit A-9653-0291

Reference mark selector A-9653-0290

Page 8

6

QUANTiC linear installation guide

QUANTiC

readhead

RTLC40 scale

FASTRACK

Ra 3.2

Optional end cover

(Pair A-9589-0058)

18

5

A

Do not cut FASTRACK

over shaded areas

2.25 ±0.5

18 ±0.1

35 max

Overall length (L+12)

Scale length (L)

Measuring length ML = (L−10)

(ML=(L−25 ) with dual limits)

10 max (gap)

1 min (gap)

Optical centreline (Incremental and reference mark)

Detail A

0.1/100

0.5

F

F = axis of motion

0.05

F

F = axis of motion

FASTRACK length = (L−24 )

*

*

Assumes 1 mm gap between scale and end covers and zero gap between FASTRACK and end covers.

†

Dimension from FASTRACK surface. ‡For alternative mechanical datum clamp methods see page 8.

NOTES: Minimum recommended FASTRACK length = 100 mm. The reference mark selector and limit actuator locations are correct for the readhead orientation shown.

RTLC40/FASTRACK: Installation drawing (adhesive datum clamp

‡

)

Nominal P limit trigger point

Nominal Q limit trigger point

P limit magnet

(A-9653-0138)

Q limit magnet

(A-9653-0139)

(Dimensions as P limit)

Reference mark selector magnet

(A-9653-0143) (Dimensions as P limit)

10

15

3.7

0.12

(Roll tol. ±0.8°)

0.55

(Yaw tol. ±0.9°)

1.5

†

0.6

(Pitch tol. ±1°)

B

Detail B

15 ±1

2 locations

for spots of Loctite® 435

™

(P-AD03-0012) to secure axis

datum position

‡

Dimensions and tolerances in mm

C

FASTRACK

thickness

0.4

Calibration rideheight: 1.9 ± 0.17

Operating rideheight: 1.9 ± 0.25

Detail C

Forward direction of readhead

relative to scale

P and Q limit

switch sensor position

9.2

Page 9

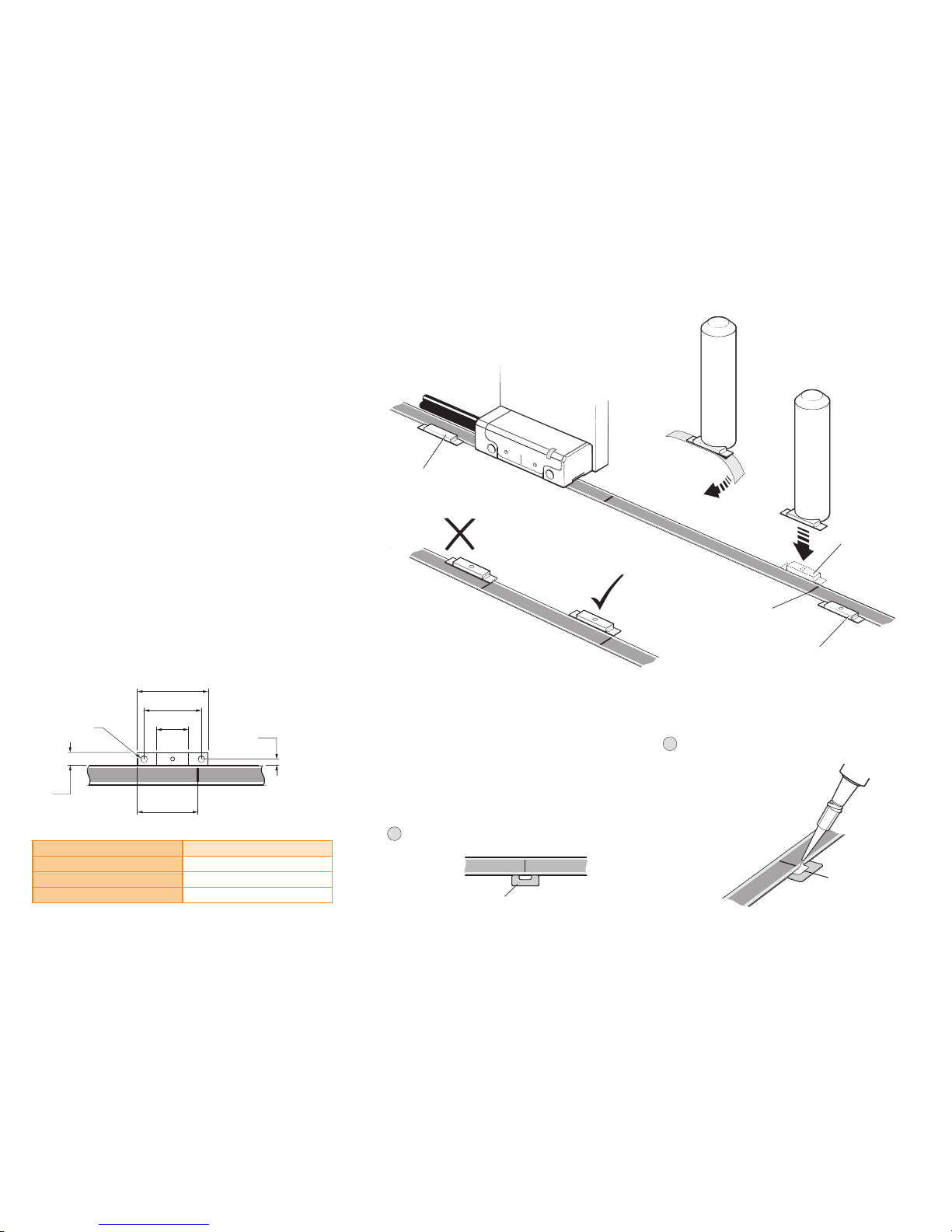

RTLC40/FASTRACK: FASTRACK and scale application

During handling or installation of FASTRACK suitable gloves should be worn to protect against injury from sharp edges.

2

Thoroughly clean and degrease

the substrate and allow to dry.

For FASTRACK location a ledge,

separate straight edge(s) or

dowels can be used.

Check alignment of ledge/separate

straight edge(s) with respect to

axis of motion

(see ‘RTLC40/FASTRACK:

Installation drawing’).

1

If required cut FASTRACK and scale to length

(separately) using guillotine (A-9589-0071)

after referring to installation drawing.

Guillotine should be held securely in place,

using a suitable vice or clamping method.

Feed FASTRACK or scale through the

guillotine as shown, and place guillotine

press block down onto the FASTRACK/scale.

Ensure the block is in the correct orientation

(as shown). Whilst holding the block in place,

in a smooth motion, pull down the lever to cut

through the FASTRACK/scale.

Before sticking FASTRACK to

the substrate bend the centre

section upwards slightly using

a small pair of pliers.

3

4

Remove backing liner and stick to substrate, locating

against ledge/separate straight edge(s) or dowels.

Ensure complete adhesion to the substrate by

applying rm nger pressure along the length

of the FASTRACK from the centre outwards

towards each end using a lint-free cloth

if required.

NOTE: Allow the FASTRACK a minimum

of 20 minutes to adhere before removing

the centre section.

IMPORTANT: Wear suitable

protective gloves whilst

carrying out this procedure

to avoid risk of cuts.

5

Engage centre section removal tool and with consistent

forward pressure remove centre section.

If the ledge method or similar is used

then the appropriate side panel on

the removal tool (A-9589-0122)

will need to be removed

as shown.

Ledge

Side panels

DO NOT CUT

FASTRACK

in these

areas

Guillotine

press block

7

QUANTiC linear installation guide

Page 10

8

QUANTiC linear installation guide

RTLC40/FASTRACK : Scale datum

The datum clamp xes the RTLC40 scale rigidly to the substrate at the location chosen.

The metrology of the system may be compromised if the datum clamp is not used.

The datum clamp does not need to be tted adjacent to a reference mark.

It can be positioned anywhere along the axis depending upon the customer’s requirements.

Mechanical clamp

Adhesive clamp

Using dispensing tip P-TL50-0209 apply Loctite 435

between scale and FASTRACK so it wicks underneath

adjacent to user selected datum location as shown.

NOTE: Drawing shows the scale datum adjacent

to the chosen reference mark.

RTLC40/FASTRACK : FASTRACK and scale application (Continued)

6

Slide RTLC scale into the FASTRACK ensuring the

scale is fed under the projections as shown.

Scale can be installed manually by either pulling or

pushing it through the FASTRACK carrier.

Alternatively use the optional

scale installation tool

(A-9589-0420) as shown,

for easy installation.

Ensure a gap

>1 mm

Projections

NOTE: For instructions on how to use the

scale installation tool, download ‘User guide

– RTL* scale installation tool (A-9589-0420)’

from the website at

www.renishaw.com/encoderinstallationguides.

IMPORTANT: If manually installing

the scale using fingers, suitable

gloves should be worn to protect

against injury from sharp edges.

7

Optional: x self-adhesive end covers

ensuring a gap of at least 1 mm between

the end of the scale and the end cover

8

Clean FASTRACK and scale

using a lint-free cloth

NOTE: When reference mark and

datum clamp aligned as shown,

reference output will be positionally

repeatable with respect to substrate.

Reference mark

selector magnet

3

Do not place clamp tip

over shaded area

IN-TRAC reference mark

12

25

RTLC40 clamp

(A-9589-0077)

M3 x 6 low head screw,

supplied with clamp

†

15 ±1

†

Additional screws available (Pack of 25 A-9584-2047)

NOTE: Only apply Loctite 435 in

these gaps to ensure best bond.

Loctite 435 will wick under the

scale to lock it to the substrate.

16

12

2.3

1.7

5 min

thread

depth

Page 11

9

QUANTiC linear installation guide

NOTE: All limit and reference selector magnets should be

aligned with the outer edges of the FASTRACK.

Limit trigger point

The limit output is nominally asserted when the readhead

limit switch sensor passes the limit magnet leading edge,

but can trigger up to 3 mm before that edge.

(See ‘RTLC40/FASTRACK : Installation drawing’).

NOTE: External magnetic elds greater than 6mT, in the

vicinity of the readhead, may cause false activation of

the limit and reference sensors.

P limit

magnet

Applicator tool

(A-9653-0201)

Remove

self-adhesive

backing paper

IN-TRAC

reference mark

Q limit magnet

RTLC40/FASTRACK : Reference mark selector and limit magnet installation

For accuracy and ease of positioning of reference mark selector and limit magnets, the applicator tool (A-9653-0201) should be used.

The magnet should be attached to the applicator tool as shown below and aligned with the outer edge of the FASTRACK.

Limit magnets can be positioned at any user dened location along the FASTRACK, but the reference mark selector

magnet should be positioned adjacent to the chosen IN-TRAC reference mark as shown below.

As the QUANTiC readhead passes the reference mark selector magnet or limit switch magnet, a force of up to 0.2 N

is generated between the magnet and the concentrators on the readhead. The design of the bracket should be

sufciently stiff so that it is able to tolerate such force without distorting. Following the clamping instructions on

the scale installation will prevent this magnetic force from disturbing the scale.

NOTE: Reference and limit magnets may creep when inuenced by magnetic materials

in close proximity. In such cases, they should be held in place using an additional

llet of epoxy glue or similar along the outer edge of the magnet assembly.

NOTE: The reference mark selector and limit actuator

locations are correct for readhead orientation shown

Reference mark

selector magnet

Page 12

10

QUANTiC linear installation guide

QUANTiC quick-start guide

This section is a quick-start guide to installing a QUANTiC readhead.

More detailed information on installing the readhead is contained on page 11 and page 12 of this installation guide.

The optional Advanced Diagnostic Tool ADTi-100* (A-6165-0100) and ADT View software† can be used to aid installation and calibration.

INSTALLATION

Ensure scale, readhead optical window and mounting faces are clean and free from obstructions.

If required, ensure reference mark selector magnet is correctly positioned, see relevant installation drawing.

Connect the readhead to receiving electronics and power-up. The set-up LED on the readhead will ash.

Install and align the readhead to maximise signal strength over the full axis of travel as indicated by a Green ashing LED.

CALIBRATION

Cycle the power to the readhead to initiate the calibration routine. The LED will single ash Blue.

Move the readhead along the scale at slow speed (<100 mm/s), without passing a reference mark, until the LED starts double ashing Blue.

The system is now calibrated and ready for use. Calibration values, Automatic Gain Control (AGC) and Automatic Offset Control (AOC) status, are stored in readhead non-volatile memory at power down.

NOTE: If calibration fails (LED remains single ashing blue), restore factory defaults by obscuring the readhead optical window on power-up (see page 12). Repeat the installation and calibration routine.

*

For more details refer to the ‘Advanced Diagnostic Tool ADTi-100 and ADT View software quick start guide’ (M-6195-9321) and ‘Advanced Diagnostic Tool ADTi-100 and ADT View software user guide’ (M-6195-9413).

†

The software can be downloaded for free from www.renishaw.com/adt.

Reference mark

Move the readhead back and forth over the selected

reference mark until the LED stops ashing.

No reference mark

If a reference mark is not being used, the calibration routine should now be

exited by cycling the power. The LED will stop ashing.

Page 13

11

QUANTiC linear installation guide

Readhead mounting and alignment

Mounting brackets

The bracket must have a at mounting surface and should provide adjustment to enable conformance to the

installation tolerances, allow adjustment to the rideheight of the readhead, and be sufciently stiff to prevent

deection or vibration of the readhead during operation.

Readhead set-up

Ensure that the scale, readhead optical window and mounting face are clean and free from obstructions.

NOTE: When cleaning readhead and scale apply cleaning uid sparingly, do not soak.

To set nominal rideheight, place the appropriate spacer with the aper ture under the optical centre of the readhead

to allow normal LED function during set-up procedure. RTLC40-S: green spacer, RTLC40/FASTRACK : black spacer.

Adjust the readhead to achieve a ashing Green LED along the full axis of travel. The faster the ash rate,

the closer it is to optimum set-up. The optional Advanced Diagnostic Tool ADTi-100 (A-6195-0100) and

ADT View software can be used to optimise signal strength in challenging installations.

See www.renishaw.com/adt for more information.

NOTE: When re-installing the readhead factory defaults should be restored, see page 12.

Roll

0° ±0.8°

Ya w

0° ±0.9°

Pitch

0° ±1°

Rideheight

2.1 ± 0.2 mm

Readhead LED diagnostics

Green Orange Red

ashing ashing ashing

Readhead set-up LED status

QUANTiC readhead and RTLC40-S

QUANTiC readhead and RTLC40/FASTRACK

Roll

0° ±0.8°

Ya w

0° ±0.9°

Pitch

0° ±1°

Rideheight

1.9 ±0.17 mm

from FASTRACK

top surface

IMPORTANT:

Use black spacer with

RTLC/FASTRACK

IMPORTANT:

Use green spacer

with RTLC-S

Mode LED Status

Installation mode

Green ashing Good set-up, maximise ash rate for optimum set-up

Orange ashing Poor set-up, adjust readhead to obtain Green ashing LED

Red ashing Poor set-up, adjust readhead to obtain Green ashing LED

Calibration mode

Blue single ashing Calibrating incremental signals

Blue double ashing Calibrating reference mark

Normal operation

Blue AGC on, optimum set-up

Green AGC off, optimum set-up

Red Poor set-up; signal may be too low for reliable operation

Blank ash Reference mark detected (visible indication at speed <100 mm/s only)

Alarm

4 red ashes Low signal, over signal, or overspeed; system in error

Page 14

12

QUANTiC linear installation guide

System calibration

NOTE: System calibration, restoring factory defaults, and enabling/disabling AGC functions can also be

carried out using the optional ADT and ADT View software. See www.renishaw.com/adt for more information.

Ensure signal strength has been optimised along the full axis of travel, the LED will be ashing Green.

Cycle the power to the readhead or connect the ‘Remote CAL’ output pin to 0 V for <3 seconds. The readhead

will then single ash Blue to indicate it is in calibration mode as detailed in ‘Readhead mounting and alignment’.

The readhead will only enter calibration mode if the LED is ashing Green.

Step 1 – Incremental signal calibration

uMove the readhead along the axis at slow speed (<100 mm/s), or less than the readhead maximum speed,

whichever is slowest, ensuring it does not pass a reference mark, until the LED starts double-ashing indicating

the incremental signals are now calibrated and the new settings are stored in the readhead memory.

uThe system is now ready for reference mark phasing. For systems without a reference mark, cycle the power

to the readhead or connect the ‘Remote CAL’ output pin to 0 V for < 3 seconds to exit calibration mode.

uIf the system does not automatically enter the reference mark phasing stage (LED continues single ashing)

the calibration of the incremental signals has failed. After ensuring failure is not due to overspeed (>100 mm/s),

or exceeding the readhead maximum speed, exit the calibration routine, restore factory defaults as detailed

below, and check the readhead installation and system cleanliness before repeating the calibration routine.

Step 2 – Reference mark phasing

uMove the readhead back and forth over the selected reference mark until the LED stops ashing and

remains solid Blue. The reference mark is now phased.

uThe system automatically exits the calibration routine and is ready for operation.

uAGC is automatically switched on once calibration is complete. To switch off AGC refer to the

‘Enabling/disabling AGC’ section.

uIf the LED continues double-ashing after repeatedly passing the chosen reference mark it is not being detected.

- Ensure that the correct readhead conguration is being used. Readheads can either output all

reference marks or only output a reference mark where a reference selector magnet is tted depending

on the options chosen when ordering.

- Check reference mark selector magnet is tted in the correct location relative to readhead orientation,

see ‘RTLC40-S installation drawing’.

Calibration routine manual exit

uTo exit the calibration routine at any stage cycle the power to the readhead or connect the ‘Remote CAL’

output pin to 0 V for <3 seconds. The LED will then stop ashing.

Restoring factory defaults

When re-installing the system, or in the case of continued calibration failure, factory defaults should

be restored.

To restore factory defaults:

uSwitch system off.

uObscure the readhead optical window (using the spacer supplied with the readhead ensuring the

cut-out is NOT under the optical window) or connect the ‘Remote CAL’ output pin to 0 V

uPower the readhead.

uRemove the spacer or, if using, the connection from the ‘Remote CAL’ output pin to 0 V.

uThe LED will start continuously ashing indicating factory defaults have been restored and the

readhead is in installation mode (ashing set-up LED).

uRepeat ‘Readhead set-up’ procedure.

Enabling/disabling AGC

The AGC is automatically enabled once the system has been calibrated (indicated by a Blue LED).

AGC can be manually switched off by connecting the ‘Remote CAL’ output pin to 0 V for >3 seconds

<10 seconds. The LED will then be solid Green.

LED Settings stored

Blue single ashing None, restore factory defaults and recalibrate

Blue double ashing Incremental only

Blue (auto-complete) Incremental and reference mark

Page 15

Troubleshooting

QUANTiC linear installation guide

13

Fault Cause Possible solutions

LED on the readhead is Blank There is no power to the readhead

u

Ensure 5 V supplied at the readhead

u

For cable variants check correct wiring of connector

LED on the readhead is Red and

I can’t get a Green LED

The signal strength is <50%

u

Check the readhead optical window and scale are clean and free from contamination

u

Restore factory defaults (see page 12) and check alignment of the readhead. In particular:

– Rideheight

– Ya w

– Offset

u

Check the scale is correct type (RTLC40)

Unable to get a Green LED over the

complete axis length

System run-out is not

within specication

u

Use a DTi gauge and check the run-out is within specications

u

Restore factory defaults

u

Realign readhead to obtain a Green ashing LED at the mid-point of the run-out

u

Recalibrate the system (see page 12)

Can’t initiate the calibration routine Signal size is <70%

u

Realign readhead to obtain a green ashing LED

During calibration the LED on the

readhead remains single ashing

Blue even after moving it along the

full axis length

The system has failed to calibrate the

incremental signals due to the signal

strength being <70%

u

Exit CAL mode and restore factory defaults (see page 12)

u

Check system set-up and realign the readhead to obtain a Green ashing LED along the full axis of travel

before recalibrating

During calibration the LED on the

readhead is double ashing Blue

even after moving it past the

reference mark several times

The readhead is not seeing a

reference mark

u

Ensure correct position of reference mark selector magnet

u

Ensure you are moving the readhead past your chosen reference mark several times

u

Check the readhead/selector magnet orientation

u

Check the readhead optical window and scale are clean and free from contamination

Page 16

QUANTiC linear installation guide

14

Troubleshooting (continued)

Fault Cause Possible solutions

No reference mark output

u

Ensure you are not over-speeding the readhead during calibration mode (maximum speed <100 mm/sec)

u

Calibrate the system (see page 12)

– If the system completes calibration mode then it has successfully seen and calibrated the reference mark

If you still don’t see a reference mark then check the system wiring

– If the system does not calibrate the reference mark (LED on the readhead remains double ashing Blue)

see above for possible solutions

Reference mark is not repeatable Only the chosen reference mark that has

been used in the calibration sequence is

repeatable, other reference marks may

not be phased

u

Ensure you are using the reference mark that has been calibrated for referencing your system

u

The readhead bracket must be stable and not allow any mechanical movement of the readhead

u

Clean the scale and readhead optical window and check for damage then recalibrate the system over

the chosen reference mark

LED on the readhead is ashing Red

over the reference mark

The reference mark is not phased

u

Ensure you are using the reference mark that has been calibrated for referencing your system as only this

reference mark will be guaranteed to remain phased

u

Clean the scale and readhead optical window and check for scratches then recalibrate the system over the

chosen reference mark (see page 12)

Multiple reference marks are

being output

The readhead reference mark option is

either option B or F, ‘All reference marks

are output’

u

Calibrate the system ensuring both Step 1 and Step 2 are completed (see page 12)

u

Ensure you calibrate the reference mark used for referencing your system as only this reference mark

will be guaranteed to remain phased

Page 17

QUANTiC linear installation guide

15

Dimensions and tolerances in mm

QUANTiC: Readhead dimensions

18

29

7.8

7.8

Optical centreline

(Incremental and reference mark)

Set-up LED

Reference mark selector sensor position

P and Q limit switch sensor position

Mounting faces

13.5

4.25

4.15

10

8.75

*

6 min

R>30 Dynamic bend radius

R>10 Static bend radius

35

23

11.5

Optical centreline marker

Ø 4.25 ±

0.2

5

2 off mounting holes M2.5 through,

counterbored Ø3 × 2.3 deep both sides.

NOTE: The recommended thread engagement is 5 min

(7.5 including counterbore) and the recommended

tightening torque is between 0.25 and 0.4 Nm.

*

Extent of mounting faces

2.5

Page 18

16

QUANTiC linear installation guide

15 way D-type connector (termination code D, H)

52 16

40

9 way D-type connector (termination code A)

52

16

31

12 way in-line circular connector (termination code X)

66

17

Output signals

*

For a readhead with a 1 m cable.

Speed

14 way JST connector (termination code J)

†

1

14

17

2.8

5

Clocked output

option

(MHz)

Maximum speed (m/s)

Minimum edge

separation*

(ns)

T

(10 µm )

D

(5 µm )

X

( 1 µm)

Z

(0.5 µm )

W

(0.2 µm )

Y

(0.1 µm )

H

(50 nm )

50 24 24 24 18.13 7.25 3.626 1.813 25.1

40 24 24 24 14.50 5.80 2.900 1.450 31.6

25 24 24 18.13 9.06 3.63 1.813 0.906 51.0

20 24 24 16.11 8.06 3.22 1.611 0.806 57.5

12 24 24 10.36 5.18 2.07 1.036 0.518 90.0

10 24 24 8.53 4.27 1.71 0.853 0.427 109

08 24 24 6.91 3.45 1.38 0.691 0.345 135

06 24 24 5.37 2.69 1.07 0.537 0.269 174

04 24 18.13 3.63 1.81 0.73 0.363 0.181 259

01 9.06 4.53 0.91 0.45 0.18 0.091 0.045 1038

Function Signal Colour

9 way D-type

(A)

15 way D-type

(D)

15 way D-type

alternative pin-out

(H)

12 way circular

connector

(X)

14 way JST

(J)

Power

5 V Brown 5 7, 8 4, 12 G 10

0 V White 1 2, 9 2, 10 H 1

Incremental

A

+ Red 2 14 1 M 7

− Blue 6 6 9 L 2

B

+ Yellow 4 13 3 J 11

− Green 8 5 11 K 9

Reference

mark

Z

+ Violet 3 12 14 D 8

− Grey 7 4 7 E 12

Limits

P Pink

–

11 8 A 14

Q Black

–

10 6 B 13

Alarm E − Orange

–

3 13 F 3

Remote CAL CAL Clear 9 1 5 C 4

Shield

–

Screen Case Case Case Case

Ferrule

†

Maximum of 20 insertion cycles for JST connector

Page 19

17

QUANTiC linear installation guide

Electrical connections

Grounding and shielding

Shield

Output

signals

5 V

Readhead

termination/connector

0 V

Customer

electronics

QUANTiC readhead

Recommended signal termination

Standard RS422A line receiver circuitry.

Capacitors recommended for improved noise immunity.

Customer

electronics

120R

A B Z−

Cable Z0 = 120R

Readhead

A B Z+

0 V

0 V

220 pF

220 pF

Single ended alarm signal termination

(Alarm signal not available with ’A’ cable termination)

Customer

electronics

5 V

1k8

4k7

4k7

100nF

100R

E−

Readhead

Limit output

(Limit output not available with ’A’ cable termination)

5 V to 24 V

R

*

P Q

*

Select R so that maximum current

does not exceed 10 mA.

Alternatively, use a suitable relay

or opto-isolator.

Remote CAL operation

CAL

0 V

Output specications

Digital output signals

Form – Square wave differential line driver to EIA RS422A (except limits P and Q)

Limits Open collector output, asynchronous pulse

(Limit output not available with ’A’ cable termination)

Repeatability

<0.1 mm

~ Length of limit actuator

P Q

Active high

Incremental† 2 channels A and B in quadrature (90° phase shifted)

Signal period P

Resolution S

A

B

Z

Reference

†

Synchronised pulse Z, duration as resolution.

Bi-directionally repeatable.

IMPORTANT: The shield should be connected to the machine earth (Field Ground).

For JST variants the ferrule should be connected to the machine earth.

Maximum readhead cable length: 3 m

Maximum extension cable length: Dependant on cable type, readhead cable length and clock speed.

Contact your local subsidiary for more information.

Remote operation of the CAL/AGC

is possible via CAL signal.

Alarm

Line driven (Asynchronous pulse)

(Not available with ’A’ cable termination)

Resolution

option code

P (

µm)

S (

µm)

T 40 10

D 20 5

X 4 1

Z 2 0.5

W 0.8 0.2

Y 0.4 0.1

H 0.2 0.05

†

Inverse signals not shown for clarity

E−

or 3-state alarm

Differentially transmitted signals forced open circuit

for >15 ms when alarm conditions valid.

Alarm asserted when:

– Signal amplitude <20% or >135%

– Readhead speed too high for reliable operation

>15 ms

NOTE: A wide reference mark option, outputting

a reference pulse for the duration of the signal

period is available.

Contact your local subsidiary for more information.

Page 20

18

QUANTiC linear installation guide

Power supply 5V −5%/+10% Typically 200 mA fully terminated

Power from a 5 V dc supply complying with the

requirements for SELV of standard IEC BS EN 60950-1

Ripple 200 mVpp maximum @ frequency up to 500 kHz

Temperature Storage −20 °C to +70 °C

Operating 0 °C to +70 °C

Humidity 95% relative humidity (non-condensing) to EN 60068-2-78

Sealing IP40

Acceleration (system) Operating 400 m/s², 3 axes

Shock (system) Operating 500 m/s², 11 ms, ½ sine, 3 axes

Vibration (readhead) Operating 100 m/s² max @ 55 Hz to 2000 Hz, 3 axes

(scale)

Operating 300 m/s² max @ 55 Hz to 2000 Hz, 3 axes

Mass Readhead 9 g

Cable 26 g/m

Readhead cable Single-shielded, outside diameter 4.25 ±0.25 mm

Flex life >20 × 106 cycles at 30 mm bend radius

UL recognised component

Maximum readhead cable length* 3 m

*Extension cables available. Contact your local Renishaw representative for further details

Renishaw encoder systems have been designed to the relevant EMC standards,

but must be correctly integrated to achieve EMC compliance. In particular,

attention to shielding arrangements is essential.

General specications

Form (H x W) RTLC40-S 0.4 mm x 8 mm (including adhesive)

RTLC40 0.2 mm x 8 mm

Datum xing RTLC40-S Loctite 435 with A-9585-0028 clamp

RTLC40 Loctite 435 or mechanical clamp (A-9589-0077)

Reference mark Customer selected IN-TRAC auto phase optical reference

mark repeatable to unit of resolution throughout specied

temperature and speed range

L ≤100 mm Single reference mark at scale centre

L >100 mm Reference marks at 50 mm spacing

(rst reference mark 50 mm from scale end)

Material RTLC40-S Hardened and tempered martensitic stainless steel tted

with a self-adhesive backing tape

RTLC40 Hardened and tempered martensitic stainless steel

Accuracy at 20 °C

(includes slope and linearity)

RTLC40 ±15 µm/m calibration traceable to International Standards

RTLC40H ±5 µm/m calibration traceable to International Standards

Linearity RTLC40 ±5 µm/m achievable with 2 point error correction

RTLC40H ±2.5 µm/m achievable with 2 point error correction

Coefcient of thermal expansion at 20 °C 10.1 ±0.2 µm/m/°C

Maximum length

10 m

†

Installation temperature 15 °C to 35 °C

†

For lengths >2 m FASTRACK with RTLC40 is recommended.

Form (H x W)

0.4 mm x 18 mm (including adhesive)

Material

Hardened and tempered martensitic stainless steel

Coefcient of thermal expansion at 20 °C 10.1 ±0.2 µm/m /°C

Mounting Self-adhesive backing tape

Minimum recommended length 100 mm

Maximum supplied length

25 m

Installation temperature 15 °C to 35 °C

RTLC40-S and RTLC scale technical specications

FASTRACK technical specications

Page 21

RSLM high accuracy linear encoder

Renishaw plc

New Mills, Wotton-under-Edge,

Gloucestershire GL12 8JR

United Kingdom

T +44 (0)1453 524524

F +44 (0)1453 524901

E uk@renishaw.com

www.renishaw.com

For worldwide contact details,

please visit our main website at

www.renishaw.com/contact

*M-9417-9089-03*

RENISHAW® and the probe symbol used in the RENISHAW logo are registered trade marks

of Renishaw plc in the United Kingdom and other countries.

apply innovation and names and designations of other Renishaw products and technologies

are trade marks of Renishaw plc or its subsidiaries.

Loctite® is a registered trademark of the Henkel Corporation.

© 2017-2018 Renishaw plc All rights reserved Issued 1118

Loading...

Loading...