Page 1

Note: This sprinkler is a UL Listed Control Mode Density Area sprinkler.

Features:

1. Utilizes Standard Response center strut solder sensor.

2. 165°F (74°C), 212°F (100°C) and 286°F (141°C) temperature ratings.

3. Available in brass, lead coated, wax coated and wax

over lead coated finishes.

4. Provides higher flows at much lower pressures for all

occupancies, especially in high density applications,

such as the protection of high-piled storage.

5. Limits density increases for plastic pallet applications per NFPA 13.

Listings & Approvals

1. Listed by Underwriters Laboratories Inc. and UL certified for Canada (cULus) to include storage applications.

2. NYC MEA 258-93-E

3. FM Approved as a storage sprinkler.

Technical Data

Applications

Wet, Dry and Pre-Action Sprinkler Systems

Hazards

Ordinary, Extra Hazard and Storage

Occupancies per NFPA 13

For Sprinkler Spacing, Positioning, and Density/Area

Flow Calculations: refer to NFPA 13

Minimum Working Pressure

7 psi (0,5 bar) residual (flowing)

Maximum Working Pressure

Rated 175 psi (12,1 bar)

Factory tested to 500 psi (34, 5 bar)

Discharge Coeffi cients (K Factor)

K=16.8 GPM/psi½ (242 LPM/bar)

½

Pipe Thread Connection

¾ NPT (R¾)

Overall Length

1

3

/

inch (79,4 mm)

8

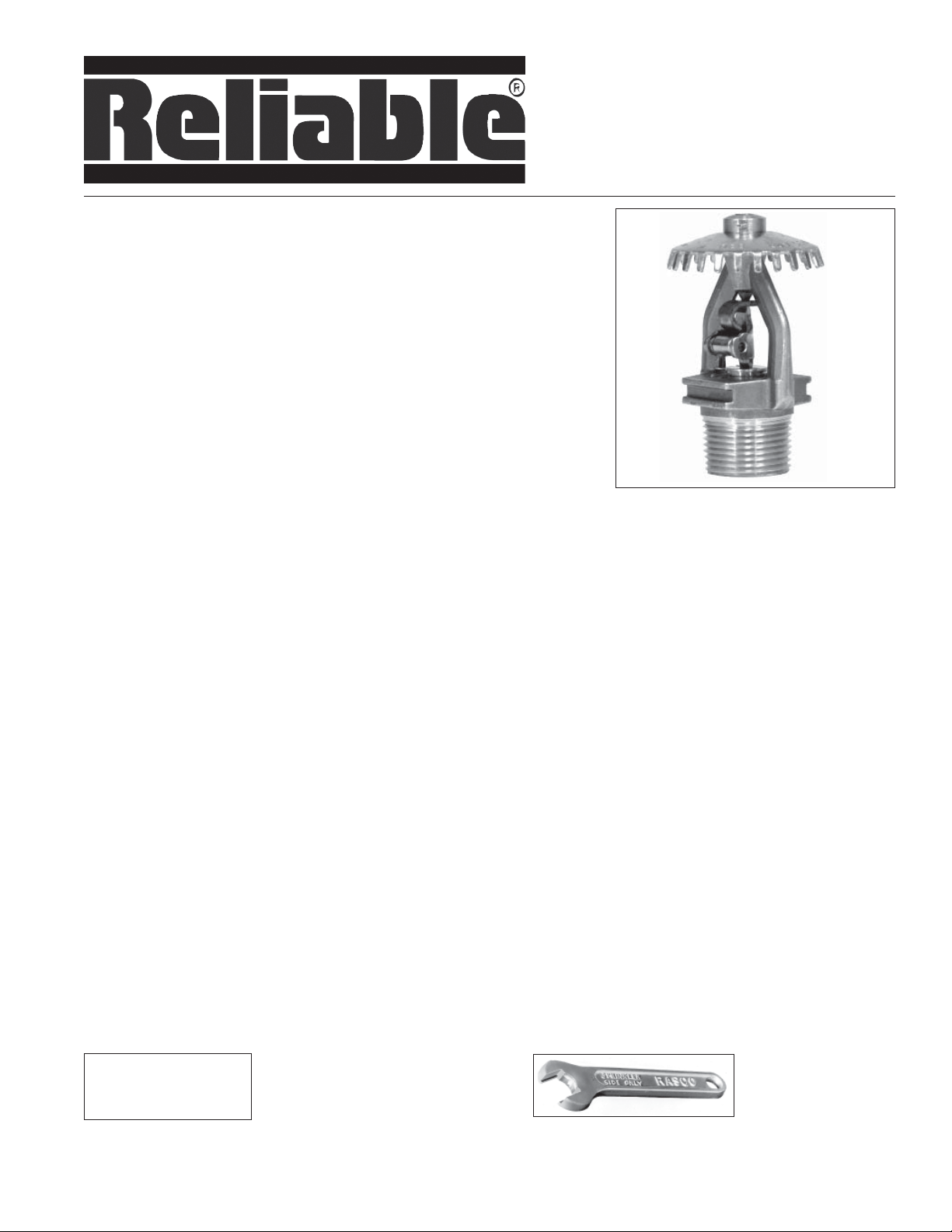

Product Description

The Reliable Model J168 Automatic sprinkler utilizes

the center strut solder in compression principle of construction. The fusible alloy is captured in the cylinder

of the solder capsule by a stainless steel ball. When

the fusible alloy melts, the ball moves into the cylinder

allowing the cylinder to separate from the center strut.

When this happens, the lever is released to spring free

from the sprinkler so that all operating parts clear the

waterway allowing the deflector to distribute the discharging water in a hemispherical pattern.

The Reliable Model J168, 16.8 K-factor sprinklers

were tested in full scale fire tests to qualify them for the

protection of rack and high piled storage.

Availability & Service

Reliable products are available through an extensive

network of domestic and international distributors. See the

Reliable Web site at www.reliablesprinkler.com for additional information.

Ordering Information

Specify:

1. Model J168 Upright

2. Temperature rating (see page 2)

3. Finish (see page 2)

4. Model J1 Installation Wrench

Bulletin 011 Rev. E

Model J168

Standard Response

Upright Sprinkler

(SIN RA1124)

Sprinkler Identifi cation Number

RA1124

Bulletin 011 Rev. E

Refer to CA-167

Model J1 Sprinkler Wrench

Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Page 2

Design Criteria

FM Approval Requirements

The Reliable Standard Response standard spray J168,

K-16.8 Upright Sprinkler is approved to be installed in accordance with FM Data Sheets 8-9 and 2-0. (FM guidelines may be different from UL and C-UL Listing criteria).

cULus Listing Requirements

The Reliable Standard Response J168 Upright Sprinkler

is cULus Listed for use in occupancy classifications up

to and including Extra-Hazard, for hydraulically calculated

wet or dry systems per NFPA 13, with a minimum operating pressure of 7 psi (48,3 kPa) in wet or dry systems. Use

the standard sprinkler positioning requirements and density/area sprinkler protection criteria provided in NFPA 13.

Also:

The J168 Sprinkler is cULus Listed for use in High-Piled

Storage Occupancies as defined in NFPA 13. This sprinkler may be used for the protection of solid piled, palletized, rack storage (single, double, multiple-row and portable), bin box, and shelf storage including, but not limited

to: encapsuled or unencapsulated Class I-IV and Group

A or B plastics, cartoned, expanded or unexpanded, as

well as exposed unexpanded. For hydraulically calculated

wet or dry systems per NFPA 13 with a minimum operating pressure of 7 psi (0,5 bar). Use the standard sprinkler

positioning requirements and density/area sprinkler protection criteria provided in NFPA 13 for High-Piled Storage

Occupancies.

Refer to NFPA 13 for specific requirements for various

combinations of building heights, storage heights, sprinkler- to-commodity clearance, storage arrangements,

commodity classifications, and lesser or greater required

design densities.

Note: The J168 Sprinkler can be used in any application

or building height as allowed by NFPA13 or FM guidelines. The J168 is a standard response standard spray

sprinkler with a larger K factor to provide greater water

flows at lower pressures.

Temperature Ratings

Sprinkler

Classifi cation

Ordinary

Intermediate

High

Lead Plated

Wax-Coated

Wax-Coated Over

Lead Plated

(1)

212°F (100°C) brown wax may be used on 286°F (141°C) sprinklers

when maximum ambient temperatures do not exceed 150°F (66°C).

(2)

Not FM Approved.

(1)(2)

(1)(2)

Rating

°F °C °F °C

165

212

286

Special Application Finishes

165°F (74°C), 212°F (100°C) and 286°F (141°C)

Temp. Ratings

165°F (74°C) Clear Wax, 212°F (100°C)

Brown Wax.

165°F (74°C) Clear Wax, 212°F (100°C)

Brown Wax.

74

100

141

Caution: The Reliable Standard Response J168 Upright

Sprinkler must be installed and maintained per the application NFPA standards, as well as the standards of other

authorities having jurisdiction.

Maximum

Ambient

Temperature

100

150

225

38

66

107

Frame

Color

Uncolored

White

Blue

2.

Page 3

Installation

The Model J168 Upright Sprinklers are to be installed as

follows:

• Install in upright position only.

• Apply pipe thread sealant to NPT threads, hand

tighten into the sprinkler fitting.

• Install sprinkler by wrench boss only.

• Wrench tighten with the dedicated J1 Sprinkler

Wrench.

• A leak tight ¾ NPT (R¾) sprinkler joint can be

obtained with a torque of 14 - 20 ft. lbs.

• Higher torques may compromise the seal or function integrity of the sprinkler.

Maintenance

Model J168 Sprinklers should be inspected and the

sprinkler system maintained in accordance with NFPA

25. Do not clean sprinklers with soap and water, ammonia or any other cleaning fluids. Remove dust by using a

soft brush or gentle vacuuming. Remove any sprinkler that

had been painted (other than factory applied) or damaged

in any way. A stock of spare sprinklers should be maintained to allow quick replacement of damaged or operated

sprinklers. Prior to installation, sprinklers should be maintained in the original cartons and packaging until used to

minimize the potential for damage to sprinklers that would

cause improper operation or non-activation.

Model J168 Standard Response

Upright Sprinkler

Sprinklers shall be standard response upright spray sprinklers cULus Listed for use in occupancy classifications up

to and including extra hazard, and for storage occupancies

in accordance with NFPA 13. Sprinkler construction shall

be a bronze, die-cast frame with grooved wrench flat and

copper-alloy deflector. Water seal assembly shall consist

of a fusible solder thermal element utilizing a center strut

solder-in-compression principle of construction with metal

Belleville spring washer, coated on both sides with Teflon

film. Sprinkler temperature rating shall be [165 °F (74 °C)]

[212 °F (100 °C)] [286 °F (141 °C)]. Sprinklers shall have

a nominal K-factor of 16.8 (241.9) and have a ¾” NPT (R)

thread. The rated working pressure shall be 175 psi (12.1

bar). Standard finish shall be bronze. Sprinklers shall be

Reliable Model J168 standard response upright sprinklers,

Bulletin 011 (SIN RA1124).

Special Application Finishes Option:

Exposed sprinklers subject to corrosive atmospheres shall

have a factory-applied [165 °F (74 °C) clear wax-coated]

[212 °F (100 °C) brown wax-coated] [lead plated for 165 °F

(74 °C), 212 °F (100 °C), or 286 °F (141 °C)] [wax-coated

over lead plated] corrosion resistant coating.

Note: 1. Grooved sprinkler boss provided to insure that the Sprinkler

wrench does not slip during installation.

Engineering Specifi cation

2. A tight ¾” NPT sprinkler joint should be obtained with a torque of 14 to 20 ft. lbs. Higher levels of torque may distort the sprinkler inlet

cause leakage or impairment.

3.

Page 4

Reliable...For Complete Protection

Reliable offers a wide selection of sprinkler components. Following are some of the many

precision-made Reliable products that guard life and property from fire around the clock.

• Automatic sprinklers

• Flush automatic sprinklers

• Recessed automatic sprinklers

• Concealed automatic sprinklers

• Adjustable automatic sprinklers

• Dry automatic sprinklers

• Intermediate level sprinklers

• Open sprinklers

• Spray nozzles

• Alarm valves

• Deluge valves

• Detector check valves

• Check valves

• Electrical system

• Sprinkler emergency cabinets

• Sprinkler wrenches

• Sprinkler escutcheons and guards

• Inspectors test connections

• Sight drains

• Ball drips and drum drips

• Retarding chambers

• Dry pipe valves

• Accelerators for dry pipe valves

• Mechanical sprinkler alarms

• Electrical sprinkler alarm switches

• Water flow detectors

The equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory

Mutual Research Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Products manufactured and distributed by Reliable have been protecting life and property for over 90 years, and are installed and serviced by the most highly

qualified and reputable sprinkler contractors located throughout the United States, Canada and foreign countries.

Manufactured by

Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

www.reliablesprinkler.com Internet Address

• Control valve seals

• Air maintenance devices

• Air compressors

• Pressure gauges

• Identification signs

• Fire department connection

Revision lines indicate updated or new data.

EG. Printed in U.S.A. 07/14

Recycled

Paper

P/N 9999970290

Loading...

Loading...