Reliable F1FR QREC Bulletin

Concealed Quick Response

Sprinkler Coverage

to 20’ x 20’ (6.0 m x 6.0 m)

Features

1. Quick response performance.

2. Push on, thread off, sturdy convenient

cover plate.

3. Factory assembled sprinkler and

cup, shipped complete with protective cap.

4. Sprinkler assembly and cover plate

separately packaged.

5. Two Versions:

• ½” (13mm) Adjustment

5

•

/

” (8mm) Adjustment

16

6. Rugged damage resistant assembly.

No exposed thermal element.

7. Utilizes the Model F1FR QREC

Pendent Sprinkler.

8. Aesthetic ceiling profile.

9. Standard finishes in white painted or

chrome plated. Other color-painted

and specialty finishes available.

For Model F1FR QREC CCP ½” K 5.6 (80) Sprinkler Types

refer to Bulletin 028 for technical specifications and

approvals.

Product Description

Model F1FR QREC Quick Response Extended Coverage

Concealed Sprinkler is an attractive, low profile concealed

sprinkler assembly. This sprinkler assembly utilizes a Model

F1FR QREC pendent sprinkler in a Model CCP cup and pushon thread-off cover plate assembly. The cup is securely factory

threaded on the sprinkler’s inlet end. The assembly is shipped

with a protective cap. The sprinkler and cup are easily installed

into the sprinkler fitting using the Model GFR2 Sprinkler Wrench.

The cover plate assembly is attached to the sprinkler cup using a flexible tooth threaded engagement. The cover plate is

attached to the skirt using 135°F (57°C) ordinary temperature

classification solder.

Bulletin 151 March 2019

Model F1FR QREC CCP

Concealed Quick Response

Extended Coverage

Sprinkler

When the ceiling temperature rises, the solder holding the

cover plate melts, allowing the release of this part and thus

exposing the Model F1FR QREC sprinkler inside to the rising

ambient temperature. The Temperature rating of the sprinkler

identified by the color of the glass bulb.

Model F1FR QREC automatic sprinkler utilizes a 3.0 mm frangible glass bulb. This sprinkler has demonstrated response

times in laboratory tests which are five times faster than standard response sprinklers. This quick response enables the

Model F1FR QREC sprinkler to apply water to a fire faster than

standard sprinklers of the same temperature rating.

Approval Type:

Quick Response Extended Coverage — Light Hazard

Technical Data:

K Factor

Nominal

Orifice

17

32

/

” (20mm) ¾” (R¾) 8.0 115.3 1,2,3 R4842

Thread

Size

¾” NPT

(R¾)

¾” NPT

(R¾)

Flow Rate

gpm (L/m)

26 (98.4)

33 (125.0)

40 (151.4)

(1)

135°F (57°C) Only

Note: 1 bar = 100 kPa

Thread

Size

Model

F1FR

QREC

F1FR

QREC

Approval

US Metric

Temp. Rating Max.

Sprinkler Cover

135°F

57°C

155°F

68°C

Coverage Area

Pressure

psi (bar)

K=8.0

(Metric 115.3)

10.6 (0,7)

17.0 (1,2)

25.0 (1,7)

Organizations

135°F

57°C

135°F

57°C

Ceiling

Max. Enclosure Area

20 x 20

Sprinkler

Ident.

Number

(SIN)

Bulb

Temp.

100°F

38°C

100°F

38°C

Width x Length

ft. x ft. (m x m)

16 x 16 (4.9 x 4.9)

18 x 18 (5.5 x 5.5)

Color

Orange

(1)

(6.0 x 6.0)

Red

(1)

Bulletin 151 March 2019

The Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

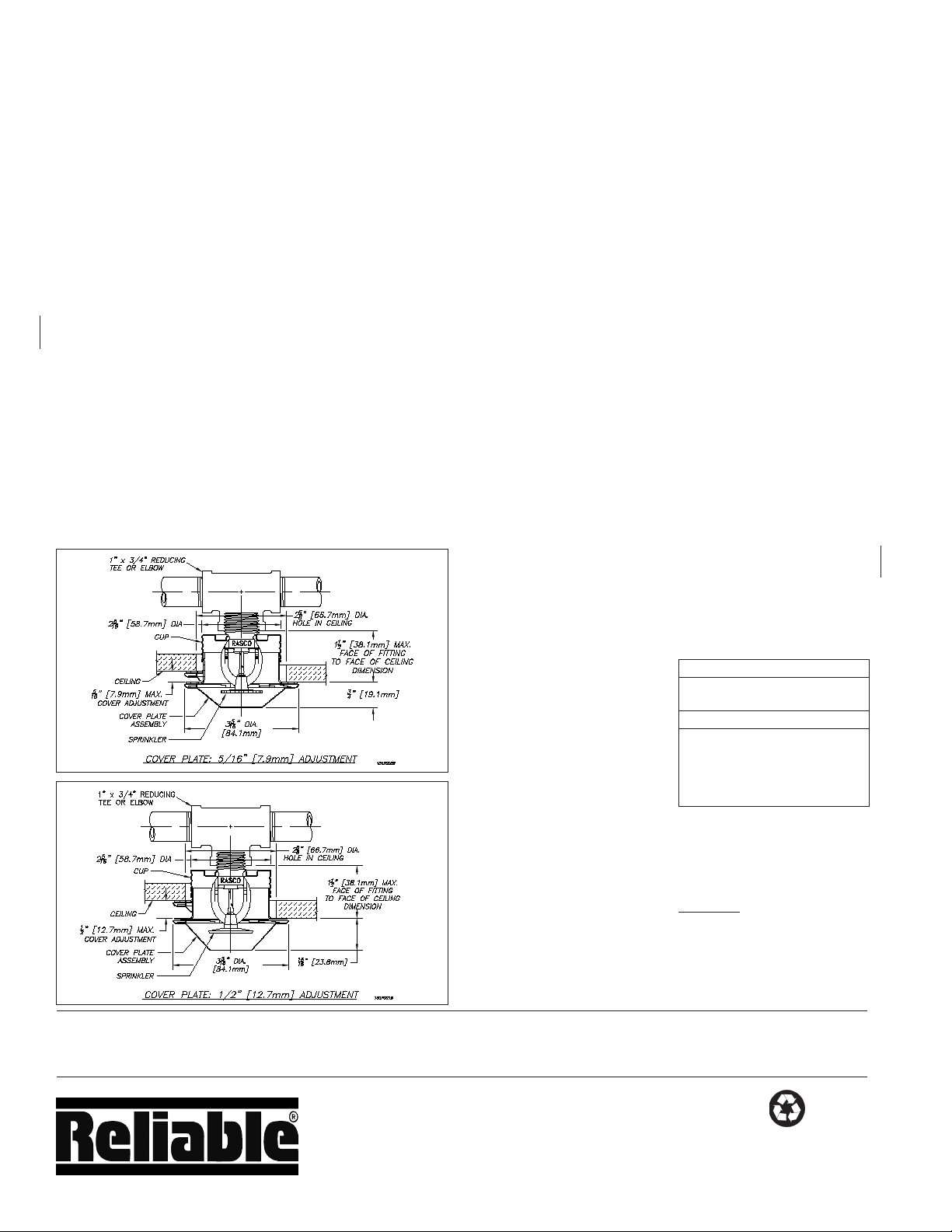

Application and Installation

Model F1FR QREC Concealed Sprinklers use 135°F (57°C)

or 155°F (68°C) Model F1FR QREC Pendent Sprinklers with a

threaded Model CCP cup which is factory attached to the sprinkler. The assembly is completed by the installation of the attractive, low profile, 135°F (57°C) rated cover plate assembly. The

cover plate and sprinkler cup are joined using a flexible tooth

threaded engagement. A choice of two cover plate assemblies

provides either ½” (13mm) or

Do not install these sprinklers in ceilings which have positive

pressure in the space above.

The sprinkler cup is factory attached to the Model F1FR QREC

Sprinkler. A Teflon*-based thread sealant should be applied to

the sprinkler threads only.

After a 2

5

/

inch (67mm) diameter hole is cut in the ceiling,

8

the sprinkler is easily installed with the Model GFR2 Wrench.

When installing a sprinkler, the protective cap is removed and

the wrench is positioned into the sprinkler/cup assembly until

the two wrench faces engage the wrenching flats on the Model

F1FR QREC Sprinkler. The sprinkler is then tightened into the

pipe fitting. When inserting or removing the wrench from the

sprinkler/cup assembly, care should be taken to prevent damage to the sprinkler. DO NOT WRENCH ON ANY OTHER

PART OF THE SPRINKLER. The cover plate assembly is then

pressed into the cup. Final adjustment is made by turning the

cover plate until the skirt flange makes full contact with the ceil-

* DuPont Registered Trademark.

5

/

” (8mm) of cover adjustment.

16

ing surface. Cover plate removal requires turning in the counter

clockwise direction.

After installation, inspect all sprinklers to ensure that there is

a gap between the cover plate and ceiling and that the four

cup slots are open and free from any air flow impediment to the

space above.

Concealed cover plate/cup assemblies are listed only for use

with specific sprinklers. The use of any other concealed cover

plate/cup assembly with the Model F1FR QREC Pendent Sprinkler or the use of the Model CCP concealed cover plate assembly on any sprinkler with which it is not specifically listed may

prevent good fire protection and will void all guarantees, warranties, listings and approvals.

Maintenance

Model F1FR QREC Concealed Sprinklers should be inspected and the sprinkler system maintained in accordance with

NFPA 25. Do not clean sprinklers with soap and water, ammonia or any other cleaning fluids. Remove dust by using a soft

brush or gentle vacuuming. Remove any sprinkler cover plate

assembly which has been painted (other than factory applied)

or damaged in any way. A stock of spare sprinklers should be

maintained to allow quick replacement of damaged or operated

sprinklers. Prior to installation, sprinklers should be maintained

in the original cartons and packaging until used to minimize the

potential for damage to sprinklers that would cause improper

operation or non-operation.

Approval Organizations

1. Underwriters Laboratories, Inc.

(UL)

2. Underwriters’ Laboratories of

Canada (ULC)

3. NYC MEA 258-93-E

UL Listing Category

Sprinklers, Automatic and Open.

Quick Response Extended Coverage Sprinklers.

Ordering Information

Specify:

1. Sprinkler Model:

F1FR QREC Pendent

17

32

/

” (20mm) Orifice, ¾” NPT

(R¾).

2. Sprinkler Temp. Rating

135°F (57°C) or

155°F (68°C).

3. Cover plate Model: CCP

4. Cover plate thread size:

¾” NPT (R¾).

5. Cover plate temp. rating:

135°F (57°C).

6. Cover plate adjustment:

Either ½” (13mm) or

(approximate adjustment).

7. Cover plate finish.

(1)

135°F (57°C) required for

20’ x 20’ (6.0m x 6.0m).

5

16

/

(1)

:

” (8mm)

Installation Wrench

Model GFR2 Sprinkler Wrench

Installation Aid

A protective cap is included for

use during installation.

Cover Plate Finishes

Standard Finishes

Chrome

White

Special Application Finishes

Bright Brass

Black Plating

Black Paint

Off White

Satin Chrome

(1)

Other finishes and colors are

available on special order.

Consult factory for details.

Note: Paint or any other coatings

applied over the factory finish will

void all approvals and warranties.

Important: The F1FR QREC

Sprinkler with the Model CCP

cover plate is not an FM Approved

combination.

(1)

The equipment presented in this bulletin is to be installed in accordance with the latest published Standards of the National Fire Protection Association, Factory

Mutual Research Corporation, or other similar organizations and also with the provisions of governmental codes or ordinances whenever applicable.

Products manufactured and distributed by Reliable have been protecting life and property for over 90 years, and are installed and serviced by the most highly

qualified and reputable sprinkler contractors located throughout the United States, Canada and foreign countries.

Manufactured by

The Reliable Automatic Sprinkler Co., Inc.

(800) 431-1588 Sales Offices

(800) 848-6051 Sales Fax

(914) 829-2042 Corporate Offices

www.reliablesprinkler.com Internet Address

Revision lines indicate updated or new data.

EG. Printed in U.S.A. 03/19

Recycled

Paper

P/N 9999970148

Loading...

Loading...