Remington IM 812-2 Installation & Maintenance Data

Installation & Maintenance Data IM 812-2

McQuay/Remington

Packaged Terminal Air Conditioners and Heat Pumps – C Vintage

Group: PTAC/PTHP

Date: April 2006

®

©2006 McQuay International

Table of Contents

General Description ............................................................ 2

Warning ............................................................................... 2

Inspection ........................................................................... 2

Nomenclature...................................................................... 3

Control Features .............................................................. 4-5

Wall Opening Requirements and Unit Dimensions ............. 6

Installation of Optional Condensate Drain Kit ..................... 7

Subbase Installation............................................................ 8

Power Supply and Control Wiring....................................... 8

Wall Sleeve Installation

Thin Wall Construction ................................................. 9

Medium Thick Wall Construction ............................... 10

General Description

McQuay®/Remington® Packaged Terminal Air Conditioners and

Heat Pumps are designed and built for through-the-wall

installation in either new or existing buildings. The self-contained refrigerant system delivers cooling to the desired space.

Heating can be accomplished with electric resistance or with

reverse cycle technology (heat pump models only). Generally,

an estimate for capacity selection is 35 BTUH per square foot

of floor space (cooling) and 4 BTUH (1.25 watts) per cubic

foot (heating). The architect or engineer must verify the selection. Note that the heat pump reverse cycle generates approximately 10 BTUs per electrical watt as compared to 3.4

BTUs per watt with resistance electric heat. The unit will restart at its last setting after a power interruption. A complete

unit consists of the following components, ordered and

shipped separately.

1. Heating/Cooling Chassis and Front Panel.

2. Wall Sleeve.

3. Outdoor Louver.

4. Subbase – Optional for 208V and 230V units but mandatory for all 265V.

5. Separate plug-in power cord (selects heater size).

NOTE: Some units with fixed heaters are also available

with factory installed power cords.

6. Electrical receptacle – Optional for 208V and 230V units

but mandatory for all 265V.

7. Plug cord cover – Optional for 208V and 230V units but

mandatory for all 265V.

Thick Wall Construction ............................................. 11

Wall Sleeve Extension and Louver Frame......................... 12

Outdoor Louvers ............................................................... 13

Installation of Louvers and Chassis .................................. 14

Equipment Start-up .......................................................... 15

Remote Mounted Thermostat ........................................... 17

Wiring Diagrams........................................................... 18-20

Scheduled Maintenance ................................................... 21

Spare Parts ....................................................................... 21

Shipping Weights .............................................................. 22

Refrigeration Cycle ........................................................... 22

Trouble Shooting .......................................................... 23-25

NOTICE

This product was carefully packed and thoroughly

inspected before leaving the factory. Responsibility

for its safe delivery was assumed by the carrier upon

acceptance of the shipment. Claims for loss or damage

sustained in transit must therefore be made upon the

carrier, as follows:

VISIBLE LOSS OR DAMAGE

Any external evidence of loss or damage must be

noted on the freight bill or carrier’s receipt, and signed

by the carrier’s agent. Failure to adequately describe

such external evidence of loss or damage may result

in the carrier’s refusal to honor a damage claim. The

form required to file such a claim will be supplied by

the carrier.

CONCEALED LOSS OR DAMAGE

Concealed loss or damage means loss or damage

which does not become apparent until the product

has been unpacked. The contents may be damaged in

transit due to rough handling even though the carton

may not show external damages. When the damage is

discovered upon unpacking, make a written request

for inspection by the carrier’s agent within fifteen (15)

days of the delivery date. File a claim with the carrier

since such damage is the carrier’s responsibility.

WARNING

!

The installer must determine and follow all applicable

codes and regulations. This equipment presents hazards

of electricity, rotating parts, sharp edges, heat and weight.

Failure to read and follow these instructions can result in

property damage, severe personal injury or death. This

equipment must be installed by experienced, trained

personnel only.

CAUTION

!

Use copper conductors only. Unit terminals are not designed to accept other types of conductors.

Failure to do so can damage equipment.

IM 812 / Page 2 of 28

WARNING

!

Inspect unit nameplate to be certain the voltage is the

same as the voltage that will be delivered to the unit. The

receptacle must match the plug on the unit cord. Improper

electrical wiring can cause property damage, severe personal injury or death.

WARNING

!

Hazardous Voltage!

Disconnect all electric power including remote

disconnects before servicing. Failure to discon-

nect power before servicing can cause severe

personal injury or death.

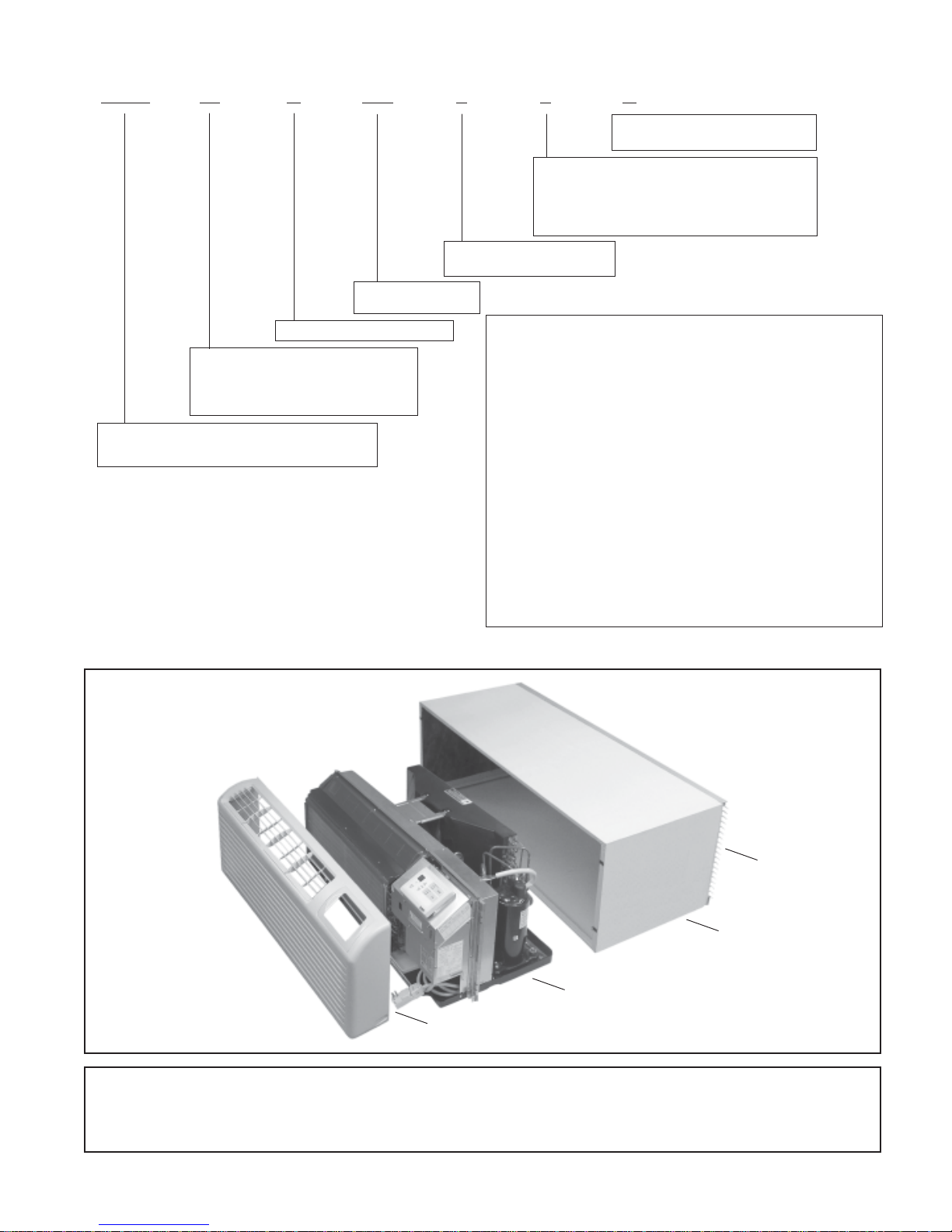

Product Nomenclature

PTAC 07 C 208 F 3 C

▲

▲

▲

▲

▲

▲

0 = 0.0 kW No Electric Heat

2 = 2.4 Nominal kW Electric Heater

3 = 3.5 Nominal kW Electric Heater

5 = 5.0 Nominal kW (30A) Electric Heater

Z = 5.0 Nominal kW (20A/265V) Electric Heater

F = FixedCord Heat

U = Universal Cord Heat

2

3

208 = 208-230V

265 = 265V

C = “C” Design Vintage

07 = 7,000 Nominal BTUH Cooling

09 = 9,000 Nominal BTUH Cooling

12 = 12,000 Nominal BTUH Cooling

15 = 15,000 Nominal BTUH Cooling

Notes

1.

All chassis ship with an Installation Manual and mounting screws.

2. Factory-installed. Check notes 5 & 6 for availability.

3. Field-installed. Check notes 5 & 6 for availability.

4. Available on size 12 & 15 units only. Order Universal Power Cord

for “Cooling Only”.

5. Available with fixed cord for all 208-230V PTAC/PTHP size 07 &

PTAC = Packaged Terminal Air Conditioner

PTHP = Packaged Terminal Heat Pump

1

1

09 units and for 265V PTHP size 09. Available with universal

power cord for all PTAC/PTHP size 12 & 15.

6. Available with fixed power cord on all PTAC/PTHP units.

Available with universal power cord on all PTAC/PTHP size

12 & 15.

7. Universal power cord with 30A plug for PTAC/PTHP size

12 & 15 only.

8. Universal power cord with 20A plug for 265V PTAC/PTHP size

12 & 15 only.

9. Includes control pad and mounting frame.

10. Wall Mounting Kit & Control Pad or 24V Wall thermostat &

Control Blank Off must be ordered separately. See accessory

tables.

▲

C = Chassis Mounted Control

W =Wall Mounted Control

4

10

5

6

7

9

8

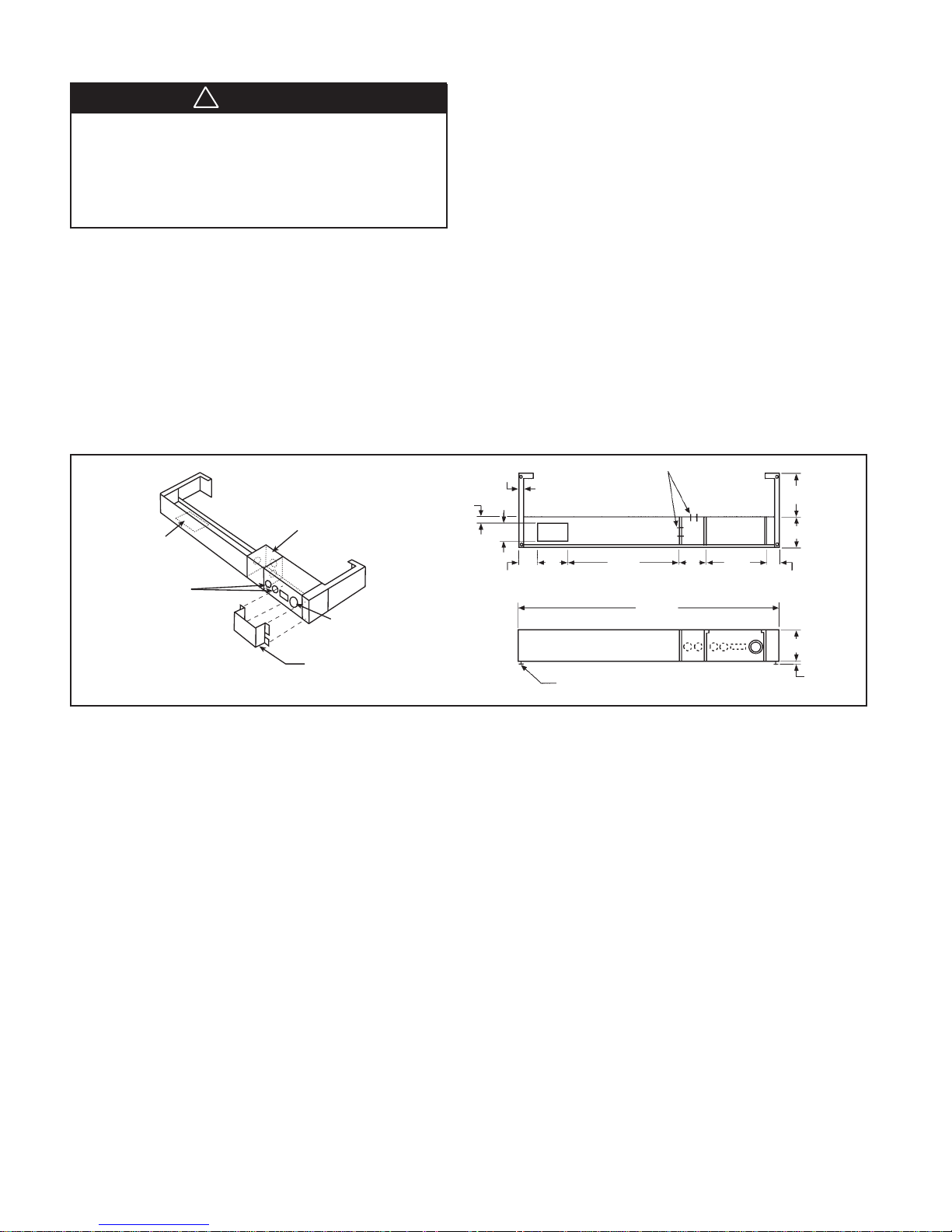

Figure 1. Exploded View of Complete Unit (Shown without subbase)

▲

Louver

▲

Wall Sleeve

▲

Chassis

▲

Front Panel

Now that you have made an investment in modern, efficient McQuay®/Remington® equipment, its care and

operation should be a high priority. For training information on all McQuay HVAC products, please visit us at

www.mcquay.com and click on Training or phone 540-248-0711 and ask for the Training Department.

IM 812 / Page 3 of 28

Control Features

Standard Control

Control Pad - Can be unit-mounted or can be remote wall

mounted. Remote mounting requires an accessory 35´ or 50´

low-voltage wire harness and snap-in decorative cover. The

mounting location must be away from cold drafts, discharge

air, outside walls, etc., because the room temperature sensor

is mounted in the control pad (if dip switch #2 of 4, behind the

access cover on front of the control box, is “ON”). A wireless

hand-held remote controller is also available as an accessory,

which allows control of the conditioner from anywhere in the

room.

Heat – Select by pressing the ON/OFF key to “ON” and the

+

왕

MODE key to “HEAT.” Use the

room temperature (60-85OF).

NOTE: Heat pumps will not operate in reverse cycle unless temperature setting is within 2

ture. Otherwise, unit will heat with electric heaters until

satisfied. The next call for heat will be reverse cycle, provided the outdoor temperature is above the 30-40

When the outdoor temperature is less than 25

the heating will be with electric resistance. Between 25oF

and 40oF, the primary heat will be reverse cycle with occasional resistance heat as required to maintain room temperature. Above 40

o

F, all heating will be by reverse cycle.

Cool – Select by pressing the ON/OFF key to “ON” and the

MODE key to “COOL.” Use the

room temperature (60-85OF).

Fan Only – Select by pressing the ON/OFF key to “ON” and

the MODE key to “FAN”. Press the FAN key to select high or

low speed. In this mode, only the indoor fan will operate and

there will be no heating or cooling.

Cool/Dry – Press the ON/OFF key to “ON” and the MODE key

to “COOL”. Press and hold the MODE key for 15 seconds to

activate “COOL/DRY”. Use the

room temperature. Select this mode when the standard Cool

mode does not provide sufficient dehumidification. The compressor and indoor low fan will cycle together and will operate

for longer periods of time to provide up to 70% more dehumidification. As a result, the room temperature differential may

increase slightly.

NOTE: COOL/DRY can not be used with SLEEP.

Fan Speed – Select fan speed by pressing the FAN key to

“AUTO”, “HIGH” or “LOW” while the unit is operating in

“HEAT”, or “COOL” mode. “AUTO” gives high fan if unit setting is more than 2

low fan if less than 2

Continuous/Cycle Fan – When dip switch #8, located on front

of the control box, behind the access cover, is in the “OFF”

position, the indoor fan will operate continuously. When dip

switch #8 is in the “ON” position, the indoor fan will cycle on

and off with the compressor or heater. In cycle fan, (dip switch

#8 “ON”) the fan will start every 7 minutes to sample the room

temperature. Fan will turn off again after 2 minutes unless heating or cooling is required.

IM 812 / Page 4 of 28

o

F above or below room temperature and

o

F above or below room temperature.

or 왓- key to set the desired

o

F of room tempera-

o

F range.

o

F, most of

+

왕

or 왓- key to set the desired

왕+ or 왓- key to set the desired

Room Freeze Protection

– When dip switch #4 of 4 (located

behind the access cover on front of the control box) is "OFF",

a unit-mounted sensor will be activated to bring on the elec-

o

tric heater and indoor fan as required to maintain a 40

-50oF

minimum temperature. This will override “OFF”, remote “OFF”,

“COOL”, “COOL/DRY”, “FAN” and “UNOCCUPIED” modes.

When dip switch #4 of 4 is “ON”, there is no freeze protection.

Also, if using a 24V wall stat, there is no freeze protection (unless provided by the wall stat).

IMPORTANT NOTE: When dip switch #4 of 4 is "ON", there

is no freeze protection.

CAUTION

!

Absence of freeze protection can result in equipment and

property damage. Make certain dip switch #4 of 4 is “OFF”,

if freeze protection is required.

Wired Remote ON/OFF

– The unit may be turned on by open-

ing, or off by closing, a set of dry contacts located up to 325´

from the unit using a pair of 22 ga. low voltage wires. The 22

ga. wires are connected to the unit using a plug and receptacle connection under the small access cover on the front of

the control box. (A plug with 2 short wires is shipped with the

chassis and plugs into “F. DESK” receptacle) The dry contacts can be a toggle switch at the front desk, a time clock,

etc. When the dry contact is closed, the unit control goes to

o

memory P1 which is set from the factory at 75

F in COOL

mode and high fan. If desired, P1 can be programmed for a

different setting. See instructions under “Motion Sensor & Door

Switch”, page 5. When the dry contact is opened and the unit

restarts, the control will automatically index to a Heat setting

o

F (if room temperature is below 68oF) or a Cool setting of

of 68

o

F (if the room temperature is above 68oF. )

75

NOTE: If the unit has been turned OFF by remote dry contacts and the room occupant presses the ON/OFF key on

the control pad, the indicator lights will come on and the

control will start beeping but the unit will not heat or cool.

Temperature Limiting

– The control temperature range as

shipped from the factory is from 60o-85oF. By using dip switches

#1-#4 of 8 (located behind the access cover on front of the

control box), the range can be changed per the following charts:

NOTE: After the limits have been set, the control display

o

will still show the full range of 60-85

F, however, the unit

will not heat or cool past the limits.

Min. Set Point SW #1 SW #2

60oF OFF OFF

64oFONOFF

68oF OFF ON

72oFONON

Max. Set Point SW #3 SW #4

75oFONON

78oF OFF ON

82oFONOFF

85oF OFF OFF

Dip Switch Description (located behind

access cover on front of control box)

Dip SWI #1–#8

#1–#4 = Temperature Limiting – see charts, page 4.

#5–#6 = Approximate outdoor temperature when unit will automatically change from reverse cycle heating to electric heat.

#5-OFF & #6-OFF = 35

#5-ON & #6-OFF = 30

#5-ON & #6-ON = 25

#7-OFF = Normal HP operation, ON = electric heat only.

#8-OFF = Constant indoor fan, ON = Cycle

Dip SW2 #1–#4

#1-OFF = Control pad activated, ON = 24V wall stat activated.

#2-OFF = Room temperature sensor on chassis, ON = sensor

on control pad.

#3-OFF = Motion & Door sw. activated, ON = Timer and Sleep

activated.

#4-OFF = Room freeze protection is activated, ON = deactivated.

NOTE: All dip switches ship from factory in the OFF position except #8 of 8 and #3 of 4 which are shipped turned

ON. Any switch changes must be followed by unplugging

and plugging in the power cord to activate the change.

Quick Heat & Cool

– This feature provides extra comfort for

the occupant during start up of an unconditioned space. When

off for more than 2 hours, the unit setting will automatically

o

F in Heat or drop 2oF in Cool to offset the radiation felt

raise 2

from the cold or warm walls, ceiling and floor. The 2oF offset is

maintained for the first cycle only. After that, the setting reverts to that shown on the digital display.

Motion Sensor & Door Switch – (activate by dip switch #3 of

4 turned OFF)

– Two receptacles under the access cover on

front of control box provide connections for the motion sensor and door switch. (Motion sensor and door switch are available from your sales representative. The motion sensor is custom-made for McQuay with both “ON” & “OFF” having no

time delay. Motion sensors by others will not work.) Two plug

and wire assemblies are included with each chassis. Connect

receptacle “MOTION” to motion sensor and “DOOR” to door

switch.

While room is occupied, the motion sensor keeps the control

“normal” so the occupant has full control of the unit. Fifteen

minutes after the occupant leaves the room, the unit goes into

memory P2. 14 hours later, if no one has entered the room,

the unit goes into memory P1. Both P1 and P2 come factory

set in COOL mode @ 75

temperature and mode by using a G11 hand held remote controller available from your sales representative.

o

F (factory setting)

o

F

o

F

o

F. They can be reprogrammed for

Programming P1 using the G11 control – press and hold

the upper + button for 3 seconds until P1 starts flashing on

the G11 display. While P1 is still flashing, press the buttons to

select temperature, fan speed, and mode for P1. Wait 15 seconds until P1 stops flashing, then press and release the upper

+ button to send the P1 program to the unit control. P1 will

flash on the unit display to show it was accepted.

Programming P2 using the G11 control – press and hold

the upper - button for 3 seconds until P2 starts flashing. While

P2 is still flashing, select temperature, fan speed, and mode

desired for P2. Wait 15 seconds until P2 has stopped flashing, then press and release the upper - button to send the P2

program to the unit control. P2 will flash on the unit display to

show it was accepted.

Control Lockout

– The unit control has an electrical lockout

feature to prevent anyone from changing the mode, temperature or fan speed. To activate this lockout, press and hold the

unit FAN key for 10 seconds until LO shows on display. To

unlock the control, press and hold the FAN key for 10 seconds until UL shows.

Remote Wall Thermostat

General – Remove the control pad from the unit by unsnap-

ping it from its base and unplugging it from the receptacle on

the control box front. The snap-in decorative cover (ordered

separately) now mounts in place of the control pad. To modify

the controls for Remote Wall Thermostat, slide dip switch #1

of 4 to ON. Also, unplug the power cord from the receptacle

and plug back in again to reset the circuit. Four to seven lowvoltage wires, as determined by the wall thermostat selected,

connect to the 7 pin receptacle CN2, behind the access cover,

on the control box front. Use the 7 pin plug and wire assembly

provided. Mount the thermostat on an inside wall. Avoid unit

discharge air, direct sunlight and cold drafts.

Operation

R, W, Y, and G terminals plus C if it requires 24V AC power

from the unit. By using all 7 low voltage connections, wall stats

with 2 stage heat & fan speed selection can also be used.

Stats can be MCO, ACO, MCO/ACO or programmable. With

the exception of “wired Remote ON/OFF”, the control features listed for the standard control pad will not be available

with the wall thermostat. Low fan speed is standard for stats

without speed selection.

– The 24V wall thermostat should have the normal

IM 812 / Page 5 of 28

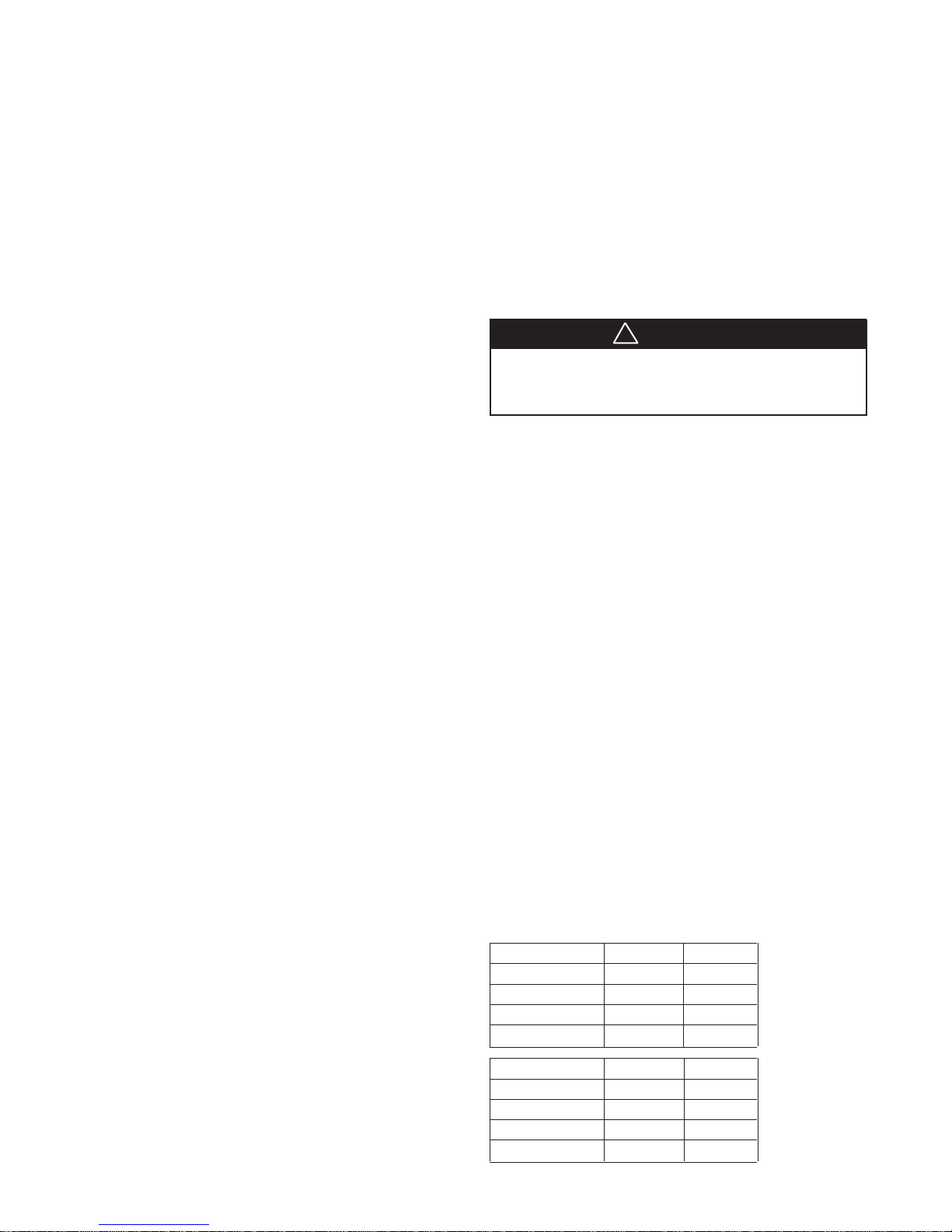

NOTICE

Unit Installation – General

Wall Opening Requirements

Before installing the unit, check the wall opening to be sure

the wall sleeve will slide into the opening unobstructed. For

masonry walls, a lintel must be used to provide support over

each opening. The rough opening should measure 16

x 421⁄4˝ wide (see Figure 2, Note 2). When a subbase is used,

1

the opening must start 3

⁄4˝ or 41⁄4˝ above the finished floor to

match the height of the subbase selected. The subbase is

available in either a 3˝ or 4˝ height and is required for 265V but

is optional for 208/230V. Each subbase has leveling legs to

provide up to 1˝ additional height. When no subbase is used,

the opening can start right at the finished floor level (208/230V

only). Leave enough space for carpeting, etc.

Figure 2. Unit Dimensions

1

⁄4˝ high

Heat pump models will generate condensate during the

heating season. If it is not desirable for this condensate

to exit outdoors from the wall sleeve drain holes, install

indoor or outdoor drain kits, available from your sales

representative (see page 7).

3/8˝ (Stamped Louver)

11⁄8˝ (Architectural Louver)

42˝

133⁄4˝

16˝

Subbase

3

13

⁄4˝

See

Note 1

Side View

3

⁄4˝

20

7˝

Top View

7˝

42˝

16˝

1/2˝

41

1

⁄2˝

See Note 1

Front View

Notes:

1. Unit pictured with subbase installed. Subbase is optional on 208V/230V units but required on all 265V units. See pages 8, 9,

10, and 11 for subbase dimensions, and details.

2. Opening needs to be 165⁄8˝ x 42

5

⁄8˝ when using a louver frame. See page 12, Figure B.

IM 812 / Page 6 of 28

Installation of Optional Condensate Drain Kit

Figure 3 illustrates the installation of the indoor drain kit. The

indoor drain kit must be installed before placing the wall sleeve

into the opening. Install as follows:

1. Locate the drain so that it will be on the room side of the

wall when the wall sleeve is installed.

2. Drill a 1/2

˝ diameter hole in the base of the wall sleeve for

the drain.

3. Drill two (2)

5/32˝ pilot holes for the mounting screws.

These holes can be located using the drain kit as a

pattern.

4. Assemble the drain kit as shown in Figure 3 and securely

fasten it to the wall sleeve with the screws provided. Use

o

either the 90

elbow or 6" straight fitting as required.

5. Install the wall sleeve as described on pages 9, 10, or 11.

Figure 3. Indoor Drain Kit

Contractor to Drill

Three (3) Holes to

Accept Drain Kit

Assembly of the outdoor drain kit should be completed after

the wall sleeve has been installed.

Note: When using the outdoor drain kit, the sleeve

must be flush or beyond the outside finished wall

(do not recess).

Install the outdoor drain kit as follows:

1. Assemble the drain kit as shown in Figure 4.

2. Choose the side of the wall sleeve to which the drain kit

is to be installed.

3. There are drain holes and pilot holes provided in the wall

sleeve from factory. Place the drain kit against the chosen drain hole and fasten securely with screws provided.

Use either the 90

4. Cover the unused drain hole with the block off plate and

gasket supplied with the drain kit.

See Detail

Below

o

elbow or 6" straight fitting as required.

Indoor

Figure 4. Outdoor Drain Kit

Square Drain Holes

Neoprene Sponge Gasket

Block Off Plate

Neoprene Sponge Gasket

Steel Mounting Plate

Steel Mounting

Plate

Square Drain Holes

1

⁄2" O.D. Drain Tube

DETAIL

Screws

Gasket

Tube

Cabinet Bottom

Steel Mounting

Plate

Indoor

1

⁄2" O.D.

IM 812 / Page 7 of 28

Subbase Installation

WARNING

!

All electrical work must be done by trained, experienced

electricians in accordance with applicable codes and standards. Kinked, bent or chaffed cords; improper grounding or fusing; improper current or voltage; or improper

installation can cause fire or electric hazards that can result in property damage, personal injury or death.

Electric Subbase

An electrical subbase is optional for 208V and 230V units, but

is standard for 265V units. It is available in two sizes: 3˝ or 4˝.

The subbase contains leveling legs for adjustment of up to 1˝

additional height. Install the wall sleeve and subbase at the

same time.

Note: A minimum of 4

into the room when using a subbase.

Figure 5. Electric Subbase

3" x 5"

Opening for

Electrical and/or

Drain Rough-In

Knockouts for

Optional Fuse &

Disconnect Switch

3

⁄8˝ of the wall sleeve must project

Electrical

Junction

Box for Main

Power Connection

Side

Extension

Piece

Receptacle

Mounting Location

Plug/Cord Cover

(Required on 265V Units Only)

Installation

1. If the minimum depth subbase is required (4

3

⁄8˝), discard

the side extension pieces. The subbase always mounts

flush with the front of the wall sleeve.

2. If more than the minimum depth subbase is required, determine the depth of the side extension pieces desired

and break at the proper score-line. Insert the side extension pieces into the front assembly and secure with two

short black screws at each side.

3. Insert leveling legs into subbase bottom flanges. Four (4)

legs will be needed if side extensions are used. Only two

(2) will be required if side extensions are not used.

4. Place the subbase on the floor and align its center line

with the center line of the wall opening. Do not fasten the

subbases to the floor. After the wall sleeve has been installed, attach the subbase to it using the two clips

provided. Adjust the subbase height so it rests tight against

the bottom of the wall sleeve.

5. The wiring should be roughed in and the conduit connected

to the electrical junction box. Complete the installation by

wiring the receptacle to the incoming power supply.

7

⁄8"

5

⁄8"

3"

21⁄2"

5"

Leveling Leg

Front Elevation (Three Front Panels in Place)

Electrical Knockouts

17"

31⁄2"

Plan

411⁄2"

0" to 93⁄8"

43⁄8"

12"

11⁄2"

3" or 4"

0" to 1"

Power Supply and Control Wiring

All wiring must be done in accordance with local and National

Electrical Code requirements. Some units have a multitap

heater, so the Kw is determined by the field-installed power

cord, and some have factory installed cords with fixed heaters. Refer to the data plate for proper overcurrent protection.

Time delay fuses or HACR circuit breakers are required to avoid

nuisance tripping.

Power Supply Wiring

208V and 230V units use a power cord that exits from beneath

the conditioner on the control (R.H.) side. The cord has a usable

length of 60˝ from where it exits the conditioner. (Do not use

extension cords.) When a subbase is not used, the receptacle

is generally mounted beneath the conditioner or on the wall

beside it (208-230V only). An electrical subbase is available

and contains a junction box for a field-mounted receptacle.

All electrical connections are made within the subbase, thus

eliminating the need for a wall-mounted receptacle (see Figure 5). The subbase is available in 3˝ or 4˝ height and can be

furnished with a factory-mounted fused disconnect and receptacle as an option. The subbase is optional for 208V and

230V, but mandatory for 265V. The 265V chassis uses a “short

cord,” which is just long enough to plug into the subbase. A

plug/cord cover is also required on 265V to make the power

cord inaccessible without the use of tools, (see Figure 5).

IM 812 / Page 8 of 28

Control Wiring

If the unit control pad will be wall mounted, rough in the 35´ or

50´ low-voltage wire harness at this time. The end of the harness, with exposed terminals (the larger black connector), will

plug into the control box at the unit. The other end (smaller

white connector), with concealed terminals, will connect to

the PC board in the control pad on the wall. At the unit, exit

the wall with enough wire harness to reach the CN5 receptacle behind the access cover on the control box front. At the

control pad mounting location on the wall, exit with only a few

inches of wire harness. Route the wire harness through the

opening in the control pad mounting plate and secure the plate

to the wall. Unplug the short cord from the PC board in the

control pad and discard. Plug in the new wire harness from

the wall and snap the control pad onto the mounting plate.

The harness should all be concealed behind the control pad

when finished. If an optional 24V wall stat will be used rather

than the control pad, rough in the 4 to 7 low voltage wires as

required by the stat. If remote ON/OFF control will be used,

rough in 2 low voltage wires (22 ga. min.) to a maximum of

325´ from the unit, (see page 4.) If unit will be connected to a

motion sensor and door switch, rough in the 4 low voltage

wires for the motion sensor and the 2 low voltage wires for the

door switch. Leave enough wire at the unit to reach the receptacles behind the access cover on front of control box.

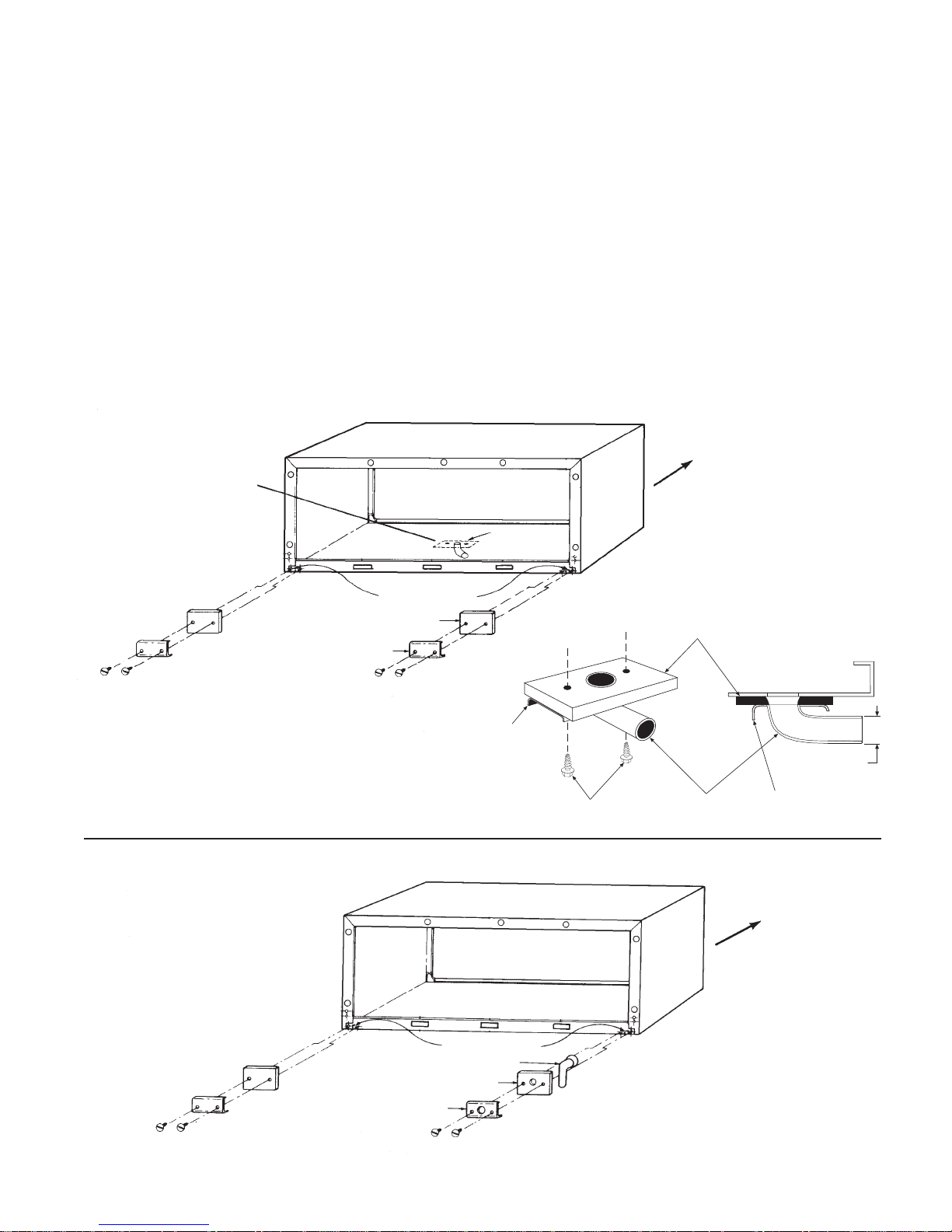

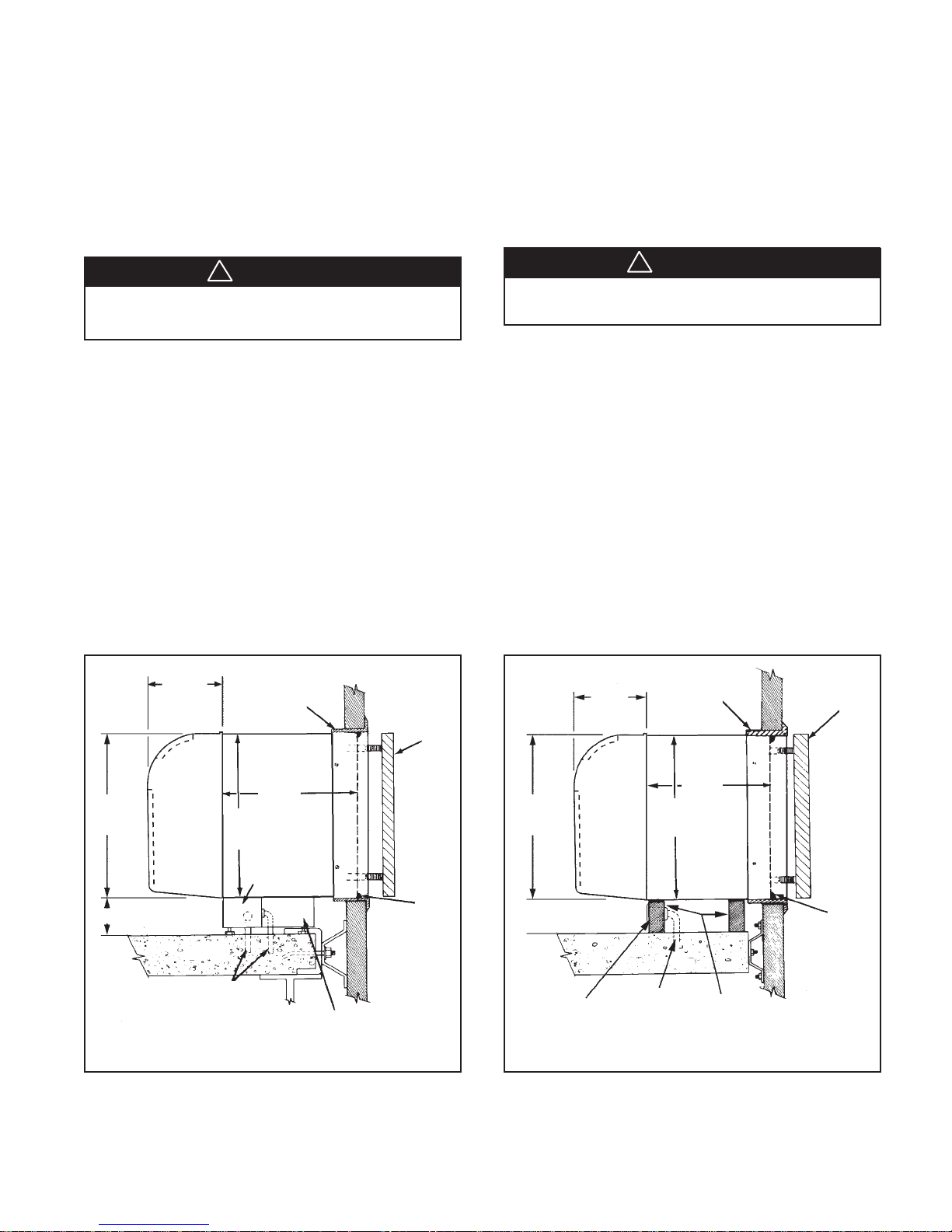

Wall Sleeve Installation – Thin Wall Construction

For panel wall and thin wall construction, a louver frame may be used. Refer to page 11 for installation of louver frame before

continuing.

Panel wall and thin wall construction varies only slightly from

frame and brick construction. Note: The center of gravity is

1

⁄4˝ from the outdoor edge of the wall sleeve. The wall sleeve

10

must be supported to the center of gravity. Support can be

from a factory-supplied subbase or from other field-supplied

materials or it can be floor mounted for 208/230V.

WARNING

!

Failure to provide proper support can result in property

damage and severe personal injury.

Install as follows:

1. Clean the opening of all debris that may interfere with

installation.

2. If the unit is to be supplied with a subbase, refer to page

8 for installation procedure. (265V always requires a

subbase.) Install the subbase and wall sleeve at the

same time.

3. If the optional drain kit is to be employed (heat pumps

only), refer to page 7 before proceeding.

4. Recess the wall sleeve so that the louver is flush with the

outside of the building. (Do not recess if using the outdoor drain kit. See page 7.)

5. Level wall sleeve left to right, pitch it 1/4" bubble to the

outdoors and secure in wall with fasteners (as shown in

Figure C, page 12). A 5/16˝ hole is provided on each side,

2˝ down from the top and 2˝ in from the rear. Additional

holes may be required to firmly secure the wall sleeve.

CAUTION

!

Do not drill holes in the bottom of the wall sleeve as it

may cause leakage.

Where a subbase is used, secure the wall sleeve to the

subbase with the two clips provided (see subbase installation, page 8).

6. Be sure the wall sleeve is mechanically attached to the

wall for a proper seal. Use the louver frame for this purpose (see Figure B, page 12).

7. Caulk the wall sleeve to the wall opening on both the inside and outside perimeter. Be careful not to plug the weep

holes. Caulking should be a resilient, non-hardening type,

such as silicone.

Figure 8. Thin Wall Construction with Standard

Electrical Subbase

7"

16"

see note

Front

Panel

Power Supply Conduit

(Alternate Entry)

Note: Subbase is available in 3" or 4" height.

Leveling legs provide up to 1" additional height.

16"

Floor

Optional

Louver Frame

3

13

⁄4"

Wall Sleeve

Electrical Subbase

Subbase Side

Extension Piece

Outdoor

Louver

Caulk

Perimeter

Both

Indoors &

Outdoors

Figure 9. Thin Wall Construction without subbase

(208/230V only)

Optional

Conduit

Louver Frame

3

13

⁄4"

16"

Wall Sleeve

Min. 2 Supports

Field Supplied

Caulk

Perimeter

Both

Indoors &

Outdoors

7"

16"

Receptacle

by Others

Front

Panel

Floor

Note: If the wall sleeve will be floor mounted, locate

the receptacle to the side.

Outdoor

Louver

IM 812 / Page 9 of 28

Loading...

Loading...