Reliable NS-ASAM, NS-Pak, Nitrogen Regulator Bulletin

Product Features

NS-ASAM

• Designed for two separate nitrogen or air sources

• Automatically switches between primary and secondary

source

• Bypass valve provided for quick fill of system

• Low-pressure switch for primary source

• For use on single or multiple systems

• Keyhole slots provided for easy wall mounting

Bulletin 254 May 2019

Nitrogen Automatic Pressure

Maintenance Devices

NS-Pak

• For bottled nitrogen use on a single system

• Low-pressure switches for nitrogen source and system

• Bypass valve provided for quick fill of system

• Keyhole slots provided for easy wall mounting

Nitrogen Regulator

• For bottled nitrogen use on single or multiple systems

• Low-pressure switch for nitrogen source

General Description

Reliable Nitrogen Automatic Pressure Maintenance Devices

are designed to connect nitrogen cylinders to dry pipe and

preaction systems. The NS-ASAM is designed to connect a

primary and secondary cylinder or bank of cylinders to single or multiple systems, and provides automatic switchover

between sources. The NS-Pak is a self-contained unit for connection of a cylinder or bank of cylinders to a single system.

The Nitrogen Regulator reduces cylinder pressure and can

be connected to the A-2 Pressure Maintenance Device on

single or multiple systems. Each device includes a low-pressure switch to signal that the nitrogen source is depleting and

needs service. High-pressure cylinders (not included) can

typically be obtained from a local source.

Model NS-ASAM

Model NS-Pak

Nitrogen Regulator

Model Product Description Listing and Approvals

NS-ASAM Nitrogen maintenance device with automatic switchover

NS-Pak

Nitrogen Regulator

Single system nitrogen maintenance device with high pressure

regulator

High-pressure regulator for connection to single or multiple pressure

maintenance devices

www.reliablesprinkler.com

cULus Listed

FM Approved

cULus Listed

FM Approved

N/A

Model NS-ASAM

Technical Specifications

Threads: 1/2” NPT

Min. Inlet Pressure: 100 psi (6.9 bar)

Max. Inlet Pressure: 250 psi (17.2 bar)

Min. Outlet Pressure: 10 psi (0.7 bar)

Max. Outlet Pressure: 70 psi (4.8 bar)

Listings and Approvals

cULus Listed

FM Approved

System Operation

Primary and secondary sources of nitrogen or air are con-

nected to the primary and secondary inlets, respectively,

of the Model NS-ASAM Pressure Maintenance Device. The

primary and secondary nitrogen or air sources should sup-

ply a recommended pressure of 120 psi (8.3 bar) to the

NS-ASAM, although a minimum pressure of 100 psi (6.9

bar) up to a maximum pressure of 250 psi (17.2 bar) are

permitted. The NS-ASAM will admit nitrogen or air from the

primary source, until the primary source depletes to a pres-

sure of approximately 80 psi (5.5 bar). Nitrogen or air from

the secondary source is admitted through the NS-ASAM,

when the pressure of the nitrogen or air supplied by the

primary source is less than approximately 80 psi (5.5 bar).

A pressure switch in the NS-ASAM is factory-set to activate

at a pressure of 90 psi (6.2 bar) to indicate depletion of

the primary source. The pressure switch includes an aux-

iliary set of contacts that may be field adjusted to indicate

loss of pressure from the secondary source. The system

pressure may be set with the system pressure regulator of

the NS-ASAM. A bypass valve is provided to rapidly intro-

duce nitrogen or air into the system. Individual low-pressure

switches (not provided) should be installed in the dry pipe

or preaction valve trim to indicate low system pressure.

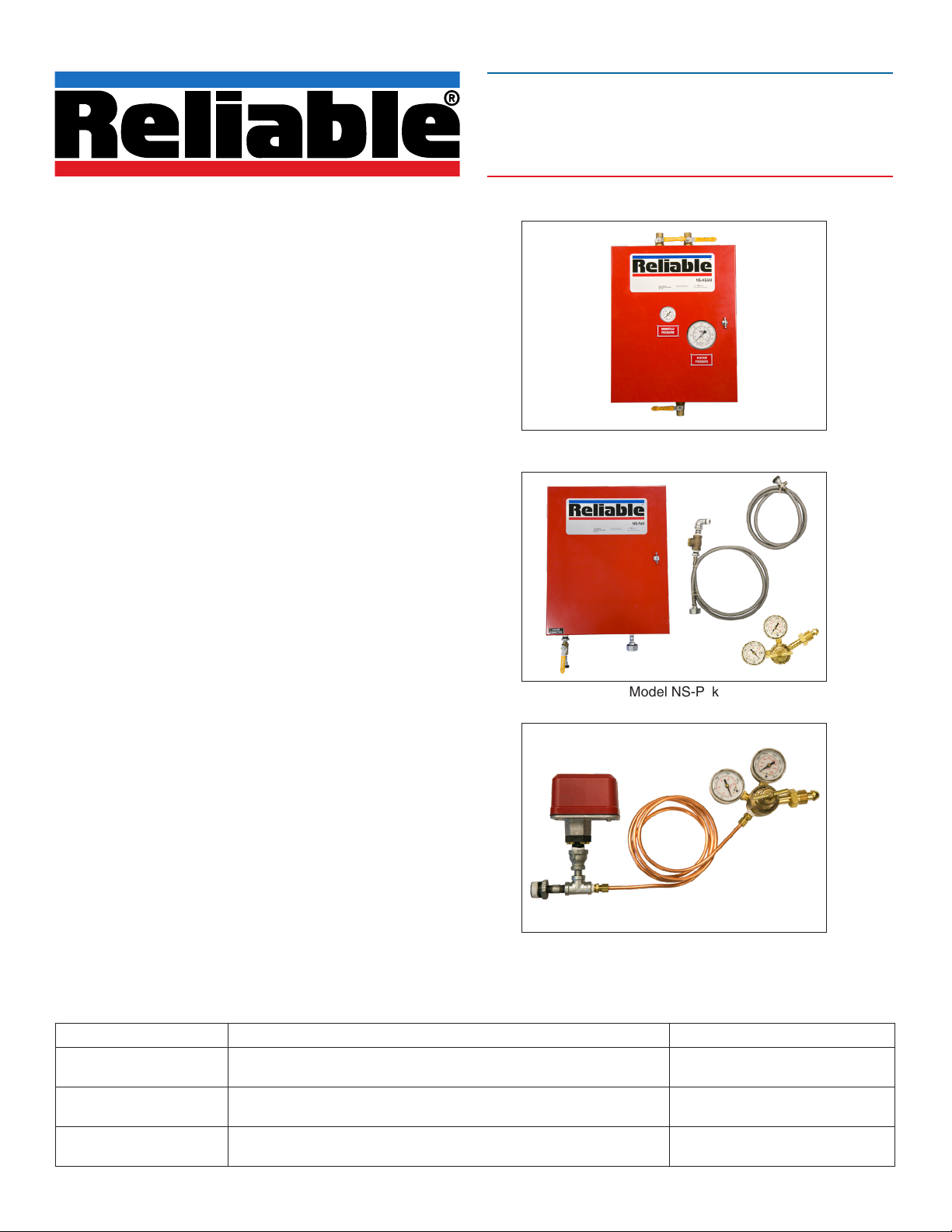

Model NS-ASAM Dimensions

Figure 1

Bulletin 254

May 2019

www.reliablesprinkler.com

Page 2 of 7

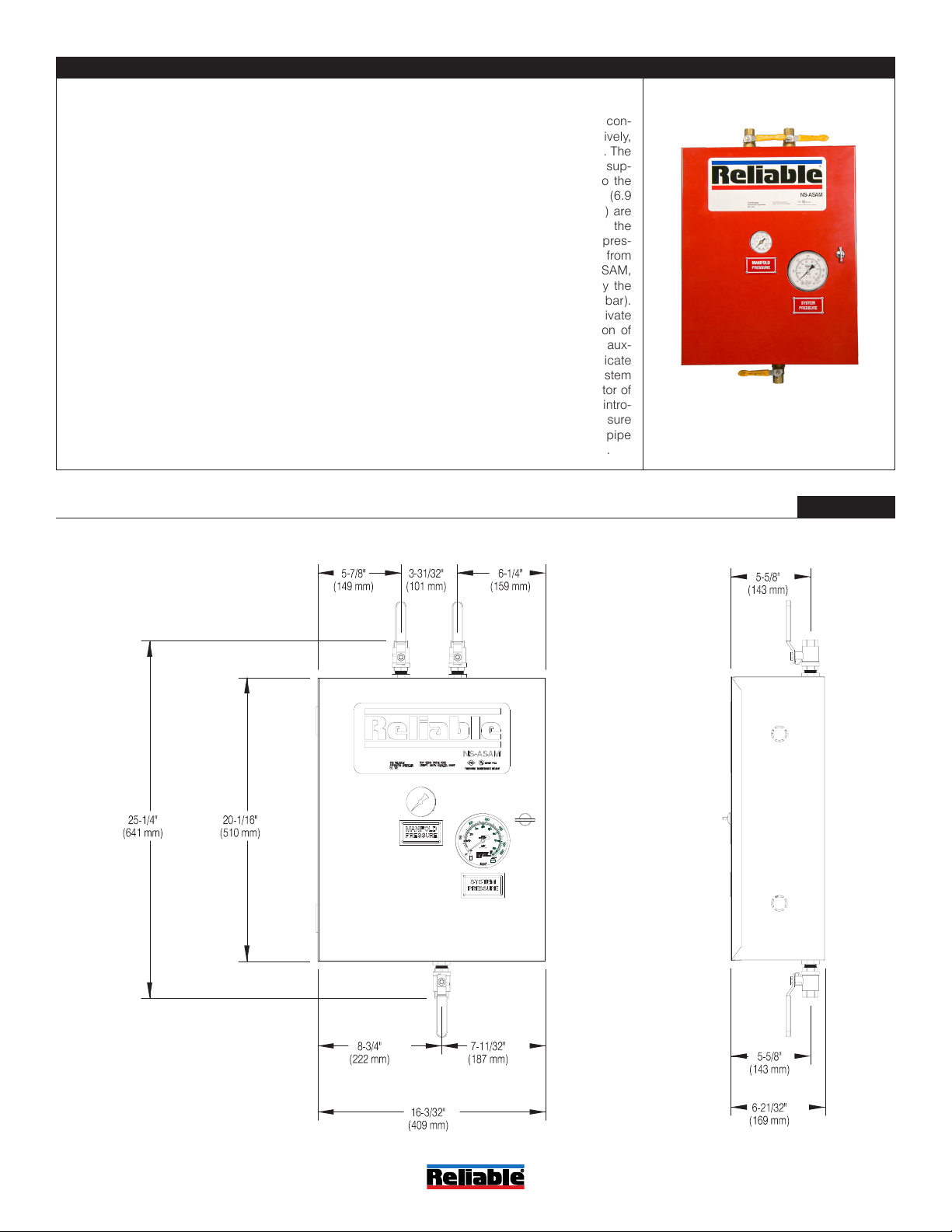

Model NS-ASAM Components

Figure 2

Installation and Adjustment

1. Securely mount the NS-ASAM enclosure to the wall using

the keyhole slots.

2. Confirm that all valves are closed.

3. Securely mount and properly pipe the primary and sec-

ondary sources of nitrogen or air in accordance with

appropriate local, state, or federal standards.

4. Connect the primary source of nitrogen or air to the prima ry inlet of the NS-ASAM and connect the secondary source

of nitrogen or air to the secondary inlet of the NS-ASAM.

5. Connect the NS-ASAM outlet to the port provided for pneu

matic supply to the sprinkler system (see note 1).

6. Before applying pressure to the sprinkler system, turn the

adjustment screw on the System Pressure Regulator within

the NS-ASAM fully counterclockwise.

7. Adjust the primary and secondary sources of nitrogen or

air to a recommended pressure of 120 psi (8.3 bar); the

minimum required inlet pressure is 100 psi (6.9 bar) and

the maximum rated inlet pressure is 250 psi (7.2 bar).

8. Open the Primary Inlet Valve and the Secondary Inlet

Valve.

9. Open the Bypass Valve and the NS-ASAM Outlet Valve to

allow nitrogen or air to flow into the system piping.

10. When the system pressure rises to within 2 psi (0.15 bar)

of the required system pressure, fully close the Bypass

Valve.

11. Slowly turn the adjustment screw of the System Pressure

Regulator clockwise to increase pressure to the level

required by the system. Tighten the lock-nut on the System

Pressure Regulator (see note 2).

12. If desired, supervise the contacts of the Pressure Switch in

accordance with NFPA 72 to provide notification that the

primary nitrogen or air source is depleted. The auxiliary

contacts of the pressure switch may also be supervised to

indicate depletion of the secondary source of nitrogen or

air. When supervising the auxiliary contacts, the primary

contacts of the pressure switch should remain at the

factory setting of 90 psi (6.2 bar) to indicate depletion of

the primary source and the auxiliary contacts should be

adjusted to a pressure setting of approximately 70 psi (4.8

bar).

13. If necessary, adjust the setting of the low-pressure switch

for each system.

14. Use a soap solution at all joints to verify leak-tight connec-

tions.

Notes:

1. When applying more that one system, each system must

have an individual Pressure Maintenance Device.

2. For multiple systems, the NS-ASAM system regulator must

be set a minimum of 5 psi above the highest system pres-

sure required. Use the regulator on the Pressure

Maintenance Device of each system to make final

adjustment.

Bulletin 254

May 2019

www.reliablesprinkler.com

Page 3 of 7

Loading...

Loading...