Page 1

Application Note

R-IN32M3 Module (RY9012A0)

R-IN32M3 Module Evaluation Board

Introduction

This document describes sample software for host microcomputers (RX66T) mounted on the R-IN32M3

Module Evaluation Board (SEM1320), which is manufactured by Shimafuji Electric Co., Ltd.

Target Device

RX66T (R5F566TKADFP)

R-IN32M3 Module (RY9012A0)

Contents

1. Overview ................................................................................................................................. 4

1.1 Overview .................................................................................................................................................. 4

1.2 Operating environment ............................................................................................................................ 5

2. Hardware configuration ............................................................................................................ 7

2.1 List of specifications ................................................................................................................................ 7

2.2 Appearance of the board ......................................................................................................................... 8

2.3 Block diagram .......................................................................................................................................... 9

2.4 Features ................................................................................................................................................ 10

2.4.1 Power supply ....................................................................................................................................... 10

2.4.2 GND ..................................................................................................................................................... 11

2.4.3 RESET and JTAG ............................................................................................................................... 12

2.4.4 R-IN32M3 Module ............................................................................................................................... 13

2.4.5 Emulator connection ............................................................................................................................ 13

2.5 External interfaces ................................................................................................................................. 14

2.5.1 Ethernet connector .............................................................................................................................. 14

2.5.2 LED ...................................................................................................................................................... 14

2.5.3 Switch .................................................................................................................................................. 16

2.5.4 Connector ............................................................................................................................................ 19

2.5.5 Jumper ................................................................................................................................................. 23

2.6 Difference between RX66T CPU Card .................................................................................................. 25

3. Sample software configuration ............................................................................................... 26

3.1 Folder structure ..................................................................................................................................... 26

3.1.1 Overview of the project ........................................................................................................................ 27

3.2 Setup of development environment....................................................................................................... 28

3.2.1 Install ................................................................................................................................................... 28

3.2.2 Connection .......................................................................................................................................... 31

R12AN0111EJ0204 Rev.2.04 Page 1 of 88

Apr.26.2021

Page 2

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3.2.3 Import project ....................................................................................................................................... 33

3.2.4 FIT Module .......................................................................................................................................... 36

3.2.5 Build project ......................................................................................................................................... 41

3.2.6 Debug .................................................................................................................................................. 42

3.3 How to use ............................................................................................................................................. 43

3.3.1 I/O mirror response (via PROFINET) .................................................................................................. 43

3.3.2 I/O mirror response (via EtherNet/IP) .................................................................................................. 48

3.3.3 I/O mirror response (via EtherCAT)..................................................................................................... 52

3.3.4 Motor Sample (via PROFINET) ........................................................................................................... 57

3.3.5 Motor Sample (via EtherNet/IP) .......................................................................................................... 59

3.3.6 Motor control (via EtherCAT) ............................................................................................................... 61

3.3.7 Remote I/O (via PROFINET) ............................................................................................................... 63

3.3.8 Remote I/O (via EtherNet/IP) .............................................................................................................. 65

3.3.9 Remote I/O (via EtherCAT) ................................................................................................................. 67

3.4 Application Implement Guide ................................................................................................................ 70

3.4.1 PROFINET .......................................................................................................................................... 71

3.4.2 EtherNet/IP .......................................................................................................................................... 76

3.4.3 EtherCAT ............................................................................................................................................. 80

4. Appendix ............................................................................................................................... 85

4.1 GOAL API .............................................................................................................................................. 85

4.2 OS Service Call ..................................................................................................................................... 85

4.3 Motor Sample ........................................................................................................................................ 86

Revision History ............................................................................................................................ 87

R12AN0111EJ0204 Rev.2.04 Page 2 of 88

Apr.26.2021

Page 3

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Terms

Description

This board

R-IN32M3 Module Evaluation Board: SEMB1320 (manufactured by Shimafuji Electric

This sample

The sample program for the host microcomputer (RX66T) that is explained in this

API

Application Programming Interface

GOAL

Generic Open Abstraction Layer

Document Type

Document Title

Document No.

Data Sheet

R-IN32M3 Module Datasheet

R19DS0109ED****

User’s Manual

R-IN32M3 Module User’s Manual: Hardware

R19UH0122ED****

User’s Manual

R-IN32M3 Module User’s Manual: Software

R17US0002ED****

Quick Start Guide

R-IN32M3 Module Application Note: Quick Start Guide

R12QS0042ED****

Application Note

Sensorless Vector Control for Permanent Magnet Synchronous

R01AN4244EJ****

User's Manual

Renesas Solution Starter Kit 24V Motor Control Evaluation

System for RX23T (Motor RSSK)

R20UT3697EJ****

Application Note

RX Smart Configurator User’s Guide: e² studio

R20AN0451ES****

List of Abbreviations and Acronyms

In this document, the terms below are defined as follows:

Co., Ltd.), which is the target board for the sample programs explained in this

document

software (SW)

document

See "R-IN32M3 Module User's Manual: Software API description”

(R17US0002ED****)』

Related documents

Motor (Implementation)

R12AN0111EJ0204 Rev.2.04 Page 3 of 88

Apr.26.2021

Page 4

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

1. Overview

1.1 Overview

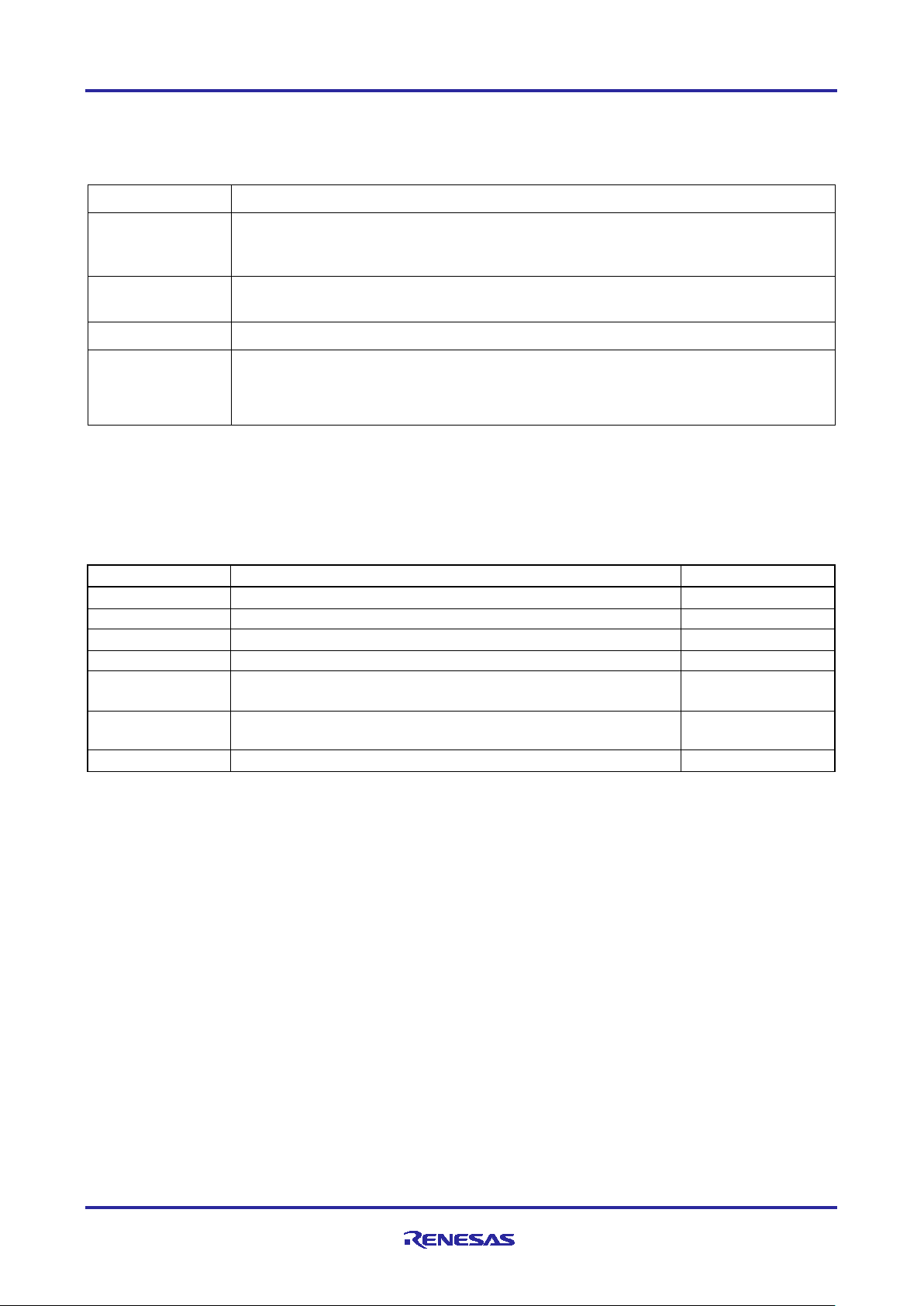

This document describes sample software for host microcomputers (RX66T) mounted on theR-IN32M3

Module Evaluation Board (SEMB1320), which is manufactured by Shimafuji Electric Co., Ltd.

RX66T is mounted on this board as the host microcomputer of the R-IN32M3 Module and communicate via

SPI.

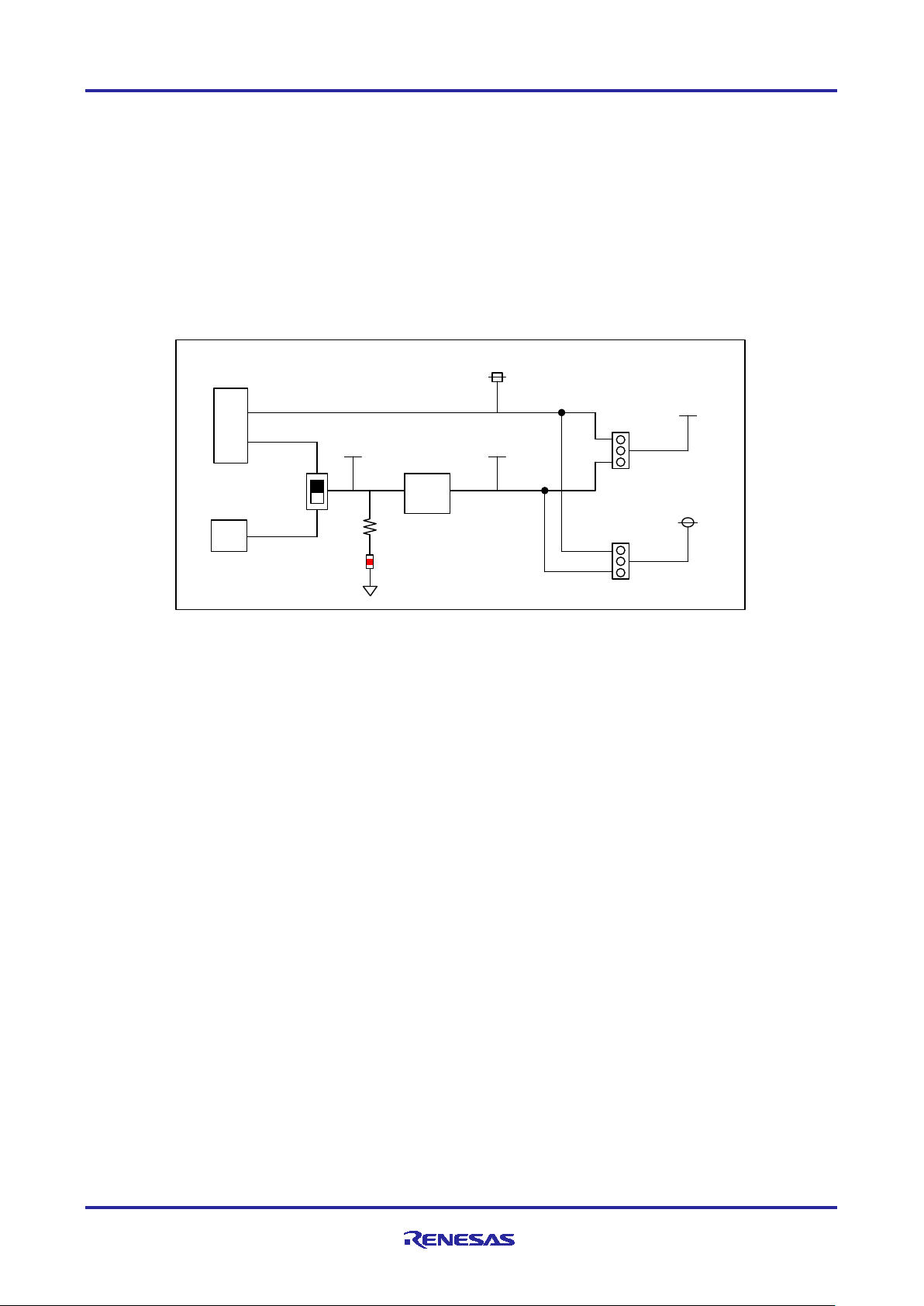

Figure 1-1 R-IN32M3 Module Evaluation Board

This board can be connected to an optional inverter board, which is included in "24V Motor Control

Evaluation System for RX23T", to evaluate motor control by industrial Ethernet protocol communication.

Figure 1-2 Photos of this board connected to the Inverter Board

R12AN0111EJ0204 Rev.2.04 Page 4 of 88

Apr.26.2021

Page 5

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

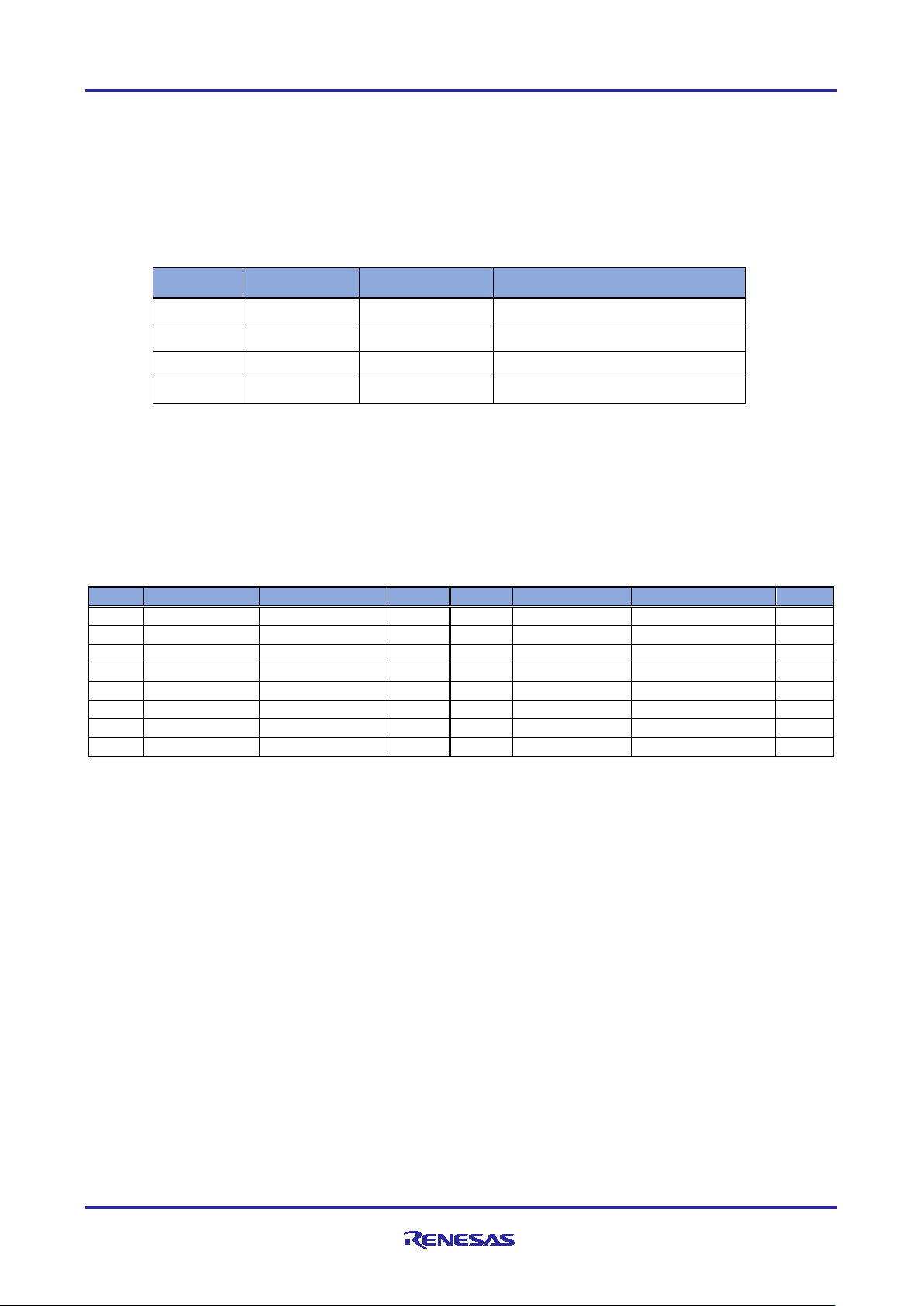

Category

Name

Version

Link

Remarks

R-IN32M3

package

Sample

-

r18an0052xx0***

Integrated

e2studio

64bit version:

V7.8.0 or later

https://www.renesas.com/softwa

RX family

package

CC-RX

V3.03.00

https://www.renesas.com/softwa

Not necessary for OS

RX family

GCC for

RX

V8.3.0.202004

https://gcc-renesas.com/rx-

RX family real-

RI600V4

V1.06.00

https://www.renesas.com/softwa

family

Not necessary for OS

RX family

FreeRTOS

FreeRTOS

V10.0.04

https://www.renesas.com/softwa

Not necessary for OS

Management

ICE

V1.3.1 or later

-

port industrial

package

Software PLC

TwinCAT

V3.1

Beckhoff Automation

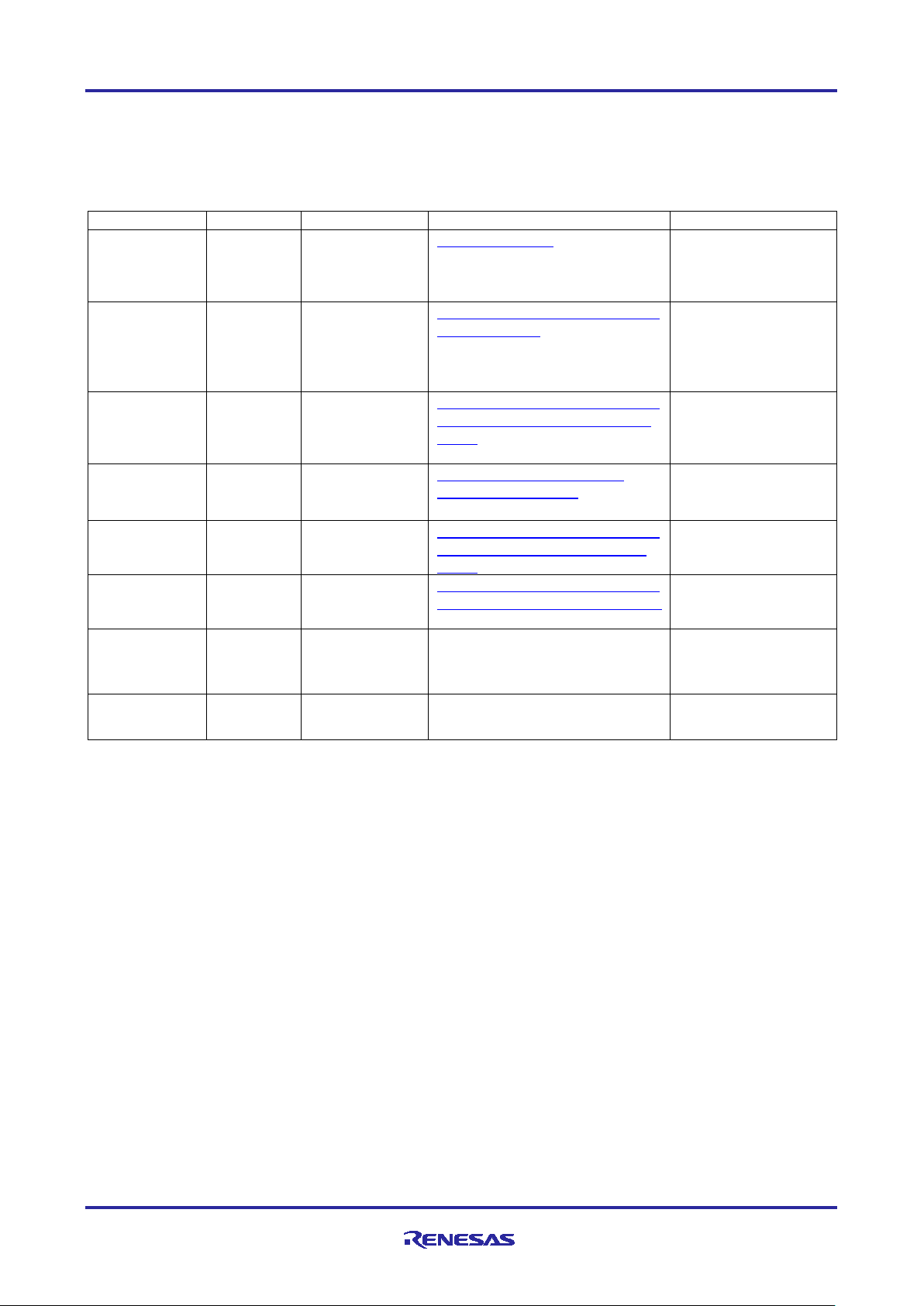

1.2 Operating environment

The operating environment of this sample software is shown in Table 1-1.

Table 1-1 Operating Environments

module

Sample

development

environment

C/C++

Compiler

GNU

Toolchain

time OS

Renesas

Tool, simple

software PLC

package

Renesas

2021-01 or later

32bit version:

re-tool/e-studio

re-tool/cc-compiler-package-rxfamily

download-toolchains

re-tool/ri600v4-real-time-os-rx-

re-tool/rx-family-renesas-freertos

less sample projects

less sample projects

less sample projects

automation GmbH

Including with Sample

of EtherCAT

GmbH

R12AN0111EJ0204 Rev.2.04 Page 5 of 88

Apr.26.2021

Page 6

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

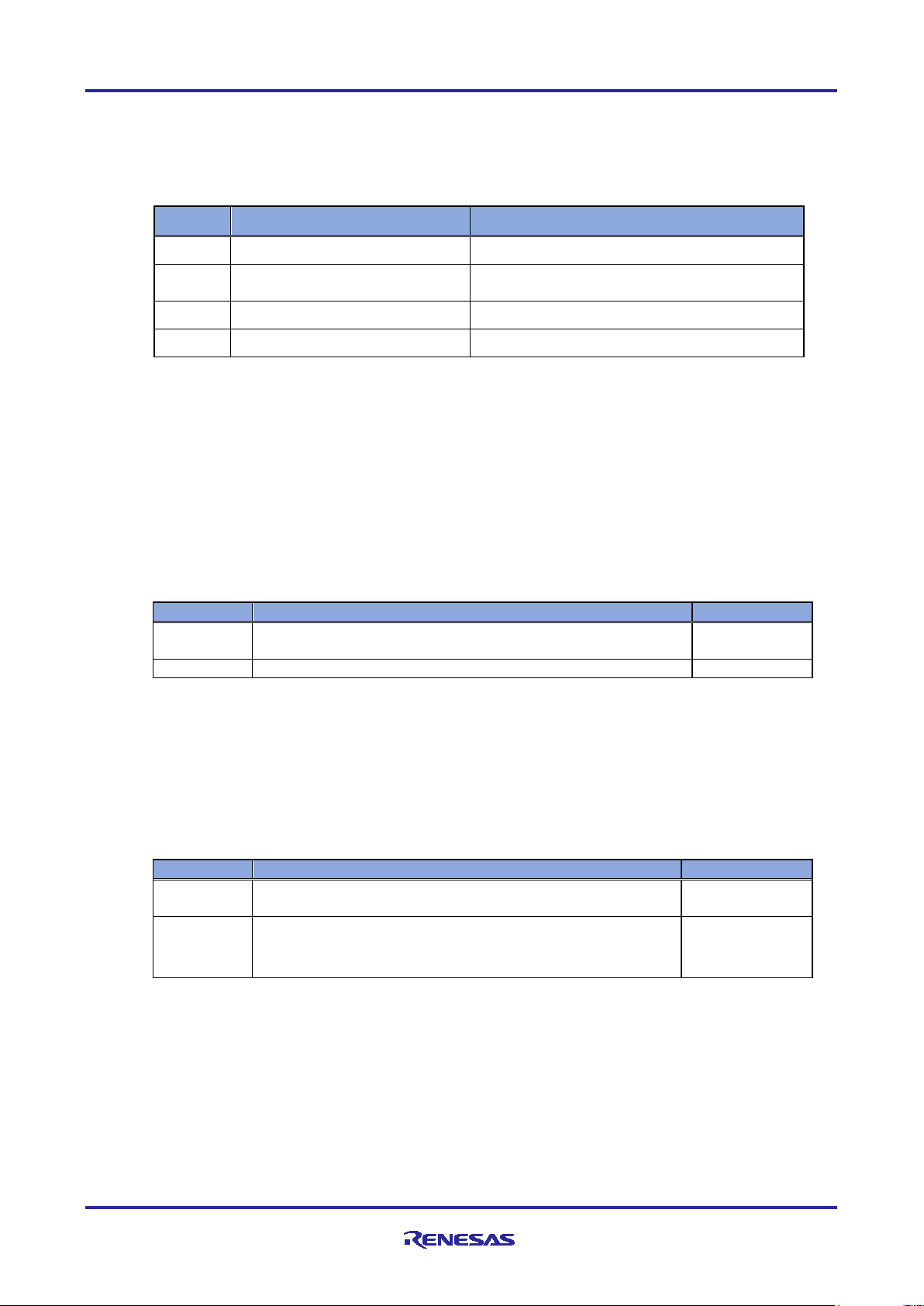

Abbreviation

Name

Description

E1

E1 emulator

On-chip debugging emulator and flash programmer

Type name:R0E000010KCE00

E2 Lite

E2 emulator Lite

On-chip debugging emulator and flash programmer

Type name:RTE0T0002LKCE00000R

Product name

Type name

Link

24V Motor Control Evaluation

RTK0EM0006S01212BJ

https://www.renesas.com/products/

One of the following emulators is required separately to run this sample software.

Table 1-2 Supported emulators

To execute the motor control samples included in this sample software, a 24V inverter board included below,

and a BLDC motor are required. In addition, a separate DC24V stabilized power supply is required.

Table 1-3 Corresponding motor control board

System for RX23T

R12AN0111EJ0204 Rev.2.04 Page 6 of 88

Apr.26.2021

Page 7

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Item

Functions and specification

5V (Supply from USB Micro B or inverter board.)

or 3.3V (from inverter board)

Flash memory

1MB

Data flash memory

32KB

MCU Input Clock

Oscillator

8MHz

E1 / E2 Lite emulator

2.54mm pitch 14pins

CNA:2.54mm pitch 20pins

CNB:2.54mm pitch 20pins

Hall sensor

B5B-XH-A

Encoder

B5B-XH-A

SCI

B4B-XH-A (not mounted)

Power input switch

DIP switch 2bit

rotary switch Hexadecimal (not mounted)

EtherCAT ID

rotary switch Hexadecimal

CPU Reset

Push switch 1bit

R-IN32M3 Module Reset

Push switch 1bit

5V power in

Red 1bit

Generic

Green 4bit

Protocol display

Green 3bit

Protocol status

Bi-Color(2bit) x 2

Pin Headers for External Extensions

2.54mm pitch 16 pins (not mounted)

while executing motor program

60mA typ.

while executing ethernet

communication program

Operating Temperature

0 ~ 45℃

Board Dimension

80mm × 110mm t = 1.6mm

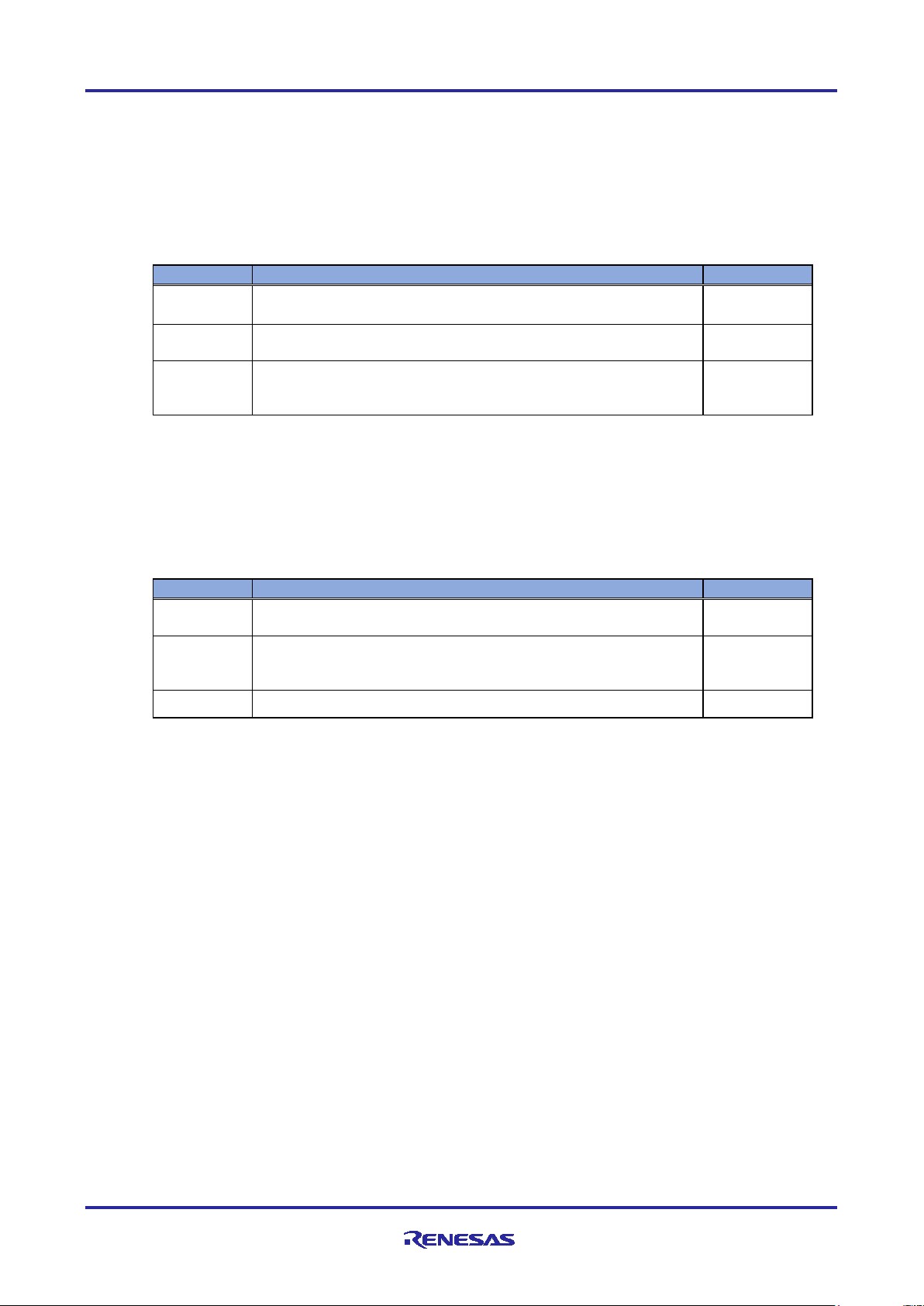

2. Hardware configuration

2.1 List of specifications

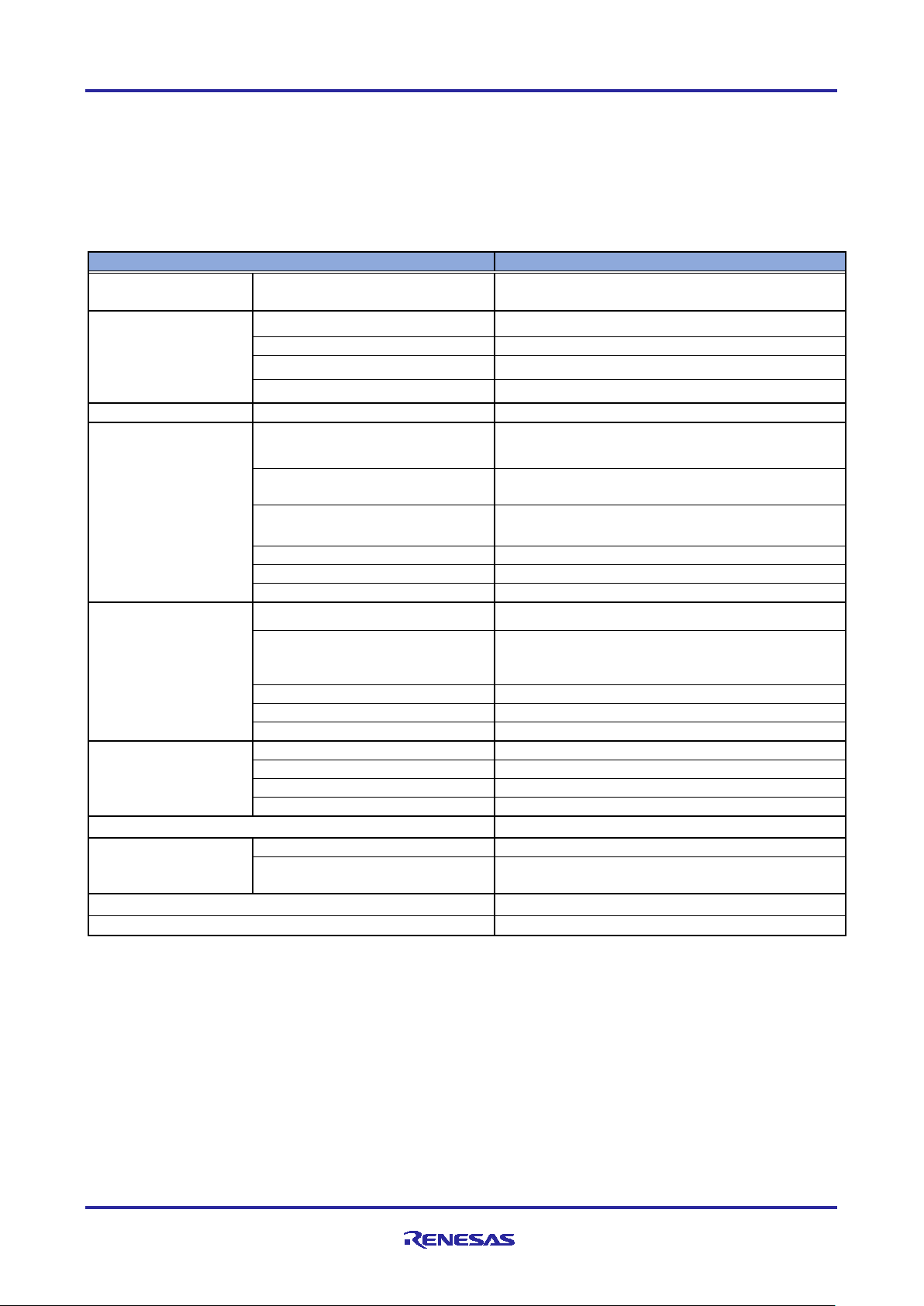

Table 2-1 shows a list of specifications for this board.

Table 2-1 Board specifications

Input Power Input voltage

Type name R5F566TKADFP

MCU

Connectors

Switches

LED

RAM 128KB

USB Micro B only input power (data line is not connected)

JTAG

Inverter Board

Slide switch SPDT

Generic

toggle switch 4bit

consumption

R12AN0111EJ0204 Rev.2.04 Page 7 of 88

Apr.26.2021

260mA typ.

Page 8

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

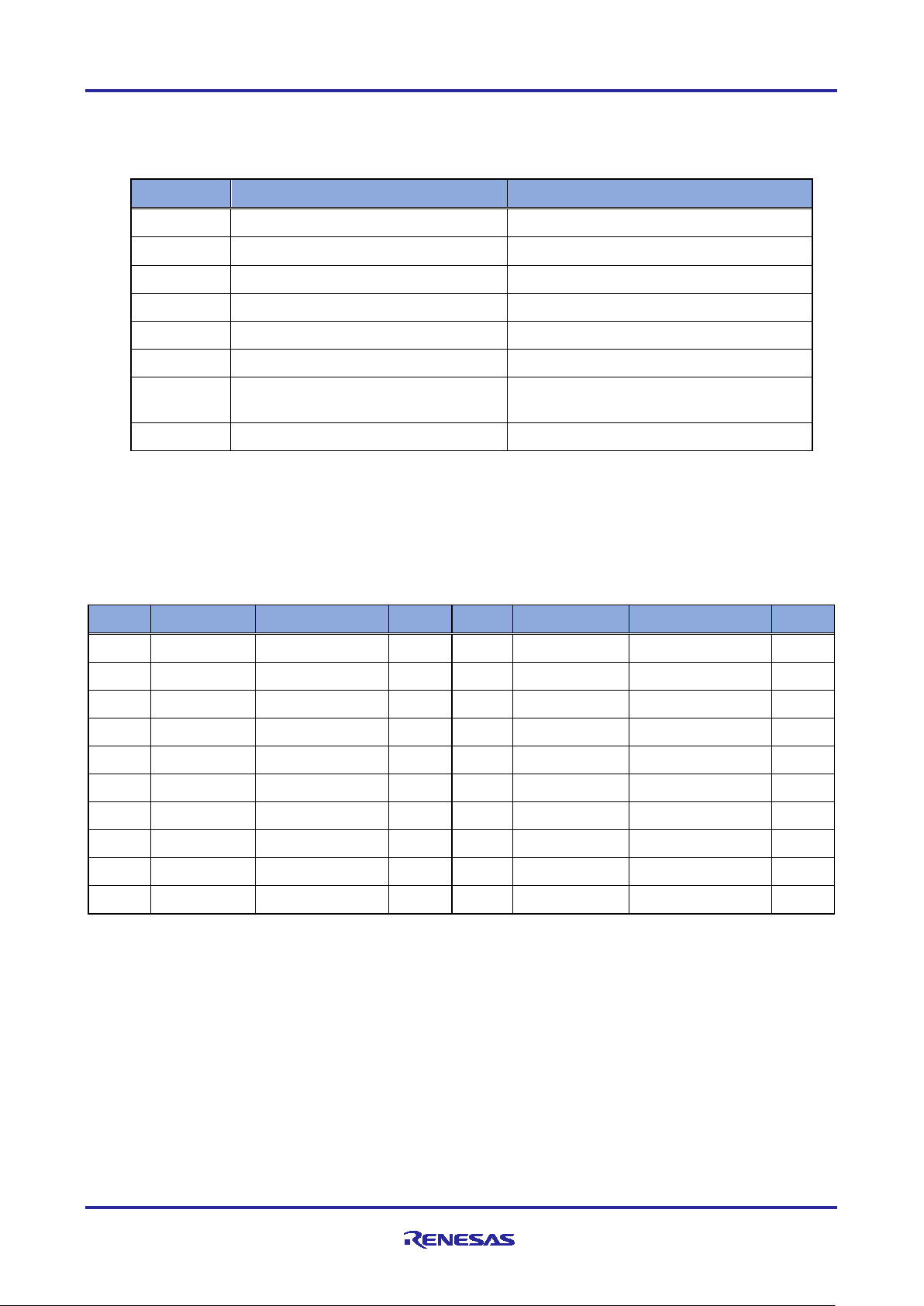

No.

Component Description

No.

Component Description

1

General purpose DIP switch

10

Inverter Board connector B

2

USB Micro B

11

Reset switch

3

Power input selector switch

12

General purpose toggle switch

4

Inverter Board connector A

13

JTAG connector

5

General-purpose rotary switch (not

mounted)

14

General purpose LED (Green)

6

EtherCAT ID switch

15

SCI connector (not mounted)

7

Protocol display LED

16

Pin header for external expansion (not

mounted)

8

R-IN32M3 Module

17

Encoder connector

9

Protocol status LED

18

Hall sensor connector

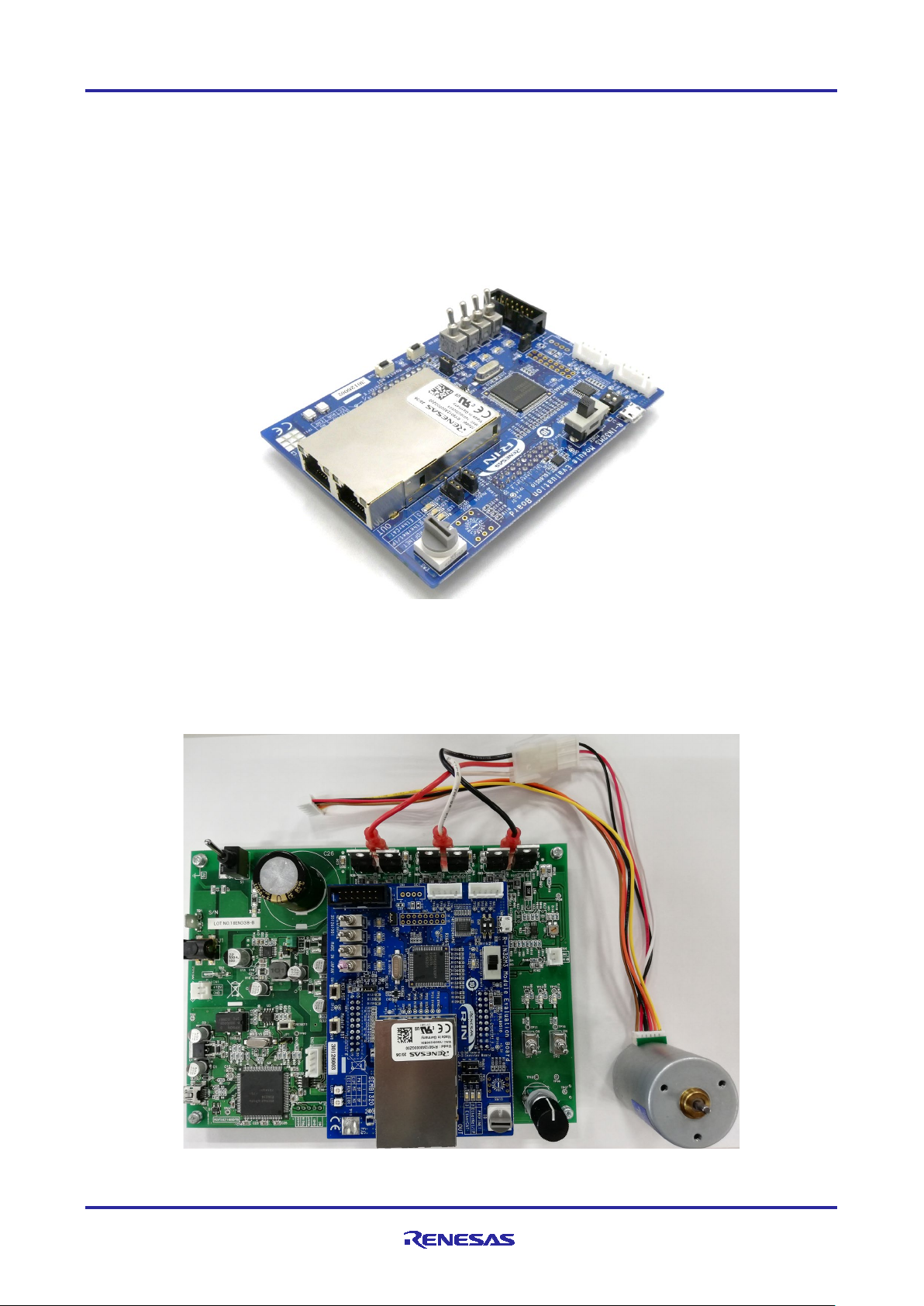

2.2 Appearance of the board

Figure 2-1 shows the appearance of this board, and Table 2-2 shows the main parts and external

interfaces.

Table 2-2

Main parts and external interfaces

Figure 2-1 Board appearance

R12AN0111EJ0204 Rev.2.04 Page 8 of 88

Apr.26.2021

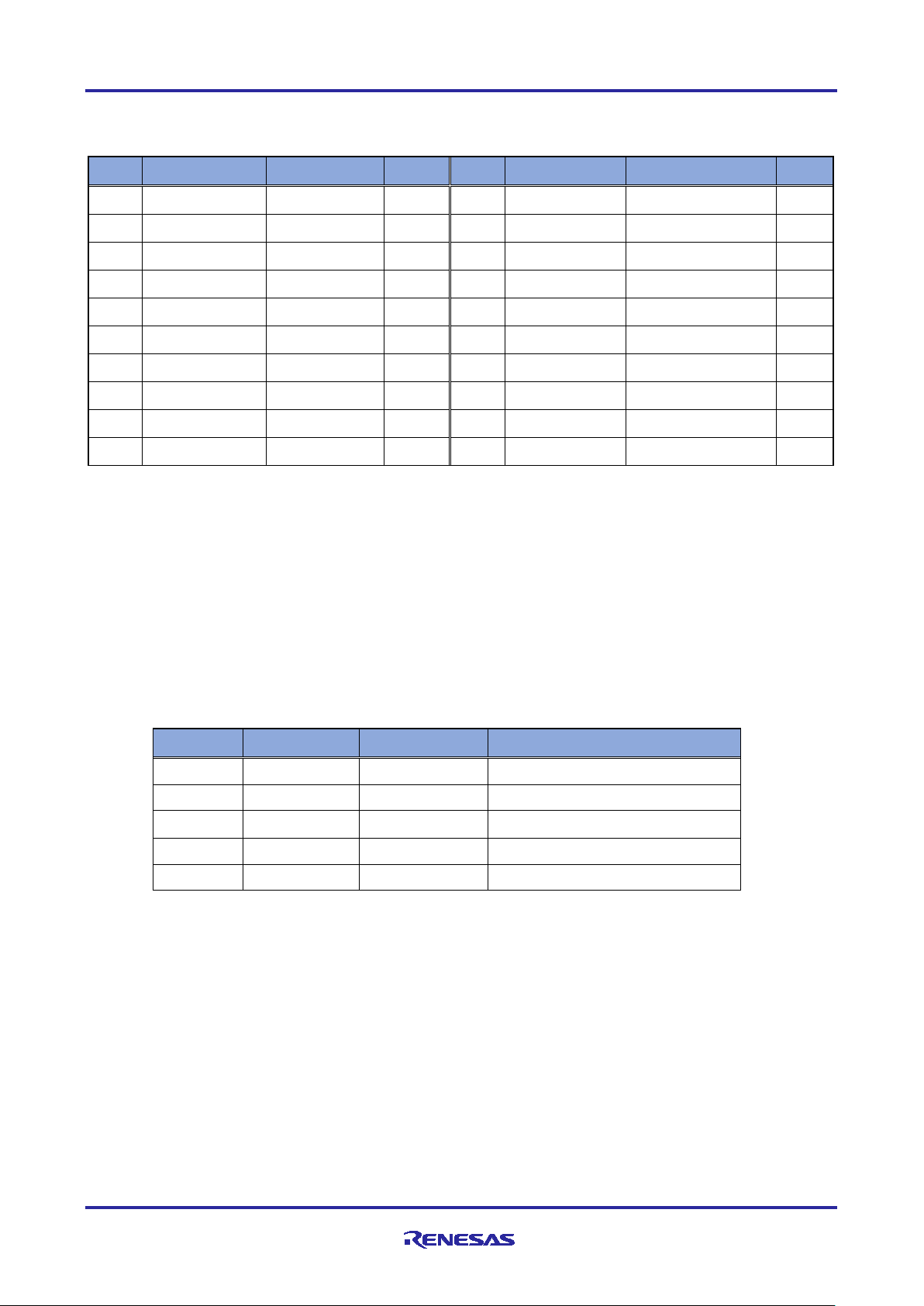

Page 9

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

LED

3bit

0Ω

0Ω

MCU

RX66T

0Ω

User SW

DIP-SW

2bit

E1 Emulator

Connector

Jumper

General LED

LED

4bit

INV_+5VA

USB_+5VA

+3.3V

INV_VCC33_ A

MCU_UVC C

Module_VCC

+5V

UVCC

AVCC

General SW

Toggle SW

4bit

RX66T

100pin

Inverter Board

Connector B

Encoder

Connector

E1 Emulator

Connector

Hall Senso r

Connector

Protocol-display

UVCC

AVCC

Power Block

Logic Block

USB Micro-B

Connector

LED

2bit

Protocol Status

Reset

SW

R-IN32M3

Modu le

R-IN32M3

Modu le

Reserve

Rotary SW

4bit

(NMT)

SCI

Connector

(NMT)

Inverter Board B

Connector

Inverter Board A

Connector

Encoder

Connector

Hall-Sensor

Connector

LDO

3.3V/1A

Jumper

Jumper

Inverter Board

Connector A

EtherCAT-ID

Rotary SW

4bit

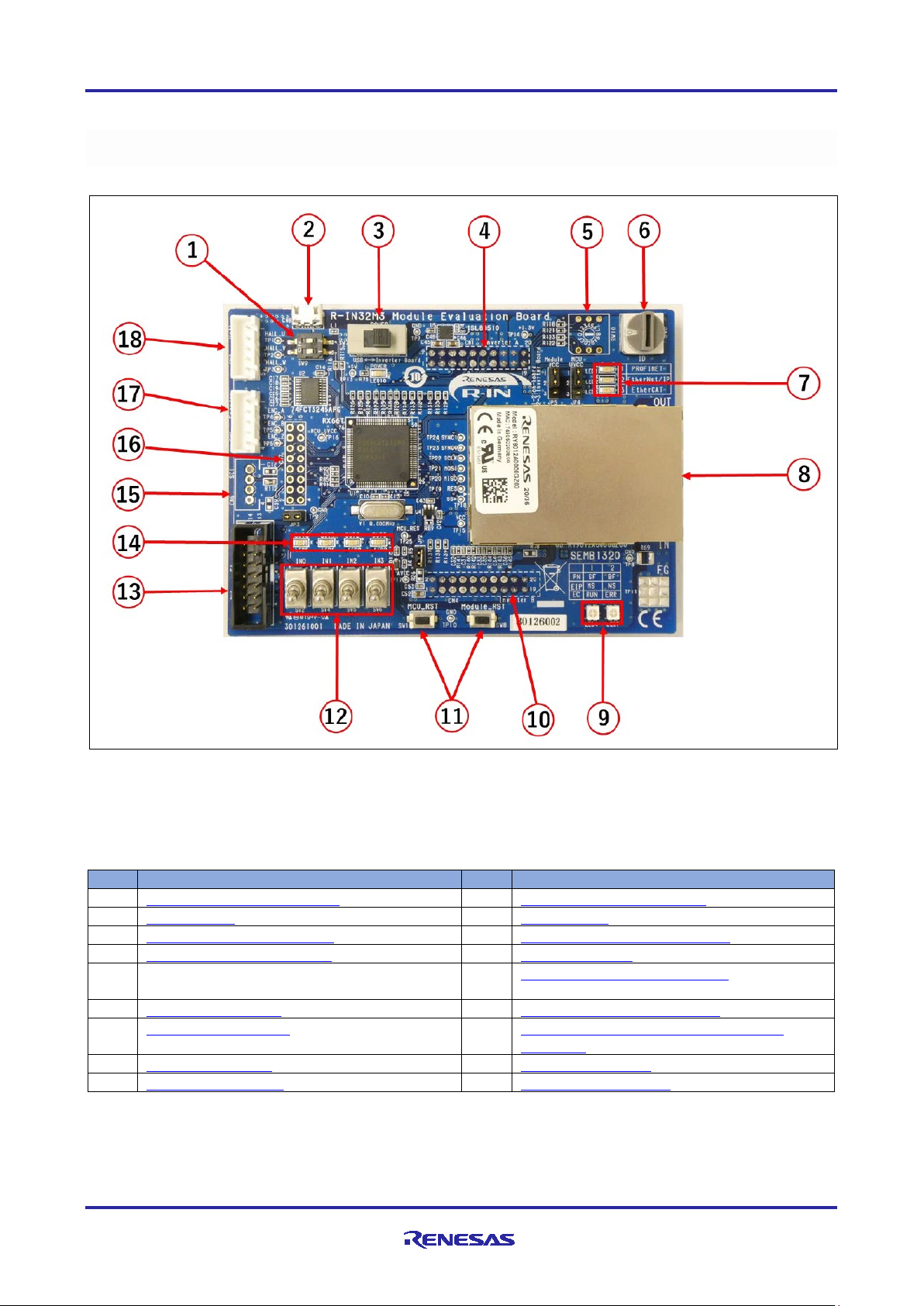

2.3 Block diagram

The block diagram of this board is shown below.

R12AN0111EJ0204 Rev.2.04 Page 9 of 88

Figure 2-2 Block diagram

Apr.26.2021

Page 10

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

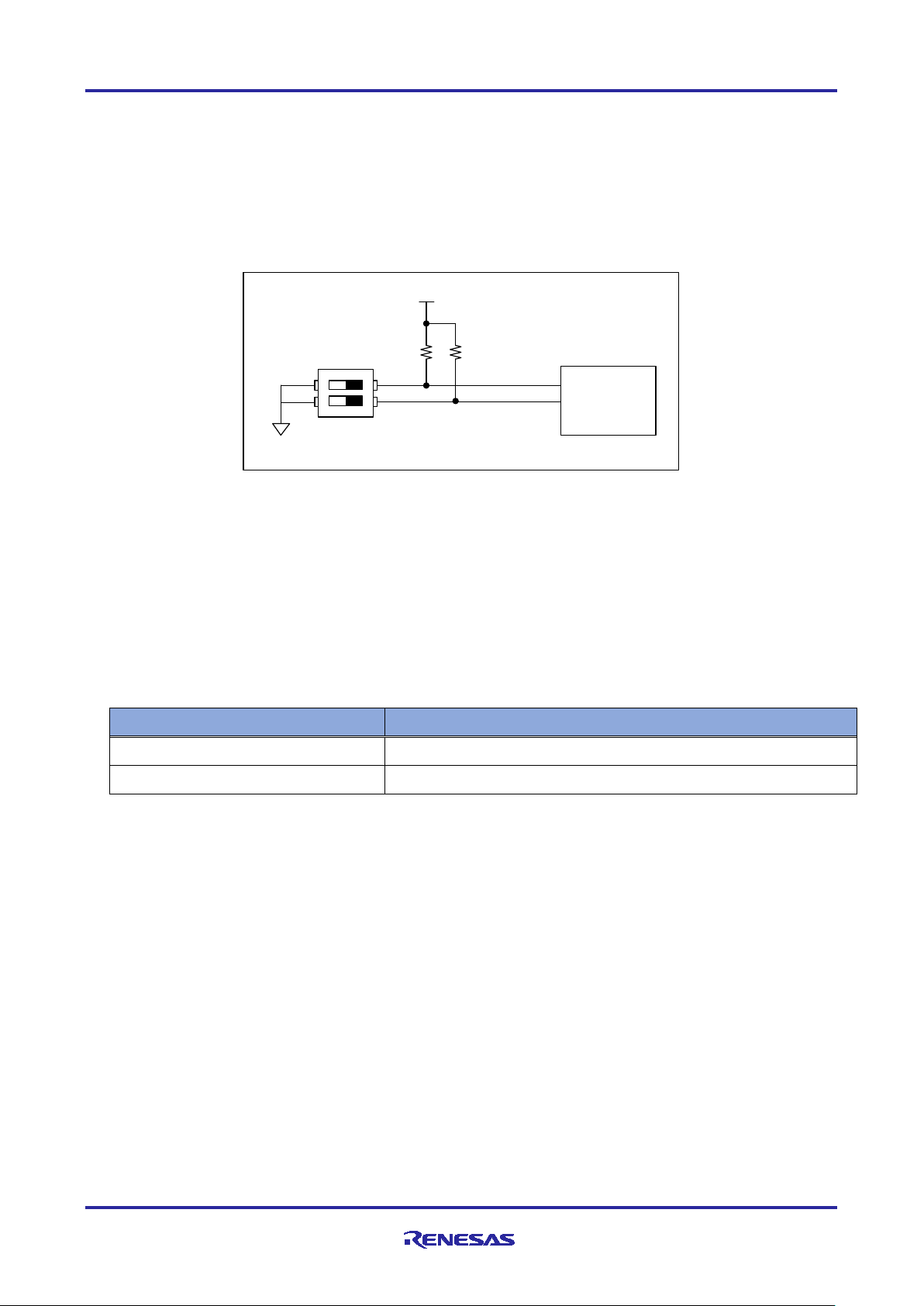

CN8

USB Micro B

CN1

Inverter Board

CNA

SW7

3.3V

LDO

LED10

+5V

+3.3V

INV_+3.3V

19

20

15

16

MCU_UVCC

Module_VCC

JP5

JP4

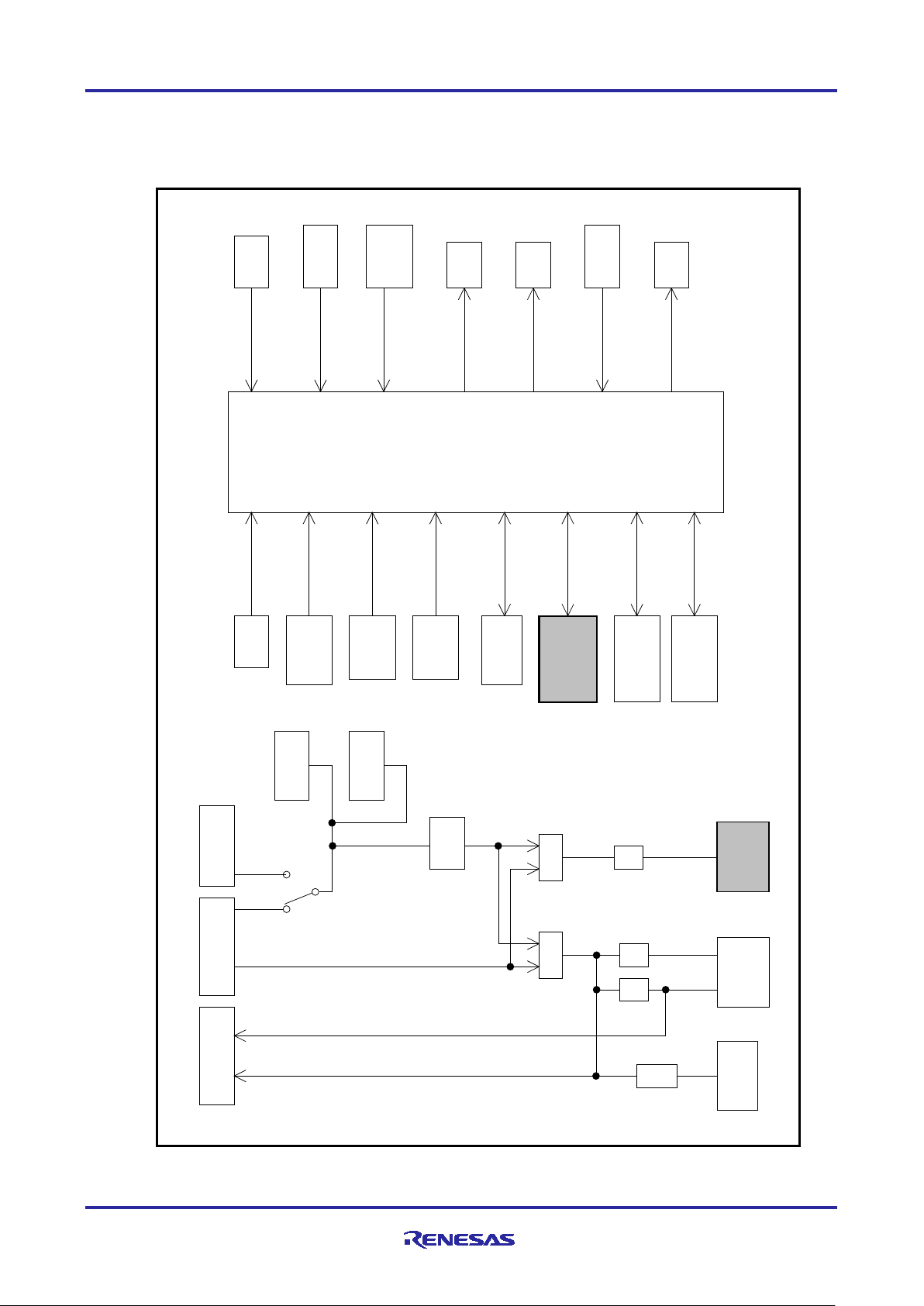

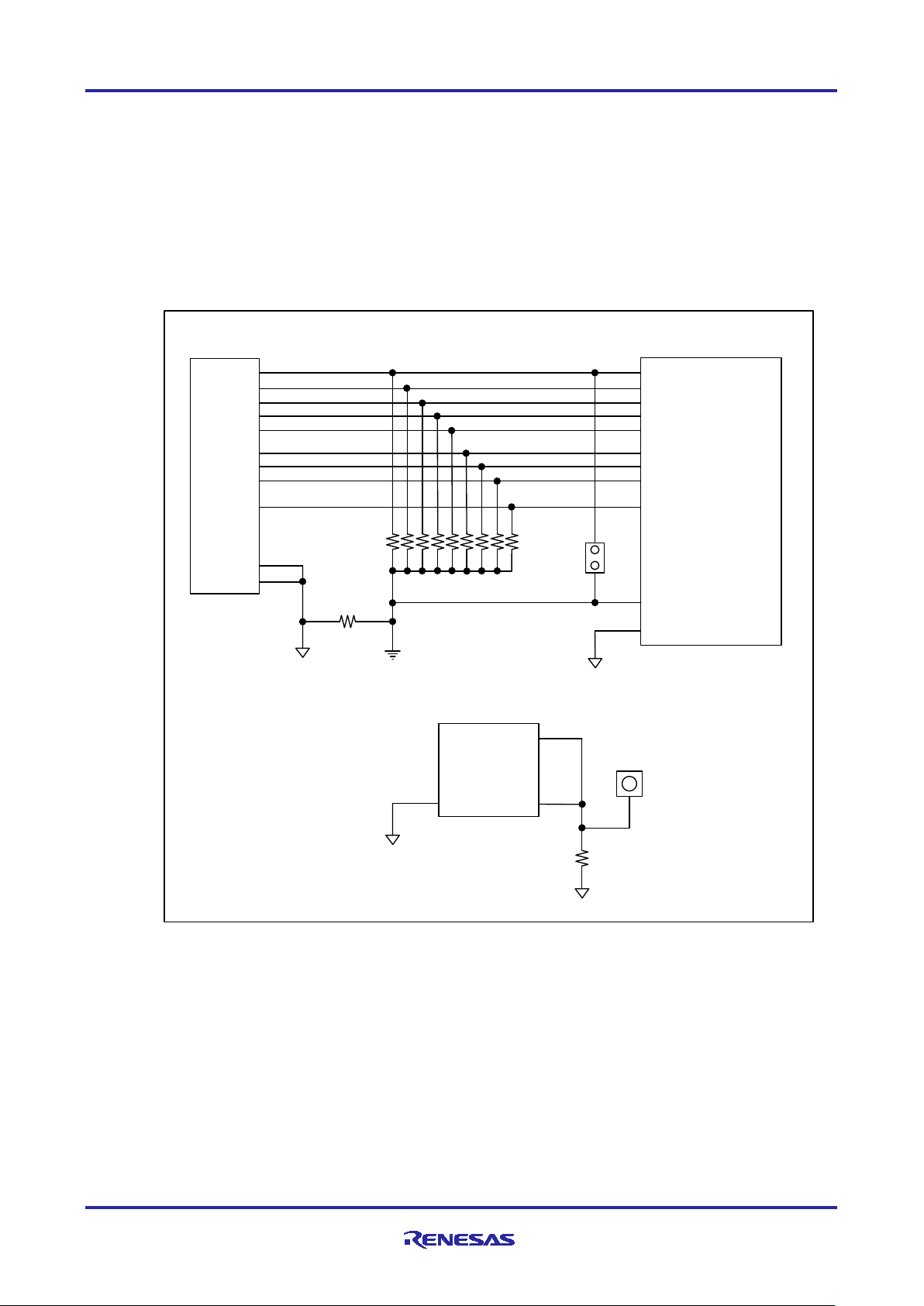

2.4 Features

2.4.1 Power supply

The board is powered by a USB Micro B connector or an Integer Board connector.

Normally, if you want to use this board alone, set SW7 at the USB Micro B connector side.

3.3V power supply method to RX66T MCU and the Module can be selected with jumper pins. For more

information, 2.5.5(3) JP4、2.5.5(4) JP5

Figure 2-3 shows power supply configuration diagram of this board.

Figure 2-3 Power diagram

R12AN0111EJ0204 Rev.2.04 Page 10 of 88

Apr.26.2021

Page 11

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

CN4

Inverter Board

CNB

4

19

20

PGAVSS1

GND1

GND2

5

IU

6

IV

7

IW

8

VPN

10

VU

11

VV

12

VW

15

VR1

GND

AVSS

PH0/AN007/PGAVSS0

AVSS

VSS

GND

P40/AN000

P41/AN001

P42/AN002

P43/AN003

P52/AN200

P53/AN201

P54/AN202

PH4/AN107/PGAVSS1

R39

0Ω

1MEGΩ

JP2

MCU

RX66T

U1

FG

GND

R-IN32M3

Module

U3

FG

GND

R69

(NM)

GND

TP11

(NM)

FG Terminal

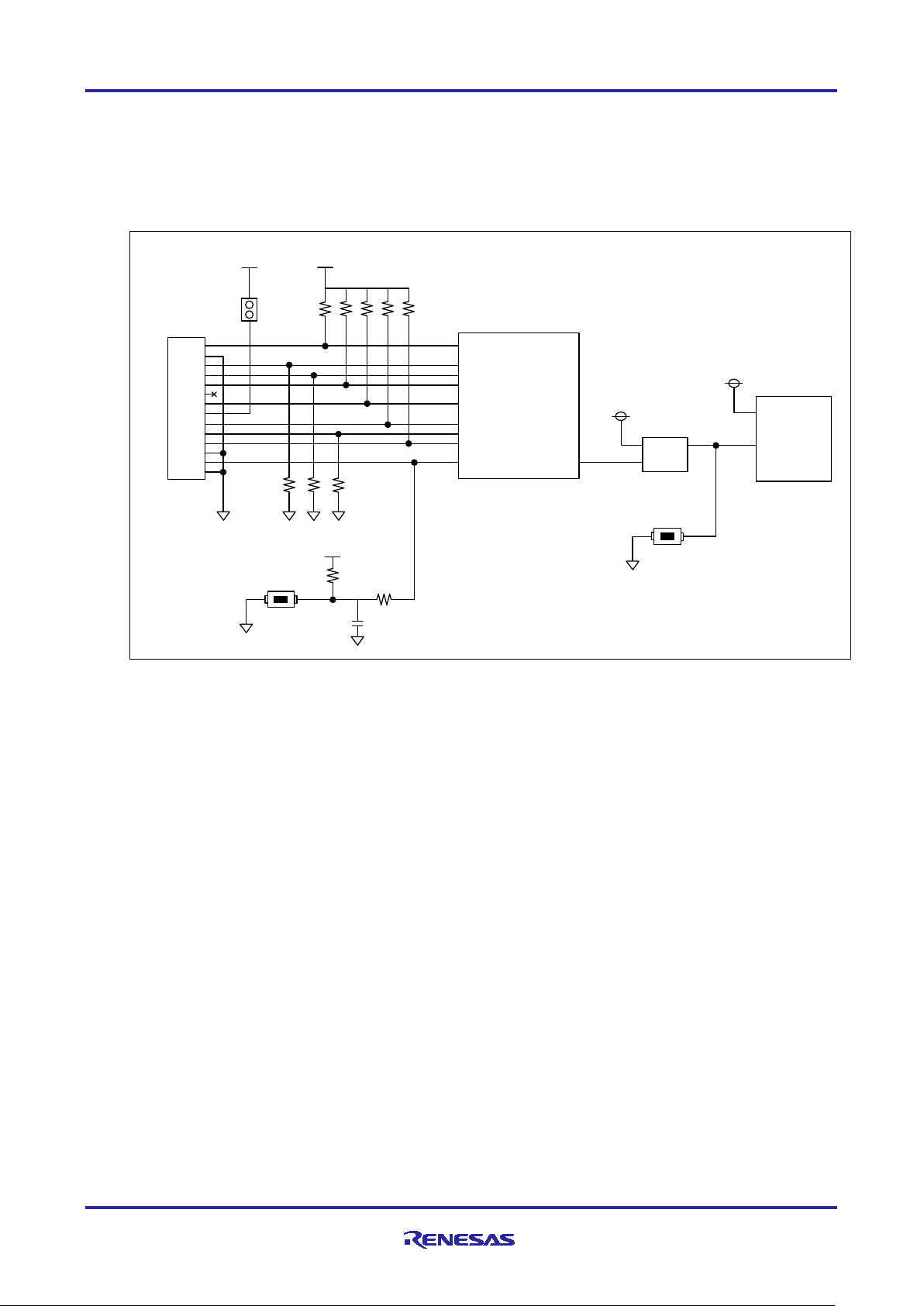

2.4.2 GND

The board's GND and AVSS are connected by R39 near CN4.

In the shipping state, JP2 is shorted, and the PGAVSS0 terminal of the MCU is connected to the AVSS.

The FG terminal of the R-IN32M3 Module is connected to the TP11 and can be connected to the GND by

mounting R69.

The connection diagram of the GND of this board is shown below.

R12AN0111EJ0204 Rev.2.04 Page 11 of 88

Apr.26.2021

Figure 2-4 GND

Page 12

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

CN1

JTAG

Connector

1

2

3

4

5

6

7

8

9

10

11

12

13

14

JP3

MCU_UVCC

MCU_UVCC

MCU

RX66T

U1

TCK

TRST#

EMLE

TDO/TXD

MD/FINED

TMS

UB

TDI/RXD

RESET#

MCU_UVCC

Module

_RESET#

RESET

IC

Module_VCC

RESET#

SW8

SW1

R-IN32M3

Module

U3

Module_VCC

VCC

2.4.3 RESET and JTAG

This board has three method of reset, "Power ON Reset", "Reset by JTAG Emulator", and "Reset by

External Switch". The reset and JTAM diagram of this board shows in Figure 2-5

Figure 2-5 RESET diagram

R12AN0111EJ0204 Rev.2.04 Page 12 of 88

Apr.26.2021

Page 13

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

U3

R-IN32M3

Module

SS#

MISO

MOSI

SCLK

SYNC0

SYNC1

MCU

RX66T

U1

PA3

PD1/SMISO8

PD2/SCK8

PD0/SMOSI8

PB6/IRQ2

PB3/IRQ9

SCLK

MOSI

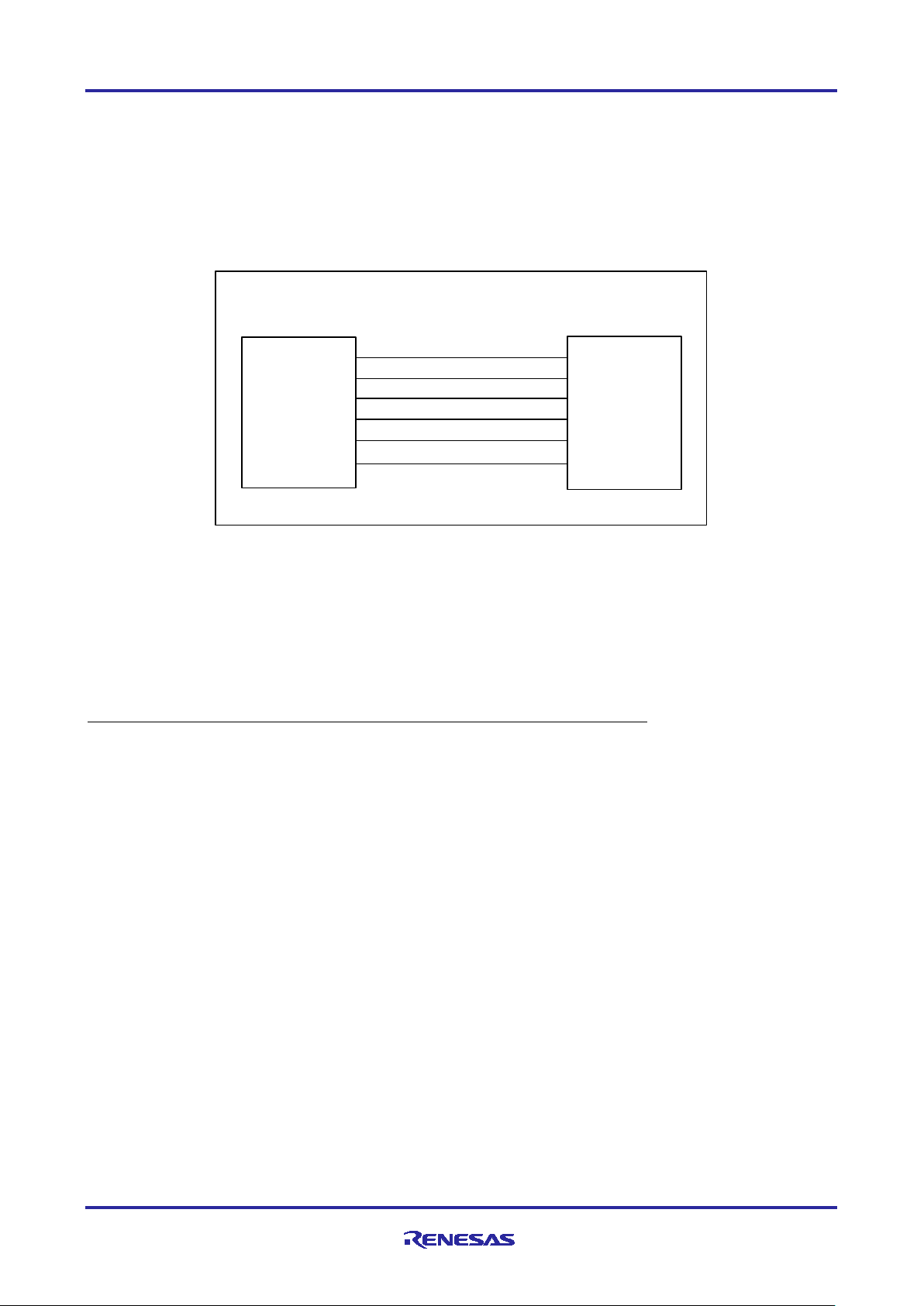

2.4.4 R-IN32M3 Module

For more information about the R-IN32M3 Module mounted on this board, see the R-IN32M3 Module User's

Manual Hardware Edition (R19UH0122EJ****).

The communication between the R-IN32M3 Module and the MCU is done via 4-wire SPI.

The SPI connection is shown in Figure 2-6. Each signal line in the SPI is not processed on this board

because a Pull-Up or Pull-Down resistor is granted in the R-IN32M3 Module.

Figure 2-6 SPI

2.4.5 Emulator connection

The RX66T program is rewritten using E1 or E2 Lite, an on-chip debugging emulator from Renesas

Electronics. The program is written by connecting E1 or E2 Lite to the Emulator connector on this board and

the USB on PC.

Do not supply power from E1, E2 Lite in the integrated development environment.

R12AN0111EJ0204 Rev.2.04 Page 13 of 88

Apr.26.2021

Page 14

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

protocol

MCU

RX66T

U1

P

94

P

95

LED

1

LED2 LED

3

MCU_

UVCC

P96

プトル表示

2.5 External interfaces

2.5.1 Ethernet connector

The R-IN32M3 Module on this board has two RJ45 network connectors.

The Ethernet switch function of the R-IN32M3 allows external connections in several network topologies,

such as dizzy chain connections. The internal PHY layer of R-IN32M3-EC can handle a variety of industrial

communication protocols and supports 10BASE-T and 100BASE-TX/FX.

2.5.2 LED

This board is equipped with a 5V power display LED, a protocol display LED, a protocol status LED

representing the status of each protocol, and a general-purpose output LED.

(1) 5V power display (LED10)

The LED10 (Red) is lit by a +5V power supply from the USB Micro B connector or the Inverter Board

connector. See Figure 2-3 for the configuration.

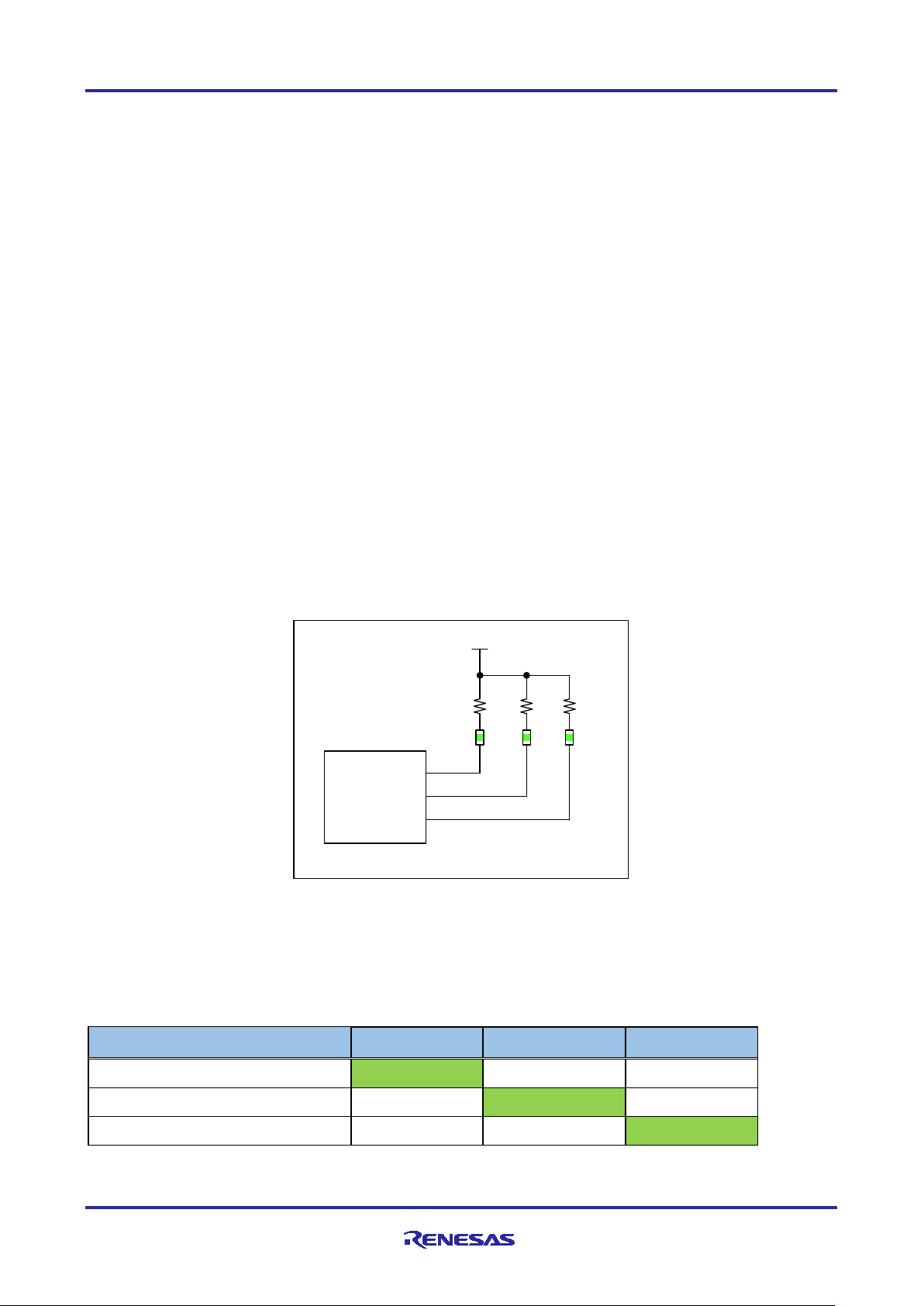

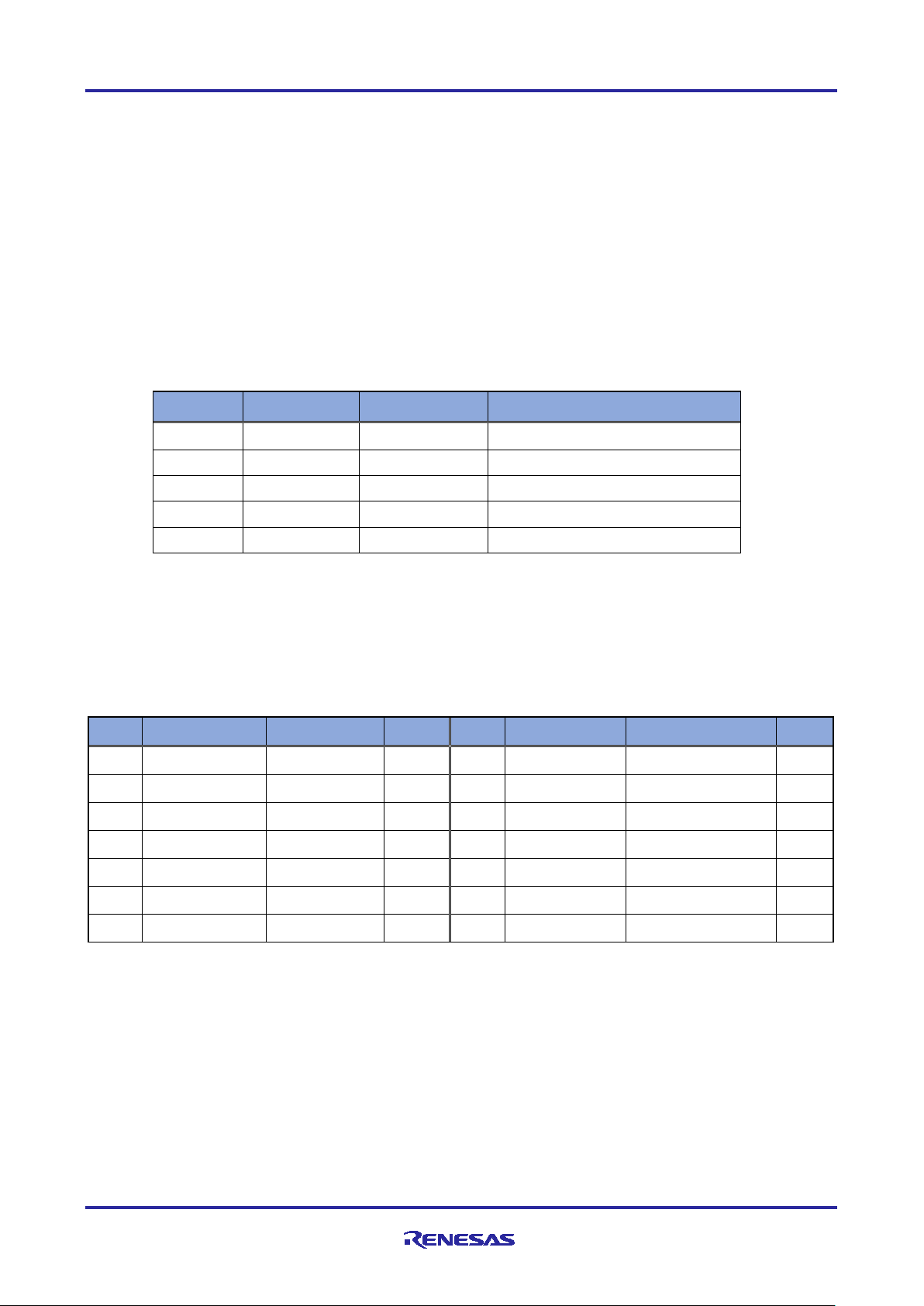

(2) Protocol display (LED1~3)

Depending on the industrial ethernet protocol selected, the project in the sample software is executed on

RX66T. Depending on the protocol running, one of LED1-3 (Green) will light up.

Figure 2-7 protocol display LED

LED display depending on the protocol is shown in Table 2-3.

Table 2-3 protocol display LED

PROFINET ON OFF OFF

LED1 (P94) LED2 (P95) LED3 (P96)

EtherNet/IP OFF ON OFF

EtherCAT OFF OFF ON

R12AN0111EJ0204 Rev.2.04 Page 14 of 88

Apr.26.2021

Page 15

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

GREEN

RED

GREEN

RED

PA0

PA1

PA2

PA4

DCP indicator

(Blink)

2

EtherNet/IP

NS

NS

MS

MS

3

EtherCAT

OFF

ERR

RUN

OFF

MCU

RX

66

T

U

1

PA2

PA4

LED4

MCU_UVCC

PA0

プ ト ルステ タス

PA1

Bi-Color

LED7

Bi-Color

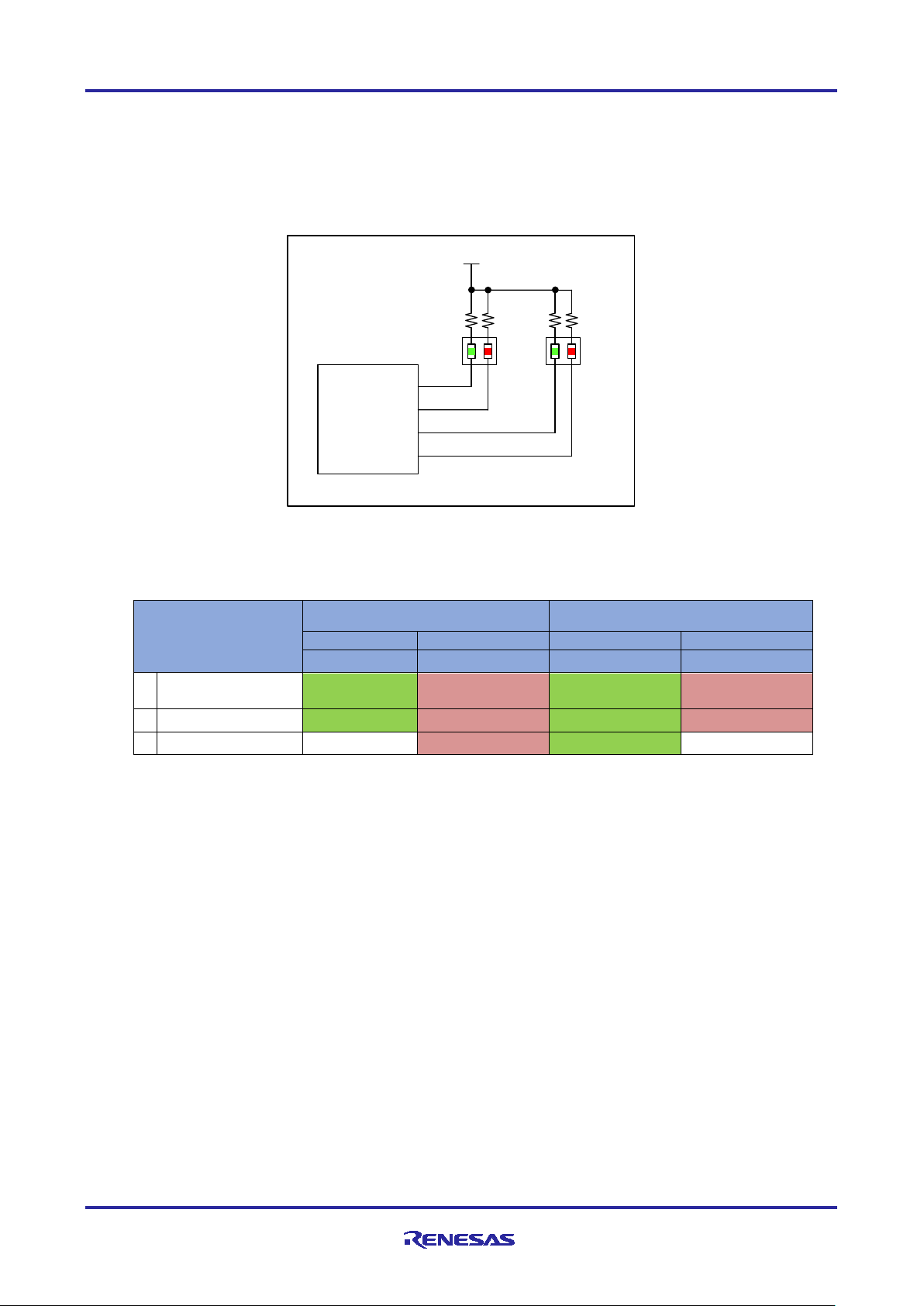

(3) Protocol status (LED4,7)

LED4 and LED7 are Bi-Color LEDs (Green / Red) that display the LED status specified in each protocol

standard.

For more information, see “R-IN32M3 Module User's Manual Software” (R17US0002ED****).

Figure 2-8 protocol status LED

Table 2-4 Protocol Status LED

LED7 LED4

Mode

1 PROFINET Connection BF

SF: system failure, BF: bus failure, DCP: discovery and configuration protocol

MS: module status indicator, NS: network status indicator,

SF

R12AN0111EJ0204 Rev.2.04 Page 15 of 88

Apr.26.2021

Page 16

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

EtherCAT Device ID

SW3

P93

P92

P91

P90

0 0 0 0 0 0 1 1 0 0 0 1 2 2 0 0 1 0 3 3 0 0 1 1 4 4 0 1 0 0 -

-

15 F 1 1 1

1

MCU

RX66

T

U

1

PE3

PE

4

LED

5

LED6

LED8

MCU_UVCC

PE1

Remote I/O LED

LED9

PE0

プトル切替スイッチ

1

2

4

8

COM

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

MCU

_

UVCC

MCU

RX66T

U1

P90

P91

P92

P93

SW3

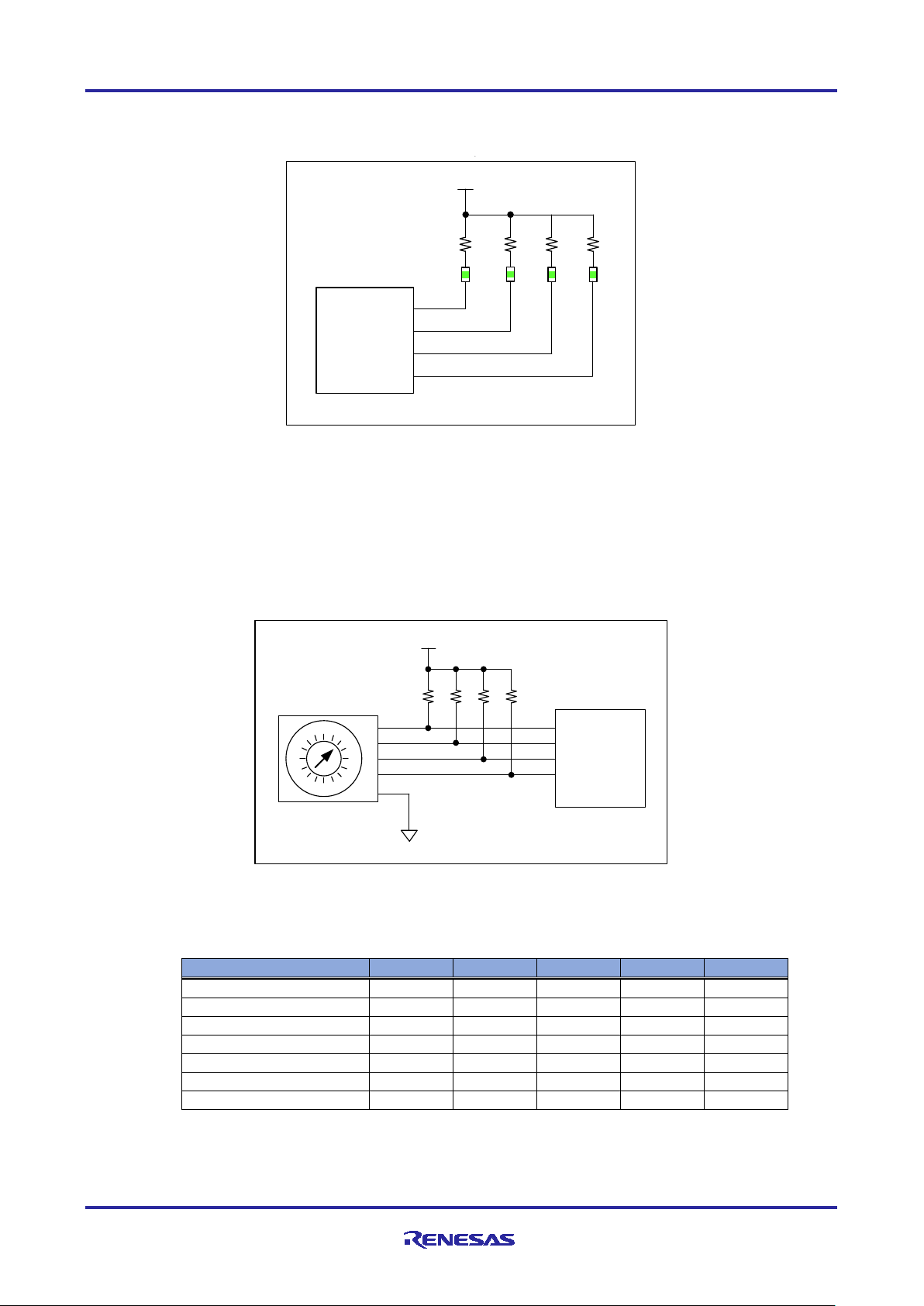

(4) General-purpose output LED (LED5,6,8,9)

4bit green LEDs (LED5, LED6, LED8, and LED9) are available for general purpose I/O applications.

Figure 2-9 General purpose LED

2.5.3 Switch

This board has several switches for EtherCAT Explicit Device ID, input for general-purpose I/O applications,

general-purpose DIP, input power, and resets.

(1) EtherCAT Explicit Device ID Switch (SW3)

When EtherCAT is selected as the protocol setting, the ID is set by SW3.

Figure 2-10 EtherCAT Explicit Device ID Switch

Table 2-5 EtherCAT ID setting

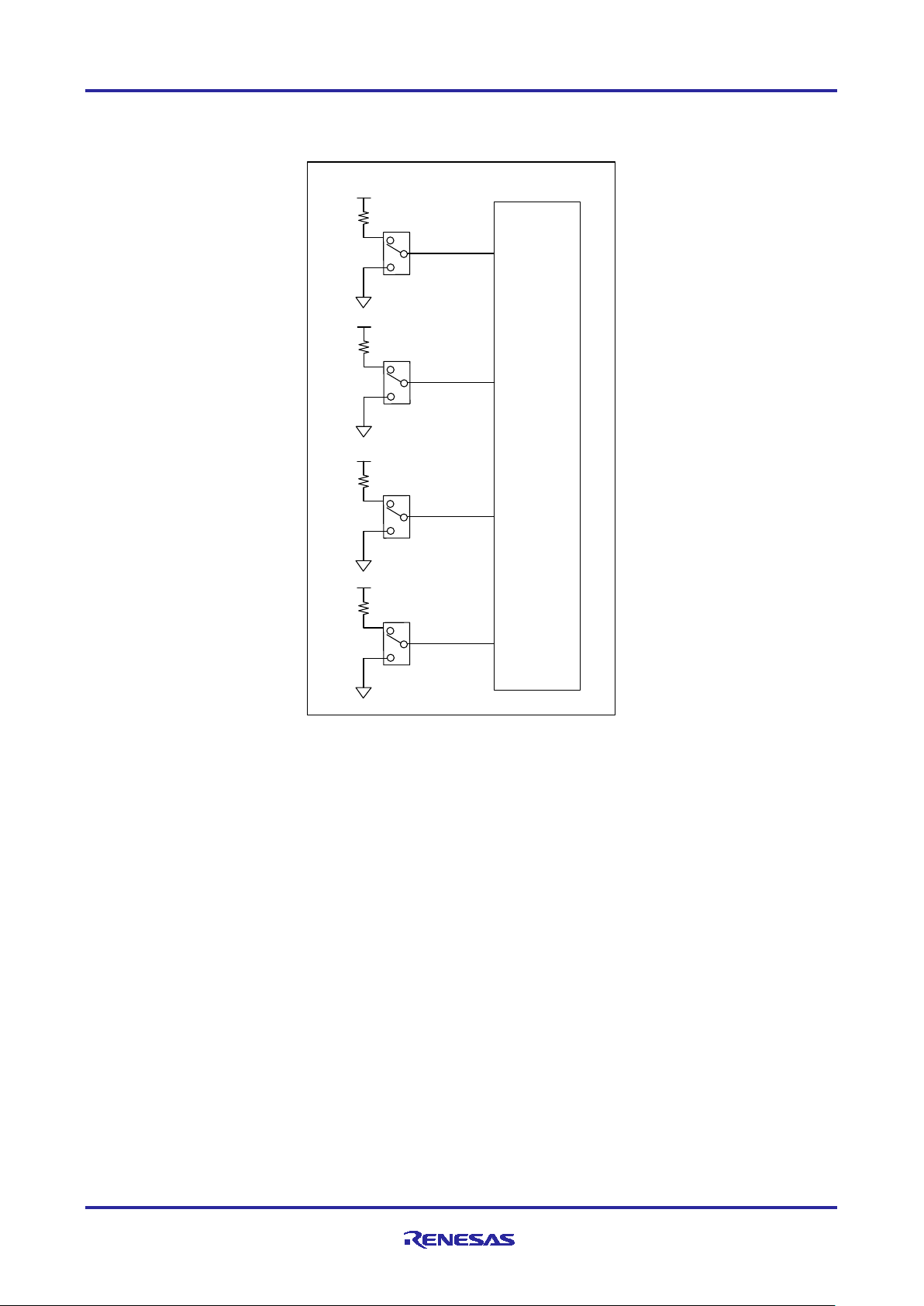

(2) General-purpose input SW (SW2,4,5,6)

SW2,4,5,6 (toggle switch) is available as an input switch for each 4bit for general purpose I/O applications.

R12AN0111EJ0204 Rev.2.04 Page 16 of 88

Apr.26.2021

Page 17

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

SW2

SW4

SW5

SW6

MCU

RX66T

U1

PB4

PB2

PB1

PB0

/ スイッチ

MCU_UVCC

MCU_UVCC

MCU_UVCC

MCU_UVCC

Figure 2-11 General purpose input SW

R12AN0111EJ0204 Rev.2.04 Page 17 of 88

Apr.26.2021

Page 18

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

SW7 Select

Description

1-2 ("USB" silkscreen side)

USB connector (CN8) supplies 5V power to this board

2-3 ("Inverter Board" silkscreen side)

5V power is supplied from the Integer Board connector A (CN1).

汎用

スイッチ

MCU_UVCC

MCU

RX66T

U1

P62

P63

SW9

ON

(3) General-input SW (SW9)

Figure 2-12 shows DIP switch, SW9, input for general purpose.

It is not used in this sample software.

Figure 2-12 Generic SW

(4) Power SW (SW7)

SW7 is a switch that selects the 5V power supply to this board. Select from the USB Micro B connector or

the Inverter Board connector to power it.

See Figure 2-3for the configuration.

Table 2-6 SW7

(5) Reset SW (SW1, SW8)

SW1 is push switch to reset the RX66T microcomputer and SW8 is one to reset the R-IN32M3 module.

See Figure 2-5 for reset configuration.

R12AN0111EJ0204 Rev.2.04 Page 18 of 88

Apr.26.2021

Page 19

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

CN

Type name

description

CN1

SFH11-PBPC-D10-ST-BK

Inverter Board connector A

CN2

B5B-XH-A

Hall sensor connector

CN3

B5B-XH-A

Encoder connector

CN4

SFH11-PBPC-D10-ST-BK

Inverter Board connector B

CN5

XG4C-1431

JTAG connector

CN6

B4B-XH-A (not mounted)

SCI connector (not mounted)

CN7

A1-16PA-2.54DSA (not mounted)

Pin Headers for External Extensions(not

CN8

10118194-0001LF

USB Micro B

pin

signal

MCU Port

Note

pin

signal

MCU Port

Note

1

LED1#

P22 2

LED2#

P21 3

LED3#

P20 4

VRL

P24 5

FO#

P70 6

NC - NC 7 WN

P76/ MTIOC4D

8 VN

P75/ MTIOC4C

9 UN

P74/ MTIOC3D

10

WP

P73/ MTIOC4B

11

VP

P72/ MTIOC4A

12

UP

P71/ MTIOC3B

13

SW1#

P23 14

SW2#

P27 15

+5VA1

- 16

+5VA2

- 17

GND

- 18

GND

- 19

VCC33_A1

- 20

VCC33_A2

-

2.5.4 Connector

Table 2-7 shows the connectors on this board (except for the RJ-45 connector with the R-IN32M3 Module).

Table 2-7 Connector List

mounted)

(1) Inverter Board Connector (CN1, CN4)

This board is equipped with an Inventor Board connector for use as a CPU card for "24V Motor Control

Evaluation System". The following is a pin assignment for the Integer Board connector:

Table 2-8 Inverter Board Connector A (CN1)

R12AN0111EJ0204 Rev.2.04 Page 19 of 88

Apr.26.2021

Page 20

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

pin

signal

MCU Port

Note

pin

signal

MCU Port

Note

1

AVCC1

- 2

AVCC2

- 3

NC - NC 4 PGAVSS1

PH0/ PGAVSS1

5 IU

P40/AN000

6 IV

P41/AN001

7 IW

P42/AN002

8 VPN

P43/AN003

9 TEMP(VOT)

-

NC

10

VU

P52 /AN200

11

VV

P53/AN201

12

VW

P54/ AN202

13

VAC

-

NC

14

IPFC

-

NC

15

VR1

PH4/AN107

16

VN - NC

17

VCCIO1

- 18

VCCIO2

- 19

GND1

- 20

GND2

-

pin

signal

MCU Port

Note

1

VCC

-

5V output

2

GND

-

3

HALL_U

P61/ IRQ5

Converted to 3.3V on this board

4

HALL_V

P60/IRQ4

Converted to 3.3V on this board

5

HALL_W

P55/IRQ3

Converted to 3.3V on this board

Table 2-9

(2) Hall sensor connector (CN2)

The Hall sensor connector (CN2) on this board is only compatible with 5V Hall sensors.

Because 5V is connected to the VCC pin, connecting the Hall sensor of 3.3V might be broken.

The signal line converts the 5V input signal to 3.3V by the level conversion IC on the board and connects it

to the MCU.

Inverter Board Connector B (CN4)

(This sample software is not supported.)

The pin assignment of the Hall sensor connector is shown below.

Table 2-10 Hall sensor connector

R12AN0111EJ0204 Rev.2.04 Page 20 of 88

Apr.26.2021

Page 21

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

pin

signal

MCU Port

Note

1

VCC

-

5V output

2

GND

-

3

ENC_A

P33/MTCLKA

Converted to 3.3V on this board

4

ENC_B

P32/MTCLKB

Converted to 3.3V on this board

5

ENC_Z

PA5/MTIOC1A

Converted to 3.3V on this board

pin

signal

MCU Port

Note

pin

signal

MCU Port

Note

1

TCK/FINEC

PD4/TCK

2 GND

-

3

TRST#

PD7/TRST#

4 EMLE

EMLE

5 TDO /TXD1

PD3/TXD1

6 NC - NC 7 MD/FINED

MD/FINED

8 VCC

- 9

TMS

PD6_TMS

10

UB

P00_UB

11

TDI/RXD1

PD5_RXD1

12

GND

- 13

RESET#

RESET#

14

GND

-

(3) Encoder connector (CN3)

The Encoder connector on this board is only compatible with Encoder with 5V operation.

Because 5V is connected to the VCC pin, connecting encoder of 3.3V might be broken.

The signal line converts the 5V input signal to 3.3V by the level conversion IC on the board and connects it

to the MCU.

(This sample software is not supported.)

The pin assignments for the Encoder connector are as follows:

Table 2-11 Encoder connector (CN3)

(4) JTAG Connector (CN5)

The pin assignments for JTAG connector is shown below.

Table 2-12 JTAG Connector (CN5)

R12AN0111EJ0204 Rev.2.04 Page 21 of 88

Apr.26.2021

Page 22

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

pin

signal

MCU Port

Note

1

VCC

-

2

TXD

P81/TXD6

3

RXD

P80/RXD6

4

GND

pin

signal

MCU Port

Note

pin

signal

MCU Port

Note

1

MCU_UVCC

- 2

MCU_UVCC

- 3

MCU_PE5

PE5 4

MCU_P01

P01 5

MCU_PE2

PE2 6

MCU_P10

P10 7

MCU_P11

P11 8

MCU_P82

P82 9

MCU_P44

P44 10

MCU_P45

P45 11

MCU_P46

P46 12

MCU_P47

P47 13

MCU_PB7

PB7 14

GND

- 15

GND

- 16

GND

-

(5) SCI Connector (CN6

The pin assignments for SCI connector, CN6 is shown below.

CN6 is not mounded on this board.

Table 2-13 SCI Connector (CN6)

(6) Connectors for external expansion (CN7

The external expansion connector (CN7) has an unused pin connected to the MCU.

The pin assignments for external expansion connectors are shown below. CN7 connectors (pin headers) are

not implemented.

Table 2-14 Connectors for external extension (CN7)

:Not Mounted)

:Not Mounted)

(7) USB micro B (CN8)

CN8 is USB Micro B connector for 5V power supply to this board. See Figure 2-3 for the power supply

diagram. By switching SW7 to the one described as "USB" with silkscreen, 5V power is supplied from CN8 to

the board.

R12AN0111EJ0204 Rev.2.04 Page 22 of 88

Apr.26.2021

Page 23

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

pin

signal

Feature

Select connection of JTAG_VCC and

MCU_UVCC

JP

Description

shipped state

Connect PGAVSS0 terminal and AVSS

# Please use this normally.

not connect

Do not connect PGAVSS0 terminal and AVSS

JP

Description

shipped state

Connect VCC pin and MCU_UVCC of the JTAG connector.

# Please use this normally.

2.5.5 Jumper

Below is a list of jumper pins on this board. Normally, please use it in the shipping state.

Table 2-15 List of Jumper pins

JP2 XJ8C-0211 Select connection of PGAVSS0 and AVSS

JP3 XJ8C-0211

JP4 XJ8D-0311 Select input of MCU_UVCC

JP5 XJ8D-0311 Select input of Module_VCC

The settings for each jumper pin are shown below.

(1) JP2

JP2 is a jumper pin for connecting the PGAVSS0 pin and AVSS of the MCU. (See Figure 2-4)

The configuration table of JP2 is shown below.

When using the inverter board, please use JP2 of this board while keeping it short (shipped state).

Table 2-16

(2) JP3

JP3 is a jumper pin for connecting the VCC pin of JTAG connector (CCN5) to the MCU_UVCC. (See Figure

2-5). The configuration table of JP3 is shown below.

Table 2-17

JP2

1-2

JP3

1-2

not connect

Do not connect VCC pin and MCU_UVCC of the JTAG

connector.

○

○

R12AN0111EJ0204 Rev.2.04 Page 23 of 88

Apr.26.2021

Page 24

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

JP

Description

shipped state

Use 3.3V LDO output on this board as MCU_UVCC input

# Please use this normally.。

Use VCC33_A of Inverter Board Connector A as MCU_UVCC.

There is no power to the MCU.

required.

JP

Description

shipped state

3.3V LDO output on this board is selected as Module_VCC

# Please use this normally.

Module_VCC.

(3) JP4

JP4 is jumper to select MCU_UVCC input. (See Figure 2-3)

The configuration table of JP4 is shown below.

Table 2-18

(4) JP5

JP5 is jumper to select Module_VCC input. (See Figure 2-3)

The configuration table of JP5 is shown below.

Table 2-19 JP5

JP4

1-2

2-3

not connect

1-2

2-3

# Select this setting in case of power supply from JTAG is

VCC33_A from Inverter Board connector A is selected as

○

○

not connect No power input to R-IN32M3 Module

R12AN0111EJ0204 Rev.2.04 Page 24 of 88

Apr.26.2021

Page 25

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

#

Item

This board

RX66T CPU Card

RTK0EMX870C00000BJ

Conn

Note

1

MPU

Type

R5F566TKADFP

R5F566TEADFP

2

ROM

1024KByte

512KByte

3

RAM

128KByte

64KByte

4

Package

LFQFP / 100 pin

The same on the left

5

Operating

3.3V

5V

6

Encoder

ENCA

58pin (P33 / MTCLKA)

The same on the left

CN3

7 ENCB

59pin (P32 / MTCLKB)

The same on the left

CN3

8

ENCZ

36pin (PA5 /

The same on the left

CN3

9

Hall sensor

HU

76pin (P61 / IRQ5)

17pin (PE0 / IRQ7)

CN2

10

HV

77pin (P60 / IRQ4)

16pin (PE1 / IRQ15)

CN2

11

HW

78pin (P55 / IRQ3)

1pin (PE5 / IEQ0)

CN2

12

Volume in

VR_1

86pin (PH4 / AN107)

68pin (P21 / AN217)

CN4

Need Volt

13

DC Link

VPN

87pin (P43 / AN003)

75pin (P62 / AN208)

CN4

14

waveform

TXD6

97pin (P81 / TXD6)

35pin (PB0 / TXD6)

CN6

Unusable

15

RXD6

98pin (P80 / RXD6)

34pin (PB1 / RXD6)

CN6

Unusable

16

Inverter

SW2#

64pin (P27)

97pin (P81)

CN1

error

17

SW1#

66pin (P23)

98pin (P80)

CN1

enable

18

LED1#

67pin (P22)

9pin (PE3)

CN1

Normal

19

LED2#

68pin (P21)

26pin (PB7)

CN1

Error

20

LED3#

69pin (P20)

32pin (PB3)

CN1

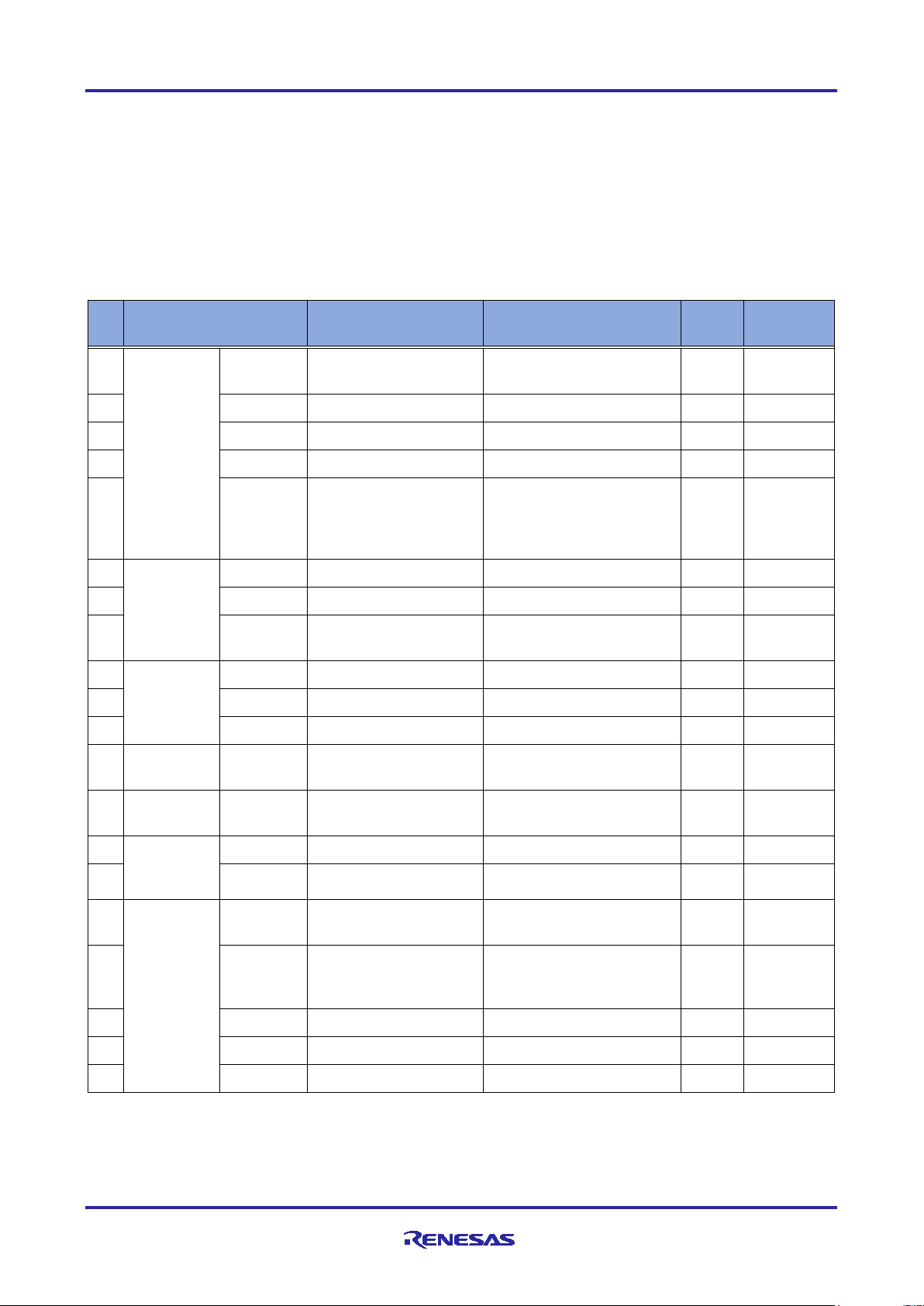

2.6 Difference between RX66T CPU Card

This board is developed referring to the RX66T CPU card (RTK0EMX870C00000BJ) and is configured to

add an industrial Ethernet communication module, but there are several differences in MCU and the

peripheral circuits. For this reason, in order for the sample software for the original RX66T CPU card to work

with this board, it is necessary to make changes that take into account the following hardware differences:

Please refer to Chapter 4.3 about changes of motor control sample software for this board.

Table 2-20 shows the major differences between original RX55T CPU card and this board about MPU

peripheral circuits and R-IN32M3 Module-related circuit.

Table 2-20

Input

input

Differences b/w RX66T CPU card and this board

(SEMB1320)

Name

power

supply

voltage

(MPU spec: 2.7~5.5V)

MTIOC1A)

(MPU spec: 2.7~5.5V)

ection

Volt detect

monitor

tool

board

interface

(*) By changing the input supply voltage from 5V to 3.3V, the voltage loading process of sample software

must be corrected. Here, this sample software is already corrected.

R12AN0111EJ0204 Rev.2.04 Page 25 of 88

Apr.26.2021

Conv (*1)

release

motor

control

Page 26

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3. Sample software configuration

3.1 Folder structure

The folder structure of this sample software is shown below.

RX66T_CCM_V***

├─appl User application

│ ├─goal_net Sample application of udp_server, tcp_client, tcp_server and udp_client

│ ├─mirror_io_sample Sample application of mirror I/O response (PROFINET, EtherNetI/P and EtherCAT)

│ ├─motor_sample Sample application of motor control (PROFINET, EtherNet/IP and EtherCAT)

│ └─remote_io_sample Sample application of Remote I/O (PROFINET, EtherNet/IP and EtherCAT)

│

├─ext Software component by 3rd party

├─goal Main part of GOAL (Generic Open Abstraction Layer *)

├─goal_global Configuration of SPI mode

├─goal_media Wrapper part to absorb device-dependent and non-dependent components

├─plat HW-dependent components (OS-dependent part, board spec, drivers)

├─projects Project files corresponding to each user application

│ ├─goal_net uITRON, FreeRTOS and OS less project files against 4 sample applications

│ ├─mirror_io_sample uITRON, FreeRTOS and OS less project files against 3 sample applications

│ ├─motor_sample uITRON, FreeRTOS and OS less project files against 3 sample applications

│ └─remote_io_sample uITRON, FreeRTOS and OS less project files against 3 samples applications

│

└─protos enhancements such as the NW protocol and MCTC (Micro Core To Core)

* For more information about GOAL, see “R-IN32M3 Module User's Manual Software API Description” (R17US0002ED****).

R12AN0111EJ0204 Rev.2.04 Page 26 of 88

Apr.26.2021

Page 27

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Protocol

Feature

PROFINET

Conformance : CC-B (RT)

I&M : 1-4

EtherNet/IP

DLR : Support

EtherCAT

DC : Support

3.1.1 Overview of the project

The protocols (PROFINET, EtherNet/IP and EtherCAT) in this sample software support the following

features:

Table 3-1 Protocol and feature

・

・Netload : I

Min Interval : 1ms

・

・

・

・Mailbox : CoE / FoE / EoE

・Profile : CiA401

I/O mirror response, motor control and Remote I/O can be evaluated with industrial ethernet protocol,

PROFINET, EtherNet/IP and EtherCAT by using the projects in this sample software.

In addition, every project supports RTOS of uITRON and FreeRTOS, and OS less system. The source code

is shared, and the project files are packaged independently.

R12AN0111EJ0204 Rev.2.04 Page 27 of 88

Apr.26.2021

Page 28

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3.2 Setup of development environment

Please refer to Chapter 1.2 for the operating environment of this sample software.

3.2.1 Install

(1) IDE e2studio

Download the version of e2studio listed in Table 1-1 from the following web site and install it on your PC.

https://www.renesas.com/software-tool/e-studio

Do not forget to check for "RX" at the screen to select [Device Family] in the middle of the installation.

(multiple selections can be made together with others)

Figure 3-1 Select device family

(2) CC-RX

If you use uITRON environment, please install CC-RX, the C/C++ compiler package for the RX family.

Download the version of this listed in Table 1-1 from the following website:

https://www.renesas.com/software-tool/cc-compiler-package-rx-family

Because it is a free trial version, the license has an expiration date and is a 60-day trial version. After 60

days, the ROM size will be limited to 128Kbyte. For more information, please refer to “CC-RX Compiler

User's Manual”.

(3) RI600V4

If you use a uITRON environment, please install a real-time OS for the RX family. Download the version

of RI6000V4 listed in Table 1-1 from the following website:

https://www.renesas.com/software-tool/ri600v4-real-time-os-rx-family

(4) GCC for Renesas RX

If you use FreeRTOS environment, please install GCC for Renesas RX, the GNU Toolchain for the RX

family. Download the version of GCC for Renesas RX listed in Table 1-1 from the following website:

https://gcc-renesas.com/rx-download-toolchains

(5) FreeRTOS

If you use FreeRTOS environment, please download FreeRTOS package through the e2studio. Specifically,

create a new temporary project in e2studio and download FreeRTOS in the process. After the download is

complete, cancel the project creation.

R12AN0111EJ0204 Rev.2.04 Page 28 of 88

Apr.26.2021

Page 29

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Since the source code of FreeRTOS is already implemented in this sample software, it does not directly

affect the build and debug of this sample software, but by downloading this, you can set the OS functions

(memory, interrupt, etc.) and generate those code in the smart configurator of e2studio.

If every project uses the same version of FreeRTOS, the download should be carried out only once on your

PC. (It is not necessary to carry out it for each project after that.) If you have already downloaded it, please

go to the next section.

2

To start the e

\Renesas\e2_studio\eclipse\e2studio.exe

Select [File] -> [New] -> [C/C++Project].

studio, execute "e2studio.exe" in the following installation folder (default case).

Figure 3-2 Select new project

In the [Templates for New C/C++ Project] dialog, select [Renesas RX] -> [Renesas CC-RX C/C++

Executable Project] -> [Next].

Figure 3-3 Select detailed project

R12AN0111EJ0204 Rev.2.04 Page 29 of 88

Apr.26.2021

Page 30

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

In the [New Renesas CC-RX C/C++ Executable Project] dialog, enter a temporary project name and select

[Next].

Figure 3-4 GCC for Renesas RX dialog

After select “FreeRTOS from “RTOS” pull down menu, select [Manage RTOS version…]. If region selection

dialog is displayed, select your region.

Figure 3-5 Select FreeRTOS

Check [RX Family Renesas FreeRTOS] and select [Download]. If the disclaimer dialog is displayed, select [I

Agree].

That is all about the download of the FreeRTOS package. Please cancel the project creation and finish.

R12AN0111EJ0204 Rev.2.04 Page 30 of 88

Apr.26.2021

Page 31

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

USB micro B

cable

PC

(LAN) Ethernet cable

e2studio

E1 emulator

Software PLC

3.2.2 Connection

(1) One board operation

Connect this board to the E1 emulator and your PC as follows:

After setting the power input switch SW7 of this board to the "USB" side (yellow arrow in Figure 3-6), power

is supplied to this board by connecting a USB micro B cable to this board.

Figure 3-6 Connection of one board operation

R12AN0111EJ0204 Rev.2.04 Page 31 of 88

Apr.26.2021

Page 32

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

PC

DC24V output AC Adapter

(LAN) Ethernet cable

e2studio

E1 emulator

Motor

Software PLC

(2) Operation with Inverter Board

To evaluate motor solution, connect the inverter board and motor to this board as follows. For information on

how to connect the inverter board to the motor, please refer to “Renesas Solution Starter Kit 24V Motor

Control Evaluation System for RX23T (Motor RSSK) Manual” (R20UT3697J).

The motor control program included in this sample software is based on " RX66T Sensorless Vector Control

for Permanent Magnet Synchronous Motor (Implementation) (R01AN4244EJ), so the encoder connector

(CN3) and the Hall sensor connector (CN2) are not required to be connected.

After setting the power input switch SW7 of this board to the "Inverter Board" side (yellow arrow in Figure

), turning on the inverter control circuit switch (S1) and connecting the +24V power supply (please

3-7

prepare separately) to the inverter board, then, power is supplied to the inverter board.

Figure 3-7 Connection with Inverter Board

R12AN0111EJ0204 Rev.2.04 Page 32 of 88

Apr.26.2021

Page 33

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3.2.3 Import project

(1) Unzip package

First, unzip the archived package of this sample software (RX66T_CCM_V***.zip) and store it in arbitrary

folder. Because e2studio cannot recognize project properly if file path is too long in the folder hierarchy,

place it in shorter path. Also, do not use multi-byte character, such as Japanese, in the folder path.

(2) Execute e2studio

Execute "e2studio.exe" to start e2studio in the following folder (default case) installed (default case):

\Renesas\e2_studio\eclipse\e2studio.exe

To check the compiler installed above, select [Window] -> [Preferences], and then select [C/C++] ->

[Renesas] -> [Renesas Toolchain Management] in the Settings dialog. In the dialog [Renesas Toolchain

Management], it can be seen whether an appropriate compiler has been added to "Renesas CCRX" or "GCC

for Renesas RX".

Figure 3-8 Renesas Toolchain Management

R12AN0111EJ0204 Rev.2.04 Page 33 of 88

Apr.26.2021

Page 34

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(3) Import project

Import the sample project into e2studio from the following steps:

[File] -> [Import…] on the right of the screen.

Figure 3-9 Import

In the [Select] dialog, select [General] -> [Existing Project into Workspace], and then select [Next>].

Figure 3-10 Select

R12AN0111EJ0204 Rev.2.04 Page 34 of 88

Apr.26.2021

Page 35

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

In the [Import Projects] dialog, select [Select root directory] check box, and then select [Browse].

Select the package of this sample software "RX66T_CCM_V***" stored in arbitrary folder at 3.2.3(1) and

select [OK].

Figure 3-11 Import Projects

After confirming that each sample project listed in [Projects] is checked, select [Finish] to import the

project.

Figure 3-12 Imported projects

R12AN0111EJ0204 Rev.2.04 Page 35 of 88

Apr.26.2021

Page 36

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3.2.4 FIT Module

(1) Download FIT Module

Sample projects in this sample software apply the FIT module. Download the FIT module from Smart

Configurator in e2studio. If every project uses the same version of FIT module, the download should be

carried out only once on the PC. (It is not necessary to carry out it for each project after that.)

If you have already downloaded it, please go to the next section. For more information, see "RX Smart

Configurator User’s Guide: e² studio" (R20AN0451ES****).

In the [Project Explorer] on e2studio, expand the sample project and select the configuration file.

Figure 3-13 Project Explore

If you see a dialog below, select [Open Perspective].

Figure 3-14 Open Perspective

R12AN0111EJ0204 Rev.2.04 Page 36 of 88

Apr.26.2021

Page 37

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Go to the [Components] tab of the Smart Configurator perspective screen and select the [Add component]

button.

Figure 3-15 Add component

In the [Software Component Selection] dialog, select [Download more software components]. If the region

selection dialog appears, select your region.

Figure 3-16 Download selection of Software Component

R12AN0111EJ0204 Rev.2.04 Page 37 of 88

Apr.26.2021

Page 38

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

After checking "RX Family Driver Package", select Download.

Figure 3-17 FIT Module Download

After the download is complete, close the [Software Component Selection] dialog. If successfully

downloaded, each element of the FIT module will be activated.

Figure 3-18 Activated FIT module

R12AN0111EJ0204 Rev.2.04 Page 38 of 88

Apr.26.2021

Page 39

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

If each component is not activated, or if each component is not latest version, go to the [Components] tab of

the Smart Configurator perspective screen and select the [Add component] button (Figure 3-15). So that, in

the [Software Component Selection] dialog, select [Configure general settings…].

Figure 3-19 General settings of Software Component

In component settings, check [Allow blocked FIT modules to be displayed] and select [Apply].

Figure 3-20 Check of component display setting

R12AN0111EJ0204 Rev.2.04 Page 39 of 88

Apr.26.2021

Page 40

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Right-click each component and select [Change version…].

Figure 3-21 Change version of component

Select [Next] -> [Finish].

If there is latest version in available versions, select [Next] -> [Finish] after selecting its version.

(2) Code generation for FIT Module

Generate the source code of the FIT module to use. Code generation needs to be done on a project-byproject level. Go to [Overview] tab of the Smart Configurator perspective screen and select [Generate Code]

button to generate the required source code.

Figure 3-22 Generate code

Now, it is ready to build the project.

R12AN0111EJ0204 Rev.2.04 Page 40 of 88

Apr.26.2021

Page 41

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3.2.5 Build project

In the [Project Explorer] on e2studio, select the sample project, select the arrow next to the [Build] button

(hammer icon), and select [HardwareDebug] from the drop-down menu.

Figure 3-23 Build project

e2studio builds the selected project. When the build is complete, "Build Finished" message can be seen in

the [Console] at the bottom of the screen.

Figure 3-24 Build finished

R12AN0111EJ0204 Rev.2.04 Page 41 of 88

Apr.26.2021

Page 42

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

3.2.6 Debug

Once the build is complete, it is possible to start debugging immediately. Select the arrow next to the [Debug]

button (bug icon) and select [Debug Configurations…].

Figure 3-25 Debug Configurations

In the [Debug Configuration] dialog, select the appropriate "xxxx HardwareDebug" from [Renesas GDB

Hardware Debugging] and select the [Debug] button to launch the debug screen.

Figure 3-26 Debug start

If a firewall warning for "e2-server-gdb.exe" is shown, check all check boxes, "Domain", "Private" and

"Public", and select [Allow access].

If asked to change the perspective in the Confirm Perspective Switch dialog, check the check box of [Always

use this setting] and select [Yes].

When the debugger screen is up and the program download is complete, select the [Restart] button to run

the program.

R12AN0111EJ0204 Rev.2.04 Page 42 of 88

Apr.26.2021

Page 43

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Sample Application

\appl\mirror_io_sample\01_pnio

Project File

\projects\mirror_io_sample\01_pnio\e2studio\RX66T\FreeRTOS

IP address

192.168.0.1

Netmask

255.255.255.0

3.3 How to use

3.3.1 I/O mirror response (via PROFINET)

This chapter describes an example of I/O mirror response via PROFINET communication by running the

following sample project (FreeRTOS version):

Project file name on e2studio:

mirror_io_sample __01_pnio __RX66T_FreeRTOS

At first, refer to Chapter 3.2. to prepare the development environment.

(1) This sample application does not require an inverter board, so connect it as shown in Figure 3-6.

(2) Build the project and run the sample application, referring to Chapters 3.2.4 to 3.2.6.

When the sample application is run, a totally 5 LEDs light up. (protocol display LED (LED1) and generalpurpose output LED (LED5, 6, 8, 9)).

Next, set fixed IP address of the PC. Open the [Network Properties] of the network adapter connected to the

R-IN32M3 Module and set the fixed IP (using 192.168.0.1 as an example, considering the description

below).

Table 3-2 Set IP address of the PC

Here, Management tool can be used as a PROFINET master. It is included with " R-IN32M3 Module

(RY9012A0) Sample Package" (R18AN0052EJ****) along with this sample software.

Execute "ice.exe" file in the folder below to start the Management tool. For more information about the

Management tool, refer to “R-IN32M3 Module (RY9012A0) Quick Start Guide” (R12QS0042ED****).

\Tool\iCommExplorer-win32.win32.x86_64_ci117-v1.3.1\iCommExplorer\ice.exe

(This path is an example of version 1.3.1. The path and folder name may differ depending on the tool

version.)

By referring to the following operation of Management tool, confirm PRIFINET connection to this sample

application and verify the I/O mirror response by cyclic communication.

R12AN0111EJ0204 Rev.2.04 Page 43 of 88

Apr.26.2021

Page 44

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

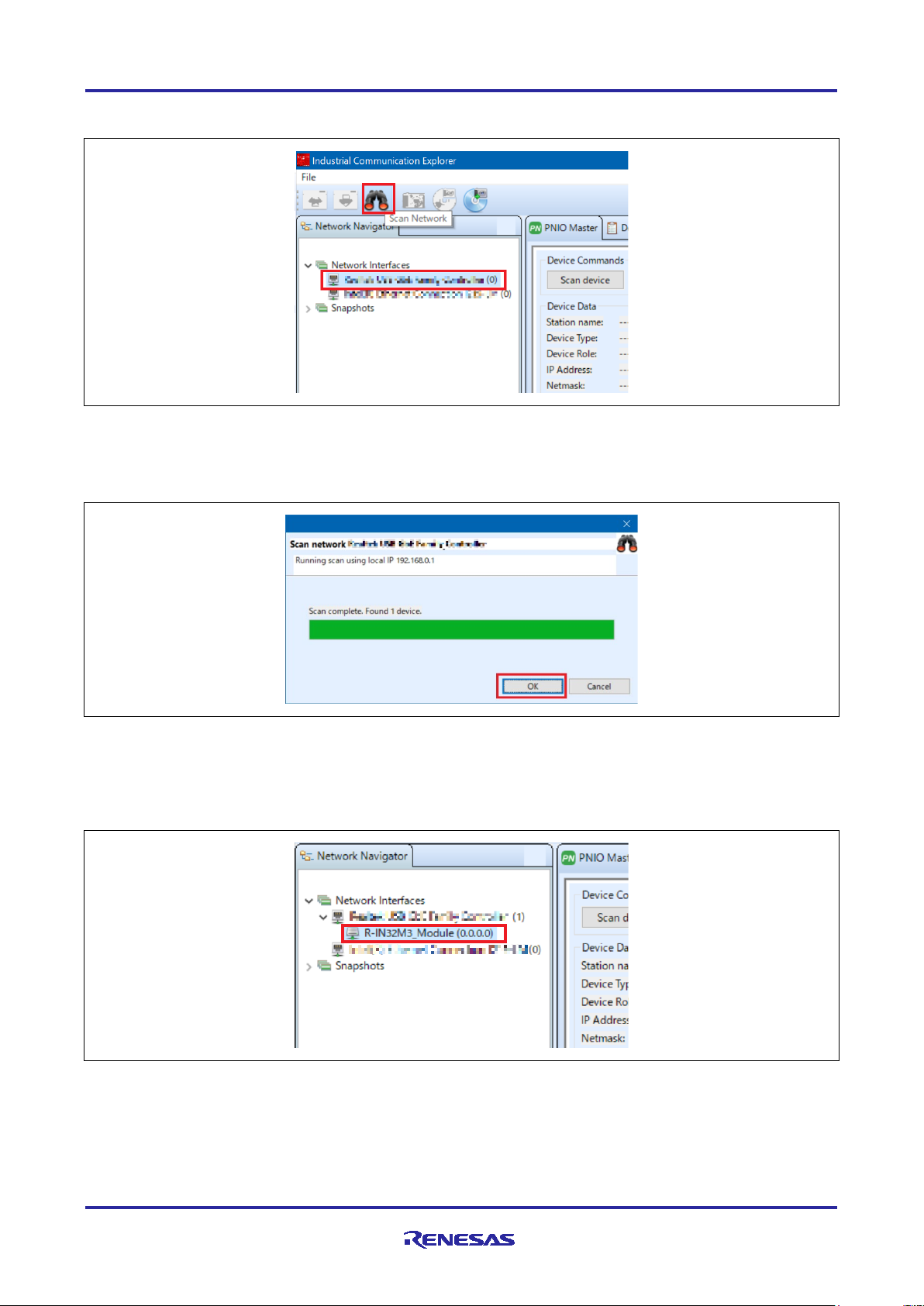

(1) Select network to use in [Network Navigator] panel and select [Scan Network] button.

Figure 3-27 Scan network

(2) “Scan complete. found 1 device” message is displayed in [Network Scan] dialog, then select [OK].

Figure 3-28 Scan completed

(3) In [Network Navigator] panel in the scanned network, R-IN32M3 Module is displayed as the new device,

so select [R-IN32M3 Module].

Figure 3-29 Select R-IN32M3 Module

R12AN0111EJ0204 Rev.2.04 Page 44 of 88

Apr.26.2021

Page 45

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(4) In order to communicate with the R-IN32M3 Module, the IP address of the R-IN32M3 Module must be in

the same IP network as the IP address of the PC. Therefore, access the configuration manager variables

(volatile memory and non-volatile memory stored configuration variables) of the R-IN32M3 Module to set the

IP address, Netmask, and Gateway.

With [R-IN32M3 Module] selected, select [Read Configuration] button while displaying the [ConfigManager]

panel.

Figure 3-30 ConfigManager

(5) In the configurations displayed in the [ConfigManager] panel, change the following items: The changed

Value will be highlighted in yellow.

- Module = GOAL_ID_NET、Variable = IP, Value = IP address (Here, for example 192.168.0.100)

- Module = GOAL_ID_NET、Variable = NETMASK, Value = Netmask (Here, for example 255.255.255.0)

- Module = GOAL_ID_NET、Variable = VALID, Value = 0x01

Figure 3-31 Set IP address

R12AN0111EJ0204 Rev.2.04 Page 45 of 88

Apr.26.2021

Page 46

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(6) Select [Write Configuration] button to download the changed Configuration Manager variables to the RIN32M3 Module.

Figure 3-32 Download Config variables

(7) If a change confirmation dialog is displayed, select [Yes]. The changed value is then transferred to the RIN32M3 Module and changed in RAM only. If change the value of Flash incorporated in the R-IN32M3

Module, use the [Save config to flash]. The changed IP address setting is applied after the system is

restarted, so restart this board.

(8) Select [PNIO Master] panel, and then select [Scan device].

Figure 3-33 PNIO Master

R12AN0111EJ0204 Rev.2.04 Page 46 of 88

Apr.26.2021

Page 47

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(9) When a PROFINET device is detected, "PNIO: Found 1 device" appears in [Messages] panel at the

bottom of the screen, and [Device Data] in the [PNIO Master] panel displays the Device Type = Renes

Electronics, IP Address = 192.168.0.10, Netmask = 255.255.255.0, displays device information of the RIN32M3 Module.

Figure 3-34 Device Data display

(10) Open the I/O panel of [PNIO Master] panel and select [Load GSDML file] button to import the GSDML

file. GSDML files can be found in the following folder:

\appl\mirror_io_sample\01_pnio\gsdml

Verify that [Slots:] and [Modules] display contents as set in GSDML, and then select [Connect] button. If the

connection is successful, this button switches to [Disconnect] button. In addition, the protocol status LED

(LED4) on this board lights up.

Figure 3-35 GSDML

R12AN0111EJ0204 Rev.2.04 Page 47 of 88

Apr.26.2021

Page 48

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Sample Application

\appl\mirror_io_sample\02_eip

Project File

\projects\mirror_io_sample\02_eip\e2studio\RX66T\FreeRTOS

(11) After the connection is complete, move the slider bar down in [PNIO Master] panel to display [I/O Data],

which monitors cyclic communication. The I/O mirror response is verified by operating 1 byte and 2byte data

of [Output Data].

<example>

- Type "0x11" in [Output Data] of [O Signed8], then "0x11" in [Input Data] of [I Signed8] is displayed

- Type "0x2233" in [Output Data] of [O Signed16], then “0x2233" in [Input Data] of [I Signed16] is displayed

Figure 3-36 Confirmation of I/O mirror

3.3.2 I/O mirror response (via EtherNet/IP)

This chapter describes an example of I/O mirror response via EtherNet/IP communication by running the

following sample project (FreeRTOS version):

Project file name on e2studio:

mirror_io_sample__02_eip__RX66T_FreeRTOS

Preparation of development environment is the same as Chapter 3.3.1.

When the sample application is run, a totally 5 LEDs light up. (protocol display LED (LED2) and generalpurpose output LED (LED5, 6, 8, 9)). Also, protocol status LED4 is light up and LED7 flashes.

Network adapter setting is the same as Chapter 3.3.1.

Management tool can be used as a EtherNet/IP master, which is also the same as Chapter 3.3.1.

By referring to the following operation of Management tool, confirm EtherNet/IP connection to this sample

application and verify the I/O mirror response by cyclic communication.

R12AN0111EJ0204 Rev.2.04 Page 48 of 88

Apr.26.2021

Page 49

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(1) In [Network Navigator] panel, select the network to use, and then select the Scan Network button.

Figure 3-37 Scan network

(2) ”Scan complete. found 1 device” message is displayed in [Network Scan] dialog, then select [OK].

Figure 3-38 Scan completed

(3) In [Network Navigator] panel in the scanned network, R-IN32M3 Module is displayed as the new device,

so select [R-IN32M3 Module].

Note that in the I/O mirror response sample application via EtherNet/IP, the IP address of the R-IN32M3

Module is fixed (the default value is 192.168.0.100)). It is in the same IP network as the PC; therefore, it is

not necessary to access the configuration manager variable of the R-IN32M3 Module to set the IP address,

Netmask, or Gateway.

Figure 3-39 Select R-IN32M3 Module

R12AN0111EJ0204 Rev.2.04 Page 49 of 88

Apr.26.2021

Page 50

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(4) Open [EtherNet/IP Master] panel and select [Scan device] button.

Figure 3-40 Scan device

(5) When an EtherNet/IP device is detected, [Messages panel] at the bottom of the screen displays "EIP:

Found 1 device" and [Device Data] in [EtherNet/IP Master] panel displays the device information for the RIN32M3 Module at 192.168.0.100.

Figure 3-41 Device Data display

R12AN0111EJ0204 Rev.2.04 Page 50 of 88

Apr.26.2021

Page 51

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(6) Open [I/O Data] panel in [EtherNet/IP Master] panel and select [Connect] button. If the connection is

successful, this button switches to [Disconnect] button. In addition, the protocol status LED (LED7) on this

board changes from flashing to lighting up (LED4 remains lit).

Figure 3-42 I/O Data panel

(7) After the connection is complete, move the slider bar down in [EtherNet/IP Master] panel to display [I/O

Data O->T] and [I/O Data T->O], which monitor cyclic communication. The I/O mirror response is verified by

operating the 32byte data of [I/O Data O->T].

<example>

- Type "12 34 56 78 90 00 00 00 00 ... 00 00 00 09 87 65 43 21" in [I/O Data O-> T], then "12 34 56 78 90 00

00 00 ... 00 00 00 09 87 65 43 21" in [I/O Data T->O] is displayed

Figure 3-43 Confirmation of I/O mirror response

R12AN0111EJ0204 Rev.2.04 Page 51 of 88

Apr.26.2021

Page 52

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Sample Application

\appl\mirror_io_sample\03_ecat

Project File

\projects\mirror_io_sample\03_ecat\e2studio\RX66T\FreeRTOS

3.3.3 I/O mirror response (via EtherCAT)

This chapter describes an example of I/O mirror response via EtherCAT communication by running the

following sample project (FreeRTOS version):

Project file name on e2studio:

mirror_io_sample__03_ecat__RX66T_FreeRTOS

To use this sample application, you need to update the firmware version of the R-IN32M3 Module to 2.0.0.0

or later. For the firmware update method, refer to “R-IN32M3 Module (RY9012A0) Quick Start Guide”

(R12QS0042ED****).

Preparation of development environment is the same as Chapter 3.3.1.

When the sample application is run, a totally 5 LEDs light up. (protocol display LED (LED3) and generalpurpose output LED (LED5, 6, 8, 9).

TwinCAT made by Beckhoff Automation can be used as a EtherCAT master. TwinCAT is available from the

Beckhoff Automation website.

http://www.beckhoff.com/

As a preparation before TwinCAT startup, you need to store the sample application’s EtherCAT Slave

information (ESI) file to TwinCAT folder on your PC.

[ESI file]

\appl\mirror_io_sample\03_ecat\esi\03_ecat_slave_renesas.xml

(Displayed name on TwinCAT: RIN32M3 Module)

[Folder to store ESI file]

C:\TwinCAT\3.1\Config\Io\EtherCAT

By referring to the following operation of TwinCAT, confirm EtherCAT connection to this sample application

and verify the I/O mirror response by cyclic communication.

(1) From the start menu on your PC, select [Beckhoff] -> [TwinCAT 3] -> [TwinCAT XAE (VS 20 xx)].

(2) After starting TwinCAT, select [File] -> [New] -> [Project] and create a new project of type [TwinCAT XAE

Project].

R12AN0111EJ0204 Rev.2.04 Page 52 of 88

Apr.26.2021

Page 53

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(3) In TwinCAT project tree, right-click [I/O] -> [Devices] and select [Scan].

Figure 3-44 Scan network

(4) Click [OK] on [HINT: Not all types of devices can be found automatically] dialog.

(5) In the [new I/O devices found] dialog, select the check box of Ethernet adapter to be scanned and click

[OK].

(6) Click [Yes] in [Scan for Boxes] dialog, scanning is started and the devices in the EtherCAT segment are

recognized automatically.

(7) When [Active Free Run] dialog is displayed, click [Yes]. In TwinCAT project tree, display [Device x] ->

[Box 1] is added under [I/O] -> [Devices].

Figure 3-45 Box 1

R12AN0111EJ0204 Rev.2.04 Page 53 of 88

Apr.26.2021

Page 54

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(8) If the EEPROM is blank and [Box 1 (PFFFFFFFF RFFFFFFFF)] is displayed, or if the ESI of different

sample application is written, it is necessary to write the ESI file of corresponding sample application to the

EEPROM. In TwinCAT project tree, double-click [Device x] -> [Box 1] -> [I/O] -> [Devices], the window is

displayed on the right side. Select the [EtherCAT] panel and click the [Advanced Settings].

If the ESI file of corresponding sample application has already been written to EEPROM, please go to steps

(14).

Figure 3-46 EEPROM setting

(9) Select [ESC Access] -> [EEPROM] -> [Hex Editor] in the left side of [Advanced Settings] dialog.

(10) In the [Hex Editor] window, click [Download from list].

(11) In [Write EEPROM] dialog, select [Renesas Electronics Corp] -> [RIN32M3 Module]. Select the ESI file

of corresponding sample application and click [OK]. This writes the ESI file is written to EEPROM. When the

writing is complete, click [OK] to close [Advanced Settings] dialog.

(12) In order to reflect the changed ESI file settings in TwinCAT project, disconnect the connected device

once. Right-click [I/O] -> [Devices] -> [Device x] and select [Remove].

Figure 3-47 Remove device

(13) Follow steps (3) to (7) for connection the device again.

R12AN0111EJ0204 Rev.2.04 Page 54 of 88

Apr.26.2021

Page 55

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(14) Double-click [I/O] -> [Devices] -> [Device x] -> [Box 1] in TwinCAT project tree, the window is displayed

on the right side. Select [Online] panel. If connection is successful, "OP" is displayed in [Current Status] and

[Requested State]. In addition, the protocol status LED (LED4) on this board lights up.

Figure 3-48 Connection successful

(15) After the connection is complete, expand [Box 1] in TwinCAT project tree and expand [TxPDO 1] and

[RxPDO 1], which monitor cyclic communication. The I/O mirror response is verified by operating 1byte data

of [digital Inputs 1-8] and [digital Outputs 1-8].

Right-click [digital Inputs 1-8], select [Add to Watch]. Similarly, right-click [digital Outputs 1-8], and select

[Add to Watch]. This can watch IN and OUT data on one screen in the [symbol Watch] panel.

Figure 3-49 Add to Watch

R12AN0111EJ0204 Rev.2.04 Page 55 of 88

Apr.26.2021

Page 56

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

(16) For operating each value, Right-click [digital Outputs 1-8] or [digital Inputs 1-8], select [Online Write…]. It

is enabled to set the value on [Set Value Dialog] dialog that is displayed.

Figure 3-50 Online Write

Figure 3-51 Set Value Dialog

<example>

- Type "12" in [Dec] of [digital Outputs 1-8], then “12” in [digital Inputs 1-8] is displayed

Figure 3-52 Confirmation I/O mirror response

R12AN0111EJ0204 Rev.2.04 Page 56 of 88

Apr.26.2021

Page 57

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Sample

\appl\motor_sample\01_pnio

Project File

\projects\motor_sample\01_pnio\e2studio\RX66T\OSless

3.3.4 Motor Sample (via PROFINET)

This chapter describes an example of motor control via PROFINET communication by running the following

sample project (OS less version):

Application

Project file name on e2studio:

motor_sample__01_pnio__RX66T_OSless

At first, refer to Chapter 3.2. to prepare the development environment.

(1) This sample application requires an inverter board, so connect it as shown in Figure 3-7.

(2) Build the project and run the sample application, referring to Chapters 3.2.4 to 3.2.6.

When the sample application is run, a totally 5 LEDs light up. (protocol display LED (LED1) and generalpurpose output LED (LED5, 6, 8, 9).

Network adapter setting is the same as Chapter 3.3.1.

Management tool can be used as a PROFINET master, which is also the same as Chapter 3.3.1.

By referring to the following operation of Management tool, confirm PROFINET connection to this sample

application and verify the motor control by cyclic communication. Since steps (1) to (9) are the same as

Chapter 3.3.1, only steps (10) and beyond are described below.

(10) Open the I/O panel of [PNIO Master] panel and select [Load GSDML file] button to import the GSDML

file. GSDML files can be found in the following folder:

\appl\motor_sample\01_pnio\gsdml

Verify that [Slots:] and [Modules] display contents as set in GSDML, and then select [Connect] button. If the

connection is successful, this button switches to [Disconnect] button. In addition, the protocol status LED

(LED4) on this board lights up.

Figure 3-53 GSDML

R12AN0111EJ0204 Rev.2.04 Page 57 of 88

Apr.26.2021

Page 58

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Operating Data

Motor control

[O Signed8] -> [Output Data]

Select movement

[O Signed16] -> [Output Data]

Specify rotation speed (Big Endian)

(11) After the connection is complete, move the slider bar down in [PNIO Master] panel to display [I/O Data],

which monitors cyclic communication. The motor control is verified by operating 1byte and 2byte data of

[Output Data].

0x00:Stop

0x01:FWD rotation (clockwise(CW))

0x02:RVS rotation (counter-clockwise(CCW))

By typing data as follows, the motor rotates FWD (CW) at the specified rotational speed.

- [O Signed8] -> [Output Data] = ”0x01”, [O Signed16] -> [Output Data] = ”0080”

Figure 3-54 CW

Also, by typing data as follows, the motor rotates RVS (CCW) at the specified rotational speed.

- [O Signed8] -> [Output Data] = ”0x02”, [O Signed16] -> [Output Data] = ”0x0070”

Figure 3-55 CCW

R12AN0111EJ0204 Rev.2.04 Page 58 of 88

Apr.26.2021

Page 59

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Sample Application

\appl\motor_sample\02_eip

Project File

\projects\motor_sample\02_eip \e2studio\RX66T\OSless

Operating Data

Motor control

1st byte in [I/O Data O->T]

Select movement

3rd and 4th byte in [I/O Data O->T]

Specify rotation speed (Big Endian)

3.3.5 Motor Sample (via EtherNet/IP)

This chapter describes an example of motor control via EtherNet/IP communication by running the following

sample project (OS less version):

Project file name on e2studio:

motor_sample__02_eip__RX66T_OSless

Preparation of development environment is the same as Chapter 3.3.4.

When the sample application is run, a totally 5 LEDs light up. (protocol display LED (LED2) and generalpurpose output LED (LED5, 6, 8, 9). Also, protocol status LED4 is light up and LED7 flashes.

Network adapter setting is the same as Chapter 3.3.1.

Management tool can be used as a EtherNet/IP master, which is also the same as Chapter 3.3.1.

By referring to the following operation of Management tool, confirm EtherNet/IP connection to this sample

application and verify the motor control by cyclic communication. Since steps (1) to (6) are the same as

Chapter 3.3.2, only step (7) and beyond are described below.

(7) After the connection is complete, move the slider bar down in the EtherNet/IP Master panel and display

[I/O Data O->T] and [I/O Data T->O], which monitor cyclic communication. The motor control is verified by

operating 32byte data of [I/O Data O->T].

0x00:Stop

0x01:FWD rotation (clockwise(CW))

0x02:RVS rotation (counter-clockwise(CCW))

R12AN0111EJ0204 Rev.2.04 Page 59 of 88

Apr.26.2021

Page 60

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

<example>

By typing data as follows, the motor rotates FWD (CW) at the specified rotational speed.

st

- 1

byte in [I/O Data O->T] = “01”, 3rd byte and 4

th

byte in [I/O Data O->T] = ”00 60”

Figure 3-56 CW

Also, by typing data as follows, the motor rotates RVS (CCW) at the specified rotational speed.

st

- 1

byte in [I/O Data O->T] = ”02”, 3rd and 4th byte in [I/O Data O->T] = ”00 70”

Figure 3-57 CCW

R12AN0111EJ0204 Rev.2.04 Page 60 of 88

Apr.26.2021

Page 61

R-IN32M3 Module (RY9012A0) R-IN32M3 Module Evaluation Board

Sample Application

\appl\motor_sample\03_ecat

Project File

\projects\motor_sample\03_ecat\e2studio\RX66T\OSless

3.3.6 Motor control (via EtherCAT)

This chapter describes an example of motor control via EtherCAT communication by running the following

sample project (OS less version):

Project file name on e2studio:

motor_sample__03_ecat__RX66T_OSless

To use this sample application, you need to update the firmware version of the R-IN32M3 Module to 2.0.0.0

or later. For the firmware update method, refer to “R-IN32M3 Module (RY9012A0) Quick Start Guide”

(R12QS0042ED****).

Preparation of development environment is the same as Chapter 3.3.4.

When the sample application is run, a totally 5 LEDs light up. (protocol display LED (LED3) and generalpurpose output LED (LED5, 6, 8, 9).

TwinCAT can be used as a EtherCAT master, which is also the same as Chapter 3.3.3.

As a preparation before TwinCAT startup, you need to store the sample application’s EtherCAT Slave

information (ESI) file to TwinCAT folder on your PC.

[ESI file]

\appl\motor_sample\03_ecat \esi\03_ecat_mtr_slave_renesas.xml

(Displayed name on TwinCAT: RIN32M3 Module (Motor sample))

[Folder to store ESI file]

C:\TwinCAT\3.1\Config\Io\EtherCAT

By referring to the following operation of TwinCAT, confirm EtherCAT connection to this sample application