REMEHA Calenta 25s, Calenta 40c, Calenta 28c, Calenta 35s Installation And Service Manual

High-efficiency wall-hung condensing gas boilers

Calenta 25s - 28c - 35s - 40c

Netherlands

EN

Installation and

Service Manual

7600585-01

EG declaration of conformity

The device complies with the standard type described in the EG

declaration of conformity. It was manufactured and commissioned in

accordance with European directives.

The original of the declaration of compliance is available from the

manufacturer.

Contents

1 Introduction ................................................................................................6

1.1 Symbols used .......................................................6

1.2 Abbreviations ........................................................6

1.3 General ..................................................................6

1.3.1 Manufacturer's liability .............................................6

1.3.2 Installer's liability .....................................................7

1.4 Homologations ......................................................7

1.4.1 Certifications ...........................................................7

1.4.2 Equipment categories .............................................9

1.4.3 Additional Directives ................................................9

1.4.4 Factory test .............................................................9

2 Safety instructions and recommendations ............................................10

2.1 Safety instructions .............................................10

2.2 Recommendations ..............................................10

3 Technical description ..............................................................................12

3.1 General description ............................................12

3.2 Main parts ............................................................12

3.3 Operating principle .............................................13

3.3.1 Gas/air setting .......................................................13

3.3.2 Combustion ...........................................................14

3.3.3 Heating and domestic hot water production ..........14

3.3.4 Control system ......................................................14

3.3.5 Adjustment ............................................................14

3.3.6 Regulation of the water temperature .....................15

3.3.7 Protection against a shortage of water ..................15

3.3.8 Maximum temperature protection .........................15

3.3.9 Skeleton Diagrams ................................................16

3.3.10 Shunt pump ...........................................................16

3.3.11 Water flow rate ......................................................17

3.4 Technical specifications ....................................17

4 Installation ................................................................................................20

4.1 Regulations governing installation ...................20

4.2 Package list .........................................................20

4.2.1 Standard delivery ..................................................20

4.2.2 Accessories ...........................................................21

040412 - 7600585-01

1

Contents

4.3 Choice of the location ........................................22

4.3.1 Data plate ..............................................................22

4.3.2 Location of the boiler .............................................22

4.3.3 Ventilation .............................................................23

4.3.4 Main dimensions ...................................................24

4.4 Positioning the boiler .........................................25

4.5 Alternatives for hydraulic connections ............26

4.5.1 Connection of the underfloor heating ....................26

4.5.2 Connection of a solar hot water tank .....................26

4.5.3 Connection of an independent hot water

tank .......................................................................27

4.5.4 Geyser use ............................................................28

4.5.5 Solo use ................................................................29

4.6 Hydraulic connections .......................................29

4.6.1 Flushing the system ..............................................29

4.6.2 Connection of the heating circuit ...........................30

4.6.3 Hydraulic connection of the water circuit for domestic

use ........................................................................31

4.6.4 Connecting the expansion vessel .........................31

4.6.5 Connecting the condensate discharge pipe ..........31

4.7 Gas connection ...................................................32

4.8 Connections for the air and exhaust

pipes ....................................................................32

4.8.1 Classification .........................................................32

4.8.2 Outlets ...................................................................33

4.8.3 Lengths of the air/flue gas pipes ...........................34

4.8.4 Specific air/flue gas applications ...........................36

4.8.5 Additional Directives ..............................................36

4.8.6 Air/Exhaust adapter ...............................................37

4.8.7 Connection of the combustion gas exhaust

pipe .......................................................................38

4.8.8 Connection of the air intake pipe ...........................38

4.9 Electrical connections ........................................39

4.9.1 Control unit ............................................................39

4.9.2 Recommendations ................................................40

4.9.3 Standard control PCB ...........................................41

4.9.4 Connecting the room thermostat ...........................42

4.9.5 Connecting the outside temperature sensor ........43

4.9.6 Connect frost protection ........................................43

4.9.7 Connecting the calorifier sensor/thermostat .........44

4.9.8 PC/Laptop connection ...........................................45

4.9.9 Shutdown input .....................................................45

4.9.10 Release input ........................................................45

040412 - 7600585-01

4.10 Optional electrical connections ........................46

4.10.1 Connection options for the 0-10 V control PCB

(IF-01) ...................................................................46

4.10.2 Connection possibilities for the PCB (SCU-

S02) .......................................................................47

2

4.11 Electrical diagram ...............................................50

4.12 Filling the system ...............................................51

4.12.1 Water treatment ....................................................51

4.12.2 Filling the siphon ...................................................51

4.12.3 Filling the system ..................................................52

5 Commissioning ........................................................................................53

5.1 Control panel .......................................................53

5.1.1 Functions of the keys ............................................53

5.1.2 Meaning of the symbols on the display .................53

5.2 Check points before commissioning ................54

5.2.1 Preparing the boiler for commissioning .................54

5.2.2 Gas circuit .............................................................55

5.2.3 Hydraulic circuit .....................................................55

5.2.4 Electrical connections ...........................................55

5.3 Commissioning the boiler ..................................55

5.4 Gas settings ........................................................57

5.4.1 Adapting to another gas type ................................57

5.4.2 Setting the air/gas ratio (Full load) ........................57

5.4.3 Setting the air/gas ratio (Part load) ......................59

5.4.4 Basic setting for the gas/air ratio ...........................60

5.5 Checks and adjustments after

commissioning ...................................................60

5.5.1 Finalizing work ......................................................60

5.6 Reading out measured values ...........................61

5.6.1 Reading the various current values .......................61

5.6.2 Readout from the hour counter and percentage of

successful starts ....................................................62

5.6.3 Status and sub-status ...........................................63

5.7 Changing the settings ........................................64

5.7.1 Parameter descriptions .........................................64

5.7.2 Modification of the user-level parameters .............66

5.7.3 Modification of the installer-level parameters ........67

5.7.4 Setting the maximum heat input for central heating

operation ...............................................................68

5.7.5 Return to the factory settings ................................69

5.7.6 Carrying out an auto-detect ...................................70

5.7.7 Setting the manual mode ......................................70

5.7.8 Setting the legionella protection function ..............70

040412 - 7600585-01

3

Contents

6 Switching off the boiler ............................................................................71

6.1 Installation shutdown .........................................71

6.2 Frost protection ..................................................71

6.3 Switching off the central heating ......................72

6.4 Shutting down domestic hot water

production ...........................................................72

7 Checking and maintenance .....................................................................73

7.1 Maintenance message ........................................73

7.2 Preventive maintenance with automated service

message ..............................................................73

7.2.1 Resetting the automatic maintenance

message ................................................................74

7.2.2 Dealing with the next maintenance message and

starting the new maintenance period ....................74

7.3 Standard inspection and maintenance

operations ...........................................................75

7.3.1 Checking the hydraulic pressure ...........................75

7.3.2 Checking the ionization current .............................75

7.3.3 Checking the transfer capacity ..............................75

7.3.4 Checking the tightness of the flue gas evacuation and

air inlet connections ..............................................76

7.3.5 Checking combustion ............................................76

7.3.6 Checking the automatic air vent ............................77

7.3.7 Checking the safety valve .....................................77

7.3.8 Checking the siphon ..............................................77

7.3.9 Checking the burner and cleaning the heat

exchanger .............................................................78

7.4 Specific maintenance operations ......................79

7.4.1 Replacing the ionization/ignition electrode ............79

7.4.2 Cleaning the plate exchanger (domestic hot water

end) and the water filter cartridge .........................79

7.4.3 Replacing the 3-way valve ....................................82

7.4.4 Replacing the non-return valve .............................83

7.4.5 Assembling the boiler ............................................84

8 Troubleshooting .......................................................................................85

040412 - 7600585-01

8.1 Error codes ..........................................................85

8.2 Shutdowns and lock-outs ..................................88

8.2.1 Blockage ...............................................................88

8.2.2 Blocking .................................................................88

8.3 Error memory ......................................................90

8.3.1 Error readout memorised ......................................91

8.3.2 Deletion of the error display ..................................92

4

9 Spare parts ................................................................................................93

9.1 General ................................................................93

9.2 Spare parts ..........................................................93

040412 - 7600585-01

5

1. Introduction

1 Introduction

1.1 Symbols used

Calenta 25s - 28c - 35s - 40c

In these instructions, various danger levels are employed to draw the

user's attention to particular information. In so doing, we wish to

safeguard the user's safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

1.2 Abbreviations

1.3 General

CAUTION

Risk of material damage.

Signals important information.

¼ Signals a referral to other instructions or other pages in the

instructions.

4 3CE: Collective conduit for sealed boiler

4 Central heating: Central heating

4 COP: Energy performance

4 DHW: Domestic hot water

4 HRU: Heat Recovery Unit

1.3.1. Manufacturer's liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

6

040412 - 7600585-01

Calenta 25s - 28c - 35s - 40c

1. Introduction

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.4 Homologations

1.4.1. Certifications

CE identification no

NOx classification

Type of connection

(Flue gas outlet)

Depending on the type of appliance and the gross heat

requirements for domestic water in accordance with NEN

5128, efficiency values up to 0,825 can be applied to

determine EPC.

Approval labels for gas

n

The boiler has been given several approval labels for gas. Stichting

Energie Prestatiekeur grants these independent labels on

performance to gas consumption appliances that meet specific

provisions on a certain number of aspects (efficiency, environmental

friendliness, comfort). The labels have the following meaning:

PIN 0063BT3444

5 (EN 297 pr A3, EN 656)

B23 , B

C

93

, B33 , C13 , C33 , C43 , C53 , C63 , C83 ,

23P

040412 - 7600585-01

7

T001057-A

T001058-A

T001055-A

T001795-A

T001059-A

1. Introduction

Calenta 25s - 28c - 35s - 40c

The labels are not guaranteed if the boiler is adapted to

G20 or G31.

HR 107 gas approval (High efficiency heating)

This means that the efficiency of the boiler when producing heating

water is 107% higher than the Gaskeur HR criterion in relation to

Hi. This means that the boiler is economical and therefore less costly

and more environmentally friendly.

HRww gas approval (High efficiency hot water)

This implies that the hot water/heating boiler produces hot water

economically and efficiently, without wasting energy or water

therefore.

CW 4 gas approval (Hot water comfort)

This means that, for the preparation of hot water, the Calenta 28c

satisfies application class 4. With the application of class 4, the

Calenta 28c is appropriate for:

4 A draw-off flow rate of at least 7,5 l/min at 60°C.

4 A shower function from 6 l/min up to at least 12,5 l/min at 40°C.

4 Filling a bathtub in less than 11 minutes with 120 litres of water at

40°C on average.

The simultaneity of these functions is not a requirement.

Parameters for which the performance of the Calenta 28c boiler

complies with the Hot Water Comfort classification:

4 Rotation speed on start-up 3000 rpm.

4 Maximum DHW rate 6200 rpm.

4 Energy-saving mode: Stop.

CW 5 gas approval (Hot water comfort)

This means that, for the preparation of hot water, the Calenta 40c

satisfies application class 5. With the application of class 5, the

Calenta 40c is appropriate for:

4 Hot water comfort.

4 A shower function from 6 l/min up to at least 12,5 l/min at 40°C.

4 Filling a bathtub in less than 10 minutes with 150 litres of water at

40 °C on average.

The simultaneity of these functions is not a requirement.

Parameters for which the performance of the Calenta 40c boiler

complies with the Hot Water Comfort classification:

4 Rotation speed on start-up 4000 rpm.

4 Maximum DHW rate 6800 rpm.

4 Energy-saving mode: Stop.

SV gas approval (Clean combustion)

8

040412 - 7600585-01

T001779-B

NZ

Calenta 25s - 28c - 35s - 40c

1. Introduction

This means that the boiler complies with the NOx Order and

provisions on clean combustion. The boiler has a gas/air coupling

combined with a fully premixed burner. For this reason, the emission

of NOx and CO is as low as possible.

NZ gas approval (Solar water heater reheating)

This implies that the hot water/heating boiler can operate on reheating

for solar water heaters. The label (solar water heater reheating) is

valid in combination with the connection kit for solar water heaters.

Owing to the possible formation of legionella, the boiler must not be

shut down or the DHW temperature set below 60°C.

1.4.2. Equipment categories

Gas category

II

, I

2L3P

2H

Gas type Connection pressure (mbar)

G20 (Gas H) 20

G25 (Gas L) 25

G31 (Propane) 30/50

The boiler is preset in the factory to operate on natural gas G25 (Gas

L).

1.4.3. Additional Directives

Apart from the legal provisions and Directives, the additional

Directives described in these instructions must also be observed.

For all provisions and Directives referred to in these instructions, it is

agreed that all addenda or subsequent provisions will apply at the

time of installation.

1.4.4. Factory test

Before leaving the factory, each boiler is set for optimum performance

and tested to check the following items:

040412 - 7600585-01

4 Electrical safety

4 Adjustment (CO2)

4 Domestic hot water mode (Only on models with domestic hot water

production)

4 Water tightness

4 Gas tightness

4 Parameter settings

9

2. Safety instructions and recommendations

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If you smell gas:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them immediately.

5. If the gas leak is before the gas meter, contact the

gas supplier.

Calenta 25s - 28c - 35s - 40c

2.2 Recommendations

DANGER

If you smell flue gases:

1. Switch the appliance off.

2. Open the windows.

3. Trace possible leaks and seal them immediately.

WARNING

4 Installation and maintenance of the boiler must be

carried out by a qualified professional in compliance

with prevailing local and national regulations.

4 When working on the boiler, always disconnect the

boiler from the mains and close the main gas inlet

valve.

4 After maintenance or repair work, check all

installations to ensure that there are no leaks.

CAUTION

10

The boiler must be installed in a frost-free environment.

Keep this document close to the place where the boiler is

installed.

Casing components

040412 - 7600585-01

Calenta 25s - 28c - 35s - 40c 2. Safety instructions and recommendations

Only remove the casing for maintenance and repair operations. Put

the casing back in place after maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance must never be

removed or covered and must remain legible during the entire lifespan

of the appliance. Immediately replace damaged or illegible

instructions and warning stickers.

Modifications

Modifications may only be made to the boiler after the written

permission of Remeha to do so.

040412 - 7600585-01

11

T000822-B T000822-D

9

8

7

6

4

5

2

3

10

12

14

13

16

17

19

20

18

15

1 21

11

3. Technical description Calenta 25s - 28c - 35s - 40c

3 Technical description

3.1 General description

High-efficiency wall-hung condensing gas boilers

4 High efficiency heating.

4 Low pollutant emissions.

Boiler type:

4 Calenta 25s - 35s: Heating only (Production of domestic hot water

can be ensured by a separate hot water calorifier).

4 Calenta 28c - 40c: Heating and domestic hot water production.

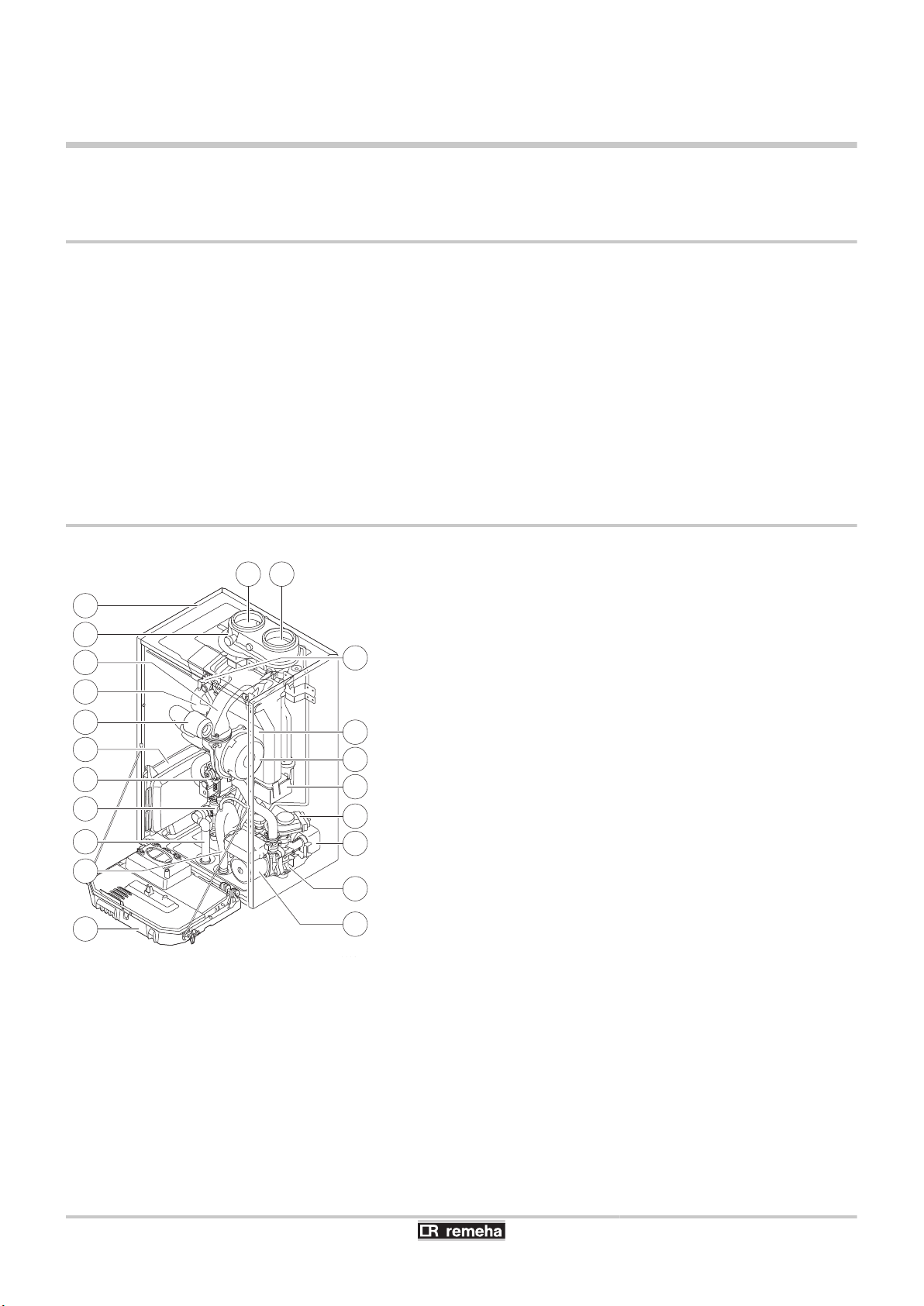

3.2 Main parts

Calenta 25s - 28c

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Flue gas outlet

Casing/air box

Outlet for measuring combustion gases

Mixer pipe

Heating flow hose

Air intake silencer

Box for the control PCBs (accessory)

Combined venturi and gas valve unit

Flow end hydroblock

Safety valve outlet pipe

Siphon

Instrument box

Shunt pump

Return end hydroblock

Plate heat exchanger (DHW) (Only on models with

domestic hot water production)

12

16

17

18

19

20

21

3-way valve (Only on models with domestic hot water

production)

Condensate receiver tank

Fan

Heat exchanger (Central heating)

Ignition/ionization electrode

Air intake

040412 - 7600585-01

T002886-C

2

14

16

15

13

17

18

19

20

3

4

5

6

7

8

9

10

11

12

1 21

Calenta 25s - 28c - 35s - 40c

3. Technical description

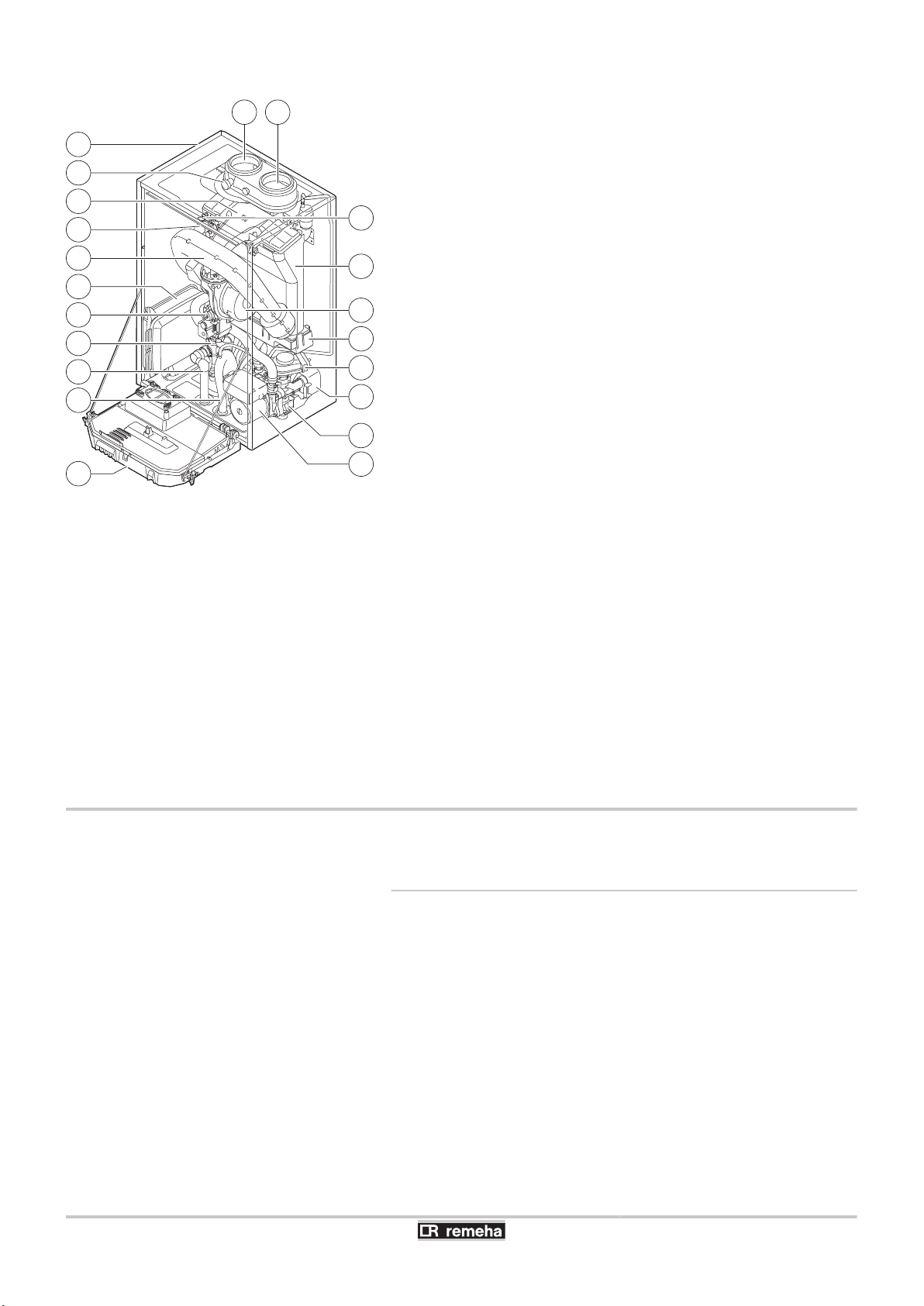

Calenta 35s - 40c

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Flue gas outlet

Casing/air box

Outlet for measuring combustion gases

Mixer pipe

Heating flow hose

Air intake silencer

Box for the control PCBs (accessory)

Combined venturi and gas valve unit

Flow end hydroblock

Safety valve outlet pipe

Siphon

Instrument box

Shunt pump

Return end hydroblock

Plate heat exchanger (DHW) (Only on models with

domestic hot water production)

3-way valve (Only on models with domestic hot water

production)

3.3 Operating principle

17

18

19

20

21

Condensate receiver tank

Fan

Heat exchanger (Central heating)

Ignition/ionization electrode

Air intake

3.3.1. Gas/air setting

The casing fitted to the boiler is also used as an air box. Air is sucked

in by the fan and gas injected into the venturi by the fan intake. The

fan rotation speed is set according to the settings parameters, the

thermal energy requirement and the temperatures measured by the

temperature sensors. The gas and air are mixed in the venturi. The

gas/air ratio ensures that the quantities of gas and air are adjusted to

each other. This provides optimum combustion on the entire output

range. The gas/air mixture is fed into the burner on top of the

exchanger.

040412 - 7600585-01

13

3. Technical description

Calenta 25s - 28c - 35s - 40c

3.3.2. Combustion

The burner heats the heating water circulating in the heat

exchanger. At a return temperature lower than around 55°C, the flue

gases cool down to a temperature lower than the dew point, thus

causing the condensation of the water vapour contained in the flue

gases in the back side of the heat exchanger. The heat released

during this condensation process (the latent heat or condensing heat)

is also transferred to the heating water. The cooled combustion gases

are evacuated via the combustion gas outlet flue. The condensation

water is evacuated via a siphon.

3.3.3. Heating and domestic hot water production

On heating and domestic hot water production type boilers, an

integrated plate exchanger heats the domestic water. A 3-way valve

determines whether the heated water is fed into the heating system

or the plate exchanger. A pick-up sensor signals that a hot water tap

is being opened. This signal is transmitted to the control panel, which

then switches the 3-way valve to the hot water position and trips the

heating pump. The 3-way valve is spring-loaded but only consumes

electricity when it switches to another position.

The heating water reheats the domestic water in the plate

exchanger. In comfort mode, if there is no hot water draw-off, the

boiler handles the periodic reheating of the plate exchanger. Any

limescale particles are kept out of the plate exchanger by a selfcleaning water filter (self-cleans once every 76 hours).

3.3.4. Control system

The boiler command, called Comfort Master©, handles a reliable

heat supply. This means that the boiler treats external negative

influences in a practical manner (notably when the water-flow is

insufficient or there are problems with air supply). In the presence of

such influences, the boiler doesn't switch into locking mode, but first

reduces his power and, depending on the nature of the

circumstances, will be temporarily out of service (blocking or stop).

The boiler will continue to supply heat as long as the situation does

not become dangerous.

3.3.5. Adjustment

The power of the boiler can be adjusted in the following ways:

14

4 On/Off setting

The output between the minimum and maximum values varies

based on the heating flow set point temperature.

4 Adjustable control

The output between the minimum and maximum values varies

based on the heating flow temperature determined by the

modulating control system.

4 Analogue setting (0-10 V)

040412 - 7600585-01

T003757-A

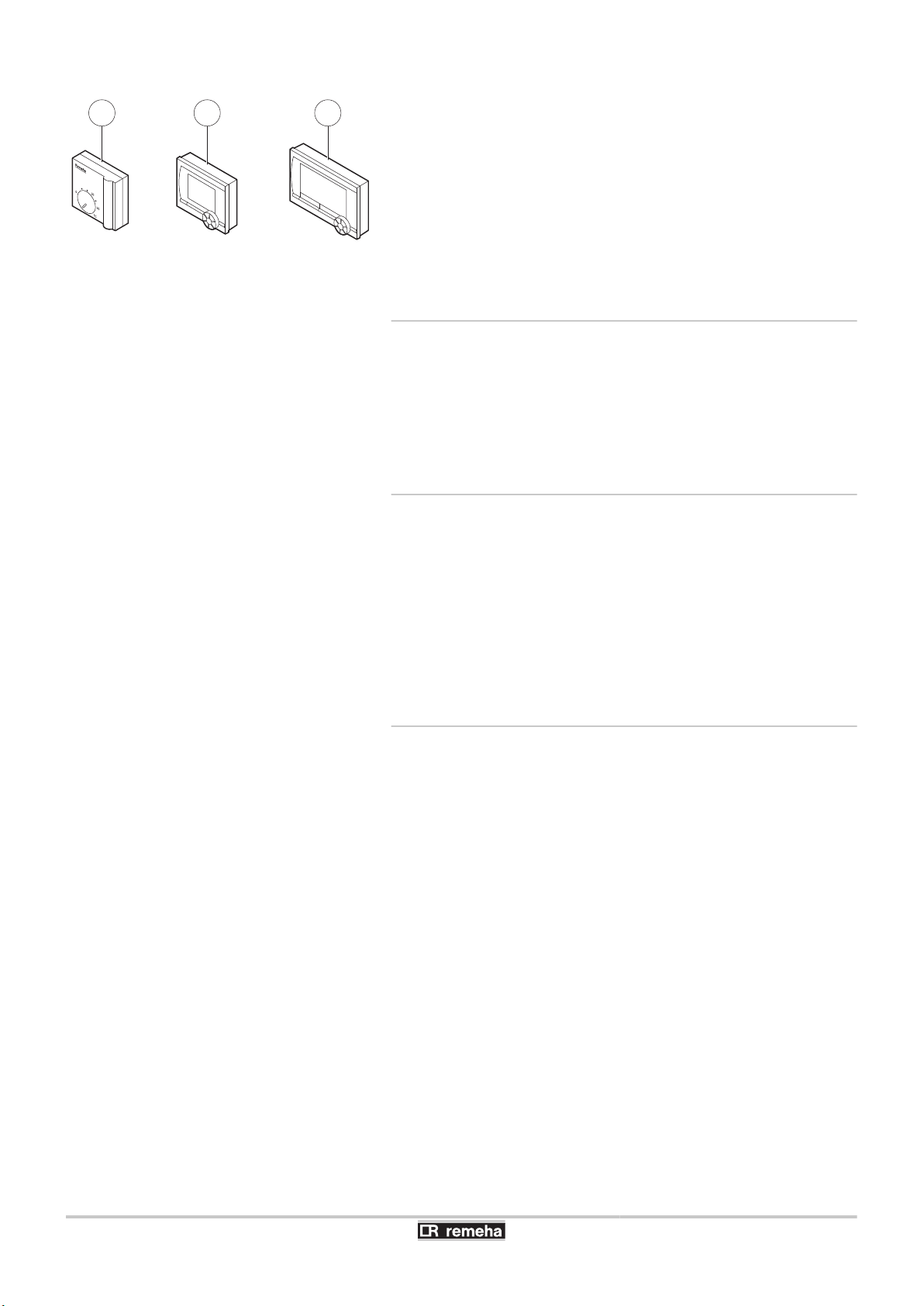

1 2 3

Calenta 25s - 28c - 35s - 40c 3. Technical description

1

2

3

Celcia 10

qSense

iSense

It is possible to connect a 2-wire on/off thermostat to the boiler such

as the Celcia 10 or a power stealing thermostat. The boiler output

can be modulated by an OpenTherm system with an appropriate

modulating thermostat such as the qSense or the iSense.

3.3.6. Regulation of the water temperature

The boiler is fitted with an electronic temperature regulator having an

outlet and return temperature probe. The flow temperature can be set

between 20°C and 90°C. The boiler reduces its power when the set

outlet-temperature is attained. The cutout temperature is the set

heating outlet-temperature + 5 °C.

3.3.7. Protection against a shortage of water

The boiler is fitted with a safety device to prevent the shortage of water

based on temperature measurements. By reducing its output when

the water flow rate is in danger of becoming insufficient, the boiler

continues to operate as long as possible. If the flow rate is too weak

ΔT ≥ 50°C or the heating flow temperature increases too much, the

boiler is locked for 10 minutes, code 5t[09. When there is no

water in the boiler or the pump is not running, the boiler goes into

safety shutdown, code e[10 at ΔT ≥ 70°C.

3.3.8. Maximum temperature protection

The overheating safety device locks the boiler when the water

temperature is too high (110°C), code e[12.

¼ For more detailed information, see chapter: "Error codes",

page 85

040412 - 7600585-01

15

R000124-A

1

4

2 3

T001874-A

1

2

3

9

8

4 5 6 7

T002537-B

0 200 400 600 800 1000 1200

Q (l/h)

10 kW

15 kW

20 kW

25 kW

615

545

435

295

437 623 830 1037

0

100

200

300

400

500

700

H (mbar)

600

3. Technical description Calenta 25s - 28c - 35s - 40c

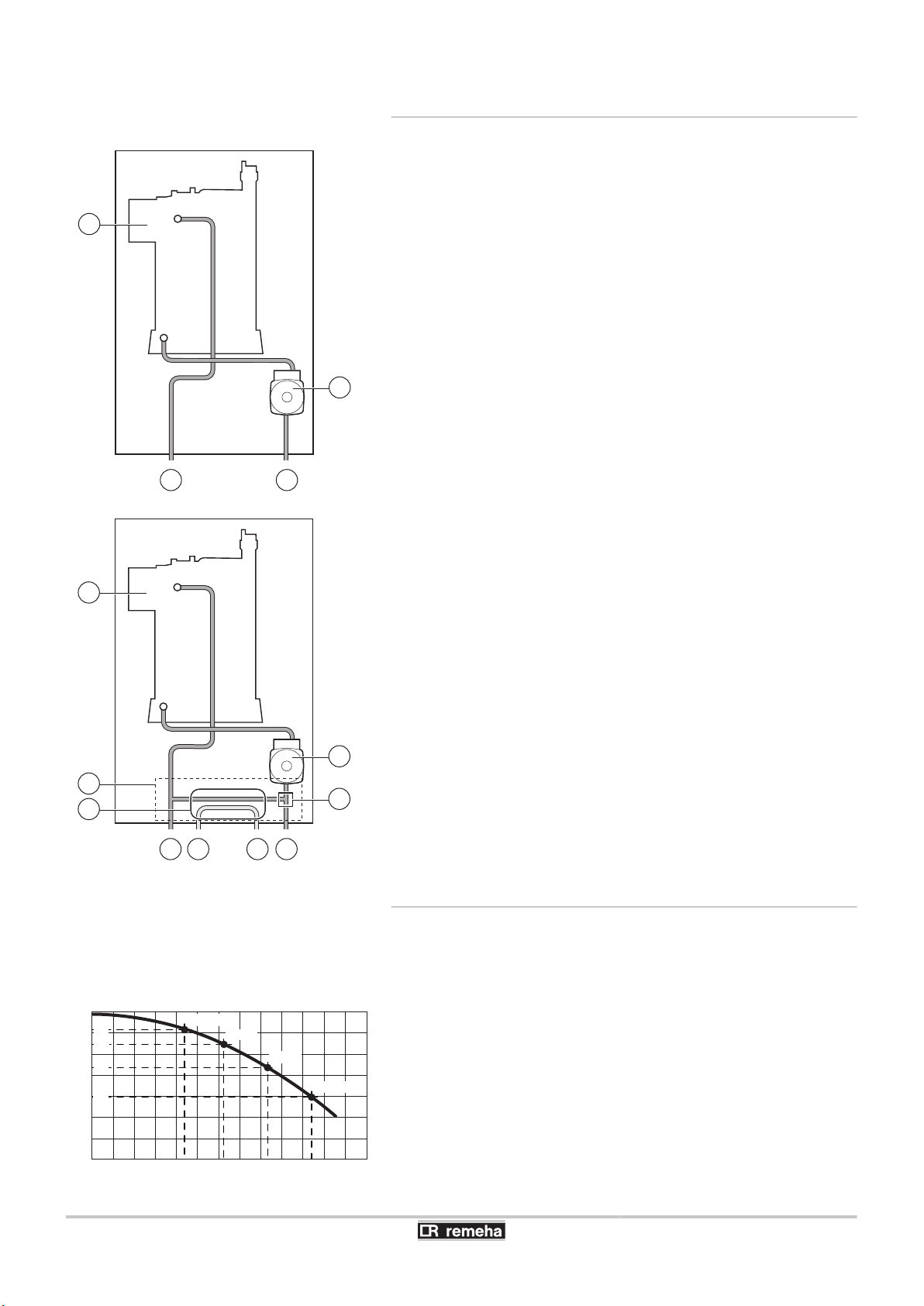

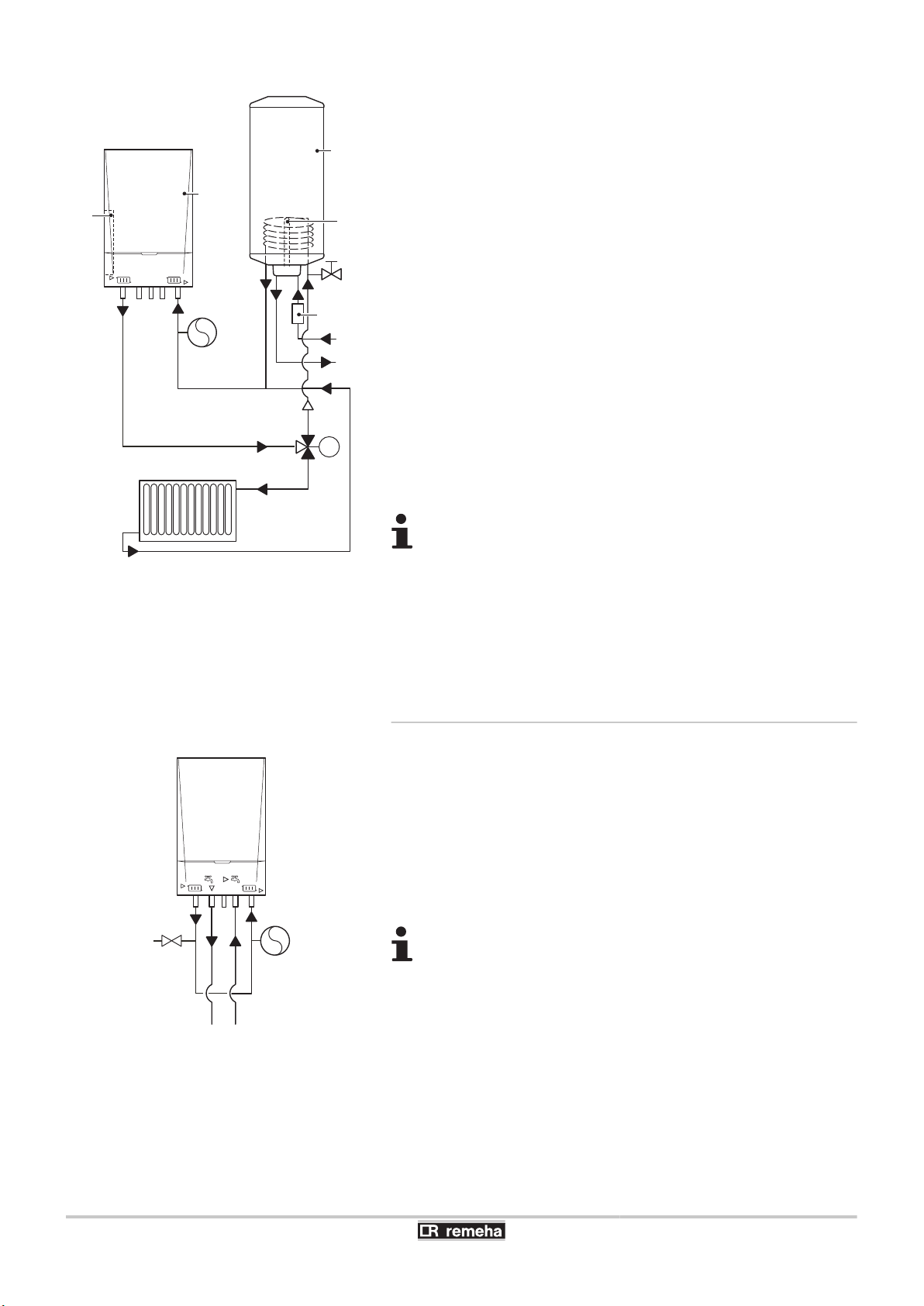

3.3.9. Skeleton Diagrams

Calenta 25s - 35s

1

2

3

4

Heat exchanger (Central heating)

Heating flow

Heating return

Shunt pump (Central heating)

Calenta 28c - 40c

1

2

3

4

Heat exchanger (Central heating)

Hydroblock

Plate heat exchanger (DHW)

Heating flow

16

5

6

7

8

9

Domestic hot water outlet

Domestic cold water inlet

Heating return

3-way valve

Shunt pump (Central heating)

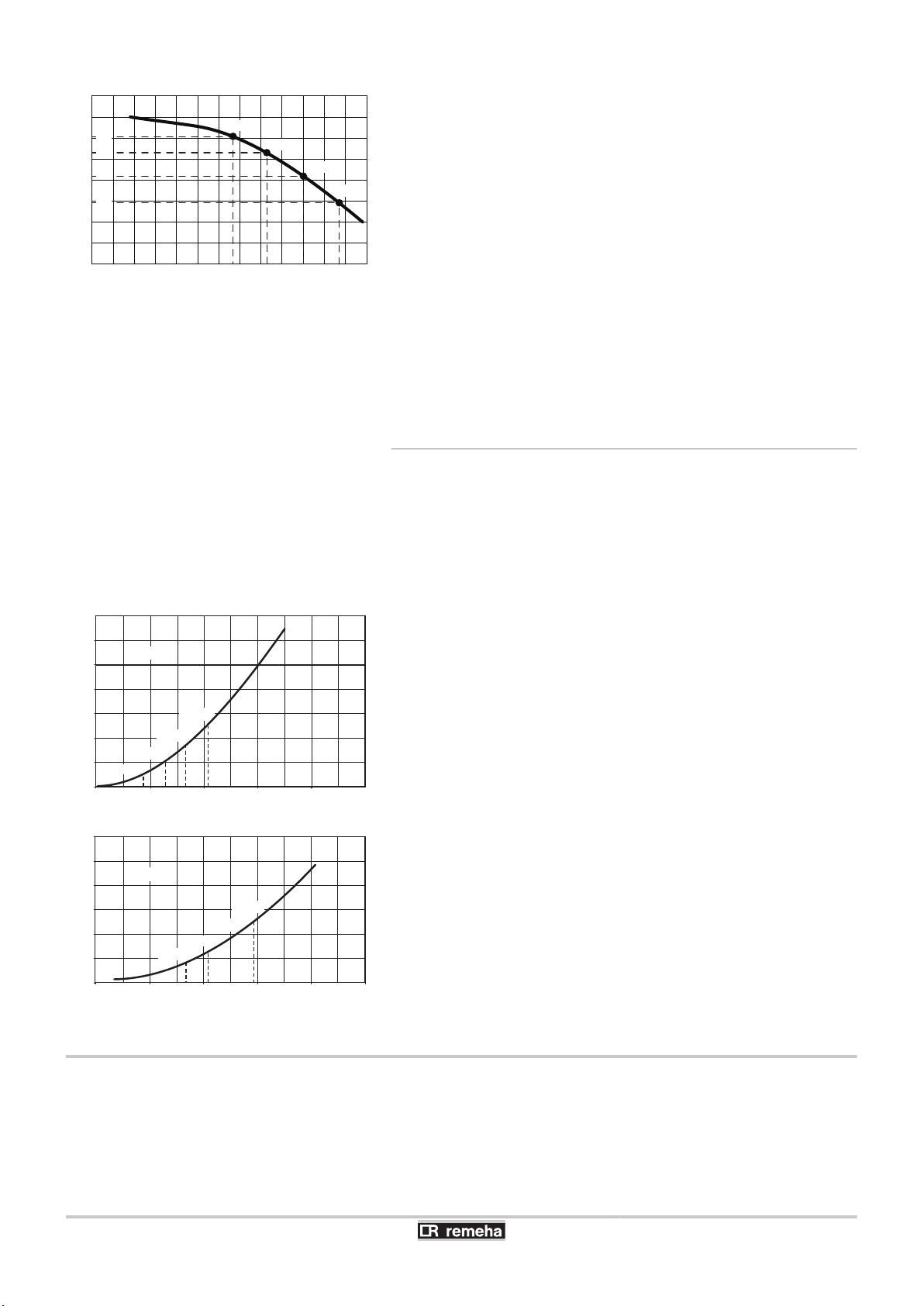

3.3.10. Shunt pump

The boiler is equipped with a circulating pump. This energy-efficient,

modulating circulating pump is controlled by the control unit based on

ΔT. The graph shows the manometric height at various outputs.

Calenta 25s - 28c

H

Q

Manometric height central heating circuit

Water flow

040412 - 7600585-01

T001748-B

0 250 500 750 1000 1250

0

100

200

300

400

500

700

800

H (mbar)

Q (l/h)

600

20 kW

25 kW

30 kW

35 kW

835 1252 1038

1465

606

418

530

291

T001978-A

0

100

200

300

400

500

600

700

0 500

1037437

15001000 2000 2500

∆p [mbar]

Q [l/h]

623 830

∆T = 20K

10 kW

15 kW

20 kW

25 kW

T001749-B

0

100

200

300

400

500

600

0 500

1043 1252 1465835

15001000 2000 2500

∆p [mbar]

Q [l/h]

∆T = 20K

20 kW

25 kW

30 kW

35 kW

Calenta 25s - 28c - 35s - 40c

3. Technical description

Calenta 35s - 40c

H

Q

Manometric height central heating circuit

Water flow

Parameters p"8 and p"9 are used to modify the pump settings:

4 If there are audible flowing noises in the system, the maximum

pump speed must be lowered using parameter p"9 (First of all,

vent the heating system).

4 If there is insufficient flow in the radiators or if they do not warm

up completely, the minimum pump speed can be increased using

parameter p"8.

¼ See chapter: "Modification of the installer-level parameters",

page 67.

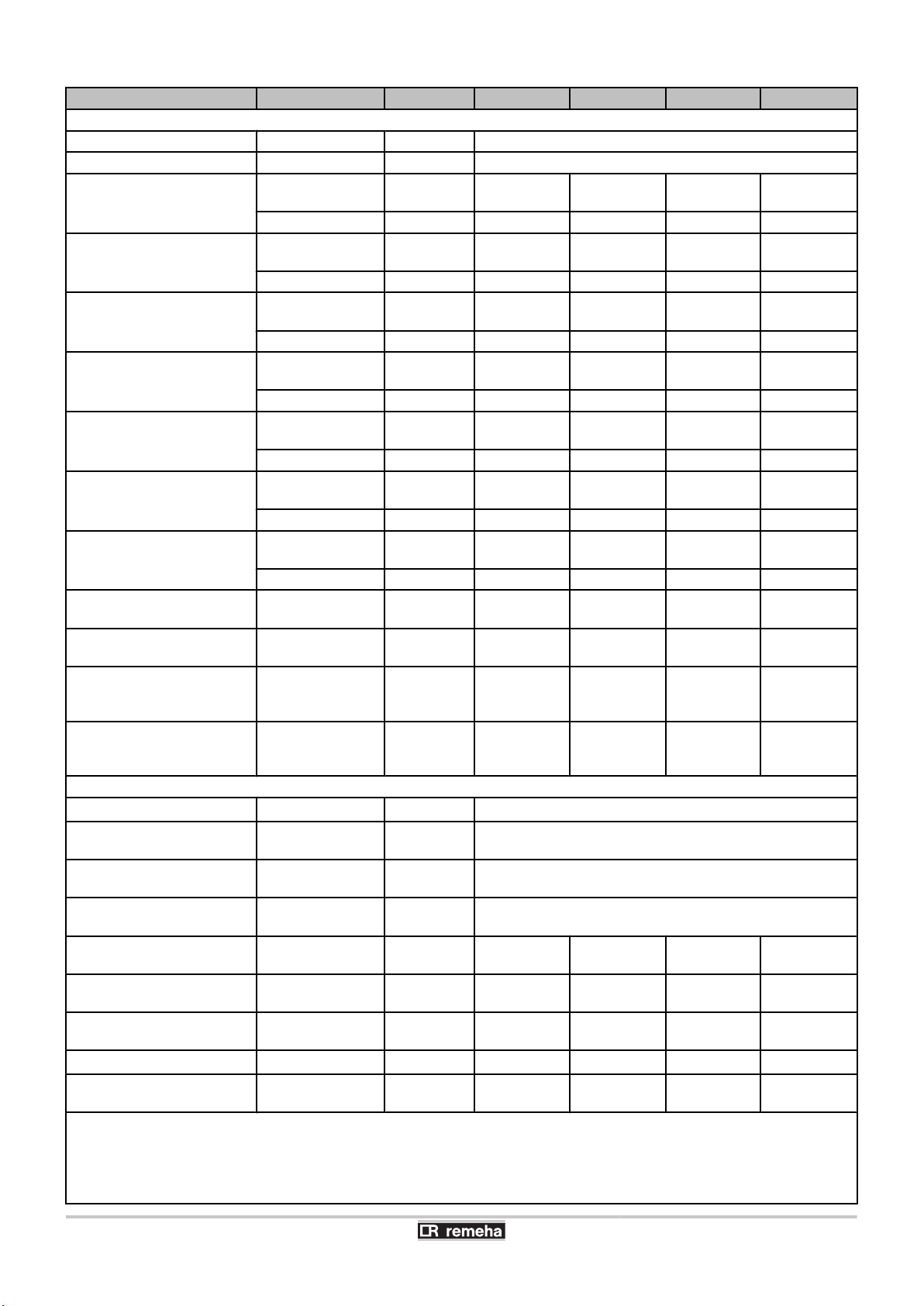

3.3.11. Water flow rate

The boiler's modulating control system limits the maximum difference

in temperature between the heating flow and return and the maximum

speed at which the flow temperature increases. In this way, the boiler

does not require a minimum water flow rate.

¼ If using thermostatic valves, see chapter: "Hydraulic

connections", page 29.

Calenta 25s

3.4 Technical specifications

040412 - 7600585-01

Δp

Q

Calenta 35s

Δp

Q

Pressure drop

Water flow (max = 1680 l/h)

Pressure drop

Water flow (max = 2460 l/h)

17

3. Technical description Calenta 25s - 28c - 35s - 40c

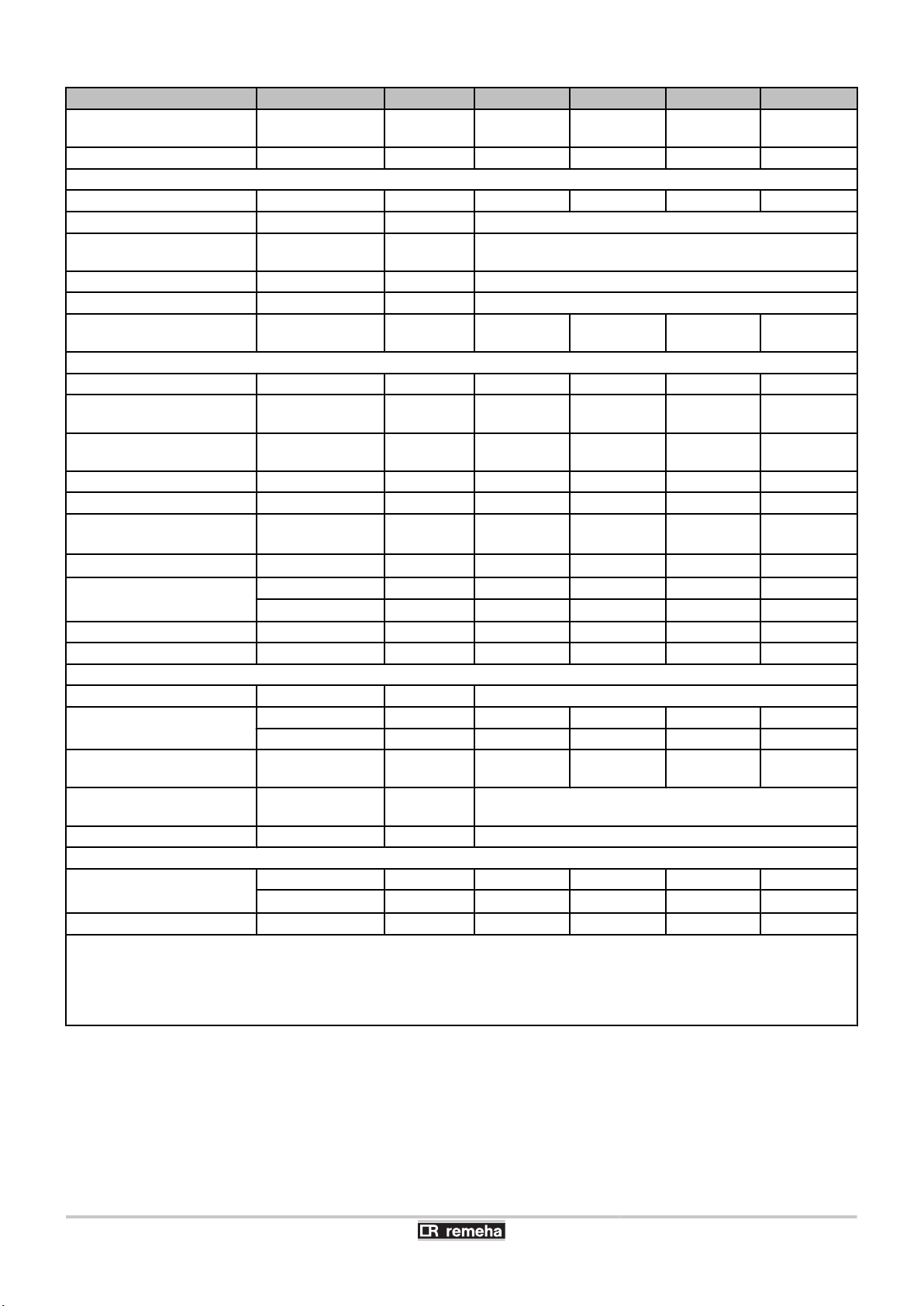

Boiler type Calenta

25s 28c 35s 40c

General

EC indentification no. PIN

Flow rate setting Adjustable

Nominal output (Pn)

Heating System (80/60 °C)

Nominal output (Pn)

Heating System (50/30 °C)

Nominal output (Pn)

DHW System

Nominal input (Qn)

Heating System (Hi)

Nominal input(Qn)

Heating System (Hs)

Nominal input (Qnw)

DHW System (Hi)

Nominal input (Qnw)

DHW System (Hs)

Heating efficiency under full

load (Hi) (80/60 °C)

Heating efficiency under full

load (Hi) (50/30 °C)

minimummaximum

Factory setting kW 24,1 19,4 34,0 23,3

minimummaximum

Factory setting kW 25,5 20,5 35,9 24,5

minimummaximum

Factory setting kW - 28,6 - 39,7

minimummaximum

Factory setting kW 25,0 20,1 35,1 24,0

minimummaximum

Factory setting kW 27,8 22,3 39,0 26,7

minimummaximum

Factory setting kW - 28,0 - 38,8

minimummaximum

Factory setting kW - 31,1 - 43,1

- % 96,3 96,3 96,9 96,9

- % 102,0 102,0 102,2 102,2

kW 5,0 - 24,1 5,0 - 24,1 6,3 - 34,0 6,3 - 34,0

kW 5,6 - 25,5 5,6 - 25,5 7,0 - 35,9 7,0 - 35,9

kW - 5,0 - 28,6 - 6,3 - 39,7

kW 5,2 - 25,0 5,2 - 25,0 6,5 - 35,1 6,5 - 35,1

kW 5,8 - 27,8 5,8 - 27,8 7,2 - 39,0 7,2 - 39,0

kW - 5,2 - 28,0 - 6,5 - 38,8

kW - 5,8 - 31,1 - 7,2 - 43,1

Modulating, Start/Stop, 0 - 10 V

0063BT3444

Heating efficiency under

partial load (Hi) (Return

- % 96,1 96,1 96,3 96,3

temperature 60°C)

Heating efficiency under

partial load (EN 92/42)

- % 108,0 108,0 108,2 108,2

(Return temperature 30°C)

Data on the gases and combustion gases

Gas categories

Gas inlet pressure G20 (GasH)minimum-

- I

2L3P

and I

mbar 17 - 30

2H

maximum

Gas inlet pressure G25 (GasL)minimum-

mbar 20 - 30

maximum

Gas inlet pressure G31

(Propane)

Gas consumption G20 (GasH)minimum-

minimummaximum

mbar 30 - 50

m3/h

0,55 - 2,65 0,55 - 2,96 0,69 - 3,71 0,69 - 4,11

maximum

Gas consumption G25 (GasL)minimum-

m3/h

0,64 - 3,08 0,64 - 3,45 0,80 - 4,32 0,80 - 4,78

maximum

Gas consumption G31

(Propane)

NOx-Emission per year (n =1)

Mass flue gas flow rate minimum-

minimummaximum

m3/h

mg/kWh 38 38

0,21 - 1,02 0,21 - 1,15 0,27 - 1,44 0,27 - 1,59

42 42

kg/h 8,9 - 42,1 8,9 - 47,1 11,1 - 57,3 11,1 - 63,9

maximum

(1) Time needed as of the start of water draw-off to obtain an increase in temperature of 40K at the appliance's water outlet for the purposes of

installation calculation, based on the draw-off flow rate CW.

(2) The specific length of the pipe Ø 10/12 mm is the maximum uninsulated length, on the understanding that, in the most unfavourable summer

situation, the appliance will supply hot water in less than 30 s with a permanent increase in temperature of 35 ºC at the draw-off point in the

kitchen.

(3) Front panel removed

18

040412 - 7600585-01

Calenta 25s - 28c - 35s - 40c 3. Technical description

Boiler type Calenta

Flue gas temperature minimum-

maximum

Maximum counter pressure

Characteristics of the heating circuit

Water content

Water operating pressure minimum bar 0,8

Water operating pressure

(PMS)

Water temperature maximum °C 110

Operating temperature maximum °C 90

Manometric height central

heating circuit (ΔT = 20K)

Characteristics of the domestic hot water circuit

CW gas approval

Specific hot water flow D

(60 °C)

Specific hot water flow D

(40 °C)

Domestic water resistance

Flow rate threshold minimum l/min - 1,2 - 1,2

Actual appliance waiting

(1)

time

Specific pipe length

Annual operational efficiency

for domestic water

Water content

Operating pressure (Pmw) maximum bar - 8 - 8

Electrical characteristics

Power supply voltage

Power consumption - Full

load

Power consumption - Part

load

Power consumption Standby

Electrical protection index

Other characteristics

Weight (empty)

Acoustic level at 1 metre

(1) Time needed as of the start of water draw-off to obtain an increase in temperature of 40K at the appliance's water outlet for the purposes of

installation calculation, based on the draw-off flow rate CW.

(2) The specific length of the pipe Ø 10/12 mm is the maximum uninsulated length, on the understanding that, in the most unfavourable summer

situation, the appliance will supply hot water in less than 30 s with a permanent increase in temperature of 35 ºC at the draw-off point in the

kitchen.

(3) Front panel removed

(2)

maximum bar 3,0

without iSense % - 90,6 - 92,3

with iSense % - 91,4 - 93,8

maximum W 116 124 129 139

Factory setting W 72 72 92 92

maximum W 21 21 22 22

maximum W 4

Total kg 30 31 32 33

Mounting

(3)

°C 30 - 80 30 - 85 30 - 75 30 - 80

Pa 120 130 140 160

l 1,7 1,7 2,3 2,3

mbar 295 295 291 291

- - 4 - 5

l/min - 8,2 - 11,1

l/min - 13,7 - 19,5

mbar - 490 - 810

s - 5,15 - 5,18

m - 23,86 - 23,83

l - 0,33 - 0,49

VAC 230

IP X4D

kg 27 28 29 30

dB(A) 42 44 45 47

25s 28c 35s 40c

040412 - 7600585-01

19

4. Installation

4 Installation

4.1 Regulations governing installation

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations.

Installation must also respect the following points:

4 This instruction manual and any other applicable documentation

4 NEN 1006: The general provisions for drinking water installations

(AVWI)

4 NEN 1010: The provisions on safety for low voltage installations

4 NEN 1078: Gas device with an operating pressure of up to 500

mbar - performance requirements - new construction

4 NPR 3378: Guide on NEN 1078

4 NEN 1087: Ventilation of residential buildings

4 NPR 1088: Explanatory instructions on NEN 1087

4 NEN 2078: Requirements applicable to industrial gas installations

4 NEN 2757: Combustive air supply and flue gas discharge for

combustion appliances

4 NEN 3028: Requirements applicable to incineration installations

4 NEN 3215: Drainage systems inside residences and residential

buildings

4 NEN 8078: Gas device with operating pressure of up to 500 mbar

- performance requirements - existing construction

4 Building Regulations

4 Local provisions from the fire brigade, public service companies

and the municipality

4 In the event of application of domestic hot water supply equipment.

Work data sheet Drinking water installations, VEWIN nr. 4.4 B

Calenta 25s - 28c - 35s - 40c

4.2 Package list

20

4.2.1. Standard delivery

The delivery includes:

4 The boiler, fitted with an earthed mains plug

4 Mounting rail and mounting accessories for wall mounting

4 Mounting template

4 Connection kit comprising sleeves and clamping rings

040412 - 7600585-01

Calenta 25s - 28c - 35s - 40c 4. Installation

4 Run-off collector for siphon and safety valve

4 Installation and Service Manual

4 Sticker: This boiler has been set for...

4 User Guide

4 Warranty card

4 Maintenance log

These installation and maintenance instructions deal only with the

items included in a standard delivery. For the installation or mounting

of any accessories supplied with the boiler, a rail or mounting frame,

for example, refer to the mounting instructions delivered with the

accessories in question.

The boiler is also available with a modular adjustment

device, such as the Combi Comfort system. In this case,

the iSense adjustment device is delivered with the

appliance.

4.2.2. Accessories

Various options are available depending on the configuration of the

installation:

Description

Mounting frame

Mounting frame connection kit, comprising stop valves, safety unit and

pressure gauge

Supporting device for feeding pipes behind the appliance

Pipe kit for connections behind the appliance (in combination with the

supporting device)

Protective cover for the connections

Propane conversion kit

Remeha Celcia 10 on/off thermostat

Remeha qSense basic modulating control system

Remeha iSense extended modulating control system

Remeha iSense integration kit

Outside temperature sensor

Passing through walls Type C1

Combustion air/flue gas adapter 80/125 mm

Combustion air/flue gas adapter 60/100 mm

Kit for connection to the water heater

DHW sensor

Kit for connection to the solar water heater

0-10V (IF-01) control PCB

Extended control PCB (SCU-S02)

Box for the control PCBs

Connection set for coupling to the heat recycling system

Cleaning accessories for the heat exchanger (central heating)

Cleaning kit for the plate heat exchanger (DHW)

Maintenance box

Recom communication kit

Installation kit for the water / gas connection if replacing Remeha Quinta

boilers

040412 - 7600585-01

21

T001539-B

T001531-A

450

min.1000

395

min.

250

min.

250

690

4. Installation Calenta 25s - 28c - 35s - 40c

4.3 Choice of the location

4.3.1. Data plate

The data plate located on top of the boiler provides important

information on the appliance: serial number, model, gas category, etc.

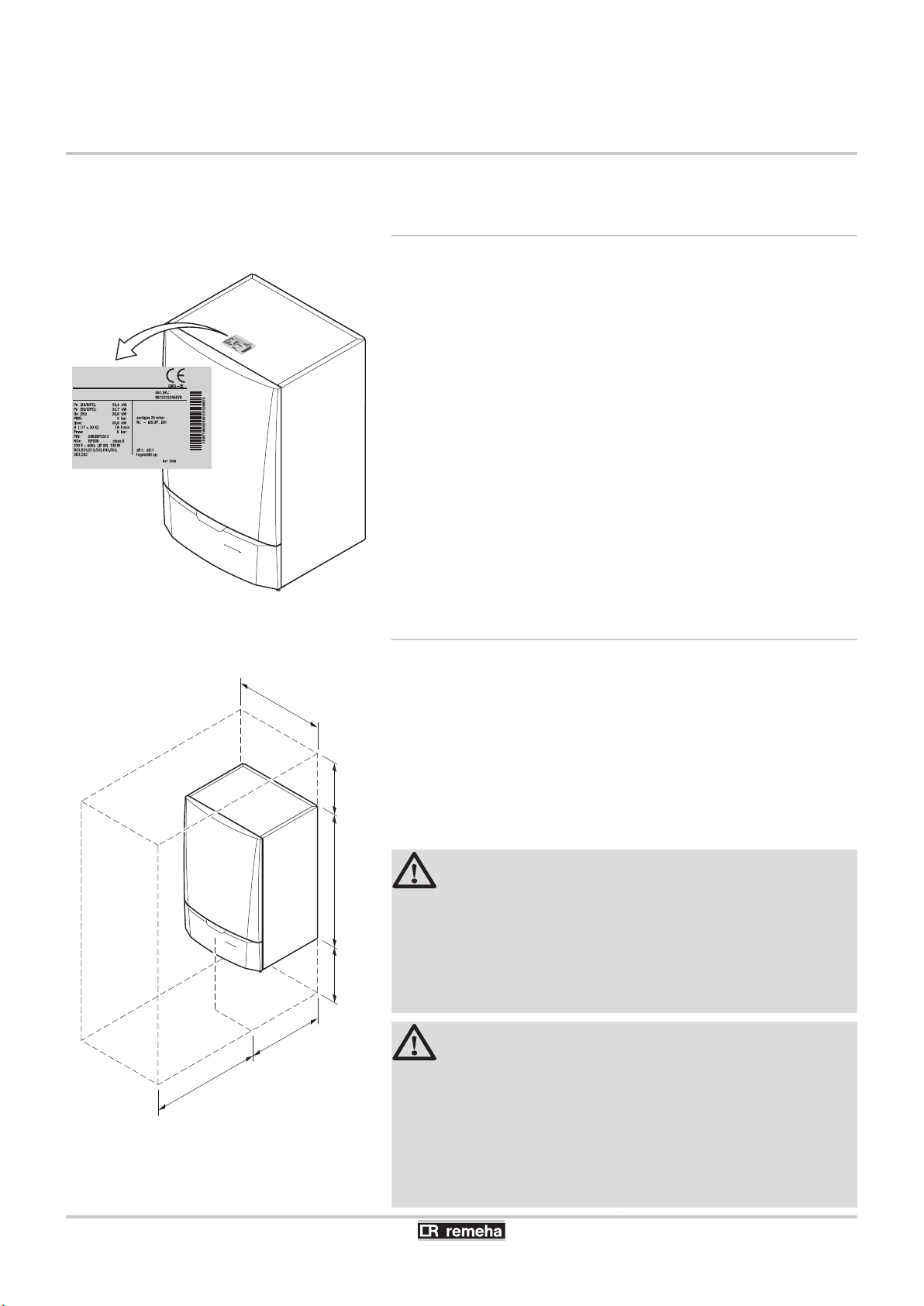

4.3.2. Location of the boiler

4 Before mounting the boiler, decide on the ideal position for

mounting, bearing the Directives and the dimensions of the

appliance in mind.

4 When choosing the position for mounting the boiler, bear in mind

the authorised position of the combustion gas discharge outlets

and the air intake opening.

4 To ensure adequate accessibility to the appliance and facilitate

maintenance, leave enough space around the boiler.

WARNING

4 Fix the appliance to a solid wall capable of bearing

the weight of the appliance when full of water and fully

equipped.

4 It is forbidden to store inflammable products and

materials in the boiler room or close to the boiler,

even temporarily.

CAUTION

4 The boiler must be installed in a frost-free

environment.

4 An earthed wall socket must be available close to the

boiler.

4 A connection to the mains drainage system for the

discharge of condensate must be available close to

the boiler.

22

040412 - 7600585-01

T000756-A

Z

OZ

1

0

B

2 3

60

225

240

T001532-A

min. 550

min.495

min. 250

50 (2)

min. 250

100

min. (1)

Calenta 25s - 28c - 35s - 40c 4. Installation

Safety rating

n

B

Z

OZ

Bathtub or shower tray

Zones

Breakdown of the exterior zone

For safety rating IP X4D, installation in the bathroom is possible in

zones 2 and 3 and in the breakdown of the exterior zone.

4 In this case, connect the 230V power supply as a fixed connection.

4 Also in this case, connect an air intake pipe.

CAUTION

In the case of a fixed connection to the power cord, you

must always install a main bipolar switch with an opening

gap of at least 3 mm (EN 60335-1).

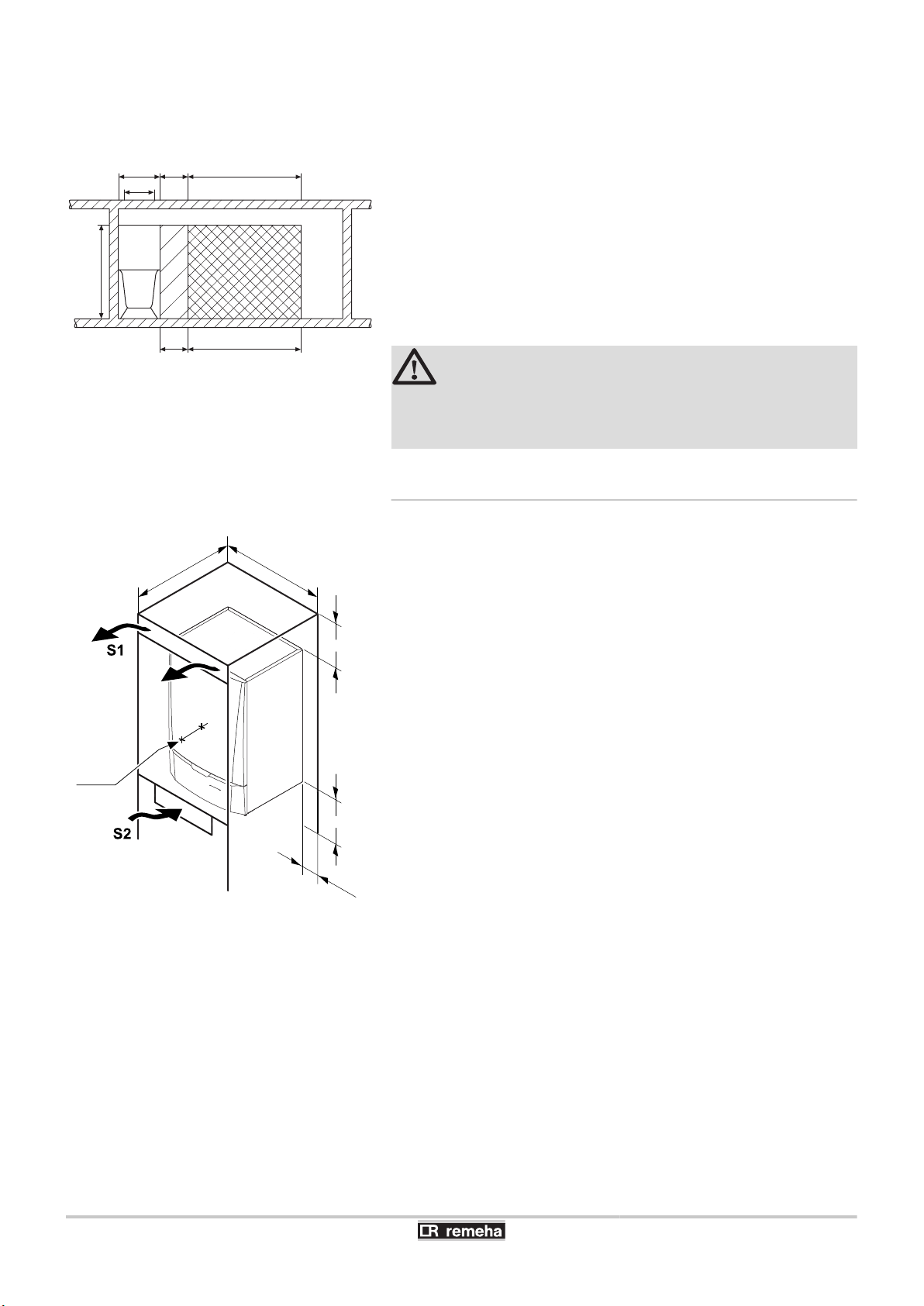

4.3.3. Ventilation

(1)

(2)

Distance between the front of the boiler and the internal

wall of the casing box.

Distance to allow on either side of the boiler.

If the boiler is installed in a closed casing, respect the minimum

dimensions given in the diagram opposite. Also allow openings to

obviate the following hazards:

4 Accumulation of gas

4 Heating of the box

Minimum cross section of the openings: S1 + S2 = 150 cm

2

040412 - 7600585-01

23

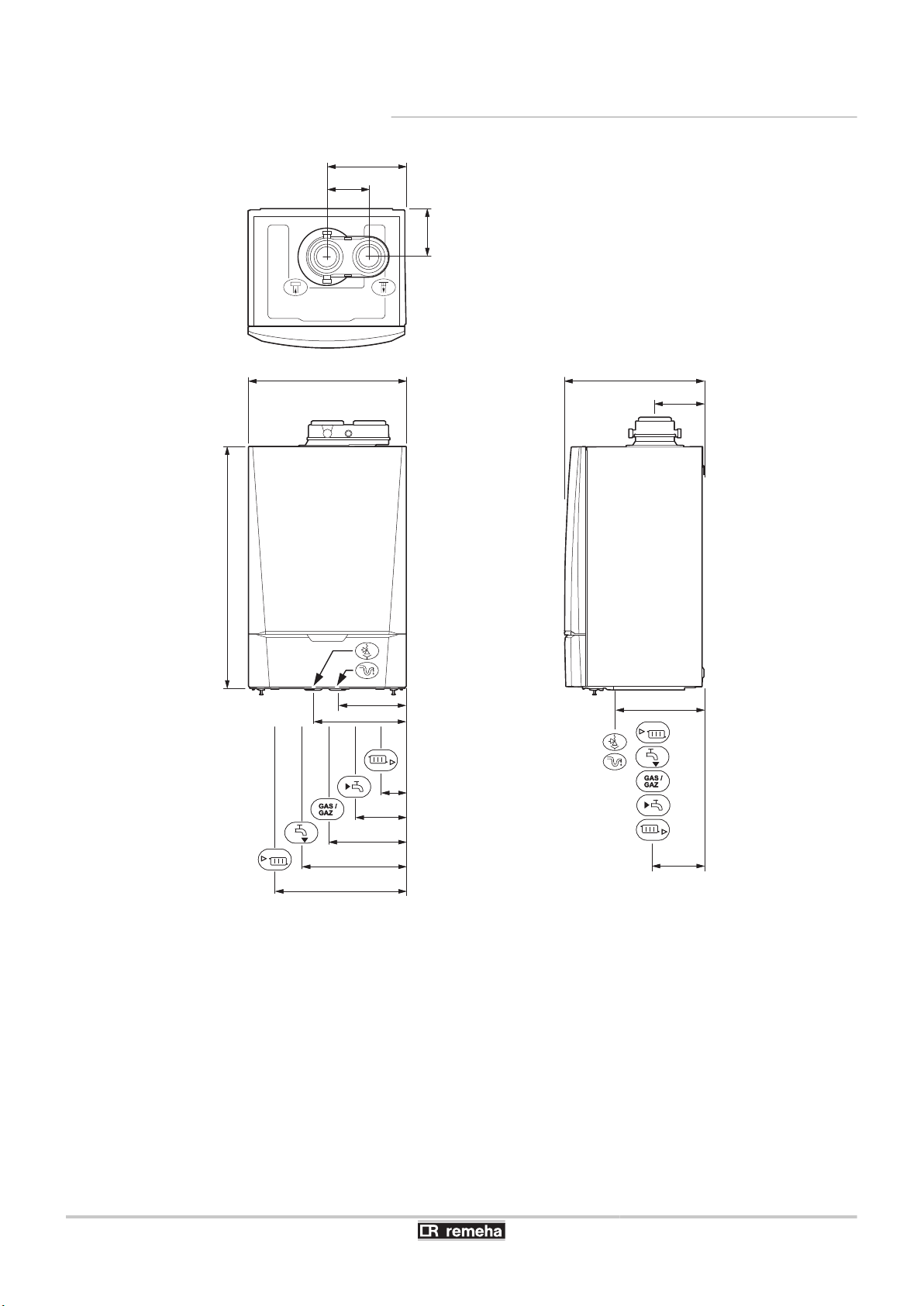

T000754-C

67

195

265

132

199

266

331

690

450

395

225

120

140

140

150

257,5

67

195

265

132

199

266

331

690

450

395

225

120

140

140

150

257,5

4. Installation Calenta 25s - 28c - 35s - 40c

4.3.4. Main dimensions

i

h

ê

j

z

x

Gas /

Gaz

Connection of the combustion gas exhaust pipe; Ø 80 mm

Connection of the air intake pipe; Ø 80 mm

Safety valve outlet pipe; Ø 25 mm

Condensates discharge; Ø 25 mm

Heating circuit return; Clamping Ø 22 mm

Domestic cold water inlet; Clamping Ø 15 mm

Gas connection; Clamping Ø 15 mm

24

y

{

Domestic hot water outlet; Clamping Ø 15 mm

Heating circuit flow; Clamping Ø 22 mm

040412 - 7600585-01

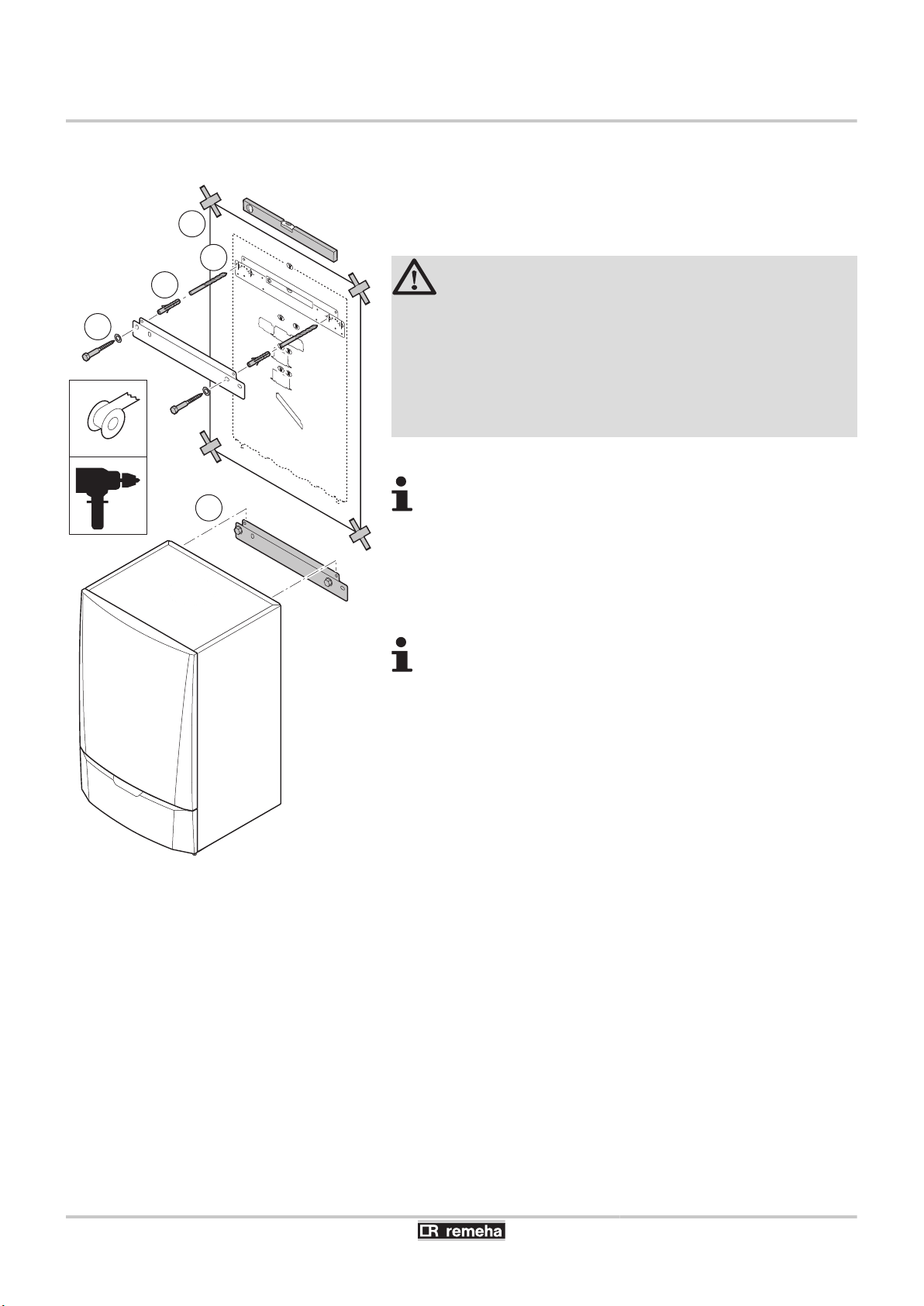

T001540-A

2

1

5

4

3

Calenta 25s - 28c - 35s - 40c 4. Installation

4.4 Positioning the boiler

The boiler is delivered with a mounting template.

A suspension clamp situated at the rear of the casing enables the

boiler to be directly suspended on the mounting bracket.

1. Position the mounting template to the wall with adhesive tape.

CAUTION

4 Using a spirit level, check that the mounting axis is

perfectly horizontal.

4 During mounting, cover up the connection points for

the air supply and the combustion gas exhaust, to

protect the boiler and its connections from dust. Only

remove this protection at the time when these

connections are made.

2. Drill 2 holes with a Ø of 10 mm.

Additional holes are provided in case one or other of the

standard locating holes prevents the correct location of the

plugs.

3. Insert the rawplugs with a Ø of 10 mm.

4. Attach the mounting bracket to the wall with the provided bolts with

a Ø of 10 mm.

5. Hang the boiler on the mounting bracket.

The relevant assembly instruction describes how to hang

the mounting frame (accessory).

040412 - 7600585-01

25

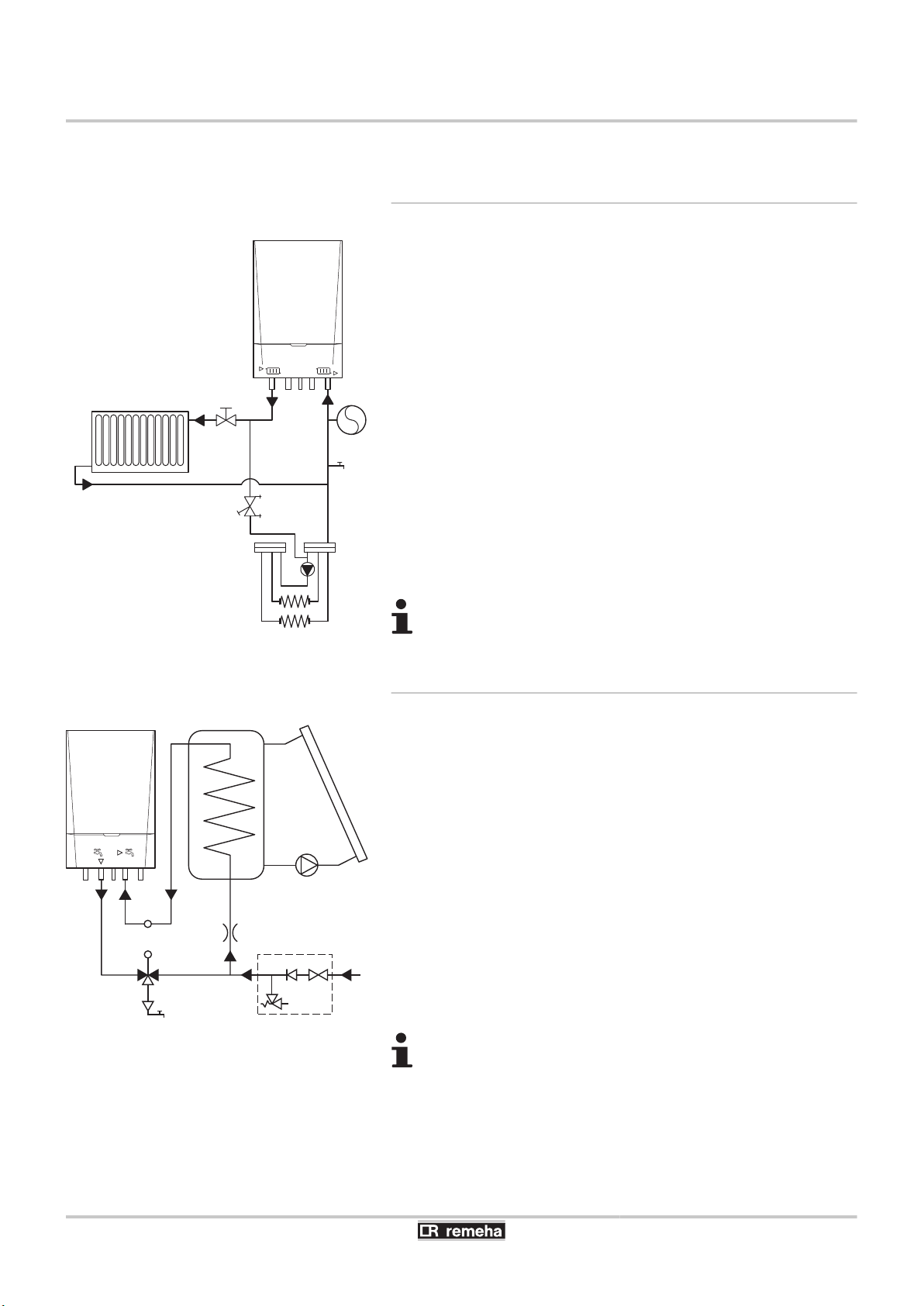

T001535-C

1

2

3

7

5

6

4

T001534-C

1

2

3

4

5

8

6

7

4. Installation Calenta 25s - 28c - 35s - 40c

4.5 Alternatives for hydraulic connections

4.5.1. Connection of the underfloor heating

1

2

3

4

5

6

7

Boiler

Expansion vessel

Stopcock

Regulator valve

Filling/drainage valve

Underfloor heating

Heating by radiators

The boiler can be connected directly to an underfloor heating circuit.

If using plastic ducting (for the underfloor heating for example), the

plastic tubes must be totally oxygen-tight according to standard DIN

4726/4729. If the synthetic ducting used in the installation does not

conform to these standards, it is advisable to hydraulically separate

the boiler circuit from the central heating circuit by installing a plate

heat exchanger.

Parameters p"8 and p"9 are used to modify the

pump settings.

4.5.2. Connection of a solar hot water tank

1

2

3

4

5

6

7

8

Boilers, of the heating and domestic hot water production type, are

Boiler

Tank

Solar collector

Pump

Flow limiter

Safety unit

Mixer valve

Solar DHW sensor SCU-S02

suitable for reheating downstream from solar DHW tanks. A kit

(accessory) is available for the connection.

See the solar domestic hot water tank's technical notes for

more information concerning hydraulic connections.

26

040412 - 7600585-01

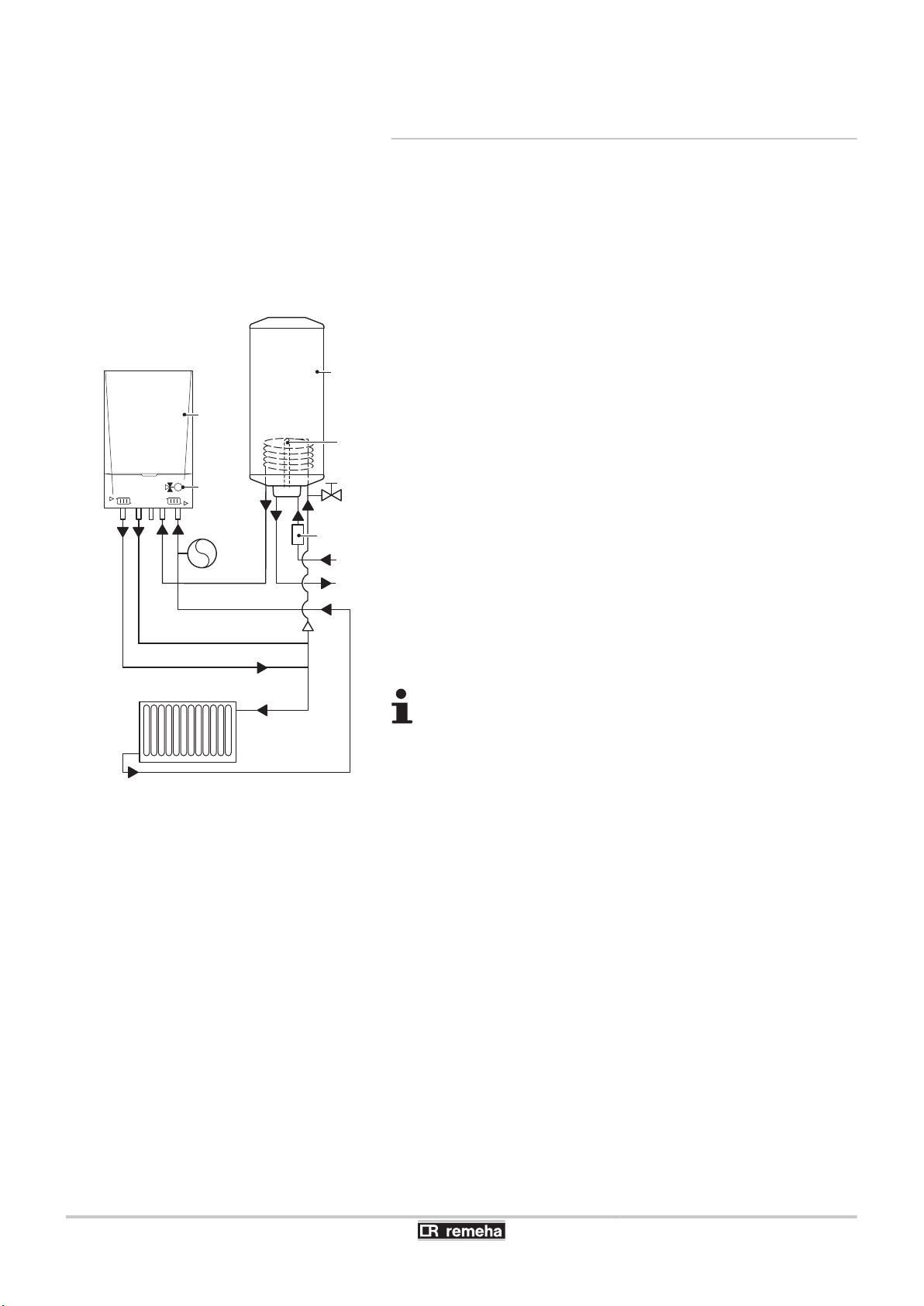

T004865-A

1

2

4

6

7

M

3

5

8

Calenta 25s - 28c - 35s - 40c 4. Installation

4.5.3. Connection of an independent hot water

tank

The standard version of the heating-only type of boiler is fitted with a

command for regulation of the hot water tank circuit. The command

is adjusted to switch preferentially to the hot water tank circuit. This

gives priority to the hot water tank when simultaneous requests for

heat come from the hot water tank and the central heating. The

indirectly heated calorifier can be connected using an internal or

external three-way valve.

Internal three-way valve

1

2

3

4

5

6

7

8

Boiler

Independent hot water tank

DHW sensor

Air vent kit of the hot water tank

Safety unit

Expansion vessel

Heating-Installation

3-way valve

The boiler connection kit must be used to install the three-way valve

in the boiler (Accessory). The three-way valve (230 V) is controlled

by the boiler control unit of the boiler.

¼ For the installation or mounting of any accessories, refer to the

mounting instructions delivered with the accessories in question.

4

A safety unit is installed at the point where cold water

arrives at the hot water tank to prevent backflow or

overpressure.

4 The central heating pipes for the boiler circuit must be

in Ø 22 mm (From Ø 15 mm to Ø 22 mm at the boiler

itself).

040412 - 7600585-01

27

T001537-C

1

2

4

8

6

7

M

3

5

9

T001536-B

1

2

3

4. Installation Calenta 25s - 28c - 35s - 40c

External three-way valve

1

2

3

4

5

6

7

8

9

Boiler

Independent hot water tank

DHW sensor

Air vent kit of the hot water tank

Safety unit

Expansion vessel

Heating-Installation

3-way valve

SCU-X02 control PCB

Control SCU-X02 must be used to install the three-way valve outside

of the boiler (Accessory). The three-way valve 24 V/230 V is

controlled by control SCU-X02. The control must be installed in the

electronics expansion kit (Accessory).

¼ For the installation or mounting of any accessories, refer to the

mounting instructions delivered with the accessories in question.

4 In order to prevent an uncontrolled flow in the heating

circuit, the return channel to the hot water tank must

always be connected directly to the return channel to

the boiler and therefore never directly connected to

the heating installation.

4 A safety unit is installed at the point where cold water

arrives at the hot water tank to prevent backflow or

overpressure.

4.5.4. Geyser use

1

2

3

The combi boiler can also be used solely for DHW operation. The

boiler can then function as a geyser. The central heating function has

to be switched off for this purpose, using parameter p3.

Boiler

Filling/drainage valve

Expansion vessel

The flow and return connections of the unit have to be

connected.

28

040412 - 7600585-01

Loading...

Loading...