Page 1

GARDEN WIZARD™

ELECTRIC TILLER

OWNER’S MANUAL

TM

MODEL 109312-01

IMPORTANT: Read and understand this manual before

assembling or operating this tiller. Improper use of tiller can

cause severe injury. Keep this manual for future reference.

Page 2

ELECTRIC TILLER

®

SAFETY

WARNINGS

WARNING: When using electric gardening appliances, basic

safety precautions should always

be followed to reduce the risk of

fire, electric shock, and personal

injury.

WARNING: This product contains chemicals known to the

State of California to cause cancer or birth defects, or other reproductive harm.

READ ALL INSTRUCTIONS

BEFORE OPERATING TILLER

1. Do not operate tiller near underground

electric cables, telephone lines, pipes,

or hoses. If in doubt contact your utility company to locate underground services. You may also contact the National One Call referral number, 1-888258-0808, for local contact information

concerning underground utilities.

2. Watch what you are doing. Use common sense. Do not operate tiller when

you are tired.

3. Only well-instructed adults should operate tiller. Never allow children to operate tiller.

4. Do not use the tiller for any job except

that for which it is intended.

5. Use only electrical voltage noted on

model plate of tiller.

WARNING: To reduce the risk

of electric shock, use only with an

extension cord intended for outdoor use, such as an extension

cord of cord type SW-A, SOW-A,

STW-A, STOW-A, SJW-A, SJOW-A,

SJTW-A, or SJTOW-A.

6. Extension Cord - Make sure your extension cord is in good condition. When using an extension cord, be sure to use one

heavy enough to carry the current your

product will draw. An undersized extension cord will cause a drop in line voltage resulting in loss of power and overheating. The table below shows the cor-

rect size to use depending on cord length

and nameplate ampere rating. If in doubt,

use the next heavier gage. The smaller

the gage number, the heavier the cord.

To reduce the risk of disconnection of

tiller cord from the extension cord during operation use the cord hitch and belt

clip described in this manual.

Total Length of Cord

Volts in Feet

120 25 50 100 150

Ampere

Rating AWG

10-12 16 16 14 12

7. Ground Fault Circuit Interrupter

(GFCI) protection should be provided

on the circuit(s) for use with this tiller.

Receptacles are available with built-in

GFCI protection and may be used for

additional measure of safety.

8. Avoid Dangerous Environments. Do

not operate tiller

• while under the influence of alcohol,

medication, or drugs.

• in rain or in damp or wet areas.

• where highly flammable liquids or

gases are present.

• if tiller is damaged, or not fully and

securely assembled.

9. Always wear eye protection which

meets or exceeds the requirements of

ANSI Z87.1.

10. Always use face or dust mask if operating tiller in dusty conditions.

11. Always dress properly. Wear the following clothing while using tiller:

• Use of rubber gloves and substantial

footwear is recommended.

•Wear protective hair covering to con-

tain long hair.

•Avoid wearing loose clothing or jew-

elry that could get caught in the rotating tines.

12. Thoroughly inspect area where the tiller

is to be used and remove all foreign

objects.

WHILE OPERATING TILLER

1. Stay alert. Use common sense while

operating tiller.

2. Be aware of extension cord while operating tiller. Be careful not to trip over cord.

Keep cord away from tines at all times.

3. Keep all children, animals, and bystanders away from tiller and extension

cord. Keep the area of operation clear

of all persons and pets.

4. Grip handlebar firmly with both hands.

Never operate tiller with one hand.

5. Be aware that tiller may unexpectedly

bounce upward or jump forward if the

tines should strike extremely hard, packed

soil, frozen ground, or buried obstacles

such as large stones, roots, or stumps.

6. Do not over reach. Maintain proper

footing and balance at all times.

7. Do not operate tiller on a slope that is

too steep for safe operation. When on

slopes, slow down and make sure you

have good footing.

8.

IMPORTANT:

by releasing the trigger lever.

9. Before starting tiller, make sure tines

are not touching foreign objects.

10. Do not allow hands or any body part or

clothing near the rotating tines.

11. Move tiller from one place to another

• with tiller stopped and unplugged.

• by rolling on attached wheel assem-

bly in the down “transport” position.

•by holding carrying handle. Never

use handlebars, tines, tine shaft, or

fender to carry tiller.

12. Do not abuse power cord. Never carry

tiller by power cord or yank it to disconnect from receptacle. Keep power

cord from heat, oil, and sharp edges.

13. Do not force tiller. It will do the job

better and with less likelihood of a risk

of injury at the rate for which it was

designed.

you can stop the tines

For more information, visit www.desatech.com

2

109363

Page 3

OWNER’S MANUAL

SAFETY

WARNINGS

Continued

MAINTENANCE AND

STORAGE OF TILLER

1. Unplug tiller from power source

• when not in use.

• before moving from one place to another.

• before servicing.

• before assembling or removing tines

or other attachments.

2. Inspect tiller before and after each use.

Check for any damage that may affect

operator safety or operation of tiller.

Check for broken or damaged parts. Do

not use tiller if damage affects safety

or operation. Have damage repaired by

authorized service center.

3. Maintain tiller with care.

•Never expose to rain or water.

•Keep handlebar dry, clean, and free

of oil or grease.

•Keep all screws and nuts tight.

• Inspect power cord often. If dam-

aged, have repaired by authorized

service center.

•Inspect extension cords often and

replace if damaged.

4. When servicing, use only identical replacement parts.

5. To reduce the risk of electric shock, this

tiller has a polarized plug (one blade is

wider than the other) and will require the

use of a polarized extension cord. The

tiller plug will fit into a polarized extension cord only one way. If the plug does

not fit fully into the extension cord, reverse the plug. If the plug still does not

fit, obtain a correct polarized extension

cord. A polarized extension cord will require the use of a polarized wall outlet.

This plug will fit into the polarized wall

outlet only one way. If the plug does not

fit fully into the wall outlet, reverse the

plug. If the plug still does not fit, contact

a qualified electrician to install the proper

wall outlet. Do not change the tiller plug,

extension cord receptacle, or extension

cord plug in any way.

6. Store idle tiller indoors - when not in

use, tiller should be stored in dry,

locked place - out of reach of children.

This manual is your guide to safe and proper

operation of this tiller. Save these in-

structions.

109363

3

For more information, visit www.desatech.com

Page 4

ELECTRIC TILLER

®

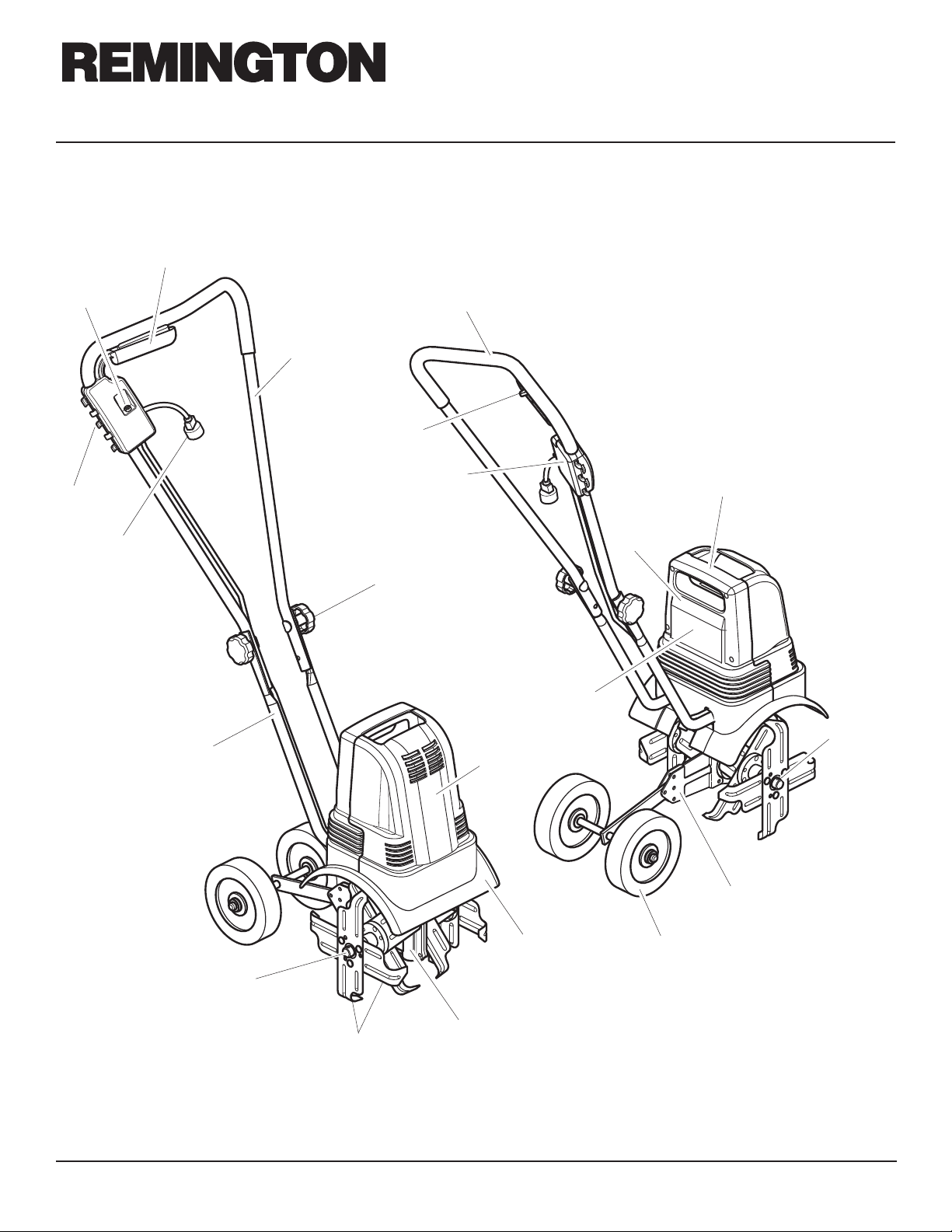

PRODUCT

IDENTIFICATION

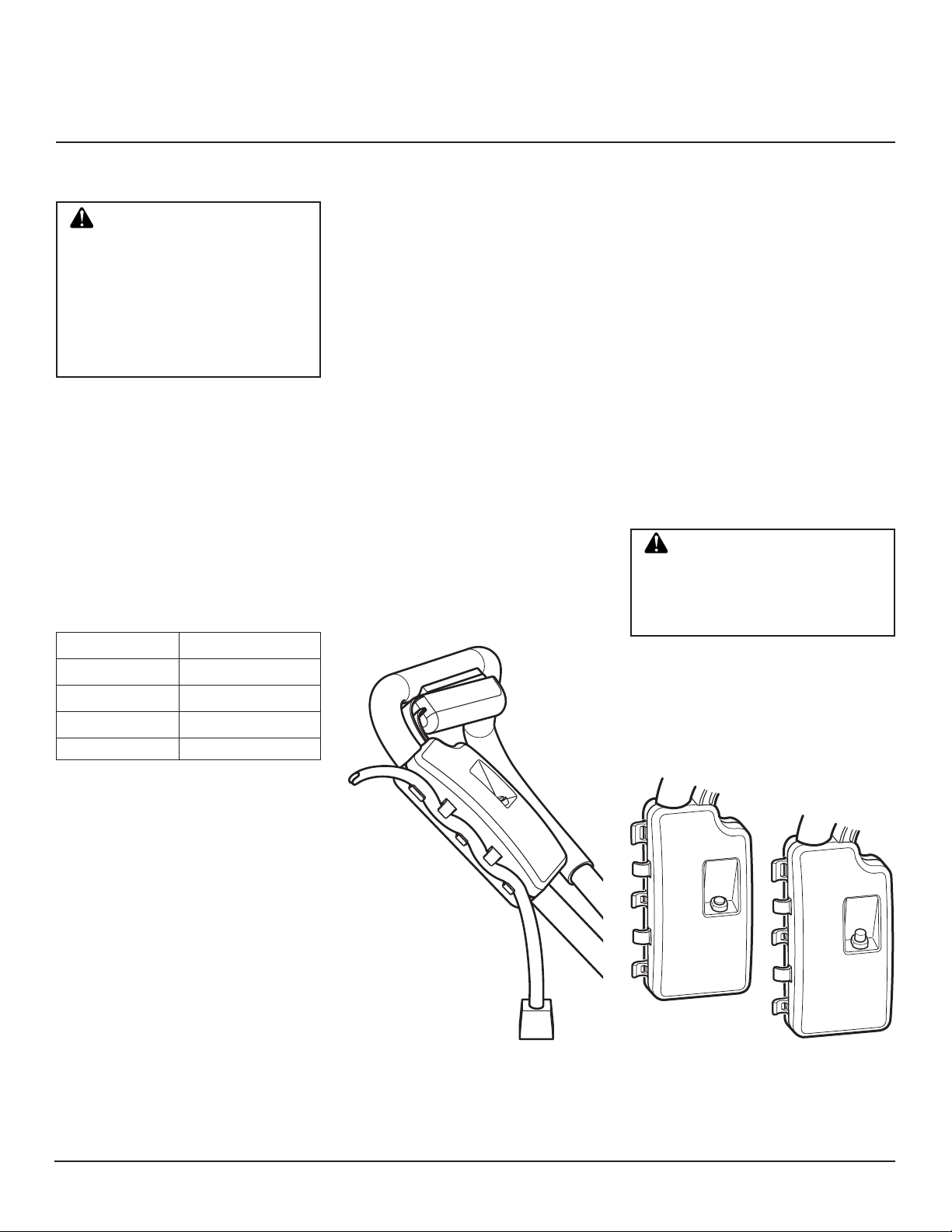

Trigger

Lever

Circuit

Breaker

Cord

Hitch

Power

Cord

Handlebar

Lock-off

Lever

Handlebar

Adjustment

Knob

Handle

Grip

Switch

Housing

UNPACKING

1. Remove all items from carton.

2. Check all items for any shipping damage. If you find any damage or if any

parts are missing, promptly inform

dealer where you bought tiller or call

1-800-858-8501.

Carrying

Handle

Rear

Housing

Lower

Handlebar

Support

Figure 1 - Electric Tiller

Tine

Shaft

Tines

Front

Housing

Transmission

Nameplate

Decal

Fender

Retaining

Clip

Wheel Mounting

Bracket

Wheel

Assembly

For more information, visit www.desatech.com

4

109363

Page 5

OWNER’S MANUAL

ASSEMBLY

UNFOLDING AND

ADJUSTING HANDLEBAR

Unfolding Handlebar

1. Loosen handlebar adjustment knobs.

Rotate the handlebar into the operating position (see Figure 2). Do not force

handlebar. If there is binding, continue

to loosen adjustment knobs. Be careful

not to pinch power cord between

handlebar and lower handlebar support.

2. Tighten handlebar adjustment knobs.

Handlebar

Adjusting Height of Handlebar

The handlebar has two possible height settings. The tiller is shipped with the handlebar mounted in the standard height or lowest

position. If this height is too short, adjust the

height of the handlebar to the extended

height or highest position.

1. Loosen and remove handlebar adjustment knobs, washers, and saddle bolts

from handlebar.

2. Position handlebar so that the bottom

holes in the handlebar line up with the

holes in the lower handlebar supports

(see Figure 3). Insert the saddle bolts

through the holes and reinstall the

washers and handlebar knobs.

3. Tighten handlebar adjustment knobs.

Saddle

Bolt

Standard Height

Adjustment Hole

Folding Handlebar For Storage

1Loosen handlebar adjustment knobs.

Rotate the handlebar forward and down

over the tiller housing (see Figure 4).

Do not force handlebar. If there is binding, continue to loosen knobs. Be careful not to pinch power cord between

handlebar and lower handlebar support.

2Tighten handlebar adjustment knobs.

Handlebar

Handlebar

Adjustment

Knob

Handlebar

Adjustment

Knob

Lower

Handlebar

Support

Figure 2 - Unfolding Handlebar

Handlebar

Adjustment

Knob

Washer

Extended Height

Adjustment Hole

Figure 3 - Adjusting Handlebar Height

Lower

Handlebar

Support

Figure 4 - Folding Handlebar Down

109363

Continued

5

For more information, visit www.desatech.com

Page 6

ELECTRIC TILLER

®

ASSEMBLY

Continued

ADJUSTING WHEEL

ASSEMBLY

Adjusting the Wheel Assembly

for Transport

1. Remove retaining clip and clevis pin

from wheel assembly mounting bracket

(see Figure 5).

2. Rotate the wheel assembly down so that

the hole in the wheel assembly lines up

with the center hole in the mounting

bracket as shown in Figure 6.

3. Insert the clevis pin through the hole as

shown in Figure 6, and insert the retaining clip in the clevis pin. The wheels are

now mounted in the transport position.

Clevis Pin

Retaining Clip

Figure 5 - Removing Retaining Clip and

Clevis Pin

Adjusting the Wheel Assembly

for Tilling

1. Remove the retaining clip from the

clevis pin and remove the clevis pin

from the mounting bracket and wheel

assembly.

2. Rotate the wheel assembly up and forward as shown in Figure 7 until the hole

in the wheel assembly lines up with the

upper hole in the mounting bracket.

3. Insert the clevis pin through the aligned

holes and insert the retaining clip into

the clevis pin. The wheels are now

mounted in the tilling position.

Figure 7 - Adjusting Wheel Assembly to

Tilling Position

TINE REMOVAL AND

INSTALLATION

WARNING: Always unplug the

tiller before placing hands near

the tines. Always wear gloves to

protect your hands from the sharp

edges of the tines.

IMPORTANT: The tiller has 4 different sets of tines. For proper

performance, the tines must always be installed correctly as

shown in Figure 8. When assembled correctly, the angled cutting edge of tines should rotate

towards the front of the tiller. The

blades of all the tines should be

pointing toward the transmission.

The tine hubs of the inner and

outer tine sets should be facing

each other as shown in Figure 8.

Tine Removal and Installation

1. Remove the retaining clips from the end

of the tine shaft.

2. Remove outer tine set from tine shaft.

3. Remove inner tine set from tine shaft.

4. Reinstall the retaining clips onto tine shaft

to prevent them from being misplaced.

5. Reverse above steps to install tines.

Tine Hubs

Toward Transmission

Figure 6 - Adjusting Wheel Assembly to

Transport Position

For more information, visit www.desatech.com

Retaining Clip

Tine

Blade

Outer

Tine Set

Tine Shaft

Cutting

Edge

Inner Tine Set

Tine Hub

Rotation of Tines

During Operation

Figure 8 - Tine Removal and Installation

6

109363

Page 7

OWNER’S MANUAL

OPERATING TILLER

WARNING: Read and understand this owners manual before

operating this tiller. Make certain

you read and understand all

Safety Warnings

3. Improper use of this tiller can

result in severe injury or death

from fire, electrical shock, or body

contact with moving parts.

EXTENSION CORDS

Always use proper extension cords with this

tiller. Use only extension cords marked for

outdoor use. The cord must be marked with

suffix W or W-A following the cord type

designations.

Use proper sized cord with this tiller. Cord

must be heavy enough to carry current

needed. An undersized cord will cause voltage drop at tiller. Tiller will lose power and

overheat. Follow cord size requirements

listed below.

Cord Length AWG Cord Size

Keep cord away from rotating tines. Inspect

cord often. Replace damaged cords.

Example:

25 feet 16 AWG

50 feet 16 AWG

100 feet 14 AWG

150 feet 12 AWG

on pages 2 and

SJTW-A or SJTW.

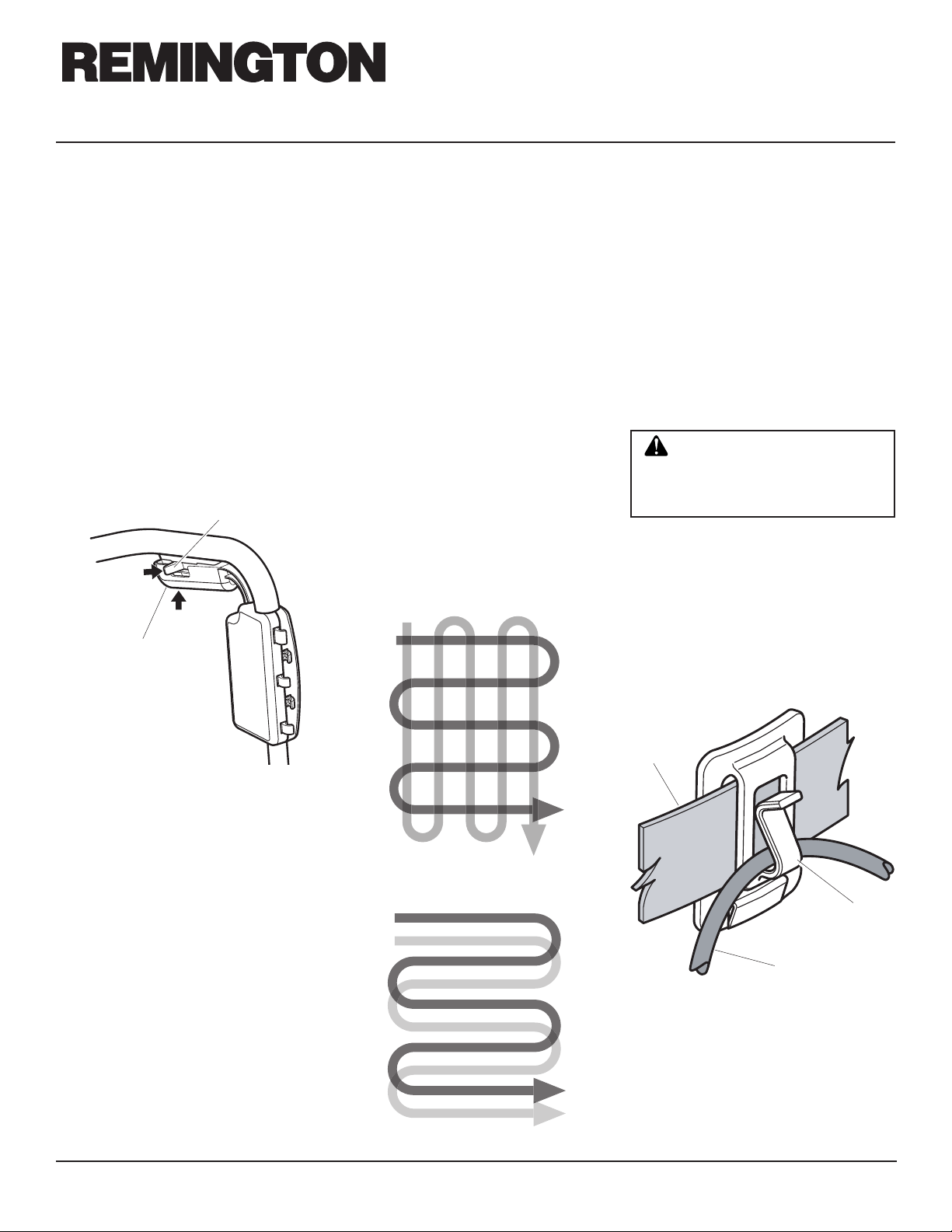

RETAINING EXTENSION

CORD

The switch housing has an extension cord

hitch made from a series of alternating hooks

(see Figure 9). This feature can be used to

secure the receptacle end of the extension

cord to the tiller handle to prevent accidental

disconnection from the power cord. A belt

clip is also included to help manage the cord

by keeping it at the users side and away from

the tiller tines.

Securing Extension Cord to

Tiller

1. Start at approximately 6 inches from

receptacle end of extension cord and

weave the cord between the hooks on

the switch housing as shown in Figure

9, so that the receptacle is hanging below the switch housing.

2. Begin weaving the extension cord on

top of the bottom hook and alternate

under and over hooks so that the cord

is ultimately on top of the last hook.

3. Plug the tiller power cord into the extension cord.

CIRCUIT BREAKER

PROTECTION

This tiller is equipped with a circuit breaker

located in the top of the switch housing (see

Figure 10). The circuit breaker provides

over-current protection to the tiller motor

should the tines become jammed or locked

by a stone, root, or other obstruction.

If the circuit breaker should trip during use,

the white circuit breaker button will pop up

out of the case and the electric motor and the

tines will stop rotating.

Resetting the Breaker

1. Fully release the trigger lever.

2. Unplug the tiller power cord from the

extension cord.

3. Dislodge or remove any obstacles from

the tines which caused the tines to jam.

WARNING: Always unplug the

tiller before placing hands near

the tines. Always wear gloves to

protect your hands from the sharp

edges of the tines.

4. Press the white circuit breaker button

back into the housing to reset (see Figure 10). The button should stay depressed when released. Plug the tiller

power cord back into the extension cord.

5. Firmly grasp the tiller grip area on the

handlebar, and resume tilling.

109363

Figure 9 - Securing Extension Cord to

Tiller

7

For more information, visit www.desatech.com

Circuit

Breaker

Set

Figure 10 - Circuit Breaker Button

Circuit

Breaker

Tripped

Continued

Page 8

ELECTRIC TILLER

®

OPERATING TILLER

Continued

STARTING TILLER

1. Grasp grip area on handlebar firmly

with both hands.

2. Use your thumb to slide the lock-off

lever all the way to the right (see Figure 11). This releases the trigger lever.

3. Squeeze the trigger lever all the way in

(see Figure 11). The motor will start

and the tines will begin to rotate. Once

the tiller is started, the lock-off lever

can be released.

4.

IMPORTANT:

the trigger lever. The motor will shut

off and the tines will stop rotating. The

trigger lever is now locked off again.

Trigger

Lever

To stop the tiller, release

Lock-off Lever

1

2

BASIC TILLER OPERATION

Use the tiller for breaking sod, preparing

seed beds, and for cultivating gardens and

flower beds. The tiller can also dig small

holes for planting saplings or potted plants.

Let the tiller do most of the work. The tines

will pull the tiller forward during operation.

By pulling tiller back towards yourself, the

tines will dig deeper and more aggressively.

For breaking sod or deep tilling, allow the tines

to pull the tiller forward to the end of your

arm’s reach, then firmly pull the tiller back

towards you. By repeatedly allowing the tiller

to move forward and then pulling the tiller

back to you, the tiller will be most effective.

If the tiller digs deep enough to stay in one

spot, gently rock the tiller side to side to start

the tiller moving forward again.

For preparing seed beds, we recommend

using one of the tilling patterns shown in

Figure 12.

Tilling Pattern One - Make two passes over

area to be tilled, the second at a right angle

to the first.

EXTENSION CORD

MANAGEMENT

As with any electric lawn and garden appliance, you will develop a common sense approach to keeping the extension cord in a safe

and logical location as you are using the tiller.

A convenient belt clip is included with the

tiller to enable you to attach the extension

cord to your waist and ease cord management (see Figure 13). It is recommended

that the belt clip and extension cord be

attached to your right side. Maintain enough

slack between the tiller and the belt clip for

easy maneuvering.

WARNING: Be aware of extension cord while operating tiller. Be

careful not to trip over cord. Keep

cord away from tines at all times.

If tilling rows, start with the row that is closest

to the household outlet you are using as an

electrical power source. Begin tilling the row

in a direction which will keep the extension

cord on your right side. When the tiller reaches

the end of the row, turn to position the tiller in

the opposite direction for the next row. Remember, keeping the extension cord behind

you and on your right side will make it easier

to manage the extension cord.

Figure 11 - Lock-off Lever and Trigger

Lever

Tilling Pattern Two - Make two passes over

area to be tilled, the second overlapping the

first.

Figure 12 - Suggested Tilling Patterns

For more information, visit www.desatech.com

Belt

Outer

Hook

Extension Cord

Figure 13 - Extension Cord Belt Clip

8

109363

Page 9

OWNER’S MANUAL

OPERATING TILLER

Continued

CLEARING TINES OF

FOREIGN OBJECTS

During use, a stone or root could become

lodged in the tines, or tall grass or weeds

may become wrapped around the tine shaft.

To clear the tines, release the trigger lever.

Unplug the tiller, and dislodge or remove

any obstacles from the tines or tine shaft.

WARNING: Always unplug the

tiller before placing hands near

the tines. Always wear gloves to

protect your hands from the sharp

edges of the tines.

To ease removal of tall grass or weeds that

are wrapped around the tine shaft, remove

one or more of the tines from the tine shaft.

See Tine Removal and Installation, page 6.

When you have cleared the tines, reinstall

tines onto tine shaft. Plug the tiller power

cord into the extension cord. Firmly grasp

the grip area of the handlebar with both

hands and resume normal tilling operation.

CLEANING AND

MAINTENANCE

WARNING: Unplug tiller from

power source before cleaning or

servicing. Severe injury or death

could occur from fire, electrical

shock, or body contact with moving tines.

WARNING: When cleaning

tiller:

• Do not submerge tiller in any

liquids.

• Do not use products that

contain ammonia, chlorine, or

abrasives.

• Do not use chlorinated clean-

ing solvents, carbon tetrachloride, kerosene, or gasoline.

CLEANING TILLER

1. To clean front and rear cover and

fender, use a soft cloth dampened with

a mild soap and water mixture. Do not

spray or pour water directly onto the

front or rear cover. Wipe the front and

rear covers and fender with the dampened cloth.

2. To remove soil and debris from the tines

and transmission, use a stiff brush or a

dampened cloth. Do not spray or pour

water directly onto tiller.

3. For easier cleaning, remove the tines

from the tine shaft. See Tine Removal

and Installation, page 6.

4. Once cleaned, wipe the tine shaft dry

and apply a light coat of oil to the shaft

before reinstalling the tines.

CHECKING TRANSMISSION

LUBRICANT

1. Unplug tiller from power source.

2. Locate the grease filler screw located

above the tine shaft on the right side of

the transmission (see Figure 14).

3. Lay the tiller on its left side. Remove

the right side tine sets for easy access

to grease filler screw. See Tine Removal

and Installation, page 6.

4. Clean the transmission to prevent dirt and

debris from entering the transmission.

5. Using a Phillips head screwdriver, remove the grease filler screw from the

transmission case.

6. If grease is not visible in the hole, add

a high-quality, automotive-grade, petroleum-based grease using standard

grease gun. Place the nozzle of the

grease gun firmly against the rim of the

hole and add grease until it begins to

seep out around the edge of the nozzle.

7. Reinstall the grease filler screw and

wipe away any excess grease.

8. Reassemble the tine sets. See Tine Re-

moval and Installation, page 6.

Grease Filler

Screw

Figure 14 - Grease Filler Screw

109363

OTHER SUGGESTED

LUBRICATION POINTS

Handlebar Adjustment Knobs: Occa-

sionally spray a silicone type lubricant

around the saddle bolts.

Tine Shaft: After each use, remove the

tines, clean the tine shaft with fine sandpaper and apply a light coat of oil to the tine

shaft. This will make future tine installation

and removal easier.

9

For more information, visit www.desatech.com

Page 10

®

ELECTRIC TILLER

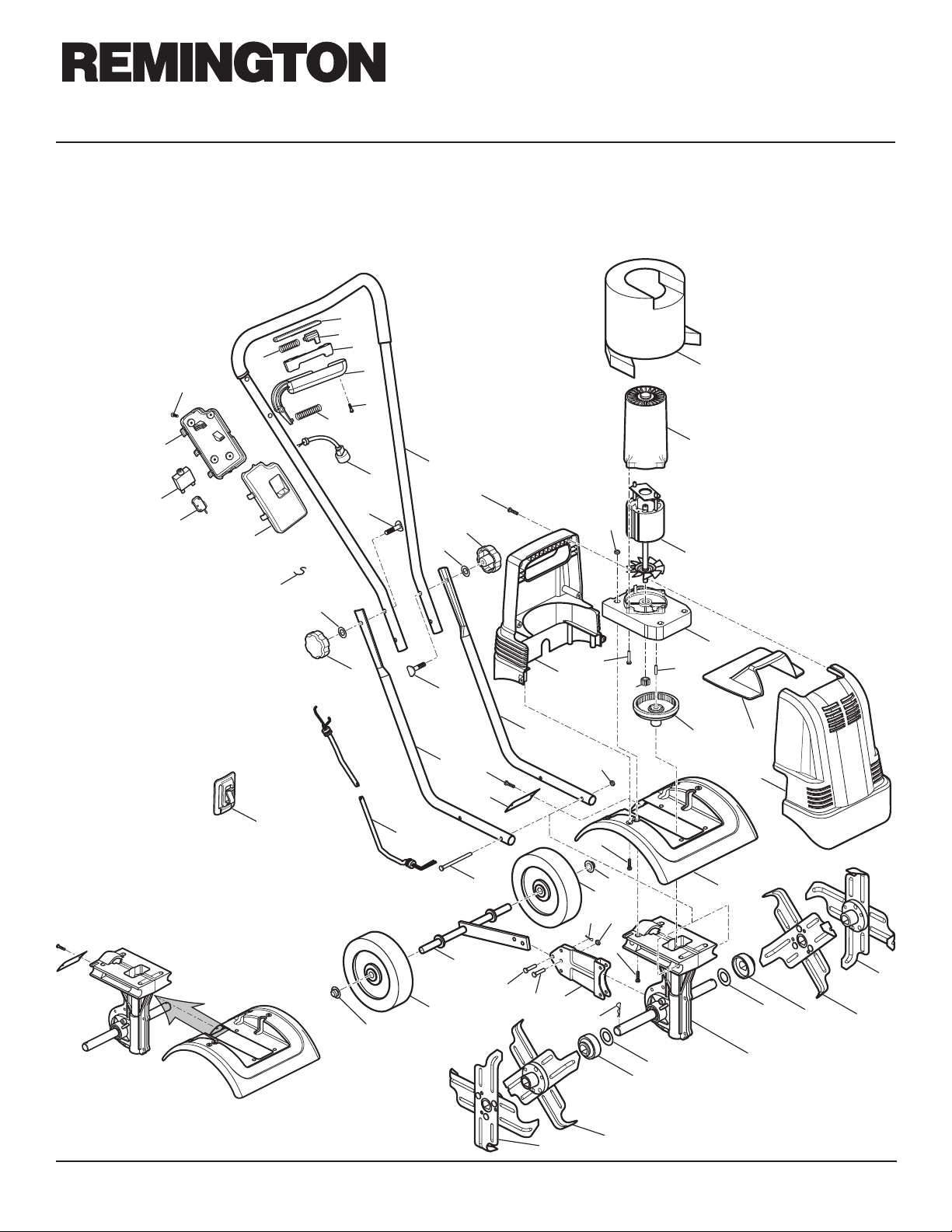

ILLUSTRATED PARTS BREAKDOWN

ELECTRIC TILLER

Model 109312-01

22

21

23

48

28

26

19

27

20

25

48

24

17

18

48

30

31

32

36

12

47

11

45

44

32

31

42

29

40

30

33

41

53

52

34

37

16

46

39

35

48

38

43

13

47

40

47

10

42

50

51

49

9

15

14

8

5

6

7

4

Assembling Fender to

Transmission

For more information, visit www.desatech.com

10

6

7

2

3

1

109363

Page 11

OWNER’S MANUAL

PARTS LIST

This list contains replaceable parts used in your tiller. When ordering parts, be sure to

provide the correct model number, then the part number and description of the desired part.

ELECTRIC TILLER

Model 109312-01

KEY PART

NO. NO. DESCRIPTION QTY.

1 109384-01 Transmission Assembly 1

2 109342-01 Tine Assembly 1

3 109342-04 Tine Assembly 1

4 109342-02 Tine Assembly 1

5 109342-03 Tine Assembly 1

6 109349-01 Felt Washer 2

7 109339-01 Dust Cap 2

8 109332-01 Fender 1

9 109333-01 Bearing Plate Assembly 1

10 H5C4-20C Bolt, Hex Head .25-20 x 2.5" 4

11 109385-01 Motor Assembly 1

12 076014 Motor Can Assembly 1

13 059045 Screw, Tap Pan Head 4

14 109343-01 Front Housing 1

15 109345-01 Air Dam 1

16 108444-01 Handle Support, Left 1

17 108443-01 Upper Handle Tube Assembly 1

18 099829-05 Shrouded Cord 1

19 107729-01 Micro Switch 1

20 109360-01 Lock Off Side Cover 1

21 109355-01 Lock Off Slide 1

22 109354-01 Stop Block 1

23 107694-01 Lock Off Spring 1

24 109357-01 Trigger Spring 1

25 109353-01 Trigger Lever 1

26 22616013 Circuit Breaker 1

27 109351-01 Upper Trigger Housing 1

KEY PART

NO. NO. DESCRIPTION QTY.

28 109352-01 Lower Trigger Housing 1

29 109347-01 Power Cord 1

30 109367-01 Bolt, Saddle Head .312-18 x 1.5" 2

31 109366-01 Handle Knob 2

32 WLE-5 External Tooth Lock Washer 2

33 108444-02 Handle Support, Right 1

34 H5C4-40C Bolt, Hex Head .25-20 x 5" 2

35 109344-01 Rear Housing 1

36 109341-01 Foam 1

37 109368-01 Clevis Pin .25 x 1" 1

38 109369-01 Retaining Clip 1

39 109356-01 Wheel Assembly Bracket 1

40 109374-01 Wheel 2

41 109358-01 Axle Assembly 1

42 109377-01 Nut Cap 2

43 109365-01 Retaining Clip 2

44 19724000 Cable Tie 4

45 109361-01 Belt Clip 1

46 H5C4-8C Bolt, Hex Head .25-20 x 1" 1

47 NEC-4C Nut, Hex Lock .25-20 7

48 107708-01

49 109336-01 Sprocket Gear 1

50 059606 Drive Gear 1

51 075676 Sprocket Roller Bearing 1

52 109350-01 Fender Plate 1

53 103708-01 Screw, PPH TPG "B" 2

Screw, Tap Pan Head

16

109363

11

For more information, visit www.desatech.com

Page 12

ELECTRIC TILLER

®

TROUBLESHOOTING

Note:

For additional help, visit our tech-

nical service web site at

www.desatech.com.

OBSERVED FAULT

Motor does not run when you squeeze trigger lever

Motor runs, but tines do not move

Tiller smokes

TECHNICAL

SERVICE

You may have further questions about assembling, operating, or maintaining this

tiller. If so, contact our Technical Service

Department at 1-800-858-8501.

You can also visit our technical service web

site at www.desatech.com.

WARNING: Unplug tiller from power source before servicing. Severe

injury or death could occur from fire, electrical shock, or body contact

with moving tines.

POSSIBLE CAUSE

1. Lock-off lever not pressed to release trigger lever

2. Extension cord connection is loose

3. Circuit breaker is tripped on tiller

4. Household circuit breaker is tripped on

open line fuse

5. Bad motor brushes

6. Open wiring on tiller

Gear train failure

Tiller damaged. Do not use tiller

REPAIR SERVICE

Note:

Only use original replacement parts.

This will protect your warranty coverage for

parts replaced under warranty.

Each authorized service center is independently owned and operated. For additional

service center or warranty information, call

1-800-858-8501 or visit our technical service web site at www.desatech.com.

REPLACEMENT PARTS

For original replacement parts, contact authorized dealers of this product or your

nearest parts central listed below.

REMEDY

1. Fully depress lock-off lever before

squeezing trigger lever (see Starting

Tiller, page 8)

2. Check cord connections

3. Check circuit breaker on tiller (see Cir-

cuit Breaker Protection, page 7)

4. Check circuit breaker or line fuse (see

Circuit Breaker Protection, page 7)

5. See authorized service center

6. See authorized service center

See authorized service center

See authorized service center

WARRANTY SERVICE

If tiller requires warranty service, return it to

nearest authorized service center. You must

show proof of purchase. If faulty materials or

workmanship caused damage, we will repair

or replace tiller without charge.

mal wear, misuse, abuse, neglect, or accidental damage is not covered under warranty.

Note:

NON-WARRANTY SERVICE

If tiller requires service, return it to nearest

authorized service center. Repairs will be

billed to you at regular repair list prices.

Nor-

For more information, visit www.desatech.com

12

109363

Page 13

OWNER’S MANUAL

PARTS DEALERS

Ray’s Portable Heater Service

3191 Myers Road

Camino, CA 95709-9550

530-644-7716

Baltimore Electric

5 Manila Drive

Hamden, CT 06514-0322

203-248-7553

1-800-397-7553

Eckley’s Small Engine

31617 Spruce Drive

Eustis, FL 32726-9592

352-357-6764

Parts Company of America

1657 Shermer Road

Northbrook, IL 60062-5362

708-498-5900

1-800-323-0620

www.grainger.com

Portable Heater Parts

342 North County Road 400 East

Valparaiso, IN 46383-9704

219-462-7441

1-800-362-6951

www.portableheaterparts.com

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

franktalk@aol.com

Lyons & Lyons Sales Co. Inc.

Glen Arm Road

Glen Arm, MD 21057-9454

410-665-6500

1-800-333-5966

lyonsco@erols.com

Master Part Distributors

1251 Mound Avenue NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

www.masterparts.net

Hance Distributors, Inc.

12795 16th Avenue North

Plymouth, MN 55441-4556

763-559-2299

www.hanceco.com

Automotive Equipment Service

3117 Holmes

Kansas City, MO 64109-1716

816-531-9144

1-800-843-3546

www.aes-lawnparts.com

Bowden Electric Motor Service

1681 S. Wesleyan Blvd.

Rocky Mount, NC 27803

252-446-4203

East Coast Energy

10 East Route 36

West Long Branch, NJ 07764-1501

1-800-755-8809

Forrest Lytle and Sons, Inc.

740 West Galbraith Road

Cincinnati, OH 45231-6002

513-521-1464

Bortz Chain Saw Shop

Road #2, Box 64A

Oley, PA 19547-9412

610-987-6452

21st Century

2950 Fretz Valley Road

Perkasie, PA 18944-4034

215-795-0400

1-800-325-4828

Laportes

2444 N 5th Street

Hartsville, SC 29550-7704

843-332-0191

MTA Distributors

555 Hickory Hills Blvd.

Nashville, TN 37189-9244

615-299-8777

1-800-264-0225

Webbs Appliance Center

1519 Church Street

Nashville, TN 37203-3004

615-329-4079

1-800-899-4079

Industrial Hardware

4109 Bainbridge Blvd.

Chesapeake, VA 23324-1403

804-543-2232

1-800-788-0008

catatem@erols.com

Mills Lawn and Garden

928 Commonwealth Place

Virginia Beach, VA 23464

757-361-9293

www.mills-parts.com

Tuco Industrial Products

5223 180th Street SW

Suite 4A-1

Lynnwood, WA 98037-4506

425-743-9533

1-800-735-1268

www.tucoheat.com

109363

13

Continued

For more information, visit www.desatech.com

Page 14

ELECTRIC TILLER LIMITED WARRANTY

Always specify model number when writing the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written warranty. We make

no other warranty, expressed or implied.

DESA Specialty Products™ warrants this electric tiller and any parts thereof, to be free from defects in material and workmanship for two years (90 days

for reconditioned unit) from the date of first purchase from an authorized dealer, provided that the product has been properly maintained and operated

in accordance with all applicable instructions. This warranty is valid for 90 Days from the date of purchase from an authorized dealer if the tiller is used

for commercial, industrial, or rental use. The bill of sale or proof of purchase must be presented at the time a claim is made under this warranty.

This warranty is extended only to the original retail purchaser. This warranty covers only the parts and labor required to restore this tiller to its proper

operating condition. Warranty parts must be obtained through factory authorized dealers and service centers for this product. These dealers and service

centers will provide original factory replacement parts. Failure to use original factory replacement parts voids this warranty.

This warranty does not apply to parts that are not in original condition because of normal wear and tear, or parts that fail or become damaged as a

result of misuse, accident, lack of proper maintenance, tampering, or alteration. Travel, handling, transportation, and incidental costs associated with

warranty repairs are not reimbursable under this warranty and are the responsibility of the owner.

To the full extent allowed by the law of the jurisdiction that governs the sale of the product, this express warranty excludes any and all other expressed

warranties and limits the duration of any and all implied warranties, including warranties of merchantability and fitness for a particular purpose to

two years from the date of first purchase, and DESA Specialty Products’™ liability is hereby limited to the purchase price of the product and DESA

Specialty Products™ shall not be liable for any other damages whatsoever including indirect, incidental, or consequential damages.

Some states do not allow limitation of how long an implied warranty lasts or an exclusion or limitation of incidental or consequential damages, so

the above limitation of damages may not apply to you.

This warranty provides the original purchaser with specific rights. For information regarding those rights, please consult the applicable state laws.

P.O. Box 90004

Bowling Green, KY 42102-9004

www.desatech.com

Industries of Canada, Inc.

2220 Argentia Road

Unit #4

Mississauga, Ontario

L5N 2K7

905-826-8010

FAX 905-826-8236

Page 15

TM

GARDEN WIZARD™

MANUAL DEL PROPIETARIO DEL

CULTIVADOR ELÉCTRICO

MODELO 109312-01

IMPORTANTE: Antes de ensamblar y operar este cultivador

lea y entienda este manual. El uso inadecuado de este

cultivador puede ocasionar lesiones graves. Guarde este

manual para futuras referencias.

Page 16

®

CULTIVADOR ELÉCTRICO

ADVERTENCIAS

SOBRE

SEGURIDAD

ADVERTENCIA: Cuando use

electrodomésticos para jardinería, deben acatarse las precauciones básicas sobre seguridad

para reducir el riesgo de incendio, sacudida eléctrica, o lesión

al personal.

ADVERTENCIA: Este producto contiene substancias químicas

conocidas en el estado de

California como causas de cáncer

o de defectos al recién nacido o de

otros daños de reproducción.

LEA TODAS LAS

INSTRUCCIONES ANTES DE

OPERAR EL CULTIVADOR

1. No opere el cultivador cerca de elementos subterráneos como cables eléctricos,

líneas telefónicas, tuberías o mangueras.

Si tiene duda sobre la ubicación de estos elementos, póngase en contacto con

su compañía de servicios. Para obtener

información local de los servicios subterráneos puede también ponerse en contacto con el número de consulta Llamada Nacional Unica al 1-888-258-0808.

2. Observe lo que está haciendo. Use el

sentido común. No opere el cultivador

cuando esté cansado(a).

3. El cultivador debe ser manejado solamente por adultos bien instruidos. No deje que

los niños manejen el cultivador.

4. No use el cultivador para ningún otro trabajo excepto para el que fue destinado.

5. Use solamente el voltaje eléctrico indicado en la placa del modelo del cultivador.

ADVERTENCIA: Para reducir

el riesgo de sacudida eléctrica,

use solamente cordón de extensión destinado para uso exterior,

por ejemplo cordón de extensión

del tipo SW-A, SOW-A, STW-A,

STOW-A, SJW-A, SJOW-A,

SJTW-A ó SJTOW-A.

6. Cordón de extensión _ Asegúrese que

su cordón de extensión esté en buenas

condiciones. Cuando lo use, esté seguro de utilizar uno suficientemente grueso para que transporte la corriente absorbida por su máquina. Un cordón de

extensión subdimensionado ocasionará caídas de voltaje en la línea lo cual

producirá pérdidas de potencia y

sobrecalentamiento. La tabla a continuación le indica el tamaño correcto de

cordón que debe usar de acuerdo a la

longitud de la extensión y a la capacidad nominal de corriente indicada en

la placa. Si tiene duda use el calibre

mayor siguiente. A menor número de

calibre, más grueso es el cordón. Para

reducir, mientras funciona, el riesgo de

desconexión del cordón del cultivador,

use el gancho del cordón y la presilla

de la correa descritas en este manual.

Longitud total del

Voltaje cordón en pies

120 25 50 100 150

Capacidad

en amperios AWG

10-12 16 16 14 12

7. El circuito a usarse con el cultivador debe

tener, como protección, cortacircuitos de

falla a tierra (GFCI). Se disponen de

tomacorrientes con protección GFCI incorporada que pueden utilizarse como

medida adicional de seguridad.

8. Evite ambientes peligrosos. No opere

el cultivador:

• Cuando se halle bajo la influencia del

alcohol, medicamentos o drogas.

• En la lluvia o en áreas húmedas o

mojadas.

• En sitios donde están presentes líqui-

dos o gases altamente inflamables.

• Si el cultivador está dañado o no está

ensamblado completamente y bien.

9. Use siempre protección visual que

cumpla o exceda los requerimientos de

ANSI Z 87.1

10. Si opera el cultivador en condiciones

de polvo, use siempre máscara facial o

para polvo.

11. Vístase siempre adecuadamente. Mientras utilice el cultivador se recomienda

usar lo siguiente:

• Guantes de caucho y calzado robusto.

•Para sostener cabellos largos use un

cobertor y protector de cabellos.

• Evite usar ropas flojas o joyas que

podrían quedar atrapadas en las púas

giratorias.

12. Inspeccione completamente el área en

donde va a usarse el cultivador y retire

cualquier objeto extraño.

MIENTRAS OPERA EL

CULTIVADOR

1. Manténgase alerta. Use el sentido común mientras opera el cultivador.

2. Esté atento al cordón de extensión

mientras opera el cultivador. Tenga cuidado de no tropezarse con el cable.

Mantenga siempre al cordón de extensión lejos de las púas.

3. Mantenga lejos del cultivador y del

cordón de extensión a todos los

niños(as), animales y curiosos. Mantenga el área de operación libre de personas y mascotas.

4. Agarre firmemente el manubrio con

ambas manos. Nunca opere el cultivador con una mano.

5. Esté alerta ya que el cultivador puede

rebotar inesperadamente hacia arriba o

saltar hacia adelante si las púas golpean

un suelo extremadamente duro,

compactado, congelado o con obstáculos enterrados como piedras grandes,

raíces o tocones.

6. No sostenga la máquina extendiendo

mucho los brazos. Mantenga siempre

el equilibrio y la estabilidad en los pies.

7. Por seguridad no opere el cultivador en

una pendiente demasiado empinada.

Cuando esté en pendientes, disminuya

la velocidad y asegúrese que sus pies

estén bien estables.

8.

IMPORTANTE:

tenerse soltando la palanca de

accionamiento.

9. Antes de arrancar el cultivador, asegúrese que las púas no estén tocando objetos extraños.

10. Tenga cuidado en no acercar las manos, cualquier parte del cuerpo o la ropa

a las púas giratorias.

Las púas pueden de-

Para más información, visite www.desatech.com

16

109363

Page 17

MANUAL DEL PROPIETARIO

ADVERTENCIAS

SOBRE

SEGURIDAD

Continuación

11. Para mover el cultivador de un lugar a

otro:

• Apáguelo y desenchúfelo.

• Hágalo rodar utilizando el conjunto

de ruedas acopladas y en posición

hacia abajo o de “transporte”.

• Sostenga el mango de transporte.

Nunca use los manubrios, púas, eje

de las púas o guardabarros para transportar el cultivador.

12. No maltrate el cordón de alimentación.

Nunca transporte el cultivador

halándolo de este cable ni tampoco lo

hale para desconectarlo del

tomacorriente. Mantenga el cordón de

alimentación lejos del calor, aceites o

de bordes cortantes.

13. No fuerce al cultivador. Este hará mejor el trabajo y con menor probabilidad de riesgo de una lesión si lo usa a

la velocidad para la que fue diseñada.

MANTENIMIENTO Y

ALMACENAMIENTO DEL

CULTIVADOR

1. Desenchufe el cultivador de la fuente

de alimentación

• Cuando no se lo use.

• Antes de moverlo de un lugar a otro.

• Antes de darle servicio.

• Antes de ensamblarlo, o antes de retirar

las púas giratorias u otros aditamentos.

2. Inspeccione el cultivador antes y después

de cada uso. Revise cualquier daño que

pueda afectar la seguridad del operador

o el funcionamiento del cultivador. Revise partes rotas o dañadas. No use el

cultivador si el daño afecta a la seguridad

o a la operación. Haga reparar el daño en

un centro de servicio autorizado.

3. Mantenga cuidadosamente al cultivador

• Nunca lo exponga a la lluvia o al

agua.

• Mantenga el manubrio seco, limpio

y libre de aceite o grasa.

•Mantenga todos los tornillos y

tuercas ajustadas.

• Inspeccione a menudo el cordón de

alimentación. Si está dañado hágalo

reparar en un centro de servicio autorizado.

• Inspeccione a menudo los cordones

de extensión y reemplácelos si están

dañados.

4. Cuando realice servicio, use solamente partes de repuesto idénticas.

5. Para reducir el riesgo de sacudida eléctrica, este cultivador tiene un enchufe

polarizado (una hoja es más ancha que

la otra) por lo que se requerirá el uso

de un cordón de extensión polarizado.

El enchufe del cultivador se adaptará

al cable de extensión polarizado solamente de una forma. Si el enchufe no

se acopla completamente en el cable de

extensión, invierta el enchufe. Si el enchufe aún no se adapta, consiga el correcto. Un cordón de extensión polarizado requerirá el uso de un

tomacorriente de pared polarizado. Esta

clavija se adaptará al tomacorriente

polarizado solamente de una forma. Si

el enchufe no se adapta completamente al tomacorriente de pared invierta el

enchufe. Si aún así el enchufe no se

adapta, póngase en contacto con un

electricista calificado para instalar el

tomacorriente de pared apropiado. No

cambie de ninguna forma el enchufe del

cultivador, la toma o el enchufe del cordón de extensión.

6. Guarde el cultivador inactivo bajo techo.cuando no lo use, el cultivador debe ser

almacenado en un lugar seco y bajo llave- fuera del alcance de los niños.

Este manual es su guía para una operación

segura y apropiada de este cultivador. Guar-

de estas instrucciones.

109363

17

Para más información, visite www.desatech.com

Page 18

®

CULTIVADOR ELÉCTRICO

IDENTIFICACIÓN

DEL PRODUCTO

Palanca de

accionamiento

Disyuntor

Gancho

del cordón

Cordón de

alimentación

Manubrio

Palanca de traba

en apagado

Caja del

interruptor

Perilla de

regulación

del manubrio

Agarradera

del mango

DESEMPAQUE

1. Retire todos los elementos del cartón.

2. Revise cualquier daño que en el transporte pudo ocasionar a estos elementos. Si encuentra algún daño o si falta

alguna parte, informe con prontitud al

distribuidor en donde compró su cultivador o llame al 1-800-858-8501.

Mango de

transporte

Caja

posterior

Soporte del

manubrio

inferior

Eje de la púa

Figura 1 – Cultivador eléctrico

Púas

Calcomanía de la placa

de características

Caja

frontal

Guardabarros

Transmisión

Presilla de

retención

Consola de montaje

de la rueda

Conjunto

rueda

Para más información, visite www.desatech.com

18

109363

Page 19

MANUAL DEL PROPIETARIO

ENSAMBLE

DESDOBLAMIENTO Y

REGULACIÓN DEL

MANUBRIO

Desdoblamiento del manubrio

1. Afloje las perillas de regulación del manubrio. Gire el manubrio a la posición de

operación (vea la figura 2). No fuerce el

manubrio. Si se nota un endurecimiento,

continúe aflojando las perillas de regulación. Tenga cuidado que el cordón de alimentación no quede apretado entre el

manubrio y su soporte inferior.

2. Apriete las perillas de regulación del

manubrio.

Manubrio

Perilla de

regulación

del manubrio

Regulación de la altura del

manubrio

El manubrio tiene dos ajustes disponibles

para la altura. El cultivador es transportado

con el manubrio colocado en la posición

estándar o de menor altura. Si la altura es

demasiado corta, regule la altura del manubrio a su posición extendida o más alta.

1. Afloje y retire del manubrio las perillas de regulación, arandelas y pernos

tipo montura.

2. Coloque el manubrio de modo que sus

orificios inferiores alineen con los orificios de los soportes inferiores del

manubrio (Vea la figura 3). Inserte los

pernos tipo montura por los orificios y

vuelva a instalar las arandelas y perillas del manubrio.

3. Apriete las perillas de regulación del

manubrio.

Perno tipo

montura

Perilla de

regulación

del manubrio

Orificio de

regulación de la

altura estándar

Arandela

Doblamiento del manubrio para

almacenarlo

1. Afloje las perillas de regulación del

manubrio. Gire el manubrio hacia adelante y hacia abajo por sobre la caja del

cultivador (Vea la figura 4). No fuerce

el manubrio. Si se nota un endurecimiento, continúe aflojando las perillas de regulación. Tenga cuidado que el cordón

de alimentación no quede apretado entre el manubrio y su soporte inferior.

2. Apriete las perillas de regulación del

manubrio.

Manubrio

Perilla de

regulación

del manubrio

Soporte inferior

del manubrio

Soporte

inferior del

manubrio

Figura 2 – Desdoblamiento del manubrio

109363

Orificio de

regulación de la

altura extendida

Figura 3 – Regulación de la altura del

manubrio

19

Para más información, visite www.desatech.com

Figura 4 – Doblamiento hacia abajo del

manubrio

Continuación

Page 20

®

CULTIVADOR ELÉCTRICO

ENSAMBLE

Continuación

REGULACIÓN DEL

CONJUNTO RUEDA

Regulación del conjunto rueda

para el transporte

1. Retire la presilla de retención y el eje

pasador de la consola de montaje del

conjunto ruedas (vea la figura 5).

2. Gire hacia abajo al conjunto rueda de modo

que, como se muestra en la figura 6, el

orificio del conjunto rueda alinee con el

orificio central de la consola de montaje.

3. Como se muestra en la figura 6, inserte

el eje pasador por el orificio e inserte

la presilla de retención en el eje pasador. Las ruedas están ahora montadas

en la posición de transporte.

Regulación del conjunto rueda

para cultivar

1. Retire la presilla de retención del eje

pasador y retire el eje pasador de la consola de montaje y del conjunto ruedas.

2. Gire el conjunto ruedas hacia arriba y

hacia adelante como se muestra en la

figura 7 hasta que el orificio del conjunto rueda alinee con el orificio superior de la consola de montaje.

3. Inserte el eje pasador por los orificios alineados y coloque la presilla de retención

en el eje pasador. Las ruedas están ahora

montadas en la posición de cultivo.

IMPORTANTE: El cultivador tiene

cuatro juegos diferentes de púas.

Para un desempeño apropiado, las

púas deben estar siempre instaladas correctamente como se muestra en la figura 8. Cuando están

ensambladas correctamente, el

borde cortante en ángulo de las

púas debería girar hacia la parte

frontal del cultivador. Las cuchillas

de todas las púas deberían apuntar

hacia la transmisión. Los cubos de

los juegos interior y exterior de las

púas deberían estar el uno frente al

otro como se muestra en la figura 8.

Retiro e instalación de la púa

1. Retire la presilla de retención del extremo del eje de las púas.

2. Retire el juego exterior de púas de su eje.

3. Retire el juego interior de púas de su eje.

4. Vuelva a instalar las presillas de retención en el eje de las púas para evitar

que estas se coloquen mal.

5. Para instalar las púas invierta los pasos

arriba indicados.

Eje pasador

Presilla de retención

Figura 5 – Retiro de la presilla de retención

y el eje pasador

Figura 6 – Regulación del conjunto rueda

a la posición de transporte

Figura 7 – Regulación del conjunto ruedas

a la posición de cultivo

RETIRO E INSTALACIÓN DE

LA PÚA

ADVERTENCIA: Desenchufe

siempre el cultivador antes de

colocar las manos cerca de las

púas. Use siempre guantes para

proteger sus manos de los bordes

cortantes de las púas.

Cubos de las púas

Hacia la transmisión

Cuchilla

de la púa

Juego de

púas

exteriores

Cubo de las púas

Rotación de las púas

durante la operación

Figura 8 – Retiro e instalación de las púas

Presilla de retención

Eje de

las púas

Borde cortante

Juego de púas

interiores

Para más información, visite www.desatech.com

20

109363

Page 21

MANUAL DEL PROPIETARIO

OPERACIÓN DEL

CULTIVADOR

ADVERTENCIA: Antes de

operar este cultivador lea y

entienda este manual del

propietario. Asegúrese de leer y

entender todas las

sobre seguridad

18 y 19. El uso inadecuado de

este cultivador puede ocasionar

lesiones graves o la muerte sea

por incendio, sacudida eléctrica

o por contacto del cuerpo con

partes móviles.

CORDONES DE EXTENSIÓN

Use siempre los cordones de extensión apropiados para este cultivador. Use solamente

cordones de extensión marcados para uso

exterior. El cordón debe estar marcado con el

subfijo W o W-A seguido de la designación

del tipo de cordón.

Use el tamaño de cordón apropiado para este

cultivador. El cordón debe ser lo suficientemente grueso para que transporte la corriente

necesaria. Un cordón subdimensionado ocasionará caída de voltaje en el cultivador. El

cultivador perderá potencia y se calentará

excesivamente. Siga los requisitos listados

más abajo referentes al tamaño del cordón.

Longitud del Calibre AWG

cordón del cordón

25 pies 16 AWG

50 pies 16 AWG

100 pies 14 AWG

150 pies 12 AWG

Ejemplo:

advertencias

de las páginas

SJTW-A ó SJTW.

SUJECIÓN DEL CORDÓN DE

EXTENSIÓN

La caja del interruptor tiene un enganche

para el cordón de extensión hecho de una

serie de ganchos alternativos (vea la figura

9). Esta característica puede ser usada para

asegurar al manubrio del cultivador el extremo del cordón de extensión que tiene

tomacorriente evitando que el cordón de

alimentación se desconecte accidentalmente. Para ayudar a manejar el cable se incluye

también una presilla de la correa la cual

mantiene el cable en el lado del usuario y

lejos de las púas del cultivador.

Para asegurar el cordón de

extensión al cultivador

1. Empiece aproximadamente a 6 pulgadas del extremo del cordón de extensión que tiene tomacorriente y entrelace el cordón por entre los ganchos de

la caja del interruptor como se muestra

en la figura 9, de modo que el

tomacorriente quede colgado por debajo de la caja del interruptor.

2. Empiece entrelazando el cordón de extensión por la parte superior del gancho inferior y alterne por debajo y encima de los ganchos de modo que el

cordón quede por último en la parte superior del último gancho.

3. Enchufe el cordón de alimentación del

cultivador en el cordón de extensión.

PROTECCIÓN CON

DISYUNTOR

Este cultivador está equipado con un disyuntor ubicado en la parte superior de la caja del

interruptor (vea la figura 10). El disyuntor

protege al motor del cultivador contra

sobrecorriente en caso que las púas llegaran

a atascarse o bloquearse en una piedra, raíz

u otra obstrucción.

Si el disyuntor se desconectara durante el

uso, el botón del disyuntor blanco saltará

fuera de la caja y el motor eléctrico y las

horquillas dejarán de girar.

Reposición del disyuntor

1. Suelte completamente la palanca de

accionamiento.

2. Desenchufe del cordón de extensión el

cordón de alimentación del cultivador.

3. Desaloje y retire cualquier obstáculo que

ocasionó el atascamiento de las púas.

ADVERTENCIA: Desenchufe

siempre el cultivador antes de

colocar las manos cerca de las

púas. Use siempre guantes para

proteger sus manos de los bordes

cortantes de las púas.

4. Pulse el botón del disyuntor blanco poniéndolo de nuevo en la caja para reconectarlo

(vea la figura 10). El botón debería quedar

presionado cuando se lo suelta. Enchufe

de nuevo el cordón de alimentación del cultivador en el cordón de extensión.

5. Sujete firmemente el área de agarre del

manubrio y continúe cultivando.

Mantenga el cordón lejos de las púas giratorias. Inspeccione a menudo el cordón. Reemplace los cordones dañados.

109363

Figura 9 – Aseguramiento del cordón de

extensión

21

Para más información, visite www.desatech.com

Disyuntor

calibrado

Disyuntor

disparado

Figura 10 – Botón del disyuntor

Continuación

Page 22

®

CULTIVADOR ELÉCTRICO

OPERACIÓN DEL

CULTIVADOR

Continuación

ARRANQUE DEL

CULTIVADOR

1. Sujete firmemente y con ambas manos

el área de agarre del manubrio.

2. Use su pulgar para deslizar completamente a la derecha la palanca de traba

en apagado (vea la figura 11). Esto suelta la palanca de accionamiento.

3. Apriete completamente la palanca de

accionamiento (vea la figura 11). El

motor arrancará y las púas empezarán

a girar. Una vez que arranca el cultivador, puede soltarse la palanca de traba

en apagado.

4.

IMPORTANTE:

vador, suelte la palanca de

accionamiento. El motor se apagará y

las púas dejarán de girar. Ahora la palanca de accionamiento está de nuevo

trabada en apagado.

Palanca de traba en apagado

1

Palanca de

accionamiento

Para detener el culti-

2

OPERACIÓN BÁSICA DEL

CULTIVADOR

Use el cultivador para romper el césped, preparar el semillero y para el cultivo de jardines

y cuadros de flores. El cultivador puede también cavar pequeños huecos para la plantación

de árboles tiernos y plantas de maceta.

Deje que el cultivador haga la mayor parte del

trabajo. Durante la operación las púas halarán

al cultivador hacia adelante. Al halar el cultivador hacia atrás donde usted se halla, las

púas cavarán más profunda y agresivamente.

Para romper el césped o cultivar a profundidad, deje que las púas halen al cultivador

hacia adelante hasta el extremo del alcance

de sus brazos, luego vuelva a halar al cultivador hacia usted. El cultivador será lo más

eficiente si permitimos repetidamente que

se mueva hacia adelante y luego halarlo

hacia atrás donde usted se halla.

Si el cultivador ya cavó lo suficiente en un sitio,

muévalo suavemente de un lado a otro para que

empiece de nuevo a moverse hacia adelante.

Para preparar el semillero, recomendamos

usar uno de los modelos de cultivo que se

muestra en la figura 12.

Modelo de cultivo uno – Realice dos pasadas

sobre el área a ser cultivada, la segunda a

un ángulo recto respecto a la primera.

MANEJO DEL CORDÓN DE

EXTENSIÓN

Igual que con cualquier podadora eléctrica o

electrodoméstico para jardín, mientras use

el cultivador aplique su sentido común para

mantener el cordón de extensión en una

ubicación segura y lógica.

Con el cultivador se incluye una presilla de

la correa que es útil y que le permite asegurar el cordón de extensión a su cintura lo

cual facilita el manejo del cordón (vea la

figura 13). Es recomendable que la presilla

de la correa y el cordón de extensión estén

asegurados a su lado derecho. Para fácil

maniobra mantenga una holgura suficiente

entre el cultivador y la presilla de la correa.

ADVERTENCIA: Mientras opera el cultivador esté alerta al cordón

de extensión. Asegúrese de no

tropezarse con el cordón. Mantenga

siempre el cordón lejos de las púas.

Cuando cultive por filas, empiece con la fila

que está más cerca al tomacorriente casero

que está usando como fuente de alimentación. Empiece cultivando la fila en una

dirección que le permita mantener el cordón

de extensión a su lado derecho. Cuando el

cultivador alcanza el extremo de la fila, gire

la posición del cultivador en dirección contraria para trabajar en la siguiente fila. Recuerde, si mantiene el cordón de extensión

detrás de usted y a su derecha, le será más

fácil el manejo de este cordón.

Figura 11 – Palanca de traba en apagado

y palanca de accionamiento

Para más información, visite www.desatech.com

Modelo de cultivo dos – Haga dos pasadas

sobre el área a ser cultivada, la segunda

traslapa a la primera.

Figura 12 – Modelos de cultivo

recomendados

22

Correa

Gancho exterior

Cordón de extensión

Figure 13 – Presilla de la correa para el

cordón de extensión

109363

Page 23

MANUAL DEL PROPIETARIO

OPERACIÓN DEL

CULTIVADOR

Continuación

RETIRO DE OBJETOS

EXTRAÑOS DE LAS PÚAS

Mientras se usa, una piedra o una raíz podría

alojarse en las púas o el césped alto o maleza

podrían envolverse alrededor del eje de las

púas.

Para limpiar las púas suelte la palanca de

accionamiento. Desenchufe el cultivador y

desaloje o retire cualquier obstáculo de las

púas o del eje de las púas.

ADVERTENCIA: Desenchufe

siempre el cultivador antes de

colocar las manos cerca de las

púas. Use siempre guantes para

proteger sus manos de los bordes

cortantes de las púas.

Para retirar con facilidad el césped alto o

malezas que estén envueltas alrededor del

eje de las púas, retire una o más púas del eje.

Vea en la página 20, Retiro e instalación de

las púas.

Cuando usted ha despejado las púas de

obstáculos, vuelva a instalarlas en el eje.

Enchufe el cordón de alimentación del cultivador en el cordón de extensión. Sujete

firmemente con ambas manos el área de

agarre del manubrio y reanude la operación

normal de cultivo.

LIMPIEZA Y

MANTENIMIENTO

ADVERTENCIA: Antes de

limpiar o dar servicio al cultivador

desenchúfelo de la fuente de

alimentación. Podrían ocurrir

lesiones graves o la muerte sea

por incendio, sacudida eléctrica

o por contacto del cuerpo con

partes móviles.

ADVERTENCIA: Cuando

limpie el cultivador:

• No lo sumerja en ningún líquido.

• No use productos que contie-

nen amoníaco, cloro o

abrasivos.

• No use solventes de limpieza

con cloro, tetracloruro de carbono, kerosene o gasolina.

LIMPIEZA DEL CULTIVADOR

1. Para limpiar la tapa frontal y posterior y

el guardabarros, use un paño suave humedecido con una mezcla de agua y jabón suave. No rocíe ni vierta el agua

directamente en las tapas frontal o posterior. Pase con un paño húmedo las tapas frontal y posterior y el guardabarros.

2. Retire la tierra y desechos de las púas y

de la transmisión, use un cepillo de cerdas duras o un paño húmedo. No rocíe ni

vierta agua directamente en el cultivador.

3. Para una limpieza más fácil, retire las

púas del eje. Vea en la página 20, Reti-

ro e instalación de las púas.

4. Una vez limpio, seque con un paño el

eje de las púas y antes de volver a instalar las púas aplique una ligera capa

de aceite al eje.

REVISIÓN DEL LUBRICANTE

DE LA TRANSMISIÓN

1. Desenchufe el cultivador de la fuente

de alimentación.

2. Localice el tornillo de engrase ubicado

arriba del eje de las púas al lado derecho de la transmisión (vea la figura 14).

3. Apoye al cultivador sobre su lado izquierdo. Retire el juego de púas del lado

derecho para tener fácil acceso al tornillo de engrase. Vea en la página 20,

Retiro e instalación de las púas.

4. Limpie la transmisión para evitar que

el polvo y los desechos entren en ella.

5. Usando un destornillador cabeza

Philips (estrella), retire el tornillo de

engrase de la caja de transmisión.

6. Si la grasa no está visible en el orificio,

usando una pistola de engrase estándar,

añada grasa a base de petróleo, de alta

calidad y con clasificación para automotores. Coloque firmemente la boquilla

de la pistola de engrase contra el borde

del orificio y añada grasa hasta que esta

empiece lentamente a fluir hacia afuera

y alrededor del borde de la boquilla.

7. Vuelva a instalar el tornillo de engrase

y con un paño retire cualquier exceso

de grasa.

8. Vuelva a ensamblar los juegos de púas.

Vea en la página 20, Retiro e instala-

ción de las púas.

Tornillo de

engrase

Figura 14 – Tornillo de engrase

OTROS PUNTOS DE

LUBRICACIÓN

RECOMENDADOS

Perillas de regulación del manubrio:

Rocíe de vez en cuando un lubricante tipo

silicona alrededor de los pernos tipo montura.

Eje de las púas: Luego de cada uso, retire

las púas, limpie el eje de las púas usando

papel lija fino y aplique una ligera capa de

aceite al eje. Esto facilitará futuras instalaciones o retiros de las púas.

109363

23

Para más información, visite www.desatech.com

Page 24

®

CULTIVADOR ELÉCTRICO

DESARME ILUSTRADO DE PARTES

CULTIVADOR ELÉCTRICO

Modelo 109312-01

22

21

23

48

28

26

19

27

20

25

48

24

17

18

48

30

31

32

36

12

47

11

45

44

32

31

42

29

40

30

33

41

53

52

34

37

16

46

39

35

48

38

43

13

47

40

47

10

42

50

51

49

9

15

14

8

5

6

7

4

Ensamble del guardabarros a la

transmisión

Para más información, visite www.desatech.com

24

6

7

2

3

1

109363

Page 25

MANUAL DEL PROPIETARIO

LISTA DE PARTES

CULTIVADOR ELÉCTRICO

Esta lista contiene las partes de repuestos usadas en su cultivador. Cuando solicite partes,

asegúrese de dar el número correcto del modelo, luego el número de parte y la descripción

de la parte deseada.

Modelo 109312-01

No. No. de

Clave Parte Descripción Cantidad

1 109384-01 Conjunto Transmisión 1

2 109342-01 Conjunto púas 1

3 109342-04 Conjunto púas 1

4 109342-02 Conjunto púas 1

5 109342-03 Conjunto púas 1

6 109349-01 Arandela de felpa 2

7 109339-01 Tapa contra el polvo 2

8 109332-01 Guardabarros 1

9 109333-01 Conjunto plancha del rodamiento 1

10 H5C4-20C Perno cabeza hexagonal

0,25-20 x 2,5 pulgadas 4

11 109385-01 Conjunto motor 1

12 076014 Conjunto carcaza del motor 1

13 059045 Tornillo autorroscante cabeza

redondeada 4

14 109343-01 Caja frontal 1

15 109345-01 Reductor de la resistencia de aire 1

16 108444-01 Soporte izquierdo del manubrio 1

17 108443-01 Conjunto tubo del manubrio

superior 1

18 099829-05 Cordón con vaina 1

19 107729-01 Micro interruptor 1

20 109360-01 Tapa lateral de la traba en

apagado 1

21 109355-01 Corredera de la traba en apagado 1

22 109354-01 Bloque de tope 1

23 107694-01 Resorte de la traba en apagado 1

24 109357-01 Resorte del gatillo 1

25 109353-01 Palanca de accionamiento 1

26 22616013 Disyuntor 1

27 109351-01 Caja superior del gatillo 1

28 109352-01 Caja inferior del gatillo 1

No. No. de

Clave Parte Descripción Cantidad

29 109347-01 Cordón de alimentación 1

30 109367-01 Perno con cabeza tipo montura

0,312-18 x 1,5 pulgadas 2

31 109366-01 Perilla del manubrio 2

32 WLE-5 Arandela de presión del diente

exterior 2

33 108444-02 Soporte derecho del manubrio 1

34 H5C4-40C Perno cabeza hexagonal

0,25-20 x 5 pulgadas 2

35 109344-01 Caja posterior 1

36 109341-01 Espuma aislante 1

37 109368-01 Eje pasador 0,25 x 1 pulgadas 1

38 109369-01 Presilla de retención 1

39 109356-01 Consola del conjunto rueda 1

40 109374-01 Rueda 2

41 109358-01 Conjunto eje 1

42 109377-01 Tapa de la tuerca 2

43 109365-01 Presilla de retención 2

44 19724000 Attache cable 4

45 109361-01 Presilla de la correa 1

46 H5C4-8C Perno cabeza hexagonal

0,25-20 x 1 pulgadas 1

47 NEC-4C Contra tuerca hexagonal 0,25-20 7

48 107708-01 Tornillo autorroscante cabeza

redondeada 16

49 109336-01 Rueda dentada 1

50 059606 Engranaje impulsor 1

51 075676 Rodamiento de rodillos de la

rueda dentada 1

52 109350-01 Placa del guardabarros 1

53 103708-01 Tornillo, PPH TPG "B" 2

109363

25

Para más información, visite www.desatech.com

Page 26

®

CULTIVADOR ELÉCTRICO

ANÁLISIS DE

AVERÍAS

Nota:

Para ayuda adicional visite nuestro

sitio web de servicio técnico

www.desatech.com.

PROBLEMA

El motor no funciona cuando se aprieta la

palanca de accionamiento

El motor funciona, pero las púas no se mueven

Sale humo del cultivador

ADVERTENCIA: Antes de dar servicio al cultivador desconéctelo de la

fuente de alimentación. Podrían ocurrir lesiones graves o la muerte sea por

incendio, sacudida eléctrica o por contacto del cuerpo con partes móviles.

CAUSA PROBABLE

1. La palanca de traba en apagado no está

presionada para que suelte la palanca de

accionamiento

2. La conexión del cordón de extensión está

floja

3. El disyuntor del cultivador está

disparado

4. El disyuntor de la casa está disparado o

un fusible de línea está abierto

5. Escobillas deterioradas del motor

6. Cableado abierto en el cultivador

Falla del tren de engranaje

Cultivador dañado. No lo use

ACCIÓN CORRECTIVA

1. Presione completamente la palanca de

traba en apagado antes de apretar la palanca de accionamiento (vea en la página 22, Arranque del cultivador)

2. Revise las conexiones del cordón

3. Revise el disyuntor del cultivador. (Vea

Protección con disyuntor, página 21)

4. Revise el disyuntor o el fusible de línea (Vea

en la página 21, Protección con disyuntor)

5. Visite un centro de servicio autorizado

6. Visite un centro de servicio autorizado

Visite un centro de servicio autorizado

Visite un centro de servicio autorizado

SERVICIO

TÉCNICO

Pueda que usted tenga preguntas adicionales acerca del ensamble, operación o mantenimiento de este cultivador. De ser así,

póngase en contacto con el Departamento

de Servicio Técnico al 1-800-858-8501.

Usted puede también visitar nuestro sitio

web de servicio técnico

www.desatech.com.

SERVICIO DE

REPARACIÓN

Nota:

Use solamente partes de repuesto

originales. Esto protegerá la cobertura de su

garantía en repuestos reemplazados bajo

esta garantía.

Cada centro de servicio autorizado opera

independientemente y tiene diferente propietario. Para mayor información sobre servicios adicionales o sobre la garantía llame

al 1-800-858-8501 o visite nuestro sitio web

de servicio técnico www.desatech.com.

PARTES DE REPUESTO

Para conseguir partes de repuesto originales, póngase en contacto con distribuidores

autorizados de este producto o con su central más cercana de repuestos que se listan

más abajo.

SERVICIO DE GARANTÍA

Si el cultivador requiere servicio de garantía, devuélvalo al centro de servicio autorizado más cercano. Debe mostrar la prueba

de compra. Si se produjo un daño por mano

de obra o materiales defectuosos, nosotros

sin ningún costo repararemos o reemplazaremos el cultivador.

bajo la garantía el uso normal, mal uso,

abuso, negligencia o daño accidental.

Nota:

No está cubierto

SERVICIO FUERA DE LA

GARANTÍA

Si el cultivador requiere servicio, devuélvalo al centro de servicio autorizado más cercano. Las reparaciones le serán facturadas a

precios de reparación regulares según lista.

Para más información, visite www.desatech.com

26

109363

Page 27

MANUAL DEL PROPIETARIO

DISTRIBUIDORES DE REPUESTOS

Ray’s Portable Heater Service

3191 Myers Road

Camino, CA 95709-9550

530-644-7716

Baltimore Electric

5 Manila Drive

Hamden, CT 06514-0322

203-248-7553

1-800-397-7553

Eckley’s Small Engine

31617 Spruce Drive

Eustis, FL 32726-9592

352-357-6764

Parts Company of America

1657 Shermer Road

Northbrook, IL 60062-5362

708-498-5900

1-800-323-0620

www.grainger.com

Portable Heater Parts

342 North County Road 400 East

Valparaiso, IN 46383-9704

219-462-7441

1-800-362-6951

www.portableheaterparts.com

sales@portableheaterparts.com

techservice@portableheaterparts.com

FBD

1349 Adams Street

Bowling Green, KY 42103-3414

270-846-1199

1-800-654-8534

franktalk@aol.com

Lyons & Lyons Sales Co. Inc.

Glen Arm Road

Glen Arm, MD 21057-9454

410-665-6500

1-800-333-5966

lyonsco@erols.com

Master Part Distributors

1251 Mound Avenue NW

Grand Rapids, MI 49504-2672

616-791-0505

1-800-446-1446

www.masterparts.net

Hance Distributors, Inc.

12795 16th Avenue North

Plymouth, MN 55441-4556

763-559-2299

www.hanceco.com

Automotive Equipment Service

3117 Holmes

Kansas City, MO 64109-1716

816-531-9144

1-800-843-3546

www.aes-lawnparts.com

Bowden Electric Motor Service

1681 S. Wesleyan Blvd.

Rocky Mount, NC 27803

252-446-4203

East Coast Energy

10 East Route 36

West Long Branch, NJ 07764-1501

1-800-755-8809

Forrest Lytle and Sons, Inc.

740 West Galbraith Road

Cincinnati, OH 45231-6002

513-521-1464

Bortz Chain Saw Shop

Road #2, Box 64A

Oley, PA 19547-9412

610-987-6452

21st Century

2950 Fretz Valley Road

Perkasie, PA 18944-4034

215-795-0400

1-800-325-4828

Laportes

2444 N 5th Street

Hartsville, SC 29550-7704

843-332-0191

MTA Distributors

555 Hickory Hills Blvd.

Nashville, TN 37189-9244

615-299-8777

1-800-264-0225

Webbs Appliance Center

1519 Church Street

Nashville, TN 37203-3004

615-329-4079

1-800-899-4079

Industrial Hardware

4109 Bainbridge Blvd.

Chesapeake, VA 23324-1403

804-543-2232

1-800-788-0008

catatem@erols.com

Mills Lawn and Garden

928 Commonwealth Place

Virginia Beach, VA 23464

757-361-9293

www.mills-parts.com

Tuco Industrial Products

5223 180th Street SW

Suite 4A-1

Lynnwood, WA 98037-4506

425-743-9533

1-800-735-1268

www.tucoheat.com

109363

27

Continuación

Para más información, visite www.desatech.com

Page 28

GARANTÍA LIMITADA DEL CULTIVADOR ELÉCTRICO

Cuando escriba a la fábrica especifique siempre el número del modelo.

Nos reservamos el derecho de enmendar en cualquier momento estas especificaciones y sin previo aviso. La única garantía válida es nuestra garantía

escrita estándar. No hacemos otra garantía expresada o implícita.

DESA Specialty Products™ garantiza por el lapso de dos años (90 días para productos recondicionados) a partir de la fecha de la primera compra

hecha donde un distribuidor autorizado que este cultivador eléctrico y cualquier parte del mismo están libres de defectos en materiales y mano de

obra, con tal que el producto haya recibido un mantenimiento y operación apropiados que estén de acuerdo a las instrucciones pertinentes. Si el

cultivador tiene uso comercial, industrial o se lo renta, esta garantía es válida por 90 días desde la fecha de compra hecha donde un distribuidor

autorizado. La factura de venta o prueba de compra debe ser presentada al momento de hacer un reclamo bajo esta garantía.

Esta garantía se extiende solamente al comprador al por menor original y cubre solamente las partes y mano de obra requeridas para restaurar este

cultivador a su condición apropiada de operación. Las partes por la garantía pueden obtenerse a través de distribuidores o centros de servicio de este

producto autorizados por la fábrica. Estos distribuidores y centros de servicio le proveerán de repuestos originales de fábrica. Si no usa repuestos

originales de fábrica esta garantía queda inválida.

Esta garantía no se aplica a las partes que debido al desgaste normal no están en condiciones originales, ni se aplica a partes que fallan o se dañan

como resultado del mal uso, accidente, falta de mantenimiento apropiado, intromisión o alteración. Los costos de viaje, manipulación transporte o