Page 1

Operator’s Manual

ICE/BEVERAGE DISPENSER

MODELS: DB90S-BC (4V)

DB90S-BC (5V)

Part No. 91772

Revised: August, 1995

THIS DOCUMENT CONTAINS IMPORTANT INFORMATION

This Manual must be read and understood before installing or operating this equipment

âREMCOR INC 1994

PRINTED IN U.S.A

Page 2

TABLE OF CONTENTS

SAFETY PRECAUTIONS 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GENERAL DESCRIPTION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLA TION INSTRUCTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

KIT 03324 INSTALLA TION INSTRUCTIONS 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE RESTRICTOR PLATE 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENT 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DAILY OR AS REQUIRED 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WEEKLY OR AS REQUIRED 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MONTHLY 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

START-UP AND OPERATING INSTRUCTIONS 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING INSTRUCTIONS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISPENSER 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGE SYSTEM 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING GUIDE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

BLOWN FUSE OR CIRCUIT BREAKER 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE DOES NOT OPEN. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GATE DOES NOT OPEN OR IS SLUGGISH. AGITATOR TURNS. 16. . . . . . . . . . .

GATE OPENS. AGITATOR DOES NOT TURN. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ICE DISPENSES CONTINUOUSLY. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLUSHY ICE. WATER IN HOPPER. 16......................................

BEVERAGES DO NOT DISPENSE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES TOO SWEET. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT SWEET ENOUGH. 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEVERAGES NOT COLD (UNITS WITH BUILT-IN COLD PLATE) 16. . . . . . . . . . .

WARRANTY 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

91772

Page 3

TABLE OF CONTENTS (cont’d)

LIST OF FIGURES

FIGURE 1. ICE DIVERTER 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 2. GATE RESTRICTOR PLATE 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

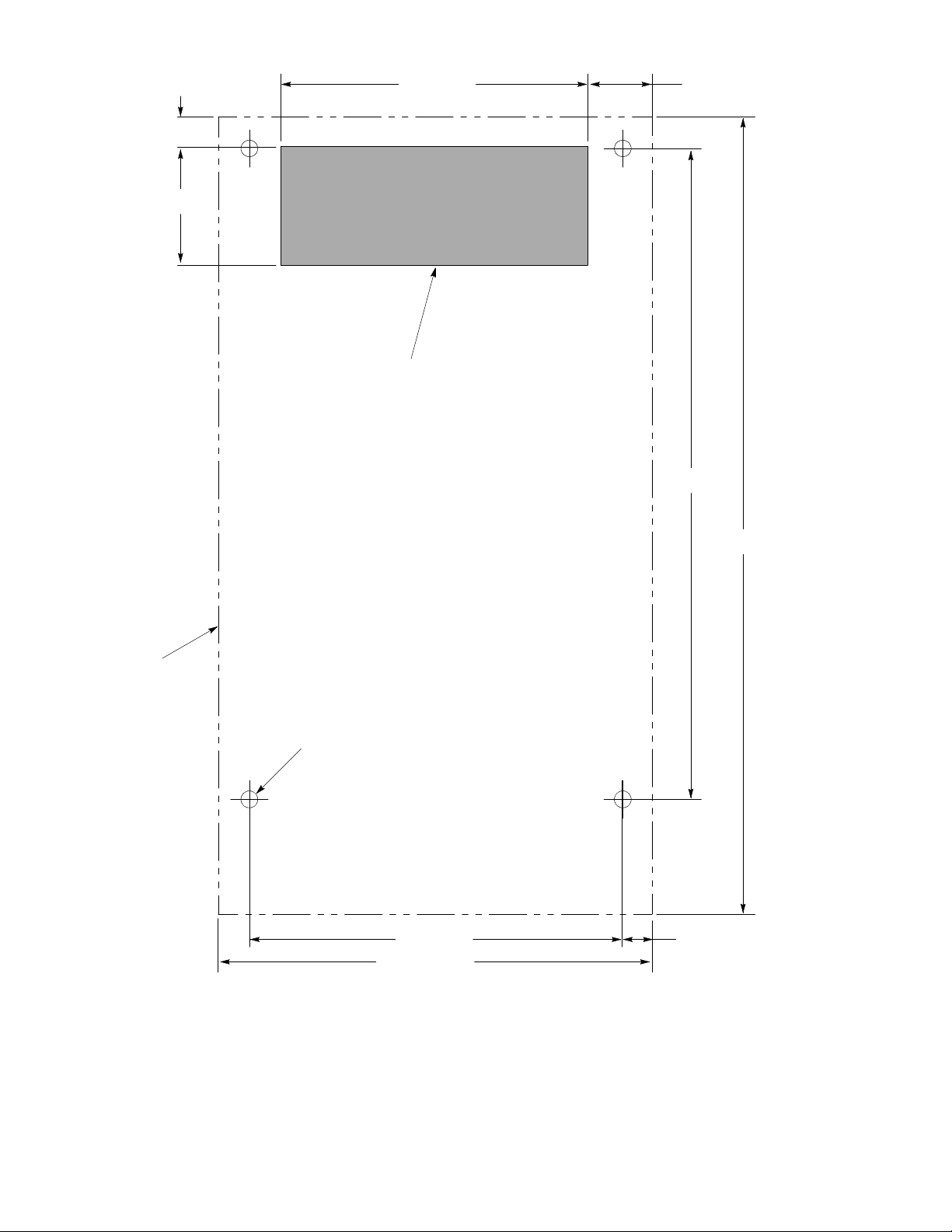

FIGURE 3. MOUNTING TEMPLATE DB90S--B STANDARD 6. . . . . . . . . . . . . . . . .

FIGURE 4. MOUNTING TEMPLATE DB90S-B & --BZ 7. . . . . . . . . . . . . . . . . . . . . .

FIGURE 5. MOUNTING TEMPLATE DB90S--BC 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 6. MOUNTING TEMPLATE DB90-BCZ 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 7. BEVERAGE SYSTEM SCHEMATIC “--B” AND “--BZ” UNITS 10. . . . . .

FIGURE 8. BEVERAGE SYSTEM SCHEMATIC --BC MODEL ( 4 VALVE) 11. . . . .

FIGURE 9. BEVERAGE SYSTEM SCHEMATIC --BC MODEL ( 5 VALVE) 12. . . . .

FIGURE 10. WIRING DIAGRAM DB 90 DISPENSER 17. . . . . . . . . . . . . . . . . . . . . . .

FIGURE 11. SOLENOID ASSEMBLY - EXPLODED VIEW & PARTS LIST 18.....

FIGURE 12. EXPLODED VIEW & PART LIST DB90-B 19. . . . . . . . . . . . . . . . . . . . . .

FIGURE 13. EXPLODED VIEW & PART LIST DB90-BZ (NO SINK) 20. . . . . . . . . .

FIGURE 14. EXPLODED VIEW & PARTS LIST DB90-BC

MERCHANDISER SECTION 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 15. EXPLODED VIEW & PART LIST DB90-BC CABINET 22. . . . . . . . . . .

FIGURE 16. EXPLODED VIEW & PARTS LIST DB90-BC

COLD PLATE SECTION 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FIGURE 17. EXPLODED VIEW & PARTS LIST DB90-BC ELECTRIC

BOX ASSEMBLY 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

LIST OF TABLES

TABLE 1. SPECIFICATIONS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manufactured Under One or More of the following Patent Numbers: 3,211,336, 3,274,792, 3,393,839,3,517,860,

3,739,842, 4,215,803,4,227,377, 4,300,359, 4,346,824

Canadian Patent Numbers: 912,514 (10/72), 936,855 (11/73), 4,429,543, 4,921,149

Other Patents Pending

91772

Page 4

SAFETY PRECAUTIONS

Always disconnect power to the dispenser before servicing or cleaning.

Never place hands inside of hopper or gate area without disconnecting power to the dispenser. Agitator rotation

occurs automatically when the dispenser is energized!

This ice dispenser has been specifically designed to provide protection against personal injury and eliminates

contamination of ice. To insure continued protection and sanitation, observe the following

ALWAYS be sure the removable lid is properly installed to prevent unauthorized access to the hopper interior and possible contamination of ice.

ALWAYS be sure the upper and lower front panels are securely fastened.

ALWAYS keep area around the dispenser clean of ice cubes.

CAUTION: Dispenser cannot be used with crushed or flaked ice.

Use of bagged ice which has frozen into large chunks can void warranty . The dispenser

agitator is not designed to be an ice crusher. Use of large chunks of ice which “jam up”

inside the hopper will cause failure of the agitator motor and damage to the hopper. If bagged ice

is used, it must be carefully and completely broken into small, cube-sized pieces before filling into

the dispenser hopper.

1 91772

Page 5

GENERAL DESCRIPTION

The Remcor “DB” series of ice dispensers will solve ice and beverage service needs in the sanitary, space saving, economical way . Designed to be manually filled with ice from any remote ice making source, these dispensers will dispense cubes (up 1-1/4” in size), cubelets, hard-chipped or cracked ice and Scotsman MH750 pellet

ice; and in addition, several flavors of post-mix beverages. “B” models contain beverage faucets only and must

be supplied with cold product from any remote cold plate or refrigerated soda factory . “-BC” models include beverage faucets and a cold plate and are designed to be supplied directly from the syrup tanks and carbonator,

with no additional cooling required.

IMPORTANT: For dispensing Scotsman “pellet” style ice (Model MH750 icemakers), REMCOR Kit

#02234 Ice Diverter must be installed on the dispenser. (See INSTALLATION INSTRUCTIONS)

Table 1. Specifications

Model: DB90S-BZ

Ice Storage: 90 lbs.

Maximum Number of Faucets Available: 4

Built-in Cold Plate: No

Electrical: 120/1/60 3A Cord Connected; 15A, 125V

Plug

Dimensions: 16” W x 29-3/4” D x 32” H

Model: DB90S-B

Ice Storage: 90 lbs.

Maximum Number of Faucets Available: 4

Built-in Cold Plate: No

Electrical: 120/1/60 3A Cord Connected; 15A, 125V

Plug

Dimensions: 16” W x 29-3/4” D x 32” H

Model: DB90S-BC

Ice Storage: 90 lbs.

Maximum Number of Faucets Available: 5

Built-in Cold Plate: Yes

Electrical: 120/1/60 3A Cord Connected; 15A, 125V

Plug

Dimensions: 16” W x 29-3/4” D x 32” H

LEGEND

Z No sink option

BC Beverage/Cold Plate System

S All Stainless Steel

B Beverage System

291772

Page 6

INSTALLATION INSTRUCTIONS

1. Locate the dispenser indoors on a level counter top.

COUNTER MOUNTING

The ice dispenser must be sealed to the counter. The template drawing indicates openings which must be

cut in the counter. Locate the desired position for the dispenser, then mark the outline dimensions on the

counter using the template drawings. Cut openings in the counter.

Apply a continuous bead of NSF International (NSF) listed silastic sealant (Dow 732 or equal) approximately 1/4” inside of the unit outline dimensions and around all openings. Then position the unit on the counter

within the outline dimensions. All excess sealant must be wiped away immediately .

2. The beverage tubes, drain line and power cord are routed through the large opening in the bottom of the

unit. See the MOUNTING TEMPLATE, for locating the required clearance hole in the counter for these utility lines.

3. SINK DRAIN ASSEMBLY: Connect the drain tube to an open drain. Additional drain tubing is provided with

the unit. The drain line must continuously pitch downward away from the unit and contain no “traps” or improper drainage will result.

A. Use tube, clamp and insulation provided to assemble drain.

B. To assure proper drainage, do not allow “trap” to form in drain line. Be sure drain line runs flat with

bottom of dispenser.

4. Connect the beverage system product lines as indicated in Figure 2 (and in Figure 3 for cold plate units).

This work should be done by a qualified service person. Note that the hoses are marked with numbers ( 1

through 4 or 5) for syrup connections On 5 valve “-BC” units, the plain water is marked “NON CARB

WATER”.

5. Clean the hopper interior (see CLEANING INSTRUCTIONS).

6. Connect the power cord to a 120 volt, 60 cycle, 3-wire grounded receptacle.

NOTE: Water pipe connections and fixtures directly connected to a potable water supply shall be

sized, installed and maintained according to Federal, State and Local Laws/

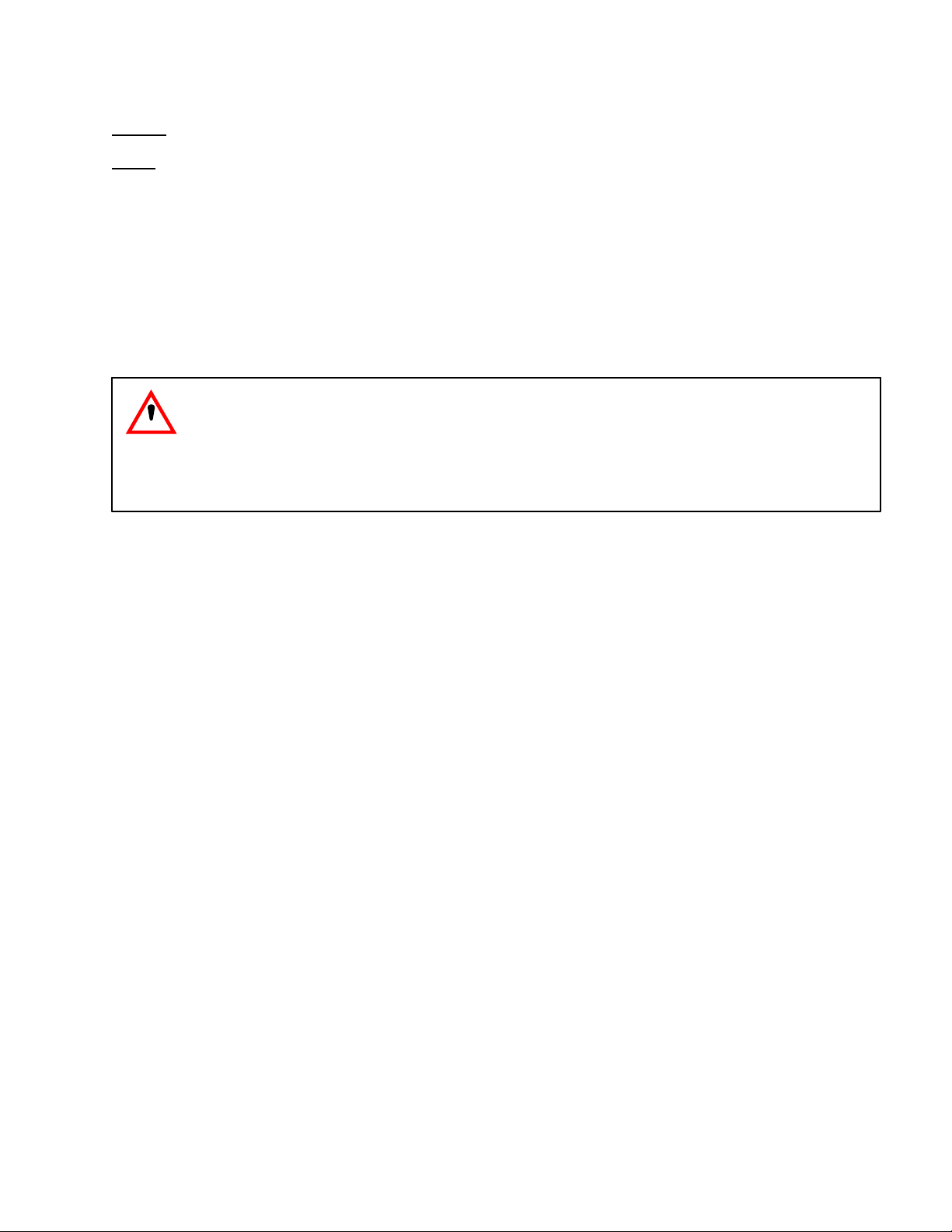

DRAIN LINE

STAINLESS STEEL ELBOW

DRAIN TUBING PROVIDED

DISPENSER BOTTOM

WITH DISPENSER

3 91772

Page 7

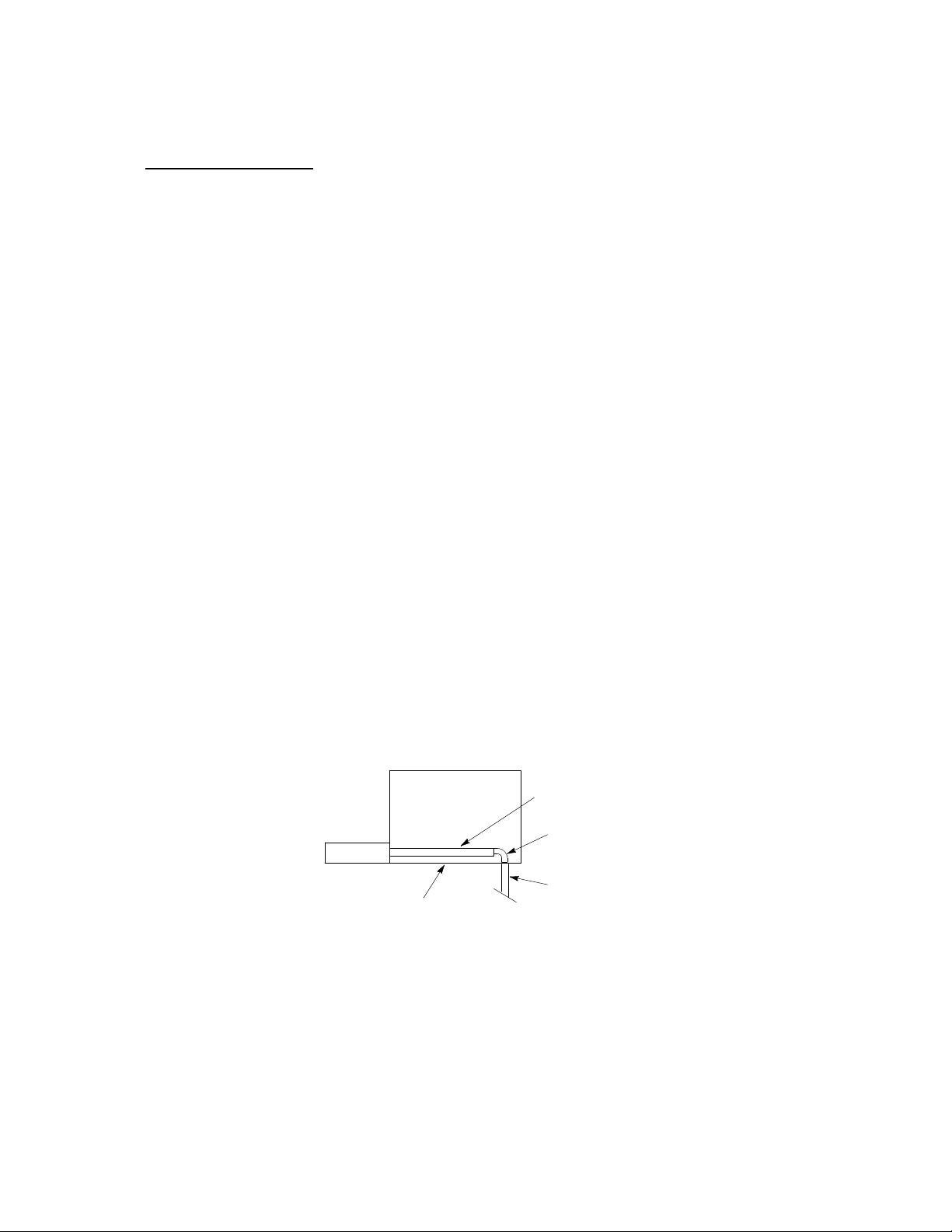

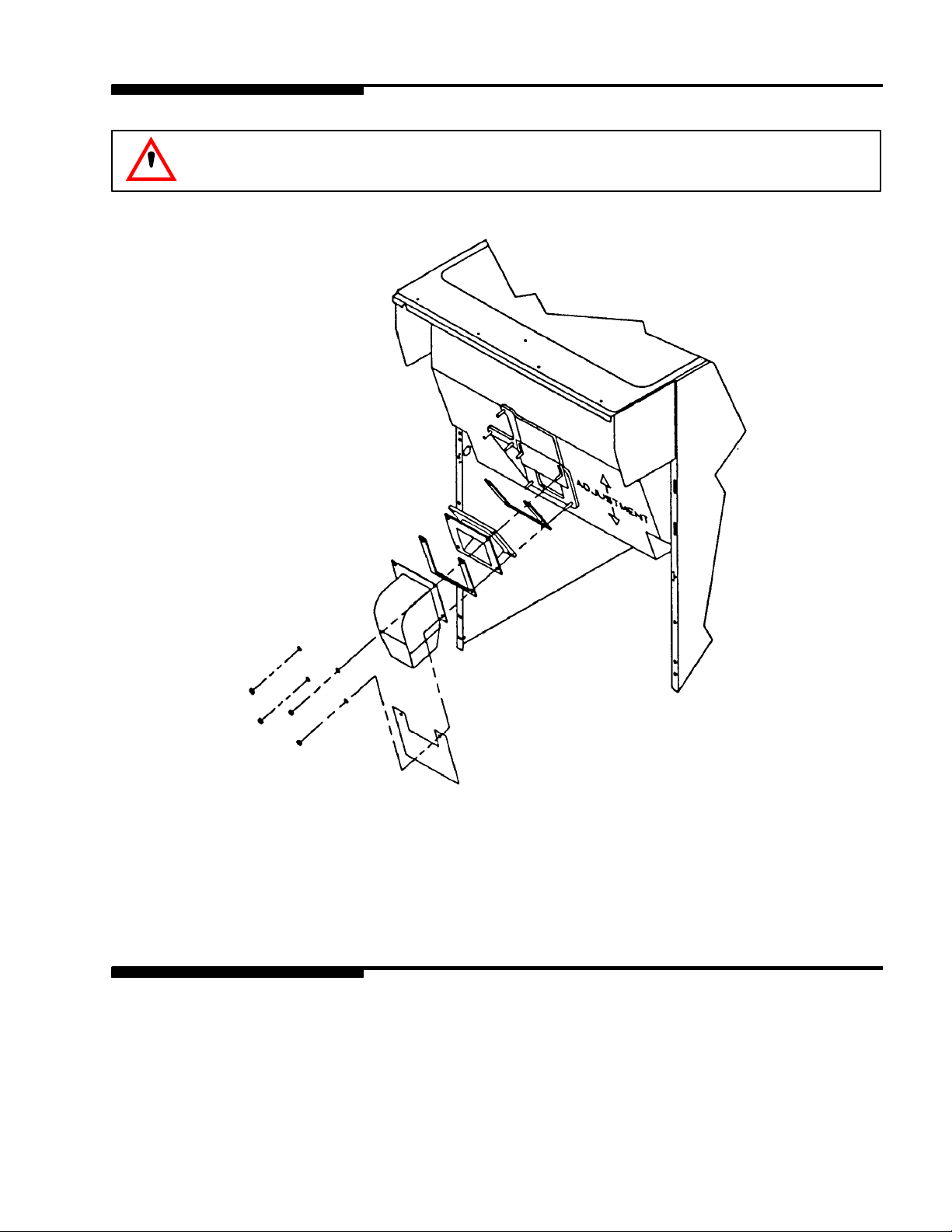

KIT 03324 INSTALLATION INSTRUCTIONS

NOTE: For dispensing Scotsman NM 650 “nugget” style and MH 750 “pellet” style ice and Wilshire

MCC500 and MCC700 compressed ice cubes.

1. Disconnect power to dispenser.

2. Remove upper front panel from dispenser.

3. Remove ice chute and discard Gate Restrictor.

4. Reinstall front panel and energize unit.

STORAGE HOPPER

GATE MOUNTING PLATE

ICE DIVERTER

P/N 27065

FLAT WASHER

10-32 NUT

ICE CHUTE

GASKET

FLANGE EXTENDS INTO

STORAGE HOPPER

THROUGH GATE OPENING

APPLY RTV TO THIS SURFACE

TO SEAL TO HOPPER GATE

MOUNTING PLATE

FIGURE 1. ICE DIVERTER

491772

Page 8

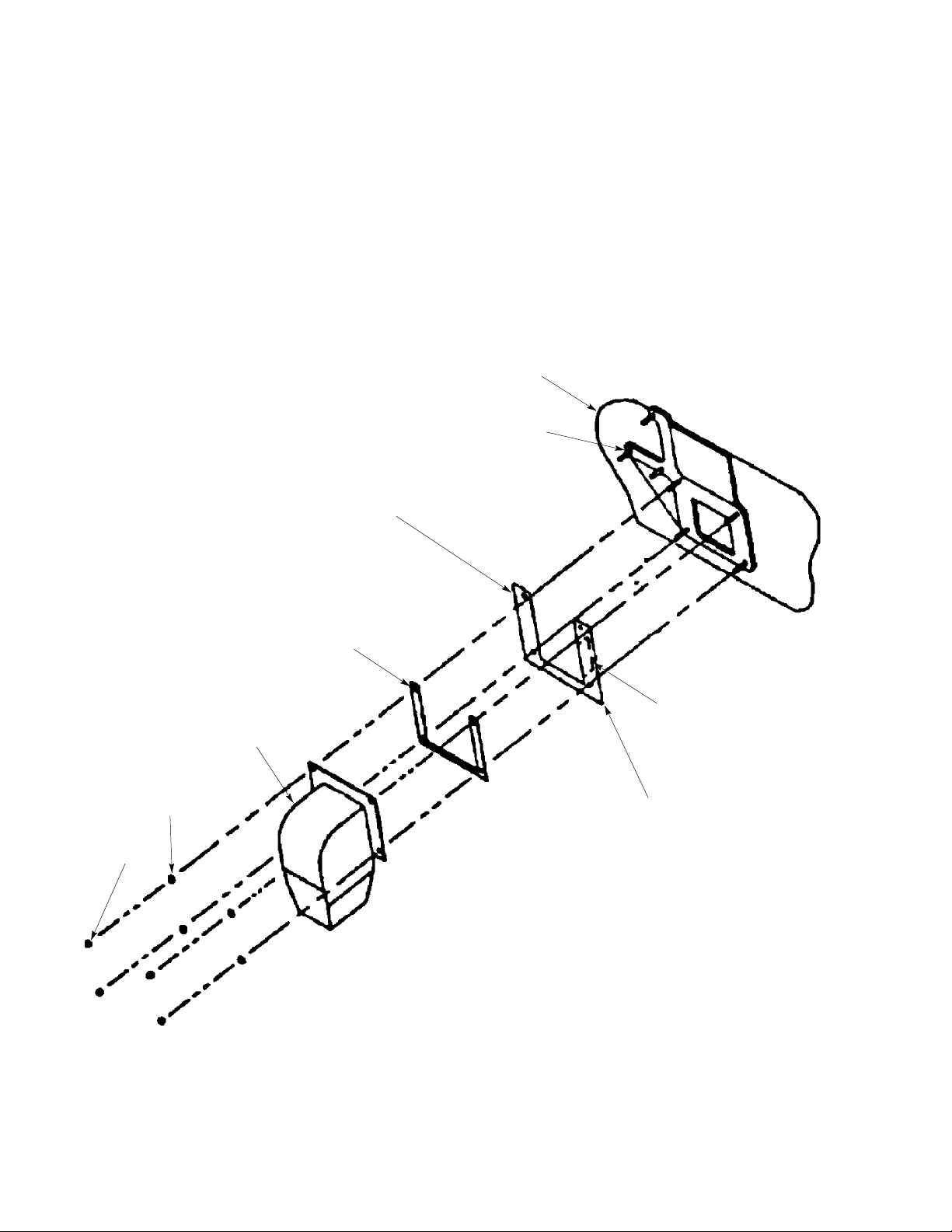

GATE RESTRICTOR PLATE

CAUTION: Disconnect power to dispenser before installing, removing or adjusting

restrictor

INSTALL PLATE

ON

STUDS AS

SHOWN

FIGURE 2. GA TE RESTRICTOR PLATE

ADJUSTMENT

This dispenser is provided with a gate restrictor plate, installed in its highest position. This plate adjusts the rate

of ice flow from the dispenser. In applications using buckets, carafes or other large containers, the plate may be

removed entirely for maximum ice flow. For glasses and cups, the plate may be adjusted downward to reduce

the flow of ice. The best position depends on the type of ice being used and the size container and must be

found by trial and error. Adjustment is made by loosening the upper two ice chute retaining nuts, sliding the restrictor plate to the desired position and re-tightening the nuts.

If the dispenser fails to dispense the ice when operated, check that the hopper has ice in it and that power is

being supplied to the unit. If the problem persists, refer to the troubleshooting guide (page 16).

5 91772

Page 9

1 1/32-IN.

4 1/2-IN.

11 1/4-IN. 2 19/64-IN.

1 7/64-IN.

REAR OPENING FOR

BEVERAGE AND UTILITIES

24 5/16-IN.

OUTLINE

OF UNIT

29 3/4-IN.

3/8 DIA.

13 3/4-IN. 1 3/64-IN.

15 27/32-IN.

NOTE: 1) Shaded areas indicate openings in

cabinet bottom needed for utilities

and beverage tubing.

FIGURE 3. MOUNTING TEMPLA TE DB90S--B STANDARD

691772

Page 10

15 1/16-IN.

OUTLINE

OF UNIT

21 1/16-IN.

REAR OPENING FOR

BEVERAGE AND UTILITIES

4 1/2-IN.

8-IN.4-IN.

16-IN.

NOTE: 1) Shaded areas indicate openings in

cabinet bottom needed for utilities

and beverage tubing.

FIGURE 4. MOUNTING TEMPLA TE DB90S-B & --BZ

7 91772

Page 11

2 1/2-IN.

29 3/4-IN.

10-IN. 2 57/64-IN.

REAR OPENING FOR

BEVERAGE AND UTILITIES

OUTLINE

OF UNIT

24 5/16-IN.

13 1/2-IN.

15 27/32-IN.

NOTE: 1) Shaded areas indicate openings in

cabinet bottom needed for utilities

and beverage tubing.

3/8 DIA.

1 3/64-IN.

FIGURE 5. MOUNTING TEMPLA TE DB90S--BC

891772

Page 12

3/8” (4

PLCS.)

FIGURE 6. MOUNTING TEMPLA TE DB90-BCZ

9 91772

Page 13

FIGURE 7. BEVERAGE SYSTEM SCHEMATIC “--B” AND “--BZ” UNITS

91772

10

Page 14

FIGURE 8. BEVERAGE SYSTEM SCHEMATIC --BC MODEL ( 4 VALVE)

11

91772

Page 15

FIGURE 9. BEVERAGE SYSTEM SCHEMATIC --BC MODEL ( 5 VALVE)

91772

12

Page 16

MAINTENANCE

The following dispenser maintenance should be performed at the intervals indicated:

DAILY or as required

Remove foreign material from the vending area sink to prevent drain blockage.

WEEKLY or as required

Clean vending area. Check for proper water drainage from the vending area sink.

MONTHLY

Clean and sanitize the hopper interior (see CLEANING INSTRUCTIONS).

START -UP AND OPERATING INSTRUCTIONS

Fill the hopper with ice. For “--BC” models with a built-in cold plate, dispense several large cups of ice (approximately 20 to 30 seconds total dispensing time) to allow ice to fill the cold plate. Add ice to the hopper as necessary to refill and replace the lid. Allow 10 to 15 minutes for the cold plate to cool down. Repeat this procedure

whenever the dispenser has been standing overnight or other long periods without ice use. On “--B” and “--BC”

models, start up the beverage system and adjust faucets to the proper brix. Contact your local syrup distributor

for complete information on the beverage system.

In normal operation, pushing the ice dispenser lever will cause ice to flow from the ice chute. Ice flow will continue until the lever is released. Pushing the lever on any faucet will provide beverage of the appropriate flavor.

CAUTION: Use caution to avoid spilling ice when filling dispenser. Immediately clean up

any spilled ice from filling or operating the unit. To prevent contamination of ice, the lid

must be installed on the unit at all times.

13 91772

Page 17

CLEANING INSTRUCTIONS

WARNING: DISCONNECT POWER BEFORE CLEANING! Do not use metal scrapers, sharp

objects or abrasives on the ice storage hopper, top cover and the agitator disk, as damage

may result. Do not use solvents or other cleaning agents, as they may attack the plastic

material.

DISPENSER

1. Clean the ice storage hopper at least once a month.

2. Lift off the agitator and the agitator disk. Wash with a mild detergent solution and rinse them thoroughly to

remove all traces of detergent.

3. Wash down the inside of the hopper and top cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

4. Replace the agitator.

5. Sanitize the inside of the hopper and agitator with a solution of 1 ounce of household bleach in 2 gallons of

water. (200 PPM)

6. Replace the agitator disk. Sanitize as described in Step 5.

7. Remove Ice Chute cover as follows:

A. Flex sides outward to disengage lower pins.

B. Lift Ice Chute cover to disengage upper pins.

C. Lower Ice Chute cover down out of unit. Note: it may be helpful to twist cover slightly.

8. Clean the inside of the ice chute and ice chute cover with a mild detergent solution and rinse thoroughly to

remove all traces of detergent.

9. Reverse steps above to reassemble ice chute.

10. Sanitize as described in Step 5.

BEVERAGE SYSTEM

1. Remove faucet spouts, wash in mild detergent, rinse and replace.

2. Disconnect electrical power to the carbonator. Shut off the water supply and close the CO2regulator to the

carbonator.

3. Disconnect the syrup tanks from the system.

4. Energize the beverage faucets to purge the remaining soda in the system.

5. Use a clean 5 gallon tank for each of the following.

A. Cleaning tank - fill with hot (120° - 140°) potable water.

B. Sanitation Tank - Fill with a chlorine sanitizing solution in the strength of 1 ounce of household bleach

(sodium hypochlorite) to 2 gallons of cold (ambient) potable water (200 PPM).

6. Repeat the following procedure on each of the units’ syrup product lines:

1491772

Page 18

A. Connect the cleaning tank to the syrup line to be sanitized and to the CO2system.

B. Energize the beverage faucet until the liquid dispensed is free of any syrup.

C. Disconnect the cleaning tank and hook-up the sanitizing tank to the syrup line and CO2system.

D. Energize the beverage faucet until the chlorine sanitizing solution is dispensed through the faucet.

Flush at least 2 cups of liquid to insure that the sanitizing solution has filled the entire length of the

syrup lines.

E. Disconnect the sanitizing tank. Hook-up the product tank to the syrup line and to the CO2system.

F. Energize the faucet to flush the sanitizing solution from the syrup line and faucet. Continue to draw on

the faucet until only syrup is dispensed.

7. Repeat Step 2 in reverse order to turn on the carbonator. Dispense at lease 1 cup of beverage from each

faucet. Check taste. Continue to flush if needed, to obtain a satisfactory tasting drink.

15 91772

Page 19

TROUBLESHOOTING GUIDE

Should your unit fail to operate properly , check that there is power to the unit and that the hopper contains ice. If

the unit does not dispense, check the following chart under the appropriate symptoms to aid in locating the defect.

Trouble Probable Cause

BLOWN FUSE OR CIRCUIT BREAKER A. Short circuit in wiring.

B. Defective gate solenoid.

C. Defective agitator motor.

GATE DOES NOT OPEN. A. No power.

B. Defective dispensing switch.

C. Blown/defective fuse or jammed gate solenoid.

GATE DOES NOT OPEN OR IS SLUGGISH.

AGITATOR TURNS.

GATE OPENS. AGITATOR DOES NOT TURN. A. Ice solidified in hopper.

A. Defective gate solenoid.

B. Weak gate spring.

C. Excessive pressure against gate slide.

B. Defective agitator motor.

C. Defective capacitor.

ICE DISPENSES CONTINUOUSLY. A. Stuck or bent push button (does not release switch).

B. Defective dispensing switch.

C. Improper switch installation.

SLUSHY ICE. WATER IN HOPPER. A. Blocked drain.

B. Unit not level.

C. Poor ice quality due to water quality or icemaker

problems

D. Improper use of flaked ice.

BEVERAGES DO NOT DISPENSE A. No 24 volt power to faucets.

B. No CO2pressure.

BEVERAGES TOO SWEET. A. Carbonator not working.

B. No CO2pressure in carbonator.

C. Faucet brix requires adjusting.

BEVERAGES NOT SWEET ENOUGH. A. Empty syrup tank.

B. Faucet brix requires adjusting.

BEVERAGES NOT COLD

(UNITS WITH BUILT-IN COLD PLATE)

A. Unit standing with no ice in hopper, no ice in cold plate

cabinet.

Contact your local syrup or beverage equipment distributor for additional information and troubleshooting of your

beverage system.

1691772

Page 20

WHEN REPLACING SOLENOID, ADJUST

TO 7/8-INCH AS SHOWN BEFORE TIGHTENING MOUNTING SCREWS.

FIGURE 10. WIRING DIAGRAM DB 90 DISPENSER

17 91772

Page 21

FIGURE 11. SOLENOID ASSEMBLY - EXPLODED VIEW & PARTS LIST

Index

No.

1 21493 1 Solenoid Mounting Plate

2# 31551 1 Solenoid Service Kit

3 70171 2 8--32 x 3/8 Phil Tr HD Screw

4 70121 2 No. 8 Lockwasher

5 50752 3 Isolator

6* 50789 2 Bumper Assembly

7* 70423 1 Cotter Pin

8* 10080 1 Gate Lift Rod

9 10081 1 Gate Lift Rod Bushing

10 50754 1 Gate Arm Bearing

11 21492 1 Gate lift Arm

12 70043 1 Flatwasher

13* 70422 1 Spring

14 70263 1 1/4-20 x 3/4 Hex Hd Screw

15 70048 1 1/4 Lockwasher

16 70066 1 1/4 Flatwasher

17 10077 1 Pivot Bearing

18 30227 1 1/4 Quick Connect Tab

19 50305 ---- Lubricant

20* 21592 1 Solenoid Linkage Pin

21* 70433 2 Retainer Ring

22 51088 ---- Loctite

----* 70438 ---- Rebuilding Kit

Part No. Quantity Description

NOTE: * Parts supplied with rebuilding kit.

# 31551 solenoid supplied with items 20 & 21.

1891772

Page 22

FIGURE 12. EXPLODED VIEW & PART LIST DB90-B

Item

No. Part No. Name

1 25734 Gate Slide

2 52072 Agitator Disk

3 32763 Ice Dispenser Switch

4 91511 Switch Label

5 31091 Transformer (-B models)

6 32745 Agitator Motor

7 50454 Motor Shaft Seal

8 52054 Lid

9 50751 Ice chute

10 51891 Gate Gasket

11 30997 Capacitor, Agitator Motor

12 31093 Gate Solenoid Assembly (See page 18 )

13 31551 Gate Solenoid Kit

14 70438 Rebuilding Kit (Gate Solenoid)

15 31406 Fuse. Gate Solenoid

16 51860 Motor, Gasket

17 27597 Agitator

PARTS FOR SINK MODEL ONLY

18 50750 Sink, Foamed

19 70426 Sink, Grill

20 27621 Sink, Ext. Weldment

19 91772

Page 23

FIGURE 13. EXPLODED VIEW & PART LIST DB90-BZ (NO SINK)

Item

No. Part No. Name

1 27534 Gate slide

2 52072 Agitator Disk

3 32763 Ice dispenser switch

4 91511 Switch Label

5 31091 Transformer (-B Models)

6 32745 Agitator Motor

7 50454 Motor Shaft Seal

8 52054 Lid

9 53015 Ice Chute back section

53016 Ice Chute Cover

10 51891 Gate Gasket

11 30997 Capacitor, Agitator Motor

12 31093 Gate Solenoid Assembly (See Page 18)

13 31551 Gate Solenoid Kit

14 70438 Rebuilding Kit (Gate Solenoid)

15 31406 Fuse, Gate Solenoid

16 51860 Motor, Gasket

17 27597 Agitator

2091772

Page 24

FIGURE 14. EXPLODED VIEW & PARTS LIST DB90-BC MERCHANDISER SECTION

Item

No. Part No. Name

1 52068 Merchandiser Panel, Plexiglass

2 27685 Bracket, Upper Merchandiser

3 28326 Merchandiser

4 32763 Ice Dispenser Switch

5 91511 Switch Label

6 32322 Cord, Lighted Merchandiser

7 27684 Bracket, Lower Merchandiser

21 91772

Page 25

FIGURE 15. EXPLODED VIEW & PART LIST DB90-BC CABINET

Item

No. Part No. Name

1 52054 Ice Storage Bin Ltd

2 70180 10-32 Thumbscrew

3 52072 Agitator Disk

4 27597 Agitator

5 52048 Ice Storage Bin

6 28410 Cabinet Wrapper

7 27534 Gate Slide

8 31093 Gate Solenoid Assembly

9 22081 Gate Restrictor

10 28328 Lower SS Panel

11 51891 Gate Gasket

12 52053 Ice Chute Conduit

13 53015 Ice Chute Back Section

53016 Ice Chute Cover

14 50454 Agitator Motor Shaft Seal

15 51860 Agitator Motor Gasket

16 32745 Agitator Motor

17 32748 Electric Box Assembly

18 27510 Cover, Electric Box

19 32747 Fluorescent Lamp

2291772

Page 26

FIGURE 16. EXPLODED VIEW & PARTS LIST DB90-BC COLD PLA TE SECTION

Item

No. Part No. Name

1 70426 Sink Grill

2 52789 Sink, Foamed

3 52099 Drain Assembly, Sink

4 27621 Sink Extension

5 51801 Gasket, Cold Plate Drain Tube

6 51775 90° PVC Fitting

7 70350 Clamp, Hose

8 28411 Base, Cabinet

9 28840 Beverage Panel

10 52225 Cold Plate Cover

11 33035 Cord, Power Supply

12 28405 Cold Plate Access Panel

23 91772

Page 27

FIGURE 17. EXPLODED VIEW & PARTS LIST DB90-BC ELECTRIC BOX ASSEMBLY

Item

No. Part No. Name

1 31621 Ballast

2 31620 Starter

3 30997 Capacitor

4 31363 Transformer Assembly

2491772

Page 28

REMCOR PRODUCT COMPANY

500 Regency Drive

Glendale Heights, IL60139-2268

Telephone(708) 980--6900

Facsimile (708) 980--8511

WARRANTY

REMCOR warrants that all equipment and parts are free from defects in material and workmanship under normal use and service. For a copy of the warranty applicable to your REMCOR product, in your country, please

write, fax or telephone the IMI Cornelius office nearest you. Please provide the equipment model number and

the date of purchase.

IMI Cornelius Offices

AUSTRALIA D P.O. 210, D RIVERWOOD, D NSW 2210, AUSTRALIA D (61) 2 533 3122 D FAX (61) 2 534 2166

AUSTRIA D AM LANGEN FELDE 32 D A-1222 D VIENNA, AUSTRIA D (43) 1 233 520 D FAX (43) 1-2335-2930

BELGIUM D BOSKAPELLEI 122 D B-2930 BRAASCHAAT , BELGIUM D (32) 3 664 0552 D FAX (32) 3 665 2307

BRAZIL D RUA ITAOCARA 97 D TOMAS COELHO D RIO DE JANEIRO, BRAZIL D (55) 21 591 7150 D FAX (55) 21 593 1829

ENGLAND D TYTHING ROAD ALCESTER D WARWICKSHIRE, B49 6 EU, ENGLAND D (44) 789 763 101 D FAX (44) 789 763 644

FRANCE D 71 ROUTE DE ST. DENIS D F-95170 DEUIL LA BARRE D PARIS, FRANCE D (33) 1 34 28 6200 D FAX (33) 1 34 28 6201

GERMANY D CARL LEVERKUS STRASSE 15 D D-4018 LANGENFELD, GERMANY D (49) 2173 7930 D FAX (49) 2173 77 438

GREECE D 488 MESSOGION AVENUE D AGIA PARASKEVI D 153 42 D ATHENS, GREECE D (30) 1 600 1073 D FAX (30) 1 601 2491

HONG KONG D 1104 TAIKOTSUI CENTRE D 11-15 KOK CHEUNG ST D TAIKOKTSUE, HONG KONG D (852) 789 9882 D FAX (852) 391 6222

ITALY D VIA PELLIZZARI 11 D 1-20059 D VIMARCATE, ITALY D (39) 39 608 0817 D FAX (39) 39 608 0814

NEW ZEALAND D 20 LANSFORD CRES. D P.O. BOX 19-044 AVONDALE D AUCKLAND 7, NEW ZEALAND D (64) 9 8200 357 D FAX (64) 9 8200 361

SINGAPORE D 16 TUAS STREET D SINGAPORE 2263 D (65) 862 5542 D FAX (65) 862 5604

SPAIN D POLIGONO INDUSTRAIL D RIERA DEL FONOLLAR D E-08830 SANT BOI DE LLOBREGAT D BARCELONA, SPAIN D (34) 3 640 2839 D FAX (34) 3 654 3379

USA D ONE CORNELIUS PLACE D ANOKA, MINNESOTA D (612) 421-6120 D FAX (612) 422-3255

SD 99-2 25 91772

Page 29

CORPORATE HEADQUARTERS:

Remcor Incorporated

500 Regency Drive

Glendale Heights, IL 60139

708. 980.6900

Loading...

Loading...