Page 1

Quick Start Guide

R01QS0021ED0060 Rev. 0.60 Page 1 of 24

Jan.31.2020

RZ/N1S Group

CONNECT IT! ETHERNET RZ/N1S-DB

Introduction

RZ/N1 is a family of scalable ARM® based industrial Ethernet switches. Due to the integrated performant

ARM® Cortex®-A7 CPU, they are ideal choice for building products such as Programmable Logic Controllers

(PLC), complex remote-IO slaves, industrial switches, gateways or operator terminals.

RZ/N1 Family consists of three devices, out of which the RZ/N1S, is an industrial ethernet communication

System on Chip with a 3 or 5-ports, depending on the respective chosen package 324BGA/196BGA.

This guide shall assist you to quickly start with your evaluation of the RZ/N1S device on the related Solution

Kit board(s) and the Solution Kit software and documentation. It represents a short guide for the first time users

with the instructions for the first startup of the board.

In addition to this document, please be aware of the extensive documentation on RZ/N1 devices, evaluation

boards and software that you may find in the Solution Kit Documentation directory.

The Solution Kit boards can solely be used for evaluation purposes. It is not allowed to use the boards for

commercial purposes.

List of reference documents

Document name

User’s Manual: System Introduction, Multiplexing, Electrical and Mechanical Information

User’s Manual: System Control and Peripheral

User’s Manual: Peripherals

User’s Manual: R-IN Engine and Ethernet Peripherals

User’s Manual: Generic Open Abstraction Layer

RZ/N1S Development Board Schematic

RZ/N1S Development Board Setup Notes

RZ/N1 U-Boot User Manual

Page 2

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 2 of 24

Jan.31.2020

List of Abbreviations and Acronyms

Abbreviation

Full Form

API

Application Programming Interface

BSP

Board Support Package

CO

CANopen Bus Protocol

DLR

Device Level Ring Protocol

EtherCAT / ECAT

EtherCAT Network Protocol

EtherNet/IP / EIP

EtherNet/IP Network Protocol

EPL

Ethernet POWERLINK Network Protocol

PNIO

PROFINET IO Protocol

PROFINET

Process Field Network Protocol

lwIP

Lightweight IP Protocol

GOAL

Generic OS Abstraction Layer, Communication Framework on RZ/N1x

LLDP

Link Layer Discovery Protocol

NVM

Non-volatile memory

OS

Operating System

RT

Real-Time

API

Application Programming Interface

HW

Hardware

SW

Software

HSR

High-Availability Seamless Redundancy Protocol

PRP

Parallel Redundancy Protocol

IBIS

I/O Buffer Information Specification for pin signal simulation

EtherCAT is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

Sercos is a registered trademark of Sercos International e.V.

Ethernet POWERLINK is the registered trademark of Ethernet POWERLINK Standardization Group (EPSG).

CAN(Controller Area Network):An automotive network specification developed by Robert Bosch GmbH of Germany

ARM is a registered trademark of ARM Limited (or its subsidiaries) in the EU and/or elsewhere. All rights reserved.

All registered trademarks or trademarks are the property of their respective owners.

Page 3

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 3 of 24

Jan.31.2020

1. Overview

The following chapters will help you setup the hardware and software environment and run a sample

application on your RZ/N1L evaluation board.

• The Solution Kit is being actively updated and new versions of it are iteratively released

• Current version of Solution Kit is providing a snapshot of the latest software and documentation

versions at the release time

The CONNECT IT! ETHERNET RZ/N1S Solution Kit is based on the RZ/N1S, a 3/5-port, industrial Ethernet

communication SoC in a 324BGA / 196BGA package. RZ/N1D features two independent blocks integrated in

a single package – a communication block based on the proven multi-protocol R-IN Engine, as well as an

application block and a variety of peripherals. In contrast to the RZ/N1D, RZ/N1S includes only a single ARM®

Cortex®-A7 CPU without an external DDR interface, but with 6MB internal SRAM. Please refer to the RZ/N1S

device documentation for further differences. Also, the RZ/N1S Solution Kit contains everything you need for

fast evaluation and rapid prototyping of multiple industrial Ethernet protocols.

The RZ/N1S Solution Kit contains

• RZ/N1S CPU Development Board

• IAR I-jet Lite debugger (incl. 20pin flat ribbon and USB-micro/A cable)

• USB Cable Micro / Type-A

• DVD RZ/N1x-DB Solution Kit for all RZ/N1x devices / boards

Additionally, one can order the RZ/N1-EB Expansion Board separately, that provides the user with the

possibility to use an expanded range of functionalities and RZ/N1S interfaces. RZ/N1-EB kit contains:

• RZ/N1-EB Expansion Board

• Power Supply 24V/750mA

• Power Supply Primary Adapters Euro/UK/JPN-US

The expansion board has no stand-alone capability and requires an RZ/N1D or RZ/N1S CPU board.

RZ/N1S

APPLICATION

ThreadX

6MB SRAM

QSPI/NAND

CAN/UART/I2C

SDIO/USB

HD Display Controller

Arm®Cortex®–A7

ETHERNET COMMUNICATION

uItron + HWRTOS

Multi-Protocol

Industrial Ethernet

Arm®Cortex®–M3

5 Port Real-Time

Ethernet Switch

GOAL

C2C

Communication

324BGA (15x15mm, 0.8mm pitch)

196BGA(12x12mm, 0.8mm pitch)

Figure 1-1: RZ/N1S Functional and HW overview

Page 4

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 4 of 24

Jan.31.2020

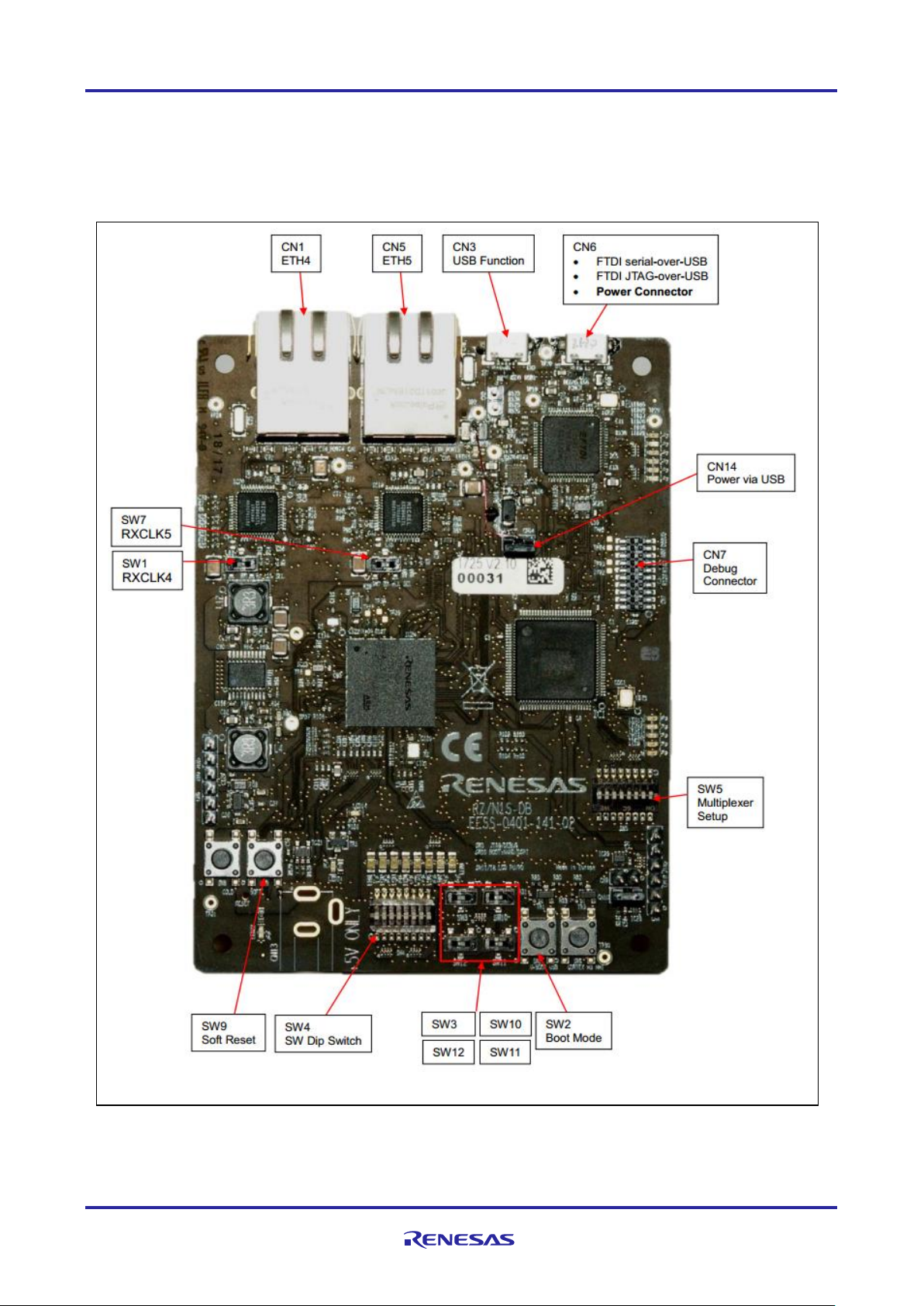

2. Hardware Setup

2.1 CPU Demo Board Setup

To get started quickly with the board, please identify the connectors on the RZ/N1S-DB CPU Board.

Figure 2-1: Board connectors overview

Page 5

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 5 of 24

Jan.31.2020

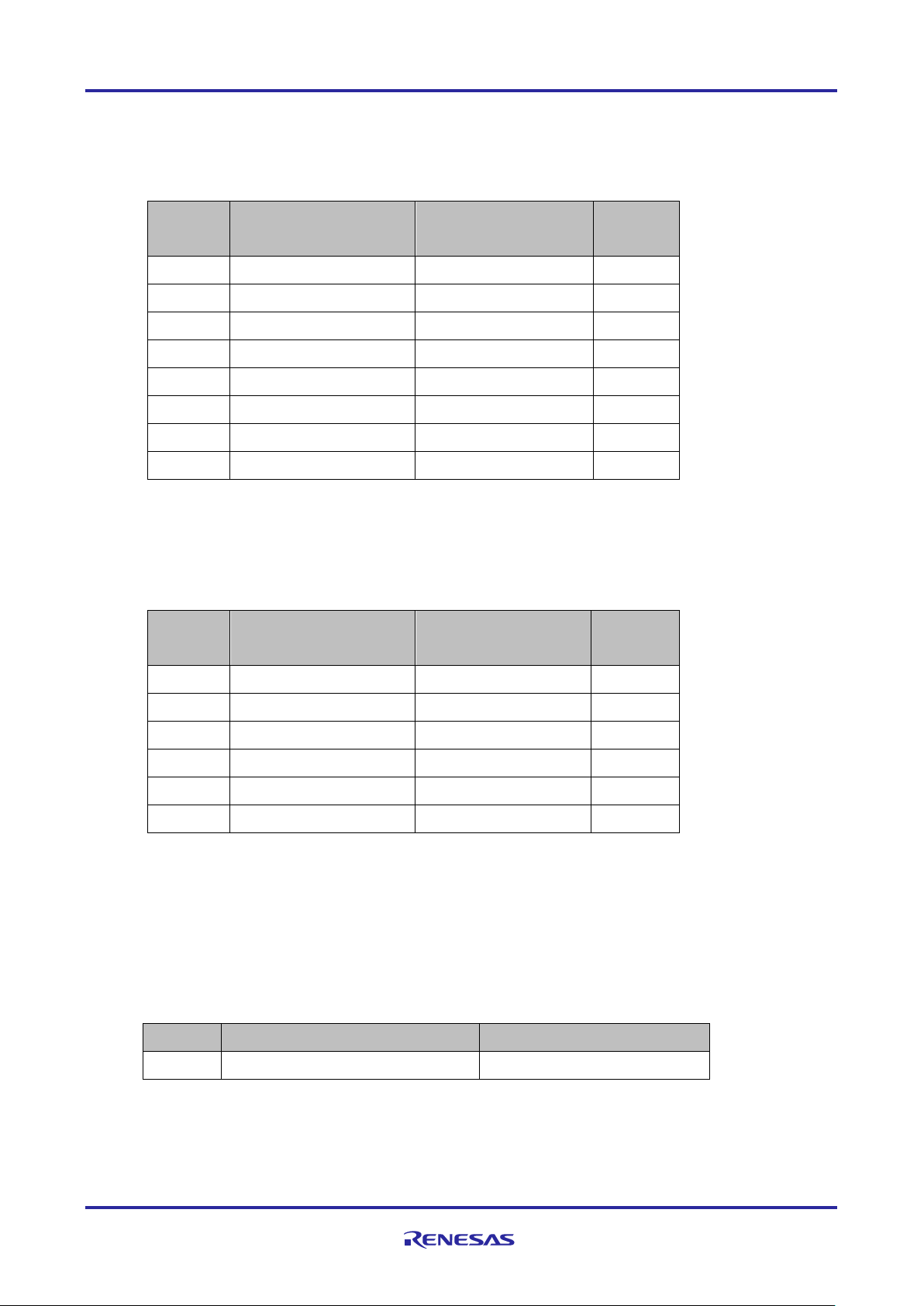

1. Switches and Jumpers

Please take care that the following switches are set.

Table 1: RZ/N1S GPIO Multiplexer DIP-Switch SW5

Number

SW ON (low)

SW OFF (high)

Default

Setting

1

RMII/MII

LCD

OFF

2

CAT/S3

PMOD

ON*

3

MSEBI

Mixed

OFF

4

RMII2 / MDIO 3

QSPI2-Memory

OFF

5

USB 1x Host 1x Device

USB 2 x Host

ON

6

ARM Debug**

FTDI Debug

ON

7

Segger Debugger

I-Jet Debugger

OFF

8

Not used

Not used

OFF

*PHY reset available only in PMOD configuration

**ARM serial debug feature is not supported with the RZ/N1S demo board from the solution kit package

Table 2: RZ/N1S Boot Config DIP-Switch SW4

Switch

SW ON (white bar)

SW OFF

Default

Setting

SW3

JTAG Mode

ARM Coresight Mode

OFF

SW10

Boot from NAND

Boot from QSPI/USB

OFF

SW11

LCD pull up

LCD pull down

ON

SW12

LCD pull up

LCD pull down

ON

SW1

RXCLK4 from PHY

RXCLK4 from GPIO61

ON

SW7

RXCLK5 from PHY

RXCLK5 from GPIO61

ON

Please refer to the schematics

Table 3: Ethernet RX Clock Selection

SW1:

RX_CLK4 Setting

Switch

On Setting (white bar) (default)

Off Setting

SW1

RXCLK4 from Phy

RXCLK4 from GPIO61

SW7:

RX_CLK5 Setting

Page 6

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 6 of 24

Jan.31.2020

Switch

On Setting (white bar) (default)

Off Setting

SW7

RXCLK5 from Phy

RXCLK5 from GPIO61

Table 4: Jumper Settings RZ/N1S-DB

USB Power

Jumper

On Setting (default)

Off Setting

CN14

Power from USB

Power from expansion board

SRESET from Debugger to RZ/N1D

Jumper

On Setting (default)

Off Setting

CN10

RZ/N1D is connected with the

SRESET from the Debugger

Debugger cannot reset the CPU

MRESETout

Jumper

On Setting

Off Setting (default)

CN9

MRESETOUT is connected to

the Debugger

Debugger cannot detect any

internal CPU reset

USB Host/Device Mode

Jumper

On Setting

Off Setting (default)

CN2

OTG mode ID

Peri Mode ID

Table 5: Push buttons

SW2:

Boot Mode Select

In case SW3 (2) has selected QSPI it is possible to boot from USB instead of the QSPI if SW2 is

pressed down during RESET.

Switch

On Setting

Off Setting

SW2

Boot from USB

Boot from QSPI

Table 6: Reset and NMI Button

SW8

Page 7

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 7 of 24

Jan.31.2020

Power On Clear

Switch

On Setting

Off Setting

SW8

POR Reset

Release POR Reset

SW9:

Soft Reset

Switch

On Setting

Off Setting

SW4

Soft Reset

Release Soft Reset

SW6:

CM3 NMI

Switch

On Setting

Off Setting

SW6

Generate CM3 NMI

Release CM3 NMI

For more information please refer to the hardware setup notes (RZ_N1S_DB_Board_Setup_Notes) and

schematics (RZ_N1S_DB_Board_Schematic) in respective board documentation folder in Solution Kit.

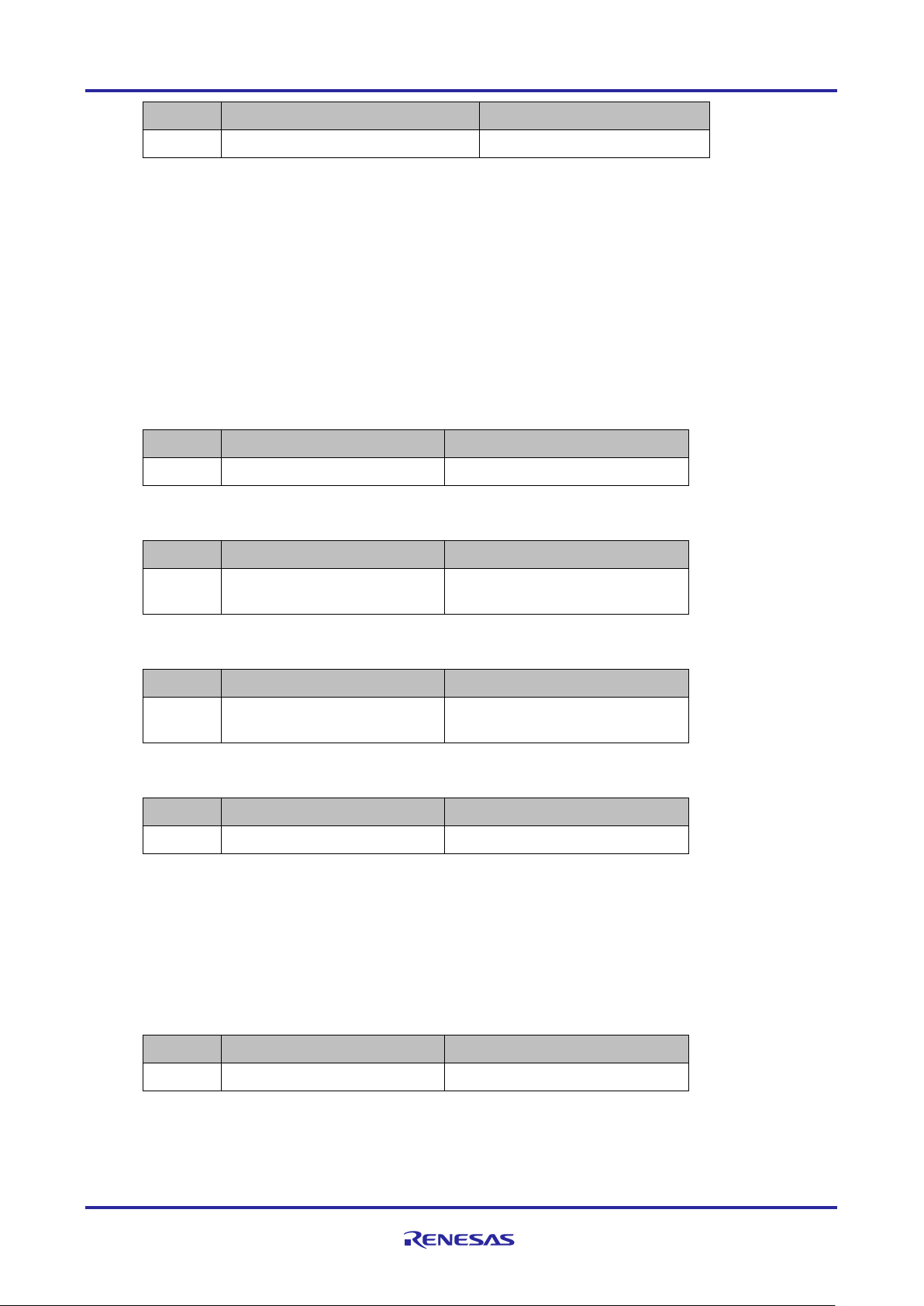

1. JTAG Debug Connector

This connection is required for software development purposes, to be able to run and debug the

software on the target. The IAR Debugger cable has one unused key pin, therefore pin 7 of the CN7

connector should be cut or bent, as shown below. After this step, you can attach your I-jet debugger

to the board via JTAG cable.

Figure 2-2: Connector CN10 with removed pin 7

Page 8

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 8 of 24

Jan.31.2020

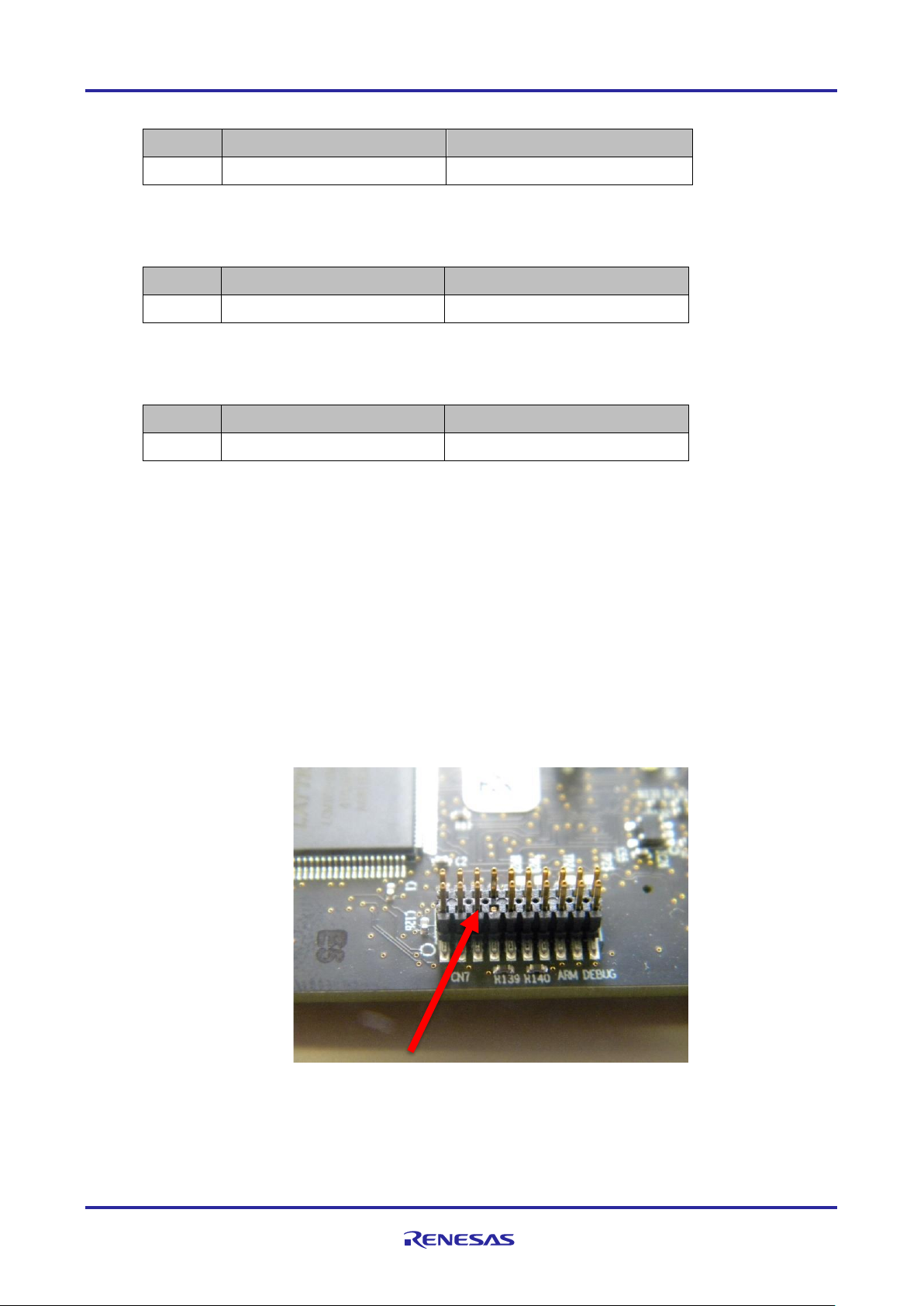

Figure 2-3: I-Jet Debugger connection

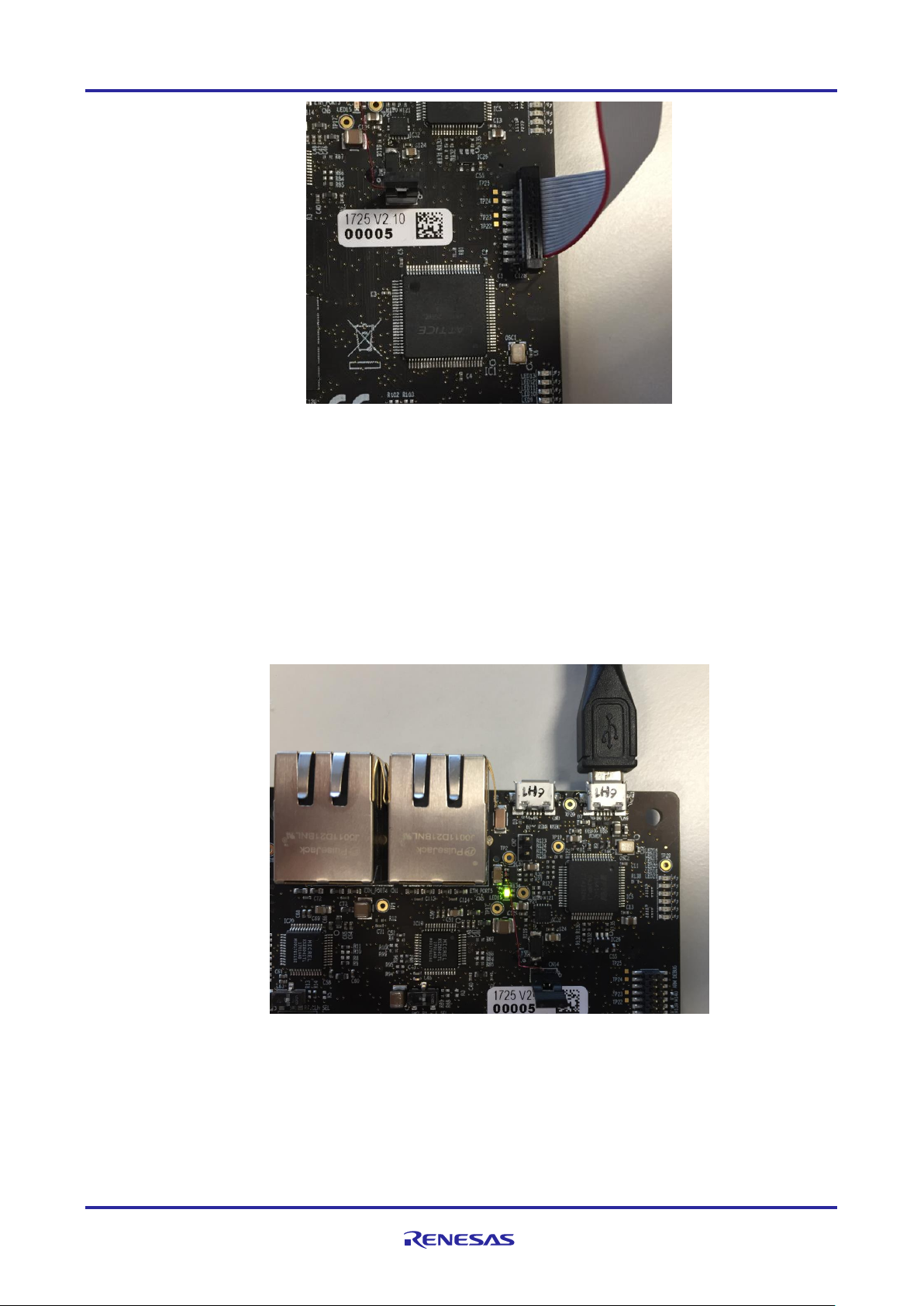

2. Power connector and serial-over-USB

The board is powered via USB connector CN6. Please make sure that the jumper CN14 is ON.

Please connect the board to your PC via USB cable to the connector CN6. The same interface is

used for serial UART communication with the board, so if you have a windows PC, after connecting

the board via USB, you should be able to see a new device registered with 4 new USB Serial COM

ports. You may use any of the terminal emulator on your PC to open a serial port connection to the

board. The board uses the 3rd port for UART output at 115200,8,n,1. On Linux PCs, if you have no

other serial-over-USB devices attached, this is accessed using /dev/ttyUSB2, provided you do not

have any other USB devices attached.

Figure 2-4: Power connector and serial over USB

If the board is not recognized by Windows, please install the FTDI driver that you may find under

…\YCONNECT-IT-RZN_V1.x\Tools\FTDI.

If the required 3.3V are supplied to RZ/N1S, the green LED24 will be lit and stay ON.

Page 9

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 9 of 24

Jan.31.2020

You can perform a soft-reset of the board by pressing SW9.

3. Ethernet Interface

The Ethernet connection to the PC or a PLC can be prepared using one of the two RJ-45 connectors

CN5 or CN1, as shown in Figure 2-5: Ethernet RJ-45 connectorsFigure 2-5. For running the

EtherCAT sample program you can use any of the two connectors. There are two PHY Micrel chips

connected to these RJ-45 connectors.

Figure 2-5: Ethernet RJ-45 connectors

Page 10

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 10 of 24

Jan.31.2020

2.2 Expansion Board Setup

If you are using the expansion board together with your RZ/N1S CPU Board, here you may find some setup

notes for it. For more information refer to the board documentation in the Solution Kit. The expansion board

comes with an external power supply to drive the expansion board and the RZ/N1x CPU board plugged onto

the connectors J1 and J2. Please note the position of the power supply selection jumper below and ensure

that the 12…24V position is chosen. This board expands the RZ/N1S CPU boards with 3 Gbit PHY ports, an

SD-Card slot, a USB Host as well as CAN, RS232, RS485, PMODs, LCD display interface with integrated

touch screen, etc.

Figure 2-6: RZ/N1-EB Expansion Board Overview

Page 11

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 11 of 24

Jan.31.2020

If using the RZ/N1-EB expansion board, please ensure the following jumper and switch settings.

Table 7: Expansion Board switch settings

CN10

CAN Rx

Connect pins 1 and 2 (CAN2)

CN11

CAN Tx

Connect pins 1 and 2 (CAN2)

CN15

PHY2/PHY3 MDC

Connect pins 2 and 3 (MDIO2)

CN16

PHY2/PHY3 MDIO

Connect pins 2 and 3 (MDIO2)

CN17

PHY1 MDC

Connect pins 1 and 2 (MDIO1)

CN18

PHY1 MDIO

Connect pins 1 and 2 (MDIO1)

J18

I2C SDA

Connect pins 1 and 2

J18

I2C SCL

Connect pins 3 and 4

W6

CAN Isolation

NO_ISO

W7

CAN Power

NO_ISO

IMPORTANT INFORMATION: Please take care about using the right 5V power supply when modifiying the

power scheme with CN14 from 12-24V to 5V! A wrong power supply can destroy the Expansion board and the

CPU board powered via the circular power supply connector J4!

Page 12

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 12 of 24

Jan.31.2020

3. Software Setup

RZ/N1S Solution Kit contains a software package on a DVD that enables the user to evaluate various

functionalities of our industrial automation multi-core chip.

The software for RZ/N1S comes as IAR compilable code and you need IAR Embedded Workbench for ARM

(EWARM) for compiling and running the software on both cores. Since RZ/N1S is a dual-core device, Table 8

gives an overview of development environments for both cores.

Table 8: Development Environment for RZ/N1S

Device

RZ/N1S

CPU

Cortex-A7

Cortex-M3

(R-IN engine)

OS

ThreadX

uITRON

(HWRTOS)

IDE

IAR EWARM

IAR EWARM

Bootloader

U-Boot*

*U-Boot is used as bootloader, it runs on Cortex A7, but it can boot images to be executed on

both cores.

Please follow the below steps to setup the software environment for RZ/N1S.

1. Install IAR EWARM

As the first step in software setup, please install the IAR EWARM -> installation file for IAR EWARM

8.22.1 can be found under YCONNECT-IT-RZN_V1.x\Tools\IAREWARM.

Please note that the current RZ/N1S software from the Solution Kit was tested only with IAR EWARM

v8.22.1. During the installation process, you will be prompted to select your license type. For evaluation

purposes, you can first choose the 30-day license.

2. Locate the RZ/N1S IAR software projects in the Solution Kit

The software is stored in the folder YCONNECT-IT-RZN_V1.x\Software in the Solution Kit. This folder

consists of software packages for all RZ/N1 platforms, not only for RZ/N1S. It is therefore important to

mention which projects are meant for being executed on RZ/N1S and how to differentiate between

projects running on Cortex A7 and on Cortex M3. Table 9 gives an overview about that.

More detailed software documentation can be found under YCONNECT-IT-

RZN_V1.x\Documents\RZN.Software. The IAR projects represent a collection of required source

files to build a Cortex M3 or Cortex A7 executable and run it on the target.

Page 13

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 13 of 24

Jan.31.2020

Table 9: Overview of IAR Projects for RZ/N1S

IAR Project

Description

CPU

Path to the workspace file in the Sol. Kit

YCONNECT-IT-RZN_V1.x\Software\...

x-ware*

Set of projects

running on the

Cortex A7

including ThreadX,

NetX Duo and

GUIx sample

applications

Cortex A7

\ThreadX\rzn1\iar\x-ware_platform.eww

GOAL

Projects**

Several example

projects showing

the different

functionalities for

the switch

management and

GOAL

Cortex M3

\GOAL\goal\projects\00410_goal\

Protocol

Stack

Projects***

Several Protocol

Stack slave

application

examples, which

are running I/O

communication

between a PLC

and RZ/N1S

Cortex M3

\GOAL\goal\projects\goal_ecat\

\GOAL\goal\projects\goal_eip_lib\

\GOAL\goal\projects\goal_epl_lib\

\GOAL\goal\projects\goal_mbs\

\GOAL\goal\projects\goal_pnio_lib\

* x-ware User Guide:

\YCONNECT-IT-RZN_V1.X\Software\ThreadX\rzn1\docs\X-Ware_Platform_RZ_N1_User_Guide.pdf

** GOAL application notes document:

\YCONNECT-IT-RZN_V1.X\Software\GOAL\doc\r11qs0008ed0131-rzn1-goal-quick-startguide-management.pdf

*** Protocol Stack quick start guides:

\YCONNECT-IT-RZN_V1.X\Software\GOAL\doc\r01an4239ej0090-rzn1-ethercat.pdf

\YCONNECT-IT-RZN_V1.X\Software\GOAL\doc\r11qs0007ed0131-rzn1-goal-quick-startguide-eip.pdf

\YCONNECT-IT-RZN_V1.X\Software\GOAL\doc\r11qs0010ed0131-rzn1-goal-quick-startguide-profinet.pdf

\YCONNECT-IT-RZN_V1.X\Software\GOAL\doc\r01an4412ej0090-rzn1-modbus.pdf

\YCONNECT-IT-RZN_V1.X\Software\GOAL\doc\r11qs0009ed0131-rzn1-goal-quick-startguide-powerlink.pdf

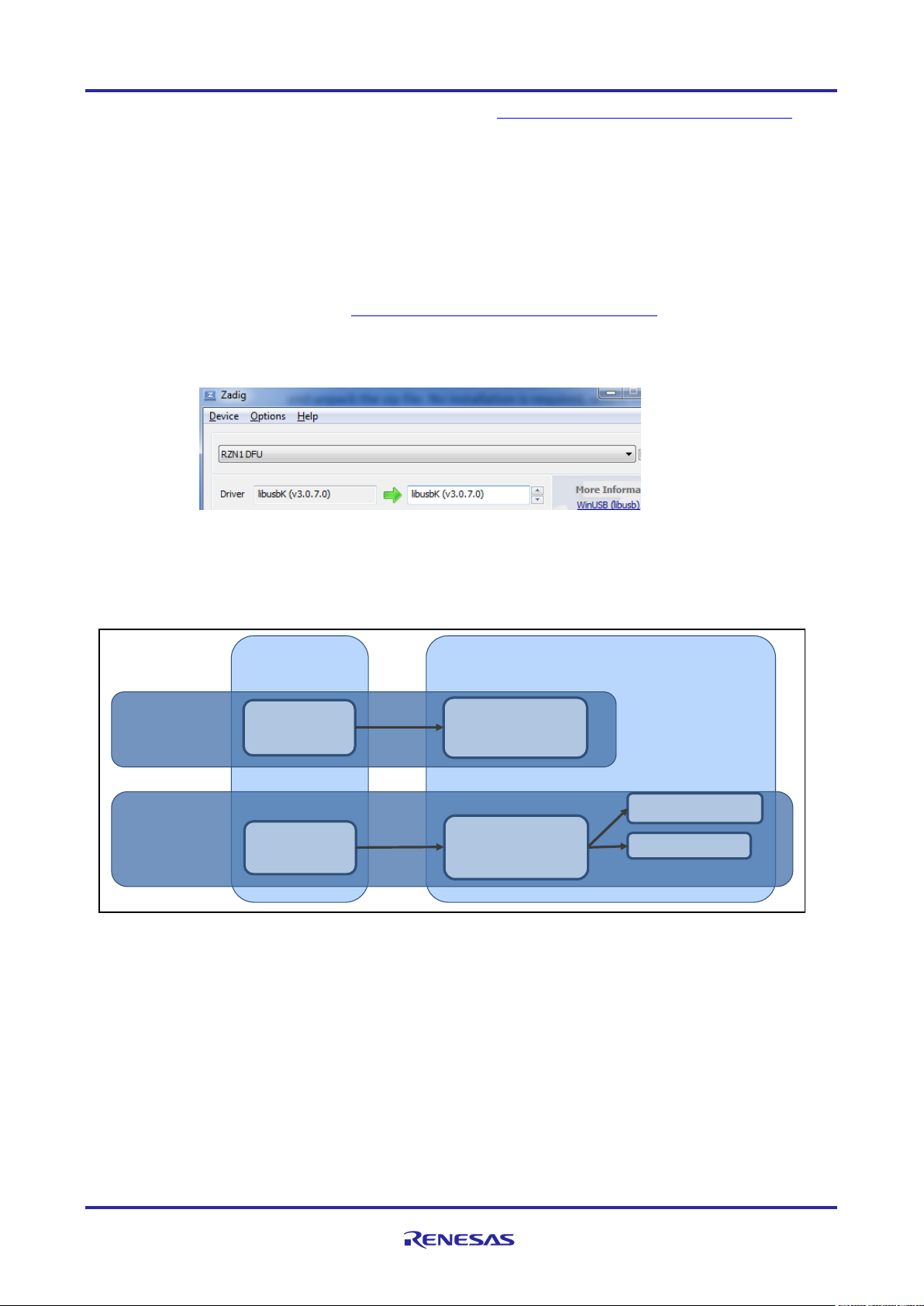

3. Write U-Boot to QSPI flash on the board

As you can see in Table 8, U-Boot is chosen as the secondary bootloader. It runs on the Cortex A7,

initializes some of the required interfaces and peripherals and it can be used to load software images for

both cores, by setting the corresponding parameters in the U-boot user console. Without U-Boot, you

cannot initiate the load of your application via IAR I-Jet Debugger to SRAM for executing on the target.

Figure 3-1 provides an overview of execution stages during programming U-Boot in Flash and later when

U-Boot is configured to read Cortex M3 and Cortex A7 Images from Flash and execute them.

After hardware reset, BootROM will start looking for the U-Boot package in QSPI. Therefore, you need to

write U-Boot in QSPI. This is done via USB DFU (Device Firmware Update). SW5 button pressed together

SW4 signals to BootROM, to switch the boot mode from QSPI to USB DFU. This is required only once, to

load U-Boot to SRAM. In the next step, you will write the U-Boot in flash. Please make sure to connect

CN3 on the board to a USB Host connector on your PC. This provides USB DFU.

Page 14

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 14 of 24

Jan.31.2020

a. Download the Windows version of dfu-util from https://sourceforge.net/projects/dfu-util/files and

unpack the zip file. No installation is required, where this document tells you to run dfu-util, simply run

the dfu-util-static.exe Windows executable from a Windows command prompt. If you are running Linux

on your PC, install the “dfu-util” package: sudo apt-get install dfu-util.

b. Start the DFU target

Connect your RZ/N1 board to your Windows PC using the USB cable, and reset your board in “Boot

from USB” mode (i.e. using DFU)

c. Register the USB device

You must register the USB Download Gadget device with the libusbk driver, you only need to do this

once. On your Windows PC:

o Download Zadig from http://zadig.akeo.ie/downloads/zadig-2.3.exe

o Launch Zadig, select "List All Devices" from the Options menu.

o Select "RZN1 DFU" from the pull-down list. Please note that the device might appear as “USB

Download Gadget”

o Select "libusbK" from the Target Driver list (to the right of the green arrow).

o Click the "Install Driver" button, this will take some time.

o Quit Zadig

d. Locate the U-Boot binary for RZ/N1S - YCONNECT-IT-RZN_V1.X\Software\U-Boot-and-Linux\u-

boot\binaries\u-boot-rzn1s324-db.bin.spkg

e. Open a terminal emulator client like TeraTerm or putty, choose the corresponding serial port, where

you board is registered to and set the serial port settings as depicted below. On Linux PCs, if you

have no other serial-over-USB devices attached, board’s serial port is accessed via /dev/ttyUSB2.

Executes in SRAM

Executes in ROM

Programming

Boot from

USB DFU

BootROM

read: USB DFU

write: SRAM

U-Boot

read: USB DFU

write: QSPI

Development

Boot from

SPI Flash

BootROM

read: QSPI

write: SRAM

U-Boot

read: QSPI

write: SRAM

R-IN Engine (CM3)

ThreadX

Figure 3-1: Flash and Boot Sequence

Page 15

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 15 of 24

Jan.31.2020

f. On the board, hold down switch SW2 (to select DFU

boot mode instead of QSPI) and press switch SW9 (soft reset). The RZ/N1 serial port should output:

** BOOTLOADER STAGE0 for RZN1 **

Boot source: USB

Download U-Boot to SRAM. On your host PC run:

dfu-util.exe -D "u-boot-rzn1s324-db.bin.spkg" in Windows from a Windows

command prompt

sudo dfu-util -D u-boot-rzn1s324-db.bin.spkg in Linux from the terminal

U-Boot should run and the RZ/N1 serial port presents you with a console, like this:

U-Boot 2017.01

Model: RZ/N1S-DB board

DRAM: 4 MiB

MMC: sdhci@0x40100000: 0

SF: Detected mx25l25635f with page size 256 Bytes, erase size 64 KiB,

total 32 MiB, mapped at 10000000

In: serial@0x40060000

Out: serial@0x40060000

Err: serial@0x40060000

Net: dwmac.44000000, dwmac.44002000

Hit any key to stop autoboot: 0

Note: If your board has previously been used and already has U-Boot environment variables

programmed into QSPI, U-Boot may attempt to start running the commands specified by the

bootcmd env variable. Interrupt this by pressing any key.

g. If your board has been programmed with an older version of U-Boot, the dfu_ext_info environment

variable may be incompatible. If so, at the U-Boot console please run:

env default -f dfu_ext_info

saveenv

h. Ensure the U-Boot/SPL region of QSPI Flash is erased, run:

sf probe

sf erase 0 10000

Page 16

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 16 of 24

Jan.31.2020

i. On the U-Boot console, run:

dfu

j. Write U-Boot to QSPI. On your host PC run:

dfu-util.exe -a "sf_uboot" -D "u-boot-rzn1s324-db.bin.spkg" in Windows

sudo dfu-util -a "sf_uboot" -D u-boot-rzn1s324-db.bin.spkg in Linux

Wait until it completes, the U-Boot console will prompt you to press Ctrl-C when done.

Note: The "sf_uboot" DFU target corresponds to the second region of the QSPI Flash. If there is a

valid SPKG written into the first region ("sf_spl"), the BootROM will load this instead of U-Boot.

Otherwise the BootROM will output messages whilst it looks for the first valid SPKG, like:

STATUS: Valid SPKG header not found (100 QSPI Flash 256-byte blocks read)

k. Press switch SW9 to reset the board, the BootROM will load and run U-Boot showing the following

output on the terminal:

** BOOTLOADER STAGE0 for RZN1 **

Boot source: QSPI

00 BOOTLOADER STAGE0 Success

*** Bootloader stage0 END ***

*** Execute 2nd Stage Bootloader which has been loaded and verified ***

U-Boot 2017.01

Model: RZ/N1S-DB board

DRAM: 4 MiB

MMC: sdhci@0x40100000: 0

SF: Detected mx25l25635f with page size 256 Bytes, erase size 64 KiB,

total 32 MiB, mapped at 10000000

In: serial@0x40060000

Out: serial@0x40060000

Err: serial@0x40060000

Net: dwmac.44000000, dwmac.44002000

Hit any key to stop autoboot: 0

l. Setup U-Boot environment variables

This sets up the U-Boot environment variables for your board. From U-Boot, set the MAC addresses

corresponding to the MAC address sticker on the board, for example:

setenv -f ethaddr 74:90:50:02:00:FD

setenv -f eth1addr 74:90:50:02:00:FE

Save the environment variables:

saveenv

We can now proceed with running the sample applications on the board. For more information on U-Boot

BSP for RZ/N1 please refer to YCONNECT-IT-RZN_V1.X\Software\U-Boot-and-Linux\Documentation\RZN1U-Boot-User-Manual.pdf.

Page 17

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 17 of 24

Jan.31.2020

3.1 Running a sample application on the RZ/N1S Board

It is straightforward to run an application on the RZ/N1S. Provided you followed the steps in the hardware

setup chapter and in the previous chapter to write U-boot in QSPI, you need to follow the steps below to load

Cortex M3 or/and Cortex A7 image in SRAM and execute it from there. Additionally, you can write the images

in flash and load them to SRAM after reset, by setting the corresponding U-Boot parameters, as described in

chapter 3.2.

3.1.1 Run and debug Cortex M3 software from RAM with IAR Debugger

1. Power the board and open a serial terminal to U-Boot as explained in the previous chapters

2. Open the IAR EWARM 8.22.1 that you previously installed

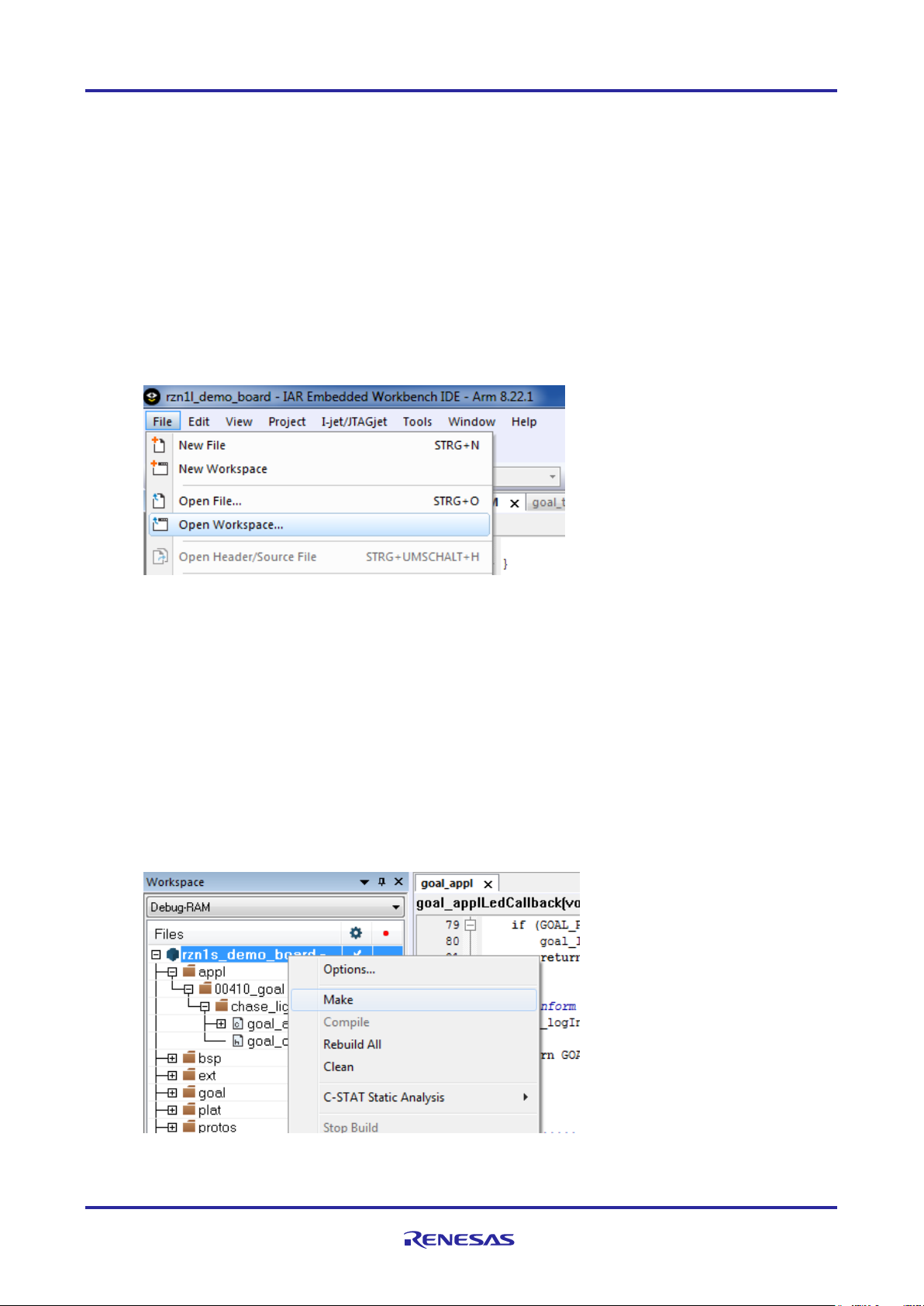

3. Click on File -> Open Workspace as depicted below

4. Select the workspace file

YCONNECT-ITRZN_V1.x\Software\GOAL\goal\projects\00410_goal\chase_lights\iar\7_70\rzn1s_demo_board\rzn

1s_demo_board.eww

There are four variants of project settings for each board configuration:

…\7_70\rzn1d_demo_board\rzn1d_demo_board.eww – RZ/N1D CPU Board

…\7_70\rzn1d_demo_board_eb\rzn1d_demo_board_eb.eww – RZ/N1D CPU Board + Expansion

…\7_70\rzn1s_demo_board\rzn1s_demo_board.eww – RZ/N1S CPU Board and

…\7_70\rzn1l_demo_board\rzn1l_demo_board.eww – RZ/N1L CPU Board

5. Select rzn1s_demo_board as shown below, right-click on the project name and click on “Make”.

6. After the project compiled with no errors nor warnings, make sure your board is powered on and that

the IAR I-Jet Debugger is connected to the JTAG connector.

Page 18

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 18 of 24

Jan.31.2020

7. Click on the “Download and Debug” button in the program control panel in IAR EWARM, as shown

below.

8. In the Debug Log window there should be no errors nor warnings and the program should be stopped

at the beginning of the main() now.

9. At this stage you can click F5 on your keyboard or “Go” button in the IAR program flow panel.

The program should be running now on your board, the LEDs are toggling from one direction to another and

you should see some info output on your serial console as shown below.

Model: RZ/N1S Demo Board

DRAM: 4 MiB

MMC: sdhci@0x40100000: 0

SF: Detected mx25l25635f with page size 256 Bytes, erase size 64 KiB, total 32 MiB, mapped at

10000000

In: serial@0x40060000

Out: serial@0x40060000

Err: serial@0x40060000

Net: , dwmac.44002000

Hit any key to stop autoboot: 0

=> [CC_I|goal_lmLogLegacy:1152] [I|goal_cmInit:209] Calculated config size of 656 in 3 modules

[CC_I|goal_lmLogLegacy:1152] [I|goal_queuePoolBufsReq:776] ID(35) requests buffers[1556]

[CC_I|goal_lmLogLegacy:1152] [I|goal_queuePoolBufsReq:777] fixed/temp = 1, 0

[CC_I|goal_lmLogLegacy:1152] [I|goal_queuePoolBufsReq:776] ID(35) requests buffers[1556]

Page 19

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 19 of 24

Jan.31.2020

[CC_I|goal_lmLogLegacy:1152] [I|goal_queuePoolBufsReq:777] fixed/temp = 2, 0

[CC_I|goal_lmLogLegacy:1152] [I|goal_queuePoolBufsReq:776] ID(35) requests buffers[1556]

[CC_I|goal_lmLogLegacy:1152] [I|goal_queuePoolBufsReq:777] fixed/temp = 1, 0

[CC_I|goal_lmLogLegacy:1152] [I|goal_taskCreate:74] creating task: Timer

[CC_I|goal_lmLogLegacy:1152] [I|goal_init:190] GOAL initialized

[CC_I|goal_lmLogLegacy:1152] [I|appl_setup:85] Chase Lights application started.

[CC_I|goal_lmLogLegacy:1152] [I|goal_memInitDone:128] fixed memory usage: 16020/196608 bytes

[CC_I|goal_lmLogLegacy:1152] [I|goal_memInitDone:129] fixed memory usage: (9%)

3.1.2 Run and debug Cortex A7 software from RAM with IAR Debugger

The steps are almost the same as the ones described in chapter 3.1.1. Reset the board by pressing SW9.

Follow the steps 1-4 from the previous chapter with the difference that you should open a Cortex A7 workspace

file in IAR EWARM (step 4):

YCONNECT-IT-RZN_V1.X\Software\ThreadX\rzn1\iar\x-ware_platform.eww

Please note that the projects, having their name ending with “_smp” are meant for the execution on the

RZ/N1D. SMP stands for Synchronous Multiprocessing and it matches the architecture of the dual-core Cortex

A7 of RZ/N1D. Nevertheless, you can also run the non-smp projects on RZ/N1D, however smp projects will

not run on the RZ/N1S, since RZ/N1S contains a single-core Cortex A7.

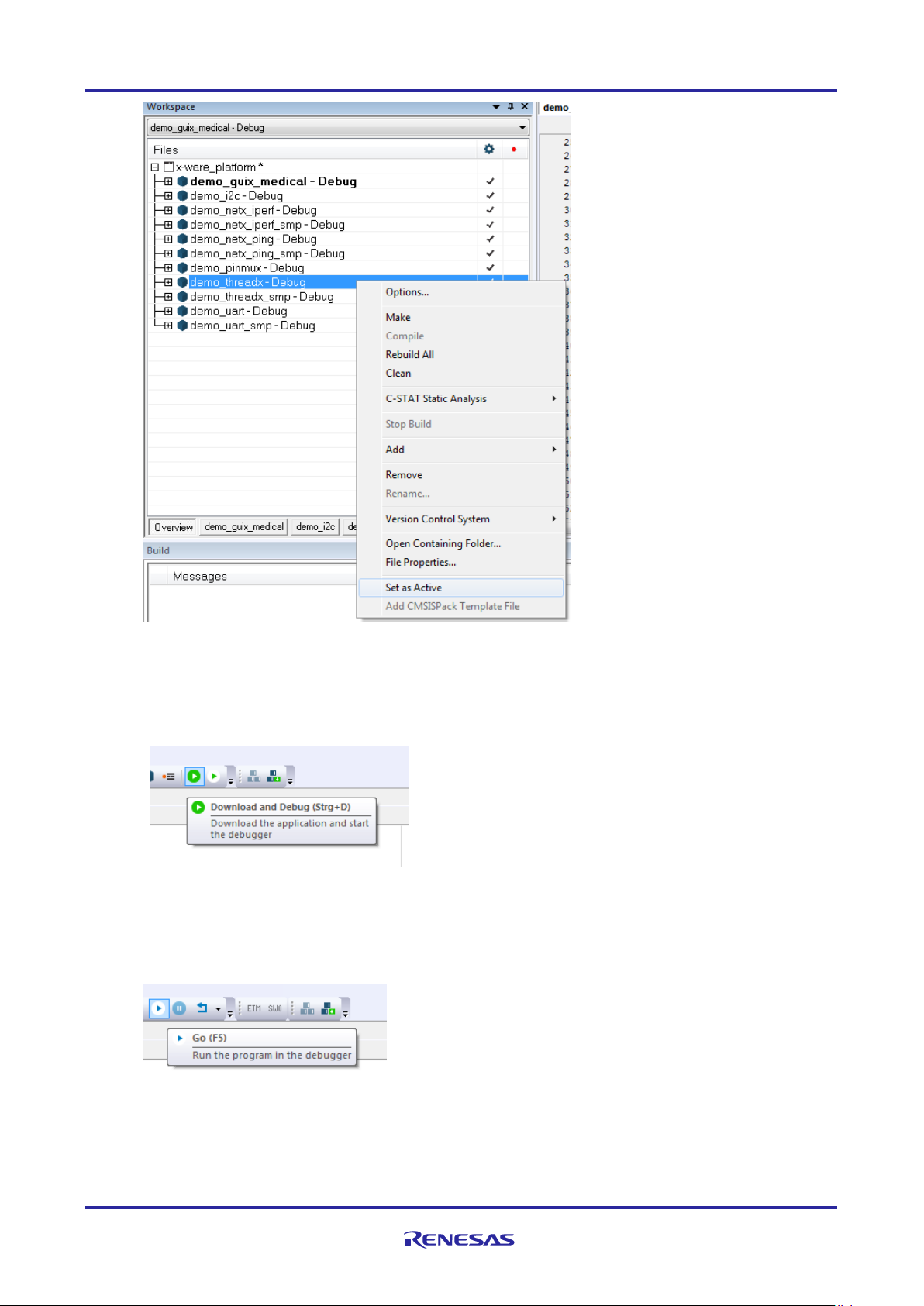

5. After opening the workspace, choose one of the projects in the workspace as shown below. Choose

demo_threadx project as an example.

Page 20

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 20 of 24

Jan.31.2020

6. Compile the project by clicking “Make”

7. After the project compiled with no errors nor warnings, make sure your board is powered on and that

the IAR I-Jet Debugger is connected to the JTAG connector.

8. Click on the “Download and Debug” button in the program control panel in IAR EWARM, as shown

below.

9. In the Debug Log window there should be no errors nor warnings and the program should be stopped

at the beginning of the main() now.

10. At this stage you can click F5 on your keyboard or “Go” button in the IAR program flow panel.

The program should be running now on your board and you should see some info output on your serial console

as shown below.

Page 21

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 21 of 24

Jan.31.2020

At the point of releasing this solution kit version, the IAR Embedded Workbench was not configured for multicore debugging (Cortex A7 and Cortex M3 simultaneously).

3.2 Boot a sample application from QSPI flash

To store your binary in QSPI Flash and be able to execute it from there after every new reset, you need to

write the images in flash and set the corresponding U-Boot parameters. Please follow the steps below to do

that.

1. Open an rzn1s_demo_board project for Cortex M3 in IAR, for example:

YCONNECT-ITRZN_V1.x\Software\GOAL\goal\projects\00410_goal\led_demo\iar\7_70\rzn1s_demo_board\rzn1s_

demo_board.eww

2. Right-click on the rzn1s_demo_board and click on “Options”. Click on “Output Converter” in the left

tab of the options window and tick the box “Generate additional output” and select raw binary output

format.

3. Compile the project. Your raw binary is in the exe folder of the project directory, for example

goal\projects\00410_goal\chase_lights\iar\7_70\rzn1s_demo_board\Debug-RAM\Exe

4. Connect CN3 on the board to a USB Host connector on your PC. This provides USB DFU. Reset the

board (SW9) and open the serial terminal to the U-boot console. In the U-boot console type: dfu

Model: RZ/N1S Demo Board

DRAM: 4 MiB

Page 22

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 22 of 24

Jan.31.2020

MMC: sdhci@0x40100000: 0

SF: Detected mx25l25635f with page size 256 Bytes, erase size 64 KiB,

total 32 MiB, mapped at 10000000

In: serial@0x40060000

Out: serial@0x40060000

Err: serial@0x40060000

Net: , dwmac.44002000

=> dfu

5. Open the command window in Windows or terminal in Linux and type the command to write the raw

binary in flash:

>dfu-util.exe -a "sf_cm3" -D "rzn1s_demo_board.bin" in Windows

sudo dfu-util -a "sf_cm3" -D "rzn1s_demo_board.bin" in Linux

dfu-util 0.9

Copyright 2005-2009 Weston Schmidt, Harald Welte and OpenMoko Inc.

Copyright 2010-2016 Tormod Volden and Stefan Schmidt

This program is Free Software and has ABSOLUTELY NO WARRANTY

Please report bugs to http://sourceforge.net/p/dfu-util/tickets/

Invalid DFU suffix signature

A valid DFU suffix will be required in a future dfu-util release!!!

Opening DFU capable USB device...

ID 045b:0239

Run-time device DFU version 0110

Claiming USB DFU Interface...

Setting Alternate Setting #5 ...

Determining device status: state = dfuIDLE, status = 0

dfuIDLE, continuing

DFU mode device DFU version 0110

Device returned transfer size 4096

Copying data from PC to DFU device

Download [=========================] 100% 40414 bytes

Download done.

state(7) = dfuMANIFEST, status(0) = No error condition is present

state(2) = dfuIDLE, status(0) = No error condition is present

Done!

6. Now your binary is stored in flash and you need to set the U-boot environment variables to boot it

after reset. Please type the following commands in the U-boot console:

Page 23

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 23 of 24

Jan.31.2020

=> setenv bootcmd "sf probe && sf read 0x4000000 d0000 80000 &&

rzn1_start_cm3"

=> saveenv

After the next reset (SW9), the Cortex M3 image is booted and executed automatically by U-Boot.

If you wish to write Cortex A7 binary in QSPI flash, you need to follow the previous steps 1-4, with the difference

that you need to select the corresponding Cortex A7 project in step 1, instead of Cortex M3 one, for example

demo_threadx project from the workspace YCONNECT-IT-RZN_V1.X\Software\ThreadX\rzn1\iar\x-

ware_platform.eww. The binary file you may find under

YCONNECT-IT-RZN_V1.X\Software\ThreadX\rzn1\iar\demo_threadx\Debug\Exe\demo_threadx.bin

5. Open the command window in Windows or terminal in Linux and type the command to write the Cortex

A7 raw binary in flash:

>dfu-util.exe -a "sf_kernel" -D "demo_threadx.bin" in Windows

sudo dfu-util -a "sf_kernel" -D "demo_threadx.bin" in Linux

6. Now your Cortex A7 binary is stored as well in flash and you need to set the U-boot environment

variables to boot it after reset. Please type the following commands in the U-boot console:

=> setenv bootcmd "dcache off&&sf probe&&sf read 0x80008000 1d0000

600000&&go 0x80008000"

=> saveenv

After the next reset (SW9), the Cortex A7 image is booted and executed automatically by U-Boot.

7. Since now you have both binaries (images) stored in flash, you could theoretically boot and execute

both from U-Boot. To do that, please type the following commands in the U-boot console:

=> setenv bootcmd "sf probe && sf read 0x4000000 d0000 80000 &&

rzn1_start_cm3&&sleep 4&&dcache off&&sf read 0x80008000 1d0000 600000&&go

0x80008000"

=> saveenv

Reset the board – SW9. Now you have both binaries running simultaneously.

Page 24

RZ/N1S Group CONNECT IT! ETHERNET RZ/N1S-DB

R01QS0021ED0060 Rev. 0.60 Page 24 of 24

Jan.31.2020

Revision History

Rev.

Date

Description

Page

Summary

0.1

22.Feb.2018

-

Draft – first revision

0.2

23.Mar.2018

-

Added eth rx clk and push button settings table and dfu-util

driver information

0.3

01.Aug.2018

-

Updates to match to the latest GOAL for solution kit v1.3.1

release

0.4

11.Sep.2018

-

Inserted important notes regarding the flexible power supply

structure on the RZ/N1 Expansion Board

0.5

24.Sep.2019

-

Modified licensing description

0.6

31.Jan.2020

-

Changed format

Page 25

General Precautions in the Handling of Microprocessing Unit and Microcontroller

Unit Products

The following usage notes are applicable to all Microprocessing unit and Microcontroller unit products from Renesas. For detailed usage notes on the

products covered by this document, refer to the relevant sections of the document as well as any technical updates that have been issued for the products.

1. Precaution against Electrostatic Discharge (ESD)

A strong electrical field, when exposed to a CMOS device, can cause destruction of the gate oxide and ultimately degrade the device operation. Steps

must be taken to stop the generation of static electricity as much as possible, and quickly dissipate it when it occurs. Environmental control must be

adequate. When it is dry, a humidifier should be used. This is recommended to avoid using insulators that can easily build up static electricity.

Semiconductor devices must be stored and transported in an anti-static container, static shielding bag or conductive material. All test and

measurement tools including work benches and floors must be grounded. The operator must also be grounded using a wrist strap. Semiconductor

devices must not be touched with bare hands. Similar precautions must be taken for printed circuit boards with mounted semiconductor devices.

2. Processing at power-on

The state of the product is undefined at the time when power is supplied. The states of internal circuits in the LSI are indeterminate and the states of

register settings and pins are undefined at the time when power is supplied. In a finished product where the reset signal is applied to the external reset

pin, the states of pins are not guaranteed from the time when power is supplied until the reset process is completed. In a similar way, the states of pins

in a product that is reset by an on-chip power-on reset function are not guaranteed from the time when power is supplied until the power reaches the

level at which resetting is specified.

3. Input of signal during power-off state

Do not input signals or an I/O pull-up power supply while the device is powered off. The current injection that results from input of such a signal or I/O

pull-up power supply may cause malfunction and the abnormal current that passes in the device at this time may cause degradation of internal

elements. Follow the guideline for input signal during power-off state as described in your product documentation.

4. Handling of unused pins

Handle unused pins in accordance with the directions given under handling of unused pins in the manual. The input pins of CMOS products are

generally in the high-impedance state. In operation with an unused pin in the open-circuit state, extra electromagnetic noise is induced in the vicinity of

the LSI, an associated shoot-through current flows internally, and malfunctions occur due to the false recognition of the pin state as an input signal

become possible.

5. Clock signals

After applying a reset, only release the reset line after the operating clock signal becomes stable. When switching the clock signal during program

execution, wait until the target clock signal is stabilized. When the clock signal is generated with an external resonator or from an external oscillator

during a reset, ensure that the reset line is only released after full stabilization of the clock signal. Additionally, when switching to a clock signal

produced with an external resonator or by an external oscillator while program execution is in progress, wait until the target clock signal is stable.

6. Voltage application waveform at input pin

Waveform distortion due to input noise or a reflected wave may cause malfunction. If the input of the CMOS device stays in the area between VIL

(Max.) and VIH (Min.) due to noise, for example, the device may malfunction. Take care to prevent chattering noise from entering the device when the

input level is fixed, and also in the transition period when the input level passes through the area between VIL (Max.) and VIH (Min.).

7. Prohibition of access to reserved addresses

Access to reserved addresses is prohibited. The reserved addresses are provided for possible future expansion of functions. Do not access these

addresses as the correct operation of the LSI is not guaranteed.

8. Differences between products

Before changing from one product to another, for example to a product with a different part number, confirm that the change will not lead to problems.

The characteristics of a microprocessing unit or microcontroller unit products in the same group but having a different part number might differ in terms

of internal memory capacity, layout pattern, and other factors, which can affect the ranges of electrical characteristics, such as characteristic values,

operating margins, immunity to noise, and amount of radiated noise. When changing to a product with a different part number, implement a systemevaluation test for the given product.

Page 26

© 2019 Renesas Electronics Corporation. All rights reserved.

Notice

1. Descriptions of circuits, software and other related information in this document are provided only to illustrate the operation of semiconductor products

and application examples. You are fully responsible for the incorporation or any other use of the circuits, software, and information in the design of your

product or system. Renesas Electronics disclaims any and all liability for any losses and damages incurred by you or third parties arising from the use

of these circuits, software, or information.

2. Renesas Electronics hereby expressly disclaims any warranties against and liability for infringement or any other claims involving patents, copyrights,

or other intellectual property rights of third parties, by or arising from the use of Renesas Electronics products or technical information described in this

document, including but not limited to, the product data, drawings, charts, programs, algorithms, and application examples.

3. No license, express, implied or otherwise, is granted hereby under any patents, copyrights or other intellectual property rights of Renesas Electronics

or others.

4. You shall not alter, modify, copy, or reverse engineer any Renesas Electronics product, whether in whole or in part. Renesas Electronics disclaims any

and all liability for any losses or damages incurred by you or third parties arising from such alteration, modification, copying or reverse engineering.

5. Renesas Electronics products are classified according to the following two quality grades: “Standard” and “High Quality”. The intended applications for

each Renesas Electronics product depends on the product’s quality grade, as indicated below.

"Standard": Computers; office equipment; communications equipment; test and measurement equipment; audio and visual equipment; home

electronic appliances; machine tools; personal electronic equipment; industrial robots; etc.

"High Quality": Transportation equipment (automobiles, trains, ships, etc.); traffic control (traffic lights); large-scale communication equipment; key

financial terminal systems; safety control equipment; etc.

Unless expressly designated as a high reliability product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas

Electronics document, Renesas Electronics products are not intended or authorized for use in products or systems that may pose a direct threat to

human life or bodily injury (artificial life support devices or systems; surgical implantations; etc.), or may cause serious property damage (space

system; undersea repeaters; nuclear power control systems; aircraft control systems; key plant systems; military equipment; etc.). Renesas Electronics

disclaims any and all liability for any damages or losses incurred by you or any third parties arising from the use of any Renesas Electronics product

that is inconsistent with any Renesas Electronics data sheet, user’s manual or other Renesas Electronics document.

6. When using Renesas Electronics products, refer to the latest product information (data sheets, user’s manuals, application notes, “General Notes for

Handling and Using Semiconductor Devices” in the reliability handbook, etc.), and ensure that usage conditions are within the ranges specified by

Renesas Electronics with respect to maximum ratings, operating power supply voltage range, heat dissipation characteristics, installation, etc. Renesas

Electronics disclaims any and all liability for any malfunctions, failure or accident arising out of the use of Renesas Electronics products outside of such

specified ranges.

7. Although Renesas Electronics endeavors to improve the quality and reliability of Renesas Electronics products, semiconductor products have specific

characteristics, such as the occurrence of failure at a certain rate and malfunctions under certain use conditions. Unless designated as a high reliability

product or a product for harsh environments in a Renesas Electronics data sheet or other Renesas Electronics document, Renesas Electronics

products are not subject to radiation resistance design. You are responsible for implementing safety measures to guard against the possibility of bodily

injury, injury or damage caused by fire, and/or danger to the public in the event of a failure or malfunction of Renesas Electronics products, such as

safety design for hardware and software, including but not limited to redundancy, fire control and malfunction prevention, appropriate treatment for

aging degradation or any other appropriate measures. Because the evaluation of microcomputer software alone is very difficult and impractical, you are

responsible for evaluating the safety of the final products or systems manufactured by you.

8. Please contact a Renesas Electronics sales office for details as to environmental matters such as the environmental compatibility of each Renesas

Electronics product. You are responsible for carefully and sufficiently investigating applicable laws and regulations that regulate the inclusion or use of

controlled substances, including without limitation, the EU RoHS Directive, and using Renesas Electronics products in compliance with all these

applicable laws and regulations. Renesas Electronics disclaims any and all liability for damages or losses occurring as a result of your noncompliance

with applicable laws and regulations.

9. Renesas Electronics products and technologies shall not be used for or incorporated into any products or systems whose manufacture, use, or sale is

prohibited under any applicable domestic or foreign laws or regulations. You shall comply with any applicable export control laws and regulations

promulgated and administered by the governments of any countries asserting jurisdiction over the parties or transactions.

10. It is the responsibility of the buyer or distributor of Renesas Electronics products, or any other party who distributes, disposes of, or otherwise sells or

transfers the product to a third party, to notify such third party in advance of the contents and conditions set forth in this document.

11. This document shall not be reprinted, reproduced or duplicated in any form, in whole or in part, without prior written consent of Renesas Electronics.

12. Please contact a Renesas Electronics sales office if you have any questions regarding the information contained in this document or Renesas

Electronics products.

(Note1) “Renesas Electronics” as used in this document means Renesas Electronics Corporation and also includes its directly or indirectly controlled

subsidiaries.

(Note2) “Renesas Electronics product(s)” means any product developed or manufactured by or for Renesas Electronics.

(Rev.4.0-1 November 2017)

Corporate Headquarters

Contact information

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas.com

For further information on a product, technology, the most up-to-date

version of a document, or your nearest sales office, please visit:

www.renesas.com/contact/.

Trademarks

Renesas and the Renesas logo are trademarks of Renesas Electronics

Corporation. All trademarks and registered trademarks are the property

of their respective owners.

Loading...

Loading...