Page 1

APPLICATION NOTE

Vector Control of Three-Phase Induction Motor Used in Driving

a Fan

RX66T Implementation

Introduction

This application note describes how to use the sample program to drive a three phase induction motor (fan

motor) with vector control using the RX66T microcontroller and the motor control development support tool

‘Renesas Motor Workbench 2.0’.

The sample program is only provided for reference purposes and Renesas does not guarantee its operation.

This sample program should only be used after thorough evaluation in an appropriate operating

environment.

In particular, high-voltage environments are extremely dangerous. The information provided here should only

be used after reading all the user's manuals for the development environment and observing all safety

precautions. Renesas Electronics assumes no responsibility for an accident or loss occurring from the use of

the development environments described in this document.

Target Device

Operation of the sample program provided with this application note has been verified for the following

device.

• RX66T (R5F66TEADFP)

Target Sample Program

The sample program discussed in this application note is the following.

[1] RX66T100_T1102_3IM_LESS_FOC_CSP_FAN_V110

RX66T100 (R5F566TEADFP) T1102 sample program: Vector Control of Three-Phase Induction Motor

Used in Driving a Fan

Reference Documents

• RX66T Group User's Manual: Hardware (R01UH0749EJ0110)

• Motor Control Application: Vector Control of Three-Phase Induction Motor (Algorithms)

• Motor Control Development Support Tool ‘Renesas Motor Workbench 2.0’

Download from https://www.renesas.com/us/en/software/D3017970.html

• Trial series "T1102" 3kW 4kVA Inverter Unit User's Manual

• RX66T CPU Card User's Manual (R12UZ0029EJ0110)

R01AN4673EJ0110 Rev.1.10 Page 1 of 45

Apr 21, 21

Page 2

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Contents

1. Overview .................................................................................................................................... 4

1.1 Development Environment ...................................................................................................................... 4

2. System Overview ....................................................................................................................... 5

2.1 Hardware Configuration .......................................................................................................................... 5

2.2 Hardware Specifications .......................................................................................................................... 6

2.2.1 User Interface ........................................................................................................................................ 6

2.2.2 Peripheral Modules ............................................................................................................................... 7

2.3 Software Configuration ............................................................................................................................ 8

2.3.1 File Configuration .................................................................................................................................. 8

2.3.2 Configuration of the Sample Program ................................................................................................... 9

2.4 Software Specifications ......................................................................................................................... 10

3. Control Program ...................................................................................................................... 11

3.1 Control ................................................................................................................................................... 11

3.1.1 Starting and Stopping the Motor ......................................................................................................... 11

3.1.2 Motor Rotation Speed Command ........................................................................................................ 11

3.1.3 Inverter Bus Voltage ............................................................................................................................ 11

3.1.4 Phase Current ..................................................................................................................................... 11

3.1.5 Modulation ........................................................................................................................................... 12

3.1.6 State Transitions ................................................................................................................................. 14

3.1.7 System Protection Functions ............................................................................................................... 15

3.2 Functions for Use in Vector Control Software Program ........................................................................ 16

3.3 Software Variables Used in the Sensorless Vector Control Program ................................................... 22

3.4 Structures Used in the Sensorless Vector Control Software ................................................................ 25

3.5 Sensorless Vector Control Software Macros ........................................................................................ 26

3.6 Control Flow (Flowcharts) ..................................................................................................................... 36

3.6.1 Main Processing .................................................................................................................................. 36

3.6.2 125-μs Period Interrupt Handling ........................................................................................................ 37

3.6.3 1-ms Interrupt Handling ....................................................................................................................... 38

3.6.4 Handling of Group Interrupt that Includes Overcurrent Detection as a Source .................................. 39

4. Development Support Tool “In Circuit Scope” ......................................................................... 40

4.1 Overview ................................................................................................................................................ 40

4.2 The Usage of RMW ............................................................................................................................... 41

4.2.1 START Button ..................................................................................................................................... 41

4.2.2 STOP Button ....................................................................................................................................... 41

4.2.3 ERROR RESET Button ....................................................................................................................... 41

4.2.4 Change Parameter Setting .................................................................................................................. 42

4.3 RMW Variables...................................................................................................................................... 43

R01AN4673EJ0110 Rev.1.10 Page 2 of 45

Apr 21, 21

Page 3

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Website and Support ...................................................................................................................... 44

Revision History .............................................................................................................................. 45

R01AN4673EJ0110 Rev.1.10 Page 3 of 45

Apr 21, 21

Page 4

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Sample

Program

Microcontroller

Inverter Board

Motor

Version of CS+

[1]

R5F566TEADFP

T1102 *2

MRS-25T *3

V8.05.00

1. Overview

This application note describes how to implement a sample program for driving three-phase induction motor

by vector control from the RX66T microcontroller, and how to use the library of ‘Renesas Motor Workbench

2.0’ (RMW)*

here uses the algorithm described in the Motor Control Application: Vector Control of Three-Phase Induction

Motor (Algorithms).

1

, that is support tool for motor control development. Note that the sample program described

1.1 Development Environment

Table 1.1 lists the elements of the development environment for the sample program covered in this

application note.

Table 1.1 Sample Program Development Environment

Contact your sales representative or authorized Renesas Electronics distributors for details on purchasing

the T1102 inverter board and technical support.

Note 1. Motor Control Development Support Tool ‘Renesas Motor Workbench 2.0’ is products of Renesas

Electronics Corporation.

Note 2. The T1102 inverter board and the In Circuit Scope development support tool are products of Desk

Top Laboratories Inc.

Website: http://desktoplab.co.jp/ (provided in Japanese only)

Note 3. MRS-25T is a product of Oriental Motor Co., Ltd.

Website: https://www.orientalmotor.co.jp/global_site/global_support/

R01AN4673EJ0110 Rev.1.10 Page 4 of 45

Apr 21, 21

Page 5

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

RX66T

A/D

converter

input

P62 / AN208

P40 / AN000

P41 / AN001

P42

/ AN002

LED output

PE3

PB7

P71/MTIOC3B(Up)

P72/MTIOC4A(Vp)

P73/MTIOC4B(Wp)

P74/MTIOC3D(Un)

P75/MTIOC4C(Vn)

P76/MTIOC4D(Wn)

MTU3c output

P70 / POE0#

Power supply circuit

Up

Vp

Wp

Un

Vn

Wn

OC

Inverter circuit

Iu Iv Iw Vw VuVv

LED1 LED2

AC input

Bus voltage

Iu_AIN

Iv_AIN

Iw_AIN

Phase currants

Phase

Current

detection

W port

V port

U port

3phase ACIM

Overcurrent detectio input

Overcurrent detection

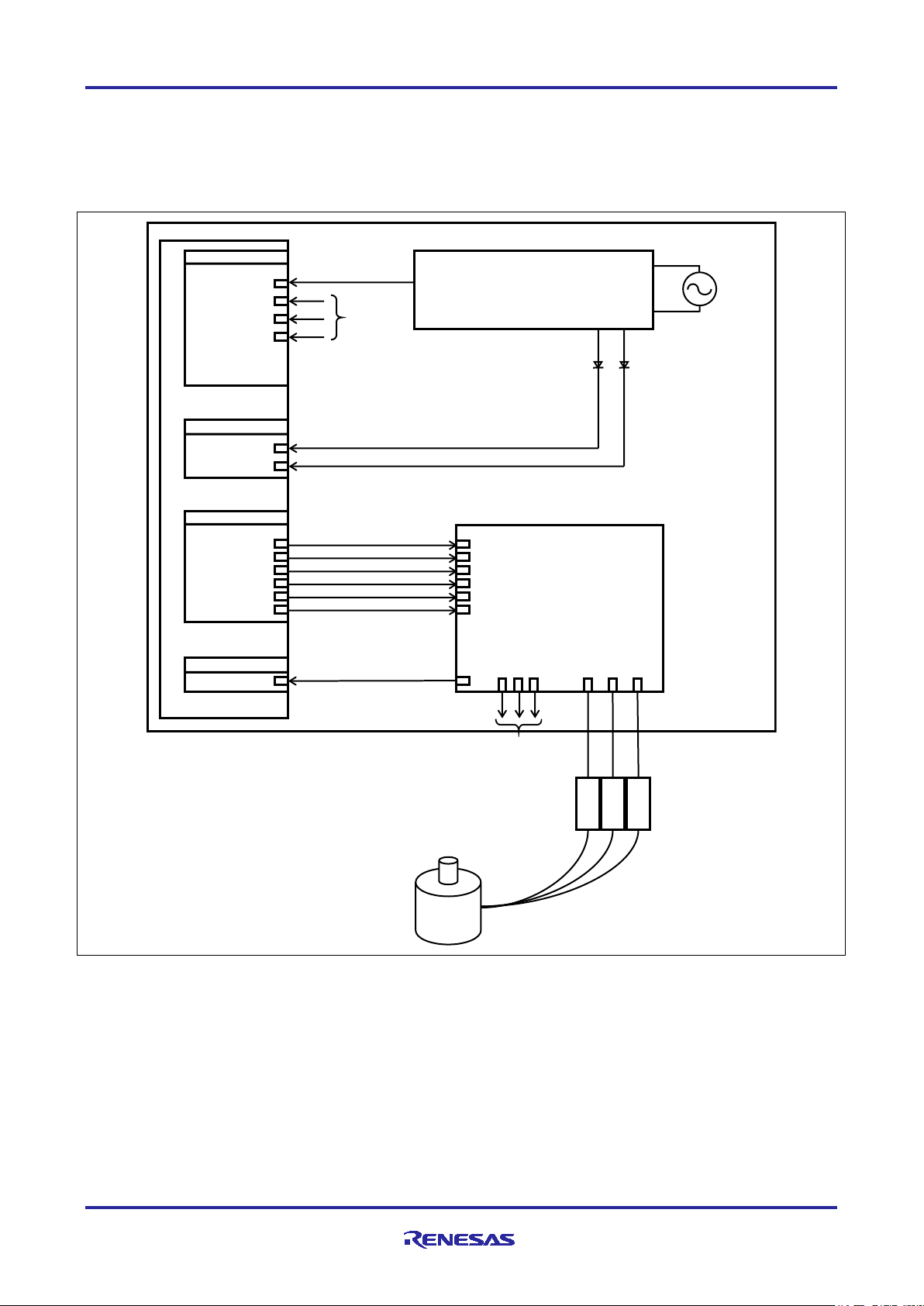

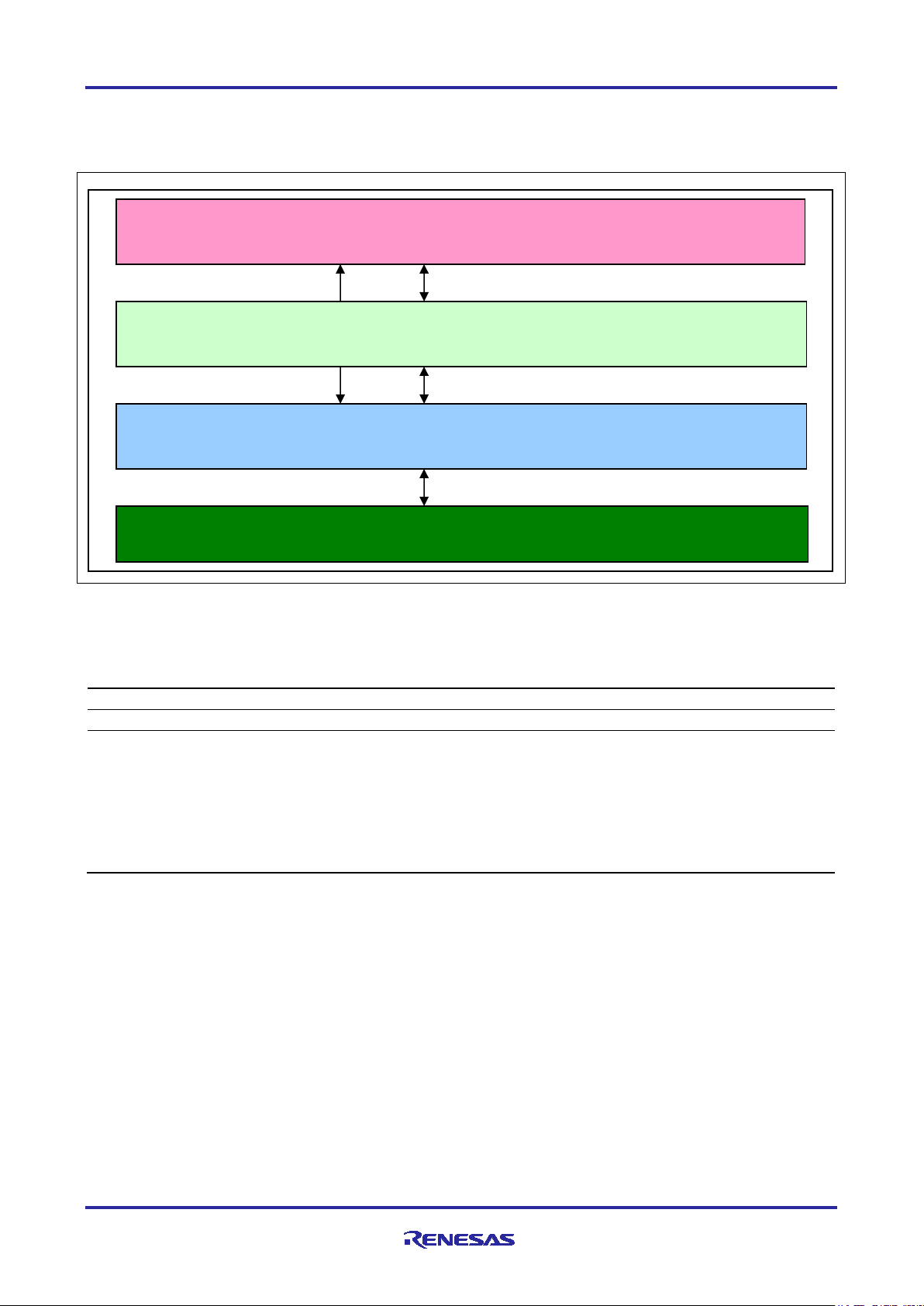

2. System Overview

This section gives an overview of the system described in this application note.

2.1 Hardware Configuration

The hardware configuration is shown below.

Figure 2.1 Hardware Configuration

R01AN4673EJ0110 Rev.1.10 Page 5 of 45

Apr 21, 21

Page 6

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Item

Interface Component

Function

LED1

Yellow-green LED

• Motor is running: On

Motor is stopped: Off

LED2

Yellow-green LED

• An error is detected: On

• Normal operation: Off

RESET

Pushbutton switch RESET1

System reset

R5F566TEADFP Pin Name

Function

P62/AN208

Inverter bus voltage measurement

PE3

LED1 on/off control

PB7

LED2 on/off control

P40/AN000

Measurement of the U-phase current

P41/AN001

Measurement of the V-phase current

P42/AN002

Measurement of the W-phase current

P63/AN209*1

Measurement of the intelligent power module (IPM) temperature

P71/MTIOC3B

Complementary PWM output (Up)

P72/MTIOC4A

Complementary PWM output (Vp)

P73/MTIOC4B

Complementary PWM output (Wp)

P74/MTIOC3D

Complementary PWM output (Un)

P75/MTIOC4C

Complementary PWM output (Vn)

P76/MTIOC4D

Complementary PWM output (Wn)

P70/POE0#

Input for the emergency signal for stopping

the PWM output on detection of an overcurrent

2.2 Hardware Specifications

2.2.1 User Interface

Table 2.1 lists the user interfaces for use in this system.

Table 2.1 User Interfaces

•

Table 2.2 lists the pin interfaces for use in this system.

Table 2.2 Pin Interfaces

Note 1. Not connected on the CPU board (function is disabled)

R01AN4673EJ0110 Rev.1.10 Page 6 of 45

Apr 21, 21

Page 7

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

MCU

12-bit ADC

CMT

MTU3d

POE3b

• Inverter bus voltage

2.2.2 Peripheral Modules

The peripheral modules for use with this system are listed below.

Table 2.3 Peripheral Modules for Use with the Sample Program

RX66T

•

Individual currents of

U/V/W phases

1-ms interval

timer

Complementary

PWM output

Initialization of the complementary PWM output port

(The pins being used for PWM output are placed in the high-

impedance state and PWM output is stopped)

(1) 12-bit A/D converter

Using 12-bit A/D converters to measure the U-, V-, and W-phase currents (I

voltage (V

).

dc

, Iv, and Iw), inverter bus

u

The operating mode differs for each converter unit. Unit 0 is set to group scan mode, with use of the

sample-and-hold function (use synchronous trigger to start conversion) and unit 2 is set to continuous

scan mode.

(2) Compare match timer (CMT)

Channel 0 of the compare match timer is used as a 1-ms interval timer.

(3) Multi-function timer pulse unit 3 (MTU3d)

The operating mode varies with channels, with channels 3 and 4 being used in complementary PWM

mode to output an active-high signal that includes dead time.

(4) Port output enable 3 (POE3)

When an overcurrent is detected (indicated by a falling edge on the POE0# pin) or when an output shortcircuit is detected, the pins being used for PWM output are placed in the high-impedance state, PWM

output is stopped, and the complementary PWM output port pins are initialized.

R01AN4673EJ0110 Rev.1.10 Page 7 of 45

Apr 21, 21

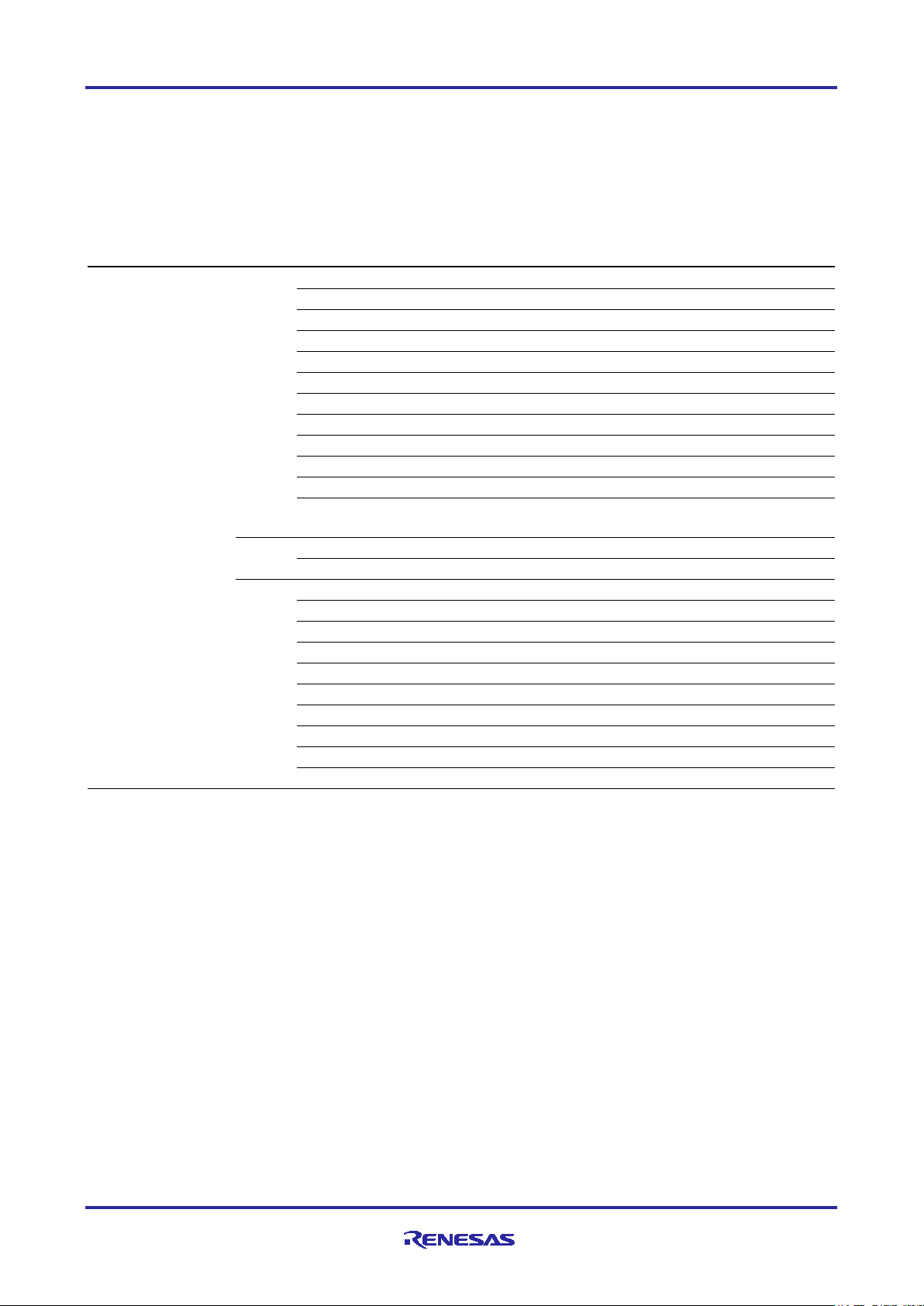

Page 8

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Sample Program

Name

File Name

Description

2.3 Software Configuration

2.3.1 File Configuration

Table 2.4 lists the folders and files for this sample program.

Table 2.4 Folders and Files for the Sample Program [1]

Folder

RX66T100_T1102_

3IM_LESS_FOC_

CSP_FAN_V100

Inc main.h Main function and user interface control header file

Ics ICS2_RX66T.lib ICS library

Src main.c Main function and user interface control header file

mtr_common.h Common definitions header file

mtr_ctrl_t1102.h Board-dependent processing header file

mtr_ctrl_rx66t100.h RX66T-dependent processing header file

mtr_3im_less_foc.h Sensorless vector control header file

control_parameter.h Control parameter header file

motor_parameter.h Motor parameter header file

mtr_ctrl_rx66t100_t1102.h Board- and RX66T-dependent processing header file

r_init_clock.h Hader file for initial setting of the clock signals for the RX66T

r_init_port_initialize.h Header file for initialization of the RX66T port pins

r_init_rom_cache.h Header file for initialization of the ROM cache of the RX66T

r_init_stop_module.h Header file for stop processing of peripheral modules of the

RX66T

ICS2_RX66T.h ICS library header file

mtr_ctrl_t1102.c Board-dependent processing

mtr_ctrl_rx66t100.c RX66T-dependent processing

mtr_interrupt.c Interrupt handlers

mtr_3im_less_foc.c Sensorless vector control

mtr_ctrl_rx66t100_t1102.c Board- and RX66T-dependent processing

r_init_clock.c Initial setting of the clock signals for the RX66T

r_init_port_initialize.c Initialization processing of the RX66T port pins

r_init_rom_cache.c Initialization processing of the ROM cache of the RX66T

r_init_stop_module.c Stop processing of the peripheral modules of the RX66T

R01AN4673EJ0110 Rev.1.10 Page 8 of 45

Apr 21, 21

Page 9

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Layer

File

Application layer

main.c

Motor control layer

mtr_3im_less_foc.c

Hardware control layer

mtr_ctrl_rx66t100_t1102.c

r_init_stop_module.c

Application layer

Hardware control layer

Hardware

T1102 inverter board and the RX66T microcontroller

Motor control layer

2.3.2 Configuration of the Sample Program

The software modules used in this sample program are shown in Figure 2.2 and Table 2.5.

User interface control

Sensorless vector control

MCU-dependent processing and inverter board-dependent processing

Figure 2.2 Configuration of the Software Modules Used in the Sample Program

Table 2.5 Configuration of the Software Modules Used in the sample Program [1]

mtr_ctrl_rx66t100.c

mtr_ctrl_t1102.c

r_init_clock.c

r_init_port_initialize.c

r_init_rom_cache.c

R01AN4673EJ0110 Rev.1.10 Page 9 of 45

Apr 21, 21

Page 10

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Item

Description

Control method

Vector control

Starting and stopping of

Handled by RMW (See the ‘com_s2_mode_system’ variable in Table 4.1.)

Detection of rotor's

magnetic pole position

Sensorless

Input voltage

AC 220 V

Carrier frequency (PWM)

16 kHz

Control period

125 µs (twice the carrier period)

Rotational speed range

500 rpm to 2000 rpm *1

System protection

• The motor control signal outputs (6 lines) are set to the inactive level in

(detection of a falling edge on the POE0# pin).

2.4 Software Specifications

Table 2.6 lists the basic specifications of this system software. See the Motor Control Application: Vector

Control of Three-Phase Induction Motor (Algorithms) for details on the vector control.

Table 2.6 Basic Specifications of the Vector Control Program (for Sample Program [1])

motor rotation

response to any of the following four conditions.

1. The current in any phase exceeds 3 A (monitored once every 125 µs).

2. The inverter bus voltage exceeds 420 V (monitored once every 125

µs).

3. The inverter bus voltage falls below 0 V (monitored once every 125

µs).

4. The speed exceeds 2600 rpm (monitored once every 125 µs).

• The pins being used for PWM output are placed in the high-impedance

state in response to external input of an overcurrent detection signal

Note 1. There may be a difference between the actual speed and the reference speed depending on the

working environment.

R01AN4673EJ0110 Rev.1.10 Page 10 of 45

Apr 21, 21

Page 11

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Item

Sample

Program

Conversion Ratio

(Inverter bus voltage: A/D converted value)

Channel

Inverter bus voltage

[1]

0 V to 686.5 V: 0000H to 0FFFH

AN208

Item

Sample

Program

Conversion Ratio

(U-, V-, W-phase currents: A/D converted value)

Channel

U-, V-, W-phase

[1]

-50 A to 50 A: 0000H to 0FFFH

Iu: AN000

3. Control Program

This section describes the sample program covered in this application note.

3.1 Control

3.1.1 Starting and Stopping the Motor

Starting and stopping of the motor are controlled by using RMW to set a value to the motor operation

variable “com_s2_mode_system”.

The variable for motor operation is read in the main loop, and if the value is found to have been changed, it

is determined that the user has set by using PMW, and the state changes according to the value. As shown

in Table 4.1, write ‘1’ to the motor operation variable will change the motor to the running state, and write ‘0’

to the motor operation variable will change the motor to the stopped state. Also write ‘3’ to the motor

operation variable will reset the error state.

3.1.2 Motor Rotation Speed Command

Using RMW to set rotation speed command value in ‘com_s2_ref_speed_rpm’. The unit of the speed

command value is rpm.

3.1.3 Inverter Bus Voltage

As shown in the table below, the measured values of the inverter bus voltage are used in producing the

modulation factor and for overvoltage detection. Detection of abnormal voltages leads to stopping of the

PWM output.

Table 3.1 Conversion Ratio for Inverter Bus Voltage

3.1.4 Phase Current

As shown in the table below, the measured values of U-, V-, and W-phase currents are used for vector

control and overcurrent detection.

Table 3.2 Conversion Ratio for U-, V-, W-Phase Currents

currents

Iv: AN001

Iw: AN002

R01AN4673EJ0110 Rev.1.10 Page 11 of 45

Apr 21, 21

Page 12

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

U V

W

ωt

ωt

ωt

ωt

U-phase switching waveform

V-phase switching waveform

Voltage between the U and V lines

(U-phase waveform) – (V-phase waveform)

Modulated wave: Command voltage value

Carrier wave (triangle wave): Produced through counting by the MTU3d timer

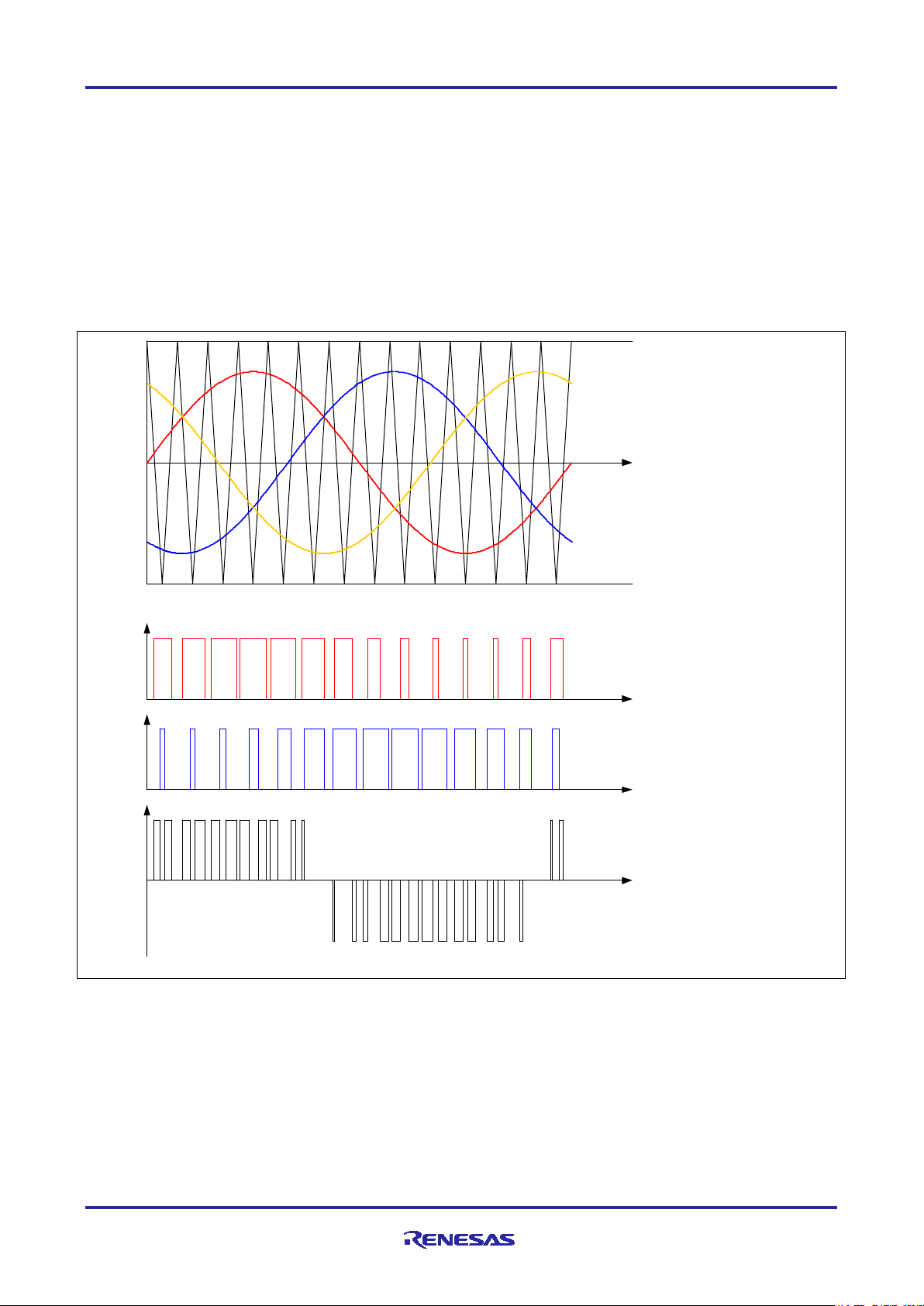

3.1.5 Modulation

In this sample program, the voltage to be input to the motor is generated by pulse width modulation (PWM).

Comparison of the PWM waveform with a triangular waveform determines the pulse width for use in

providing the input voltage.

(1) Triangle Wave Comparison Method

This is the method for the physical output of the desired voltage. The pulse width for the voltage to be output

is determined on the basis of the results of comparing the command voltage waveform with the carrier

waveform (triangle wave). The desired voltage is output as a pseudo-sinusoidal waveform by switching the

output on when the voltage is greater than that produced by the carrier wave and off when the voltage is

lower than that produced by the carrier wave.

Figure 3.1 Concepts of Triangle Wave Comparison Method

R01AN4673EJ0110 Rev.1.10 Page 12 of 45

Apr 21, 21

Page 13

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Average voltage

t

V

T

ON

T

OFF

T

ON

+ T

OFF

T

ON

Duty = × 100 [%]

E

V

m =

m: Modulation factor V: Command value voltage E: Inverter bus voltage

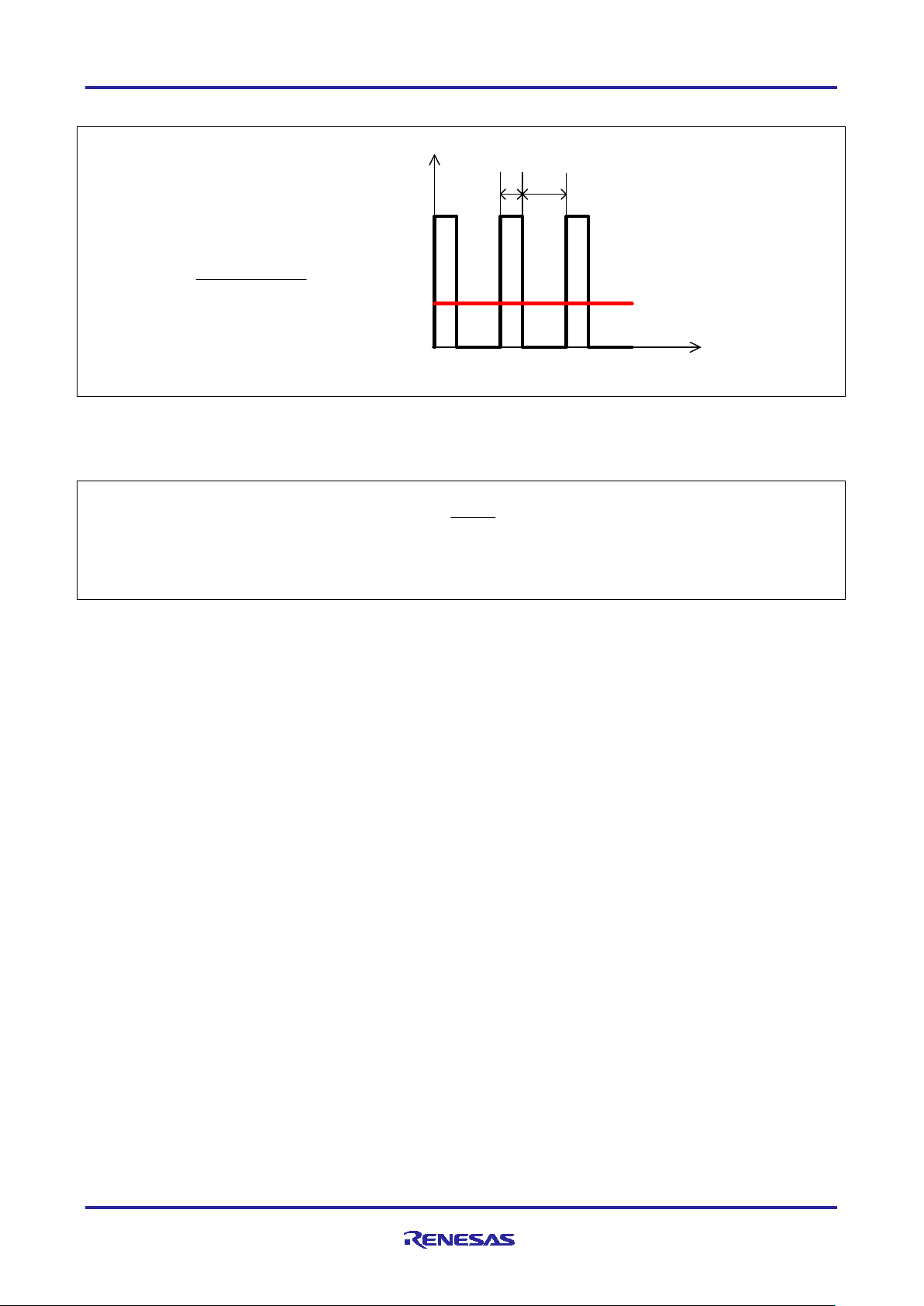

Here, as shown in Figure 3.2, the ratio of the output voltage pulse to the carrier wave is called duty.

The modulation factor m is defined as follows.

Figure 3.2 Definition of Duty

A desired control is accomplished by setting this modulation factor to the register for use in determining the

PWM duty.

R01AN4673EJ0110 Rev.1.10 Page 13 of 45

Apr 21, 21

Page 14

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

RUN MODE

START MODE

[ when offset current detection finish ]

BOOT MODE

CONTROL MODE

[ERROR EVENT]

ERROR MODE

STOP MODE

[RESET EVENT]

[STOP EVENT]

[RUN EVENT]

RESET

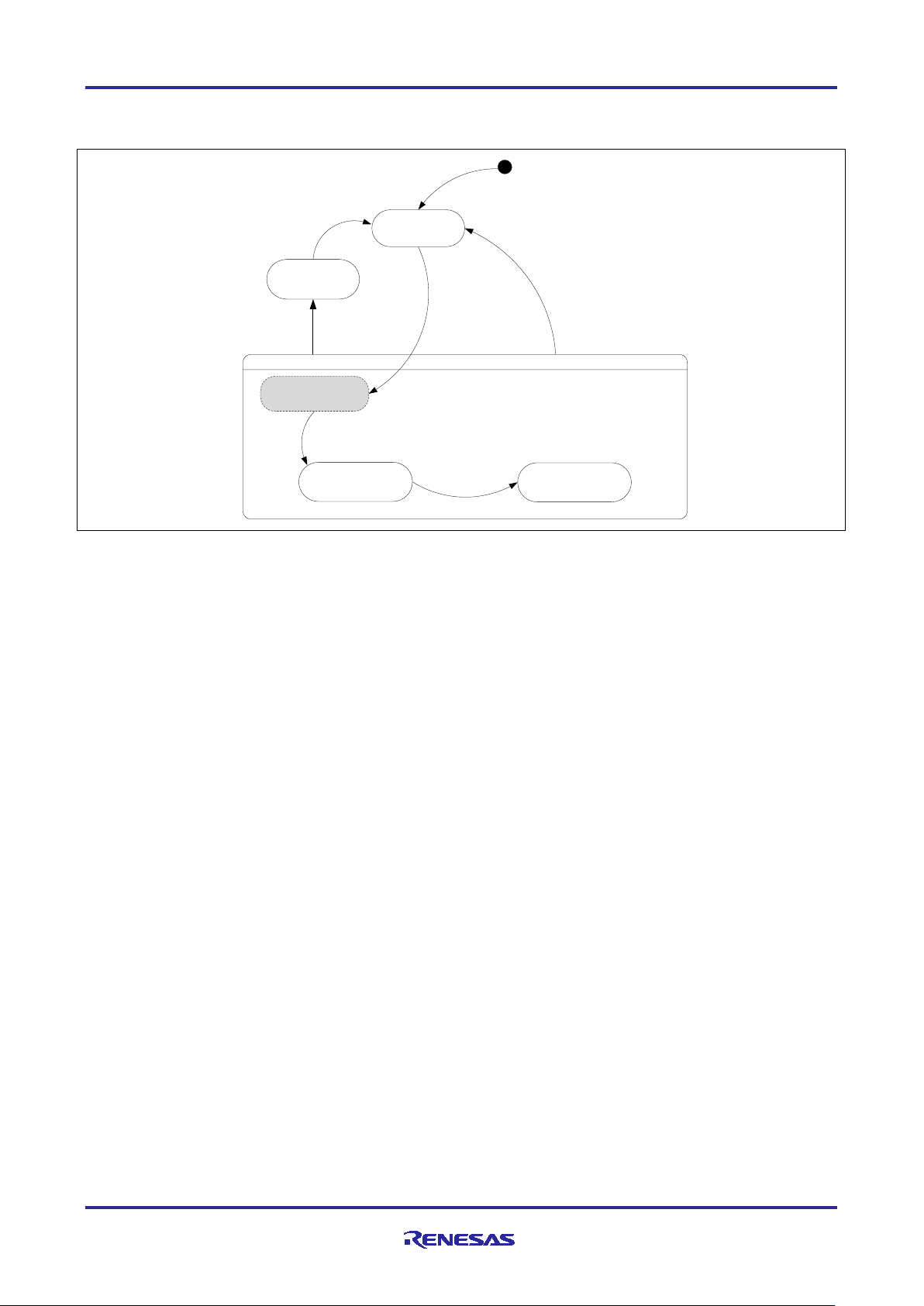

3.1.6 State Transitions

Figure 3.3 shows the state transitions within the sensorless vector control program.

Figure 3.3 State Transitions within the Sensorless Vector Control Program

R01AN4673EJ0110 Rev.1.10 Page 14 of 45

Apr 21, 21

Page 15

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Error

Item

Value

Overcurrent error

Overcurrent limit value [A]

3

Monitoring cycle [µs]

125

Overvoltage error

Overvoltage limit value [V]

420

Monitoring cycle [µs]

125

Undervoltage error

Undervoltage limit value [V]

0

Monitoring cycle [µs]

125

Rotational speed error

Speed limit value [rad/s] (electrical angle)

272

Monitoring cycle [µs]

125

3.1.7 System Protection Functions

This control program detects the following five errors and initiates an emergency stop in response to each of

them. See Table 3.3 for the values used for the system protection functions.

• Overcurrent error

The PWM output pins are placed in the high-impedance state in response to an emergency stop signal

(over current detection) from the hardware.

In addition, U-, V-, and W-phase currents are monitored in overcurrent monitoring cycles. When an

overcurrent (the current exceeding the overcurrent limit value) is detected, the CPU initiates an

emergency stop of the PWM output (in response to detection by the software).

• Overvoltage error

The inverter bus voltage is monitored in overvoltage monitoring cycles. When an overvoltage (the voltage

exceeding the overvoltage limit value) is detected, the CPU initiates an emergency stop of the PWM

output.

• Undervoltage error

The inverter bus voltage is monitored in low-voltage monitoring cycles. The CPU initiates an emergency

stop of the PWM output when low voltage (the voltage falls below the limit value) is detected.

• Rotational speed error

Rotational speed is monitored in speed monitoring cycles and if the speed limit is exceeded, the CPU

initiates an emergency stop of the PWM output.

Table 3.3 Values for the System Protection Functions in Sample Program [1]

R01AN4673EJ0110 Rev.1.10 Page 15 of 45

Apr 21, 21

Page 16

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Function Name

Processing Overview

•

3.2 Functions for Use in Vector Control Software Program

The control program uses multiple control functions as listed in the table below. See the flowcharts and the

source code for more detailed information on the processing performed by these functions.

Table 3.4 Control Functions (1/7)

main.c main

Input: None

Output: None

Calls the hardware initialization function

• Calls the user interface initialization function

• Calls the main processing variables initialization function

• Calls the function to execute state transitions and events

• Main processing

⇒ Calls the function that performs the main processing

ics_ui

Input: None

Output: None

software_init

Input: None

Output: None

mtr_ctrl_t1102.c R_MTR_ChargeCapacitor

Input: None

Output: None

ic_gate_on

Input: None

Output: None

led1_on

Input: None

Output: None

led2_on

Input: None

Output: None

led1_off

Input: None

Output: None

led2_off

Input: None

Output: None

get_sw1

Input: None

Output: (uint8) u1_temp/ the state of SW1

get_sw2

Input: None

Output: (uint8) u1_temp/ the state of SW2

get_sw3

Input: None

Output: (uint8) u1_temp/ the state of SW3

get_vr1

Input: None

Output: (uint16) u2_temp/ rotational speed

command

⇒ Calls the watchdog timer clear function

For use by the ICS user interface

Initializes variables used in the main processing

Waits for the charging time for the smoothing capacitor

Sets the gate signal used for inrush prevention to the ON state

Turns on LED1

Turns on LED2

Turns off LED1

Turns off LED2

Gets the state of SW1

Gets the state of SW2

Gets the state of SW3

Gets the A/D converted value of the rotational speed

command

R01AN4673EJ0110 Rev.1.10 Page 16 of 45

Apr 21, 21

Page 17

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Function Name

Processing Overview

Output: None

Output: None

Output: None

File Name

Function Name

Processing Overview

Output: None

Calls the function that clears the high-impedance state

• Current PI control

Speed PI control

Table 3.4 Control Functions (2/7)

mtr_ctrl_rx66t100.c R_MTR_InitHardware

Input: None

mtr_init_cmt

Input: None

Output: None

mtr_init_poe3

Input: None

init_wdt

Input: None

Output: None

clear_wdt

Input: None

Output: None

mtr_clear_oc_flag

Input: None

Output: None

mtr_clear_cmt0_flag

Input: None

Table 3.4 Control Functions (3/7)

Initializes clock signals and peripheral modules

Initializes the CMT

Initializes the POE3

Initializes the WDT

Clears the WDT

Releases the high-impedance state

Clears the interrupt flag

mtr_interrupt.c mtr_groupBL1_interrupt

Input: None

mtr_over_current_interrupt

Input: None

Output: None

mtr_mtu4_interrupt

Input: None

Output: None

mtr_cmt0_interrupt

Input: None

Output: None

Group interrupt which includes an overcurrent detection as a

source

•

Calls the overcurrent detection processing

Overcurrent detection processing

• Calls the event processing selection function

• Changes the motor status

•

Called once every 125 µs

• Vector control

Called once every 1 ms

• Startup control

•

R01AN4673EJ0110 Rev.1.10 Page 17 of 45

Apr 21, 21

Page 18

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Function Name

Processing Overview

Output: None

•

Output: (uint8)u1_state/ motor status

Output: (uint8)u1_state/ motor status

Output: None

Table 3.4 Control Functions (4/7)

mtr_3im_less_foc.c R_MTR_InitSequence

Input: None

R_MTR_ExecEvent

Input: (uint8)u1_event/ event that occur

Output: None

mtr_act_run

Input: (uint8)u1_state/ motor status

mtr_act_stop

Input: (uint8)u1_state/ motor status

Output: (uint8)u1_state/ motor status

mtr_act_none

Input: (uint8)u1_state/ motor status

Output: (uint8)u1_state/ motor status

mtr_act_reset

Input: (uint8)u1_state/ motor status

Output: (uint8)u1_state/ motor status

mtr_act_error

Input: (uint8)u1_state/ motor status

mtr_start_init

Input: None

Output: None

mtr_stop_init

Input: None

Sequence processing initialization

Updates the motor state

• Calls the function that handles the appropriate

processing in response to events that occur

•

Calls the function that initializes the variables used at

motor startup

•

Calls the function that starts motor control

Calls the function that terminates motor control

No processing

Initializes global variables

Calls the function that terminates motor control

Initializes only those variables needed at motor startup

Initializes variables needed at motor stop

mtr_pi_ctrl

Input: MTR_PI_CTRL *pi_ctrl/ structure for PI

control

Output: (float32)f4_ref/ PI control output value

mtr_set_variables

Input: None

Output: None

R_MTR_IcsInput

Input: MTR_ICS_INPUT *ics_input/ structure for

ICS

Output: None

Used in PI control

Sets the motor variables

Sets up buffers

R01AN4673EJ0110 Rev.1.10 Page 18 of 45

Apr 21, 21

Page 19

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Function Name

Processing Overview

Output: None

Output: (uint8)g_u1_direction

Output: None

Output: None

Table 3.4 Control Functions (5/7)

R_MTR_SetDir

Input: (uint8)dir/ rotational direction

R_MTR_GetSpeed

Input: None

Output: (float32)f4_speed_rpm/ speed

R_MTR_GetDir

Input: None

R_MTR_GetStatus

Input: None

Output: (uint8)g_u1_mode_system/ motor staus

mtr_error_check

Input: None

Output: None

mtr_set_speed_ref

Input: None

Output: None

mtr_set_iq_ref

Input: None

mtr_set_id_ref

Input: None

Output: None

mtr_calc_mod

Input: (float32) f4_vu/ U-phase voltage

(float32) f4_vv/ V-phase voltage

(float32) f4_vw/ W-phase voltage

(float32) f4_vdc/ bus voltage

Sets the direction of rotation

Acquires the speed calculation value

Acquires the value of the rotational direction

Acquires the motor status

Error monitoring and detection

Sets the command used for speed control

Sets the δ axis current command

Sets the γ axis current command

Modulation factor calculation

R01AN4673EJ0110 Rev.1.10 Page 19 of 45

Apr 21, 21

Page 20

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Function Name

Processing Overview

Output: None

Output: None

Output: None

Output: None

Table 3.4 Control Functions (6/7)

mtr_ctrl_rx66t_t1102.c mtr_init_mtu

Input: None

mtr_init_io_port

Input: None

Output: None

mtr_init_ad_converter

Input: None

init_ui

Input: None

Output: None

mtr_ctrl_start

Input: None

Output: None

mtr_ctrl_stop

Input: None

Output: None

mtr_get_iuiviwvdc

Input: (float32)*f4_iu_ad/ A/D converted value of U-phase

current

(float32)*f4_iv_ad/ A/D converted value of V-phase

current

(float32)*f4_iw_ad/ A/D converted value of W-phase

current

(float32)*f4_vdc_ad/ A/D converted value of Vdc

Initialization of the MTU3d

Initialization of the I/O ports

Initialization of the A/D converters

Initialization of the user interfaces

Motor startup processing

Motor stop processing

A/D conversion of U-, V-, and W-phase

currents and inverter bus voltage

mtr_get_ipm_temperature

Input: None

Output: (int16)s2_temp/A/D converted value of the IPM

temperature voltage

mtr_clear_mtu4_flag

Input: None

mtr_inv_set_uvw

Input: (float32)f4_modu/ U phase modulation factor

(float32)f4_modv/ V phase modulation factor

(float32)f4_modw/ W phase modulation factor

Output: None

mtr_init_register

Input: None

Output: None

A/D conversion of the IPM temperature

Clears the interrupt flag

PWM output setting

Initialization for the PWM value comparison

R01AN4673EJ0110 Rev.1.10 Page 20 of 45

Apr 21, 21

Page 21

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Function Name

Processing Overview

Output: None

Output: None

Output: None

Table 3.4 Control Functions (7/7)

r_init_clock.c R_INIT_Clock

Input: None

CGC_oscillation_main

Input: None

Output: None

CGC_oscillation_PLL

Input: None

CGC_oscillation_HOCO

Input: None

Output: None

r_init_port_initialize.c R_INIT_Port_Initialize

Input: None

Output: None

r_init_rom_cache.c R_INIT_ROM_Cache

Input: None

Output: None

r_init_stop_module.c R_INIT_StopModule

Input: None

Initialization of the clock signals

Main clock oscillation setting

PLL clock oscillation setting

HOCO clock oscillation setting

Initialization of ports that are not present

Initialization of the ROM cache

Stops peripheral modules which are running after a reset

R01AN4673EJ0110 Rev.1.10 Page 21 of 45

Apr 21, 21

Page 22

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Variable Name

Type

Content

Remark

3.3 Software Variables Used in the Sensorless Vector Control Program

The table below lists the variables used in the control program.

Table 3.5 List of Variables (1/3)

g_u1_mode_system uint8 State management 0: Stop mode

1: Run mode

2: Error mode

g_u2_run_mode uint16 Operating mode management 0: Boot mode

2: Control mode

g_u2_ctrl_mode uint16 Control mode management 1: Open loop mode

5: Sensorless vector control mode

g_u1_error_status uint8 Error status management 1: Overcurrent error

2: Overvoltage error

3: Rotational speed error

7: Low voltage error

8: IPM temperature error

0xFF: Undefined error

g_f4_vdc_ad float32 Inverter bus voltage [V]

g_f4_vd_ref float32 γ axis output voltage command [V]

g_f4_vq_ref float32 δ axis output voltage command [V]

g_f4_iu_ad float32 U-phase current [A]

g_f4_pre_iu_ad float32 Previous U-phase current value [A]

g_f4_iv_ad float32 V-phase current [A]

g_f4_pre_iv_ad float32 Previous V-phase current value [A]

g_f4_iw_ad float32 W-phase current [A]

g_f4_pre_iw_ad float32 Previous W-phase current value [A]

g_f4_offset_iu float32 U-phase current offset [A]

g_f4_offset_iv float32 V-phase current offset [A]

g_f4_offset_iw float32 W-phase current offset [A]

g_f4_id_lpf float32 γ axis current [A]

g_f4_iq_lpf float32 δ axis current [A]

g_f4_pre_id_lpf float32 Previous γ axis current value [A]

g_f4_pre_iq_lpf float32 Previous δ axis current value [A]

g_f4_kp_id float32 γ axis current PI control proportional

gain

g_f4_ki_id float32 γ axis current PI control integral gain

g_f4_lim_id float32 γ axis current PI control limit value [A]

g_f4_ilim_id float32 γ axis current PI control integral limit

value

g_f4_kp_iq float32 δ axis current axis current PI control

proportional gain

g_f4_ki_iq float32 δ PI control integral gain

g_f4_lim_rotor_speed_rad float32 Rotor speed PI control limit value Electrical angle [rad/s]

g_f4_ilim_rotor_speed_rad float32 Rotor speed PI control integral limit

value

g_f4_id_ref float32 γ axis current command [A]

g_f4_iq_ref float32 δ axis current command [A]

g_f4_ref_stator_speed_rad float32 Stator speed command Electrical angle [rad/s]

[A]

Electrical angle [rad/s]

R01AN4673EJ0110 Rev.1.10 Page 22 of 45

Apr 21, 21

Page 23

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Variable Name

Type

Content

Remark

g_f4_slip_speed_rad

float32

Slip speed

Electrical angle [rad/s]

g_f4_speed_rad

float32

Calculated speed value

Electrical angle [rad/s]

g_f4_ref_speed_rad

float32

Speed command

Electrical angle [rad/s]

g_f4_max_speed_rad

float32

Maximum speed command value

[rad/s]

g_f4_refu

float32

U-phase voltage command

[V]

g_f4_refw

float32

W-phase voltage command

[V]

g_f4_speed_lpf_k

float32

Speed LPF gain

g_f4_offset_lpf_k

float32

Current offset LPF gain

control)

value

g_f4_offset_calc_time

float32

Current offset calculation time

[ms]

g_f4_voltage_drop_k

float32

Voltage drop correction gain

g_f4_modv

float32

V phase modulation factor

rotor_speed

MTR_PI_CTRL

Rotor speed PI control structure

Table 3.5 List of Variables (2/3)

g_f4_slip_k float32 Slip speed gain

g_f4_ref_speed_rad_pi float32 Calculated value for speed PI control Electrical angle [rad/s]

g_f4_angle_rad float32 Rotor interlinkage flux phase [rad]

g_f4_min_speed_rad float32 Minimum speed command value [rad/s]

g_f4_refv float32 V-phase voltage command [V]

g_f4_inv_limit float32 Phase voltage limit value [V]

g_f4_current_lpf_k float32 Current LPF gain

g_u1_direction uint8 Rotational direction command 0: CW

1: CCW

g_u1_enable_write uint8 Variable for use by the user interface of

the ICS

g_u2_cnt_adjust uint16 Counter for use in current offset

calculation

g_u1_flag_id_ref uint8 γ axis current command management

flag

0: γ axis current increases

1: γ axis current is constant

2: γ axis current is constant (speed

g_f4_temp_speed_rad float32 Variable for holding speed value Electrical angle [rad/s]

g_f4_temp_ref_speed_rad float32 Variable for holding speed command

g_f4_angle_compensation float32 Phase compensation constant

g_f4_voltage_drop float32 Voltage drop correction threshold [V]

g_f4_modu float32 U phase modulation factor

g_f4_modw float32 W phase modulation factor

id_ACR MTR_PI_CTRL γ axis current PI control structure

Electrical angle [rad/s]

R01AN4673EJ0110 Rev.1.10 Page 23 of 45

Apr 21, 21

Page 24

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Variable Name

Type

Content

Remark

g_f4_kp_speed

float32

Speed PI control proportional gain

g_f4_lim_iq

float32

axis current PI control limit value

[A]

1: Speed changes

Table 3.5 List of Variables (3/3)

g_f4_ki_speed float32 Speed PI control integral gain

δ

g_f4_ilim_iq float32 δ axis current PI control integral limit

value

g_u1_dir_buff uint8 Variable for storing the commanded

rotational direction

g_f4_id_ref_buff float32 Variable for storing γ axis current

command

g_f4_iq_ref_buff float32 Variable for storing δ axis current

command

g_u1_flag_iq_ref uint8 δ axis current command management

flag

g_u1_flag_speed_ref uint8 Speed command management flag 0: Speed = 0

[A]

0: CW

1: CCW

[A]

[A]

0: δ axis current 0

1: Speed PI output

mtr_p MTR_PARAMETER Motor parameters and control

parameters

g_u1_flag_offset_calc uint8 Current offset calculation flag 0: Calculated at transition to boot

g_f4_boot_id_up_step float32 γ axis current additional value at startup [A]

g_f4_fluctuation_limit float32 Speed fluctuation limit [rad/s]

g_f4_ctrl_ref_id float32 γ axis current command [A]

g_u2_cnt_id_const uint16 γ axis current flux stabilization wait time

counter

g_f4_id_const_time float32 γ axis current flux stabilization wait time [ms]

g_f4_accel float32 Acceleration [rad/s2]

g_f4_ipm_temperature_ad float32 The IPM temperature that is converted

to voltage

speed MTR_PI_CTRL Structure for use in speed PI control

ics_input_buff MTR_ICS_INPUT Structure for the ICS user interface

mode

1: Calculated at transition to boot

mode (first time only)

[V]

R01AN4673EJ0110 Rev.1.10 Page 24 of 45

Apr 21, 21

Page 25

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Member Name

Type

Description

Remarks

f4_err

float32

Differential

f4_kp

float32

PI control proportional gain

f4_ki

float32

PI control integral gain

f4_limit

float32

PI control output limit value

f4_refi

float32

PI control integral output value

f4_ilimit

float32

PI control integral limit value

f4_mtr_rs

float32

Stator resistance

[Ω]

f4_mtr_rr

float32

Rotor resistance

[Ω]

f4_mtr_m

float32

Magnetizing inductance

[H]

f4_mtr_ls

float32

Stator leakage inductance

[H]

f4_mtr_lr

float32

Rotor leakage inductance

[H]

f4_mtr_m_lr

float32

f4_mtr_m/f4_mtr_lr

f4_mtr_rr_lr

float32

f4_mtr_rr/f4_mtr_lr

f4_mtr_sigma

float32

1.0 - f4_mtr_m/f4_mtr_ls * f4_mtr_m_lr

f4_mtr_ls_sigma

float32

f4_mtr_ls * f4_mtr_sigma

[rpm]

1: CCW

f4_kp_speed

float32

Speed PI control proportional gain

f4_ki_speed

float32

Speed PI control integral gain

f4_kp_iq

float32

axis current PI control proportional gain

f4_ki_iq

float32

axis current PI control integral gain

f4_speed_lpf_k

float32

Speed LPF gain

f4_current_lpf_k

float32

Current LPF gain

f4_mtr_rs

float32

Stator resistance

[Ω]

f4_mtr_rr

float32

Rotor resistance

[Ω]

f4_mtr_m

float32

Magnetizing inductance

[H]

f4_mtr_lls

float32

Stator leakage inductance

[H]

f4_mtr_llr

float32

Rotor leakage inductance

[H]

f4_offset_lpf_k

float32

Current offset value LPF gain

[rpm]

[rpm]

f4_ctrl_ref_id

float32

axis current command

[A]

f4_boot_id_up_time

float32

Rise time at γ axis current startup

[ms]

f4_id_const_time

float32

axis current/flux stabilization wait time

[ms]

acceleration/deceleration step size

f4_fluctuation_limit

float32

Speed fluctuation limit

[rad/s]

coefficient

f4_offset_calc_time

float32

Current offset adjustment time

[ms]

f4_voltage_drop

float32

Voltage drop correction threshold

[V]

f4_voltage_drop_k

float32

Voltage drop correction gain

3.4 Structures Used in the Sensorless Vector Control Software

The table below lists the structures used in the control program.

Table 3.6 List of Structures

MTR_PI_CTRL

MTR_PARAMETER

MTR_ICS_INPUT s2_ref_speed int16 Speed command Mechanical angle

s2_direction int16 Rotational direction 0: CW

δ

δ

s2_max_speed int16 Maximum speed Mechanical angle

s2_min_speed int16 Minimum speed Mechanical angle

γ

γ

f4_accel float32 Rotational speed command

f4_delay float32 Voltage output delay compensation

R01AN4673EJ0110 Rev.1.10 Page 25 of 45

Apr 21, 21

Page 26

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

File Name

Macro Name

Definition Value

Remarks

3.5 Sensorless Vector Control Software Macros

The table below lists the macro definitions used in this control program.

Table 3.7 List of Macro Definitions (1/12)

main.h MAX_SPEED CP_MAX_SPEED_RPM Maximum value of the speed command

(mechanical angle) [rpm]

MIN_SPEED CP_MIN_SPEED_RPM Minimum value of the speed command

(mechanical angle) [rpm]

IQ_PI_KP CP_IQ_PI_KP δ axis current PI control proportional gain

IQ_PI_KI CP_IQ_PI_KI δ axis current PI control integral gain

SPEED_PI_KP CP_SPEED_PI_KP Speed PI control proportional gain

SPEED_PI_KI CP_SPEED_PI_KI Speed PI control integral gain

SPEED_LPF_K CP_SPEED_LPF_K Speed LPF gain

CURRENT_LPF_K CP_CURRENT_LPF_K Current LPF gain

STATOR_RESISTANCE MP_STATOR_RESISTANCE Stator resistance [Ω]

ROTOR_RESISTANCE MP_ROTOR_RESISTANCE Rotor resistance [Ω]

MUTUAL_INDUCTANCE MP_MUTUAL_INDUCTANCE Magnetizing inductance [H]

STATOR_LEAKAGE_

INDUCTANCE

ROTOR_LEAKAGE_

INDUCTANCE

OFFSET_LPF_K CP_OFFSET_LPF_K Current offset value LPF gain

CTRL_REF_ID CP_CTRL_REF_ID γ axis current command [A]

BOOT_ID_UP_TIME CP_BOOT_ID_UP_TIME Rise time at γ axis current startup [ms]

ID_CONST_TIME CP_ID_CONST_TIME γ axis current flux stabilization wait time [ms]

ACCEL_MODE0 CP_ACCEL_MODE0 Acceleration

FLUCTUATION_LIMIT CP_FLUCTUATION_LIMIT Speed fluctuation limit

DELAY CP_DELAY Voltage output delay compensation

OFFSET_CALC_TIME CP_OFFSET_CALC_TIME Current offset calculation time [ms]

VOLTAGE_DROP CP_VOLTAGE_DROP Voltage drop compensation threshold [V]

VOLTAGE_DROP_K CP_VOLTAGE_DROP_K Voltage drop compensation gain

POLE_PAIRS MP_POLE_PAIRS Constant used for pole pairs count correction

M_CW 0 Rotational direction

M_CCW 1

ICS_INT_LEVEL 6 ICS interrupt priority level

SW_ON 1 Active-high

SW_OFF 0

Table 3.7 List of Macro Definitions (2/12)

MP_STATOR_LEAKAGE_

INDUCTANCE

MP_ROTOR_LEAKAGE_

INDUCTANCE

Stator leakage inductance [H]

Rotor leakage inductance [H]

coefficient

motor_parameter.h MP_POLE_PAIRS 1 Pole pairs count

MP_STATOR_RESISTANCE 25.0 Stator resistance [Ω]

MP_ROTOR_RESISTANCE 12.5 Rotor resistance [Ω]

MP_MUTUAL_INDUCTANCE 1.00 Magnetizing inductance [H]

MP_STATOR_LEAKAGE_INDUCTANCE 0.080 Stator leakage inductance [H]

MP_INDUCTANCE 0.080 Rotor leakage inductance [H]

R01AN4673EJ0110 Rev.1.10 Page 26 of 45

Apr 21, 21

Page 27

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

MTR_PWM_TIMER_FREQ

160.0

PWM timer count frequency [MHz]

MTR_DEADTIME

2.5

Dead time [µs]

[MHz]

MTR_AD_FREQ

+ MTR_DEADTIME_SET

MTR_PORT_UP

PORT7.PODR.BIT.B1

U phase (positive phase) output port

MTR_PORT_VP

PORT7.PODR.BIT.B2

V phase (positive phase) output port

MTR_PORT_WP

PORT7.PODR.BIT.B3

W phase (positive phase) output port

MTR_PORT_LED1

PORTE.PODR.BIT.B3

LED1 output port

MTR_LED_ON

0

MTR_INPUT_V

220 * 1.41421356

Power supply voltage [V]

MTR_HALF_VDC

MTR_INPUT_V/2.0

Power supply voltage / 2 [V]

of the measured current

SCALING

of the measured IPM temperature

MTR_OVERVOLTAGE_LIMIT

420.0

High voltage limit value [V]

LIMIT

MTR_IC_GATE_ON

1

MTR_PORT_SW2

PORT1.PIDR.BIT.B1

SW2 input port

Table 3.7 List of Macro Definitions (3/12)

mtr_ctrl_rx66t100_

t1102.h

MTR_CARRIER_FREQ 16.0 Carrier frequency [kHz]

MTR_DEADTIME_SET MTR_DEADTIME *

MTR_PWM_TIMER_FREQ

MTR_AD_FREQ 40.0 A/D converter operating frequency

MTR_AD_SAMPLING_CYCLE 45.0 A/D conversion cycle count

MTR_AD_SAMPLING_TIME MTR_AD_SAMPLING_CYCLE /

MTR_AD_TIME_SET MTR_PWM_TIMER_FREQ *

MTR_AD_SAMPLING_TIME

MTR_CARRIER_SET (MTR_PWM_TIMER_FREQ *

1000 / MTR_CARRIER_FREQ / 2)

MTR_HALF_CARRIER_SET MTR_CARRIER_SET / 2 Carrier setting (intermediate value)

MTR_PORT_UN PORT7.PODR.BIT.B4 U phase (negative phase) output port

MTR_PORT_VN PORT7.PODR.BIT.B5 V phase (negative phase) output port

MTR_PORT_WN PORT7.PODR.BIT.B6 W phase (negative phase) output port

MTR_PORT_LED2 PORTB.PODR.BIT.B7 LED2 output port

MTR_LED_OFF 1

Dead time setting

A/D conversion time [µs]

Setting used to assure the A/D

conversion time

Carrier setting

Low active

MTR_IC_GATE_ON_V MTR_INPUT_V * 0.8 Power supply voltage × 80%[V]

MTR_ADC_SCALING 0x7FF ADC offset adjustment constant

MTR_CURRENT_SCALING 100.0f/4095.0 Resolution for use in A/D conversion

MTR_VDC_SCALING 686.0f/4095.0 Resolution for use in A/D conversion

of the measured inverter bus voltage

MTR_IPMTEMPERATURE_

MTR_OVERCURRENT_LIMIT 3.0 Current limit value [A]

MTR_UNDERVOLTAGE_

LIMIT

MTR_

OVERIPMTEMPERATURE_

MTR_PORT_IC_GATE PORT2.PODR.BIT.B4 Inrush current prevention circuit ports

MTR_PORT_SW1 PORT1.PIDR.BIT.B0 SW1 input port

MTR_PORT_SW3 PORT8.PIDR.BIT.B2 SW3 input port

5.0f/4095.0 Resolution for use in A/D conversion

0.0 Low voltage limit value [V]

3 IPM temperature limit value [V]

R01AN4673EJ0110 Rev.1.10 Page 27 of 45

Apr 21, 21

Page 28

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

MTR_INT_DECIMATION

1

Interrupt decimation count

(MTR_INT_DECIMATION + 1)

MTR_RS

MP_STATOR_RESISTANCE

Stator resistance [Ω]

MTR_M

MP_MUTUAL_INDUCTANCE

Magnetizing inductance [H]

INDUCTANCE

MTR_LR

MTR_M + MTR_LLR

MTR_RR_LR

MTR_RR / MTR_LR

MTR_LS_SIGMA

MTR_LS * MTR_SIGMA

MTR_TWOPI_3

MTR_TWOPI / 3

2π / 3

MTR_SQRT_3

1.7320508f

√3

MTR_RPM_RAD

MTR_TWOPI / 60

2π / 60

MTR_IQ_PI_KI

CP_IQ_PI_KI

axis current PI control integral gain

MTR_SPEED_PI_KI

CP_SPEED_PI_KI

Speed PI control integral gain

MTR_CURRENT_LPF_K

CP_CURRENT_LPF_K

Current LPF gain

value [A]

MTR_LIMIT_IQ

1.0

Speed PI control output limit value [A]

[rpm]

[rpm]

Table 3.7 List of Macro Definitions (4/12)

mtr_3im_less_

foc.h

MTR_CTRL_PERIOD (MTR_INT_DECIMATION + 1) /

(MTR_CARRIER_FREQ * 1000)

MTR_CONTROL_FREQ (MTR_CARRIER_FREQ * 1000) /

MTR_POLE_PAIRS MP_POLE_PAIRS Pole pairs count

MTR_RR MP_ROTOR_RESISTANCE Rotor resistance [Ω]

Control period [s]

Control frequency [Hz]

MTR_LLS MP_STATOR_LEAKAGE_

INDUCTANCE

MTR_LLR MP_ROTOR_LEAKAGE_

MTR_LS MTR_M + MTR_LLS

MTR_M_LR MTR_M / MTR_LR

MTR_SIGMA 1.0f - MTR_M / MTR_LS * MTR_M_LR

MTR_TWOPI 2 * 3.14159265 2π

MTR_SQRT_2 1.41421356f √2

MTR_SQRT_2_3 0.81649658f √(2/3)

MTR_IQ_PI_KP CP_IQ_PI_KP δ axis current PI control proportional

MTR_SPEED_PI_KP CP_SPEED_PI_KP Speed PI control proportional gain

MTR_SPEED_LPF_K CP_SPEED_LPF_K Speed LPF gain

Stator leakage inductance [H]

Rotor leakage inductance [H]

gain

δ

MTR_OFFSET_LPF_K CP_OFFSET_LPF_K Current offset value LPF gain

MTR_LIMIT_ID 3.0 γ axis current PI control output limit

MTR_I_LIMIT_ID 3.0 γ xis current PI control integral limit

value [A]

MTR_I_LIMIT_IQ 1.0 Speed PI control integral limit value[A]

MTR_MAX_SPEED_RPM CP_MAX_SPEED_RPM Maximum speed (mechanical angle)

MTR_MAX_SPEED_RAD MTR_MAX_SPEED_RPM *

MTR_POLE_PAIRS*MTR_TWOPI / 60

MTR_MIN_SPEED_RPM CP_MIN_SPEED_RPM Minimum speed (mechanical angle)

MTR_MIN_SPEED_RAD MTR_MIN_SPEED_RPM *

MTR_POLE_PAIRS*MTR_TWOPI / 60

Maximum speed (electrical angle)

[rad/s]

Minimum speed (electrical angle)

[rad/s]

R01AN4673EJ0110 Rev.1.10 Page 28 of 45

Apr 21, 21

Page 29

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

MTR_SPEED_LIMIT

MTR_MAX_SPEED_RAD * 1.3

Speed limit value [rad/s]

SPEED_RAD

value [rad/s]

MTR_BOOT_ID_UP_TIME

CP_BOOT_ID_UP_TIME

Rise time at γ axis current startup [ms]

Table 3.7 List of Macro Definitions (5/12)

mtr_3im_less_

foc.h

MTR_LIMIT_ROTOR_SPEED_

RAD

MTR_I_LIMIT_ROTOR_

MTR_CTRL_REF_ID CP_CTRL_REF_ID γ axis current command

MTR_MAX_SPEED_RAD * 1.2 δ axis current PI control output limit value

[rad/s]

MTR_MAX_SPEED_RAD * 1.2 δ axis current PI control integral limit

MTR_BOOT_ID_UP_STEP CP_CTRL_REF_ID/MTR_BOOT_

ID_UP_TIME

Step size at γ axis current startup

R01AN4673EJ0110 Rev.1.10 Page 29 of 45

Apr 21, 21

Page 30

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

MTR_ID_CONST_TIME

CP_ID_CONST_TIME

axis current/flux stabilization wait time [ms]

MTR_FLUCTUATION_LIMIT

CP_FLUCTUATION_LIMIT

Speed fluctuation limit [rad/s]

MTR_CTRL_PERIOD

MTR_VOLTAGE_DROP

CP_VOLTAGE_DROP

Voltage drop correction threshold [V]

MTR_EVERY_TIME

0

Current value calculation

MTR_CW

0

MTR_FLG_CLR

0

MTR_ID_UP

0 γ axis current increases

MTR_ID_CONST_CTRL

2

Normal operation

MTR_IQ_SPEED_PI_OUTPUT

1

Normal operation

MTR_START_MODE

0x01

Start mode

MTR_ZERO_PEC_MODE

0x00

Zero-position measurement mode

MTR_HALL_120_MODE

0x02

Hall sensor 120° operating mode

MTR_ENCD_FOC_MODE

0x04

Encoder vector operating mode

ERROR

MTR_OVER_SPEED_ERROR

0x03

Excessive speed error

ERROR

MTR_UNKNOWN_ERROR

0xff

Undefined error

MTR_MODE_RUN

0x01

Motor running state

MTR_SIZE_STATE

3

Number of states

MTR_EVENT_RUN

0x01

Motor start event

MTR_EVENT_RESET

0x03

Motor reset event

Table 3.7 List of Macro Definitions (6/12)

mtr_3im_less_

foc.h

γ

MTR_ACCEL_MODE0 CP_ACCEL_MODE0 Acceleration

MTR_DELAY CP_DELAY Phase compensation constant

MTR_ANGLE_COMPENSATION MTR_DELAY *

MTR_OFFSET_CALC_TIME CP_OFFSET_CALC_TIME Current offset calculation time [ms]

MTR_VOLTAGE_DROP_K CP_VOLTAGE_DROP_K Voltage drop correction gain

MTR_ONE_TIME 1 Current offset value calculation (first time only)

Rotational direction

MTR_CCW 1

Flag management

MTR_FLG_SET 1

MTR_ID_CONST 1 γ axis current is fixed

MTR_IQ_ZERO 0 δ axis current is 0

MTR_BOOT_MODE 0x00 Boot mode

MTR_CTRL_MODE 0x02 Control mode

MTR_OPENLOOP_MODE 0x01 Open-loop mode

MTR_LESS_120_MODE 0x03 BEMF sensorless 120° operating mode

MTR_LESS_FOC_MODE 0x05 Sensorless vector control mode

MTR_OVER_CURRENT_

MTR_OVER_VOLTAGE_

ERROR

MTR_TIMEOUT_ERROR 0x04 Timeout error

MTR_UNDER_VOLTAGE_

MTR_OVER_

IPMTEMPERATURE_ERROR

MTR_MODE_STOP 0x00 Stopped state

MTR_MODE_ERROR 0x02 Error state

0x01 Overcurrent error

0x02 Overvoltage error

0x07 Low voltage error

0x08 IPM temperature abnormality error

MTR_EVENT_STOP 0x00 Motor stop event

MTR_EVENT_ERROR 0x02 Motor error event

MTR_SIZE_EVENT 4 Number of events

R01AN4673EJ0110 Rev.1.10 Page 30 of 45

Apr 21, 21

Page 31

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

CP_ID_PI_KP

0.05 γ axis current PI control proportional gain

CP_IQ_PI_KP

0.5 δ axis current PI control proportional gain

CP_SPEED_PI_KP

0.0025

Speed PI control proportional gain

CP_SPEED_LPF_K

0.3

Speed LPF gain

CP_OFFSET_LPF_K

0.1

Current offset value LPF gain

CP_MIN_SPEED_RPM

500

Minimum speed (mechanical angle) [rpm]

CP_BOOT_ID_UP_TIME

100.0

Rise time at γ axis current startup [ms]

CP_ACCEL_MODE0

0.1

Acceleration during start mode [rad/s2]

CP_DELAY

1.0

Phase delay compensation constant

CP_VOLTAGE_DROP

8.0

Voltage drop correction threshold [V]

Table 3.7 List of Macro Definitions (7/12)

control_parameter.h

CP_ID_PI_KI 0.05 γ axis current PI control integral gain

CP_IQ_PI_KI 0.5 δ axis current PI control integral gain

CP_SPEED_PI_KI 0.00005 Speed PI control integral gain

CP_CURRENT_LPF_K 1.0 Current LPF gain

CP_MAX_SPEED_RPM 2000 Maximum speed (mechanical angle) [rpm]

CP_CTRL_REF_ID 0.4 γ axis current command

CP_ID_CONST_TIME 500.0 γ axis current/flux stabilization wait time [ms]

CP_FLUCTUATION_LIMIT 200.0 Speed fluctuation limit [rad/s]

CP_OFFSET_CALC_TIME 256 Current offset calculation time [ms]

CP_VOLTAGE_DROP_K 0.0 Voltage drop correction gain

R01AN4673EJ0110 Rev.1.10 Page 31 of 45

Apr 21, 21

Page 32

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

B_NOT_USE

0

Not in use

(Clock source: the main clock)

MAIN_CLOCK_Hz

8000000L

Number of frequencies of the main clock oscillator (Hz)

clock

B_NOT_USE: Not in use (the PLL clock is stopped)

Table 3.7 List of Macro Definitions (8/12)

r_init_clock.h

B_USE 1 In use

B_USE_PLL_MAIN 2 Use the PLL clock.

B_USE_PLL_HOCO 3 Use the PLL clock.

(Clock source: HOCO)

REG_VOLSR *2 C0h Used in making the following settings:

Usage of the USB, usage of the PGA pseudo-

differential input and its voltage, and the level of the

VCC voltage when the RIIC is in use (the value to be

set in the VOLSR register).

SEL_MAIN B_USE Used in selecting oscillation or stopping of the main

clock.

B_USE: In use (the main clock oscillates)

B_NOT_USE: Not in use (the main clock is stopped)

REG_MOFCR 30h For setting the driving ability of the main clock oscillator

(the value to be set in the MOFCR register)

REG_MOSCWTCR 53h The value set in the wait control register for the main

REG_PLLCR *1, *2 1F11h (When the PLL clock is

sourced from the HOCO clock)

2700h (Other than above)

SEL_PLL B_USE_PLL_MAIN Used in selecting oscillation or stopping of the PLL

SEL_HOCO B_NOT_USE Used in selecting oscillation or stopping of the HOCO

Setting of the division ratio and multiplication factor for

the PLL (the value to be set in the PLLCR register).

1F11h: Selects the HOCO clock as the clock source

with division by 2 and multiplication by 16

2700h: Selects the main clock as the clock source with

division by 1 and multiplication by 20.

clock.

B_USE_PLL_MAIN: In use (with the main clock as the

source for the PLL)

B_USE_PLL_HOCO: In use (with the HOCO clock as

the source for the PLL)

clock.

B_USE: In use (the HOCO clock oscillates)

B_NOT_USE: Not in use (the HOCO clock is stopped)

Note 1. The meanings of the values depend on the clock source selected for the system clock.

Note 2. Change the setting value of the PLLCR register as required in accord with the description of the

RX66T Group User’s Manual: Hardware.

R01AN4673EJ0110 Rev.1.10 Page 32 of 45

Apr 21, 21

Page 33

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

FREQ_16MHz

00h

Number of frequencies of HOCO: 16 MHz

FREQ_20MHz

02h

Number of frequencies of HOCO: 20 MHz

CLK_HOCO

0100h

Clock source: PLL

CLK_PLL

0400h

Clock source: The main clock

0080 0000h (other than above)

MEMWAIT_1WAIT

0

Memory wait cycles: 0 cycle

Table 3.7 List of Macro Definitions (9/12)

r_init_clock.h

FREQ_18MHz 01h Number of frequencies of HOCO: 18 MHz

REG_HOCOCR2 FREQ_20MHz The number of frequencies of HOCO

FREQ_16MHz: 16 MHz

FREQ_18MHz: 18 MHz

FREQ_20MHz: 20 MHz

CLK_MAIN 0200h Clock source: HOCO

SEL_SYSCLK CLK_PLL The clock source for the system clock.

CLK_PLL: PLL

CLK_HOCO: HOCO

CLK_MAIN: The main clock

REG_SCKCR *1, *2 2082 1202h (when PLL is selected)

0080 0000h (when HOCO is

selected)

Used in setting the division ratio for the internal

clock signals and the PCLK control (value to be

set in the SCKCR register)

REG_SCKCR2 0011h Division ratio for the USB clock (when the USB is

not in use).

MEMWAIT_0WAIT 1 Memory wait cycles: 1 cycle

REG_MEMWAIT *3 MEMWAIT_1WAIT Used in selecting the number of memory wait

cycles.

MEMWAIT_0WAIT: 0 cycle

MEMWAIT_1WAIT: 1 cycle

Note 1. The meanings of the values depend on the clock source selected for the system clock.

Note 2. Change the setting value of the SCKCR register as required in accord with the description of the

RX66T Group User’s Manual: Hardware.

Note 3. If ICLK is faster than 120 MHz, set the number of wait cycles to 1.

R01AN4673EJ0110 Rev.1.10 Page 33 of 45

Apr 21, 21

Page 34

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

WITH

1

Function included

WITH: Product with the PGA pseudo differential input

File Name

Macro Name

Definition Value

Remarks

CACHE_ENABLE

1

Enables caching of the ROM

AREA_DISABLE

NON_CACHEABLE_AREA_DISABLE: Disabled

Table 3.7 List of Macro Definitions (10/12)

r_init_port_initialize.h

WITHOUT 0 Function not included

PGA_DEFAMP WITH Used in selecting the product with/without the PGA

pseudo differential input.

WITHOUT: Product without the PGA pseudo

differential input

USB_MODULE WITHOUT Used in selecting the product with/without the USB.

WITHOUT: Product without the USB

WITH: Product with the USB

PIN_SIZE 100 The number of pins for use

Table 3.7 List of Macro Definitions (11/12)

r_init_rom_cache.h

CACHE_DISABLE 0 Disables caching of the ROM

NON_CACHEABLE_

0 Disables the non-cacheable area

NON_CACHEABLE_

AREA_ENABLE

SEL_ROM_CACHE CACHE_ENABLE Enables or disables caching of the ROM.

SEL_NON_

CACHEABLE_AREA0

SEL_NON_

CACHEABLE_AREA1

1 Enables the non-cacheable area

CACHE_ENABLE: Enables caching

CACHE_DISABLE: Disables caching

NON_CACHEABLE_

AREA_DISABLE

NON_CACHEABLE_

AREA_DISABLE

Selects enabling or disabling of non-cacheable area

0.

NON_CACHEABLE_AREA_ENABLE: Enabled

NON_CACHEABLE_AREA_DISABLE: Disabled

Selects enabling or disabling of non-cacheable area

1.

NON_CACHEABLE_AREA_ENABLE: Enabled

R01AN4673EJ0110 Rev.1.10 Page 34 of 45

Apr 21, 21

Page 35

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

File Name

Macro Name

Definition Value

Remarks

ENABLE

MODULE_STOP_ENABLE: Enters the module-stop state.

MODULE_STOP_ENABLE: Enters the module-stop state.

Table 3.7 List of Macro Definitions (12/12)

r_init_stop_module.h MODULE_STOP_

MODULE_STOP_

DISABLE

MSTP_STATE_

DMACDTC

MSTP_STATE_

ECCRAM

MSTP_STATE_

RAM

1 Enters the module-stop state.

0 Exits the module-stop state.

MODULE_STOP_

DISABLE

MODULE_STOP_

DISABLE

MODULE_STOP_

DISABLE

Selects entry to or exit from the module-stop state by the

DMAC and DTC.

MODULE_STOP_DISABLE: Exits the module-stop state.

Selects entry to or exit from the module-stop state by the

ECCRAM.

MODULE_STOP_DISABLE: Exits the module-stop state.

MODULE_STOP_ENABLE: Enters the module-stop state.

Selects entry to or exit from the module-stop state by the

RAM.

MODULE_STOP_DISABLE: Exits the module-stop state.

R01AN4673EJ0110 Rev.1.10 Page 35 of 45

Apr 21, 21

Page 36

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Main processing

Initialization of peripheral modules

Initialization of user interfaces

Initialization of variables used in

main()

Wait for the capacitor to be

charged.

Clear watchdog timer

Sequence processing initialization

Reset processing

Acquire the switch state

Change motor operating mode based on

com_s2_mode

_system value

Control LEDs

ICS initialization

3.6 Control Flow (Flowcharts)

3.6.1 Main Processing

Figure 3.4 Main Processing

R01AN4673EJ0110 Rev.1.10 Page 36 of 45

Apr 21, 21

Page 37

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

End

Calculate U

-

, V

-,

W

-phase currents

Acquire inverter bus voltage value

Error check

γ

axis calculation

Command voltage calculation

Modulation and coordinate inverse transformation

Calculate PWM register setting values

Set PWM registers

Current PI control

Acquire A/D converted values of U

-,

V

-,

W-

phase

currents and inverter bus voltage

Coordinate transformation

Stator speed measurement

Voltage drop correction

125-µs period interrupt

3.6.2 125-μs Period Interrupt Handling

Figure 3.5 125-μs Period Interrupt Handling

R01AN4673EJ0110 Rev.1.10 Page 37 of 45

Apr 21, 21

Page 38

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

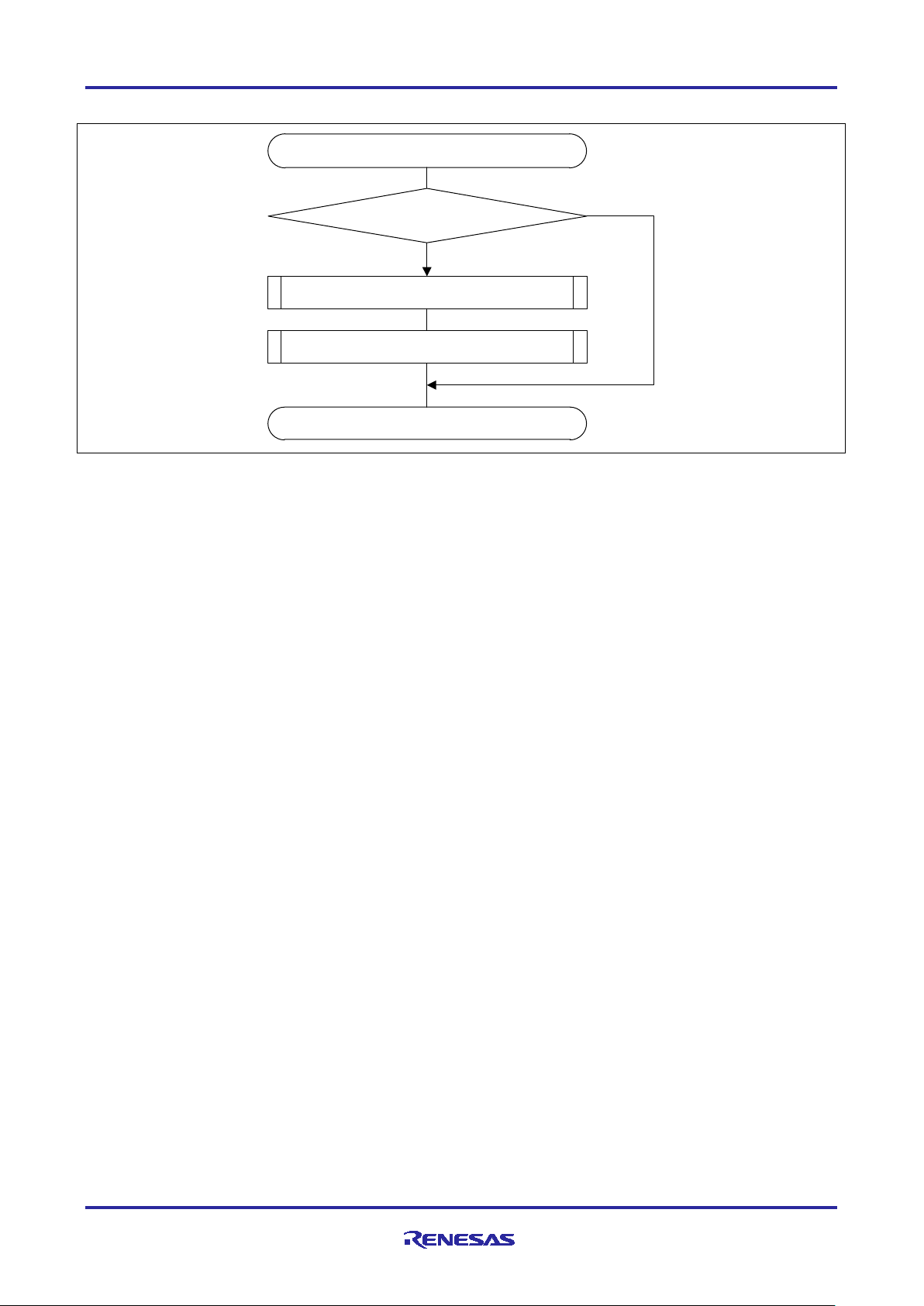

1-ms interrupt handling

Run mode

?

End

No

Set rotation direction

Yes

Normal mode

?

Normal control

Startup control

Slip speed gain calculation

No

Yes

3.6.3 1-ms Interrupt Handling

Figure 3.6 1-ms Interrupt Handling

R01AN4673EJ0110 Rev.1.10 Page 38 of 45

Apr 21, 21

Page 39

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Group interrupt including

overcurrent detection as a source

End

Motor stop processing

Release the high-impedance state

Overcurrent detected?

No

Yes

3.6.4 Handling of Group Interrupt that Includes Overcurrent Detection as a Source

Figure 3.7 Handling of Group Interrupt that Includes Overcurrent Detection as a Source

R01AN4673EJ0110 Rev.1.10 Page 39 of 45

Apr 21, 21

Page 40

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

4. Development Support Tool “In Circuit Scope”

4.1 Overview

‘Renesas Motor Workbench 2.0’ is support tool for development of motor control system. ‘Renesas Motor

Workbench 2.0’ can be used with target software of this application note to analyze the control performance.

The user interfaces of ‘Renesas Motor Workbench 2.0’ provide functions like rotating start/stop command,

setting rotation speed command, etc…Please refer to ‘Renesas Motor Workbench 2.0 User’s Manual’ for

usage and more details.

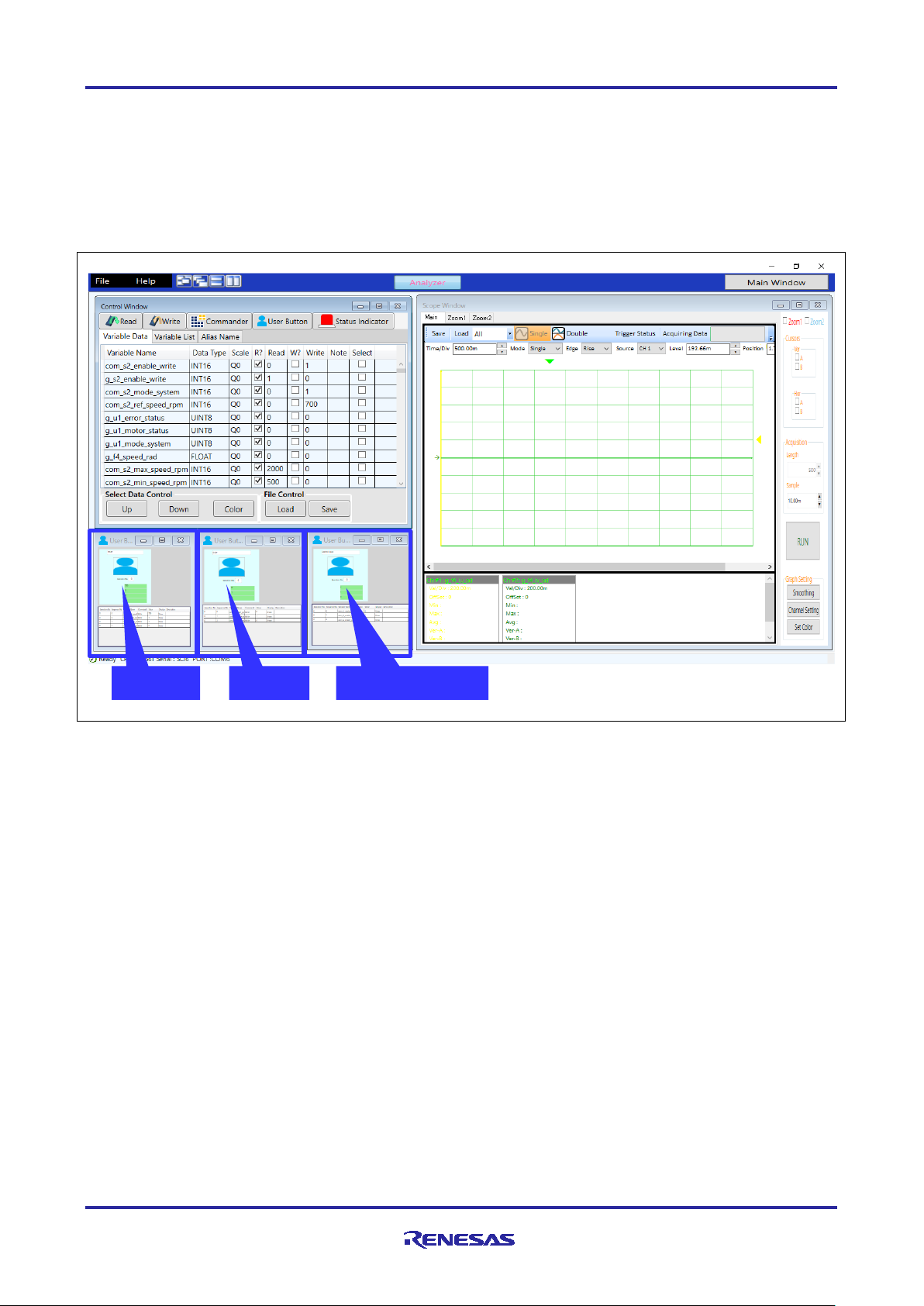

Figure 4.1 Renesas Motor Workbench-Appearance

R01AN4673EJ0110 Rev.1.10 Page 40 of 45

Apr 21, 21

Page 41

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

START

STOP

ERROR RESET

4.2 The Usage of RMW

Following shows how to use RMW to operate a motor. The RMW screen is shown in Figure 4.2. The screen

consists of three parts of the window. The control window is located in the upper left corner, the user button

is located int the lower left corner, and the scope window is located in the right side. In RMW, the user button

is used for basic operations, such as starting/stopping the motor. The function of each button is shown

below.

Figure 4.2 The Usage of RMW

4.2.1 START Button

The user button located on the left side is the START button. Use this button to set speed command value

and operate the motor. Enter the speed command value in rpm unit in the value column of

‘com_s2_ref_speed_rpm’. Then click the image part in the button to transition to the motor operating state

and accelerate to the set speed command value. However if errors occurred, the motor will not operating.

To change the motor rotation speed in the operating state, change the speed command value and click the

image part of the button to accelerate or decelerate the motor.

4.2.2 STOP Button

The user button located in the center is the STOP button. Click the image part in the button to switch to the

motor stop state.

4.2.3 ERROR RESET Button

The user button located in the right side is the ERROR RESET button. Click the image part in the button to

resets the error status.

R01AN4673EJ0110 Rev.1.10 Page 41 of 45

Apr 21, 21

Page 42

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

Step1

Write the desired value

Step2

Step3

Press the read button to read the current value and

Step4

Press the read button

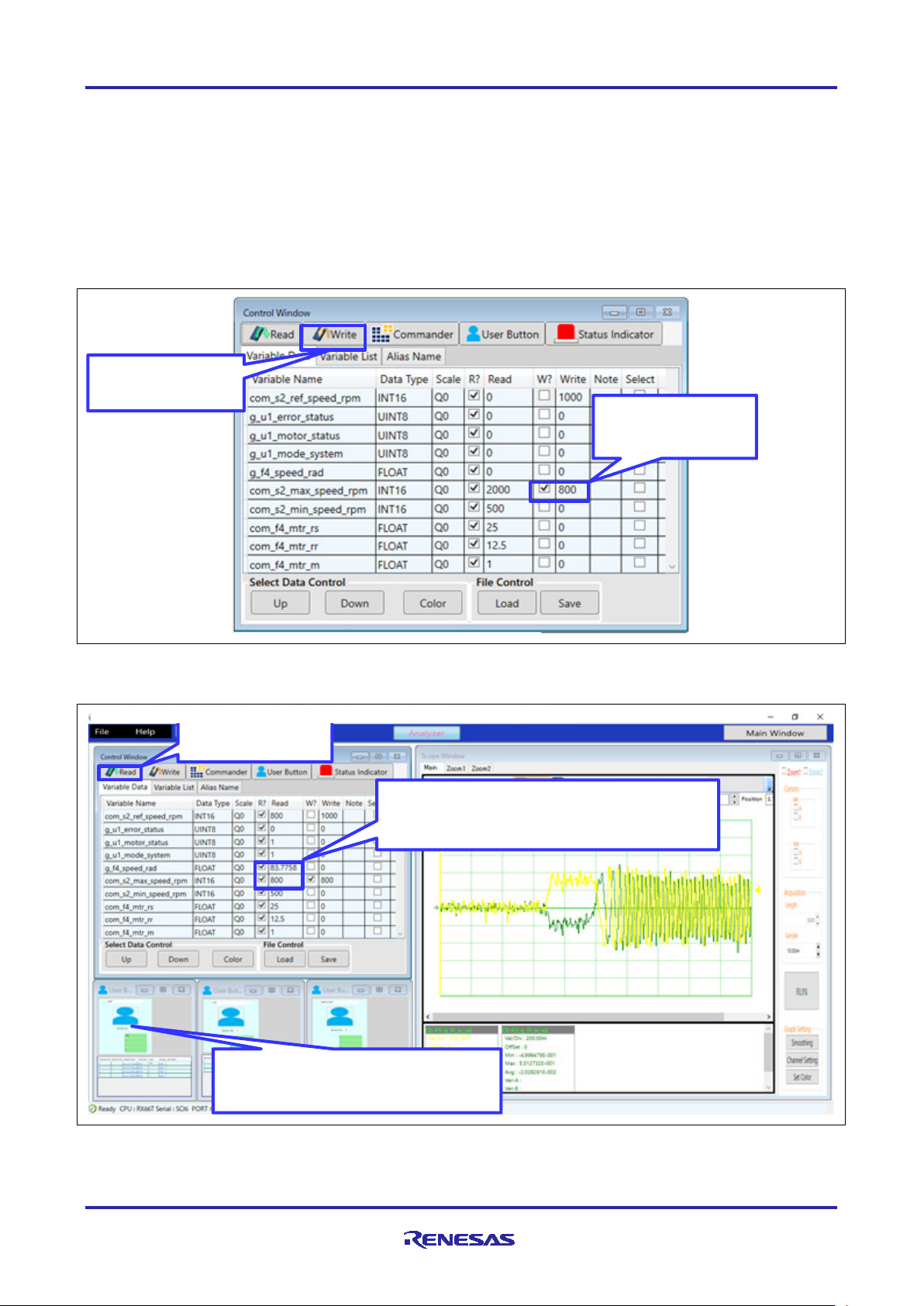

4.2.4 Change Parameter Setting

The following is an example using RMW to change maximum speed value. The procedure for changing

parameters are shown in Figure 4.3 and Figure 4.4. The same procedure is used to change the other

parameters.

To set and write parameters as shown in steps 1 and 2 in Figure 4.3. When the START button is pressed to

operate the motor, the set parameters are reflected in the motor control layer variables. Figure 4.4 shows.

The result when the speed command is set to 1000rpm. Although the speed command value is set to

1000rpm, the maximum speed is limited to 800rpm.

Press the write button

Put a check mark

Figure 4.3 Setting parameters

confirm the motor speed is limited by the maximum

speed value(800rpm = 83.7758 rad/s).

Set the speed command value to 1000rpm,

Press START button (Reflect parameter)

Figure 4.4 Parameter reflection confirmation

R01AN4673EJ0110 Rev.1.10 Page 42 of 45

Apr 21, 21

Page 43

RX66T Implementation

Vector Control of Three-Phase Induction

Motor Used in Driving a Fan

RMW Variable

Type

Usage

(Motor Control Layer Variable)

4.3 RMW Variables

Table 4.1 lists the variables for use with the RMW. Note that modifications to these variables will not be

reflected in the motor control layer variables at the point these RMW variables are modified. The motor

control layer variables are written and modified at the point the value of g_s2_enable_write is written to

com_s2_enable_write.

Table 4.1 RMW Variables

Target Variable

com_s2_mode_system int16 State management

0: Stop mode

1: Run mode

3: Reset

Com_s2_direction int16 Rotational direction g_u1_dir_buff

com_s2_ref_speed_rpm int16 Speed command g_f4_ref_speed_rad

com_f4_kp_speed float32 Speed PI control proportional gain g_f4_kp_speed

com_f4_ki_speed float32 Speed PI control integral gain g_f4_ki_speed

com_f4_kp_iq float32 δ axis current PI control proportional gain g_f4_kp_iq

com_f4_ki_iq float32 δ axis current PI control integral gain g_f4_ki_iq

com_f4_speed_lpf_k float32 Speed LPF gain g_f4_speed_lpf_k

com_f4_current_lpf_k float32 Current LPF gain g_f4_current_lpf_k

com_f4_mtr_rs float32 Stator resistance mtr_p.f4_mtr_rs

com_f4_mtr_rr float32 Rotor resistance mtr_p.f4_mtr_rr

com_f4_mtr_m float32 Magnetizing inductance mtr_p.f4_mtr_m

com_f4_mtr_lls float32 Stator leakage resistance mtr_p.f4_mtr_ls

com_f4_mtr_llr float32 Rotor leakage inductance mtr_p.f4_mtr_lr

com_f4_offset_lpf_k float32 Current offset LPF gain g_f4_offset_lpf_k

com_s2_max_speed_rpm int16 Maximum speed g_f4_max_speed_rad

com_s2_min_speed_rpm int16 Minimum speed g_f4_min_speed_rad

com_f4_ctrl_ref_id float32 γ axis current command g_f4_ctrl_ref_id

com_f4_boot_id_up_time float32 Rise time at γ axis current startup g_f4_boot_id_up_step

com_f4_id_const_time float32 γ axis current/flux stabilization wait time g_f4_id_const_time

com_f4_accel float32 Rotational frequency command

acceleration step size

com_f4_fluctuation_limit float32 Speed fluctuation limit g_f4_fluctuation_limit

com_f4_offset_calc_time float32 Current offset adjustment time g_f4_offset_calc_time

com_f4_delay float32 Voltage output delay compensation

coefficient

com_f4_voltage_drop float32 Voltage drop correction threshold g_f4_voltage_drop

com_f4_voltage_drop_k float32 Voltage drop correction gain g_f4_voltage_drop_k

com_s2_enable_write int16 Variable write enable —