REMEHA Avanta Plus 35c, Avanta Plus 28c, Avanta Plus 39c, Avanta Plus 24s Installation And Service Manual

1

• Remeha Avanta Plus 28c

• Remeha Avanta Plus 35c

• Remeha Avanta Plus 39c

• Remeha Avanta Plus 24s

Remeha Avanta Plus

Installation and service manual

Remeha Avanta Plus

2

Remeha Avanta Plus

INTRODUCTION

1 SAFETY 5

1.1 General safety 5

1.2 Safety during assembly and installation 5

1.3 Safety during installation, inspection and maintenance 5

2 INSTALLATION 7

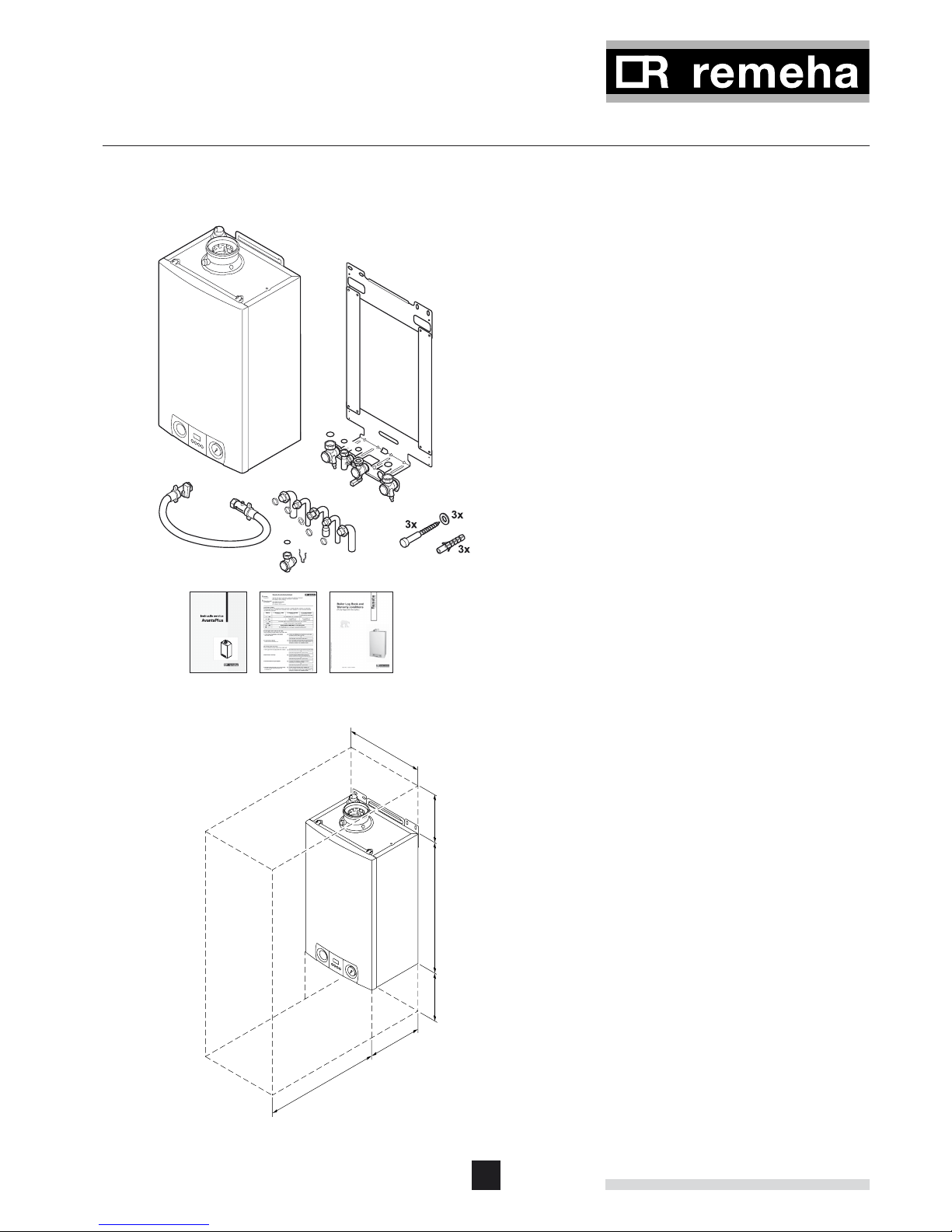

2.1 Scope of delivery 7

2.2 Mounting the boiler 7

2.2.1 Clearance requirements 7

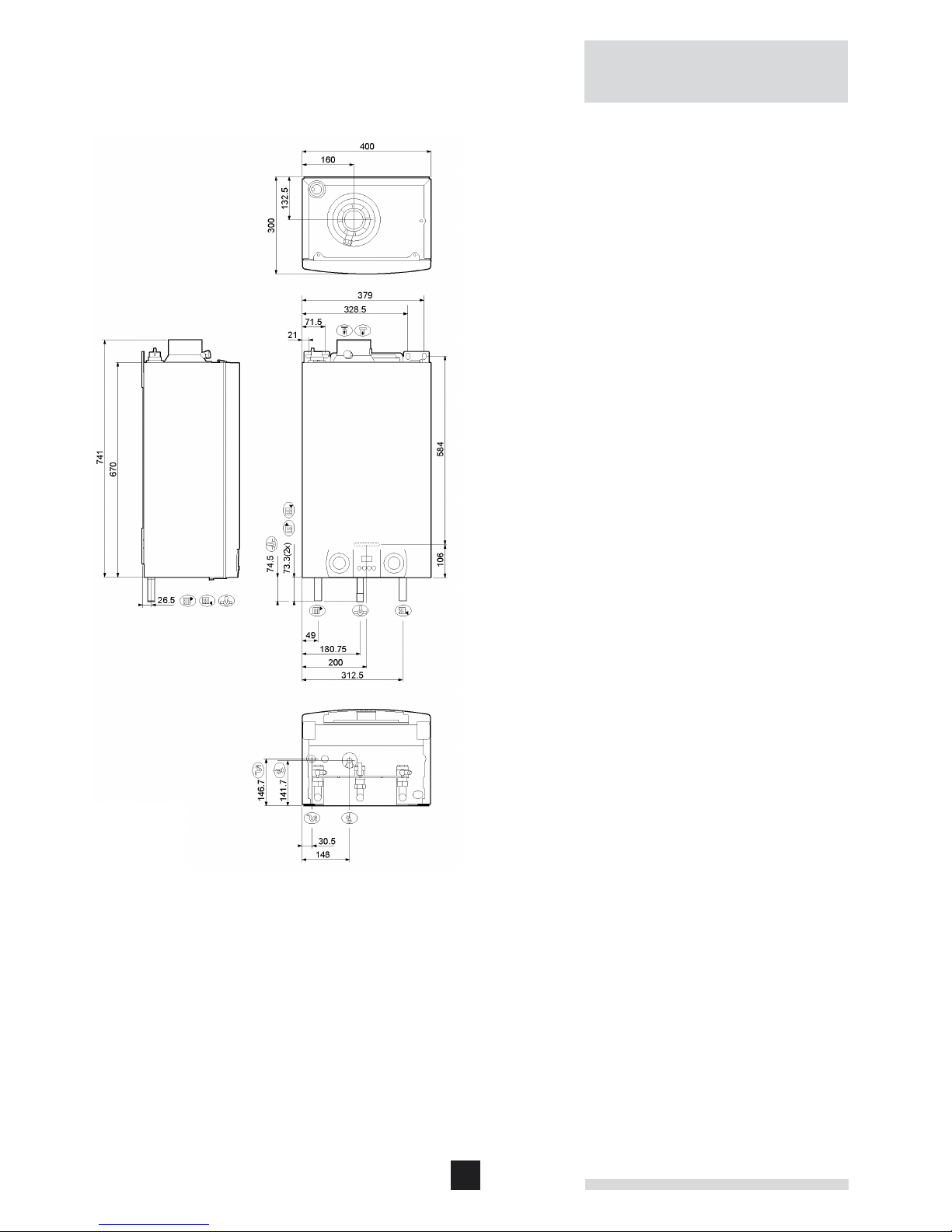

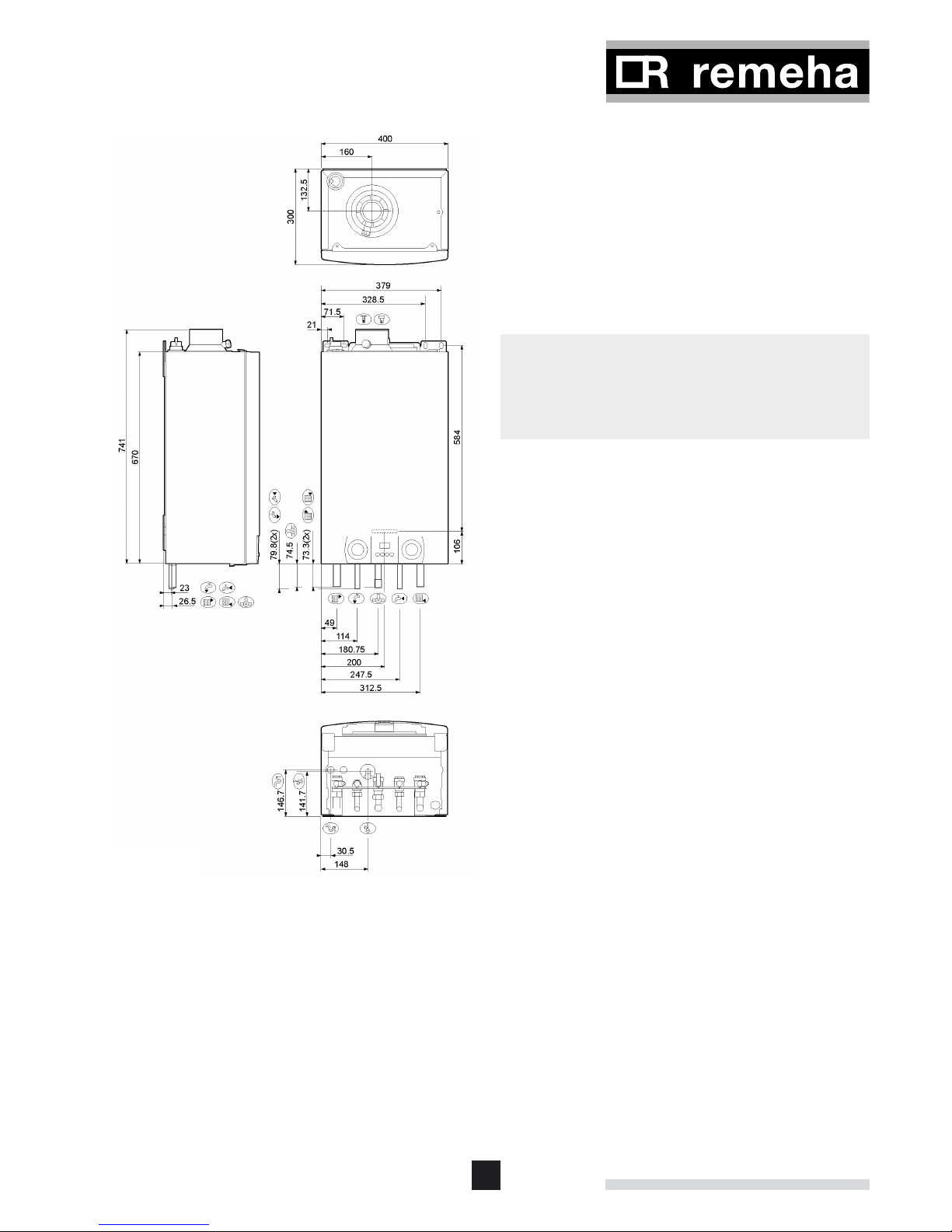

2.2.2 Dimensions and connection points. 8

2.2.3 Mounting the Remeha Avanta Plus 10

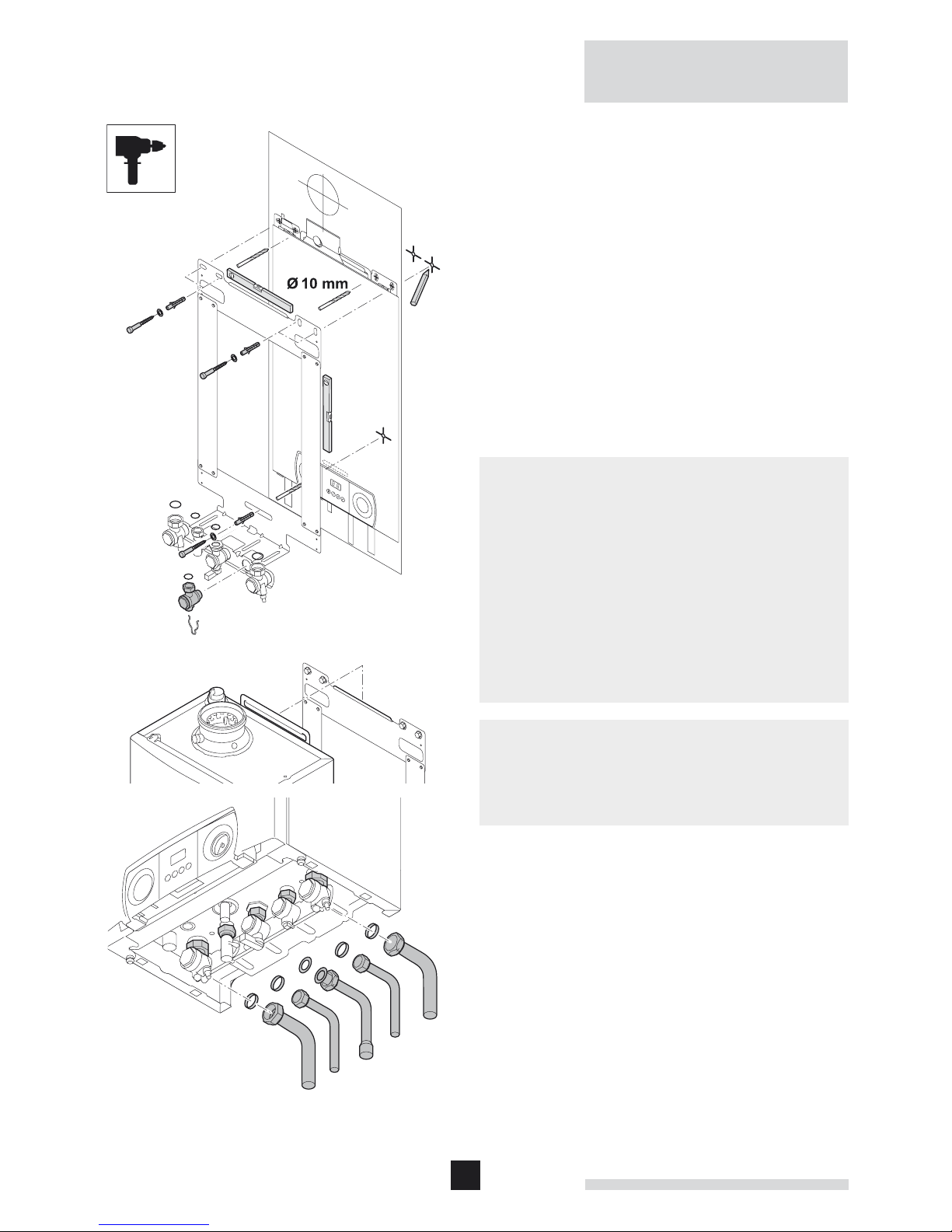

2.3 Water-side connections 10

2.3.1 Water fl ow 10

2.3.2 Circulation pumps 11

2.3.3 Additional guidelines for the domestic and CH water 11

2.3.4 Water treatment 11

2.3.5 Safety valve discharge 12

2.3.6 Expansion vessel 13

2.3.7 Connecting DHW pipes (Combi-type only) 13

2.3.8 Connecting the ‘CH return’ 14

2.3.9 Connecting ‘CH fl ow’ 14

2.3.10 Connecting condensate drain 15

2.3.11 Connecting under fl oor heating 15

2.4 Gas-side connections 15

2.4.1 Additional guidelines for gas connections 15

2.4.2 Connecting the gas supply 16

2.5 Flue terminal and air supply connections 16

2.5.1 Flue terminal positions 16

2.5.2 Room sealed fl ue 17

2.5.3 Connecting the fl ue terminal and air supply 18

2.6 Electrical connection 19

2.6.1 The control unit 19

2.7 Connecting external controls 20

2.7.1 On/off control – room temperature (volt free switching) 22

2.7.2 Time control using an internal or external 230 V clock 23

2.7.3 Connecting a 230 V time clock in combination with a modulating room control 23

2.7.4 Modulating control – room or outside compensation 23

2.7.5 Connecting an outside temperature sensor 24

2.7.6 Connecting the DHW sensor/thermostat 25

2.7.7 Connecting a frost protection device 25

2.7.8 Connecting an external interlock 26

2.7.9 Connecting remote alarm and boiler run indication 26

2.7.10 Connecting a PC/PDA 26

2.8 Wiring diagram 27

2.9 Commissioning 27

2.9.1 Control Panel 27

2.9.2 Additional guidelines for commissioning 27

2.9.3 Putting the boiler into operation 27

2.9.4 Normal start-up procedure 33

2.9.5 Error during the start-up procedure 33

2.9.7 Adjust the boiler according to the system 35

2.9.8 Changing the parameters at service level (with access code) 35

2.9.9 Changing the maximum output (Hi) for CH operation 37

2.9.10 Restore factory settings 39

3

2.10 Putting the boiler out of operation 39

2.10.1 Boiler with frost protection, during longer periods of non-use 39

2.10.2 Boiler without frost protection, during longer periods of non-use 39

3 INSPECTION AND MAINTENANCE 40

3.1 Inspection 40

3.1.1 Checking the water pressure 41

3.1.2 Checking the fl ue pipes and air supply pipes for leaks 41

3.1.3 Checking the condensate siphon 42

3.1.4 Checking the ignition electrode 42

3.1.5 Checking the combustion 42

3.2 Maintenance 43

4 ERRORS 49

4.1 General 49

4.2 Error codes 49

4.3 Control stop or shut down 51

4.4 Error memory 51

4.4.1 Error read outs 52

4.4.2 Deleting errors 52

5 SERVICE PARTS 53

5.1 General 53

6 EC DECLARATION 56

7 REGULATIONS 57

7.1 EC regulations 57

7.2 Remeha factory test 57

8 TECHNICAL SPECIFICATIONS AND WORKING PRINCIPLE 58

8.1 Technical data 58

8.2 The boiler components 59

8.3 Working principle 59

8.3.1 Regulating 60

8.3.2 Advanced boiler control (‘abc

®

’-control) 60

8.3.3 Regulating the water temperature 61

8.3.4 Low fl ow / water protection 61

8.3.5 High Limit temperature protection 61

9 EFFICIENCY DATA AND GAS EFFICIENCY LABELS 62

9.1 Annual effi ciency 62

9.2 Water-side effi ciency 62

4

Remeha Avanta Plus

INTRODUCTION

The Remeha Avanta Plus is a series of high-efficiency fully

condensing central heating boilers, for wall mounting,

available in the following types:

• Remeha Avanta Plus 28c, 35c and 39c

- with integrated domestic hot water system (Combi-type)

• Remeha Avanta Plus 24s

- without integrated domestic hot water system

(System-type)

LT.AL.W7H.000.001

These technical instructions contain useful and important information for the correct installation, operation and maintenance

of the Remeha Avanta Plus combi and system boilers.

o

Read these instructions carefully before putting the boiler into

operation, familiarise yourself with their control functions and

operation, strictly observing the instructions given. Failure to

do so may invalidate warranty or prevent the boiler from

operating correctly.

The installation, commissioning, inspection and servicing of the

boiler must be carried out by a competent Corgi registered engineer who holds valid ACOPS certification and in accordance

with current gas safety (installation and use) regulations, the

building regulations and all other relevant codes of practice.

All electrical work must be carried out by a competent engineer and to be installed in accordance with the current IEE

regulations.

o

On commissioning the certificate in the Boiler Service Log

book (supplied with the boiler) must be completed and left on

site with a copy send on to Broag Ltd for registration purposes.

If you have any questions, require an engineer to call on site,

or if you need more information about specific subjects relating

to this boiler, or it's installation please do not hesitate to contact our technical help line 0118 978 3434.

o

When contacting Broag with a problem on the boiler, please

have available the boiler type, Serial No (located on the

bottom of the casing), and the symptoms or fault code (the

fault code is a series of flashing red digits in the display panel).

The data published in these technical instructions is based on

the latest information (at date of publication) and may be subject to revisions.

We reserve the right to continuous development in both design

and manufacture, therefore any changes to the materials or

technology employed may not be retrospective nor may we be

obliged to adjust earlier supplies accordingly.

5

1 SAFETY

1.1 General safety

The following pictograms are used in this Installation and Service manual to specifically draw certain points to your attention:

Tip o Useful tip or practical advice.

Indication z Important instruction in carrying out a

particular operation.

Warning m Possible danger of personal injury or

material damage to the regulator,

building or environment.

Danger { Serious personal injury can occur

because of risk of electric shocks.

1.2 Safety during assembly and installation

Observe the appropriate safety measures, as given in these

instructions.

m

Can you smell gas? What to do:

• do not smoke and do not create any flame or sparks;

• do not use any electric switches;

• turn off the gas tap;

• open windows and doors;

• trace possible leaks and seal them.

Warning! If the leak is before the gas meter, alert your gas

supplier, TRANSCO, tel. 0800 111 999

m

Can you smell smoke or flue gasses? What to do:

• isolate power supply.

• open windows and doors;

• trace possible leaks and seal them.

1.3 Safety during installation, inspection and

maintenance

Under the current Gas Safety (Installation & Use) Regulations,

the Remeha Avanta Plus, in common with all gas appliances,

must be installed by a competent person in accordance with

that regulation.

Statutory regulations in any country, cannot be overridden by

any of the notes or instructions from the manufacturer.

Compliance with National Standards does not provide any

degree of immunity from legal obligations. In the UK, the

installation must be in accordance with the national and local

norms and requirements.

For any issues or circumstances not addressed within these

instructions, please call our Customer Care Department.

6

Remeha Avanta Plus

The Remeha Avanta Plus (combi and system) is a WRAS

(Water regulations) approved product.

LT.AL.W7H.000.074

Remeha Avanta Plus (combi and system) - PIN:

0063BQ3009

Gas Council numbers: Remeha Avanta Plus 28c: 47-673-02

Remeha Avanta Plus 35c : 47-673-03

Remeha Avanta Plus 39c: 47-673-04

Remeha Avanta Plus 24s: 41-288-05

Classification type for evacuation of the combustion products;

according EN 483: see Par. 8.1.

Health and safety information

• The weight of the Avanta Plus system and combi boilers

exceed the maximum lift weight for one person.

• All sealants and gaskets are free from harmful products. On

first firing the boiler, a smell from the sealants and gaskets

may be present and should cease after a short period.

7

400

min.600

3

00

min. 250

min.

2

50

670

2 INSTALLATION

2.1 Scope of delivery

The standard delivery of the Remeha Avanta Plus boiler

includes:

LT.AL.W7H.000.011

- the boiler (including pressure gauge and safety valve);

- mounting plate (including isolation valve set and washers);

- nylon plugs and screws for fixing mounting plate;

- copper tails 15/22 mm;

- mounting template;

- filling loop;

- Boiler Service Log Book;

- Installation and Service manual and Users guide.

This Installation and Service manual deals with the standard

supplied boiler only. For the installation or assembly of any

optional accessories supplied with the boiler, such as stand off

frame, pipework kits, cover plate, control kits, etc, please refer

to the Assembly Instructions supplied with these accessories.

2.2 Mounting the boiler

Packed in the box with the Remeha Avanta Plus box is this

Installation and Service manual. Read instructions and remarks

carefully. This section includes the guidelines and instructions

for the connection of gas, water, electricity, safety devices, the

regulator, control unit, flue discharge and air supply.

2.2.1 Clearance requirements

The gas and water connections are located on the bottom of

the boiler whilst the air in and flue gas outlet is located on the

top of the boiler. The boiler is supplied as standard with pipework tails to allow connections facing downwards.

Optional stand off frame and pipework kits are available

to enable the pipework to run upwards behind the boiler if

required. For installation, servicing and inspection min. 600

mm in front of the boiler is required. If this free space is

obtained by opening a door or removing a panel, the boiler

may be installed for instance in a closed cupboard.

We do recommend a side clearance of 0.5 cm so that the unit

is easy to open, with a free space of 25 cm under the appliance and 25 cm above the appliance, as the minimum requirement.

LT.AL.W7H.000.003

8

Remeha Avanta Plus

System-type

Return connection Ø 22 mm

Flow connection Ø 22 mm

Gas connection Ø 22 mm

Combustion air inlet Ø 100 mm (concentric)

Flue duct Ø 60 mm (concentric)

Condensate drain connection ¾”

(standard overflow pipe size)

º Connection safety valve Ø 15 mm

2.2.2 Dimensions and connection points.

LT.AL.W7H.000.005

9

Combi-type

Return connection Ø 22 mm

Flow connection Ø 22 mm

Gas connection Ø 22 mm

Combustion air inlet Ø 100 mm (concentric)

Flue duct Ø 60 mm (concentric)

DHW inlet (cold) connection Ø 15 mm

¢ DHW outlet (hot) connection Ø 15 mm

Condensate drain connection ¾”

(standard overflow pipe size)

º Connection safety valve Ø 15 mm

z

• Based on the guidelines and the required installation

space, determine where to mount the Remeha Avanta

Plus.

• In determining the boiler position, consider carefully the

flue outlet position and any pluming consequences.

LT.AL.W7H.000.002

10

Remeha Avanta Plus

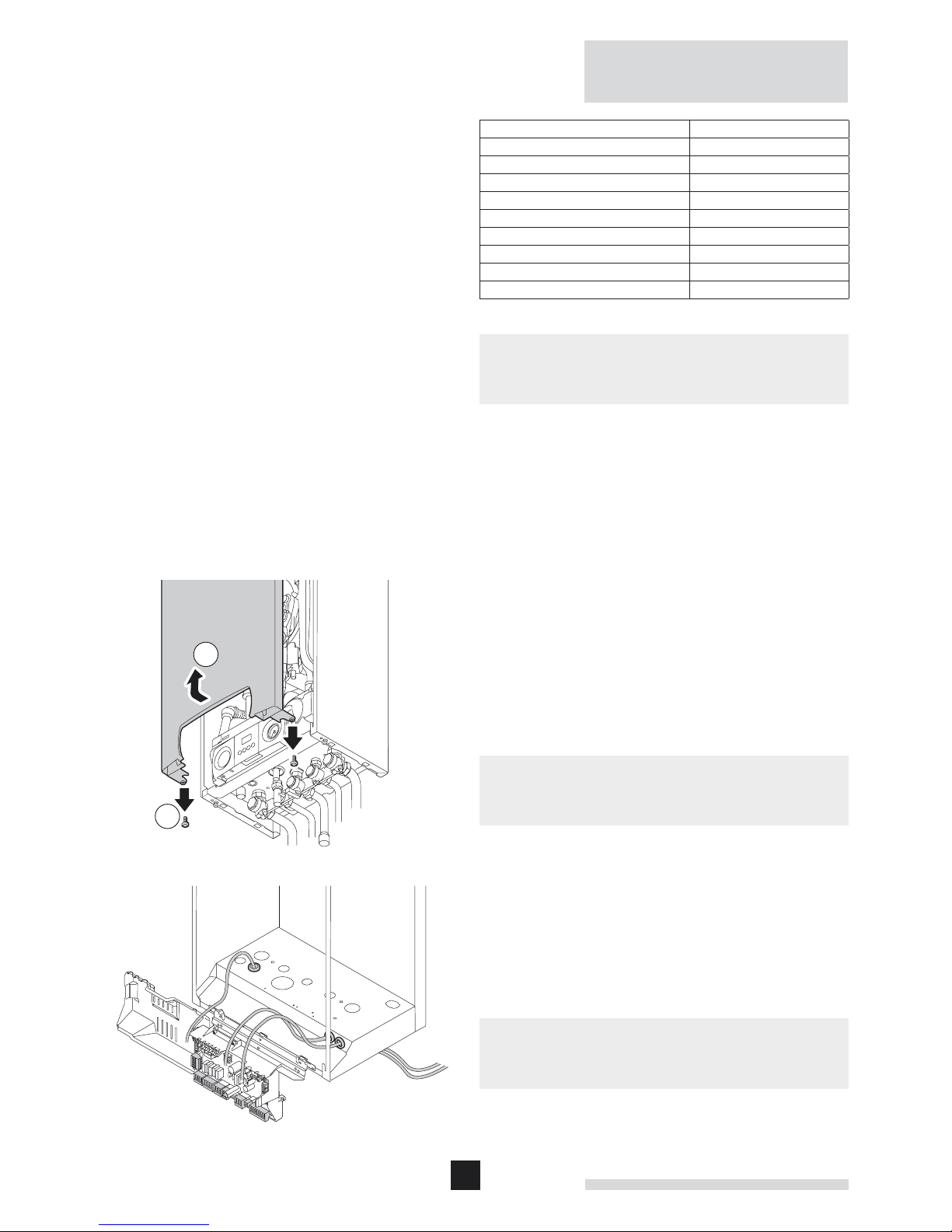

2.2.3 Mounting the Remeha Avanta Plus

LT.AL.W7H.000.012

• Remove the mounting plate and template from the box.

• Using the template determine and mark the position of the

three mounting holes and center line of flue, making sure

the plate is absolutely level.

• Drill the (Ø 10 mm) holes.

• Fit the (Ø 10 mm) plugs.

• Fit (Ø 8 mm) screws into the plugs.

• Check the mounting plate is level and tighten the screws.

• Fit the valve set to the mounting plate.

• Fit fibre washers on the CH valves.

• Remove boiler from the box and suspend it on mounting

plate.

• Connect the valves to the boiler remembering to fit fibre

washers supplied.

• Connect the supplied copper tails to the isolating valves.

m

• The boiler should be mounted on a suitable vertical wall

which is able to support the weight of the boiler.

• The boiler should be mounted in a room which, even during

severe cold weather, remains frost-free.

• If the boiler is to be installed in a timber framed building,

please refer to British Gas publication: ‘Guide for Gas

Installations in Timber frame Housing’, reference DM2.

• In a new installation it is possible to fit just the wall plate and

valve set to enable the system pipework to be completed

and tested before fitting the boiler at a later date (place

fibre washers supplied in a safe place for use when fitting

the boiler).

z

• Make sure the boiler and any open connections are

protected from building etc. dust during the installation.

• There must be a 3 amp fused switched spur within 1m of

the boiler.

• Provision must be made for the condensate discharge.

2.3 Water-side connections

2.3.1 Water flow

An internal automatic flow by-pass is supplied in the Avanta

Plus to ensure correct operation on systems fitted with TRV’s

on all heat emitters. The ‘abc

®

’ control also monitors the temperature difference across the flow and return connections and

the rate of temperature rise and will automatically regulate the

boiler output to ensure that it remains operational for as long

as possible without the need to ‘lock out’ requiring a manual

re-set.

11

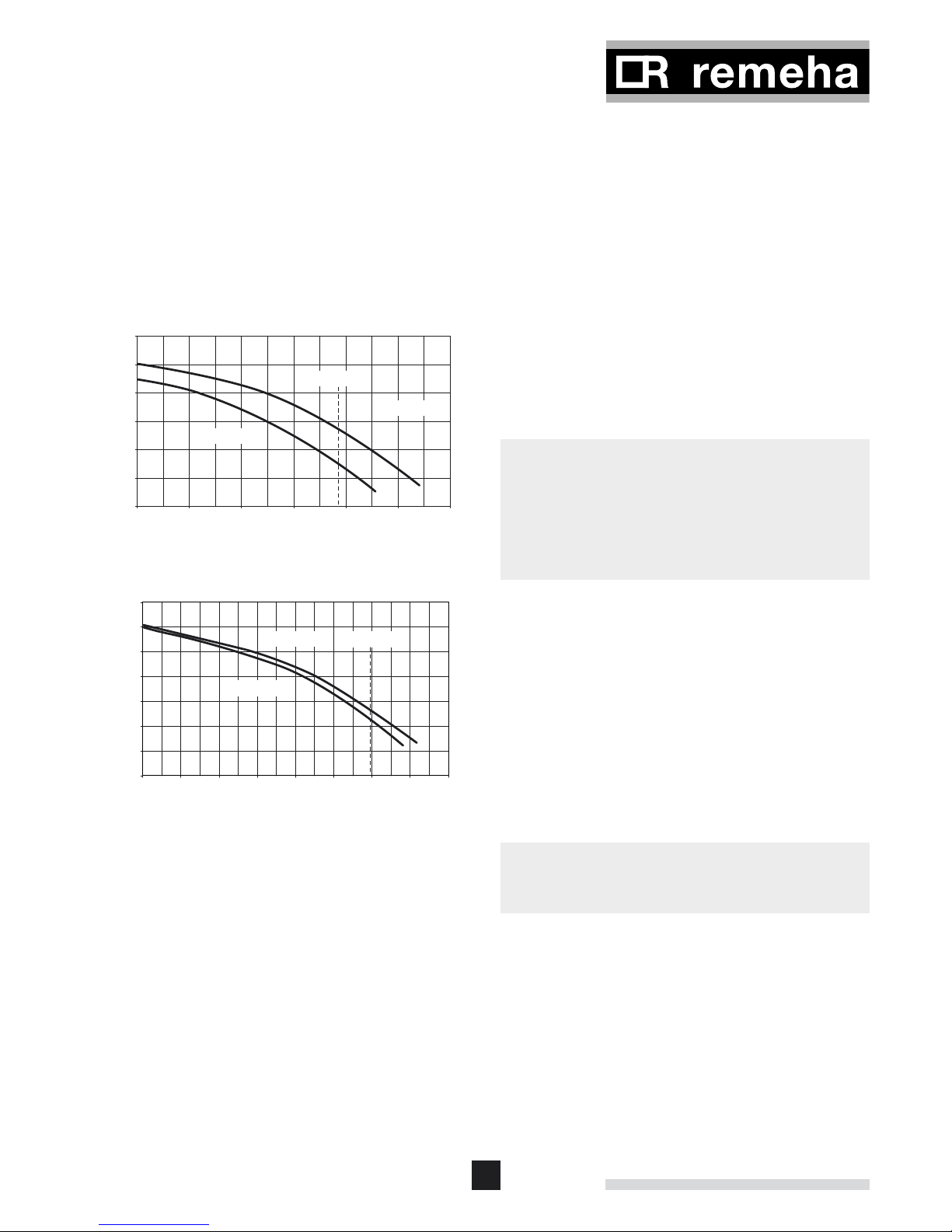

Residual head UPR 15-60

0

100

200

300

400

500

600

0 200 400 600 800 1000 1200

CH-flow [l/h]

Residualhead[mbar]

dT 20°C 18kW

Pump 'high'

Pump 'low'

Residual head UPR 15-70

0

100

200

300

400

500

600

700

0 200 400 600 800 1000 1200 1400 1600

CH- flow [l/h]

Residual head [mbar]

Pump 'high'

Pump 'low'

dT 20°C 28kW

2.3.2 Circulation pumps

The Remeha Avanta Plus 24s and 28c are fitted with the

Grundfos UPR 15-60 and the Avanta Plus 35c and 39c with

the UPR 15-70, two-speed circulation pumps. The control unit

ensures that when the hot-water function is active, the pump

runs at ‘high’. The factory setting of the pump for CH function is ‘low.’ If necessary, the service installer can adjust this

to ‘high’ by switching parameter 21 (from 0 to 1) see par.

2.9.8.

LT.AL.W7H.000.013

LT.AL.W7H.000.014

2.3.3 Additional guidelines for the domestic and CH water

• The system should be filled with mains cold water (for the

UK this will usually have a pH of between 7 and 8).

• Power flush the pipes and radiators thoroughly to remove

all fluxes and debris before connecting the boiler to the central heating system in accordance with BS 7593 (1992).

m

• The temperature of the central heating pipes and the

radiators can rise to 95°C.

• Use untreated tap water only to fill the CH system.

• The pH value of the system water must be between 6 and 9.

• In case inhibitors are being used, please follow the

instructions given in par. 2.3.4.

2.3.4 Water treatment

If used correctly water treatment can improve the boilers

efficiency and increase the anticipated life expectancy of the

boiler. For further information a special document “Quality

requirements CH water” is available from Broag.

As most systems contain a variety of metals, it is considered

good practice to provide some form of water treatment in order

to prevent or reduce the following:

• Metallic corrosion

• Formation of scale and sludge

• Microbiological contamination

• Chemical changes in the untreated system water

m

All scale deposits however small will reduce the efficiency of

the boiler and should be prevented.

Suitable chemicals and their use should be discussed with a

specialist water treatment company prior to carrying out any

work (environmental aspects, health aspects). The specification of the system and manufacturers recommendations must

be taken into account, along with the age and condition of

the system. New systems should be flushed thoroughly to

BS 7593(1992) to remove all traces of flux, debris, grease

and metal swarf generated during installation. Care to be

taken with old systems to ensure any black metallic iron oxide

sludge and other corrosive residues are removed, again by

power flushing, ensuring that the system is drained completely

from all low points.

12

Remeha Avanta Plus

z

Please ensure that the new boiler plant is not in circuit when

the flushing takes place, especially if cleansing chemicals are

used to assist the process.

It is important to check the inhibitor concentration after installation, system modifications, filling the system and every service

in accordance with these instructions.

For the correct dosage and the suitability of inhibitors for use

with our boilers and for further information on water treatment

or system cleaning we advise direct contact with either of the

following companies:

‘Copal

®

’ manufactured by:

Fernox, Cookson Electronics

Forsyth Road

Sheerwater

Woking

Surrey GU21 5RZ

Tel No: 01483 793200

Fax No: 01483 793201

Email: sales@fernox.com

Web site: www.fernox.com

or:

Sentinal ‘X100

®

’ manufactured by:

BetzDearborn Ltd

Sentinal

Foundry Lane

Widnes

Cheshire WA8 8UD

Tel No: 0151 424 5351

Fax No: 0151 420 5447

2.3.5 Safety valve discharge

A pressure relief safety valve is fitted in the boiler set to the

maximum operating pressure of the boiler at 3 bar.

If the pressure in the boiler becomes too high the pressure is

relieved by releasing water outside via the safety valve discharge pipe. The safety valve discharge pipe must be at least

15 mm Ø. The discharge should be terminated facing downwards exterior to the building in a position where discharging

water will not create danger or nuisance but remains in a visible position.

13

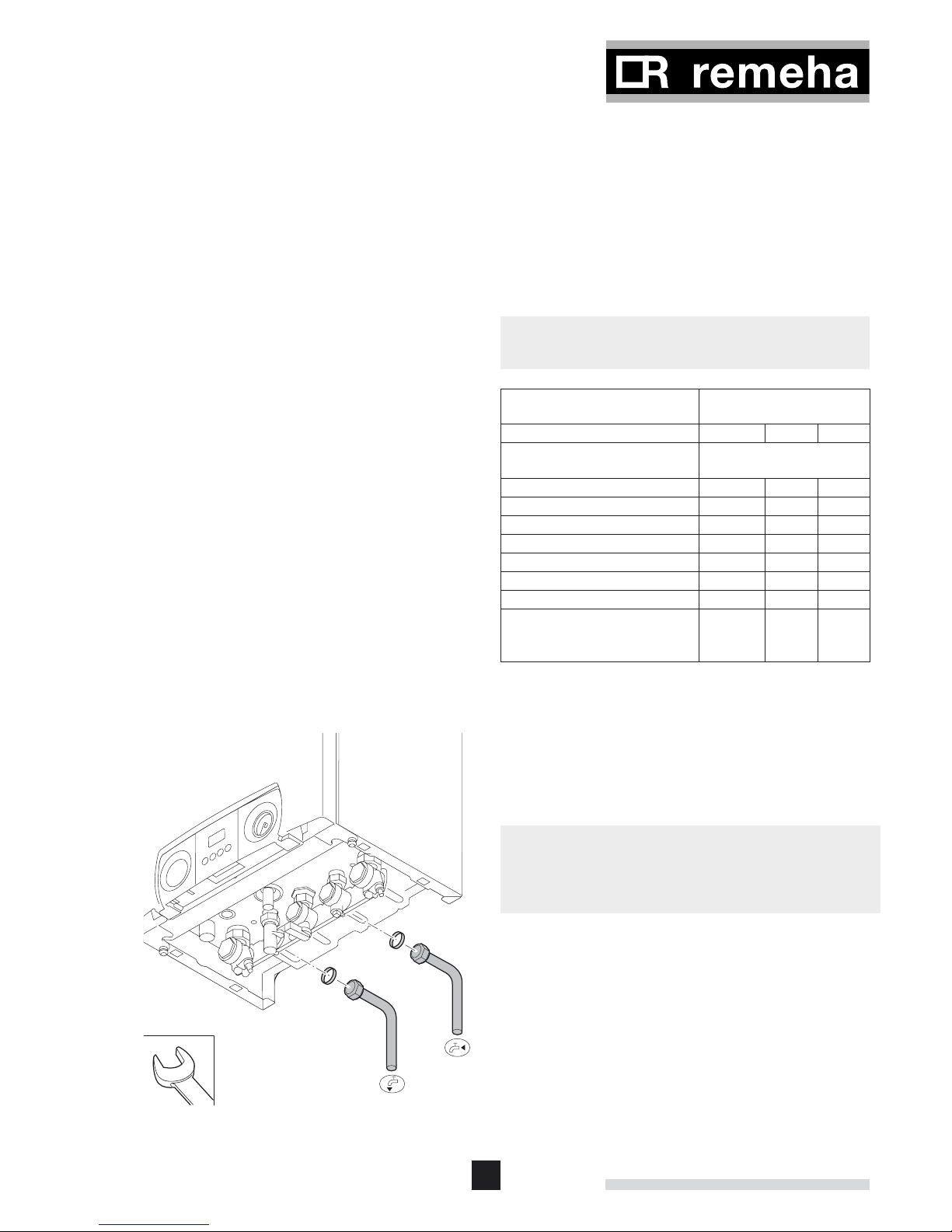

2.3.6 Expansion vessel

An 8 litre expansion vessel (with the vessel charge set to 1.0

bar) is fitted as standard within the boiler case and is suitable

for use in a heating system with a water content up to 100

litres, operating at a flow temperature of 80°C, a maximum

pressure of 3 bar and a maximum system static head of 5

metres above the boiler. If the system water content is greater

than 100 litres, or the system static head above the boiler is

greater than 5 m, an additional vessel must be installed in the

system to allow for the increase in expansion, see table 01.

m

Install additional vessel according BS 5449, part1.

Boiler Safety Valve Setting

(Bar) 3.0

Vessel Charge (Bar) 0.5 1 1.5

Heating System Water Content

(Litres)

Expansion Vessel Size

(Litres)

100 4.8 8.0 13.3

125 6.0 10.0 16.6

150 7.2 12.0 20.0

175 8.4 14.0 23.3

200 9.6 16.0 26.6

250 12.0 20.0 33.3

300 14.4 24.0 39.9

For other system volumes,

multiply the system volume

by the factor across:

0.048 0.080 0.133

table 01 Expansion Vessel Size

2.3.7 Connecting DHW pipes (Combi-type only)

LT.AL.W7H.000.015

• Fit the outlet pipe for hot water to the DHW outlet ¢ 15 mm

Ø connection.

• Fit the inlet pipe for cold water to the DHW inlet 15 mm

Ø connection.

z

• The DHW pipes must be connected in accordance with

current regulations.

• For plastic pipes, follow the manufacturer’s instructions

(for connection).

14

Remeha Avanta Plus

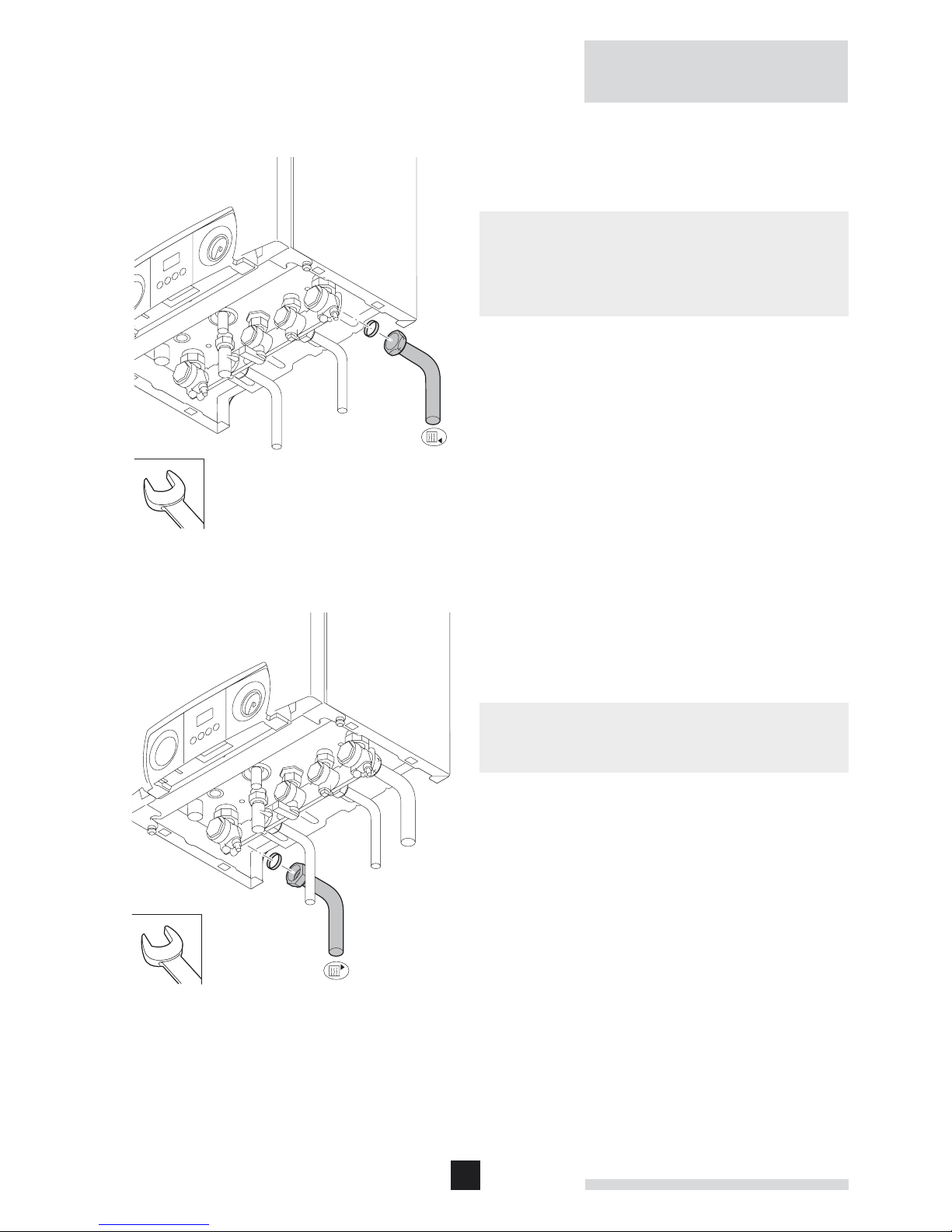

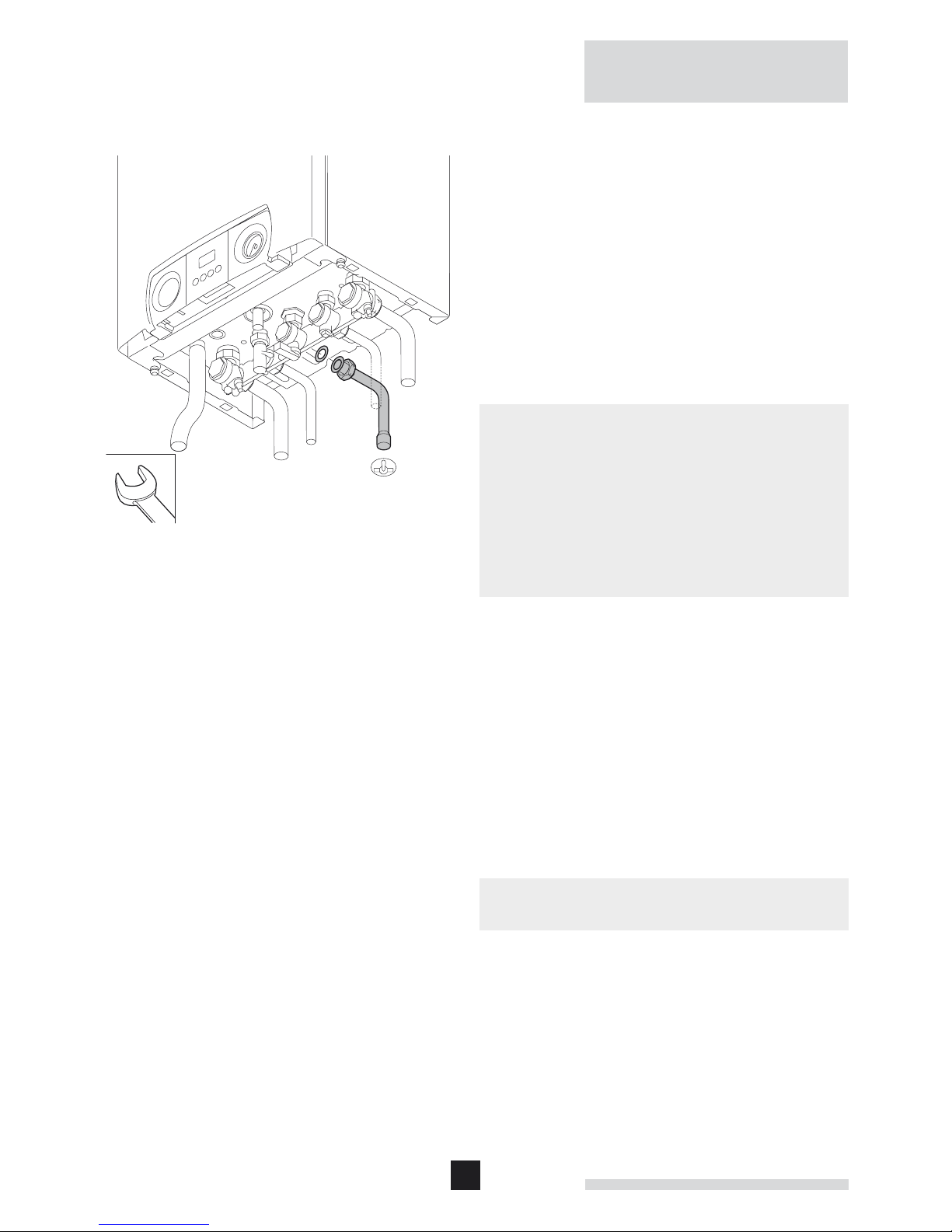

2.3.8 Connecting the ‘CH return’

LT.AL.W7H.000.016

• Fit the inlet pipe for CH water to the ‘CH return’ 22 mm

Ø connection.

o

The Remeha Avanta Plus has a drain cock built into the return

isolating valve

It is considered good practice to install an air separator / dirt

removal device in the return to the boiler.

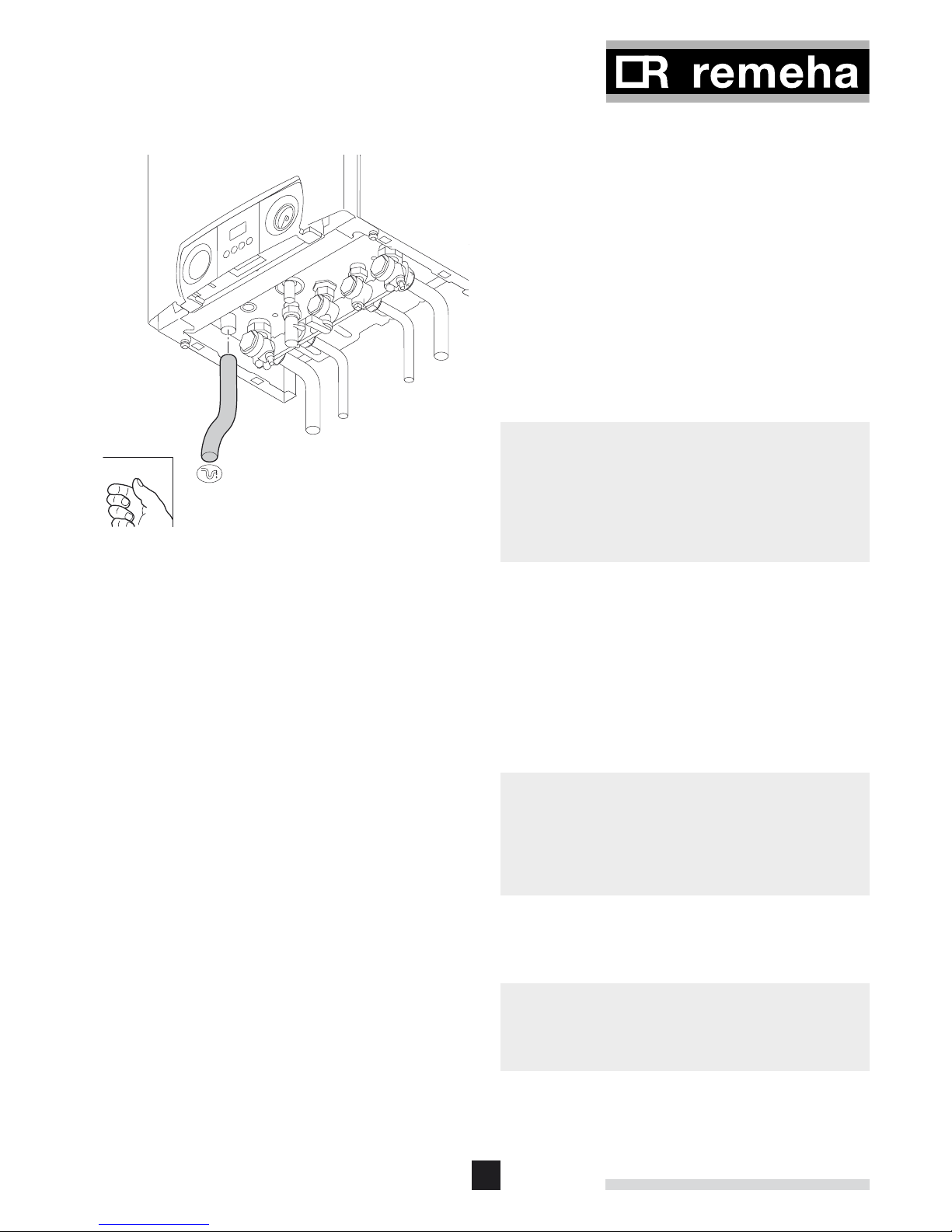

2.3.9 Connecting ‘CH flow’

LT.AL.W7H.000.017

• Fit the outlet pipe for CH water to the ‘CH flow’ 22 mm

Ø connection.

o

The Remeha Avanta Plus has a drain cock built into the flow

isolating valve.

15

2.3.10 Connecting condensate drain

LT.AL.W7H.000.018

• Connect the condensate drain outlet to a suitable

waste water drain point using acid resisting pipe work

(i.e. - ¾” overflow). To enable the siphon in the boiler to be

removed / serviced, the connection should not be a permanent one (i.e. “push fit” system).

• To prevent the risk of freezing connect the condensate into

an internal vertical soil pipe using a tundish (air break) c/w

a min 75 mm water seal trap.

• If the condensate pipe has to run externally make sure

this is done by realizing the shortest possible route, and

increase the diameter to at least 1¼” or insulate it with

weather resistant insulation.

• The drain should slope at least 3 cm per meter, with a maximum horizontal length of 5 m.

z

• If connecting into an internal discharge branch (i.e. sink

waste etc) the connection must be down stream of the

existing waste trap.

• Fill the boiler siphon with water before operation, to prevent

flue gasses discharging into the room.

• The condensate drain must be connected in accordance

with current regulations.

2.3.11 Connecting under floor heating

The Remeha Avanta Plus can be connected directly to an

under floor heating system.

If plastic pipes have been used they must be made oxygen diffusion proof in compliance with DIN 4726/4729.

When installing under floor heating with a separate pump, the

layout should be such that the under floor heating pump cannot cause a flow to the boiler if there is no heat demand. A low

loss header should therefore be fitted between the system and

the boiler.

z

Please ensure that the residual pump duty of the boiler is

sufficient for the resistance of the under floor system. If not a

low loss header should be used to separate the boiler from

the under floor circuit to allow a separate pump sized for the

resistance of the under floor system to be used.

2.4 Gas-side connections

2.4.1 Additional guidelines for gas connections

m

Before installation, check that the gas meter has sufficient

capacity for the demand. Remember to consider the

consumption of all household appliances.

16

Remeha Avanta Plus

2.4.2 Adjusting boiler to other gas-type

The Avanta Plus boilers are suitable for both natural gas and

propane firing. For the Avanta Plus 39c an optional LPG-set is

needed. The boilers are supplied as standard set for natural

gas (H), therefore the following procedure must be carried out

BEFORE the boilers are fired and commissioned for the first

time on propane: Adjust the fan speed (see Par. 2.9.8) and

adjust the gas/air ratio (see Par. 2.9.3).

2.4.3 Connecting the gas supply

LT.AL.W7H.000.019

• Before starting any work on the gas supply, turn off the

main isolation valve.

• Connect the gas supply to the 22 mm Ø boiler con-

nection.

m

• Make sure there is no dirt in the gas pipe. Blow through the

pipe before installation or tap well to purge.

• Make sure that the minimum gas service pressure is high

enough (in full load > 17 mbar).

• Preferably install a gas filter in the gas pipe to prevent the

gas block from getting dirty.

• The gas supply must be connected, tested for soundness

and purged by a qualified Engineer and in accordance with

BS6891.

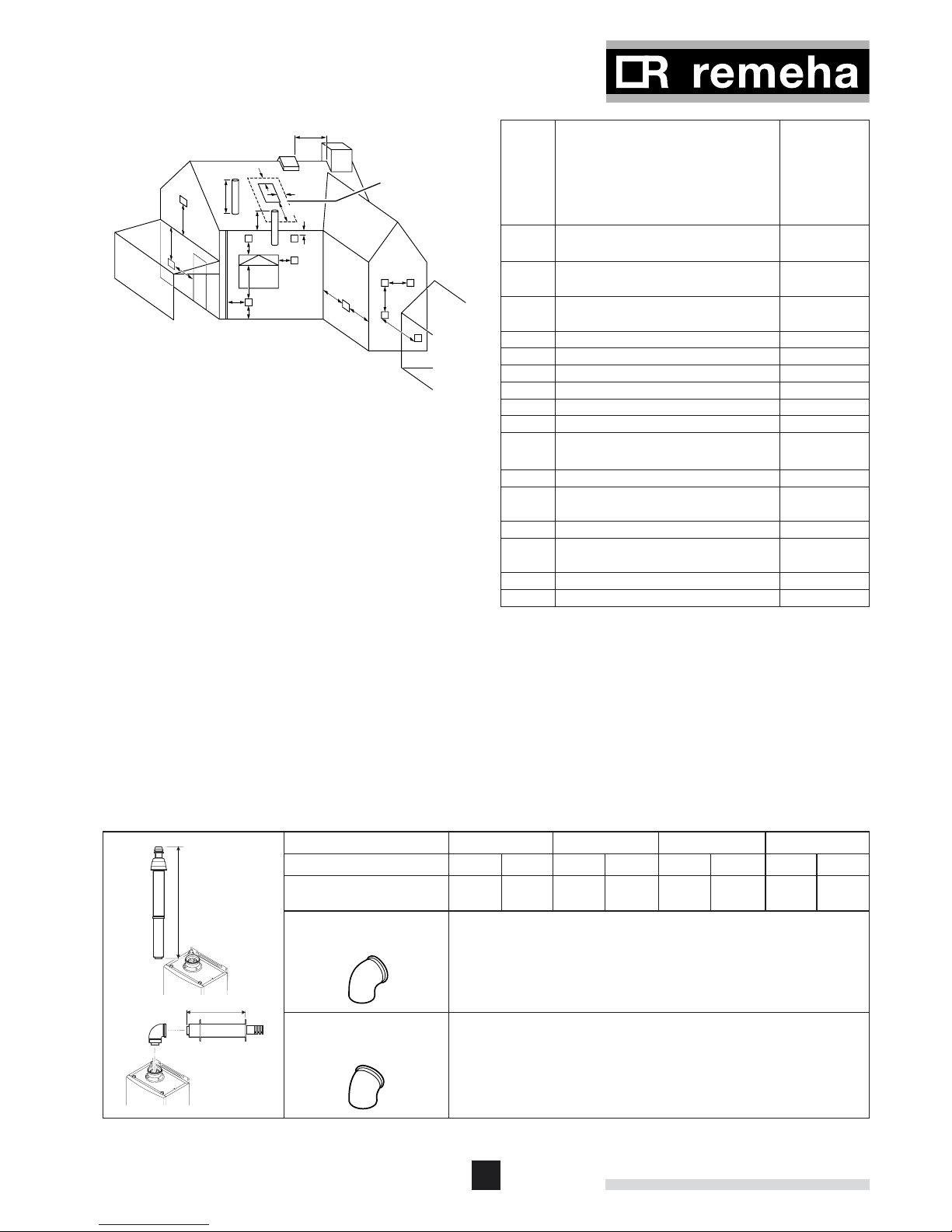

2.5 Flue terminal and air supply connections

The Remeha Avanta Plus is only suitable for room sealed

operation with a standard concentric connection 60/100 mm Ø

or the optional 80/125 mm Ø connection.

Detailed recommendations for air supply and flue terminals are

given in BS 5440.

2.5.1 Flue terminal positions

The flue terminal must be located with care to ensure that the

products of combustion are dispersed properly in all weather

conditions and cause minimum nuisance to the building user

or any adjacent buildings. If the terminal is positioned less

than 2 m above the ground, balcony, or flat roof where access

by persons is possible a suitable guard must be employed.

z

The boiler will produce a water vapour plume during normal

operation.

Positions for the Remeha Avanta

Plus are shown in the figure

and table 02.

17

G

G

A

A

B

600 mm

600 mm

2000 mm

D,E

S

S

F

P

H

C

J

J

L

M

K,N

No flue must penetrate

area within dotted lines

round roof light

LT.AL.W7H.000.020

Dimen-

sions

Terminal location Minimum

distance

(in mm)

to terminal

(room

sealed)

A Directly below an opening, air brick,

opening window, etc.

300

B Above an opening, air brick, opening

window, etc.

300

C Horizontally to an opening, air brick,

opening window, etc.

300

D Below a gutter or sanitary pipe work 40

1)

E Below the eaves 40

1)

F Below a balcony or carport roof 40

1)

G Above ground, roof or balcony level 300

H From vertical drain/soil pipe work 40

1)

J From an internal or external corner 40

1)

K From a surface or boundary facing the

terminal

600

2)

L Vertically from a terminal on same wall 1500

M Horizontally from a terminal on same

wall

300

N From a terminal facing the terminal 1200

P From an opening in a carport (e.g.

door, window) into the building

1200

R From a vertical structure on the roof n/a

S Above an intersection with the roof

n/a

table 02 Minimum distances to terminal

1)

= We advise to use deflectors in case of these small dis-

tances.

2)

= Where the terminal is positioned directly opposite an

opening in the facing wall the min will be 2 m.

n/a = not applicable.

2.5.2 Room sealed flue

See table 03 for the maximum pipe length of flue ducts and air

supply pipes for this ‘room sealed’ application.

It is not necessary to provide combustion air to the room or

internal space in which the boiler is installed.

24s 28c 35c 39c

Diameter in mm Ø

60/100 80/125 60/100 80/125 60/100 80/125 60/100 80/125

Maximum length ‘L’

allowed [m]

6 29 6 29 7 30 5 25

Eq. Length of 90° elbow 1.4

Eq. Length of 45° elbow 0.65

L

VRS roof

mounted

room sealed

terminal

L

80/125 or 60/100

table 03 Maximum pipe lengths for fl ue duct and air supply in

room sealed application

18

Remeha Avanta Plus

158 mm

ø 125 mm

2

1

2

1

z

For flue installations not covered by this booklet, please

contact our technical help line 0118 978 3434.

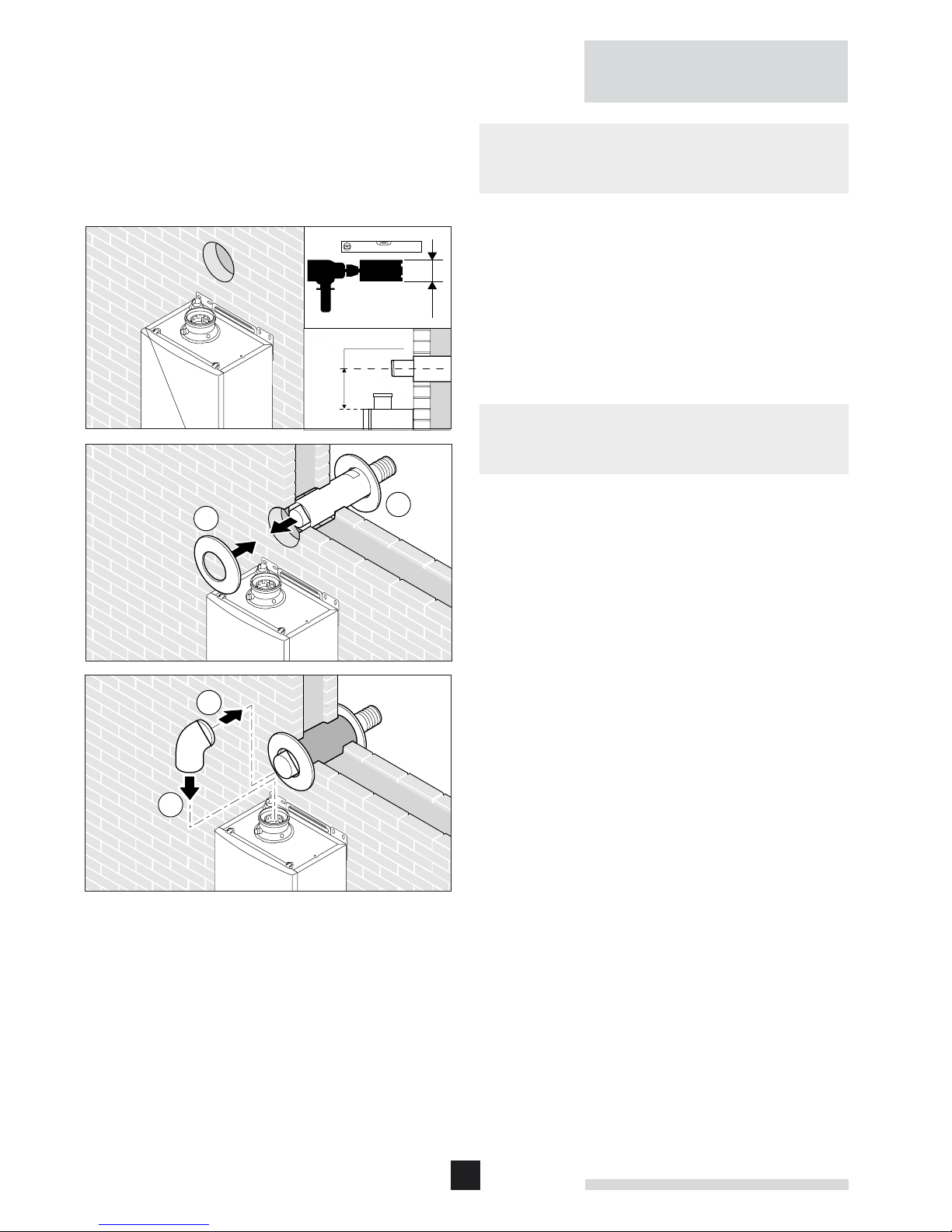

2.5.3 Connecting the flue terminal and air supply

LT.AL.W7H.000.021

• Check the depth of the wall and cut the terminal to suit

– taking note of the cutting instructions supplied with it

• Core drill a 125 mm Ø hole in the wall, fit the rubber closure

plate at the exit end and slide the terminal through the wall

until the closure plate is clear of the outer edge of the wall

– pull back the terminal till the closure plate is flush then fit

inner wall closure to secure.

z

• All connections must be airtight and waterproof.

• Horizontal extension sections should slope towards the

boiler (at least 3 cm per metre).

19

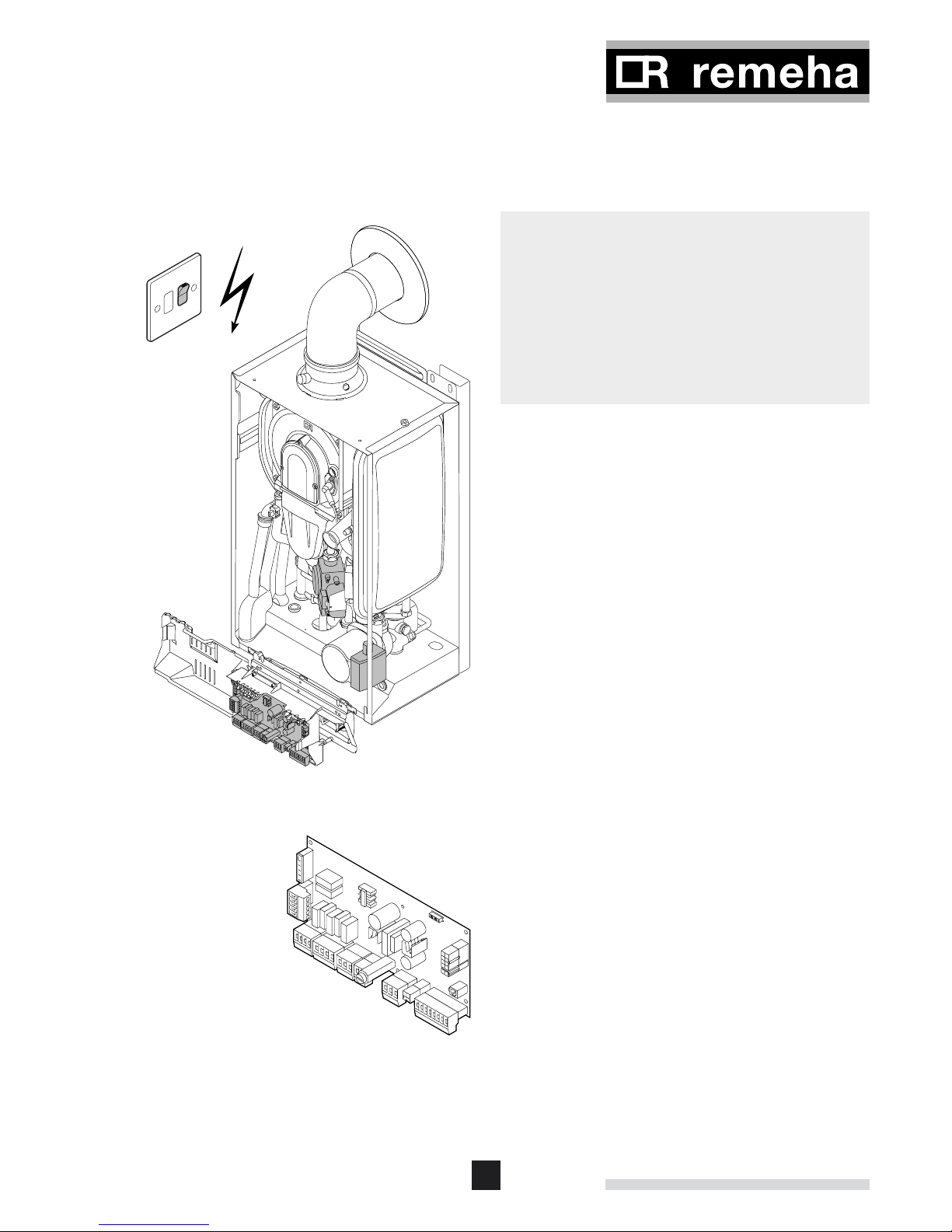

230 V

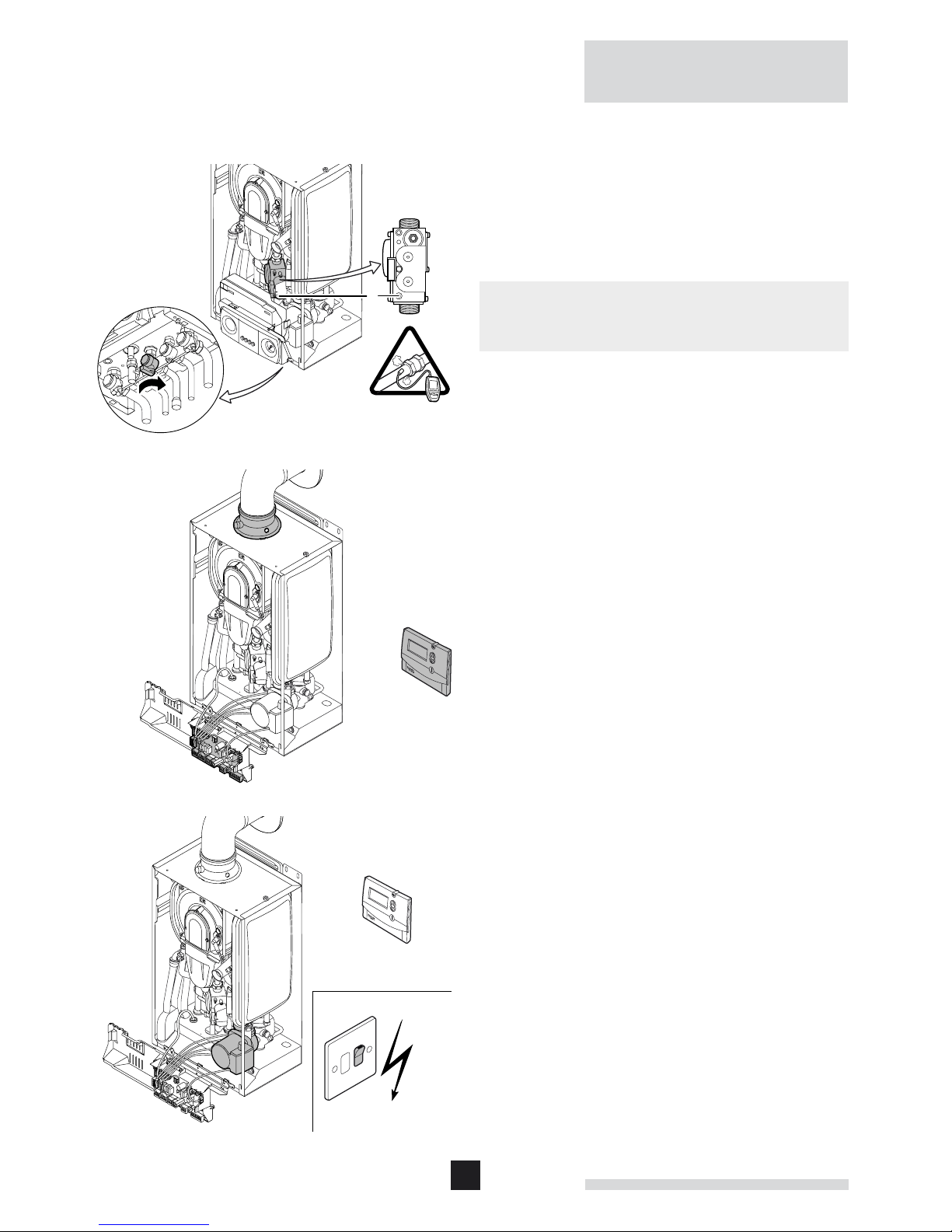

2.6 Electrical connection

• Connect the boiler to the fused (3 amp) switch spur unit

adjacent to boiler.

• The switch unit must always be accessible.

LT.AL.W7H.000.022

{

When the switch spur is on the following components of this

appliance can be live (230 V):

• electrical connection pump;

• electrical connection gas combination block;

• electrical connection three-way valve;

• most parts of the control unit;

• ignition transformer;

• X1, X2, X4, X5, X6 and X7 terminal strip;

• 230 V supply cable connection.

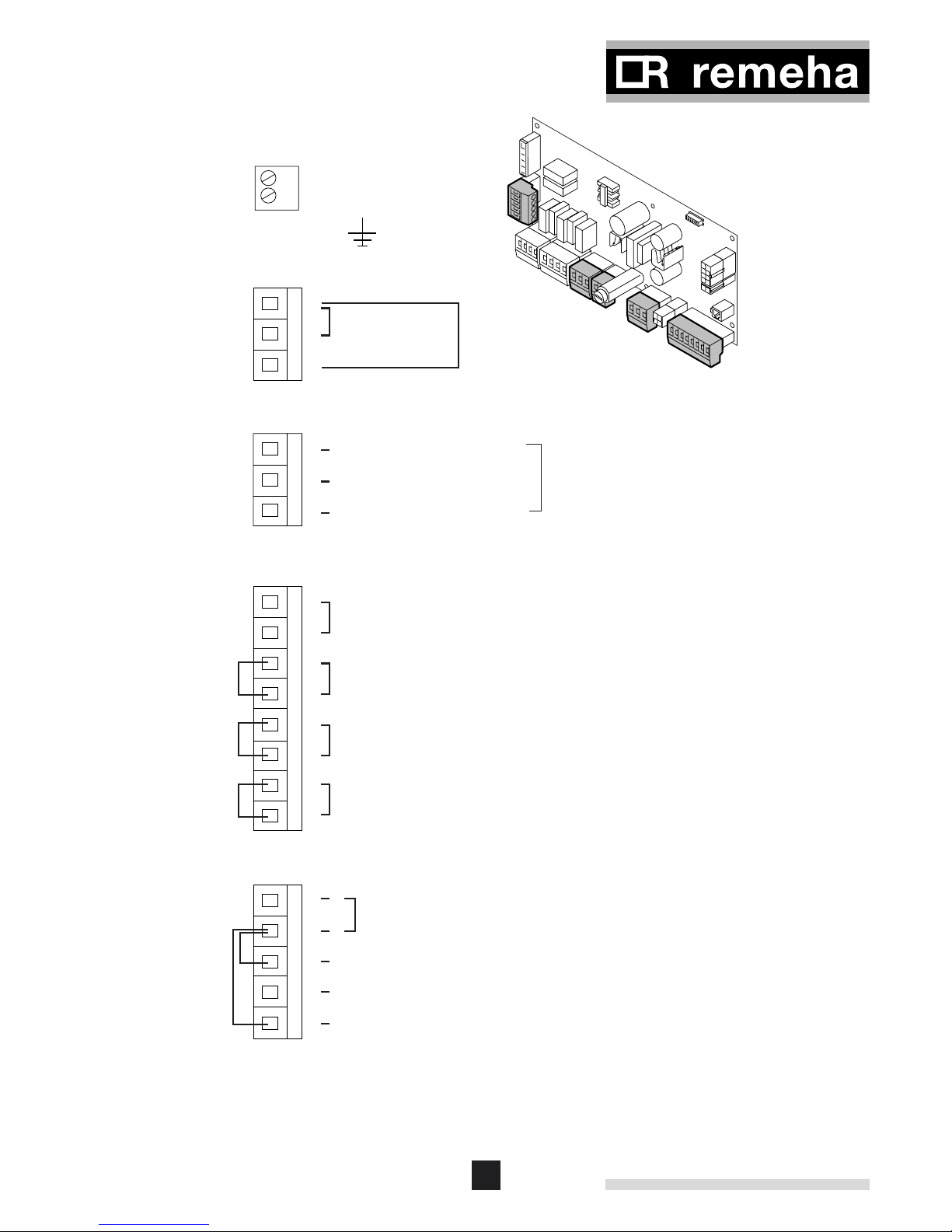

2.6.1 The control unit

The Remeha Avanta Plus has an electronic regulation and

control unit with an integrated ionisation flame detector. The

heart of the boiler control unit is a microprocessor, the ‘abc

®’

,

which controls and protects the boiler.

LT.AL.W7H.000.023

The boiler is not phase sensitive. The maximum rated input is

between 115 and 180 W (depending on boiler type).

The boiler is fully pre-wired internally, all external connections

can be made using the terminal strips X5 - X7 - X9 and 230

V input (X2 terminal). See the diagram for the position of the

connectors and fuse (F2) on the control unit.

The most important properties of the control unit are summarized in table 04.

20

Remeha Avanta Plus

1

2

Manufacturer Sit Controls

Supply voltage 230 V – 1ph – 50 Hz

Pre-purge time 3 s

Post-purge time 5 s

Ignition time 2.5 s

Safety time 5 s

Anti-cycling time 3 till 10 min.

Fuse value F1 (230 V) 2 AT

DC fan (for 24s, 35c and 28c) 24 VDC

AC fan (for 39c only) 230 VAC

table 04 Control unit characteristics

m

Any loads other than those specified above are only allowed if

an isolating transformer is used.

The output of the Remeha Avanta Plus can be controlled in

the following ways:

On/off control – volt free switching - The boilers internal

control will modulate the output to achieve the flow temperature set point of the boiler. This contact is on the X9 terminal

strip (low voltage only).

Modulated control – Open Therm - The external controls will

modulate the boiler’s output to achieve the flow temperature

determined by the modulating regulator. This contact is on the

X9 terminal strip (low voltage only).

On/off control – 230 V switching - The boilers internal control will modulate the output to achieve the flow temperature

set point of the boiler. This contact is on the X2 terminal strip

(230 VAC only).

Modulated control – Open Therm in combination with an

externally mounted simple 230 V switching time clock -

The boiler will provide room compensated heating and time

control over CH and DHW (System boiler).

z

• All connections on terminal X1, X2, X4, X5, X6 and X7 are

230 VAC.

• All connections on terminal X9 are low voltage only.

2.7 Connecting external controls

• Release the two screws at the bottom of the front casing

and remove the front casing.

• Feed the cables through the grommet in the base of the

boiler.

• Connect the cables to the relevant connectors, as shown in

the diagrams.

LT.AL.W7H.000.024

{

• Isolate power supply at the fused spur before carrying out

any work on the boiler controls.

21

L

N

230v - 3 Amp

Power Supply

Terminal

Block X5

X2

X5

X6

X7

X9

Terminal

Block X9

Exist

links

Exist

links

Terminal

Block X2

1

Neutral

2

Open valve to DHW (230v)

3

Open valve to HTG (230v)

Outside sensor (red band) for direct boiler weather compensation

or when used in conjuction with a compatable Open Therm

control eg: Chronotherm or Celcia 20

DHW sensor (red band) or volt free thermostat (make on temp fall)

Remove existing link to use this function

External interlock (volt free)

Remove existing link to use function

Modulating - using Open Therm control

eg: Honeywell Chronotherm or Celcia 20

On / Off - using volt free switching control

eg: Celcia 10 or low volt room thermostat

Power supply to external time clock -230v

Switch live (230v) from external time clock DHW demand

Remove existing link 4-3 to use this function

Switch live (230v) from external time clock HTG demand

Remove existing link 4-1 to use this function

NOTE: Terminal blocks are not in line as shown - diagramatic only

For external DHW priority

diverting valve on System boiler

when used in conjunction with

"Open Therm" compensation

Terminal

Block X7

Terminal

Block X6

1

2

Common Alarm

(Closes on alarm)

Boiler Run

(Closes on run)

3

1

2

3

4

5

6

7

8

5

4NL

3

2

1

E

LT.AL.W7H.000.025

22

Remeha Avanta Plus

X9

Terminal

Block X9

Modulating - using Open Therm control

eg: Honeywell Chronotherm or Celcia 20

On / Off - using simple volt free switching control

1

2

3

4

5

6

7

8

Exist

links

X2

Exist

links

Terminal

Block X2

Power supply to external time clock -230v

Switch live (230v) from external time clock DHW demand

Remove existing link 4-3 to use this function

Switch live (230v) from external time clock HTG demand

Remove existing link 4-1 to use this function

5

4NL

3

2

1

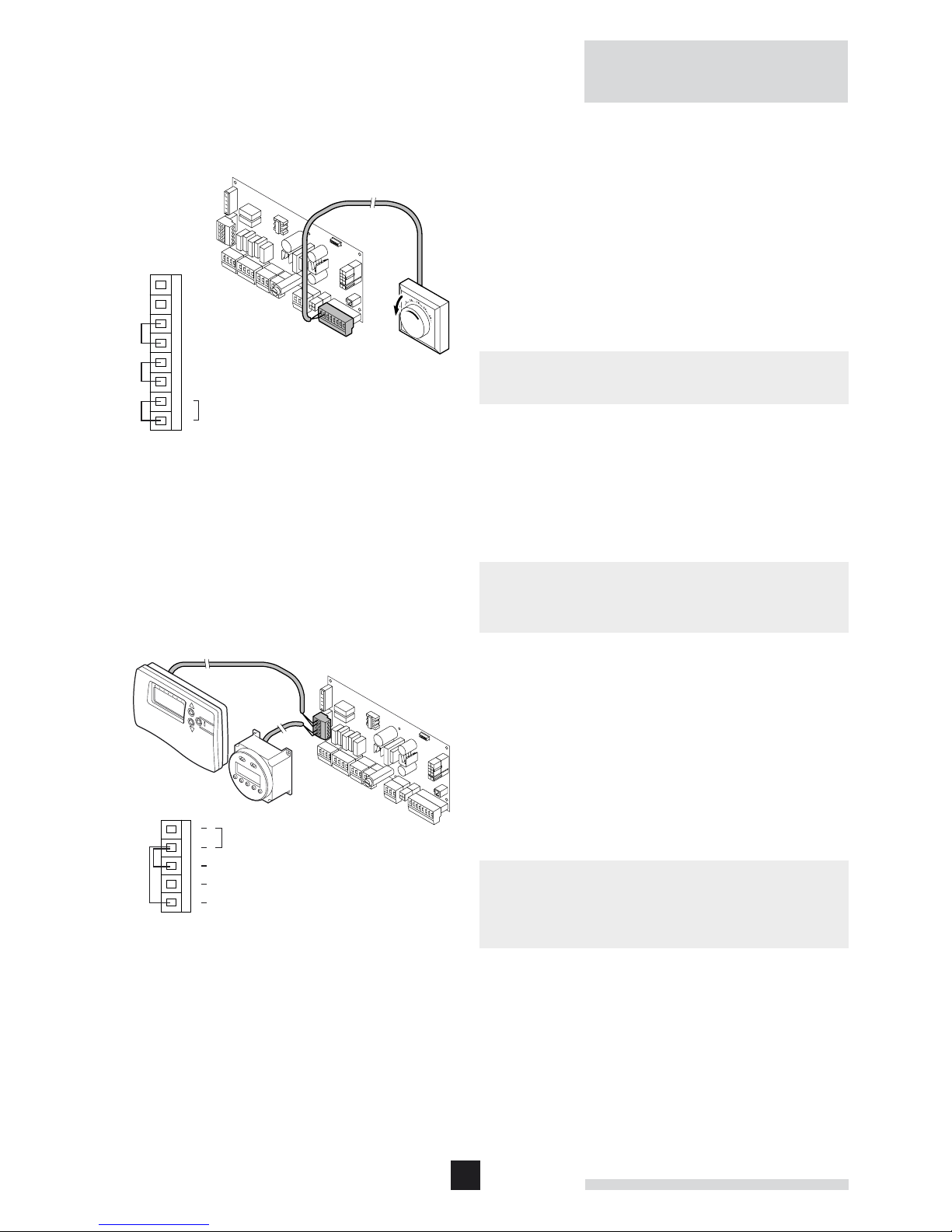

2.7.1 On/off control – room temperature (volt free

switching)

LT.AL.W7H.000.026

The Remeha Avanta Plus can be connected to a 2-wire on/off

thermostat, such as the Remeha Celcia 10.

Mount the thermostat in a reference room (usually the living

room).

• Remove existing link between connectors 7 and 8 of the X9

terminal strip before use;

• Connect the 2-wire 24 V room thermostat to connectors 7

and 8 of the X9 terminal strip.

z

If a room thermostat with an anticipation resistor is being used,

parameter p5 should be changed from 0 to 1, see par. 2.9.8.

2.7.2 Time control using an internal or external 230 V

clock

{

When the switch spur is on, the terminal strip X2 will be live

(230 V).

LT.AL.W7H.000.027

• A 230 V two channel time clock for CH and DHW control

can be connected to the Remeha Avanta Plus

.

Live 230 V supply for the time clock - connect to connectors

4 (N) and 5 (L) on X2 terminal strip.

• For CH - remove existing link between connectors 4 and 1

of the X2 terminal strip and connect the 230 V output from

the time clock to terminal 1 on the terminal strip X2.

• For DHW - remove existing link between connectors 4 and

3 of the X2 terminal strip and connect the 230 V output from

the time clock to terminal 3 on the terminal strip X2.

m

For this option to function correctly a link or room control must

be fitted between connectors 7 and 8 of X9 terminal strip

(Remove existing link before use).

23

X9

Terminal

Block X9

Modulating - using Open Therm control

eg: Honeywell Chronotherm or Celcia 20

On / Off - using simple volt free switching control

1

2

3

4

5

6

7

8

Exist

links

LT.AL.W7H.000.028

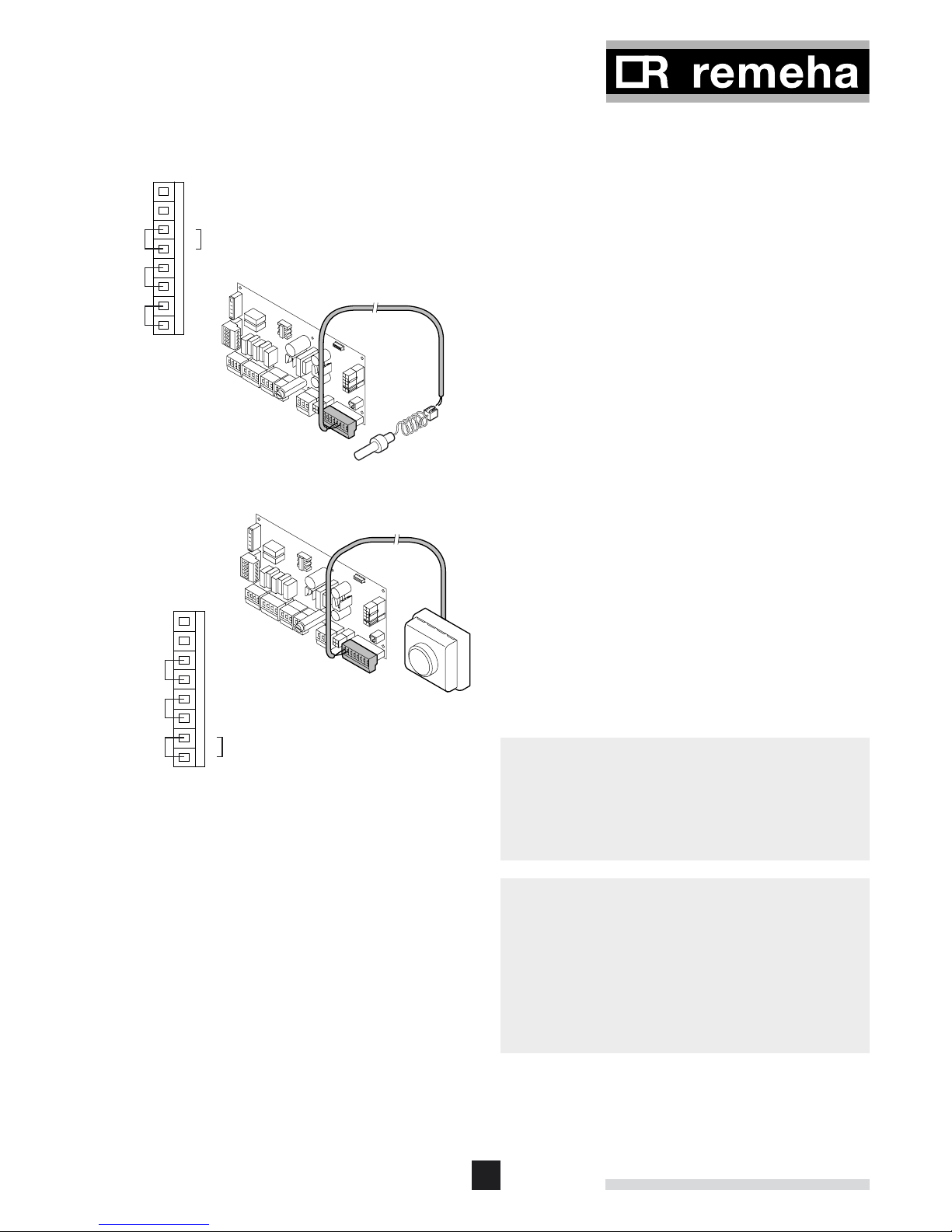

2.7.4 Modulating control – room or outside compensation

2.7.3 Connecting a 230 V time clock in combination with

a modulating room control

With an externally mounted simple 230 V switching time clock

connected to connectors on X2 terminal strip and a Celcia 15

connected to connectors 7 and 8 of X9 terminal strip (remove

existing link between connectors 7 and 8 before use), the

Remeha Avanta Plus will provide room compensated heating

and time control over CH and DHW (System boiler).

o

An OpenTherm® room modulating control (Celcia 15) used in

conjunction with a simple external 230 V time clock will

provide easy to set up and operate - timed room compensation heating

The Remeha Avanta Plus has an OpenTherm

®

interface. This

enables our modulating range of OpenTherm

®

room controls

(e.g. the Remeha Celcia 15 or 20) to be connected without

any further modifications.

• Mount the control in a reference room (usually the living

room).

• Connect the two-wire interface cables to connectors 7 and

8 of the X9 terminal strip (remove existing link between

connectors 7 and 8 before use).

• When using the Celcia 20 it is possible to add the outside

sensor to provide weather compensation with room adjustment. Connect the outside sensor to connectors 1 and 2 of

the X9 terminal strip.

24

Remeha Avanta Plus

X9

Terminal

Block X9

Outside sensor (red band) for direct boiler weather compensation

or when used in conjuction with a compatable Open Therm

control eg: Chronotherm or Celcia 20

1

2

3

4

5

6

7

8

Exist

links

20

40

60

75

01020-15

Factory setting

If the DHW water temperature on the OpenTherm® control can

be adjusted, then the Remeha Avanta Plus will supply water at

the temperature determined at the OpenTherm

®

with the maximum being set in the boiler.

OpenTherm

®

is an industry standard modulating control avail-

able from several control manufacturers.

z

The Remeha Avanta Plus can therefore be controlled directly

by any other controls with this OpenTherm® logo

2.7.5 Connecting an outside temperature sensor

LT.AL.W7H.000.029

An outside temperature sensor can be connected to connectors 1 and 2 of the X9 terminal strip.

The boiler will regulate the output using the set point of the

internal heat curve.

This can be set as follows:

- Outside temperature minimum set point = -15°C (adjustable

with parameter p29 to between 0 and -30°C)

- Outside temperature maximum set point = 20°C (adjustable

with parameter p28 to between 0 and 40°C)

- Flow temperature set point at maximum outside tempera-

ture = 20°C (adjustable with parameter p27 to between

0 and 60°C)

- Flow temperature set point at minimum outside temperature

= 20°C (adjustable with parameter p1 to between

20 and 85°C)

LT.AL.W7H.000.030

o

An outside sensor used in conjunction with a simple 230 V

time clock will provide easy to set up and operate - timed

weather compensation heating based on the above graph.

25

X9

Terminal

Block X9

DHW sensor (red band) or volt free thermostat (make on temp fall)

Remove existing link to use this function

1

2

3

4

5

6

7

8

Exist

links

X9

Terminal

Block X9

Modulating - using Open Therm control

eg: Honeywell Chronotherm or Celcia 20

On / Off - using simple volt free switching control

1

2

3

4

5

6

7

8

Exist

links

2.7.6 Connecting the DHW sensor/thermostat

LT.AL.W7H.000.031

• If an external DHW calorifier is being used with the Avanta

Plus system boiler a volt-free DHW control sensor or thermostat can be connected to connectors 3 and 4 of the X9

terminal strip after removing the existing link. The control

will automatically detect whether a sensor or a thermostat

has been connected.

2.7.7 Connecting a frost thermostat

The boiler must be installed in a frost-free area to prevent the

condensate drain from freezing. However if the temperature of

the CH water in the boiler drops too low, the integrated boiler

protection device is activated as follows:

- at a water temperature below 7°C: the circulation pump is

switched on;

- at a water temperature below 3°C: the boiler is switched on;

- when the water temperature is above 10°C: the boiler is

switched off and the circulation pump runs for another 15

minutes.

o

• A frost thermostat should preferably be installed in rooms

with a high frost risk.

• Connect the frost thermostat in parallel to the room thermo

stat - connectors 7 and 8 of the X9 terminal strip (remove

existing link between connectors 7 and 8 before use).

m

• This function is a protection device for the boiler only, not

for the system or building fabric.

• If a frost thermostat or a modulating room control,

connected across connectors 7 and 8 is activated, the

boiler will operate continuously to achieve the flow set point.

• If the Celcia 20 control has been fitted, with an outside

sensor the boiler and building fabric will be protected.

See the installation documentation supplied with the control.

26

Remeha Avanta Plus

X9

Terminal

Block X9

External interlock (volt free)

Remove existing link to use this function

1

2

3

4

5

6

7

8

Exist

links

X7

Terminal

Block X7

1

2

Common Alarm

(Closes on alarm)

Boiler Run

(Closes on run)

3

X10

2.7.8 Connecting an external interlock

LT.AL.W7H.000.033

The Remeha Avanta Plus is supplied with an external interlock

function. A volt free switching device (i.e. external gas pressure switch, safety thermostat for under floor heating) can be

connected to connectors 5 and 6 of the X9 terminal strip after

removing the existing link. When this circuit is open the boiler

will shut down with the display showing (code 9) and will

restart when the circuit is closed.

LT.AL.W7H.000.034

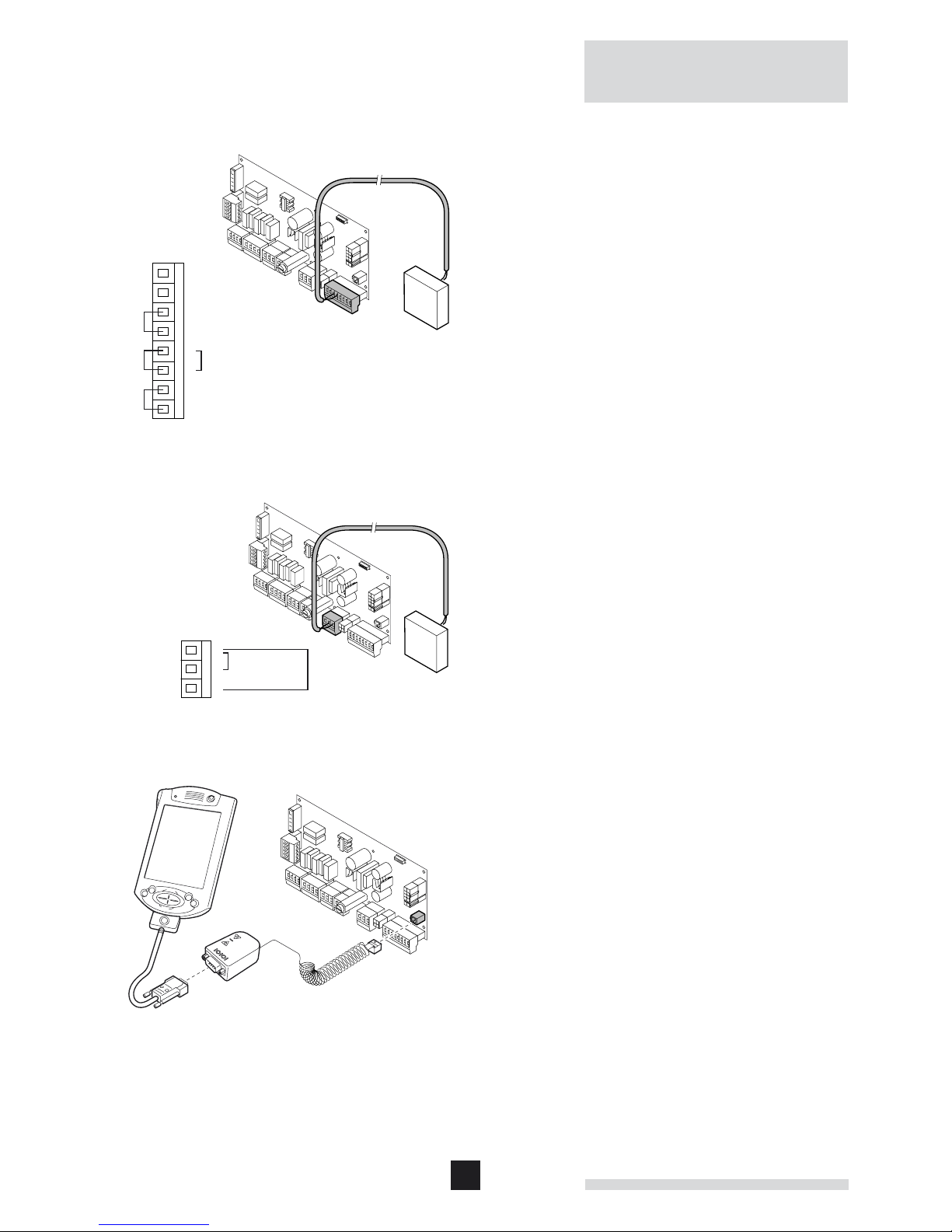

2.7.10 Connecting a PC/PDA

LT.AL.W7H.000.035

Using the optional Recom interface package a PC or PDA can

be connected to the X10 “telephone connector”. Using the

Recom PDA service software you can load, change and download various boiler settings and readings. See the user instructions supplied with the software/hardware.

2.7.9 Connecting remote alarm and boiler run indication

As standard the boiler is supplied with 3 volt free connectors

on terminal X7. They can be used for an external gas valve,

remote alarm and boiler run indication.

• Common alarm signal connect to connectors 1 and 2 on

terminal X7. Contact closes on lock out. For this purpose

set parameter 24 from 0 to 1.

• Boiler run signal connect to connectors 1 and 3 on terminal

X7. Contact closes on heat demand. For this purpose set

parameter 24 from 0 to 2.

• Connect an external gas valve to connectors 1 and 3 on

terminal X7. Contact closes when the gas valve is activated. For this purpose set parameter 24 from 0 to 3.

27

X13

X15

X1

X9

X6

X5

X4

X3

X8

X7

X10

X0

X2

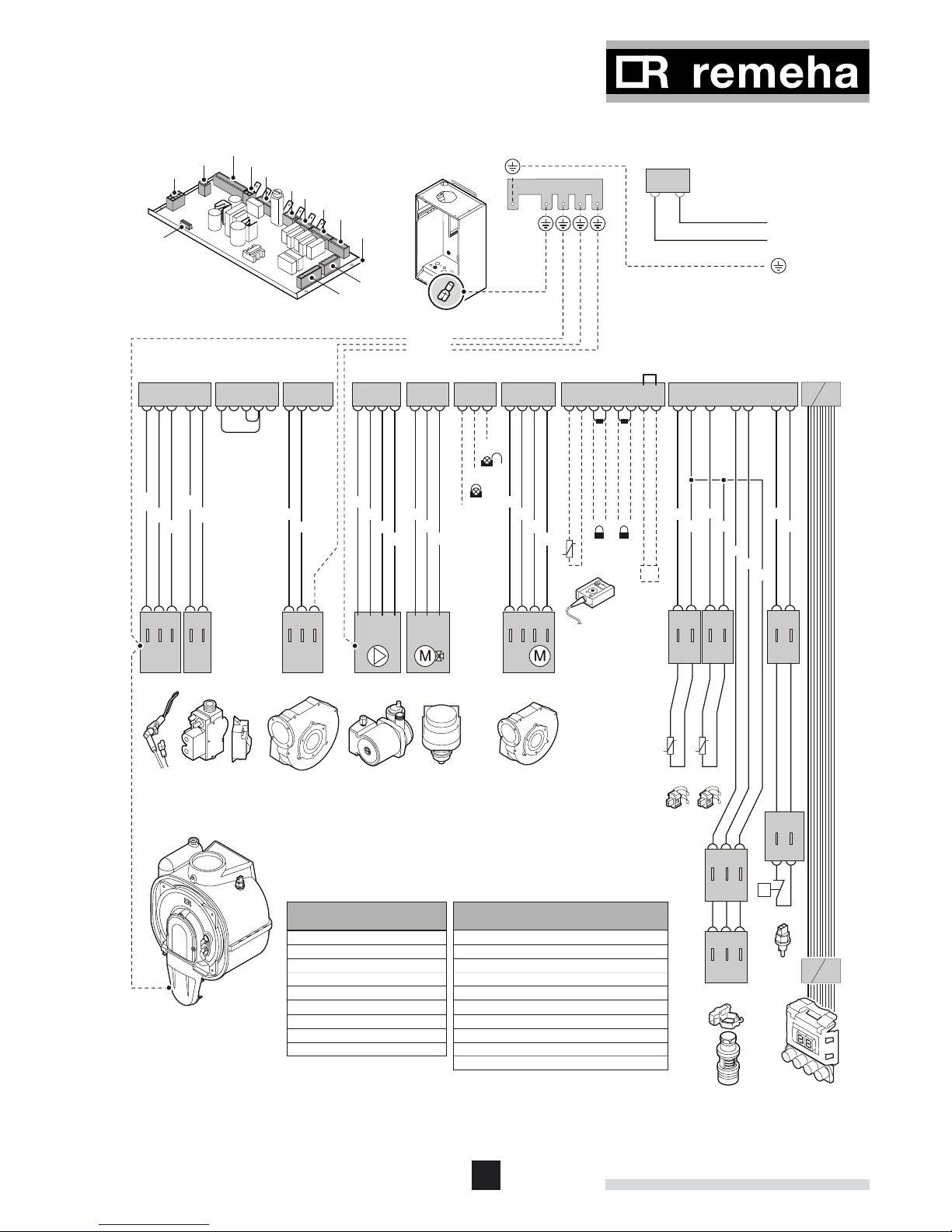

X6X0

L N

X1

4 5 1 3 2X21 2 3 4 5X31 2 3 4X41 2 3 4

X8

1 2 3 4X91 2 3 4 5 6 7 8

X13

4 1 3 7 5 6 8

X15X5

1 2 3

1 2

Power supply

230V, 50Hz

L

123

GCV FAN*

*Only for

39c boiler

BP

X31 X81X21X22

15

N

BR

GN/YW

GN/YW

BKBRBL

WH

GY

BR

BK

WH

BK

RD

WH

COMM.

NC.

NO.

BL

WH

GN

RDWHBL

WH

BK

BK

OR

GN

WH

YW

Blocking up entry

Blocking up entry

Compensator / Open Therm

TOs

BR

BR

BL

BL

X7

1 2 3 1 10

1 10

123

DV

1542

FAN

HLT

RsAs

12 12 12

12

T

X134 X133 X131

Fs

123

X132

123

X132A

X131A

BK BLACK

BL BLUE

BR BROWN

GN GREEN

GN/YW GREEN/YELLOW

GY GRAY

RD RED

WH WHITE

YW YELLOW

WIRE COLOURS

As Flow sensor

BP Boiler pump

Fs Flow switch

CP Circulation pump

DV 3-way valve

GCV Gas combination valve

HLT High limit thermostat

Os Outdoor sensor

Rs Return sensor

- - - - Will not be supplied or wired.

BOILER COMPONENTS

*

2.8 Wiring diagram

LT.AL.W7H.000.234

* Remove existing link between connectors 7 and 8 before use

28

Remeha Avanta Plus

1

2345

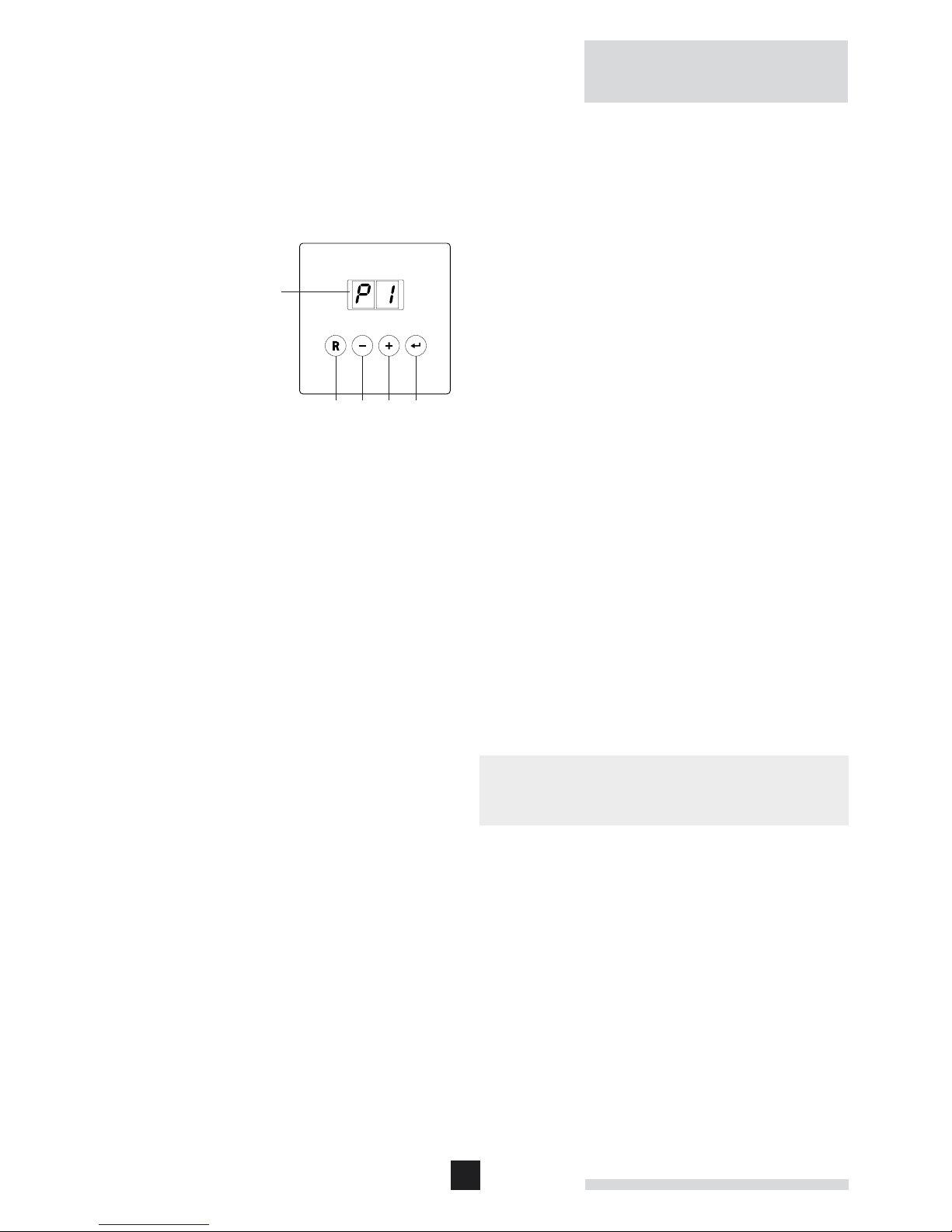

2.9 Commissioning

2.9.1 Control Panel

The control panel of the Remeha Avanta Plus has 4 function

keys and a LED display. The function keys are used to read

or change the settings and temperatures.

LT.AL.W7H.000.036

1 = display

2 = [reset] key

3 = [-] key

4 = [+] key

5 = [enter] key

The display has two positions and displays information on the

current operating status of the boiler and any errors. Numbers,

dots and/or letters can appear in the display. The symbols

above the function keys indicate what the function of that particular key then is.

If no key is pressed for longer than three minutes with the

“boiler in stand-by mode”, only one dot is lit. With the “boiler

operating”, two dots are displayed.

• Press any key and the current boiler status and operation

code will appear in the display.

• In the event of a fault, the fault code is displayed instead of

the dots.

2.9.2 Additional guidelines for commissioning

• When commissioning, use the Boiler Log Book.

• Work through all the stages of this section, complete the

commissioning details in the supplied Boiler Log Book and

send a copy of the completed documents to Broag to register the boiler.

• The boiler is supplied as standard for use with Natural Gas

and tested at an operating pressure of 20 mbar.

m

The boiler must not be put into operation with a different type

of gas without reference to Broag.

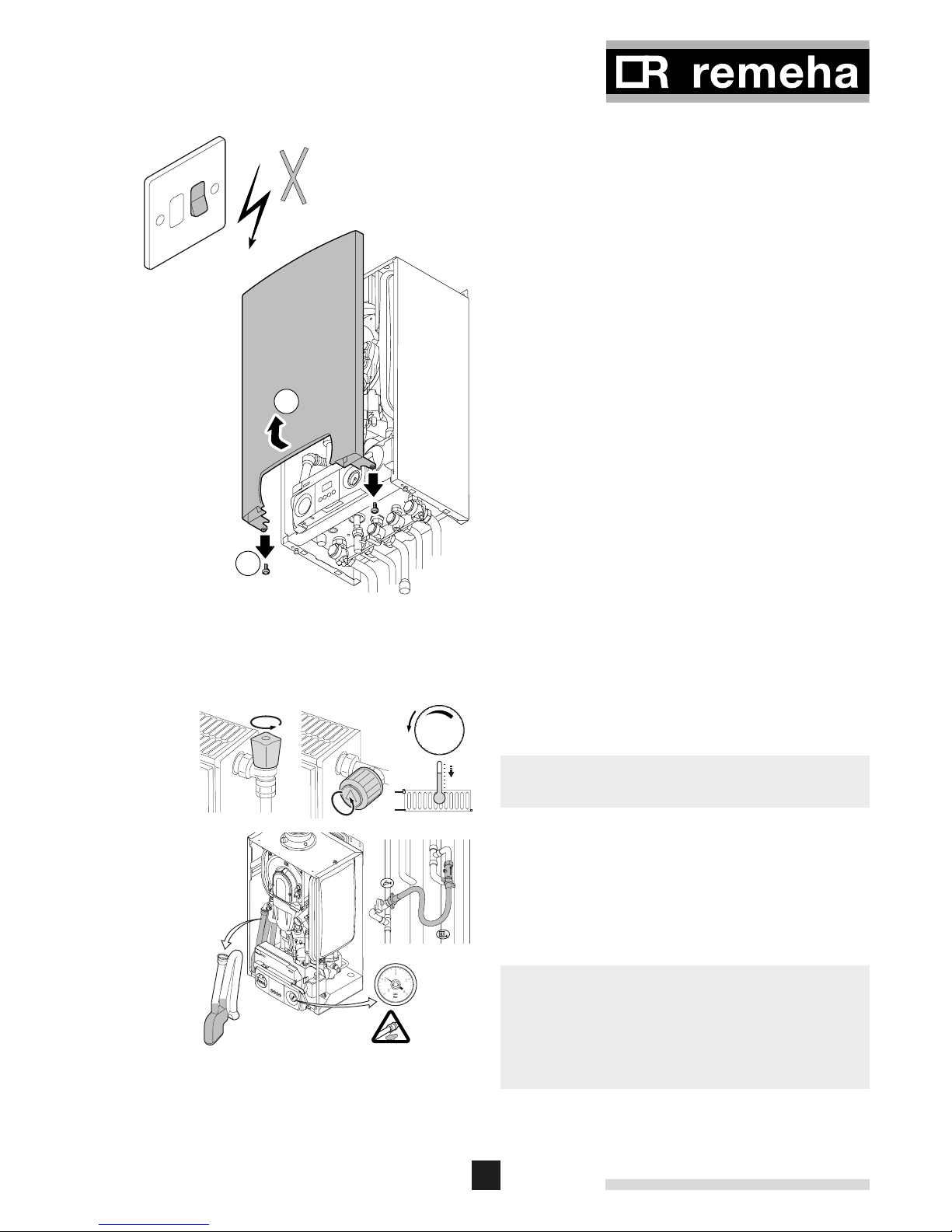

2.9.3 Putting the boiler into operation

This section details the procedure for putting the boiler into

operation. There are 7 stages to the procedure:

1. Isolating the power supply and opening the front cover;

2. Checking the connections and making the boiler operational;

3. Switching the boiler on and setting the controls;

4. Checking/setting the gas/air ratio at full load;

5. Checking/setting the gas/air ratio at low load;

6. Making the boiler ready for use;

7. Instructing the user.

29

1

2

230 V

Check

1,2 bar

1

2

3

4

1. Isolating the power supply and opening the front cover

LT.AL.W7H.000.037

• Switch off the boiler at the fused spur and remove the fuse;

• Remove the front panel (release the two screws at the bot-

tom of the front panel, pull the bottom of the panel; forward

and lift off the two pins on the top of the main casing).

2. Checking the connections and making the boiler

operational

z

Open the valves on all the radiators connected to the central

heating system before filling the system with water.

LT.AL.W7H.000.038

• Open the valves on all the radiators connected to the

central heating system;

• Fill the system with water to the design operating pressure

(normal for a one/two storey house 1.2 bar, minimum

pressure 1 bar, maximum pressure 2.5 bar);

• Whilst filling, air from the system will escape through the

automatic air vents and the pump.

m

• When the vent caps start leaking water, close them with

the vents caps supplied.

• Avoid water getting into the boiler.

• Check the condensate siphon. This should be filled to the

mark with clean water if necessary.

30

Remeha Avanta Plus

230 V

Check

C

• Check the integral boiler pump – remove chrome centre

screw to vent pump and spin the shaft to check that the

impellor can move freely;

• Check that all boiler connections are watertight;

LT.AL.W7H.000.039

• Open the boiler gas valve and check the static pressure to

the boiler at the measurement point (C) on the gas block.

m

The boiler has been factory tested for natural gas at 20 mbar.

The minimum gas inlet pressure is 17 mbar for natural gas.

• Check that the gas supply to the boiler is gas tight (in

compliance with the current regulations, see Chapter 7 the

maximum test pressure at the gas pipe inlet, with the boiler

gas valve open, is 60 mbar.

• Vent the gas pipe by unscrewing the measurement point

(C) on the gas block (tighten it again as soon as the pipe is

fully vented).

• Check that the gas connections in the boiler are sealed.

• Check that all electrical connections, including the earth

connection, have been made correctly.

• Check the electrical connections to the thermostat and

other external controls.

• Check that the flue-gas and air-supply connections are

sealed.

LT.AL.W7H.000.040

3. Switching the boiler on and setting the controls

LT.AL.W7H.000.041

• Replace the fuse in the spur and switch on the 230 V

power supply.

• Set the controls to heat demand.

• The boiler will begin an automatic venting-programme

(which lasts approx. 3 minutes) and will do this every time

the power supply is isolated.

• The boiler now starts to run. The operational status is

shown in the display. The normal operating status finally

shows 0 in the display.

Loading...

Loading...